- Features of BIRPEX products

- Cross-linked polyethylene - what are the seams?

- Installation nuances

- Which pipes are best for underfloor heating?

- The first option - we use metal-plastic for a warm floor

- What is cross-linked polyethylene

- Properties and characteristics of PEX pipes

- No. 2. PEX pipe stitching method

- Features of cross-linked polyethylene

- Advantages and disadvantages

- Cross-linked polyethylene or metal-plastic

- Cross-linked polyethylene (PEX) pipes for underfloor heating

- Conclusion

Features of BIRPEX products

The advantages of cross-linked polyethylene have been known for several decades, but the rather high cost prevented the material from being widely used in our country. Everything changed with the advent of the Russian manufacturer BIR PEX, which launched the production of good quality products at an affordable price.

Before the start of production, BIR PEX carried out research in order to identify the most optimal material option, which is necessary in the climatic conditions of Russia and the CIS countries. BIR PEX products include several systems for heating, water supply and underfloor heating, namely:

- BIR PEX Optima;

- BIR PEX Standard;

- BIR PEX Standard Uf-Stop;

- BIR PEX Light (floor heating system).

Beer pex pipes

All BIR PEX products are manufactured using modern English equipment, which guarantees high quality. The main advantages of the BIR PEX pipe can be briefly described as follows:

- Increased resistance to cracking;

- Operating temperature up to 90 ˚С;

- Working pressure - 65 atmospheres at 20 ˚С;

- High allowable loads;

- Long term use.

All BIR PEX products are equipped with compression, crimp or pressure fittings, which allows installation of communication systems even for people who do not have a special tool. The use of the BIR PEX pipe makes it possible to replace the hidden section of the pipe without dismantling the wall or floor, which is impossible for other types of pipeline.

Cross-linked polyethylene - what are the seams?

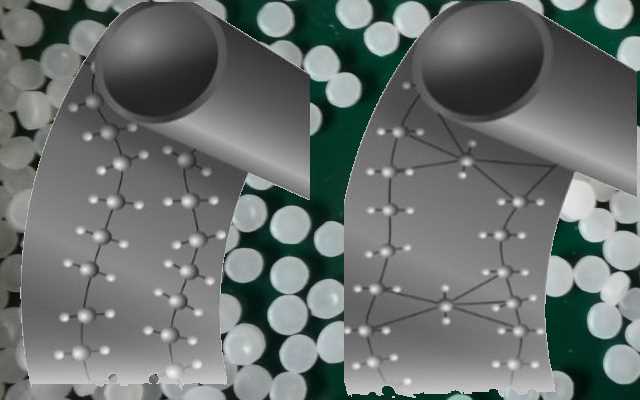

There are absolutely no seams in cross-linked polyethylene. "Crosslinking" occurs during their production at the molecular level. Ethylene molecules create a complex and strong three-dimensional polymer chain. The resulting polymer is designated by the letters PE-X.

Technologically, various physical and chemical production methods are used.

Depending on the technology used in production, the following is added after PE-X in the material designation:

a - production is carried out by heating with the use of peroxides;

b - silane and catalysts are used, at high humidity;

c - electrochemical method, when electron bombardment of polymer molecules is performed;

d - a variant that is practically not found in household stores, created using nitrogen technology.

That is, the strength and durability of "cross-linked" polyethylene is laid down at the stage of initial production, at the level of molecular bonds - which must still be damaged.

Underfloor heating for the home is best laid using polyethylene products labeled PE-Xa. They will endure repeated freezing / thawing and will not burst at the same time at the junction of cross-linked polyethylene and fittings.

The high combustion temperature of 400 C guarantees the safety of the heating system even with small fires in the room. And if the fire nevertheless got through the concrete screed to the polyethylene pipes, then they would rather melt, decomposing into carbon dioxide and water.

They will not “leak” and retain their rigidity at coolant temperatures up to +120 C, which is quite enough for the selected heating system.

Installation nuances

For a heating circuit made of polyethylene pipes, it is recommended to use products with a diameter of 16 mm. The heat transfer from them will have acceptable performance, and additional reinforcement of the concrete screed will not be required. It will be enough to pour 6 cm unreinforced concrete over them.

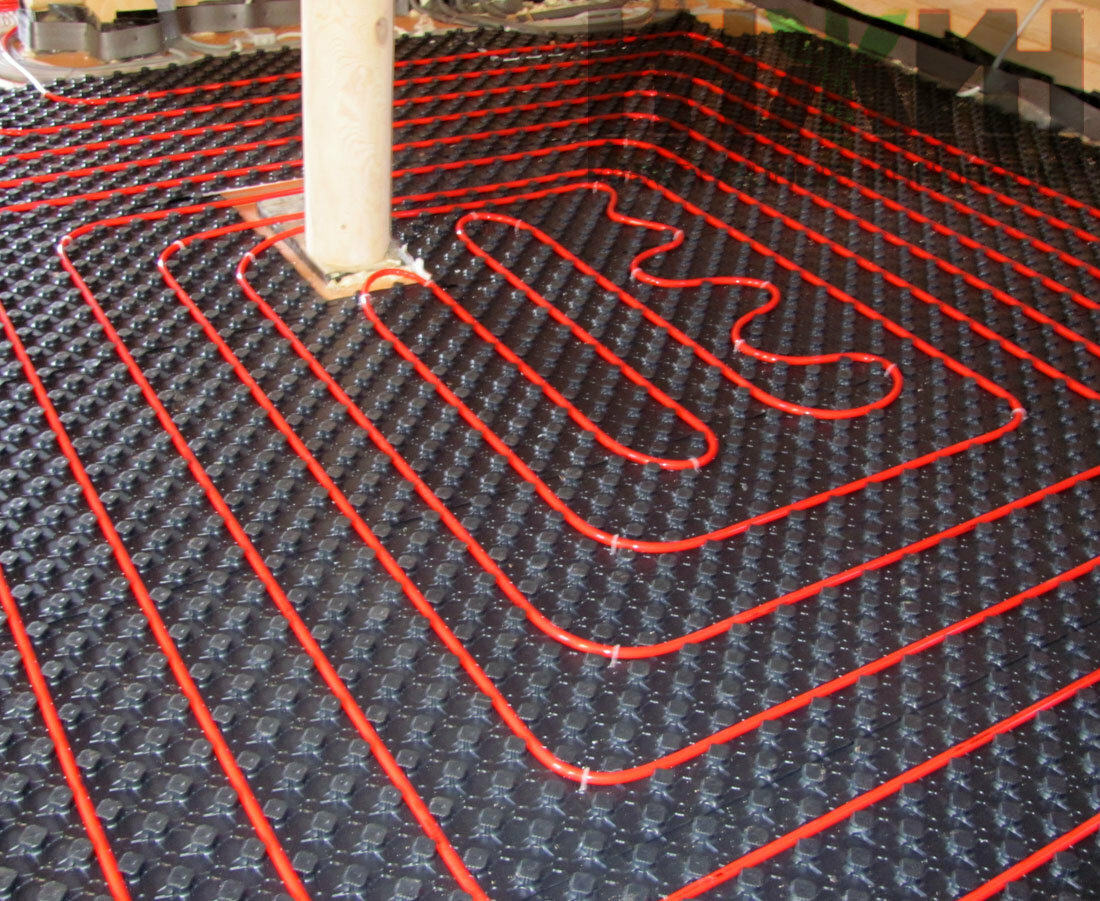

The installation process of the circuit consists in the seamless laying of a polyethylene pipe in a spiral, from the center of the room to the junction with the collector of the "warm floor" system. Where both ends connect to the manifold fitting. The connection can be made: crimp, welded or press method.

In the first case, a compression ring with a lock nut is put on the end, it is put on the fitting, and the nut is tightened. In the second variant, electric welding is used, which heats polyethylene. Which, having melted, after turning off welding, hardens, forming a strong connection.

For the third method, press sleeves are used, which are inserted into a pipe stretched with a special tool, after which it returns to its diameters and tightly settles in the fitting fitting.

You should know that such connections hold pressure in different ways - crimping 2.5 MPa, press 5 MPa, and welding 10-12 MPa. The choice of the junction of pipes with a collector must be selected in accordance with the parameters of the water heater of the underfloor heating system.

Also interesting: and here you can book cheap flights from Moscow to Osaka. After a good renovation, you can treat yourself to a great vacation. Good luck with the repair and rest!

Which pipes are best for underfloor heating?

A pipe for a warm floor must meet very specific requirements, such as:

- resistance to mechanical stress;

- long service life;

- resistance to corrosion;

- environmental Safety;

- low coefficient of linear expansion;

- elasticity;

- high heat transfer;

- ability to absorb noise.

In varying degrees, these characteristics correspond to a number of materials. Quite successfully, pipes from:

- copper;

- corrugated steel;

- metal-plastic;

- polypropylene;

- polyethylene.

Copper pipes are a high-end and time-tested option. However, their cost is high in itself. In addition, you will need to spend money on a polymer shell, which is necessary when installing copper in a screed, and on special brass fittings.

It is easier to work with corrugated steel and its consumption will be somewhat less, with almost the same performance characteristics as copper.But the price of the material will be just as high.

Metal-plastic structures are relatively "young" and perfectly perform the role of a transport highway when installing a warm floor. However, scale can build up inside threaded fittings over time. In addition, during installation, there is a high probability of a pipe cut.

In polypropylene pipes, with such advantages as an affordable price, simple installation and low physical weight, the indicators of linear expansion when heated are “lame”. When installed in a concrete screed, they must be reinforced with fiberglass and aluminum.

XLPE pipes are considered the most modern choice for the installation of underfloor heating, since their characteristics meet the technological requirements to the fullest extent. Among the shortcomings, one can note the insufficient flexibility of the material, due to which the pipes do not hold their shape well during installation.

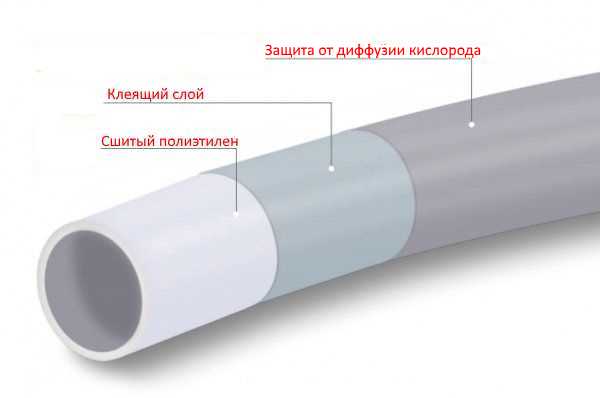

The XLPE pipe with anti-diffusion protection includes a special layer of aluminum that prevents the penetration of oxygen or water vapor through the pipe walls.

A wide selection of pipes, fittings, manifolds and other types of products for engineering networks is offered by the STOUT brand.

Stout offers a wide range of pipes

The STOUT metal-plastic pipe is designed specifically for Russian operating conditions

The first option - we use metal-plastic for a warm floor

A metal-plastic pipe is a high-tech product, marking (MP), which is a composite. Five layers form the basis of the structure, performing their specific functions. The inner and outer layers are polyethylene, tightly bonding to the inner layer made of foil.Between the foil and the polyethylene layers there are two adhesive layers that provide the entire structure with the necessary stability.

At first glance, the channel is a complex type-setting structure - a composite. However, this design was created specifically for underfloor heating. Due to the presence of a metal layer inside the channel, the maximum possible transfer of thermal energy occurs. Metal-plastic pipes for underfloor heating allow you to create uniform heating of the floor surface, using a fairly wide pitch when laying water circuits.

The inner layer has smooth walls, which makes such pipes resistant to the formation of calcium deposits. Corrosion to such material is not terrible. The combination of aluminum foil and polyethylene provides the entire circuit with the necessary strength, not inferior in strength to copper pipelines. This consumable has both its obvious advantages and disadvantages. However, for a number of reasons, MP pipes are often chosen for the installation of warm water floors.

Underfloor heating, in which metal-plastic pipes are used, has the following advantages:

- a metal-plastic pipeline has a low expansion coefficient, which has a beneficial effect on the state of the concrete screed;

- water circuits are resistant to corrosion and inert in terms of reaction to chemicals;

- water heating loops keep the working pressure of the coolant well;

- heating circuits made of this material have high sound insulation;

- the pipeline holds its shape during the process of pouring the surface with concrete.

The last advantages that influence the choice of this particular type of consumable include durability.Pipes laid in a concrete screed can function normally for 30-40 years.

Metal-plastic withstands operating pressure up to 10 atmospheres and retains its main technological characteristics at a coolant temperature of 95C. From the point of view of practicality and manufacturability, metal-plastic pipes behave perfectly during the installation of heating circuits. The channel is easily bent, which makes it possible to lay the contour in any way, serpentine or spiral, schemes in which a large number of bends are provided.

The disadvantages of metal-plastic are rather nuances of the technological use of pipelines made from this material. This may include the following:

- with poor manufacturing quality, delamination of the aluminum and polyethylene layer may occur (difference in the parameters of the coefficients of linear expansion);

- the use of metal fittings for connections can lead to the formation of scale on the inner surface of the joints;

- pinching the fitting during the installation of the pipeline can lead to the formation of a crack in the polyethylene;

Metal-plastic and underfloor heating in your home is a good combination, a reasonable, worthy and justified choice. In this case, you can get a reliable and efficient heating system, while saving quite a significant amount on consumables. Therefore, you can safely proceed to the calculation of the consumption of pipes necessary for the installation of heating circuits.

What is cross-linked polyethylene

With a certain impact on a simple polyethylene, you can start some changes in the hydrogen atoms, in which new bonds appear between the carbon atoms. This process of obtaining new additional carbon bonds is called crosslinking.The high advantages of cross-linked polyethylene, achieved through enhanced joint development of scientists and manufacturers, are expressed in the following:

- long service life, up to 50 years;

- increased strength and flexibility;

- restoration of shape after damage;

- the possibility for use in installation work on the assembly of underfloor heating;

- application in the assembly of the heating system and water pipes.

Intermolecular bonds: on the left - ordinary polyethylene, on the right - cross-linked polyethylene. Also, cross-linked polyethylene has fire-fighting qualities, it has excellent heat resistance to very high temperatures. And, on the contrary, due to the increased softness of cross-linked polyethylene, the products can easily withstand the increase in water frozen in them. For owners of country houses, dachas, a pipeline made of cross-linked polyethylene is an ideal option. All basic requirements will comply with the standards:

- maintaining the required pressure;

- maintaining the temperature regime;

- long service life, without any accidents.

Properties and characteristics of PEX pipes

In the manufacture of cross-linked polyethylene, it is directly affected by various methods and substances. In this regard, the level of strength of the crosslinking of pipes varies and differs. High rate goes up to 85%

The cross-linking method is important, because depending on it, the number of formed additional bonds changes. I distinguish four stitching methods

The finished product is called PEX. The name is very simply deciphered: the first two letters stand for "polyethylene", and the last letter is a symbol for crosslinking.Now REHAU is considered the leader in the manufacture of cross-linked polyethylene, and in our country its products are in demand.

PEX pipe mainly consists of three layers:

- the inner first layer is cross-linked polyethylene;

- outer - ethylene vinyl glycol oxygen barrier (EVON)

- adhesive layer.

The multi-layered pipes are explained by the instability of the substance to UV rays, as well as the ability to pass oxygen. Both contribute to rapid wear.

Specifications:

- minimum diameter up to 16 mm;

- extreme high temperature during operation in heating structures 90 -95 0С;

- product wall up to 2 mm;

- weight of a linear meter up to 110 g;

- thermal conductivity up to 0.39 W / mk., and density 940 kg / m3;

- the volume of liquid contained in the communication is up to 114 ml;

- operation of the pipeline, when heated to +750С, is guaranteed up to 50 years, and at a critical temperature of 95 ºС and strong pressure, this period is reduced to 15 years;

- solvent resistant;

- with the help of special fittings, structures can be built in any direction and configuration.

Important! The process of making a crosslink occurs under the action of an electron flow. As a result, there is a connection of free branches with very strong side bonds between atoms.

It turns out the form of a crystal lattice of stronger, harder materials.

No. 2. PEX pipe stitching method

The most important parameter when choosing XLPE pipes is the method of crosslinking used by the manufacturer. It determines the number of formed additional bonds, and consequently, the performance of the product.

For the formation of additional bonds (bridges) in polyethylene, the following crosslinking methods are used:

- cross-linking with peroxide, such pipes are marked PEX-A;

- silane crosslinking, PEX-B;

- radiation crosslinking, PEX-C;

- nitrogen crosslink, PEX-D.

PEX-A pipes are obtained by heating raw materials with the addition of peroxides. The crosslink density of this method is maximum and reaches 70-75%. This allows us to talk about such advantages as excellent flexibility (maximum among analogues) and memory effect (when unwinding the coil, the pipe almost immediately takes its original straight shape). Bends and creases that may appear during the installation process can be corrected if a little heat the pipe with a building hair dryer. The main disadvantage is the high price, since peroxide crosslinking technology is considered the most expensive. In addition, chemicals are washed out during operation, and somewhat more intensively than in other PEX pipes.

PEX-B pipes are produced in two stages. First, organic silanides are added to the feedstock, resulting in an unfinished pipe. After that, the product is hydrated, and as a result, the crosslink density reaches 65%. Such pipes are characterized by a low price, they are resistant to oxidation, have high pressure indicators at which the pipe breaks. In terms of reliability, they are practically not inferior to PEX-A pipes: although the percentage of crosslinking is lower here, the bond strength is higher than with peroxide crosslinking. Of the minuses, we note rigidity, so it will be problematic to bend them. In addition, there is no memory effect here, so the original shape of the pipe will not be restored well. When creases appear, only couplings will help.

PEX-C pipes are obtained with the so-called. radiation crosslinking: polyethylene is exposed to electrons or gamma rays.The production process requires careful control, because the uniformity of crosslinking depends on the location of the electrode relative to the pipe. The degree of cross-linking reaches 60%, such pipes have a good molecular memory, they are more flexible than PEX-B, but cracks can form on them during operation. Creases are corrected only by couplings. In Russia, such pipes are not widely used.

PEX-D pipes are produced by treating polyethylene with nitrogen compounds. The degree of cross-linking is low, about 60%, therefore, in terms of performance, such products are significantly inferior to analogues. The technology has actually become a thing of the past and is hardly used today.

PEX-EVOH pipes can be found on sale. They differ not in the way of cross-linking, but in the presence of an external additional anti-diffusion layer made of polyvinylethylene, which further protects the product from oxygen entering the pipe. According to the method of stitching, they can be any.

PEX-A pipes are considered the highest quality, but their high cost makes many use PEX-B pipes. These two types of products are the most widely used on the market, and the choice between them depends on the budget, personal preferences and the characteristics of the pipeline that needs to be built with their help.

Do not confuse XLPE pipes with:

- low-pressure polyethylene pipes, they can withstand temperatures not exceeding + 40 ° C and are suitable only for cold water supply systems;

- pipes made of uncrosslinked Pert polyethylene, there are no intermolecular bonds in them, instead of them there is an interlacing of polymer chains and their adhesion. Such pipes have recently appeared on the market, withstand temperatures up to + 70C;

- pipes made of heat-resistant polyethylene.They are also able to withstand high temperatures (due to the introduction of heat-resistant additives into the polymer), but they will not be able to work at high temperature and other loads for as long as PEX pipes.

Features of cross-linked polyethylene

Cross-linked polyethylene is produced by physical or chemical means. When it is created, the units of ethylene molecules form a three-dimensional (three-dimensional) grid with cells by means of cross-links. Cross-linked polyethylene as a material is designated PE-X. According to the production method, they are distinguished: PE-Xa, PE-Xb, PE-Xc, PE-Xd.

PE-Xa is a polymer formed by heating with peroxides. PE-Xb polyethylene is obtained by moisture treatment with a catalytic agent and an implanted silane. PE-Xc is a material formed after electron bombardment of polymer molecules. PE-Xd is extremely rare and is produced using nitrogen technology.

Pipes made of cross-linked polyethylene of the PE-Xa brand are best suited for underfloor heating.

There are several types of pipes made of cross-linked polyethylene, they differ in the way they are made.

Advantages and disadvantages

Cross-linked polyethylene pipes for underfloor heating have a number of advantages:

- Elasticity. This allows you to apply the most optimal level of bending when laying, without the risk of subsequent cracking and kinks. Rehau products are considered especially high-quality in this regard.

- Environmental friendliness. Cross-linked polyethylene contains no harmful components that would be released during heating. This gives a guarantee of safety in laying underfloor heating inside residential premises.

- High combustion temperature.The material begins to melt only after reaching a temperature of +400 degrees. As a result of the decomposition of the substance, water and carbon dioxide are formed, which are completely non-toxic.

- Excellent performance. Equipped with cross-linked polyethylene, the system is not afraid of rotting, corrosion and chemical attack. All this is the key to long-term and flawless operation of a water-heated floor.

- Frost resistance. In the case of a significant decrease in temperature, polyethylene products are not deformed.

- sound absorbing ability. Thanks to this, there is no noise from the coolant circulating inside the circuit.

As for the weaknesses of polyethylene, they usually indicate the need for competent installation work. For example, turning sections are recommended to be securely fixed, because. this material does not hold the convex configuration given to it very well. In addition, not very good resistance of polyethylene products to direct sunlight was noticed.

It is necessary to lay the contour as carefully as possible, avoiding any damage to the protective layer.

Cross-linked polyethylene or metal-plastic

XLPE pipes and metal-plastic pipes are the main competitors when it comes to arranging plumbing, heating systems or underfloor heating. They have a lot in common. Both types of pipes are quite flexible, durable, resistant to corrosion and relatively easy to install - you certainly won’t have to weld anything. True, metal-plastic pipes are still easier to install than PEX pipes, with which you need to be extremely careful.

Metal-plastic pipes have a slightly higher thermal conductivity coefficient (0.45 versus 0.38), but they will not survive freezing inside the coolant.PEX pipes, after the water in the system has melted, can be operated as before. Moreover, some types of PEX pipes easily restore their shape. Resistance to high temperatures and pressure is high for both types of pipes: metal-plastic can withstand pressure up to 25 atm at a temperature of 250C, it can be operated at coolant temperatures up to + 950C with a short-term increase to + 1200C, however, the maximum pressure is 10 atm. Thus, the performance characteristics are quite comparable with those of the XLPE pipes that we cited above.

The choice depends mainly on the features of the operation of the water supply system and the budget. The spread of prices among pipes, even within the same group, is significant, but PEX pipes are often cheaper than metal-plastic ones.

Cross-linked polyethylene (PEX) pipes for underfloor heating

PEX pipes are particularly soft and elastic. They are wear-resistant and durable. Supplied in large coils up to 600 meters. Due to this, they can be laid in a single line without soldering and additional fasteners, which eliminates the risk of leakage or mechanical damage during installation. Durable - service life up to 50 years. Possess high temperature stability without loss of service life. Withstand temperatures up to +95°C. In addition, such a pipe can be poured with concrete. The only negative is that because of their elasticity, they must be fixed to the floor with additional clamps to avoid unwinding. If you answer the question which pipe for a water-heated floor is better or optimal in terms of price and quality, then cross-linked polyethylene will be the leader here.

Two types of PEX pipes are used:

PEX-A (peroxide crosslink).The technology used to crosslink this type of polyethylene pipe ensures a uniform and high degree of crosslinking, resulting in unique strength properties. This makes the pipe durable, especially at the junctions with fittings. PEX-A is an environmentally friendly material.

PEX-B (silanol crosslink). Less expensive stitching method. Unlike PEX-A, after extrusion, the degree of crosslinking does not exceed 15%, which requires additional heat treatment at high temperature to increase the degree of crosslinking. It is less environmentally friendly. The cost of PEX-B is lower than the cost of PEX-A.

Conclusion

The technology of warm water floors implies the need to comply with many nuances. However, before starting work, it is imperative to think about what is more important for you - fast heating or low cost. Metal-plastic products are characterized by rapid heating and excellent thermal conductivity, and are also characterized by ease of installation. But sewn polyethylene costs less, and also allows you to save on laying intervals, which is especially true for large areas.