- I have a warranty or service contract, do I need a maintenance contract?

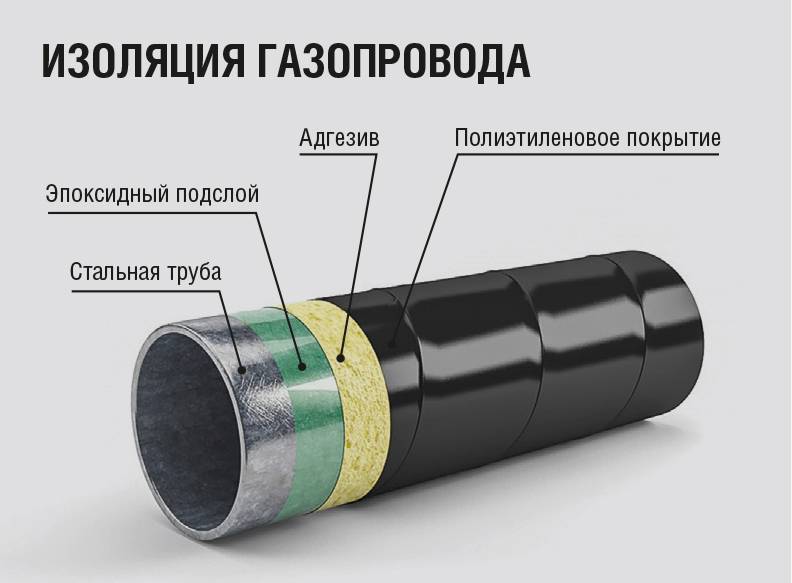

- Factors affecting the condition of pipes

- Replacing obsolete gas equipment is a necessary safety condition!

- Replacing obsolete gas equipment is a necessary safety condition!

- What can be done to extend the service life?

- Normative service life of steel pipes according to GOST

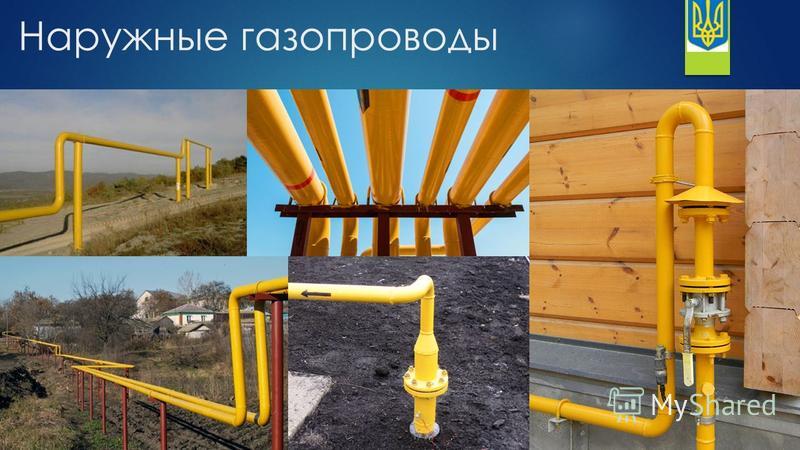

- Types of pipeline

- Pipe wear calculation

- ASSESSMENT OF THE TECHNICAL CONDITION OF EXTERNAL (ABOVEGROUND) AND INTERNAL GAS PIPELINES

- 4.1. Evaluation of the density of above-ground and internal gas pipelines

- 4.2. Assessment of the condition of the pipe metal

- 4.3. Assessment of the state of welded joints

- 4.4. General assessment of the technical condition of the above-ground and internal gas pipelines

- Types of pipeline

- Maintenance

- Legal Framework: What Does the Law Say?

- What to do if the service life of the gas pipeline has expired?

- What to do if the service life of the gas pipeline has expired?

- Maintenance

- Pipe wear calculation

- CRITERIA FOR ASSESSING THE TECHNICAL CONDITION OF OVERGROUND AND INTERNAL GAS PIPELINES

- Repair work

- Conclusions and useful video on the topic

I have a warranty or service contract, do I need a maintenance contract?

The manufacturer, the seller of the equipment establish a warranty period for the operation of the equipment.Often, service providers offer the user to conclude additional service contract, according to which a specific unit that has failed is replaced free of charge, but only if the failure occurred due to the fault of the manufacturer.

The rules for the use of gas establish: TO VKGO / VDGO - works and services to maintain the entire range of equipment that is part of the VKGO / VDGO (gas pipelines, disconnecting devices, gas-using equipment, security systems and gas pollution control, chimneys and ventilation ducts), in a technically sound condition , which meets the requirements for it in relation to specific operating conditions (paragraph 2 of the Rules for the Use of Gas).

According to the Rules for the use of gas, each owner is obliged to ensure that a specialized organization (not a service department!) Performs scheduled maintenance of the VDGO / VKGO at least once a year.

The service contract can only be considered from the point of view of carrying out additional measures to maintain the individual devices that are part of the VKGO / VDGO in good condition. At the same time, the service contract does not comply with the requirements of the Rules for the use of gas and is not a contract for maintenance of VKGO / VDGO.

Factors affecting the condition of pipes

The service life of pipes is reduced under the influence of external conditions

The service life of a gas pipeline depends on a number of objective and subjective factors that can extend or shorten it. Practice shows that most ground and underground lines retain their performance even after the warranty period has expired, sometimes exceeding it several times.However, there are frequent precedents when the network collapsed long before the end of the billing period.

The following factors influence the operation time of communications:

- Errors in design that led to subsequent deformations and ruptures.

- Violations of laying technology, expressed in weak joints, ignoring the use of sleeves when passing through walls.

- The quality of the materials used in the installation.

- The content of alkalis and acids in the soil, leading to metal corrosion.

- Air humidity.

- Compliance with the schedule for the inspection of facilities.

All these factors lead to the fact that pipes from the same batch can serve completely different times.

Replacing obsolete gas equipment is a necessary safety condition!

Replacing obsolete gas equipment is a necessary safety condition!

The average life of gas appliances in accordance with the passports of manufacturers is 10 years. At the same time, obsolete and obsolete gas equipment cannot ensure reliable trouble-free operation and efficient use of natural gas.

If you operate worn-out, non-repairable gas equipment, you put yourself in danger.

Maintenance of the gas stove should be carried out at least once every three years. And after the expiration of its service life and a satisfactory condition, maintenance is carried out at least once a year, which incurs additional costs for the subscriber during its operation.

Gazprom Gas Distribution Arkhangelsk LLC strongly recommends that you, before the scheduled maintenance deadline, replace the gas stove that has worked out the standard operating life established by the manufacturer. After the expiration of the standard service life of the in-house gas equipment, LLC

Gazprom Gas Distribution Arkhangelsk has the right to suspend gas supply in accordance with clause 80 of the Rules for the use of gas in terms of ensuring safety when using and maintaining in-house and in-house gas equipment when providing utility services for gas supply, approved by Decree of the Government of the Russian Federation dated May 14, 2013 No. 410.

LLC Gazprom Gas Distribution Arkhangelsk once again reminds of the need to comply with the requirements of the rules safe use of gas in everyday life when operating gas appliances.

In order to avoid emergency situations, gas consumers are prohibited from:

• carry out unauthorized gasification of households (apartments), rearrangement, replacement and repair household gas-using equipment, gas cylinders and valves;

• make changes to the design of household gas-using equipment, change the structure of smoke and ventilation systems, seal ventilation ducts, wall up or seal “pockets” and hatches intended for cleaning chimneys;

• turn off safety and regulation automation, use gas when gas appliances, automation, fittings are out of order, especially when gas leaks are detected;

• use gas in violation of the density of masonry, plastering of chimneys, unauthorized installation of dampers in chimneys of gas stoves;

• use gas without carrying out regular checks and cleanings of smoke and ventilation ducts within the time limits determined by the Rules for the use of gas in terms of ensuring safety when using and maintaining in-house and in-house gas equipment when providing utility gas supply services.

Dear gas consumers, we remind you that the current legislation obliges you to conclude an agreement on the maintenance and repair of in-house (in-house) gas equipment with a specialized organization, since timely maintenance is a guarantee of your safety.

Replacing obsolete gas equipment is a necessary safety condition!

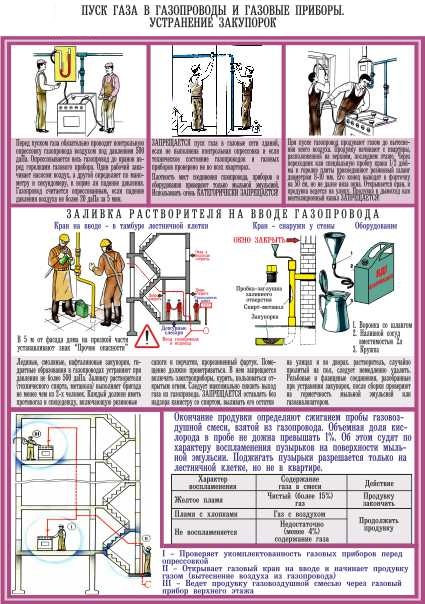

What can be done to extend the service life?

In fact, how long the gas pipeline will last depends, among other things, on the consumer.

To extend the period of its work, it is necessary to systematically follow simple rules:

- Rule #1 Timely inspection and inspection of pipes. To do this, let the inspectors in and try to stay at home if the time of the inspection is announced in advance.

- Rule #2 Turning on the equipment in the correct sequence. Carrying out pressure testing of the gas system in accordance with the instructions and safety rules. The consumer must know which valve is responsible for what. If you are not aware of this, it is better to consult the gas workers serving your home.

- Rule #3 Urgent inspection in case of suspected gas leakage. Call the gas service immediately. They are required to promptly leave for the specified address. Before their arrival, it is better to turn off the gas valve in the apartment.

You can check the leak yourself as follows: in pipe sections where the smell of gas is especially noticeable, anoint the suspicious place with soapy foam. If bubbles begin to swell in the area, there is most likely a leak.

However, this is not a 100% leak detection method, much less a professional one. But for domestic use, in the absence of professional equipment, it is quite suitable and, as practice shows, is quite effective.

To check for a gas leak, lubricate the valve and welding points with soapy suds

If the above describes what needs to be done in order to extend the service life and normal operation of internal gas pipelines, then below it says what should not be done on the contrary:

- tie / wrap pipes with ropes;

- reinstall equipment / change sections of the gas pipeline independently;

- check for leaks with open flame sources (lighters or matches);

- deform (twist / bend) the hoses connecting the system to the stove.

It is necessary to follow these rules not only in order to extend the "life" of your gas pipes, but also to eliminate the risks of dangerous situations.

Normative service life of steel pipes according to GOST

One of the important characteristics of the product is, among other things, the period of operation. Any material wears out over time, but this time can be very different and depends on the load, on additional factors and, of course, on the quality of the product itself. The standard service life of steel water pipes largely determines their purpose.

Types of pipeline

Several types of metal products are used in heating and water supply systems:

- black steel pipes - steel of a different grade is used in the manufacture, but does not have corrosion resistance. Such rolled metal needs additional protection - painting, for example;

- galvanized steel pipes - products are covered with a layer of zinc. The latter forms a galvanic couple with iron and is destroyed by an electrochemical reaction, protecting the steel from corrosion. It is obvious that the service life according to SNiP and GOST for such a model is much longer;

- stainless steel - alloys with the addition of nickel and chromium. Depending on the value of the alloying additive, steel can be resistant to corrosion under normal conditions, is characterized by increased resistance, which allows it to be used in sea water, for example, and also not oxidize under the influence of not only moisture, but also high temperature. The product does not need protection, however, its cost is noticeably higher;

- copper - rarely, but used in domestic conditions. They are distinguished not only by resistance to corrosion, but also by disinfecting properties.

Each option from the list can be used for water supply, gas pipelines, heating, and not only water, but also steam. However, their service life will be different.

Alas, this option is not particularly durable. Even with the most careful painting and care, they rust over time. The fact is that after the construction of communications, individual fragments are inaccessible, and it is impossible to renew the paint, for example.

In addition, black steel loses its smoothness rather quickly.And this leads to the fact that the water and gas or heating pipe “overgrows” rather quickly: first, very small debris and salt deposits are held on the uneven surface, and then increasingly large particles of rust, fibers, and lime deposits. The rate at which deposits build up is directly proportional to the hardness of the water.

Constant contact with moisture - in the bathroom, for example, in the toilet, leads to faster destruction of the material, which is reflected in the norms of SNiP. Here, the weak link is often the seams: the first fistulas appear precisely on the welds and on the thread, where the wall thickness decreases.

The standard operating time is as follows:

- the service life of steel water pipes - a riser or an eyeliner, is 15 years;

- a heating system assembled from gas steel pipes is usable for 10 years;

- heated towel rails in the bathroom can "work" for 15 years;

- according to GOST, the standard service life of a gas pipeline made of steel pipes is 30 years.

In fact, various destructive factors significantly reduce the operating time. So, for example, a pipeline with cold water wears out much faster than with hot water, as it rusts faster: condensation appears in the warm season. Yes, and the pipeline overgrows faster, since there are special additives in hot water that prevent this.

Pipe wear calculation

When planning inspections and repairs of pipeline systems, specialists of gas services are not limited only to external inspections and laboratory tests. Such events are productive, but covering all the houses in a big city with them is simply unrealistic.

To develop a schedule for repairs, specialists use formulas developed on a scientific basis and observational practice.

For calculations, the following initial data are taken:

- design voltage;

- strength factor;

- Wall thickness;

- minimum long-term strength of the material.

The indicators imply the technical properties of the material at an air temperature of 20 degrees.

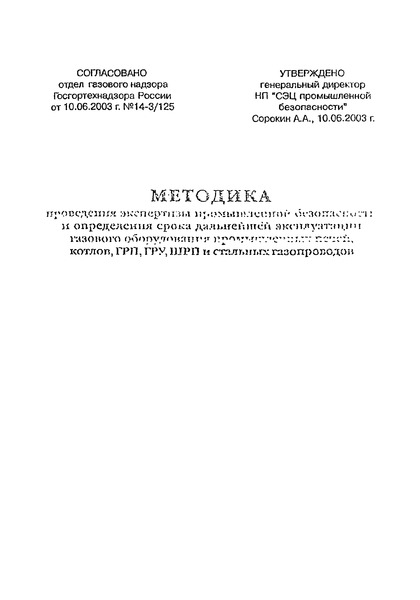

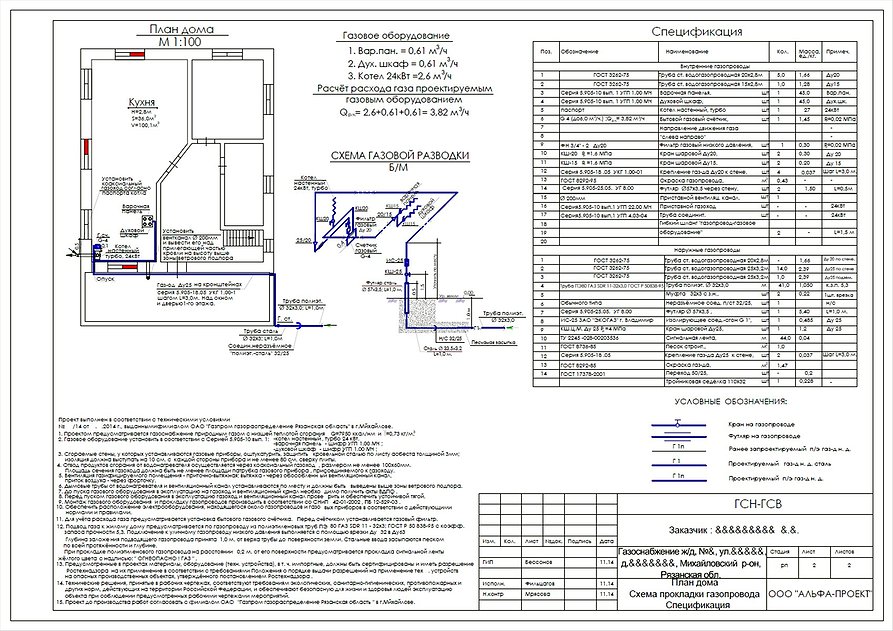

ASSESSMENT OF THE TECHNICAL CONDITION OF EXTERNAL (ABOVEGROUND) AND INTERNAL GAS PIPELINES

4.1. Evaluation of the density of above-ground and internal gas pipelines

4.1.1. The assessment of the density of gas pipelines is carried out on the basis of statistical information about the technical condition of the gas pipeline from the beginning of operation in accordance with Table. one.

If the length of the surveyed section of the gas pipeline is less than 1 km, the score (in points) is determined by reducing the number of leaks to a length equal to 1 km.

For example, the length of the tested section of the gas pipeline is 400 m, one leak was found on it, therefore, the number of leaks, reduced to a length of 1 km, would be 2.5. This value in the table. 1 corresponds to a score of 1 point.

Table 1

| Cases of gas leaks associated with damage from a rupture of a gas pipeline or welded joints that have occurred since the start of operation on each kilometer of the surveyed gas pipeline | Evaluation, points |

| More than 2 | 1 |

| 2 | 2 |

| 1 | 3 |

| 5 |

4.2. Assessment of the condition of the pipe metal

When measuring the thickness of the walls of a gas pipeline, pulsed resonant thickness gauges should be used, which make it possible to determine the thickness with one-sided access. Thickness gauges "Quartz-6", "Quartz-14", "UIT-T10" can be recommended for this purpose.

Upon receipt of unsatisfactory results of measurements of the wall thickness of at least one measurement, the scope of control is increased by at least twice and is established by the technical manager of the power facility.Upon receipt of three or more unsatisfactory results of wall thickness measurements in the section of the tested gas pipeline, the entire section of the gas pipeline must be replaced.

The assessment of the pipe metal condition is carried out on the basis of data obtained as a result of direct measurement of the pipe wall thickness in accordance with Table. 2.

table 2

| Thinning of the gas pipeline wall from the passport (design) value, % | Evaluation, points |

| More than 20 (at least three measurements) | 1 |

| More than 20 (less than three dimensions) | 2 |

| Less than 20 (for all measurements) | 3 |

| Less than 10 (for all measurements) | 5 |

Gas pipelines that have received a score of one point for the condition of the pipe metal, regardless of the total score received according to other criteria, are subject to replacement.

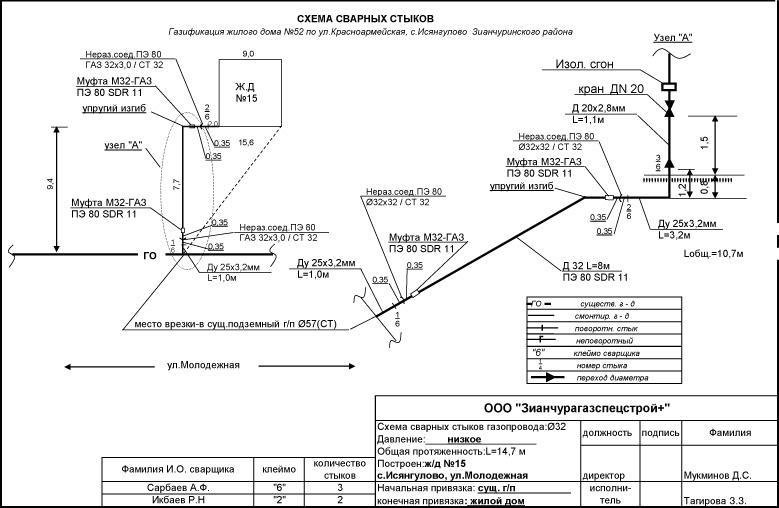

4.3. Assessment of the state of welded joints

The quality check of welded joints should be carried out in accordance with the requirements of the “Standard Instructions for Monitoring and Extending the Service Life of the Metal of the Main Elements of Boilers, Turbines and Pipelines of Thermal Power Plants: RD 34.17.421-92” (M.: SPO ORGRES, 1992).

Control of welded joints of gas pipelines by a physical method should be carried out selectively from the number of joints that did not pass ultrasonic testing upon acceptance into operation in the amount of 10%, but at least one joint welded by each welder on the tested gas pipeline. The control results should be documented in a protocol in accordance with the requirements of SNiP 3.05.02-88. If the results of checking welded joints by physical methods are unsatisfactory, it is necessary to check twice the number of joints welded by a welder whose welded joint was recognized as unsatisfactory according to the control results.If, upon re-checking by physical methods, at least one of the checked joints turns out to be of unsatisfactory quality, all joints made by the welder on the gas pipeline are subject to verification.

The quality assessment of welded joints is carried out according to Table. 3.

Table 3

| Joint quality | Number of joints from the total checked number, % | Evaluation, points |

| Defective | Over 50 | 1 |

| Less than 50 | 2 | |

| Less than 20 | 3 | |

| Less than 10 | 4 | |

| Suitable | 100 | 5 |

If, as a result of the check, it is established that 50% or more of the checked joints are defective, then a score of one point is put down, and the gas pipeline, regardless of the total score obtained according to other criteria, is subject to replacement.

4.4. General assessment of the technical condition of the above-ground and internal gas pipelines

The overall assessment of the technical condition of the gas pipeline is carried out according to a point system by summing up the estimates for each indicator, determined in accordance with Table. 1-3.

Gas pipelines that have received an overall score of 6 points or less are subject to replacement.

Gas pipelines that have received an overall score of 7 to 10 points are subject to overhaul in ascending order of points.

Gas pipelines that have received an overall score of more than 10 points are considered fit for further operation, and their technical condition is satisfactory.

Application

Mandatory

| APPROVE:______________________ (job title) ______________________ (Full name.) "____" __________ 199_ (the date) |

Types of pipeline

Several types of metal products are used in heating and water supply systems:

- black steel pipes - steel of a different grade is used in the manufacture, but does not have corrosion resistance. Such rolled metal needs additional protection - painting, for example;

- galvanized steel pipes - products are covered with a layer of zinc. The latter forms a galvanic couple with iron and is destroyed by an electrochemical reaction, protecting the steel from corrosion. It is obvious that the service life according to SNiP and GOST for such a model is much longer;

- stainless steel - alloys with the addition of nickel and chromium. Depending on the value of the alloying additive, steel can be resistant to corrosion under normal conditions, is characterized by increased resistance, which allows it to be used in sea water, for example, and also not oxidize under the influence of not only moisture, but also high temperature. The product does not need protection, however, its cost is noticeably higher;

- copper - rarely, but used in domestic conditions. They are distinguished not only by resistance to corrosion, but also by disinfecting properties.

Maintenance

Regular maintenance of gas pipelines makes it possible to identify and eliminate an emergency and extend their service life.

Maintenance of gas pipelines includes the following activities:

- External inspection for detection of external damage, corrosion, peeling of the protective coating.

- Monitoring the performance of shut-off and control valves.

- Checking the tightness of the system by pressure testing.

- Restoring the integrity of joints.

- Removing rust, applying a new protective coating.

- Replacement of emergency fragments.

- Check equipment for leaks and leaks.

Only qualified employees of the gas service have to perform these manipulations.

Legal Framework: What Does the Law Say?

According to the Order of November 21, 2013 N 558, which regulates the safety rules for handling liquefied gas.

Technical inspection of an underground gas pipeline is carried out after the expiration of the estimated service life, which is for:

- steel pipes - 40 years;

- polyethylene pipes - 50 years.

Pipelines assembled from polymer pipes last longer due to higher resistance to mechanical and chemical influences, as well as the absence of prerequisites for the appearance and settlement of mold fungus.

In this case, during such diagnostics, the following parameters should be checked:

- tightness of the gas pipeline;

- protective coating (for steel pipes);

- the state of the material from which the gas pipeline is made;

- quality of welding at the joints.

Early inspections are carried out only in case of accidents or reliable information about the deformation of gas pipelines underground.

Surveys are still carried out in accordance with the instructions with RD 204 of the RSFSR 3.3-87, approved back in 1987. The provisions contained in Decree of the Government of the Russian Federation of October 29, 2010 N 870 contain rather vague wording regarding this issue.

Thus, paragraph 76 states that the operational life is determined at the time of design, taking into account the conditions for ensuring the safety of objects, the forecast regarding changes in their parameters, as well as guarantees for pipe products given by the manufacturer.

In addition, this act refers to the fact that the gas pipeline can be operated even after the expiration of its service life, if the diagnostics did not reveal any serious violations in the operation of the system and defects in the pipes. Based on the results of such diagnostics, the boundary periods of operation should be re-established.

As for outdoor gas pipelines and equipment, as a rule, their service life is shorter

In any case, you should always pay attention to their working "experience", which is indicated by the manufacturer.

For example, the manufacturer "Gazovik" for GRPSH-6, 10 and 10MS determines the following terms:

- medium (before write-off) - 15 years;

- warranty term - 5 years.

But the “First Gas Company” in the passports for most of its GRSF indicates a 20-year period, which, by the way, is the average for GRSF installations.

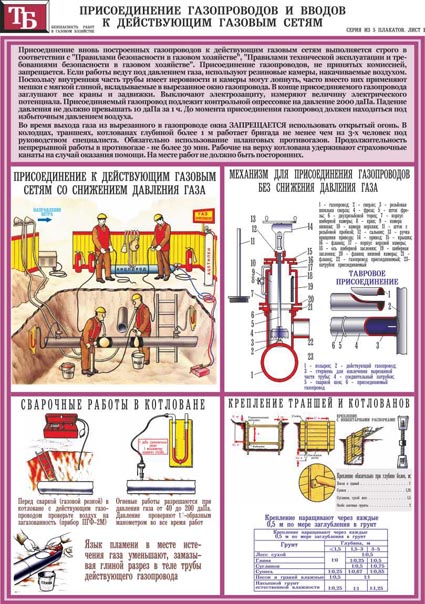

What to do if the service life of the gas pipeline has expired?

In the event of the expiration of their service life, they must be repaired, which provides for the complete or partial replacement of elements.

If the competent persons have already carried out an inspection and come to the conclusion that a replacement is necessary, the consumer does not need to do anything. Repair work must be carried out by employees of GorGaz or other similar services serving the facility.

Each consumer must be familiar with the rules for operating the gas pipeline, and also be able to shut off the gas supply to the apartment if necessary.

For a complete replacement of the gas pipeline, a mobile team is sent to the site, which removes the failed sections of the main passage to the common house complex of pipes, and then looks at the situation.

Partial replacement of pipes in a multi-storey building is carried out by cutting off old sections and placing new ones by welding.

Such events are carried out strictly according to safety rules:

- The access of gas to the pipes is blocked.

- The site to be replaced will be completely vented of the gas in accordance with the safe handling of hazardous facilities.

- Cut off the old section.

- By welding, a new element is mounted in its place.

- Checking the integrity and tightness of the site.

- Starting the gas flow through the pipe after purging them.

Repair of gas equipment cannot be done independently. This is a complex and dangerous process that can only be carried out by employees of the gas industry with the necessary equipment.

Moreover, the fact that such work was carried out, as well as the date of their implementation, it is necessary to enter information into the data sheet, in which all actions carried out with the system are noted. This is necessary in order to subsequently be able to determine the service life of the new gas pipeline.

To extend the life of the internal gas pipeline, operate it in accordance with the rules. For example, do not kink the hose that supplies gas from the system to the stove

If the consumer suspects that the pipes have become unusable, he can make an application to the relevant utilities and wait for the arrival of their employees, but in no case should you check your version without their presence.

What to do if the service life of the gas pipeline has expired?

In the event of the expiration of their service life, they must be repaired, which provides for the complete or partial replacement of elements.

If the competent persons have already carried out an inspection and come to the conclusion that a replacement is necessary, the consumer does not need to do anything. Repair work must be carried out by employees of GorGaz or other similar services serving the facility.

For a complete replacement of the gas pipeline, a mobile team is sent to the site, which removes the failed sections of the main passage to the common house complex of pipes, and then looks at the situation.

Partial replacement of pipes in a multi-storey building is carried out by cutting off old sections and placing new ones by welding.

Such events are carried out strictly according to safety rules:

- The access of gas to the pipes is blocked.

- The site to be replaced will be completely vented of the gas in accordance with the safe handling of hazardous facilities.

- Cut off the old section.

- By welding, a new element is mounted in its place.

- Checking the integrity and tightness of the site.

- Starting the gas flow through the pipe after purging them.

Repair of gas equipment cannot be done independently. This is a complex and dangerous process that can only be carried out by employees of the gas industry with the necessary equipment.

Moreover, the fact that such work was carried out, as well as the date of their implementation, it is necessary to enter information into the data sheet, in which all actions carried out with the system are noted. This is necessary in order to subsequently be able to determine the service life of the new gas pipeline.

If the consumer suspects that the pipes have become unusable, he can make an application to the relevant utilities and wait for the arrival of their employees, but in no case should you check your version without their presence.

Maintenance

Gas pipeline maintenance is carried out by licensed companies

Gas pipeline maintenance is carried out by licensed companies

Regular maintenance of gas pipelines makes it possible to identify and eliminate an emergency and extend their service life.

Maintenance of gas pipelines includes the following activities:

- External inspection for detection of external damage, corrosion, peeling of the protective coating.

- Monitoring the performance of shut-off and control valves.

- Checking the tightness of the system by pressure testing.

- Restoring the integrity of joints.

- Removing rust, applying a new protective coating.

- Replacement of emergency fragments.

- Check equipment for leaks and leaks.

Only qualified employees of the gas service have to perform these manipulations.

Pipe wear calculation

An example of calculating a gas pipeline according to input data

When planning inspections and repairs of pipeline systems, specialists of gas services are not limited only to external inspections and laboratory tests. Such events are productive, but covering all the houses in a big city with them is simply unrealistic.

To develop a schedule for repairs, specialists use formulas developed on a scientific basis and observational practice.

For calculations, the following initial data are taken:

- design voltage;

- strength factor;

- Wall thickness;

- minimum long-term strength of the material.

The indicators imply the technical properties of the material at an air temperature of 20 degrees.

CRITERIA FOR ASSESSING THE TECHNICAL CONDITION OF OVERGROUND AND INTERNAL GAS PIPELINES

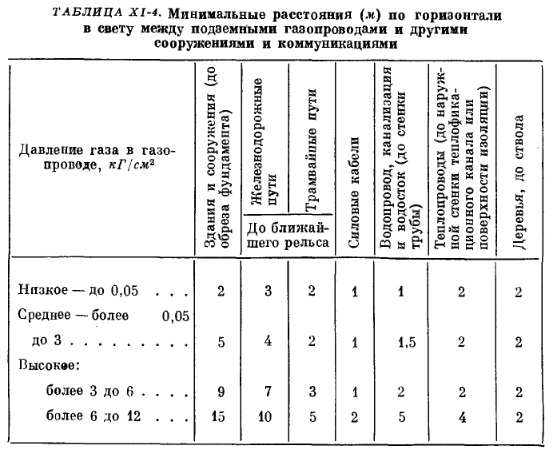

2.1. The main criteria that determine the technical condition of gas pipelines when establishing the need for their repair or replacement are: the density of gas pipelines, the condition of the pipe metal and the quality of welded joints.

2.2. When determining the state of density of gas pipelines, gas leaks associated with damage to the metal of the pipe and with the opening and rupture of welds detected during operation (according to operation data) should be taken into account.

This should not take into account gas leaks caused by mechanical damage to the gas pipeline during construction or repair work, which are episodic in nature and not associated with a general deterioration in the technical condition of the gas pipeline, as well as gas leaks that occurred during operation through valve leaks and in flange connections or from - for damage to fittings not associated with a general deterioration in the technical condition of the gas pipeline.

2.3. When determining the condition of the pipe metal, it is necessary to measure the wall thickness of the straight section of the gas pipeline with a diameter of 150 mm or more, measure the thickness of the stretched part of one bend on each gas pipeline Dy 50 mm or more.

The wall thickness of the straight section should be measured every 50 m of the internal gas pipeline, but not less than one on the gas pipelines of each boiler or hydraulic fracturing, and every 200 m of the above-ground external gas pipeline, but not less than one. Wall thinning should not exceed the values regulated by OST 108.030.40-79, OST 108-030.129-79 and TU 14-3-460-75.

The results of measurements of the wall thickness of gas pipelines must be reflected in the acts, which should be stored along with the passports of gas pipelines.

The act must be accompanied by a diagram of the gas pipeline with the designation of the places for measuring the thickness of the walls of the gas pipeline.

2.4. The quality of welded joints is determined in accordance with the requirements of SNiP 3.05.02-88, GOST 16037-80, RD 34.17.302-97 “Steam and hot water boilers. Steam and hot water pipelines, vessels. Welded connections. Quality control. Ultrasonic control. Basic Provisions” (OP 501 TsD-75). - M .: NPP "Norma", 1997.

Quality control of welded joints on existing gas pipelines is carried out in cases where:

during operation on this gas pipeline, cases of opening or rupture of welded joints were observed;

when checking for tightness, it was found that the place of leakage is a poor-quality welded joint.

If during operation on this gas pipeline there were no breaks in the joints and no leakage was recorded through them, then the joints are recognized as fit and they are not checked.

2.5. The technical condition of gas pipelines for each criterion should be evaluated according to a point system in accordance with Sec. 4 of these Recommendations.

Repair work

Gas leakage is a factor that requires urgent repair of pipes and taps

Gas leakage is a factor that requires urgent repair of pipes and taps

Planned pipeline repair works are carried out after the expiration of the warranty period established by their manufacturers. However, a preventive inspection is carried out every 5-10 years, depending on the operating conditions of the system. Special devices are used, examinations of various kinds are carried out. Based on the results of the audit, a protocol and a work plan are drawn up.

There are the following signs that indicate the need for repair:

- wall thinning;

- violation of welding seams;

- leak detection;

- the appearance of rust;

- fading or fading of paint.

The repair procedure involves the complete or partial replacement of pipes. Rejected sections are cut out and new fragments are installed in their place.

The repair procedure involves the complete or partial replacement of pipes. Rejected sections are cut out and new fragments are installed in their place.

This process is carried out in the following sequence:

- Shutting off the gas supply to the riser.

- The pipeline is pumped with air.

- Cut out damaged areas.

- New pipes are being welded on.

- The system is checked for leaks.

- Steel parts are painted yellow, and in apartments to the taste of the residents.

The final stage is the preparation of an act of work performed.

Conclusions and useful video on the topic

For calculations, the strength is taken into account, determined at a temperature of 20 ° C for a service life of 50 years according to ISO 9080:

Compliance with the terms stipulated by building codes and guaranteed by the manufacturer is necessary to ensure the safe operation and operation of the system. Checking the technical condition of the gas supply, which belongs to the category of explosive communications, is a necessary measure. It will save you from risks and a lot of problems.

Please write comments in the block below, post photos and ask questions on the topic of the article. Tell us about your experience in inspecting gas pipes and identifying their critical technical condition. Share useful information that may be useful to site visitors.