- Ways to increase efficiency

- Calculation of the power of a gas boiler depending on the area

- Calculation of a single-circuit heating boiler

- How to calculate the power of a double-circuit boiler

- Calculation of the power of an indirect heating boiler

- What will lead to success?

- Equipment class

- Burner type

- Electricity

- heat exchanger

- The intensity of the equipment

- Places for installing a gas boiler

- Clocking and power of the Immergas boiler

- Location of the floor gas boiler

- Maintainability of the heat exchanger

- What you need to pay special attention to when choosing a gas boiler

- Type of gas burner

- Procedure for replacing gas appliances

- Unauthorized replacement of a gas boiler consequences

- The period of technical examination of the boiler and fittings

- Price categories of gas boilers

- How to choose a gas meter

- The main types of household gas meters

Ways to increase efficiency

In order for the heating system to work with minimal heat loss, you should familiarize yourself with effective methods, how to improve the efficiency of a gas boiler. To do this, it is necessary to exclude all types of heat loss as much as possible.

- To reduce the percentage of physical underburning, you should monitor the condition and cleanliness of the flame tubes and the water circuit.Soot forms on the pipeline, and scale builds up on the circuit, so these elements of the heating system require regular cleaning.

-

There should be no excess air in the gas boiler, since heat, which could be used to heat the coolant, also goes into the chimney with it. This problem can be solved by installing a draft limiter on the chimney.

- Throttle adjustment. This can be done using a thermometer installed in the boiler. You just need to put the damper in such a position that at the same time the maximum temperature of the coolant is reached.

- Ensure that normal traction is maintained. It decreases as a result of the narrowing of the cross section of the chimney. You can avoid this if you regularly clean the outlet pipe, because soot sticks to its walls.

- It is necessary to clean the combustion chamber regularly, as soot forms on the surface of its walls, which increases fuel consumption.

Installation of a coaxial chimney

If you are looking for options on how to increase the efficiency of a gas boiler, pay attention to which chimney is installed. Traditional discharge pipes have a number of disadvantages, the main of which is the dependence on weather conditions. An alternative to a conventional chimney can be a coaxial chimney, which has the following advantages:

An alternative to a conventional chimney can be a coaxial chimney, which has the following advantages:

- significantly increases the efficiency of a gas boiler;

- resistant to high temperatures;

- can be made in different versions;

- allows you to save fuel;

-

ensures long-term temperature maintenance in the room.

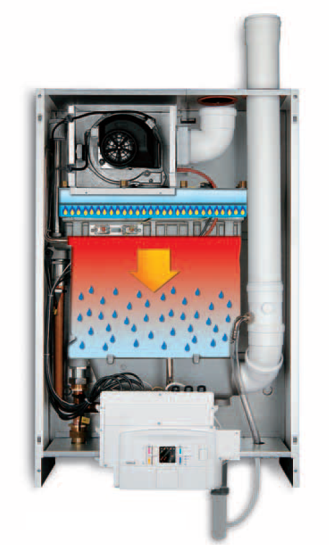

The device of a coaxial chimney does not require much effort.The design consists of two exhaust pipes of different diameters, exhaust gases are transported through one, oxygen-saturated air through the other.

If you do not have experience with heating equipment, but there is a need to resolve the issue of how to improve the efficiency of a gas boiler, contact the specialists. They will perform work at the highest level, ensuring the most efficient functioning of the heating system of your home.

Calculation of the power of a gas boiler depending on the area

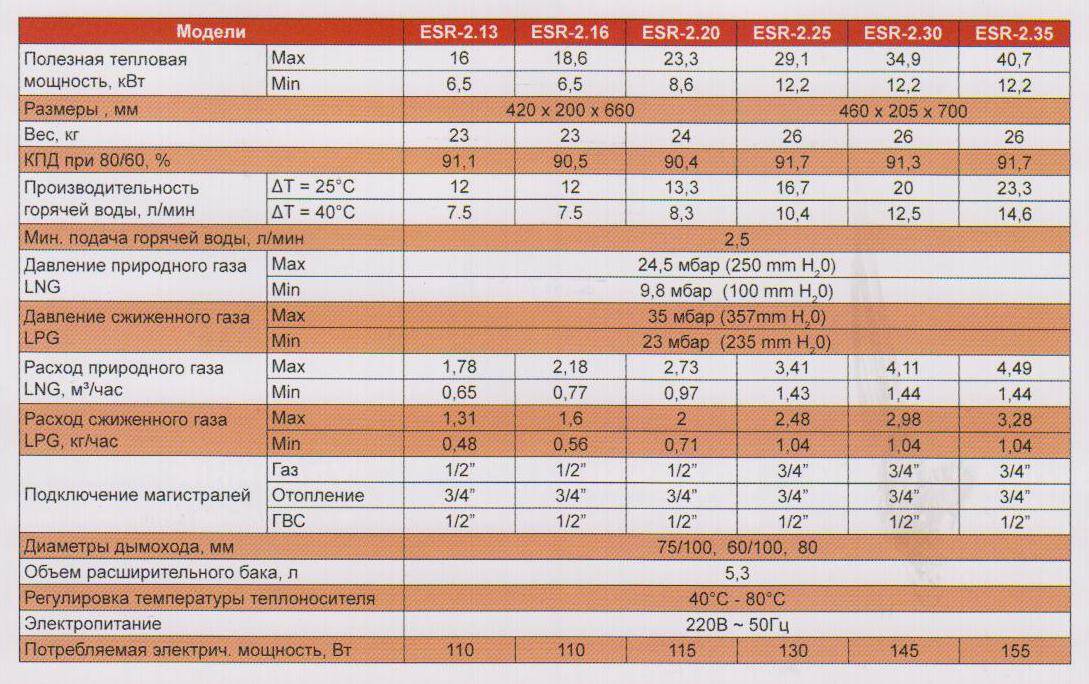

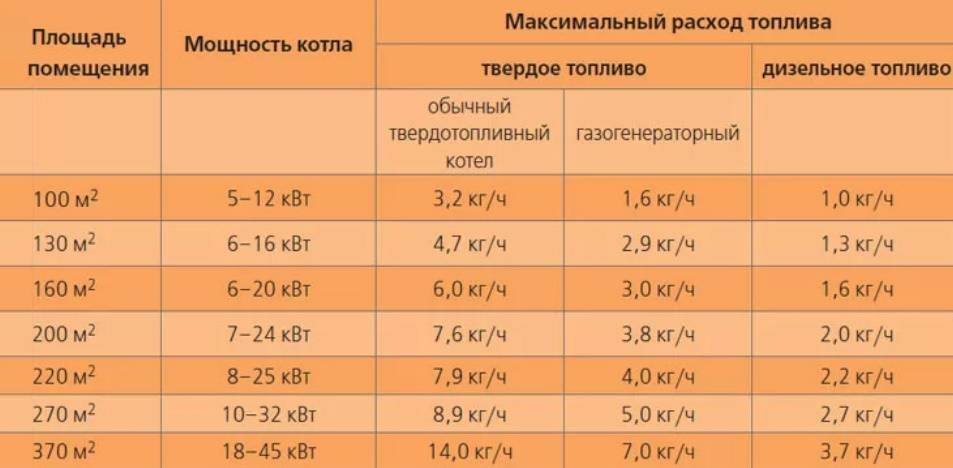

In most cases, an approximate calculation of the thermal power of the boiler unit is used for heating areas, for example, for a private house:

- 10 kW per 100 sq.m;

- 15 kW per 150 sq.m;

- 20 kW per 200 sq.m.

Such calculations may be suitable for a not very large building with an insulated attic floor, low ceilings, good thermal insulation, double-glazed windows, but no more.

According to the old calculations, it is better not to do it. Source

Unfortunately, only a few buildings meet these conditions. In order to carry out the most detailed calculation of the boiler power indicator, it is necessary to take into account a full package of interrelated quantities, including:

- atmospheric conditions in the area;

- the size of the residential building;

- coefficient of thermal conductivity of the wall;

- the actual thermal insulation of the building;

- gas boiler power control system;

- the amount of heat required for DHW.

Calculation of a single-circuit heating boiler

Calculation of the power of a single-circuit boiler unit of wall or floor modification of the boiler using the ratio: 10 kW per 100 m2, must be increased by 15-20%.

For example, it is necessary to heat a building with an area of 80 m2.

Calculation of the power of a gas heating boiler:

10*80/100*1.2 = 9.60 kW.

In the case when the required type of device does not exist in the distribution network, a modification with a larger kW size is purchased. A similar method will go for single-circuit heating sources, without a load on hot water supply, and can be used as the basis for calculating gas consumption for a season. Sometimes, instead of living space, the calculation is performed taking into account the volume of the residential building of the apartment and the degree of insulation.

For individual premises built according to a standard project, with a ceiling height of 3 m, the calculation formula is quite simple.

Another way to calculate the OK boiler

In this option, the built-up area (P) and the specific power factor of the boiler unit (UMC) are taken into account, depending on the climatic location of the facility.

It varies in kW:

- 0.7 to 0.9 southern territories of the Russian Federation;

- 1.0 to 1.2 central regions of the Russian Federation;

- 1.2 to 1.5 Moscow region;

- 1.5 to 2.0 northern regions of the Russian Federation.

Therefore, the formula for the calculation looks like this:

Mo=P*UMK/10

For example, the required power of a heating source for a building of 80 m2, located in the northern region:

Mo \u003d 80 * 2/10 \u003d 16 kW

If the owner will install a double-circuit boiler unit for heating and hot water, professionals advise adding another 20% of the power for water heating to the result.

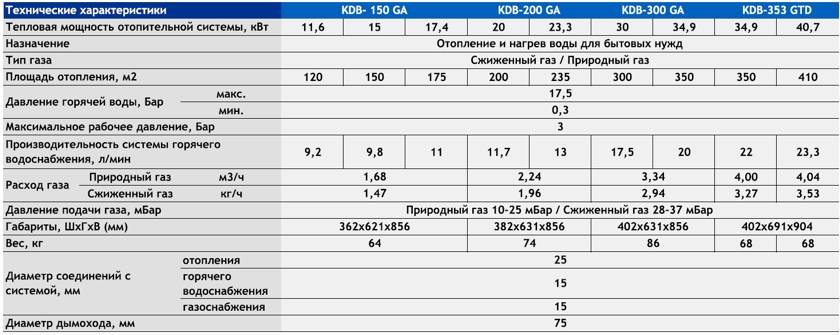

How to calculate the power of a double-circuit boiler

The calculation of the heat output of a double-circuit boiler unit is carried out on the basis of the following proportion:

10 m2 = 1,000 W + 20% (heat loss) + 20% (DHW heating).

If the building has an area of 200 m2, then the required size will be: 20.0 kW + 40.0% = 28.0 kW

This is an estimated calculation, it is better to clarify it according to the rate of water use of hot water supply per person. Such data are given in SNIP:

- bathroom - 8.0-9.0 l / min;

- shower installation - 9 l / min;

- toilet bowl - 4.0 l / min;

- mixer in the sink - 4 l / min.

The technical documentation for the water heater indicates what heating output of the boiler is required to guarantee high-quality water heating.

For a 200 l heat exchanger, a heater with a load of approximately 30.0 kW will suffice. After that, the performance sufficient for heating is calculated, and at the end the results are summarized.

Calculation of the power of an indirect heating boiler

In order to balance the required power of a single-circuit gas-fired unit with an indirect heating boiler, it is necessary to establish how much heat exchanger is required to provide hot water to the residents of the house. Using the data on the norms of hot water consumption, it is easy to establish that the consumption per day for a family of 4 will be 500 liters.

The performance of an indirect heating water heater directly depends on the area of \u200b\u200bthe internal heat exchanger, the larger the coil, the more heat energy it transfers to water per hour. You can detail such information by examining the characteristics of the passport for the equipment.

Source

There are optimal ratios of these values for the average power range of indirect heating boilers and the time to obtain the desired temperature:

- 100 l, Mo - 24 kW, 14 min;

- 120 l, Mo - 24 kW, 17 min;

- 200 l, Mo - 24 kW, 28 min.

When choosing a water heater, it is recommended that it heats the water in about half an hour. Based on these requirements, the 3rd option of the BKN is preferable.

What will lead to success?

First of all, this skill. Only personal experience will help in the future to win.

In second place is the top technology

. Experienced gamers do not recommend using stock vehicles, as slow tanks that do not provide effective fire support are too boring

That is why it is important to improve tanks to the top with the help of free experience.

An important factor is. Training and retraining is best done at the expense of gold.

In each battle, you should have gold shells with you, which more effectively pierce opponents. The more often this happens, the better the result of the team.

Equipment class

Economical gas boilers are designed for extended service time - according to consumer reviews, this is 30 years of uninterrupted operation, when repairs were carried out as needed.

Middle class units with regular maintenance rarely last more than 15 years. These are devices of the middle price category, the most popular among consumers, where methods of unhealthy competition are used (premature wear of parts, failure of working elements, etc.). Savings of 15-20 thousand rubles ultimately lead to the need to either replace equipment or constantly contact service workers. Among the frequent problems are loss of water temperature, unauthorized shutdown, attenuation of the burner, failure of the electronic unit, etc.

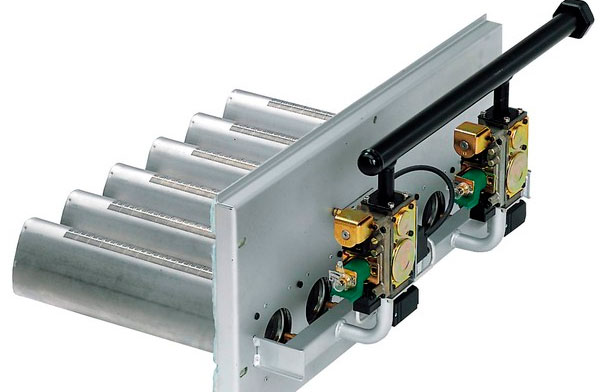

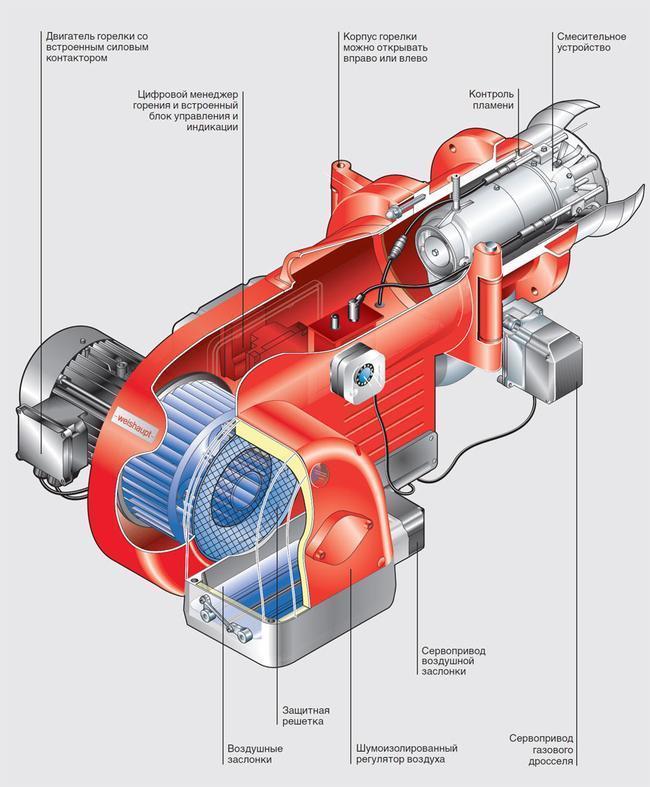

Burner type

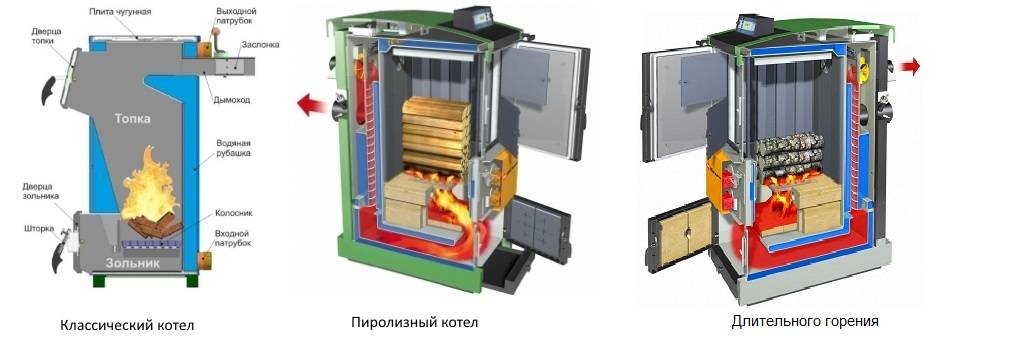

Gas equipment works on two types of burners:

- atmospheric;

- inflatable.

In the first variant, the process of formation of the gas-air mixture occurs naturally. In the inflatable - in the first chamber, air is mixed with gas, passes into the second, where the combustion process takes place.In such designs, natural gas burns without residue, which increases the efficiency to maximum values and, together with it, reduces operating costs by an average of a third.

Electricity

The key problem of the normal operation of gas equipment is the unstable operation of the power grid. In the absence of a voltage stabilizer or at least a UPS, another power surge in the network can become fatal when the electronic control board, electrical and / or electrically controlled elements fail:

- ignition;

- gas valve, etc.

heat exchanger

The material from which the heat exchanger is made is also important, how quickly scale will collect on it. In this case, the choice should be made in favor of separate copies, since on bithermic heat exchangers, in contrast to them, scale forms many times faster.

The intensity of the equipment

Initially, when choosing gas equipment, they make a calculation by power. You can never take it back to back - with constant work, the resource will be exhausted very quickly. You should always make a margin of at least 20%. All equipment is built on impulse operation, respectively, the fewer impulses, the more stable the unit will work.

In any case, the gas boiler works exactly as long as its main components work. If you take preventive measures in a timely manner, install protective filters against scale, voltage stabilizers, undergo maintenance on time, you will be provided with more than 15 years of work.

Places for installing a gas boiler

floor standing boiler in the attic

Before you install the boiler, you should carefully approach the question of where it can be installed.It can be mounted on residential floors in separate rooms and on the basement, annex or basement. The area for installation of the boiler must be at least fifteen square meters, and the ceiling must have a height of at least 2.5 meters. A fire door with a third type must be installed. The walls must have a fire resistance of at least 0.75 hours and, in accordance with the design features, zero limits for determining open flames. In the room where the installation of a gas boiler is planned, a sewer pipe is laid, with a diameter of 5 centimeters or more. If the room is located on the ground floor or lower, then it is necessary to make a separate exit to the street.

Clocking and power of the Immergas boiler

Firm and model of equipment:

Immergas Eolo Star 24 kV

David:

Hello. I really need your advice. I re-read and reviewed a bunch of material, but did not find the answer to my question. Boiler Immergaz Eolo Star 24-kilowatt, CO 4 panel radiators with a total capacity of 7500 watts and a dryer in the bathroom, the coolant in the system is about 40 liters.

Room thermostat installed. The coolant temperature is 75 degrees. Boiler operation: after the boiler is turned off by the thermostat, there is a pause of about 2 hours, the water in the system cools down to 24-30 degrees and after the thermostat closes the contacts, the boiler turns on and runs at minimum power for 5 minutes and gradually increases to the maximum until the water reaches 75 degrees.

Then it modulates to a minimum (set to 45%) and before the thermostat works, it has time to cycle twice. In the menu, I lowered the power to 5% and the boiler stopped clocking

I can’t understand this: when working with a thermostat, in my opinion, it is important that the boiler heats up the apartment faster and that the apartment keeps the temperature longer

The passport indicates that the minimum heating power is 11.5 kilowatts. Which is more profitable in terms of gas consumption: fast heating of the coolant and then work at a minimum to maintain the temperature. The manufacturer does not recommend lowering the power by less than 30 percent due to a decrease in efficiency. What is more important: efficiency reduction or boiler operation without clocking?

Answer:

Hello David. My opinion is that clocking is definitely bad for any unit, including the boiler. Clocking leads to additional wear of the components and, as a result, to excessive fuel consumption and a reduction in the life of the boiler. In addition - thermal shocks in CO, the danger of overheating of the coolant and other troubles associated with improper operation of heating equipment ...

There can be only one reason for the boiler clocking - insufficiently efficient operation of the entire CO. In this case, there can be only two reasons:

- incorrect calculation;

- incorrect installation of CO.

However, not a single heat engineer can take into account all the nuances when creating CO ...

As an option, you can install a modulating burner - a burner with variable power. But this is a "half" solution. It is better to install an additional tank for the coolant - a heat accumulator between the boiler and CO. It will serve as a compensator for temperature changes.

The boiler "pumps" heat into the heat accumulator, and CO - consumes this heat as needed (need). Everything is very simple. Personally, I have 200 liters and there are no problems with clocking).

If you have any questions - write.

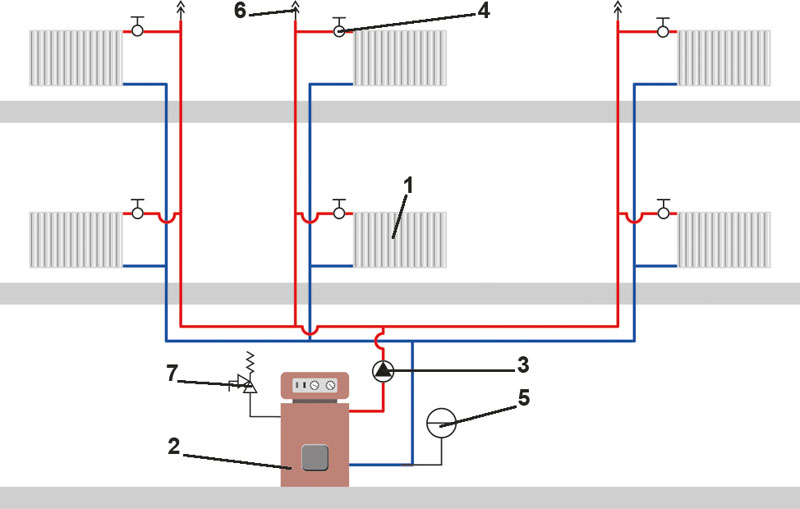

Location of the floor gas boiler

floor boiler installation diagram

If your choice would be stopped on a floor-type boiler, then you should immediately think about where it will be located. After that, it is required to bring gas pipes and mount a chimney. In order to comply with safety standards, the boiler must be installed on special stands. To do this, it is necessary to prepare a wooden formwork with a tedious area, pour a form a few centimeters high with cement mortar. The boiler can be installed on the podium after curing.

It is worth remembering that the chimney pipes must be carefully insulated. This is required so that the combustion products do not cool down in the chimney before they go outside. If carbon monoxide cools in the pipe, it will lose its volatile properties and instead of the street, it will return back to the boiler, and from the boiler to the room.

Maintainability of the heat exchanger

As noted above, the heat exchangers of modern gas boilers are made of: copper, stainless steel, cast iron. According to reviews, under the right operating conditions, the service life of a steel heat exchanger in a gas boiler is 15-20 years, and a cast-iron one up to 30 years. The life of a copper coil is limited to 5-10 years.

In single-circuit heating heat generators, one coil is installed, which transfers the thermal energy obtained during the combustion of fuel to the coolant. Depending on the design, two heat exchangers (primary and secondary) or one bithermic one can be installed in double-circuit boilers.

- In the first option, the primary coil is responsible for heating the coolant and is installed in the upper part of the boiler plant (above the burner). The secondary is responsible for creating a hot water supply.

- Bithermic has a “tube in a tube” design. A coolant for the heating system moves in the space between the outer and inner tubes; water flows through the inner tube of the heat exchanger to provide hot water.

Any heat exchanger is prone to scale formation. This is especially true for devices through which hard tap water circulates. A separate coil is enough to simply rinse or replace the failed section.

In a bimetric heat exchanger, scale forms much faster than its separate counterpart. Deposits that have appeared in the inner tube of such a device are almost impossible to eliminate. Heat transfer will gradually decrease, which means that in order to maintain the desired temperature regime of water, it will be necessary to increase the amount of fuel burned. Continuous operation of the boiler in this mode will significantly reduce its service life.

It should be understood that the repair of a bithermic heat exchanger is practically impossible, a complete replacement of the entire module is required. And this is a rather expensive process that can pull up to 50% of the initial cost of the heating installation.

We recommend that you watch the video.

In it, a representative of the manufacturer talks about the types and varieties of heat exchangers used in boiler plants

What you need to pay special attention to when choosing a gas boiler

With such a variety of different models, it is difficult to make your choice in favor of a particular one. But the price should not be the main selection criterion. For efficient operation, a modern boiler must meet a number of basic requirements: 1. No Frost system that prevents freezing of the main components of the boiler, and in an improved form, the general heating system.2. Advanced or universal type of burner - conventional ones are not very economical. 3. Basic equipment must include: 3.1. Membrane-type expansion tank with a volume of at least 7% of the total volume of the heating network. 3.2. Circulation pump. 3.3. A set of sensors for controlling the temperature of the coolant in the boiler, on radiators, and preferably an air temperature control sensor. 4. Boilers of foreign manufacturers must be adapted to the gas and electric networks of Russia. 4.1. The presence of an automatic burner on a piezocrystal or electric spark is mandatory. A burner with an incandescent element is desirable, which will make the operation of the boiler more economical and safer with low-calorie or unrefined fuel. 4.2. Products must be certified. 4.3. The operating pressure range of gas and water is preferably the widest possible. 4.4. Built-in surge protection system. Otherwise, you will have to buy and install an expensive filter. The ability to connect via a UPS with an output to an external battery is welcome.

Only after the presence of all the listed nodes and the fulfillment of the requirements, it is possible to compare the price of devices of comparable power.

Each person chooses the best for himself. In the concept of "best" each of the buyers puts his own meaning. Reliability? Safety? Price? Appearance? All this can be correlated with gas boilers. What are the best gas heating boilers? It all depends on what features you prioritize.

Many gas boilers have an automation system, pumps that run on electricity. Such boilers cannot function without a constant supply of electricity. If there are power outages, such devices will not work.

It is worth considering such a characteristic of boilers as the type of combustion chamber. Equipment with an open chamber burns the air in the room. For such boilers, an equipped chimney and a constant flow of air from the outside are required. It should also be noted that their body overheats, so a boiler with an open combustion chamber should not be installed next to counters, wooden furniture and curtains. Boilers with a closed chamber have a coaxial pipe in their structure, which absorbs air from the street and brings it back. Such a boiler is an economical option, since a uniform mixing of gas and air occurs in a coaxial pipe, so the boiler body with a closed combustion chamber does not overheat.

The modern market is to choose gas heating boilers to your taste, and which one is better for the buyer to decide. The choice of equipment depends on the needs that are most important to the consumer.

Type of gas burner

In a gas boiler, heat energy is obtained by burning fuel. To create and burn a gas-air mixture, a burner is used, which can have two versions:

- Atmospheric.

- Forced draft burner.

In the first type of device, the formation and mixture of air and gas is carried out naturally by means of draft.

In the chamber of an atmospheric boiler, gas combustion does not occur completely: combustion products remain on the air duct, electrodes, and heat exchanger, which reduce the heating efficiency of the coolant. Thus, the boiler with an atmospheric burner operates with a greater load, which significantly reduces its service life.

The design of pressurized burners provides for the presence of two chambers: in the first, air is mixed with fuel; in the second, the direct process of combustion of the mixture takes place.

In turbocharged boilers (equipped with forced draft burners), the fuel burns out completely, which increases efficiency and reduces the load on the unit. This fact gives the right to conclude that turbocharged boilers have a slightly longer service life compared to their atmospheric counterparts.

Procedure for replacing gas appliances

The legislation provides for certain rules for replacing a gas boiler in a private house. This procedure should be carried out in the following steps:

- With a technical passport for a new gas boiler, they contact the gas supply company to obtain technical conditions.

- After considering the application, the organization issues technical specifications: if the characteristics of the new boiler are similar to the old one, then you only need to obtain a chimney pipe inspection certificate; if the location of any element of the system changes, then it is necessary to order a new project in a specialized organization; if the unit will have a large capacity, then it may be necessary to renegotiate the contract for the supply of gas.

- Now you can conclude an agreement to replace the gas boiler with a specialized organization. You need to get a building permit from them.

- All collected documents are submitted to the gas service for a permit.

- Obtaining permits.

It happens that the gas service does not give permission for a replacement, but the reasons for the refusal are always indicated. In this case, you should correct the comments identified by the gas service and submit the documents again.

When replacing one model of a gas boiler with another, keep in mind the following:

- models with an open combustion chamber can only be placed in specially equipped boiler rooms; to remove smoke, a classic chimney is required;

- boilers with a closed combustion chamber with a power of up to 60 kW can be placed in any non-residential premises (kitchen, bathroom, hallway) with an area of at least 7 m²;

- the room where the unit will be located should be well ventilated and have an opening window.

Unauthorized replacement of a gas boiler consequences

All work related to gas supply should be directly carried out only by employees of those organizations that have a special license for such work. Unauthorized replacement or installation of a gas boiler, at best, can lead to a large fine and numerous problems.

Replacement and installation better gas boiler entrust only to specialized workers who will perform all work in accordance with all standards and rules. A professional team will carry out high-quality installation and connection, and this will be the key to the successful and uninterrupted operation of new equipment for quite a long time.

The sequence of procedures for replacing the boiler:

- An application is written to the gas industry to obtain a permit;

- Changes are made in the project;

- An agreement is concluded with a specialized company that will install and connect;

- The old device is being dismantled;

- A new device is being installed;

- Acceptance and delivery to special gas control bodies.

Having done everything correctly and correctly, you thereby create security, warmth and comfort for your loved ones at home. And thus, the boiler will delight you with its serviceability and work for a long time.

The period of technical examination of the boiler and fittings

The operation of a gas boiler must be not only stable and efficient, but also safe. Therefore, each owner in due time must submit his heating device for examination, which is carried out by the inspectors of Kotlonadzor. They check the technical condition of the device, compliance with the rules for installing and operating the heater.

The examination is carried out according to the following plan:

- Once a year, the inspector conducts an external inspection of the operating boiler and fittings, if necessary, identifies external defects and sets the deadlines for their correction.

- An internal inspection of the boiler is carried out every three years. This event must be prepared in advance: the boiler is stopped, cooled, cleaned of scale and soot, the condition of the walls, rivets and welds is checked, and there are no cracks or corrosion of the metal.

- Once every six years, a hydraulic test of the heater is carried out. This is necessary in order to check the tightness of pipes, as well as riveted and welded joints. If the inspector has no doubts about the operability and safety of the heating equipment, the event may be postponed for three months.

Based on the results of the check, a resolution is issued on the possibility of using the boiler in the future and an entry is made in a special journal.

Price categories of gas boilers

As a rule, the retail price of a boiler is one of the indicators of its reliability.Condensing heating installations belong to the most expensive category of heating equipment.

With proper operation and regular maintenance, the manufacturer's declared "life" of such units is 30 years. This is due to the use of high-quality materials, which are necessary when obtaining thermal energy from combustible fuel and condensate.

Convection boiler equipment usually belongs to the middle price category. The average, declared by the manufacturer, the operating life of installations of this type varies from 10 to 15 years. In convection heat generators, heat energy is generated exclusively by gas combustion, which leads to higher temperature loads on materials.

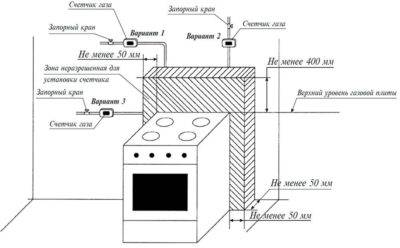

How to choose a gas meter

Despite the fact that in order to agree on a project for installing a metering device, it is required to provide a technical passport for the flow meter, the choice of equipment should be carried out only after consultation with specialists. Be sure to ask for a list of approved devices, as unlicensed devices cannot be put into operation.

In order to choose a flow meter, its technical characteristics should also be taken into account, paying particular attention to two criteria: throughput and type of device

The first criterion depends on the number and power of gas appliances installed in the house. For one slab, for example, a throughput of 1.6 m3/h is sufficient. This parameter is indicated on the front panel and you can find it out by looking at the value indicated after the letter “G”, that is, in this case, you need a device marked G1.6.

The choice of meter depends on the throughput of gas appliances. For example, if for a gas stove it is from 0.015 to 1.2 m3 / h, then a meter with parameters of 1.6 m3 / h is optimal. In the event that several devices are installed and operated, the minimum values of the least powerful and the limiting data of the highest flow must be taken into account.

But it must be taken into account that it is often an impossible task to ideally select a flowmeter for such a requirement, therefore the maximum values are taken into account. For example, if the minimum plate consumption is 0.015 m3 / h, and the maximum throughput of the boiler is 3.6 m3 / h, then you should purchase a meter marked G4

However, it is imperative to take into account the fact that the meter will be allowed to be installed if the deviation in the minimum value does not exceed 0.005 m3 / h. Otherwise, it may be necessary to install separate metering devices and, as a result, maintain two separate personal accounts

The main types of household gas meters

When choosing a counter, it is necessary to take into account its type, which determines the principle of its operation, as well as the accuracy of the data obtained. According to this criterion, individual consumers can choose devices:

- membrane. These gas meters are characterized by low price, high reliability and quite reliable values. But they are very noisy devices;

- rotary devices. These devices are popular due to their compact size and rather low price, but they have a short service life and are not distinguished by high measurement accuracy;

- ultrasonic devices. These meters are electronic devices and have high measurement accuracy.They are quite compact, silent and can be integrated into a common system for remote data transmission.

Also, when choosing a gas meter, one should take into account its installation location, since these devices are right- and left-hand

It is also necessary to take into account on which section of the pipe the installation will be carried out: horizontal or vertical. You also need to decide on the location of the gas meter: in the house, in a warm, heated room, or on the street

In the latter case, you should buy a device with thermal correction, as evidenced by the letter "T" on the front panel of the device, indicated next to the throughput of the device.

Particular attention should be paid to the date of issue of the meter, since it is it that is the starting point for determining the calibration interval, which is individual and ranges from 3 to 15 years