- Introduction

- SNiPs for ventilation and air conditioning

- Which brand of ventilator is better to choose

- Why is ventilation necessary?

- Question 2

- Ventilation equipment for domestic and semi-industrial purposes

- Standard monobloc air handling units

- Design features of the device

- Passive ventilation systems.

- On the wall

- Active ventilation systems

- Water heater

- Electric heater.

- breather

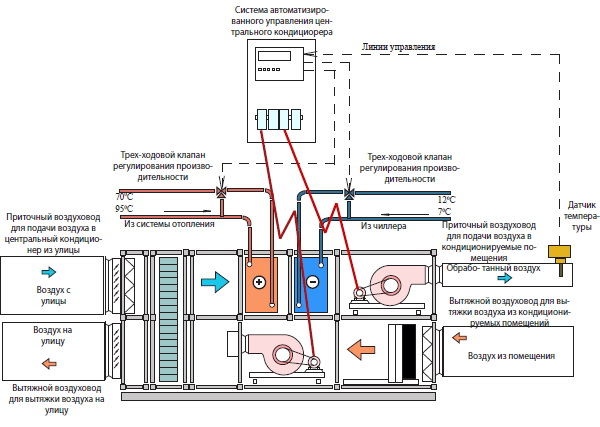

- air conditioning process

- How does it work?

- Requirements for ventilation and air conditioning

- Types of systems

- Advantages and disadvantages of ventilation systems, types of ventilation

Introduction

In 2019, Russia plans to put into operation 10–20 million m² of commercial real estate, for the most part at the expense of commercial space and administrative buildings for social purposes (medical and educational institutions, museums, etc.)

It is important that all this volume of real estate correspond to modern ideas about cost-effectiveness in construction, reliability and energy consumption. The lion's share of the latter is spent on HVAC systems. The goal of improving the energy efficiency of such systems, drawing up recommendations common to designers, and amending the existing regulatory and technical documentation becomes relevant.

In the context of this goal, this article solves the problem of identifying common patterns and potential omissions at the design stage, which can serve as a scientific foundation for achieving the above goal.

The goal of improving the energy efficiency of such systems, drawing up recommendations common to designers, and amending the existing regulatory and technical documentation becomes relevant. In the context of this goal, this article solves the problem of identifying common patterns and potential omissions at the design stage, which can serve as a scientific foundation for achieving the above goal.

The specificity of the studies of individual authors, whose publications are devoted, for example, only to religious objects (Orthodox churches), and even in certain climatic conditions, does not allow extrapolating the results of their work to solve the above problem. The impossibility of applying the methods of calculation and methods of analysis of foreign scientists in the conditions of the Central part of the Russian Federation has already been shown on the example of systems passive solar heating . At the same time, Kai and Brown describe heating and ventilation systems in the United States, citing energy consumption values for several principles of equipment layout and control, obtained from laboratory and field tests. Using exclusively software methods, Maccarini et al. model the prospects for applying the idea of obtaining thermal energy released when the state of aggregation of some materials changes, for the simultaneous heat and cold supply of consumers connected to centralized systems.

Increasing the energy efficiency of external heat supply systems (heat networks) is a popular topic of publications in the domestic press, however, the methods and tools used for this are not always applicable to the internal engineering systems of buildings, especially in the context of developing the relevant sections of design and working documentation.

On the other hand, among the general applicable methods and means are the replacement of traditional valves with ball valves and a decrease in the thermal conductivity coefficient while increasing the life of thermal insulation.

SNiPs for ventilation and air conditioning

Installation of ventilation systems is a prerequisite for modern construction design. For thoughtful air circulation, standards developed over decades are taken into account. They are issued in the form of rules or standards SNiP. This abbreviation means “Building Norms and Rules”, the basis of which was laid by the developers of building schemes, engineers and natural scientists back in Soviet times. It is they who regulate the minimum area of living space per person, the mandatory presence of ventilation shafts in common houses and the minimum radius of the chimney in the private sector.

SNiPs are generally accepted standards, mandatory rules and building codes that cover all niches of modern construction. They describe in detail all the standards for the construction of structures of any type, as well as the calculation formulas and additional regulatory documentation. Everything is thought out in them for safe installation and efficient functioning of air conditioning and ventilation systems in buildings, including private houses.

Which brand of ventilator is better to choose

When buying a ventilator, its manufacturer plays an important role. The top brands in the world include:

- Vents is the largest manufacturer of ventilation equipment in Europe. The Ukrainian company appeared in the 90s of the 20th century. In 2019, its range exceeds 10,000 products and is aimed at air conditioning industrial, commercial and private facilities. Vent automatic ventilators are among the most popular on the market.

- Ventec is a young Russian company that specializes in ventilation and aspiration systems, as well as in the manufacture of metal frame and case products. Here you can order standard equipment or non-standard options for air conditioning. The main difference of the manufacturer is customer-oriented service.

- Siegenia is a brand of window fittings and ventilation systems with a 140-year history. Its products are manufactured in 5 factories and shipped worldwide through 30 offices in different countries.

- Ballu is a company specializing in climate and engineering technology. Own research laboratories allow you to tirelessly improve the level of products and expand the range. Its products are shipped to 30 countries.

- Tion is a young and actively developing Russian brand engaged in the creation of smart ventilation, as well as products for energy-efficient air filtration and disinfection.

Why is ventilation necessary?

Air renewal helps to prevent diseases of the cardiovascular and central nervous system, increased sweating, impaired attention, and chronic diseases in people with weak immunity.

The standard ventilation system allows:

- reduce the concentration of dust and other small particles in the air;

- choose a comfortable temperature for work;

- remove exhaust gases and aggressive components that cause allergies.

Of course, you can open the windows, but then dust and dirty air will enter the room. And in the cold season, heating costs will increase. Also, drafts adversely affect human health.

Question 2

By

method of supplying fresh

air and remove polluted

ventilation systems are divided into three

groups:

natural,

mechanical and mixed.

ventilation

With

natural

prompting (including occasional

ventilation)

design if it is admissible according to

terms of reference

technological process or stay

people, as well as storage of products or

materials. ventilation

With

furnic

prompting

should be designed if required

meteorological conditions and cleanliness

indoor air

cannot be ventilated

with a natural urge. mixed

ventilation

design, if permissible and possible

partial use of ventilation with

natural

inducement to inflow or remove

air.

By

the purpose of the ventilation system is divided

on the workingwhose

and emergency.

workers

systems

constantly create the necessary

meteorological, sanitary and hygienic,

fire and explosion proof

terms. emergency

systems

ventilation include

into operation only when the working

ventilation, seal failure or

sudden release into the air

industrial premises of hazardous

toxic or explosive

substances, as well as air pollution

couples and

gases of the 1st and 2nd hazard classes

(GOST 12.1.005

and GOST 12.1.007).

By

way of air exchange of the ventilation system

can be subdivided

on the general exchange

and local.

General ventilation

characterized by the supply or removal

air through ductless

system or channel system,

located in

ventilated room. Such ventilation

satisfied if

no need for toxicity

limit distribution

emitted hazards defined,

areas of the premises, as well as, if

hazards are distributed evenly across

everything

room. This ventilation system is

depending on the applied

method of supplying or removing air

intended

for indoor dilutions harmful

emissions (heat, moisture,

vapours, gases and dust) to harmless

maximum allowable

concentration. It provides maintenance

general meteorological

and sanitary air

conditions during

the entire volume of the production facility,

at any point.

local

ventilation is characterized by

with it are created

special meteorological and

sanitary and hygienic

and explosion-proof working conditions

place. This is achieved

removal of polluted local air

exhaust

ventilation and clean air supply

to the local workplace

supply ventilation.

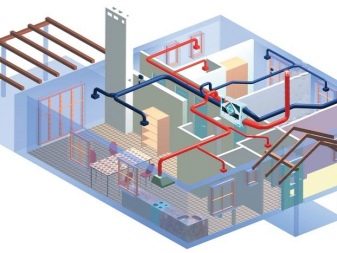

Ventilation equipment for domestic and semi-industrial purposes

This market segment is dominated by ventilation equipment from three European manufacturers: Ostberg (Sweden), Systemair / Kanalflakt (Sweden) and Remak (Czech).These trademarks have been represented in Moscow for a long time, and their equipment has managed to establish itself as a good element base for building inexpensive and reliable stacked systems of supply and exhaust ventilation (the term "set-up system" means that the ventilation system is assembled, like a designer, from separate components: fan, filter, heater, automation).

In the last few years, new manufacturers have appeared on the Moscow market: Wolter (Germany), Ventrex (Eastern Europe), Korf (Russia), Arktos (Russia), Breezart (Russia) and others. Under these brands, quite reliable ventilation equipment is produced, so the choice of a particular manufacturer is determined by the price and subjective preferences of the customer.

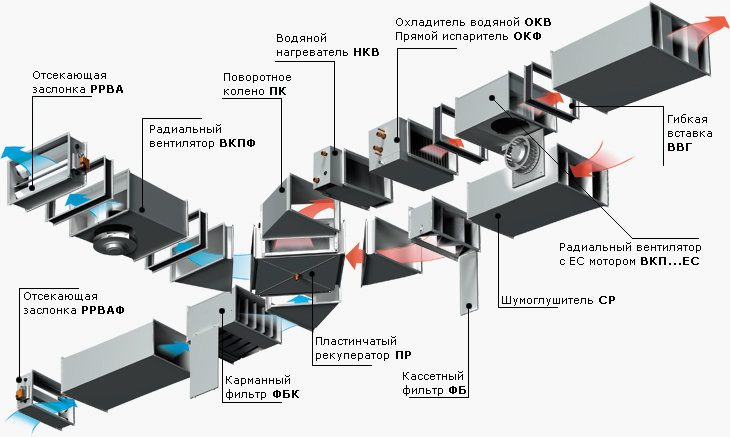

A special place in this segment is occupied by monoblock air handling units. These units, in contrast to stacked systems, are a ready-made ventilation system, all components of which are assembled in a single soundproof housing. Until recently, this class of ventilation units was one and a half to two times more expensive than similar type-setting systems. Recently, however, several manufacturers have released compact monobloc systems, the cost of which is very close to the cost of stacked systems.

Monoblock supply systems are presented on the market by both foreign and Russian manufacturers. From a consumer point of view, domestic air handling units are not inferior to imported ones, since they are assembled from the same components and, in addition, adapt to Russian conditions (for example, a more powerful heater is installed, designed for low outdoor temperatures).At the same time, the spread of prices for monoblock units from different manufacturers can reach 50%. Comparative characteristics of the most popular series of monoblock systems are given in the table.

Standard monobloc air handling units

| Trademark | Series | Producing country | Productivity range, m³/h | Price range | Peculiarity |

| Ostberg | SAU | Sweden | From 185 to 785 m³/h | High | Electric heating, dimensions 225×319×760 mm |

| Systemair / Pyrox | TLP | Sweden | From 125 to 1200 m³/h | High | Electric heating, dimensions 489×489×1004 mm |

| TA-Mini | 150 to 600 m³/h | High | Electric heating, dimensions 320×320×1040 mm | ||

| F16/F30/K25/CG23 | 1000 to 5000 m³/h | High | Water heating, dimensions from 358×670×1270 mm | ||

| Wolter | ZGK140-20 / ZGK160-40 | Germany | From 800 to 3700 m³/h | High | Water or electric heating, dimensions from 335×410×600 mm |

| Ventrex | TLPV | Eastern Europe | From 125 to 1200 m³/h | Average | Analog of the TLP series (Systemair) |

| Arktos | Compact | Russia | 1000 to 2000 m³/h | Average | Water or electric heating, dimensions from 335×410×800 mm |

| Breezart | Lux, Aqua, Mix, Cool | Russia | From 350 to 16000 m³/h | Average | Water or electric heating, built-in automation, built-in mixing unit, dimensions from 468×235×745 mm |

| hummingbird | — | Russia | From 500 to 1000 m³/h | Average | Electric heating, built-in automation, dimensions from 530×300×465 mm |

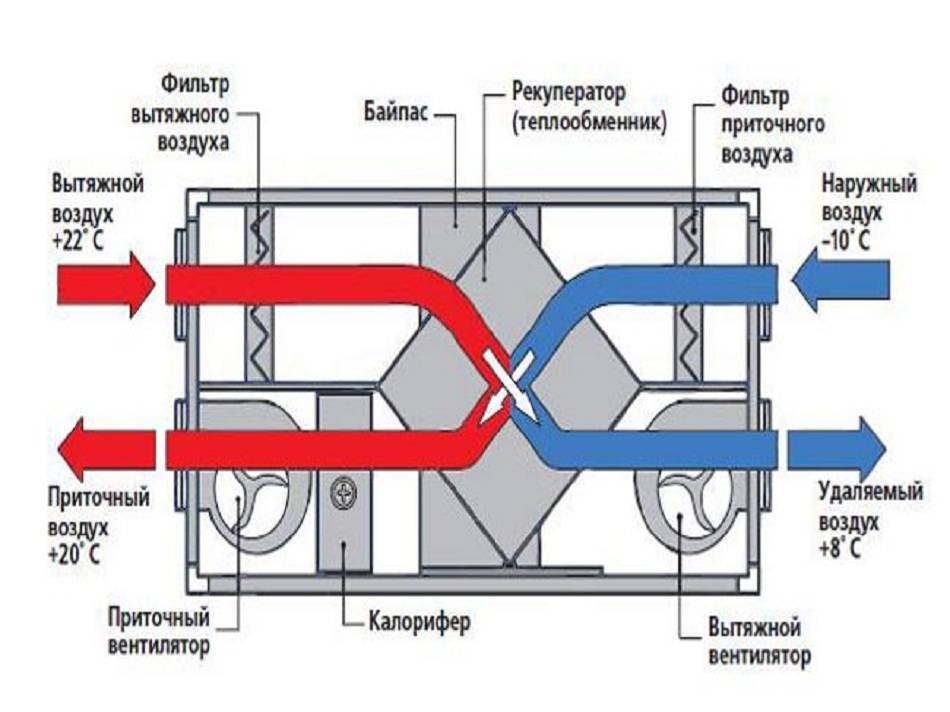

There is also a whole class of ventilation equipment with elements of energy-saving technologies. These are supply and exhaust systems with heat recovery. Recuperation is the partial transfer of heat from the exhaust air to the supply air using a special device - a heat exchanger.Such systems can save up to 80% of the energy spent on heating during the cold season. However, at present, installations with recuperation are not widely used due to the high cost and technical complexity of implementing such schemes.

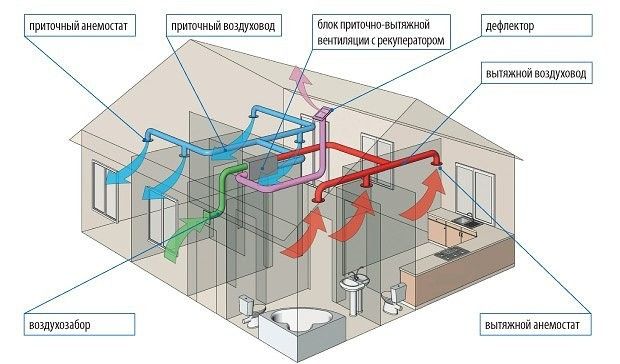

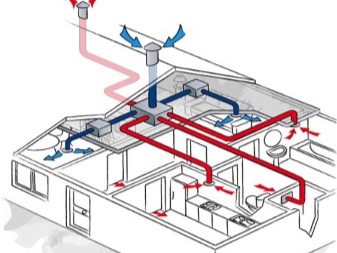

Design features of the device

The main elements of supply ventilation

- Air intake grill. Acts as an aesthetic design, and a barrier that protects debris particles in the supply air masses.

- Supply ventilation valve. Its purpose is to block the passage of cold air from the outside in winter and hot air in summer. You can make it work automatically using an electric drive.

- Filters. Their purpose is to purify the incoming air. I need a replacement every 6 months.

- Water heater, electric heaters - designed to heat the incoming air masses.

- For rooms with a small area, it is recommended to use ventilation systems with electric heating elements, for large spaces - a water heater.

Elements of supply and exhaust ventilation

Additional elements

- Fans.

- Diffusers (contribute to the distribution of air masses).

- Noise suppressor.

- Recuperator.

The design of ventilation directly depends on the type and method of fixing the system. They are passive and active.

Passive ventilation systems.

Such a device is a supply ventilation valve. The scooping of street air masses occurs due to the pressure drop. In cold weather, the temperature difference contributes to the injection, in the warm period - the exhaust fan. The regulation of such ventilation can be automatic and manual.

Automated regulation directly depends on:

- the flow rate of air masses passing through the ventilation;

- air humidity in the space.

The disadvantage of the system is that in the winter season such ventilation is not effective for heating the house, since a large temperature difference is created.

On the wall

Refers to the passive type of supply ventilation. Such an installation has a compact box that is mounted on the wall. To control the heating, it is equipped with an LCD display and a control panel. The principle of operation is to recuperate internal and external air masses. To heat the room, this device is placed near the heating radiator.

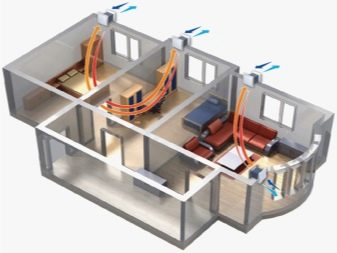

Active ventilation systems

Since in such systems it is possible to regulate the intensity of fresh air supply, such ventilation for heating and space heating is more in demand.

According to the principle of heating, such a supply heater can be water and electric.

Water heater

Powered by heating system. The principle of operation of this ventilation system is to circulate air through a system of channels and tubes, inside which there is hot water or a special liquid. In this case, heating takes place in a heat exchanger built into the centralized heating system.

Electric heater.

The principle of operation of the system is to convert electrical energy into thermal energy using an electric heating element.

breather

This is a compact device, small size for forced ventilation, heated. To supply fresh air, this device is attached to the wall of the room.

Breather Tion o2

Breezer construction o2:

- Channel consisting of an air intake and an air duct. This is a sealed and insulated tube, due to which the device draws air from outside.

- Air retention valve. This element is an air gap. It is designed to prevent the outflow of warm air while the device is turned off.

- Filtration system. It consists of three filters, which are installed in a certain sequence. The first two filters clean the air flow from visible contaminants. The third filter - deep cleaning - from bacteria and allergens. It cleans the incoming air from various odors and exhaust gases.

- Fan for air supply from the street.

- Ceramic heater, which is equipped with climate control. Responsible for heating the inflow of air flows and automatic temperature control.

air conditioning process

Even in the warm season, it is problematic to carry out a simple air exchange without the use of special devices. Therefore, it is advisable to use additional equipment.

In summer, the air is moist and warm. Air conditioning will ensure that it is cleaned and a lower temperature is established. For example, split systems, industrial air conditioners and a chiller-fan coil are suitable.

But in the cold season, the air is frosty and less humid. Naturally, do not forget about filtering. However, you still need to heat and humidify the air, which the heater successfully copes with, guaranteeing an increase in temperature to a comfortable level.

This process is often provided by mixing: cold streams are combined with warm ones. The air is cooled in special chambers due to the ingress of small drops of water.

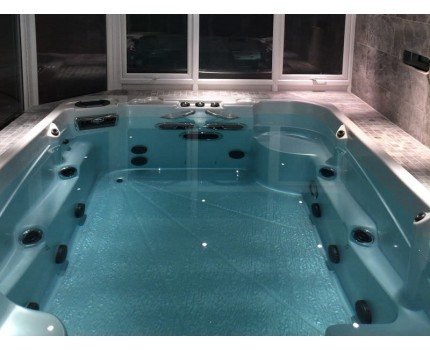

There are also rooms that require a special approach to the organization of ventilation. For example, in gyms with swimming pools, water constantly evaporates, increasing the level of humidity. Water evaporates from the pools, which condenses on the walls and ceiling of the room.

Dehumidifiers are designed to solve such problems. The disadvantage of the latter is the lack of ventilation. The air remains in the room, but the moisture level decreases. Therefore, the concentration of oxygen decreases, which negatively affects the well-being of people.

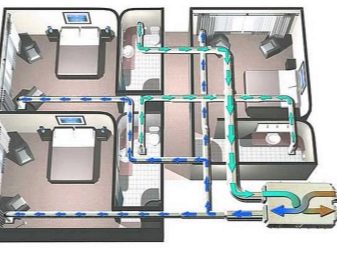

How does it work?

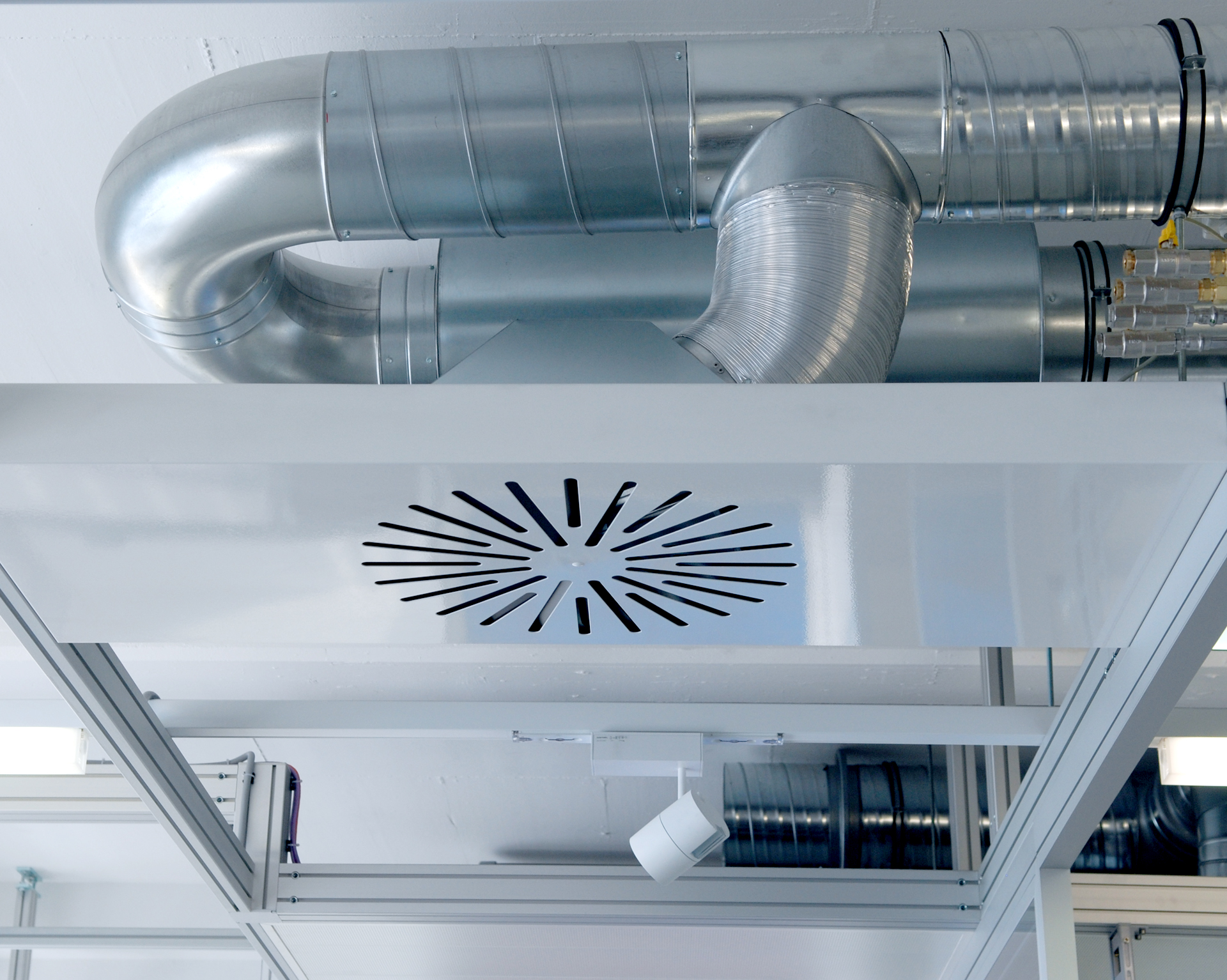

Air masses penetrate into the room and are removed from it with the help of wind, temperature difference, pressure difference inside and outside the structure. Mechanical ventilation will work well if a convector is installed in the room and a fan is installed outside. Each building needs to be equipped with channels that supply and exhaust air. This type of ventilation is based on two independent air outlet channels. The task of the first is to conduct clean air inside the room, and the second is to return it to the outside. In order for the work to be effective, the interconnection of components - additional elements are equipped in each channel.

- The external air intake is equipped with protective grilles.

- There is an air outlet channel that is able to receive, transport and distribute air flow.

- Filter for mechanical cleaning. This part removes impurities, particles and contaminants when air enters it.

- Gate valves, shutters, fittings.

- Dryer, recuperator. They remove excess moisture.

- Fans that are needed to move air at the optimum speed.

- System for electronic controls.

The principle of operation of the ventilation system is as follows:

- external supply of fresh air by a fan;

- heating or cooling air with a convector;

- filtration from harmful impurities and gases;

- the flow of air masses into the structure;

- air outlet that is exhausted to the outside through channels using a pressure drop.

For the flawless functioning of such an exhaust system, a well-designed scheme is required. These works are best performed when designing a construction site. There are a number of things to keep in mind when creating a schema.

- The location where the unit will be installed. The location of the ventilation should be as comfortable as possible for use.

- The parameters of the paths and channels that will be laid for the removal of air, its supply and exhaust.

- Location of the control system.

- Points where clean air will be taken in and exhausted air will be discharged.

Requirements for ventilation and air conditioning

Studies have confirmed that the vast majority of infectious diseases are transmitted by aerosol (airborne droplets).

Modern apartment buildings, public and administrative buildings, industrial production, entertainment complexes and other places where a large number of people gather are areas of high aerobiological hazard. And therefore they are considered the main places for the spread of infections transmitted by aerosol.

Ventilation and air conditioning systems in this case are one of the ways to protect against the spread of infection.

The purity of the indoor air directly depends on the cleanliness of the ventilation ducts. Thus, studies by the World Health Organization prove that indoors with untreated ventilation, the air is 10 times more toxic than outside the building.

The purity of the indoor air directly depends on the cleanliness of the ventilation ducts. Thus, studies by the World Health Organization prove that indoors with untreated ventilation, the air is 10 times more toxic than outside the building.

The ventilation system consists of elements of special equipment combined with each other, designed to process and change air in a closed room. The use of a ventilation system allows you to systematically supply fresh air into the room, cleaning the room from the exhaust.

An air conditioning system is a complex of special equipment for recreating and maintaining automatically the necessary parameters of the air environment in a room, regardless of external or internal atmospheric conditions.

We have given a comparative review of ventilation and air conditioning systems in this material.

If bacteria, mold, fungus form inside these systems due to dirt, they become dangerous for human life. Understanding this, the legislator obligated homeowners, managers of residential and non-residential premises, leasing premises or renting premises under a lease agreement, as well as other users of premises, to ensure regular cleaning of air exchange systems.

The main law, which prescribes the standards of maintenance, organization and control over the exclusive observance of sanitary norms and rules, the algorithm of measures to maintain the cleanliness of these systems, is the Federal Law of March 30, 1999 No. population").

This law provides that a system designed for indoor air circulation will be considered clean if there are no humidification zones and visible pollution on the internal surfaces of the air ducts through which the air flow passes. The same applies to special network and ventilation equipment.

Concerning pollution, the ventilation and air conditioning system will be considered requiring cleaning and disinfection if pollution has been visually detected on the internal surfaces of the connecting pipes of the system. Cleaning is also required if, as a result of laboratory tests, particles of pollution enter the room, the presence of dangerous bacteria, fungus and mold in the environment of air ducts and timely replacement of filters are required.

Checking of air conditioning and ventilation systems should be carried out at least once every six months as part of the production control over the sanitary condition of the equipment.

The established standards of sanitary rules and regulations for indoor air do not allow the presence of harmful microflora in the ventilation and air conditioning system itself. To determine the presence of pathology will allow the study of the surface of ventilation components (filters, silencers, humidifiers, cooler heat exchangers, drainage trays of recuperators)

The established standards of sanitary rules and regulations for indoor air do not allow the presence of harmful microflora in the ventilation and air conditioning system itself. To determine the presence of pathology will allow the study of the surface of ventilation components (filters, silencers, humidifiers, cooler heat exchangers, drainage trays of recuperators)

Types of systems

The supply ventilation unit with air heating is available in several types. It can be central ventilation, which will heat a large industrial premises, or an office center, or it can be individual, for example, in an apartment or in a private house.

In addition, all heated ventilation systems are divided into the following types:

- With recovery. In fact, this is a heat exchange system, when the incoming masses come into contact with the outgoing masses and exchange heat. This option is suitable only for regions with not very cold winters. These systems are referred to as passive ventilation circuits. It is best to place them near the radiators.

- Water. Such a heated supply works either from a boiler or from a central heating battery. Its main advantage is energy savings. Supply ventilation with water heating of air is especially popular with consumers.

- Electrical. Requires significant electricity consumption. According to the principle of operation, this is a simple electric heating element that heats the air with its constant movement.

Supply ventilation can also differ in the way air is forced into the room. There are natural options, and there are forced ones, when air is taken in with the help of fans. The types of ventilation also differ according to the type of control. These can be manual models or automatic, which are controlled using a remote control or from a special application on the phone.

Advantages and disadvantages of ventilation systems, types of ventilation

Each of these types of ventilation has its own advantages and disadvantages. You should be aware of them so as not to get into a mess. Let's look at all the options:

| System type | pros | Minuses |

| Natural | Does not require third-party equipment and connection to a power source. Does not break, practically does not require maintenance. It works completely silently and can be combined with air conditioning technology. | Low intensity of air exchange. Insufficient rate of metabolic processes leads to the formation of fungus and the settling of condensate. There is no way to regulate air exchange processes. In the absence of wind and temperature difference, it practically does not work. |

| Mechanical | Completely autonomous operation, independent of external factors: air temperature and the presence of winds. The air entering a residential building can undergo additional processing: purification, heating, humidification. | A lot of money needs to be spent on the installation of mechanical ventilation in private homes. The system needs regular maintenance. |

| Supply | It has the function of adjusting the temperature regime and the volume of incoming air. Differs in the compact sizes and high functionality. It can simultaneously heat and purify the atmosphere. | Needs a noise reduction system and requires a separate installation site away from residential areas. Requires periodic maintenance and repair. |

| exhaust | Allows you to control the volume of outgoing streams. Unaffected by the vagaries of the weather. Easy to install. | It does not give the possibility of adjusting the incoming air, it requires installation and operation costs. Requires maintenance. |

| Supply and exhaust | Qualitatively cleans the air flow and makes the atmosphere as comfortable as possible for a person. Safe to use. | High cost of installation and operation. Cannot be used with air conditioning systems. Needs a separate installation room and noise reduction system. |