- Wire twisting

- How to connect copper and aluminum wires without problem moments?

- TV coaxial cable connection

- Twisted connection of tinsel wire with a single-core or stranded conductor

- Terminal clamps

- Terminal block

- Terminals on plastic blocks

- Self-clamping terminals

- Terminal blocks

- Polyethylene terminal blocks

- Plastic screw terminals

- Self-clamping terminal blocks

- Terminal blocks with levers Vago

- Crimping with sleeves: technology features

- Terminal connection

- Connect wires with ease

- Types of terminal blocks

- Important Wiring Notes

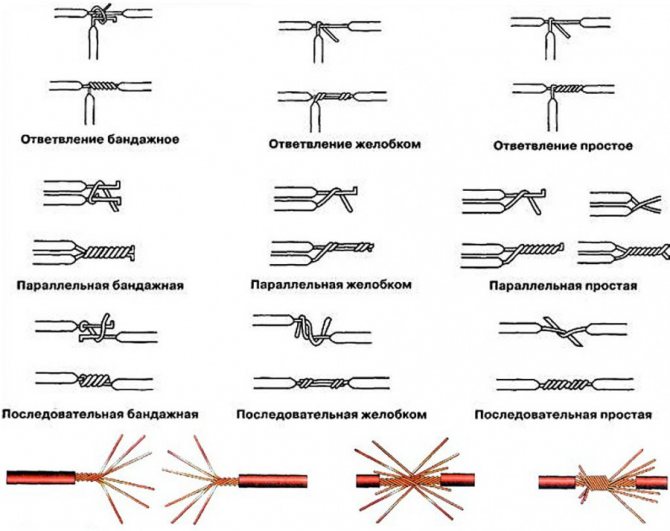

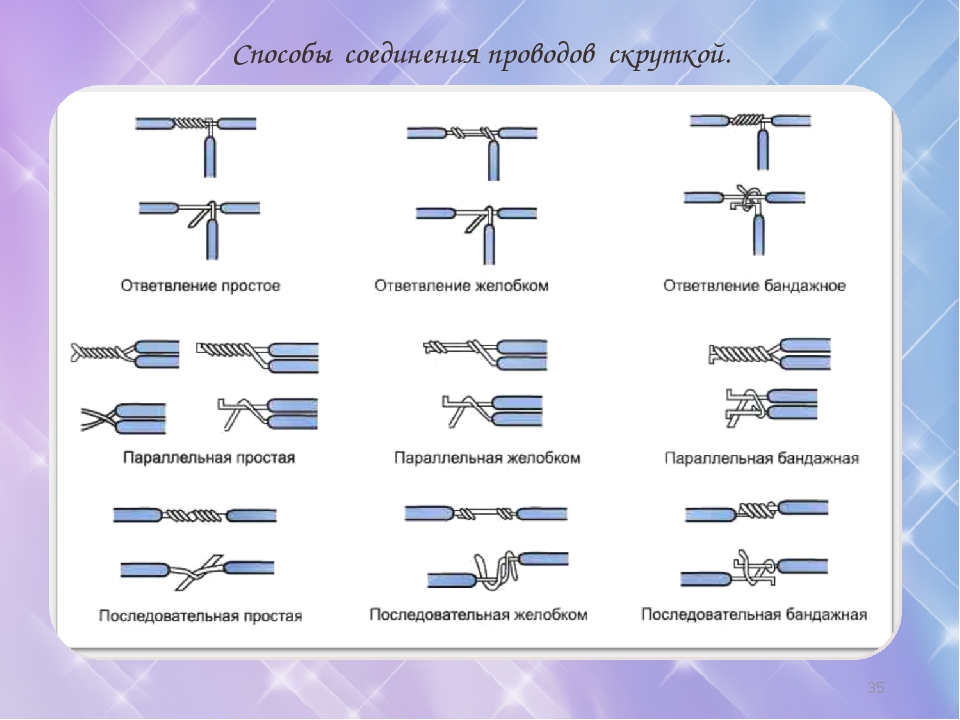

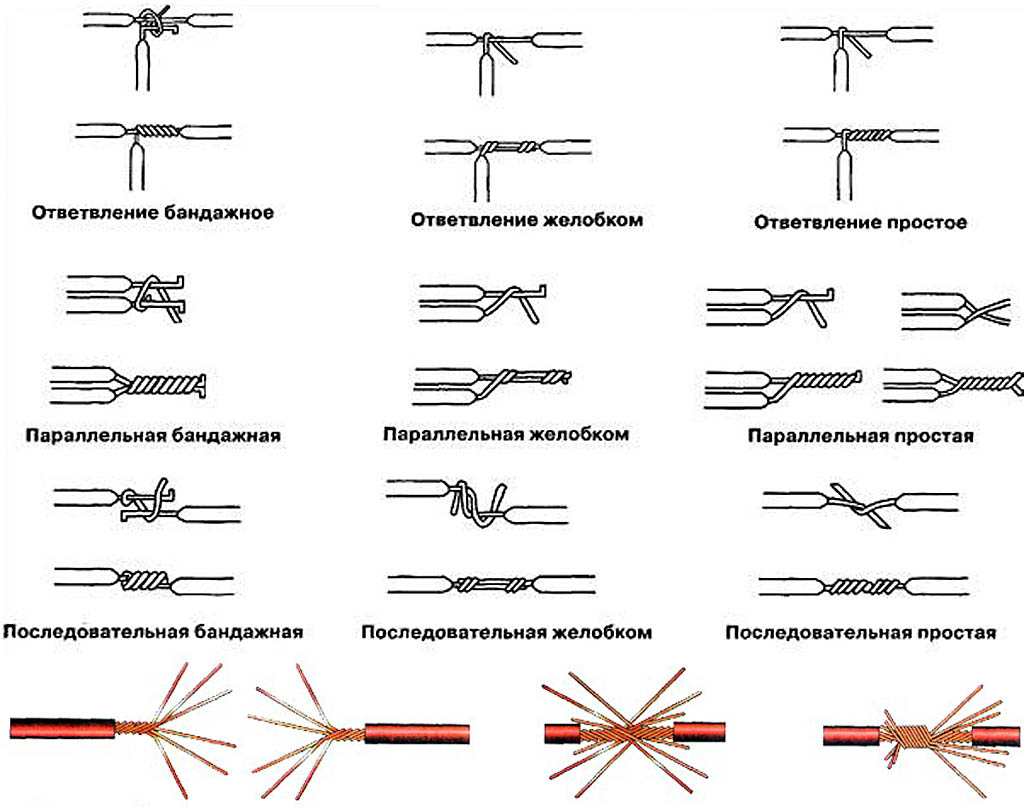

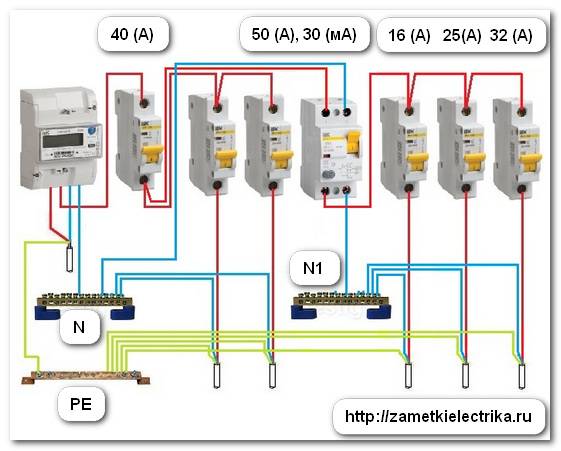

Wire twisting

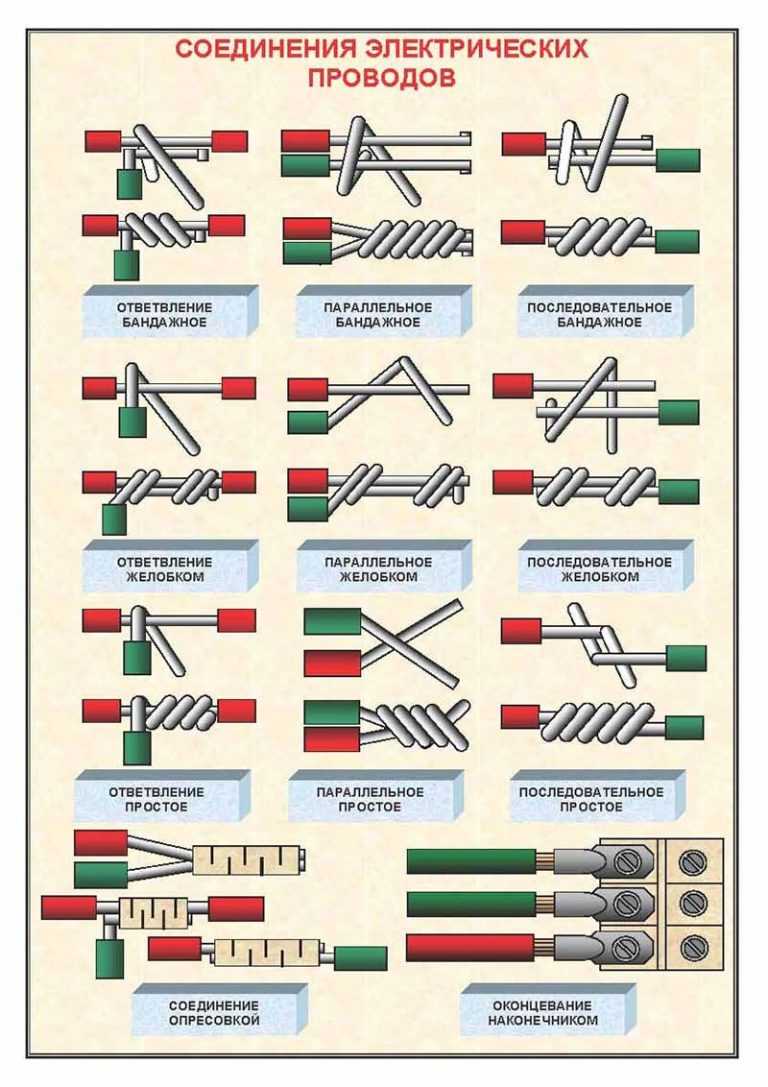

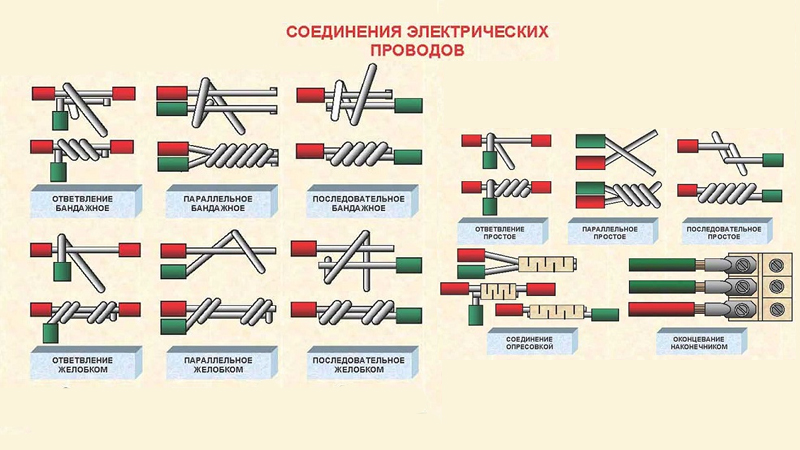

The simplest way to connect two or more conductors is the so-called twist. This connection is made using various techniques, of which simple twisting is the most intuitive.

The connection of two flexible stranded wires in the form of a simple parallel twist provides reliable contact between the two wires, but the twist does not tolerate vibration and the force applied to break.

With the help of parallel twisting, it is possible to connect a copper solid and stranded wire, due to the additional bending of the solid wire, this connection is more reliable than when connecting two stranded wires.

Aluminum wires of various sections are connected in a similar way.

The use of parallel twisting makes it possible to provide electrical contact simultaneously between two or more wires.

With a simple twist, an electrical connection of an additional wire to the main wiring line can be performed without breaking it.

The same connection method can be used to join together a tap from a solid wire with a flexible or solid main wire.

To connect two wires together, their serial twisting can be used, for which each connected wire is "wound" on the other.

This method of connecting wires allows you to ensure optimal contact and reliability of the connection, but only for two wires.

The connection of rigid wires to each other can be performed using a bandage twist. To do this, the wires to be connected are applied parallel to each other, after which they are fixed in this position with the help of a softer wire, which is tightly laid on the bare surface of the wires.

The tighter the twisting or winding is, the better the electrical contact between the conductors will be.

Using a bandage, you can connect two or more conductors or organize taps.

To improve fixation, you can perform additional bending of the monolithic wire, thereby fixing the bandage.

During installation, it is necessary to ensure that the twisted parts of the conductors are completely stripped of insulation, the copper or aluminum surface of the conductors must be clean and free from oxidation.If necessary, before twisting, the surface of the wires to be connected must be cleaned with a knife or sandpaper. To increase the density of twisting, and, as a result, electrical contact between the conductors, twisting with pliers is allowed.

It is important to remember the main rule of installation - you can not directly connect copper and aluminum wiring

How to connect copper and aluminum wires without problem moments?

Everyone knows that there are two reasons why this is not recommended:

The junction can get very hot, and this is considered very dangerous;

But this can be avoided by using:

- Terminal blocks;

- A method based on the use of Wago;

- Connection with bolts;

- Branch clamp method - used in open space.

All you have to understand is that the correct connection of the wires guarantees a reliable supply of voltage to the points of its consumption. But, if you do everything right, this does not guarantee that the connections will always be reliable, so you can only increase their service life. Sometimes you have to carry out repairs, because nothing lasts forever.

TV coaxial cable connection

It is possible to extend or splice a coaxial television cable in three ways:

- TV extension cable, on sale are from 2 to 20 meters

- using an adapter TV F socket - F socket;

- soldering with a soldering iron.

You can familiarize yourself with the step-by-step instructions for connecting a coaxial television cable by visiting a separate article on the site “Connecting a TV cable”.

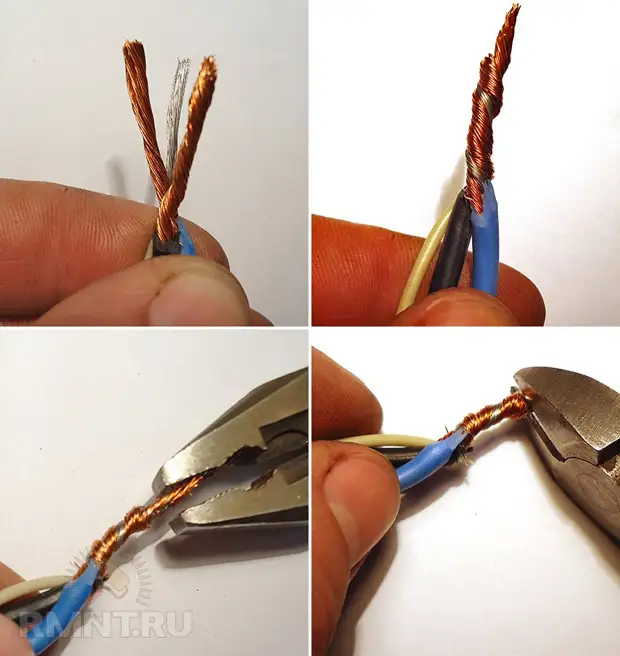

Twisted connection of tinsel wire with a single-core or stranded conductor

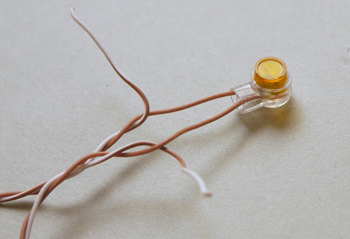

If necessary, to give the cord a very high flexibility and at the same time greater durability, the wires are made using a special technology. Its essence lies in the winding of very thin copper ribbons on a cotton thread. Such a wire is called tinsel.

The name is borrowed from tailors. Gold tinsel is used to embroider the parade uniforms of high military ranks, coats of arms and much more. Copper tinsel wires are currently used in the production of high-quality products - headphones, landline telephones, that is, when the cord is subjected to intense bending during use of the product.

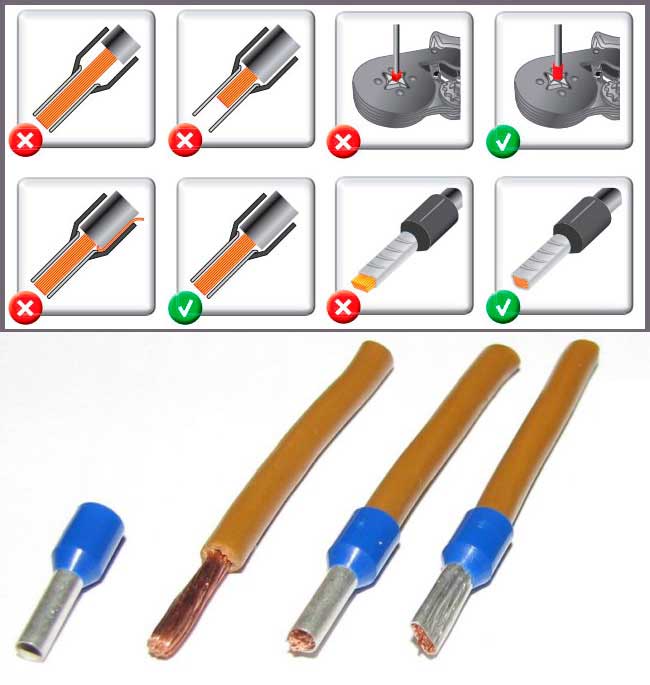

As a rule, there are several conductors of tinsel in the cord, and they are twisted together. Soldering such a conductor is almost impossible. To attach tinsel to the contacts of products, the ends of the conductors are crimped into the terminals with a special tool. To perform a reliable and mechanically strong connection by twisting without a tool, you can use the following technology.

10-15 mm tinsel conductors and conductors with which it is required to connect tinsel to a length of 20-25 mm with a shift with a knife in the manner described in the site article “Preparing wires for installation” are released from insulation. The tinsel thread is not removed.

Then the wires and the cord are applied to each other, the tinsel is bent along the conductor and the core of the wire is tightly wound onto the tinsel pressed against the insulation. It is enough to make three to five turns. Next, the second conductor is twisted. You will get a fairly strong twist with a shift. Several turns are wound with insulating tape and the connection of tinsel with a single-core wire is ready. Thanks to shear technology, the connections do not need to be insulated individually.If you have a heat-shrinkable or PVC tube of a suitable diameter, you can put on a piece of it instead of an insulating tape.

If you want to get a straight connection, then you need to turn the single-core wire by 180 ° before insulating. In this case, the mechanical strength of the twist will be greater. The connection of two cords with tinsel-type conductors to each other is carried out according to the technology described above, only for wrapping a piece of copper wire with a diameter of about 0.3-0.5 mm is taken and at least 8 turns must be made.

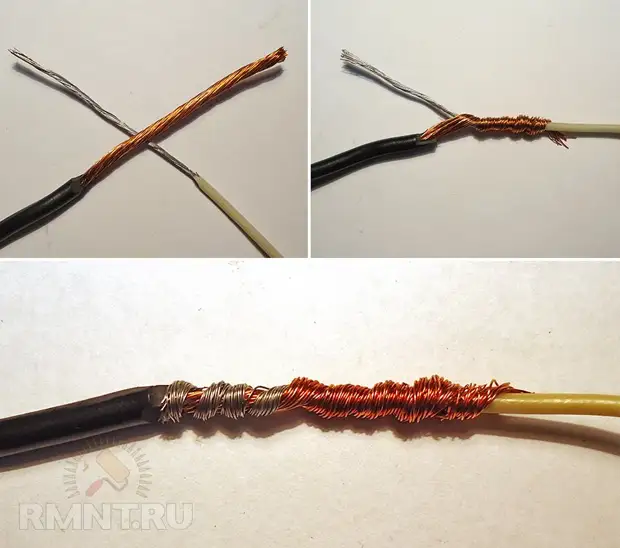

Terminal clamps

Terminal blocks for connecting wires give one indisputable advantage, they can connect wires of different metals. Both here and in other articles, we have repeatedly reminded that it is forbidden to twist aluminum and copper wires together. The resulting galvanic couple will result in the occurrence of corrosive processes and the destruction of the connection.

And it doesn't matter how much current flows at the junction. Sooner or later, the twist will still start to heat up. The way out of this situation is precisely the terminals

The way out of this situation is precisely the terminals.

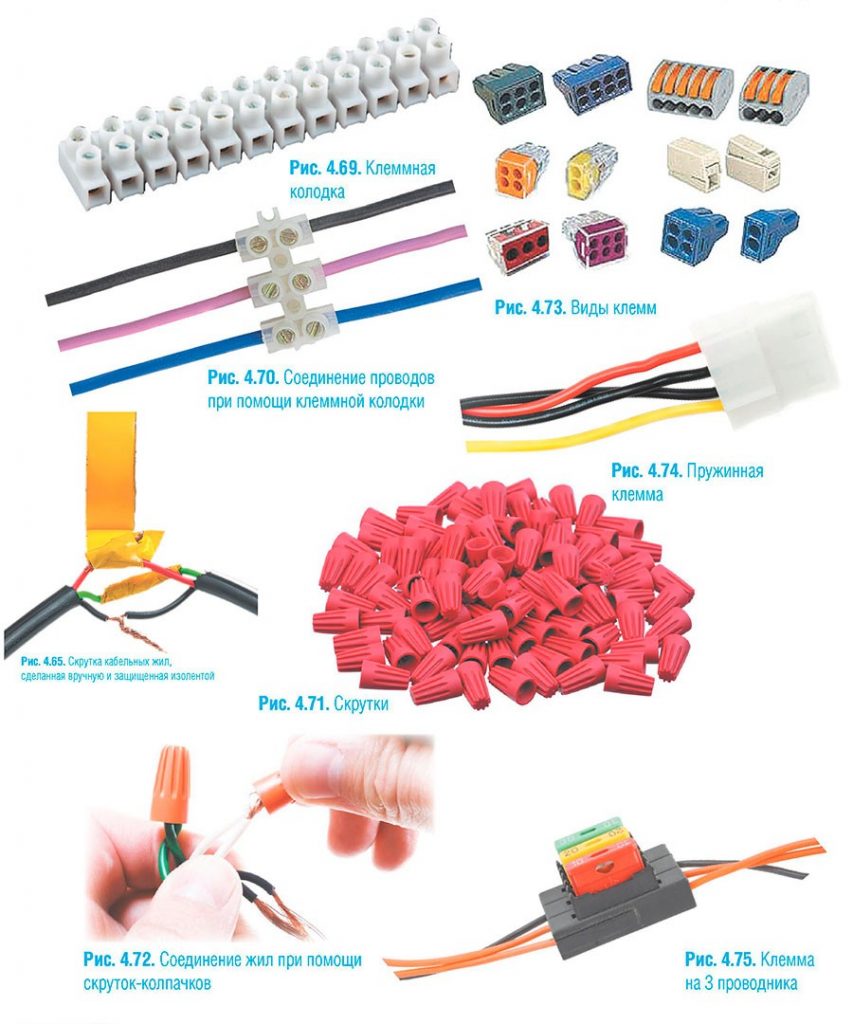

Terminal block

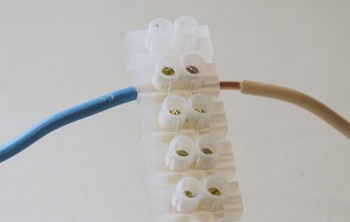

The simplest and cheapest solution is polyethylene terminal blocks. They are not expensive and are sold in every electrical store.

The polyethylene frame is designed for several cells, inside each there is a brass tube (sleeve). The ends of the cores to be connected must be inserted into this sleeve and clamped with two screws.It is very convenient that as many cells are cut off from the block as it is necessary to connect pairs of wires, for example, in one junction box.

But not everything is so smooth, there are also disadvantages. Under room conditions, aluminum begins to flow under screw pressure. You will have to periodically revise the terminal blocks and tighten the contacts where the aluminum conductors are fixed. If this is not done in a timely manner, the aluminum conductor in the terminal block will loosen, lose reliable contact, as a result, spark, heat up, which can result in a fire. With copper conductors, such problems do not arise, but it will not be superfluous to make a periodic revision of their contacts.

Terminal blocks are not intended for connecting stranded wires. If stranded wires are clamped into such connecting terminals, then during tightening under pressure of the screw, the thin veins may partially break, which will lead to overheating.

In the case when it becomes necessary to clamp stranded wires into the terminal block, it is imperative to use auxiliary pin lugs

It is very important to choose its diameter correctly so that the wire does not pop out later. The stranded wire must be inserted into the lug, crimped with pliers and fixed in the terminal block. As a result of all of the above, the terminal block is ideal for solid copper wires.

With aluminum and stranded, a number of additional measures and requirements will have to be observed

As a result of all of the above, the terminal block is ideal for solid copper wires. With aluminum and stranded, a number of additional measures and requirements will have to be observed.

How to use terminal blocks is shown in this video:

Terminals on plastic blocks

Another very convenient wire connector is a terminal on plastic pads. This option differs from terminal blocks by a smooth metal clamp. In the clamping surface there is a recess for the wire, so there is no pressure on the core from the twisting screw. Therefore, such terminals are suitable for connecting any wires in them.

In these clamps, everything is extremely simple. The ends of the wires are stripped and placed between the plates - contact and pressure.

Such terminals are additionally equipped with a transparent plastic cover, which can be removed if necessary.

Self-clamping terminals

Wiring using these terminals is simple and quick.

The wire must be pushed into the hole to the very end. There it is automatically fixed with the help of a pressure plate, which presses the wire to the tinned bar. Thanks to the material of which the pressure plate is made, the pressing force does not weaken and is maintained all the time.

The internal tinned bar is made in the form of a copper plate. Both copper and aluminum wires can be fixed in self-clamping terminals. These clamps are disposable.

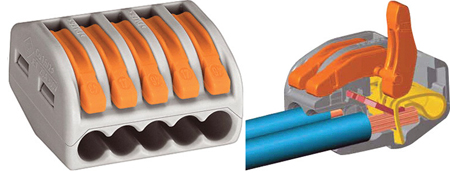

And if you want clamps for connecting reusable wires, then use terminal blocks with levers. They lifted the lever and put the wire into the hole, then fixed it there by pressing it back. If necessary, the lever is raised again and the wire protrudes.

Try to choose clamps from a manufacturer that has proven itself well. WAGO clamps have especially positive characteristics and reviews.

The advantages and disadvantages are discussed in this video:

Terminal blocks

Convenient and modern way to connect wires.Currently, there are several types of terminal blocks.

Polyethylene terminal blocks

One of the most common terminal blocks, as they are sold in every store. The cables in this case are connected using two screws, which are located inside the terminal block.

The advantages of such a connection are ease of use, low cost. But polyethylene terminals have a lot of disadvantages:

- aluminum cables cannot be connected, since the screws of the terminal block compress the metal and, due to its structure, it begins to deform under pressure, which leads to poor contact;

- stranded wires cannot be connected (this is due to the design of the terminal block);

- brittleness of the material (brass, which is used in this case, tends to be easily deformed if the screws are tightened strongly).

Plastic screw terminals

They have a similar clamping mechanism, but are of better quality and more reliable due to the materials used.

Self-clamping terminal blocks

Most often there are Vago firms. To connect cables in this way, it is enough to strip the cables to the desired length and insert them into a special terminal block connector. The metal plate inside the mechanism will press the cable, thus fixing it securely.

- from 2 to 8 cables can be interconnected (depending on the type of terminal block);

- it is possible to connect aluminum cables, since the metal plate gently presses them and does not deform;

- ease of use.

The disadvantage of self-clamping terminal blocks is that it is quite problematic to get the cable without damaging the terminal block. But still, this can be done if you start turning the cable along its axis and slowly pulling it out.

Terminal blocks with levers Vago

The terminal blocks consist of a plastic case on the outside, levers and internal metal clamping plates. To create a contact, you just need to strip the wires to the required length, insert them into the terminal block connector and clamp the lever.

The main advantages of such a terminal block:

- the possibility of using different types of conductors (copper and aluminum);

- reusable (opened the lever, took out the cable and inserted a new one).

Among the shortcomings, it can be indicated that when installing networks, such terminal blocks take up a relatively large amount of space.

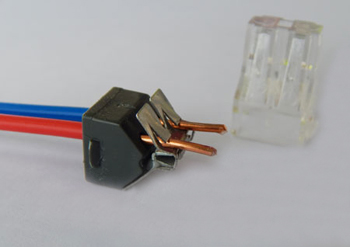

They consist of a transparent plastic body and several pointed metal teeth with a plate. In this version, the cable is simply inserted into the terminal block (without removing the insulating coating) and it is clamped with pliers. Thus, metal cutters break through the insulation of the wires and create contact between them.

This connection method is simple and does not require special skills. However, such terminal blocks have several disadvantages:

- can only be used to connect conductors with low current (telephone wires, cables for lighting);

- disposability in use. To disconnect the contact, it is necessary to cut the wires at the base of the terminal block. Thus, part of the wire is also lost.

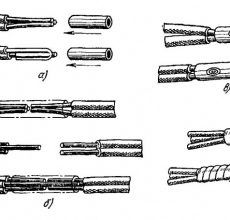

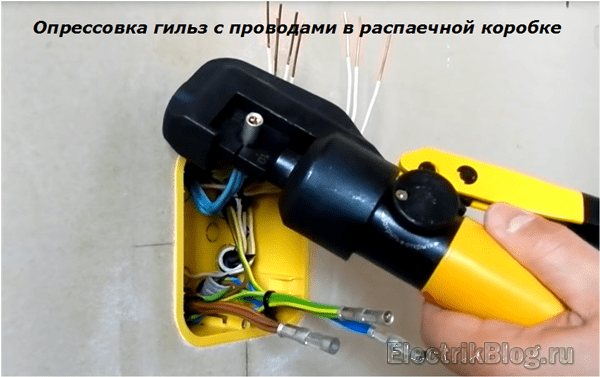

Crimping with sleeves: technology features

The installation method is based on creating a tight contact between metal conductors placed inside a tube of the same material and compressing the entire structure under a certain force with a uniform distribution of the acting load.

Good electrical contact is created by co-deforming the metals.

The sleeve (tube for connecting wires) is produced by the industry for specific wire sizes and their number. They can be designed to connect cores from:

- copper;

- aluminum;

- and even copper with aluminum.

Copper sleeves (GM) can be produced with additional tin and bismuth tinning. They are designated GML, marked by high resistance to corrosion.

Aluminum sleeves are designated GA. To connect wires made of copper and aluminum, GAM sleeves are used, and with an insulation layer they designate GSI.

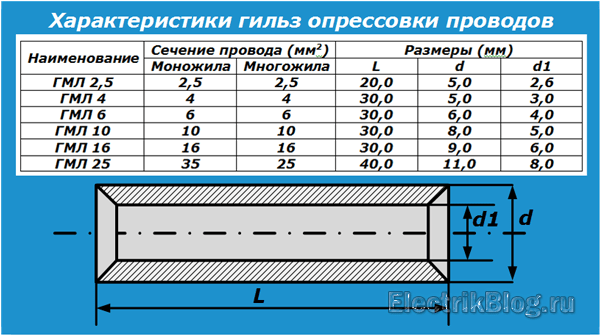

Their sizes can be found in the catalogs. As an example, I give the main characteristics of a part of the GML shells in a small table.

The dimensions of the sleeve are specially selected for the cross section of the switched wire. Their correct choice affects the quality of the electrical connection.

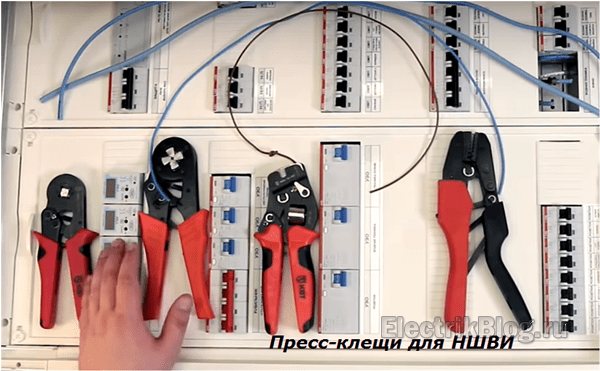

For crimping, a special tool is used: press tongs. If you work with pliers, hammers and other improvised means, then the contact created will be of poor quality.

Press tongs are available in various designs and operating principles for crimping different types of sleeves and tips.

According to the same principle, lugs are selected and crimped on stranded wires for their connection to the terminals of electrical equipment.

This is especially true for automotive technology, where the wiring is subjected to increased mechanical vibrations and electrical loads. Yes, and in the household network there is installation with flexible conductors.

As an example - retro wiring in a wooden house. Although this is not the only case.

Crimping of conductors is a rather large and complex topic that allows you to create a high-quality connection of electrical contacts. Andrey Kulagin explains its technology well in his video. I recommend to look.

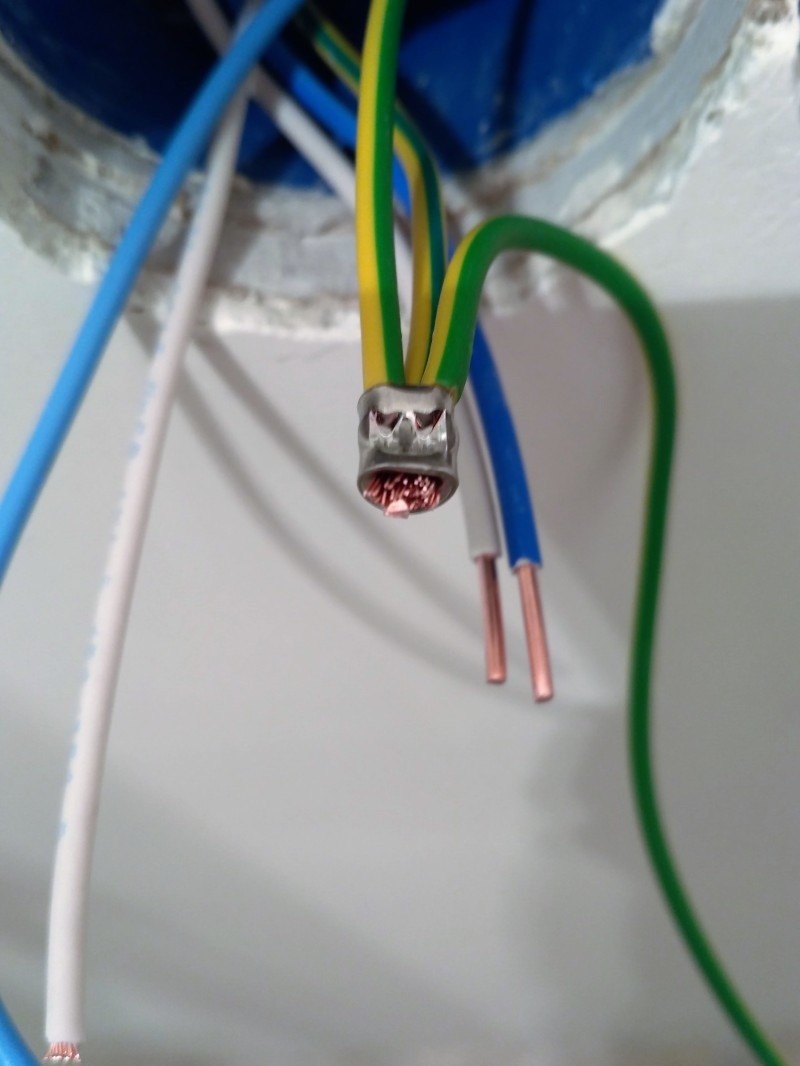

Terminal connection

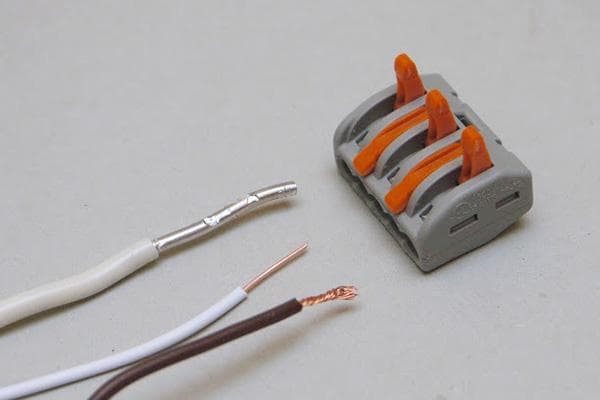

The next type of wire connection, which should be considered in more detail, is the connection with contact clamps (in other words, the use of WAGO terminal blocks, they are also called flat-spring contact clamps).

Currently, wires are increasingly connected with terminal spring clips. In this case, you do not have to twist or solder anything, you just need to strip the ends of the wires by about 12 mm and insert them into the clamp holes.

Scheme of connecting wires with contact clamps: a - connection of an aluminum single-core wire with a pin output: 1 - nut; 2 - split spring washer; 3 - shaped washer; 4 - steel washer; 5 - pin output; b - connection of a two-core wire with a flat contact screw clamp; c - connection of the core with a clamp-type terminal; g - contact spring clamp.

Here's what the design will look like.

These terminals are filled with a special contact paste, which, when an aluminum conductor is connected, removes the oxide film from it and prevents re-oxidation. That is, during installation, you can safely connect both a copper conductor and an aluminum conductor to one terminal block.

Many experts scold this type of connection for one reason or another. But still, it is quite reliable and it has a number of advantages:

- Conductors are not damaged.

- Reliable protection against accidental contact with current-carrying connections.

- Each conductor has its own terminal space.

- Connecting together both copper and aluminum conductors.

- It is possible to measure the electrical parameters of the circuit without breaking the insulation.

- Safety and order when using these terminal blocks in wiring boxes.

- Short circuit and heating at the connection point are completely excluded.

- Clamps of this series are the best option for connecting wires at currents up to 25 A.

- Instant installation of conductors.

There are terminal blocks of this type for stranded wires.

There are other connection methods, less popular, that you can do yourself.

Scheme of the contact clamp device: 1 - screw; 2 - spring washer; 3 - washer or base of the contact clamp; 4 - current-carrying core; 5 - stop, limiting the spreading of the aluminum conductor.

Screw terminals are contacts in which the wire is fastened with screws. The clamp itself is mounted on the underlying surface with screws. In some cases, screw terminals may look like this:

Cable clamps - these devices help to connect the strands of wires without cutting the TPG. Used to branch wires from the main line.

This kind of compression is a bit outdated. Now they are trying to use a slightly different design, which does not need to be disassembled and when using which it is not necessary to clean the section of the line from insulation, since they are self-piercing. That is, when tightening the nut, which is located on top of the clamp, special teeth pierce the insulation of the conductor and thereby ensure reliable contact. In another hole, you can insert another conductor and thereby make a branch.

Panel terminals or busbars –

this connection method is used when you need to connect several conductors. For example, when connecting suitable neutral wires to a common one.

Soldering - connecting wires with a soldering iron and special solders.

Whatever connection you choose, try to do it thoroughly and without haste, so as not to blame yourself in the future if the unexpected happens.

Connect wires with ease

You can put the duty tape in the far drawer: you won't need it anymore. Instead of this:

- We go to the nearest store and buy terminals (clamps). The issue price is 8-50 rubles. It is advisable to take WAGO 222 terminals with levers. As the electrician explained, they are the most reliable and easy to use.

- We clean both wires to the depth of the terminal block, about 1 cm.

- We collect the cores of the stranded wire into a tight bundle and twist it slightly.

- Both conductors must be straight and clean.

- Raise the levers and put both wires into the holes. We clamp, lowering the levers down.

Ready. With this method of connection, you do not need to think about the quality of twisting and insulation. The wire length remains the same. If necessary, the lever can be lifted and the wire removed - that is, the clip is reusable.

Clamp WAGO 222 is 2 holes and more. It is designed for connecting copper single- and stranded wires with a cross-sectional area of 0.08–4 mm, used in household electrical networks with voltages up to 380 V. Lamps, electricity meters, garlands and much more are connected using the terminal block.

Types of terminal blocks

It is worth saying that the terminal blocks are different:

- Screw terminals in polyethylene sheath. The most common, inexpensive and structurally simple. Inside the insulating shell there is a brass sleeve with two screws - they are used to screw the wires inserted into the holes on both sides. The downside is that screw terminals are not well suited for aluminum conductors and stranded wires.Under the constant pressure of the screw, aluminum becomes fluid, and thin veins are destroyed.

-

Screw terminals with metal plates. More reliable design. The wires are clamped not with screws, but with two plates with characteristic notches. Due to the increased pressure surface, these terminals are suitable for stranded wires and aluminium.

- Self-clamping express terminal blocks. No less simple design, but much more convenient. It is enough to put the wire into the hole until it stops, and it will be securely clamped. Inside are a miniature tinned copper shank and a fixing plate. Also, manufacturers often put a paste inside - a mixture of technical petroleum jelly and quartz sand. It removes the oxide film from the aluminum surface and subsequently prevents it from forming again.

To connect an aluminum wire to a copper wire (no matter how many lived they have), a special terminal block with paste is required. The fact is that copper and aluminum form a galvanic couple

When metals interact, the destruction process starts. The resistance at the connection point increases, as a result of which the structure begins to heat up. Often this leads to melting of the insulation or, even worse, sparks. The greater the current, the faster the destruction occurs.

Important Wiring Notes

We note important points regarding electrical wires.

- All wires twisted together should not hang somewhere in the air! They must be placed in a junction (junction box).

- In all wire connections, make sure that the bare ends of the wires are completely hidden in the connection block. i.e.try to make the connection so that after this connection it would be impossible to reach the bare end of the wire by hand.

- Do not try to get the wire from those pads that are not intended for this. For example, there are craftsmen who manage to remove wires from wago terminals. But I do not recommend doing this, since such a withdrawal is always associated with wire deformation. And this is unacceptable, because the load in the network should be experienced by whole wires, and not half-broken ones, which can lead to short circuits.

This is where the article ends. We have studied in detail the question of how to connect the wires in the apartment. Now, when moving the outlet from one place to another, you can easily extend the wires by laying them in the wall and making the right connection.

They put these pads at home for me ... It would be better if they did everything on the twists. The outlet doesn't work and that's it. I called an electrician, he immediately said that the problem was in the pads and that they (problems) would appear periodically. I got into the box and for sure: I turned the wire in the block, the socket worked. And problems cannot but appear: in the block, the wires are pressed with thin petals, very similar to steel ones. So I will look for something else instead of pads ...

Honestly, I'll tell you that at home I made all the connections through the pads. The kitchen has a lot of electricity supply: 3 sockets, heated floor. dishwasher, extractor hood, microwave and all on pads that are hidden in junction boxes or sockets.

I do not argue, there are cases, but this is more the exception than the rule. Could be a defective batch. And the examples are very different. someone and wall falling apart after plastering, and someone for 25 years has no problems.But this does not mean that now you do not need to plaster the walls. Somewhere the technology was broken. Therefore, here you need to study the problem, look deeper, why this is happening. And if the twists were the most reliable, then the firemen would not forbid them.

Hello. I'm wiring a mini-bakery. Everything is great except for one thing. The fact is that I open an enterprise in a remote corner from civilization in a small village. The city is 2000 km and only by plane. So I stocked up on everything. Apart from wires of course. And here the wires somehow found the usual white two-core and three-core aluminum noodles with a cross section of 1.5 sq. mm. and copper three-core 2.5 sq. mm. Electricity is three-phase. I spent 2-core noodles for lighting, and three-core sockets with memory. I have only three equipment supplying 380 watts. Dough mixer 2.4 kW, Flour sifter 1.2 kW, Oven 19.2 kW. Since there is no choice, all three conducted wiring with a cross section of 2.5 sq. Mm. In addition to the oven, the dough mixer and flour sifter work perfectly. But when I turn on the stove after 5 minutes, the RCD 63A 30Ma turns off the electrical supply. I think that this is due to the cross section of the wire. on the instructions, I found that you need to use a wire with a cross section of 6 sq. mm. How can you get out of the situation. Of course, it would be great to find a wire of 6 sq. mm. But I only have 2.5 sq mm. Can you please tell me if it is possible to use a three-wire as one wire, i.e. connect all three to one?

Yes. It would be optimal to make all three cores of one wire 1 phase (it will turn out 7.5 sq mm), another 3 core wire for the second phase, and also for the third phase, also for zero (also respectively 7.5 sq mm), and grounding. Under such loads (about 60 A), no terminals can withstand (except screw ones.but for myself I wouldn’t risk it), you need twists that are irradiated and soldered (use acid-free flux solder and a simple gas burner + futorka (a copper tube with a diameter of 25 mm has one end rolled onto a holder so that the solder does not leak out, approximately 3 cm deep), Or a welding machine and an electrode for copper (scald the ends of the twists until all the cores are welded together in a twist into a ball at the end).