- Purpose of pastes

- Methods for sealing threaded pipe joints

- Using a push-in connection: a quick guide

- Main advantages and disadvantages

- Features of the correct threaded pipe joint

- Overview of detachable plumbing connections

- The nuances of the socket connection of parts

- Option #1 - no o-ring

- Option #2 - with o-ring

- Option # 3 - socket method using welding

- Types of seals

- Linen

- Sealing tape

- Sealant anaerobic

- Installation rules

- Installation of collet fittings (video)

- Socket pipe connection without O-ring

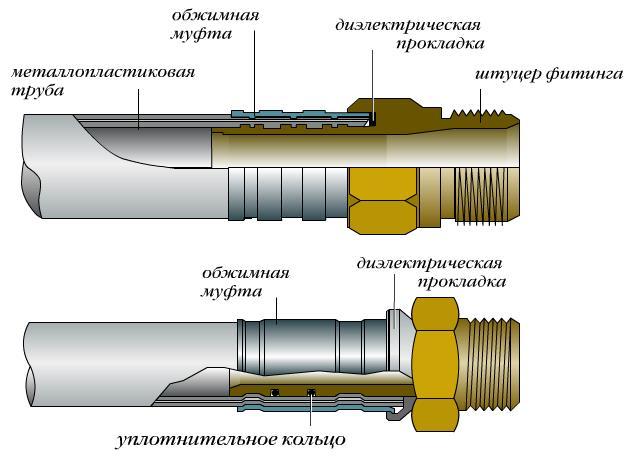

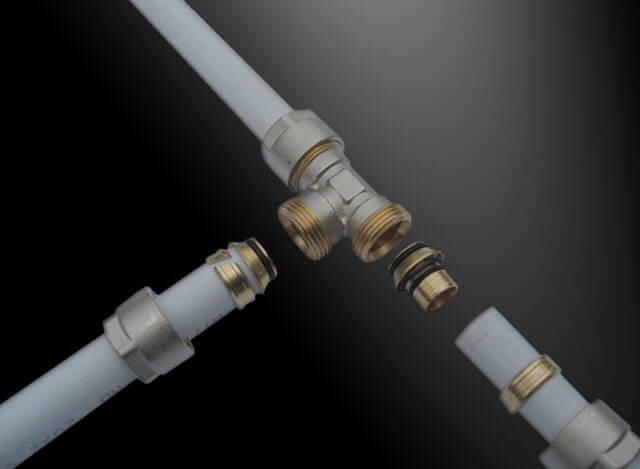

- Push-in fittings for metal-plastic pipes

- What is a trumpet

Purpose of pastes

The composition of plumbing paste may be different, but the purpose is the same: sealing threaded joints. It is used as an auxiliary material for the installation of heating systems, pipelines for the movement of drinking and industrial water, natural gas pipelines, plumbing equipment, etc.

To seal threaded joints, different pastes are used. It provides connecting elements, threads, fittings from rotting and corrosive processes.The use of paste eliminates the loss of tightness of joints, protects flax fibers, since it is used together with them, from possible drying. The substance is an excellent fixative for flax. Using these materials in combination for the installation of pipelines, it is very easy to align the connections, and in the future - dismantling work.

The quality of sealing pastes is indicated by the presence of certificates.

Methods for sealing threaded pipe joints

Sealing pipe connections is necessary to prevent leakage of liquids and gases. High-quality sealant for threaded water pipes will prevent leaks in the future.

In the case of threaded connections, sealing can be carried out in several ways:

- Use of pads. This method requires a sufficient thickness of pipe cuts at the ends. Pipe ends themselves usually do not provide a hermetically compressed connection, but the use of gaskets makes it possible to eliminate this problem. In particular, this sealing option is often used in union nut connections.

- Windings for carving. With this method, the thread is sealed by strapping with all kinds of winding materials: polymer threads and tapes, pipe compounds and other types of hardening sealants, sealing pastes and lubricants, natural or artificial fibers, etc.

- Sealing by deformation of materials. This option is used in low-pressure plastic pipelines connected with a thread. A plastic pipe, equipped with an external thread, is screwed with an emphasis into another, in which the thread is located inside.With this screwing, the plastic undergoes deformation and fills the intermediate threaded space well, leaving practically no gaps.

As for the connection of high-pressure pipelines, a conical type of threaded pipe connections is usually used here (about “What are high-pressure pipelines, what are they made of, how are they used”). With this method, as it is screwed in, one pipe is pressed against the other more and more tightly, leaving almost no intermediate gaps between the threaded grooves. However, additional sealing is still required for such pipes, and especially durable varieties of synthetic sealants are used here.

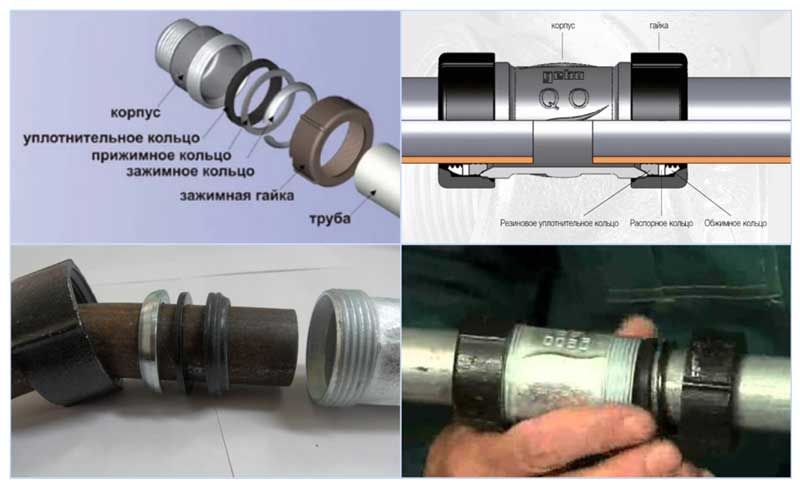

Using a push-in connection: a quick guide

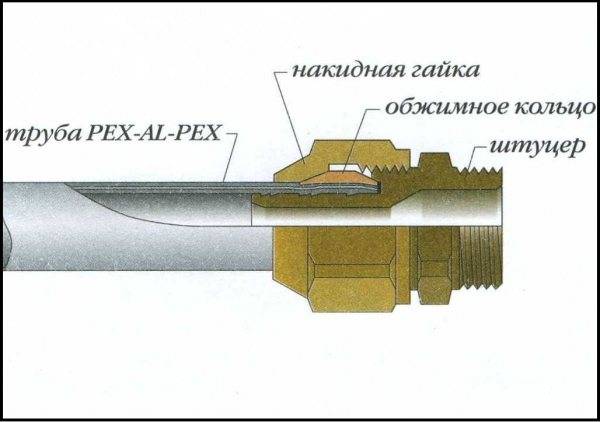

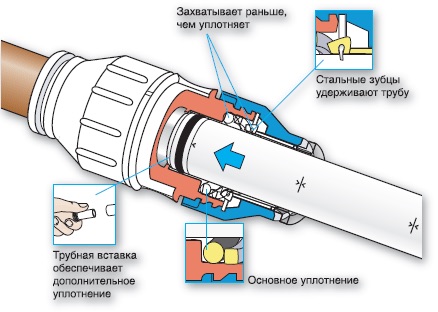

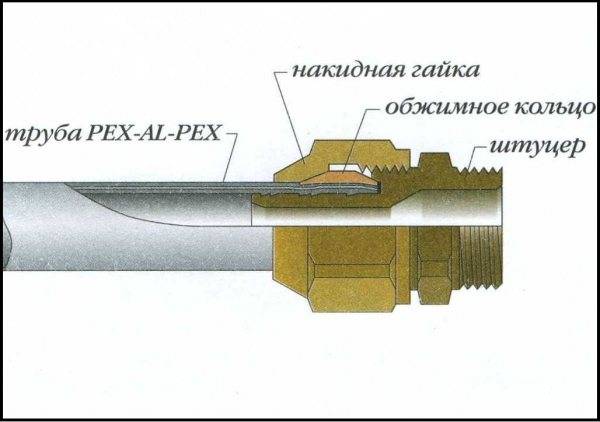

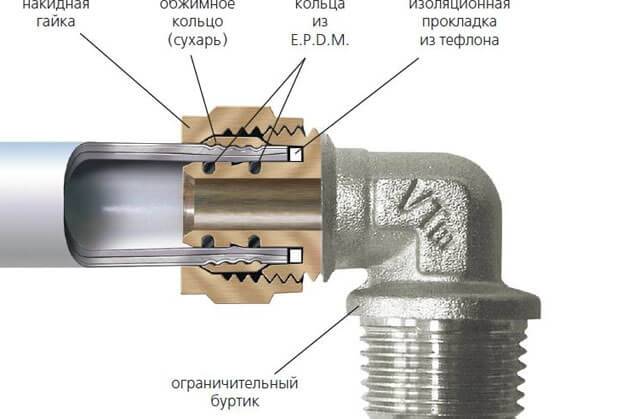

Collet joints are used to fasten metal-plastic pipes. The method, like the material, is new, but has already earned recognition. This method even surpassed the use of non-separable compression fittings.

Push-in fitting scheme:

- Collet. It is a metal tail with a rubber seal.

- Crimp ring. Thanks to him, a tight connection is created when the product is tightened on the pipe.

- Cap nut. It is used to tighten the ferrule.

Before using the collet, you should read the instructions and watch the training video

The installation of such a device is quite simple. First, cut the pipe with a cutter. Then the union nut and the ferrule are put on. The pipe is pulled into the device until it stops. The compression ring is directed to the end of the pipe. Next, the union nut is screwed onto the fitting.

One of the advantages of the collet is the ability to disassemble it, but there are certain difficulties.During dismantling, sealing rings are damaged. That is why all installation work should be carried out as correctly as possible in order to exclude subsequent repair work.

Certain types of collets are used for plastic products. The pipe is loaded into the body of the product, and then the ferrule and nut are tightened. This results in a sealed joint.

Main advantages and disadvantages

The clamps used to connect pipes, the basis of which is the collet, began to be used relatively recently, but have already become popular among professional specialists and home craftsmen. The reason for this popularity lies in the advantages of these connectors over conventional type fittings.

Low cost

This parameter consists of both the price of the clamps themselves and the cost of their installation, which does not require the use of expensive equipment and special tools. It is also important that the replacement of such connecting elements, if required, will also not be associated with serious financial costs.

Availability

Buying collet-type fittings for pipes of almost any diameter does not present any particular problems today. In addition, on the modern market, you can find collet-type clamps of any size, as well as designed for pipes made of various materials.

Ease of use

To learn how to qualitatively connect pipes using collet clamps, it will take very little time and a minimum set of tools used.

The durability of the created connection

Under normal pipeline operating conditions, a collet-type clamp can last for decades.Only significant mechanical loads and corrosion processes occurring in the pipeline can disable it.

Reliability

This advantage of collet clamps is provided both by the mechanical characteristics of the formed connection and its exceptional tightness.

Reusable

Unlike welded joints and fittings, which are connected to plastic pipes using heat, push-in connectors can be used repeatedly

Such an important quality of collet clamps makes it possible to significantly simplify the process of repairing pipelines, for the installation of which they were used. In addition, the possibility of multiple use of push-in fittings allows you to replace individual sections of the pipeline without dismantling the entire system.

Detachable connection of a metal-plastic pipe using a collet fitting

If we talk about the minuses of collet-type clamps, then the most significant of them should be attributed to the fact that such connecting elements weaken over time. This leads to leaks in piping systems. Meanwhile, it is not difficult to eliminate a leak that has arisen for this reason: for this, it is enough to tighten the collet fitting.

It is precisely because of this lack of collet clamps that they should be placed in those places in the pipeline where they are directly accessible. Fitting elements, the basis of which is a collet, cannot be used inside walls and other building structures. Push-in fittings are tightened to improve their tightness, as a rule, no more than once a year.

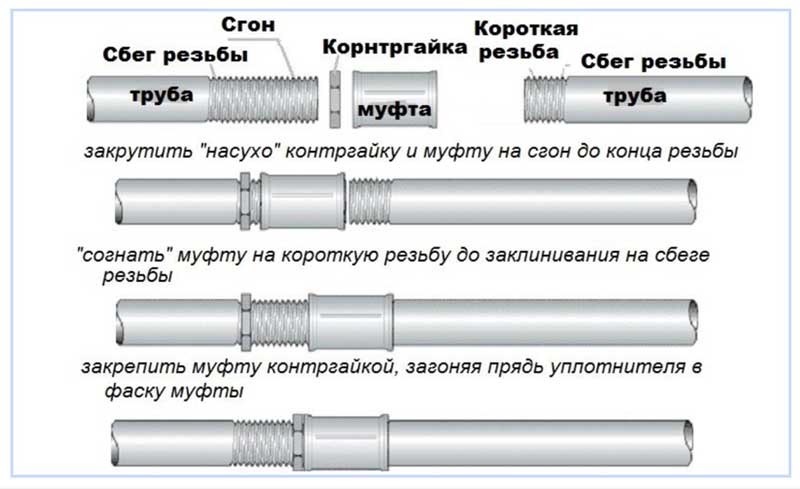

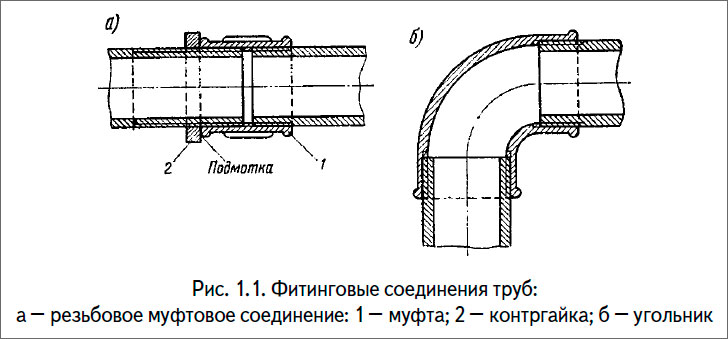

Features of the correct threaded pipe joint

A threaded pipe connection is a detachable joint that is made using a spiral or helical surface called a thread. This connection is one of the most common, as it provides tightness, reliable connections and is easy to install.

To connect the parts with a threaded joint, it is enough to twist two elements that have a thread of a suitable diameter. To detach the parts, it is enough to perform the reverse action - the parts simply unwind.

It is advisable to make threaded connections in those sections of the pipeline where you can periodically monitor them, because the thread can weaken during long-term operation, as well as for various reasons, as a result of which the connection ceases to be tight. In this case, it is necessary to carry out repair work.

Threaded way of connecting pipes.

The thread is most often rolled onto pipes using special equipment, but some craftsmen cut it with their own hands using a die. This requires great attention and care, because otherwise the thread will be uneven, and the part will be damaged and unsuitable for further use.

Threading work is performed in the following sequence:

Cut off the part with the desired dimensions, leaving an allowance for the threaded part. Then the pipe is fixed in a vice in such a way as to prevent its scrolling.

With great care and caution, the die is baited onto the end of the pipe. Even with a slight misalignment, a crooked thread can result.

The required number of turns is cut.

To facilitate the procedure, lubricate the pipe with machine oil. If the die is stuck, it means that the chips that form during threading interfere with it. To remove it, make one turn back, and then continue to work.

When cutting thread on a pipe that is located close to walls or other planes, it is impossible to carry out a full turn with the tool. Therefore, in this case, you can use die holders with ratchet mechanisms.

When making a threaded connection of pipes, it is imperative to use a seal, otherwise the tightness of the connections cannot be guaranteed. The sealant can be a special foamed tape. You can use traditional impregnated flax or hemp for this ueli.

Plumbing pipe connections for the most part are quite easy and quick to do with your own hands. With proper observance of the instructions, these works are carried out with high quality and relative speed.

The main condition is the correct choice of the appropriate type of connection and the selection of all the elements that are necessary for this. Only if you follow these rules will you get a reliable and durable pipe connection.

admin

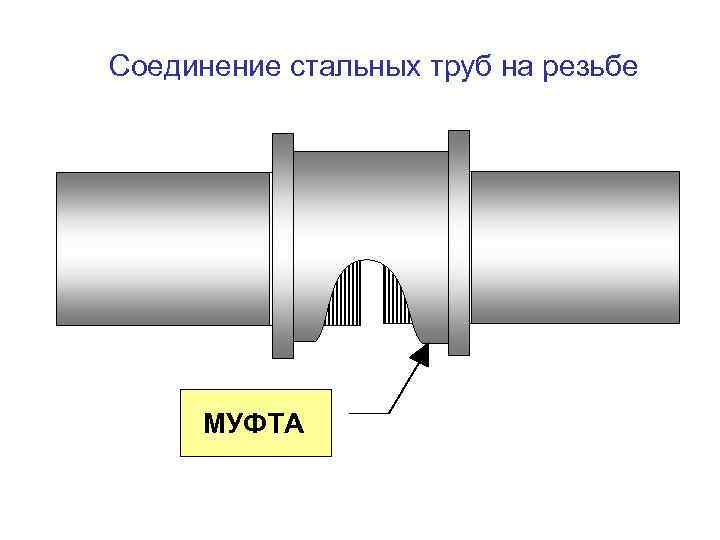

The connection method, in which the end of the other is inserted into the expanded part of one elbow, is a common technique for installing water pipes and sewer systems. The socket, that is, the expanded part of the pipe, firmly and reliably joins the assembly without additional welding seams.

Overview of detachable plumbing connections

All known methods of connecting pipes can be classified into two classes - detachable and one-piece. In turn, detachable connections are flanged and coupling.One-piece methods include such connections as socket, collet, butt welding, adhesive.

Connections, which, if necessary, can be disassembled and then put back into place, greatly simplify the maintenance and repair of pipelines. These connections are mainly used in the formation of internal communications.

The advantage of the method is its ease of implementation. No chemical or thermal effects are used here. A malfunction of a pipeline connected in this way is easy to identify and eliminate.

A tight fit in the plumbing connection of pipes is ensured by the use of special parts. There are 2 types of joints related to the detachable type: flanged and fitting. The first is used when you need to articulate large diameter pipes, and the second is more suitable for domestic pipelines.

The following article, which we recommend reading, will acquaint you with the varieties, characteristics and marking of polypropylene pipes and fittings used in the connection.

Fittings used in plumbing systems are installed at control points, at turns, branches. They are cast and compression. In terms of functionality, the following types of fittings can be distinguished:

To help a novice plumber, this scheme. It will facilitate the selection of fittings that meet the specific conditions encountered in the construction of the pipeline

A set of fittings is selected depending on the specifics of a particular pipeline. According to the method of attaching them to the pipe, fittings are clamping, threaded, press, threaded, used for welding and soldering.

They produce fittings for metal-plastic pipes, they are used in the formation of crimp and press connections. For the articulation of polypropylene pipes, fittings are produced that are used both in bonding and welding. For copper pipes make fittings and for press connections, and for soldering.

The process of assembling a metal-plastic pipeline using compression fittings will be presented by the following selection of photos:

Image gallery

Photo from

Compression fittings for the assembly of metal-plastic pipelines should be selected according to a pre-compiled scheme. Angle, socket and other connectors must be of the same company as the pipes

The place for installing the connector is marked directly on the object. On the pipe, you need to leave two ends of the fitting and the depth of immersion of the pipe into it

According to the mark indicating the depth of immersion of the pipe into the fitting, we perform cutting. In cutting, we use a pipe cutter designed specifically for metal-plastic pipes

If branches with hot and cold water are located nearby, we put on a warming corrugation on the hot line. It prevents condensation

We calibrate the ends of the pipes to be connected before connecting to remove irregularities and chamfer 1 mm

We install a union nut with a sealing split ring on the pipe so that the ring is inside the connection

We use two keys to make connections. With one we keep the pipes from turning, with the second we tighten the nut without excessive force

Installation of elbow, cross, tees and conventional fittings is carried out in the same sequence. After assembling the pipeline, its tightness is checked by supplying water to the pipes

Step 1: Selection of fittings for making connections

Step 2: Marking out the location of the connector

Step 3: Cut the pipe with a pipe cutter

Step 4: Installing the thermal corrugation

Step 5: Pipe calibration before connection

Step 6: Installing the flare nut

Step 7: Making a Compression Connection

Step 8: Assembling the pipeline of any complexity

This is interesting: Calculation of weight, mass, volume of a pipe (and other parameters) - formulas and examples

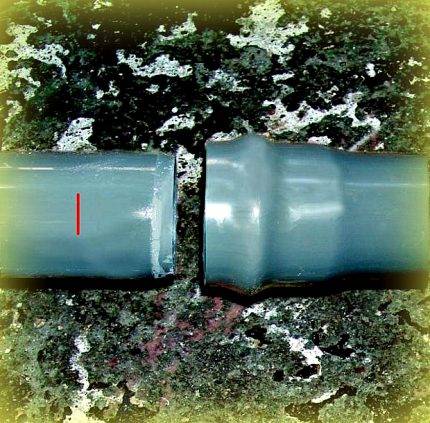

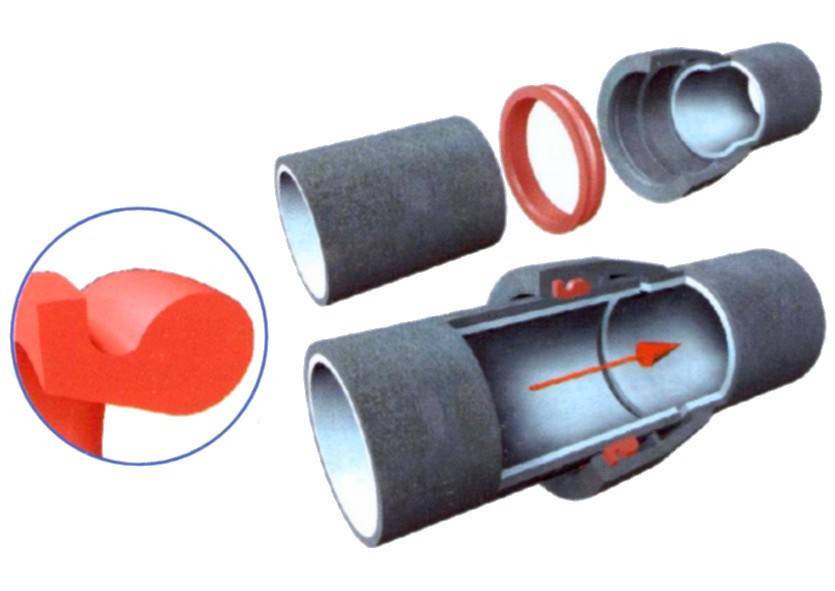

The nuances of the socket connection of parts

The socket method of connecting parts is very simple. The edge of one pipe has a larger diameter, it is he who forms the socket into which the end of the other element is inserted. To make the connection tight, a special rubber O-ring is inserted into the socket, or another seal is used. Installation of a pipeline with connections of this type is not particularly difficult and resembles the assembly of a designer. There are varieties of socket connections.

Option #1 - no o-ring

The method is very often used to connect sewer cast iron pipes. Details are measured. The inserted element is laid on wooden bars and sawn off along the intended line. The end of the outer part of the part must be free of cracks or notches and strictly perpendicular to the axis of the pipe. The prepared pipe is inserted into the socket. The gap inside it must be sealed. Oiled hemp or tarred flax is used as a sealant. The first layer is wound into the pipe with a ring, so that the ends of the strands do not get inside the part. The seal is caulked with a hammer and screwdriver.

The remaining layers of material are laid in the same way until approximately two-thirds of the depth of the socket is filled. The last layer is laid sealant without impregnation, which may prevent adhesion to the solution. The remaining distance to the end of the pipe is filled with cement mortar or silicone sealant, asbestos-cement mixture, bituminous mastic and similar compounds.

To seal the socket joint of pipes without a sealant, tarred flax or oiled hemp is used.

Option #2 - with o-ring

It is considered one of the main ways to connect plastic pipes. In this case, the tightness is ensured by a rubber ring, which is clamped between the flat end of the pipe and the socket walls. The seal, which can be either with special plastic inserts or without them, allows you to partially compensate for the possible misalignment of the axes of the connected parts. However, uneven deformation of the sealing band on the ring can cause leaks in the articulation area. Therefore, the curvature of the axis should be no more than the thickness of the pipe wall per linear meter of the pipeline.

When installing a socket connection with a sealing ring, it is necessary to monitor the alignment of the centers. Otherwise, the skew of the pipe will provoke deformation of the seal and, as a result, insufficient sealing of the joint.

Some manufacturers produce models of tees and elbows not at a straight line, but at an angle of 87 °. Thus, the pipe, which is laid down under a slope, enters the socket without distorting the rings. During installation, to prevent damage to the seal, a chamfer is made on the smooth end of the pipe and lubricated with soap, glycerin or silicone.Oils are not allowed. The socket connection with an O-ring is made as follows:

We check the presence of an o-ring in the socket and a chamfer on the smooth end of the pipe

We clean the parts from possible contamination, apply lubricant.

We place the smooth edge of the structure all the way into the socket and put a mark.

Carefully remove the part from the socket, pushing it out no more than 11 mm, while focusing on the mark set earlier. The resulting gap will compensate for temperature changes in the length of the pipe

On average, one socket compensates for the lengthening of a two-meter pipeline fragment.

If it is required to connect pipes of different materials in this way, special transition pipes are used.

Option # 3 - socket method using welding

Contact socket welding is designed for plastic parts and is carried out using special equipment. In the connection process, a mechanical or manual welding machine is used, equipped with special devices for heating the elements. This is a mandrel designed to melt the inner surface of the part, and a sleeve that heats the outer part of the pipe.

Polypropylene pipes are connected by socket welding. For this procedure, a special welding machine is used, which heats the parts to the desired temperature.

The connection process is quite simple. A set of sleeve-mandrel is selected, corresponding to the diameter of the pipes to be connected. Devices are installed on the platform of the device and warmed up. Parts are put on the equipment and heated to the desired temperature. After it is reached, the elements are quickly and accurately removed and connected with a precise movement until they stop.The connection is left motionless until the plastic cools down and completely hardens.

Types of seals

If it is planned to use a threaded connection for pipe assembly, then it is imperative to use additional sealing agents.

Linen

Linen tow is used for sealing. Additionally, silicone or sanitary paste is used, this is necessary to protect the winding from drying out.

This is a cheap and reliable method of sealing, but it is not very convenient to use. The work is done like this:

- the necessary part of the tow is separated from the bundle;

- the separated beam must be carefully smoothed out; places of twisting or kinks should not be allowed on it;

- put tow on the thread so that the middle of the beam is at the top, then with an effort to wind it onto the thread, turning clockwise, you need to wind both hanging “tails”;

- apply sanitary paste, smooth, achieving a uniform coating;

- tighten the connection with the key.

Sealing tape

This is a modern sealing material that is more convenient to use. The work must be done like this:

- tear off a piece of the required length;

- wind the tape clockwise;

- tighten the connection with a wrench.

Sealant anaerobic

This is the most modern material for sealing the joint; its use does not require the use of tools. It will be possible to tighten the parts without using a key, that is, manually.

This circumstance allows installation even in inconvenient places where it is difficult to wield a key. To make the joint tight, you need to use the sealant correctly, namely:

do not apply this composition to plastic parts, this material is designed to work with steel pipelines;

it makes no sense to apply sealant to dirty or wet threads, in which case it will not be possible to achieve the required degree of tightness. The surface to which the sealant is to be applied must be clean and dry. To obtain a better result, it is desirable to additionally degrease the surface.

To make a connection with a sealant is quite simple, you need:

- apply composition;

- connect the parts using the thread;

- leave the junction for a while so that the composition has time to harden. The time required for polymerization is indicated on the packaging of the sealant.

So, threaded connections are used quite often during the installation of pipelines, especially if the work is carried out using metal pipes. In addition, such a connection can be used if you need to make a joint between elements from different materials.

Installation rules

Although it is very easy to connect both straight and corner joints with push-in fittings, it is still worth knowing some rules.

They will allow you to carry out installation work without wasting time and effort.

Stages of installation and dismantling of compression fittings

In order to mount a pipeline from plastic or metal-plastic pipes using clamp fittings, you will need:

- Scissors for cutting metal-plastic. If you do not have scissors, and the amount of work is small, there is no need to purchase them. You can use a regular metal saw.However, a cut made in this way must be carefully processed with a drill or large sandpaper.

- Calibrator. This equipment is needed to give the cut a round shape, since the pipe may be slightly flattened during the cutting process. The role of the calibrator may well be performed by a metal rod with a circular cross section.

- Wrenches of the appropriate diameter. You can also use a wrench or wrench.

See also: How to solder plastic pipes for plumbing video

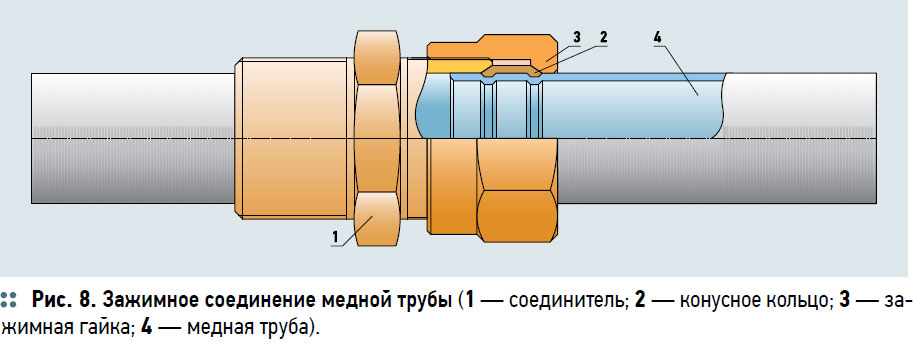

Installation of a fitting on a copper tube

Having prepared all the tools, pipes and necessary fittings, you can proceed with the installation work.

- We cut off from the pipe, using special scissors or a nail file for metal, the desired segment. We carefully monitor that the cut is as straight as possible - perpendicular to the passing stream.

- We clean the cut so that there are no burrs on it.

- We flare with a calibrator to a round shape.

- We put a nut in place of the cut, and then a clamping ring - a collet.

- We insert the inner end with sealing rubber bands into the pipe. For easier connection and ensuring the integrity of the seals, it is better to moisten the cut point with water.

- Carefully screw the clamping nut onto the thread with your hands, pulling the collet with it. Watch carefully so that there are no distortions.

- Next, tighten the nut very sensitively with a wrench.

- If you come across a poor-quality connector and a crack appears on the nut or other part of it, do not try to close your eyes to it. It is better to replace the fitting immediately.

Installation of collet fittings (video)

A fitting is an adapter that connects sections of a pipeline for various purposes.It can connect pipe sections of different and the same diameter, perform angular turns, wiring to several lines, and also connect various elements (faucets, meters, filters) to the system. Pneumatic collet fittings are considered the most optimal connections in terms of price and quality.

The requirements for all fittings are the same: their reliability and strength must correspond to the strength of the pipe material, the connection itself must have a high degree of tightness.

Socket pipe connection without O-ring

Often, sewer cast-iron pipes are connected in this way. First you need to measure the details. Then lay the element that will be inserted into another part on wooden blocks, and cut along the line planned in advance.

The outer part of the part must have a flat end, on which there is not a single crack or notch. In addition, it is necessary that the end face be perpendicular to the axis of the pipe.

After the preparation described above, the pipe is inserted into the socket, and the internal gap is sealed.

The sealant can be made with oiled hemp or tarred flax. A seal should be inserted into the pipe with a ring so that the ends of the strands do not fall inside the part. Then the seal must be caulked using a hammer and screwdriver.

Types of socket pipe connection.

By the same principle, it is necessary to lay the remaining layers of the sealant until about two-thirds of the depth of the socket is filled. The last layer of sealant is laid without impregnation, since it does not give adhesion to the solution.

Cement mortar or silicone sealant, asbestos-cement mixture, bituminous mastic or other similar composition is poured into the remaining gap.

The connection of plastic pipes is carried out using a socket method. In this case, sealing is carried out using tarred flax or oiled hemp. The socket connection of other materials (cast iron, ceramics) is sealed with tarred hemp cord, bituminous putty or cement mortar.

Push-in fittings for metal-plastic pipes

The main distinguishing feature of collet fittings is the possibility of multiple assembly and disassembly. Push-in fittings for metal-plastic pipes are more expensive than their closest counterparts, but it pays off due to the quality described above.

If we compare the design of these fittings with traditional threaded elements, then the presence of a sealing ring - a collet - will become noticeable first of all. It is this element that allows you to achieve reliable sealing of the connection.

The design of the push-in fitting includes:

- Body made of brass;

- Crimp ring;

- Rubber sealing gasket.

These detachable fittings for metal-plastic pipes have many types: various tees, crosses, adapters and others. In addition to versatility, all these elements have a sufficient margin of safety and are very reliable, which makes it possible to use them in the arrangement of various pipelines.

The same, for example, tees are very common elements that are required when installing most systems. This type of fitting allows you to branch the main line, thereby ensuring the operability of the system.

A variation of such a fitting is a cross, which is a complicated tee, spaced on two sides. This design is most often used to equip two separate pipeline branches.

Tees can be:

- Crimp;

- Threaded;

- For installation under the press sleeve.

In addition to the installation method, tees are also divided into types depending on the method of manufacture. There are two types - regular and combined parts.

Combined tees, in turn, are classified as follows:

- With external thread;

- With internal thread;

- With cap nut.

What is a trumpet

Pipes and fittings with sockets

When asked what a bell is, there are a number of answers:

- part of a wind instrument; "Trumpet" URPK 5 - a rocket launcher in service with the Armed Forces of the Russian Federation; a form of clothing; a docking element for household communications.

A bell is a funnel or cone, the outer diameter of which is much larger than the inner one. This term includes elements having the shape of a pipe with a flared edge.

In plumbing, pipes or their fittings are expanded at one or both ends to provide a strong and vibration-resistant fixing. The socket simplifies work on fitting the units: the end of the pipe inserted into the socket remains motionless even before being hermetically sealed or secured with a welded seam.