- Types of seals

- About push-in connectors

- Application of collet fittings

- Overview of detachable plumbing connections

- Socket connection method

- Connection without ring seal

- Flare connection with O-ring

- Overview of detachable plumbing connections

- The nuances of the socket connection of parts

- Option #1 - no o-ring

- Option #2 - with o-ring

- Option # 3 - socket method using welding

- Mounting technology

- Advantages

- Engine power and control system

- Conclusions and useful video on the topic

Types of seals

Sealing threaded connections in plumbing is the main condition for the strength of joints and spurs. Various products are used as sealants:

- dry linen strands can protect the thread from corrosion. They are recommended to be impregnated with drying oil, special paste, or adhesive waterproof compounds;

- It is possible to seal the threaded connection using various sealants based on a synthetic polymer base. They retain a strong structure for a long time, protect against rust. Anaerobic polymer compositions can cover any surface;

- in a large assortment on the shelves are special cords impregnated with sealants, tapes made of durable nylon, impervious fluoroplastic, and other protective adhesive winding for pipes. These seals are screwed over the threads when connecting the elements.

It is recommended to discuss the choice of sealant with a store consultant.

WATCH VIDEO

It is better to entrust the work of laying communication lines to a specialist with specialized skills. The reliability of the pairing depends on the correct choice of materials, the method of sealing. Of great importance are the types of threads and threaded connections. For self-installation, careful study of the instructions is required. When assembling plumbing and sewer structures, remember: the quick-connect connection of pipes by the threaded method is carried out only in places accessible for maintenance.

About push-in connectors

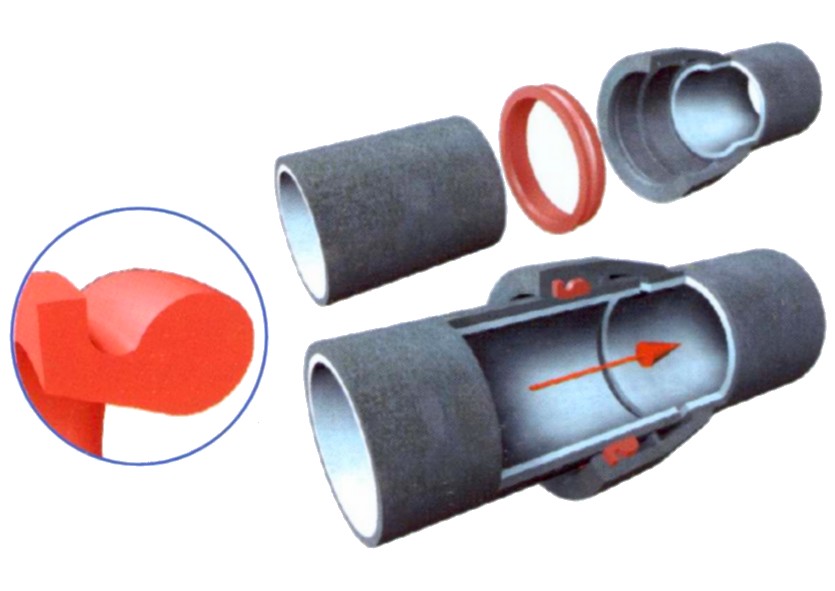

The main feature of the design of such parts is the presence of a special sealing ring (or two), which allows for reliable fixation and sealing of the pipeline. This ring automatically clamps the pipe when it is inserted into the fitting, which made the installation process of such systems very simple.

In order to remove the hose from this element, you just need to lightly press on the sealing ring, which should be pressed towards the fitting. As you can see, pneumatic collet fittings are very easy to install, although this simplicity has its drawbacks.

For example, only durable hoses and water pipes made of polyurethane and polyethylene are suitable for fixing in this way.Soft PVC pipes for sewage can be deformed under the pressure of the sealing ring, which will lead to depressurization of the system. However, this will not happen if you use the connecting elements for their intended purpose.

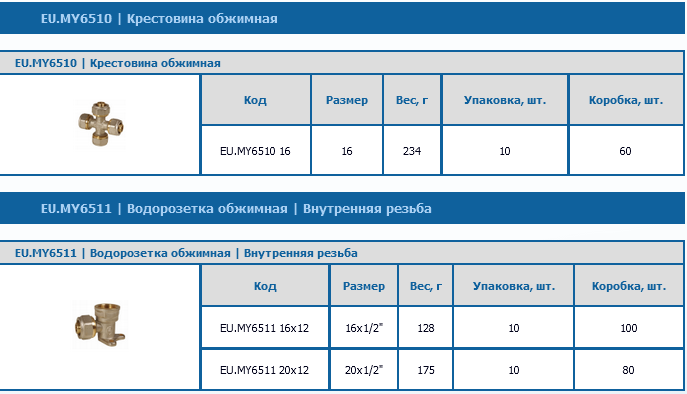

Application of collet fittings

Collet or compression fittings are used in a wide variety of areas of work.

Their main characteristics are:

- The possibility of transporting various kinds of working media, the temperature of which does not exceed 175 degrees Celsius, and the working pressure is 1.6 MPa.

- The passage diameter of such parts varies from 8 to 100 mm along the internal passage.

- Permissible conveyed media include gases, solvents, hydraulic oil, water, etc.

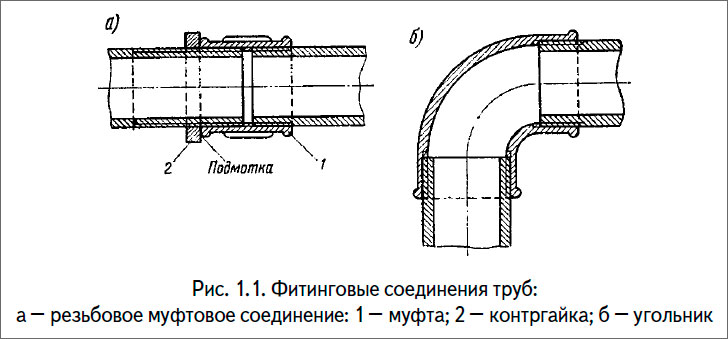

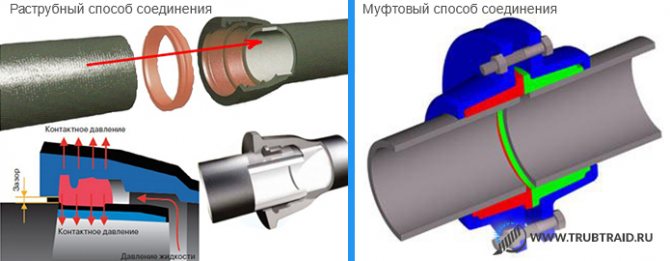

Overview of detachable plumbing connections

All known methods of connecting pipes can be classified into two classes - detachable and one-piece. In turn, detachable connections are flanged and coupling. One-piece methods include such connections as socket, collet, butt welding, adhesive.

Connections, which, if necessary, can be disassembled and then put back into place, greatly simplify the maintenance and repair of pipelines. These connections are mainly used in the formation of internal communications.

The advantage of the method is its ease of implementation. No chemical or thermal effects are used here. A malfunction of a pipeline connected in this way is easy to identify and eliminate.

A tight fit in the plumbing connection of pipes is ensured by the use of special parts. There are 2 types of joints related to the detachable type: flanged and fitting.The first is used when you need to articulate large diameter pipes, and the second is more suitable for domestic pipelines.

The following article, which we recommend reading, will acquaint you with the varieties, characteristics and marking of polypropylene pipes and fittings used in the connection.

Fittings used in plumbing systems are installed at control points, at turns, branches. They are cast and compression. In terms of functionality, the following types of fittings can be distinguished:

To help a novice plumber, this scheme. It will facilitate the selection of fittings that meet the specific conditions encountered in the construction of the pipeline

To help a novice plumber, this scheme. It will facilitate the selection of fittings that meet the specific conditions encountered in the construction of the pipeline

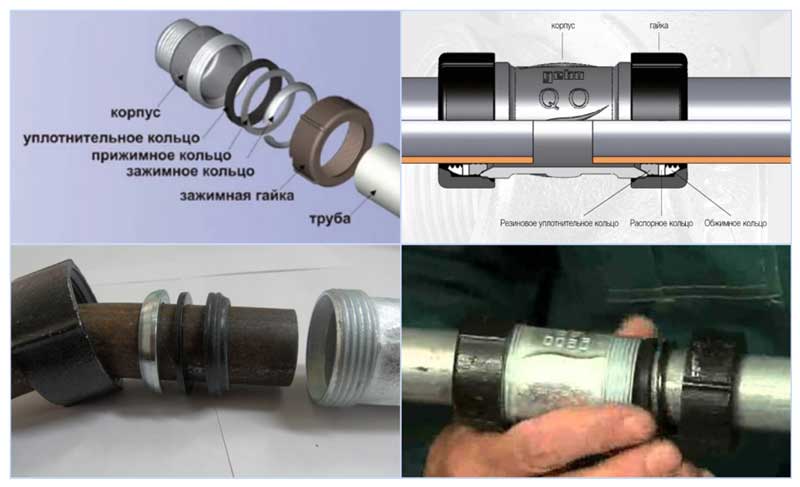

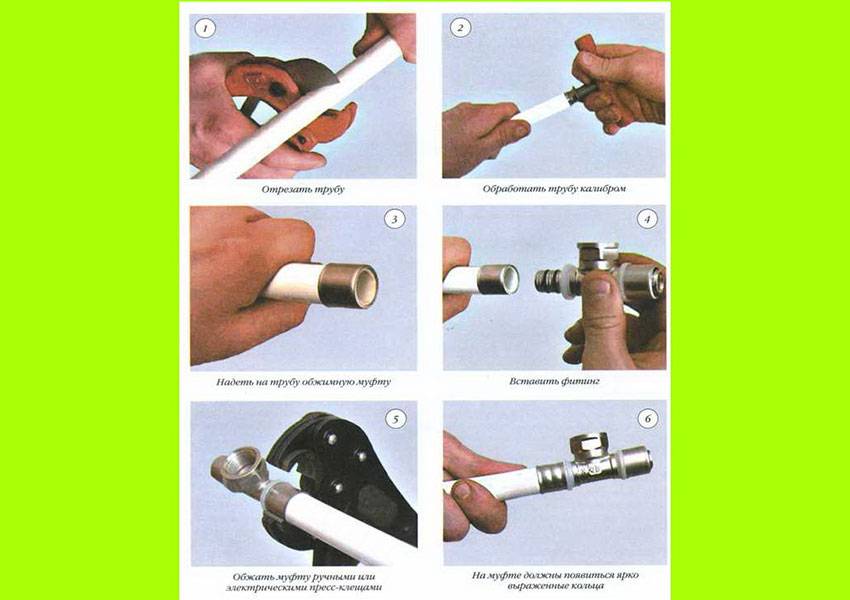

A set of fittings is selected depending on the specifics of a particular pipeline. According to the method of attaching them to the pipe, fittings are clamping, threaded, press, threaded, used for welding and soldering.

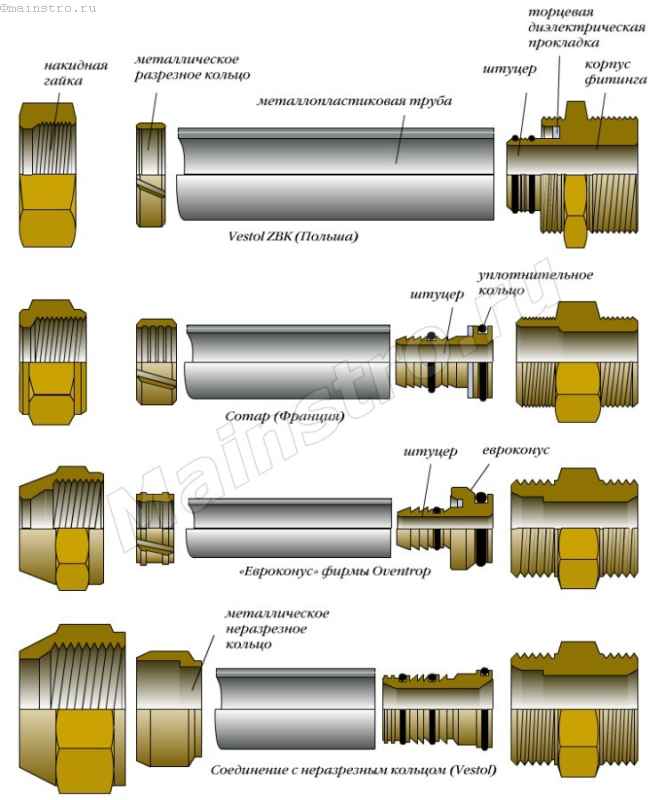

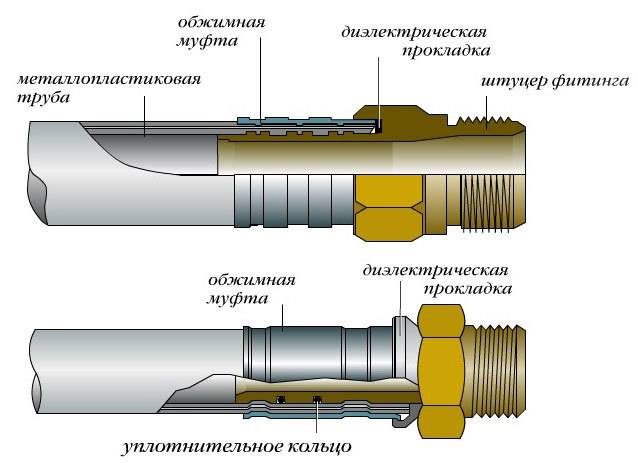

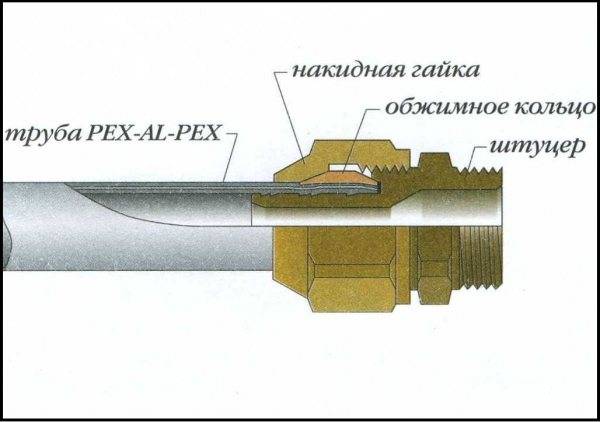

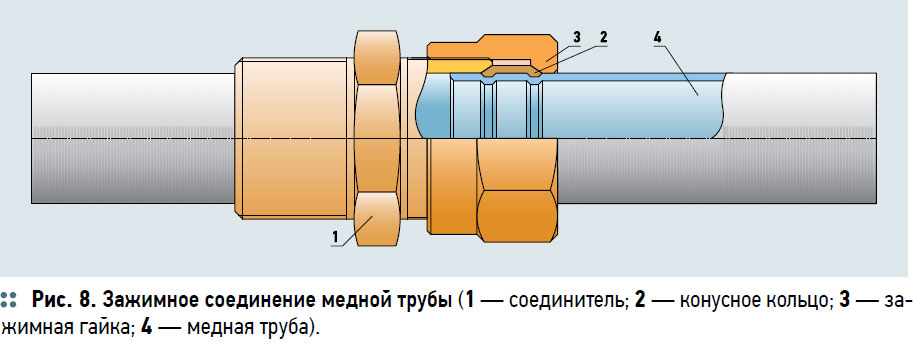

They produce fittings for metal-plastic pipes, they are used in the formation of crimp and press connections. For the articulation of polypropylene pipes, fittings are produced that are used both in bonding and welding. Fittings for copper pipes and for press connections, and for soldering.

The process of assembling a metal-plastic pipeline using compression fittings will be presented by the following selection of photos:

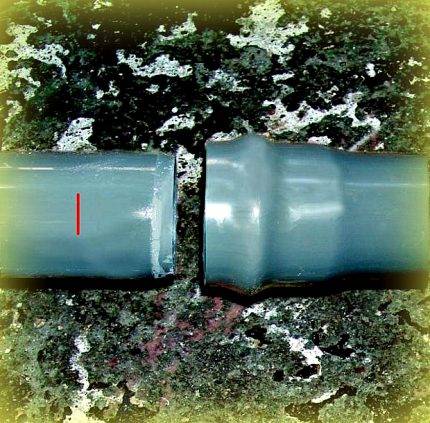

Socket connection method

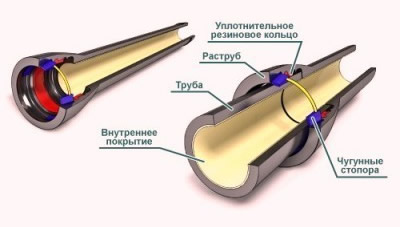

A socket is a mounting extension designed to create a secure connection. The principle is based on the fact that the end of a pipe with a smaller cross section is inserted into a pipe of a larger diameter. Seal the connection by using a sealant placed in the socket or gluing with a water-resistant compound.

A connection of this type is used in the installation of gravity pipelines for both internal and external sewage systems, pressure external water pipes and sewer networks

Depending on the material of the pipes and their diameter, one of several existing variants of the socket joint is chosen: with a sealing ring, without a ring, welding, gluing.

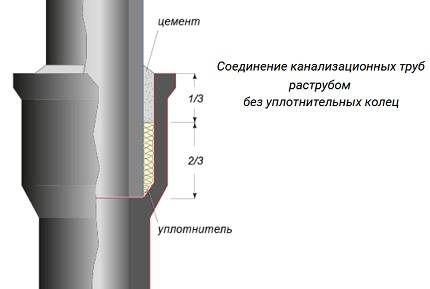

Connection without ring seal

Without a sealing ring, cast-iron pipes are most often connected. The inserted pipe is shortened, the end is processed so that there are no notches and cracks left in it. The tail part of the articulated pipe is inserted into the socket.

The resulting gap is filled with a rope of oiled hemp or tarred linen strands. First, the sealant is laid in a ring and minted in the socket, tapping with a hammer on a special wooden spatula or screwdriver

In this case, it is important to ensure that the ends of the material do not get inside the pipeline.

The layer-by-layer laying of the sealant is continued until the socket is filled to 2/3 of its depth. For the last layer, an untreated sealant is used, because. oils or resin will impair adhesion when filling the remaining space in the socket with cement.

To obtain a solution, cement grades 300 - 400 and water are needed to dilute it. The components are taken in a ratio of 9:1. The cement is tamped into the socket and covered with a wet rag for a better setting.

The highest quality seal is the use of expanding cement. It is prepared just before use by adding water to the container with the main component in a ratio of 2: 1, followed by thorough mixing and pouring into the socket.When hardened, the cement self-compacts and becomes completely waterproof.

Sometimes, instead of cement, an asbestos-cement mixture is used, made from M400 cement and high-quality asbestos fiber in a 2: 1 ratio. Water is added immediately before laying in an amount of about 11% by weight of the dry mix. Instead of cement-based sealers, they use bituminous, silicone sealants, clay, the last layer of which is strengthened by applying bitumen or oil paint.

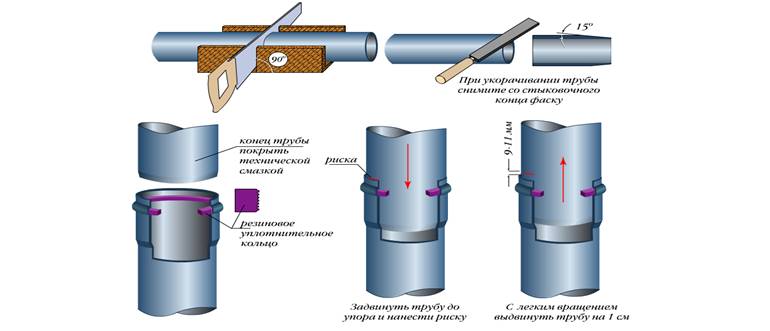

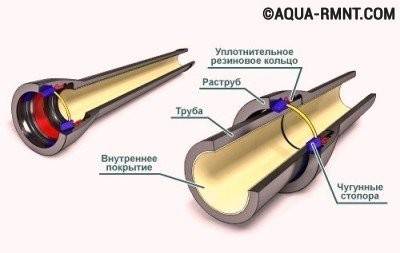

Flare connection with O-ring

This method is most often used when arranging an intra-house sewer system. A rubber ring sandwiched between the socket and the pipe inserted into it gives a tight connection. Therefore, the method is not only simple, but also reliable.

The sealing ring to some extent smooths out the differences in the axes between the two connected pipes, but only if the axes on each meter of the composite pipeline are displaced by an amount not exceeding the thickness of the pipe wall. If this condition is violated, then the likelihood of leakage as a result of uneven deformation of the seal increases.

The procedure for connecting pipes with a socket. The parts to be joined are cleaned of dirt and dust. In order not to damage the sealing ring during installation, the smooth end of the pipe is pre-lubricated with soap, glycerin or special silicone grease. Oils cannot be used for this purpose. In addition to lubrication, the ring will be protected from damage by a chamfer made at the connecting end of a pipe of a smaller diameter at an angle of 15⁰

To determine the depth of pressing the free shank of the pipe into the socket, the sealing ring is temporarily removed.Then, placing the pipe in the socket until it stops, mark the place where the inserted part is in contact with the socket. During installation, the pipe is slightly extended in relation to the mark - by 0.9 - 1.1 cm. This distance will balance the internal stresses that appear in the system during temperature fluctuations.

Experts recommend that before placing the ring, dip it in soapy water and squeeze it a little. This will greatly simplify its insertion into the socket recess. In order to minimize the amount of misalignment, some manufacturers began to produce fittings with an angle of 87⁰ instead of 90⁰. The pipe enters the socket at an angle and the ring does not warp.

When there is a need to connect pipes made of materials of various kinds, transition pipes are used. Such a pipe size as the inner diameter must correspond to the outer section of the pipe to be connected. In the case of articulation of the socket of a polymer pipe with a pipe made of cast iron, a double seal is applied to the end of the second one and a branch pipe is mounted.

Overview of detachable plumbing connections

All known methods of connecting pipes can be classified into two classes - detachable and one-piece. In turn, detachable connections are flanged and coupling. One-piece methods include such connections as socket, collet, butt welding, adhesive.

Connections, which, if necessary, can be disassembled and then put back into place, greatly simplify the maintenance and repair of pipelines. These connections are mainly used in the formation of internal communications.

The advantage of the method is its ease of implementation. No chemical or thermal effects are used here.A malfunction of a pipeline connected in this way is easy to identify and eliminate.

A tight fit in the plumbing connection of pipes is ensured by the use of special parts. There are 2 types of joints related to the detachable type: flanged and fitting. The first is used when you need to articulate large diameter pipes, and the second is more suitable for domestic pipelines.

The following article, which we recommend reading, will acquaint you with the varieties, characteristics and marking of polypropylene pipes and fittings used in the connection.

Fittings used in plumbing systems are installed at control points, at turns, branches. They are cast and compression. In terms of functionality, the following types of fittings can be distinguished:

To help a novice plumber, this scheme. It will facilitate the selection of fittings that meet the specific conditions encountered in the construction of the pipeline

A set of fittings is selected depending on the specifics of a particular pipeline. According to the method of attaching them to the pipe, fittings are clamping, threaded, press, threaded, used for welding and soldering.

They produce fittings for metal-plastic pipes, they are used in the formation of crimp and press connections. For the articulation of polypropylene pipes, fittings are produced that are used both in bonding and welding. For copper pipes, fittings are made for both press connections and soldering.

The process of assembling a metal-plastic pipeline using compression fittings will be presented by the following selection of photos:

Image gallery

Photo from

Compression fittings for assemblies of metal-plastic pipelines should be selected according to a pre-compiled scheme. Angle, socket and other connectors must be of the same company as the pipes

The place for installing the connector is marked directly on the object. On the pipe, you need to leave two ends of the fitting and the depth of immersion of the pipe into it

According to the mark indicating the depth of immersion of the pipe into the fitting, we perform cutting. In cutting, we use a pipe cutter designed specifically for metal-plastic pipes

If branches with hot and cold water are located nearby, we put on a warming corrugation on the hot line. It prevents condensation

We calibrate the ends of the pipes to be connected before connecting to remove irregularities and chamfer 1 mm

We install a union nut with a sealing split ring on the pipe so that the ring is inside the connection

We use two keys to make connections. With one we keep the pipes from turning, with the second we tighten the nut without excessive force

Installation of elbow, cross, tees and conventional fittings is carried out in the same sequence. After assembling the pipeline, its tightness is checked by supplying water to the pipes

Step 1: Selection of fittings for making connections

Step 2: Marking out the location of the connector

Step 3: Cut the pipe with a pipe cutter

Step 4: Installing the thermal corrugation

Step 5: Pipe calibration before connection

Step 6: Installing the flare nut

Step 7: Making a Compression Connection

Step 8: Assembling the pipeline of any complexity

This is interesting: Calculation of weight, mass, volume of a pipe (and other parameters) - formulas and examples

The nuances of the socket connection of parts

The socket method of connecting parts is very simple. The edge of one pipe has a larger diameter, it is he who forms the socket into which the end of the other element is inserted. To make the connection tight, a special rubber O-ring is inserted into the socket, or another seal is used. Installation of a pipeline with connections of this type is not particularly difficult and resembles the assembly of a designer. There are varieties of socket connections.

Option #1 - no o-ring

The method is very often used to connect sewer cast iron pipes. Details are measured. The inserted element is laid on wooden bars and sawn off along the intended line. The end of the outer part of the part must be free of cracks or notches and strictly perpendicular to the axis of the pipe. The prepared pipe is inserted into the socket. The gap inside it must be sealed. Used as a sealant oiled hemp or tarred linen. The first layer is wound into the pipe with a ring, so that the ends of the strands do not get inside the part. The seal is caulked with a hammer and screwdriver.

The remaining layers of material are laid in the same way until approximately two-thirds of the depth of the socket is filled. The last layer is laid sealant without impregnation, which may prevent adhesion to the solution. The remaining distance to the end of the pipe is filled with cement mortar or silicone sealant, asbestos-cement mixture, bituminous mastic and similar compounds.

To seal the socket joint of pipes without a sealant, tarred flax or oiled hemp is used.

Option #2 - with o-ring

It is considered one of the main ways to connect plastic pipes. In this case, the tightness is ensured by a rubber ring, which is clamped between the flat end of the pipe and the socket walls. The seal, which can be either with special plastic inserts or without them, allows you to partially compensate for the possible misalignment of the axes of the connected parts. However, uneven deformation of the sealing band on the ring can cause leaks in the articulation area. Therefore, the curvature of the axis should be no more than the thickness of the pipe wall per linear meter of the pipeline.

When installing a socket connection with a sealing ring, it is necessary to monitor the alignment of the centers. Otherwise, the skew of the pipe will provoke deformation of the seal and, as a result, insufficient sealing of the joint.

Some manufacturers produce models of tees and elbows not at a straight line, but at an angle of 87 °. Thus, the pipe, which is laid down under a slope, enters the socket without distorting the rings. During installation, to prevent damage to the seal, a chamfer is made on the smooth end of the pipe and lubricated with soap, glycerin or silicone. Oils are not allowed. The socket connection with an O-ring is made as follows:

We check the presence of an o-ring in the socket and a chamfer on the smooth end of the pipe

We clean the parts from possible contamination, apply lubricant.

We place the smooth edge of the structure all the way into the socket and put a mark.

Carefully remove the part from the socket, pushing it out no more than 11 mm, while focusing on the mark set earlier. The resulting gap will compensate for temperature changes in the length of the pipe

On average, one socket compensates for the lengthening of a two-meter pipeline fragment.

If it is required to connect pipes of different materials in this way, special transition pipes are used.

Option # 3 - socket method using welding

Contact socket welding is designed for plastic parts and is carried out using special equipment. In the connection process, a mechanical or manual welding machine is used, equipped with special devices for heating the elements. This is a mandrel designed to melt the inner surface of the part, and a sleeve that heats the outer part of the pipe.

Polypropylene pipes are connected by socket welding. For this procedure, a special welding machine is used, which heats the parts to the desired temperature.

The connection process is quite simple. A set of sleeve-mandrel is selected, corresponding to the diameter of the pipes to be connected. Devices are installed on the platform of the device and warmed up. Parts are put on the equipment and heated to the desired temperature. After it is reached, the elements are quickly and accurately removed and connected with a precise movement until they stop. The connection is left motionless until the plastic cools down and completely hardens.

Mounting technology

When installing pipes using collet fittings, it is required to fix the collet into the inside of the structure. The outer nut is screwed on with an adjustable wrench. Thus, an optimal level of tightness of the structure is achieved. The same actions are performed with the second part of the structure.

It should be remembered that these elements exert considerable pressure on the structure. For this reason, if plastic pipes are being installed, the clamping level should be controlled. With excessive use of force, the structure can be severely deformed. For this reason, it is necessary to try to regulate your efforts, avoiding the occurrence of cracks on the product. If you want to learn more about the features of these crimping devices and the specifics of their installation, you can always see photos on this topic.

Advantages

Push-in fittings appeared on the market relatively recently, but they quickly gained the attention of a consumer audience. And this is not surprising, because they are distinguished by a number of important advantages:

- democratic value;

- Ability to find items in each store of the corresponding profile;

- Easy to install;

- Tightness, quality and reliability of connections;

- Durability;

- The possibility of reuse, which allows the use of elements in structures that are planned, after a certain period of time, to be dismantled.

However, push-in fittings also have disadvantages. In particular, this is a gradual weakening of the clamp. For this reason, such connections require regular tightening.

When installing pipes, it is important not to forget about ensuring unhindered access to the connections. It is also important to remember that structures with such connections cannot be laid in walls. This reduces the breadth of their use, but not significantly.

This reduces the breadth of their use, but not significantly.

If you are interested in collet fittings for pipes, on our website you can see their photos, images with ready-made connections.Whether to purchase these connectors or think about other options depends on your specific situation, the specifics of the installation of the system, and your personal preferences. If you are going to install structures yourself, you will be able to appreciate the ease of working with this type of element.

pipe fitting

To ensure uninterrupted water supply to apartment buildings, plastic pipes are often used. They gained popularity due to their long service life, special reliability and safety in operation. In addition, the installation of plastic pipes is quite simple and fast, due to their flexible design.

However, such pipes provide for connecting fastening with each other, as well as with other equipment for the plumbing system. As a result of this, the question will definitely arise: how to choose the most ideal option, so that in addition it serves for a long time and is easy to install? The answer is simple - such an important element will be collet fittings, time-tested and simple connecting devices.

For copper pipes, the use of push-in fittings is quite rare, which is required when a certain flexibility of the material is needed.

water outlet double

Engine power and control system

There are three gradations of milling cutters: low, medium and high power. High drive performance is required for longer cutter lengths. So, for artistic milling and making grooves up to 10 mm deep, low-power milling machines with a power of up to 800 watts are quite enough. In turn, the processing of edges of worktops, the manufacture of quarters and joinery processing of massive parts require the use of tools with a power of over 2 kW.

The power of the router should be chosen carefully: due to the work at high speeds, the gyroscopic effect is clearly manifested, which makes it difficult to hold the tool in your hands. On the other hand, an increase in power is associated with an increase in the dimensions and weight of the tool, which greatly complicates the processing of small parts that require a delicate approach.

Any router should be equipped with a speed controller, preferably an electronic type. The diameter of the cutters can vary widely, therefore, to achieve the correct cutting speed, it is required to set the rotation speed from 10 thousand rpm to 35 thousand rpm. The speed setting range for different milling cutters can vary greatly, this parameter is determined by the type of materials being processed and the size of the cutters that will be used during work. It must be remembered that the scale of the speed controller is marked conditionally, and therefore the user manual must necessarily contain a speed correspondence table.

To work with precious woods or artificial stone, the router must be equipped with so-called constant electronics. This is a small spindle speed control unit that maintains the set speed regardless of the load on the engine and the current mains voltage. Without this option, it is almost guaranteed that there will be inhomogeneity of the milled surfaces.

Conclusions and useful video on the topic

The author talks about the nuances and problems that arise when joining pipes during the installation of sewers:

The author of this video shares a way to solve his problem:

Properly connecting pipes is very important. The joint has always been the weakest point of the pipeline

If it is performed with errors, then, as a result, leaks, blockages, and sometimes pipe ruptures will certainly occur.

Therefore, before proceeding with the independent installation of plumbing communications, you need to study all existing connection methods. If the matter seems complicated, you can always turn to plumbers.

Tell us about your own experience gained during the assembly of plumbing systems. It is possible that you know the nuances of installation and formation of connections that will be useful to site visitors. Please write comments in the block below, post photos with process steps, ask questions.