- Buildings made from plastic bottles

- Greenhouses from plastic bottles

- Pergolas and other auxiliary structures made of bottles

- Beauty is in the details

- Plastic greenhouse

- Recycling plastic bottles as a business with calculations

- Advantages and disadvantages of business

- Collection of raw materials and sale of finished products

- Number 3. bottle garden path

- No. 7. Butterflies from plastic bottles

- Plastic butterflies for decoration

- What you need for self-processing

- bottle buildings

- No. 8. Palm tree from plastic bottles

- insect trap

- How to melt plastic waste at home

- Process description

- What do you need to recycle at home?

- Following Precious Plastic Project

- Simple mechanism for cutting plastic bottles

- Moisture control in the garden

- Recycling PET bottles as a business idea

- Necessary equipment for recycling PET bottles

- Equipment for the manufacture of plastic containers

- Where to take waste PET bottles

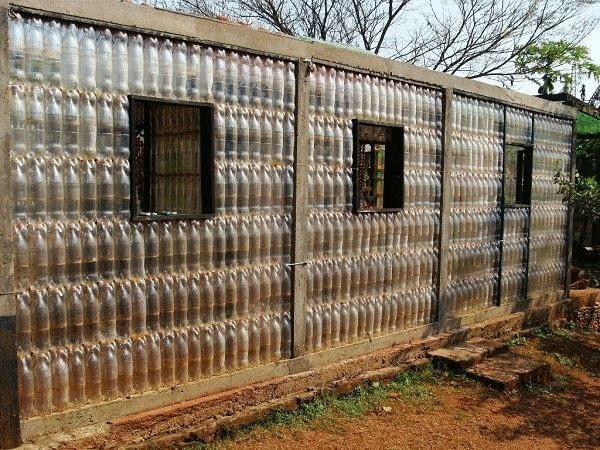

Buildings made from plastic bottles

These are not funnels with pots, but something more serious. Entrepreneurial people can build something out of anything. Plastic bottles, for example, make excellent greenhouses and gazebos.

Greenhouses from plastic bottles

A finished medium-sized greenhouse costs more than 15 thousand rubles. I know for sure, because I was interested in this issue. Add to that the cost of assembly.Not everyone can figure out what's what. But there is an alternative that is not inferior in performance and will cost you ... only 500-700 empty plastic bottles!

The plastic from which the bottles are made is 20 times stronger than dense polyethylene. It keeps the temperature perfectly, does not melt in the sun and can serve for decades. A plastic bottle greenhouse has several advantages:

- she is cheap;

- durable;

- easily repaired;

- light in weight, it can be rearranged if necessary;

- looks pretty cute.

I took a look at different sites and realized that there are 2 main ways to use plastic bottles in construction:

- The bottom of each bottle is cut off. A thin rail is taken and all the bottles are strung on it. Get ready-made building strips.

- The bottom and neck of the bottles are cut off. Then what happened - the middle part - is cut along. It turns out a rectangular piece of plastic. We iron it with an iron (necessarily through hard paper) to level it. From such sheets we sew more sheets. Preferably, over the top. You can use an awl; for fastening parts - cord thread or wire. It is not recommended to sew with thread or fishing line - the seams will quickly rot and disperse.

When the sheets (slats) are ready, you can make a frame. It is made from ordinary wooden bars with a hammer and nails. Form - any. You can - a house, you can - a triangle. And then we attach what we made from bottles to the frame. In the first case, the planks should be placed as close to each other as possible so that the wind does not walk. Well, you can always stick it with tape. In general, you'll figure it out!)) And in the second case, ready-made plates from plastic bottles are simply nailed to a wooden frame.

The important thing is the roof. In general, a good frame can withstand a rather heavy weight, but knowledgeable people advise covering the roof not with bottles, but with polycarbonate sheets. Or something to strengthen for the winter - suddenly it will pile up a lot of snow.

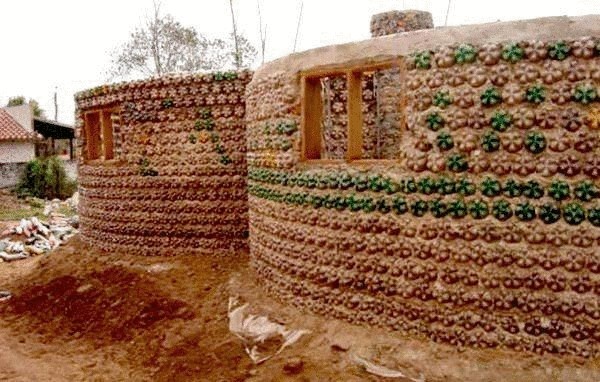

Pergolas and other auxiliary structures made of bottles

I’ll tell you right away that even houses are built from bottles, and what kind! A feast for the eyes! But mostly glass bottles are used - they are stronger all the same. And they do not need to be filled with additional sand.

The technology for building a gazebo from plastic bottles is, in general, simple. The child will understand. We fill the bottles with sand. These will be our "bricks". We mark out the shape of the gazebo, think over the architecture, make a cement mortar, a base and erect walls!

There are, however, subtleties. For example, it is better to lay a reinforcing mesh between the rows of masonry - the structure will be stronger. In addition, until the solution is completely dry, it is better to hold the bottles with something so that they do not spread. Well, we follow the rules that are usual for laying a brick wall. Everything will work out!

Although you can make a lighter gazebo - something like a greenhouse:

In conclusion, I want to say this. Friends, let's, if possible, find some more useful use for garbage than a landfill. To have as few landfills as possible on the planet. And then even the seabed was dirtied.

In the spring I am generally very angry with people. The snow is melting, the first “snowdrops” are opening up to my eyes ... I even wrote to the newspaper, tried to influence my conscience somehow - it’s useless. I think I should print this post and spread it to all my neighbors))).

Of course, there are not all options for using plastic bottles in the country ... You can also make boats ... mugs, chairs ... In general, anything!

Beauty is in the details

Staying in the country should not be limited to working moments

Therefore, it is extremely important to equip its territory in such a way that it looks well-groomed and beautiful. The use of plastic bottles in the country as a material for decorating the house, yard and garden will help equip the territory and turn it into an excellent recreation area

Consider a couple of original ideas.

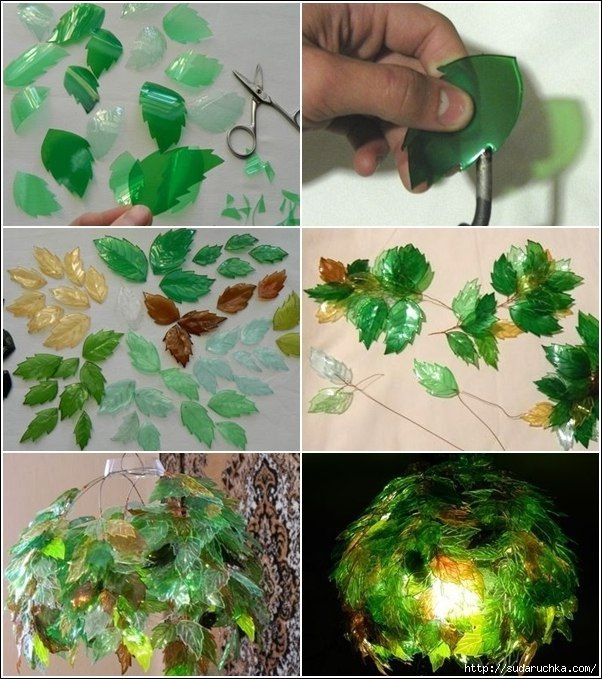

Idea #1: Weightless Pendants

To bring this idea to life, it is necessary to cut off the figured bottom from each small bottle (0.5l) so that flower-shaped molds are obtained. Next, you need to connect all the elements together with a thin fishing line, soldering its ends. The connection style may be different and depend on the desire of the master. If, for example, the pendant will be used as a curtain on door or window opening, then the elements must be connected in long chains. If you use it as decorations for trees in a recreation area, then it is preferable to combine elements into chains of various lengths. Plastic bottles converted in this way into crafts for giving with their own hands they can be of various colors, but they look more gentle if they are made in light colors.

Idea #2: "Rainbow Charm"

From plastic bottles of various sizes, cut the bottom in the same way as in the previous case. Finished elements need to be painted in different colors, depicting the middle, as in live colors. It is also necessary to make leaves for flowers, which can be made from the middle part of the container. Finished decorations should decorate the fence, pillars, walls of the house in a chaotic manner. You can fix the elements with superglue, nails, as well as buttons.

Plastic greenhouse

To make a greenhouse out of plastic, you will need certain skills. Usually only men do it. Such a building will have several advantages, namely:

Free greenhouse

- Price. A medium-sized greenhouse costs about 20 thousand rubles, the use of plastic will save this money;

- Durability;

- Simplicity in carrying out repairs;

- If necessary, the greenhouse can be rearranged, as it will be light;

Cut off the neck and bottom to get a rectangular plastic plate

First you need to prepare the material. It is immediately worth considering that you will need a lot of bottles. Each of them needs to cut off the neck and bottom, so that there are no bends left on the container. Next, the bottle is cut along the entire length. To get a plastic rectangular plate, the material can be ironed, but only through thick paper.

Plastic must be connected using cedar thread or wire

It is better to fasten plastic together with a cedar thread or wire, and make holes with an awl. It is not recommended to use fishing line or threads, as the seams will rot and disperse over time.

To make a frame for a greenhouse, you can use ordinary wooden planks. Its form can also be absolutely any, depending on the idea.

How to make a table for the New Year 2019 really festive and budget? 135+ (Photo) beautiful DIY serving (+ Reviews)

Recycling plastic bottles as a business with calculations

A business based on recycling will always be highly profitable.The use of used plastic bottles for the production of polymer chips, with the proper organization of the marketing process of finished products, can not only quickly return the invested money, but also provide a constant, high income.

Advantages and disadvantages of business

The positive aspects of organizing the processing of plastic bottles include the following: Business is socially significant The process of environmental pollution with various plastics is so great that can count on assistance from the administration of the locality where plastic processing will be organized.

Recycling plastic bottles

The low level of competition in this business is a big advantage for those businessmen who open a plastic bottle recycling business this year.

In addition to the advantages, such a business has disadvantages:

- To open a mini-factory for the processing of plastic bottles, you will need to issue a large number of permits. In our country, this issue of recycling is not fully regulated and therefore only the legal registration of such an enterprise can take about 6 months.

- At first, it is quite difficult to arrange the supply of raw materials for processing. To market finished products, it is also necessary to establish difficult relationships with manufacturers of plastic products.

- Great dependence of plastic bottle recycling on manual labor.For the full functioning of even a small processing plant, it is necessary to hire a sufficient number of workers who need to pay salaries, as well as make payments to the pension fund and the CHI fund.

Despite all the difficulties that may arise at the preparatory stage, a well-established process for the supply and marketing of products, as well as production technology, will make it possible to receive significant dividends from the funds invested in processing in a short time.

The technological process of processing is carried out in the following sequence:

- Collection of used plastic bottles.

- Sorting of raw materials.

- Manual removal of metal paper and rubber from each bottle.

- Pressing raw materials.

- Pressed raw materials are loaded onto a conveyor for processing.

The result of processing will be flex, which is plastic flakes. Flex is used to make bottles or other plastic products. It is necessary to organize the bottle recycling process in such a way that the equipment does not stand idle. In order to ensure the operation of the equipment, a large amount of raw materials will be required. The most suitable places for collecting products are all kinds of landfills. You can open a collection point for plastic bottles from the population. In large cities, containers with the inscription: “for plastic bottles” can be placed in residential areas. Bottle recycling equipment

To equip a small processing plant, you need to purchase:

- Sorting conveyor.

- Vibrating sieve.

- Crusher.

- Centrifuge.

- Cork separator.

- Washing capacity.

- Drying.

This equipment will cost at least 4,000,000 rubles.If you buy equipment in the secondary market, you can save up to 50% of the cost of a new production line.

Collection of raw materials and sale of finished products

For the full functioning of the processing line, a constant supply of raw materials is necessary, therefore, it is necessary to diversify the channels for receiving bottles for processing as much as possible. It can also be direct buying from the population or from catering enterprises. Most of the raw materials can be obtained free of charge if containers for plastic bottles are installed in places where garbage is collected.

The less money spent on the purchase of raw materials, the lower the cost of production and the higher the profitability of the enterprise. Serious problems with the sale of finished products, as a rule, do not arise.

Flex, which is obtained as a result of the processing of bottles, is readily bought up by wholesale parties, manufacturers of various plastic products.

Number 3. bottle garden path

If there are an indecent amount of plastic bottles, then they can be used to decorate garden paths. For this purpose, all the same bottoms are used, which have a noticeable relief, which means that it will be pleasant to walk on them barefoot, but it is inconvenient to carry some loads, therefore, with the help of plastic bottles, it is better to equip secondary paths that are walked only on foot.

The cut bottoms are laid on loose sand, and efforts must be made so that each element is completely filled with sand, which will prevent further deformation. A more durable option is to lay the bottoms on concrete that has not yet hardened, which is very often used to fill garden paths.In this case, we get the decoration of a boring gray concrete path, and to make the summer cottage even more fun and interesting, you can lay out some kind of pattern from the bottoms or bottle caps.

No. 7. Butterflies from plastic bottles

Since plastic is a fairly plastic material, resourceful summer residents came up with the idea of making butterflies, flowers, palm trees, various animals, and even stuffed animals and cartoon characters out of it. About everything in order.

Creating butterflies from plastic bottles is a simple and creative task. You will need not too dense bottles, from which their middle part is cut out and cut lengthwise to make plates: necks and bottoms can be useful for other crafts. In advance, it is necessary to prepare several templates of butterflies, their contours are transferred to plastic with a marker, now it is only necessary to cut out the resulting figure with scissors. Butterfly wings are bent so that they look as natural as possible, the butterfly must be symmetrical. Now it remains only to color the blank, what are they used for acrylic paints or ordinary nail polishes, beads, rhinestones and any other decorations, depending on the idea. When the paint dries, you can glue a mustache made of wire with strung beads. You can hang these butterflies anywhere.

#gallery-5 {

margin: auto;

}

#gallery-5 .gallery-item {

float: left;

margin-top: 10px;

text-align: center;

width: 33%

}

#gallery-5 img {

border: 2px solid #cfcfcf;

}

#gallery-5 .gallery-caption {

margin-left: 0;

}

/* see gallery_shortcode() in wp-includes/media.php */

Plastic butterflies for decoration

Products are used to decorate areas with flowers. To make plastic butterflies, you will need the following:

Butterflies to decorate the site

- Multicolored bottles.

- Candle.

- Kapron thread.

- Wire.

- Beads and beads for jewelry.

- Reliable adhesive.

- Awl and scissors.

- Paints (acrylic).

You can smooth the edges and give the products the necessary shape with the help of fire.

On each, it is necessary to remove the bottom and necks so that a cylinder is obtained. Next, it needs to be cut along the entire length. From the resulting plastic sheet, you can start cutting butterfly wings. Next, a candle is set on fire in order to smooth the edges and give the products the necessary shape with the help of melting.

Decorate flower beds with plastic bottle butterflies

A stiff wire with multi-colored beads put on it can serve as a body for a butterfly. To decorate the wings, acrylic paints and beads are used. When all the parts are ready, they just need to be glued with glue.

Decorate the butterflies using acrylic paints and beads

Gift for the New Year 2020: what interesting things can you give? Sweet, childish, relevant. 90+(Photo) Best Presents

What you need for self-processing

Recycling is a very time-consuming process that requires a special approach. Devices and machines come to the rescue. However, having learned the price of an exclusive device and its dimensions, many begin to wonder if it is worth it. After all, even huge plants with millions in profits have a low percentage of profitability. And here you need a device worth 200 thousand rubles, and sometimes even more than one.

Needlework and fiction help out enthusiasts. The fact is that you can assemble the necessary devices by using improvised materials or by altering home appliances. The main DIY plastic recycling machines:

- Schroeder.

- Agglomerator.

- extruder.

Each of the devices is designed to perform a certain process on the way of packaging to a new life. Some tasks will not require special equipment. Grinding, for example, can be done with ordinary scissors or a tape cutter. Such a tool is made from a knife and washers fixed on a horizontal static object. They cut plastic bottles into a plastic thread.

The shredder is made from a drill and grinder discs, fixed with intermediate washers. Such a device can quickly grind a huge amount of containers in a short time. A small amount of starting material can be cut with ordinary scissors. The product after such processing is called "flex".

Agglomerator - a device for sintering. At home, even an oven can be used for this purpose.

But you should be careful. It is better to abandon such an idea in favor of cheap home-made analogues.

They can be ordered from craftsmen who will quickly produce the desired unit.

An extruder is a kind of chamber, passing through which the mass takes the form of a thread or another shape and is cleaned.

bottle buildings

In order to lay down the wall of the house, plastic bottles are filled with barren earth, clay or sand. Experts say that the humidity of the filler does not play a special role here. The most important thing is to screw the bottle cap very tightly and pick up containers of the same size.

"Environmental bricks" are laid in rows on the cement mortar side by side to each other. The solution is again put on top in a thick enough layer so that all the containers are covered with it. Then again lay out the bottles in a checkerboard pattern.

The necks of the bottles are pulled together with additional synthetic twine, rubber cords or soft wire in such a way that it looks like a plaster mesh. It is possible to completely wall up the "bricks" only after they are tied.

The wall looks very creative when the pattern of the bottoms is cleared of the solution. Thanks to this, you can get an interesting "star pattern". But you can completely plaster the wall by hiding the building material inside.

But construction should not begin from the walls. First, round vertical columns should be built at the corners of the building - they will hold the entire structure. They will also require filled plastic bottles, which are fastened together with cement mortar. They just lay the first circular row on a dug hole, into the center of which they break in and pour reinforcement with concrete. Containers with filler are laid in a concentric circle, a few centimeters away from the pin, with their necks inward, already on a layer of concrete. The necks are tightly pulled together with a soft wire so that they are in contact. All gaps between the "bricks" are filled with mortar and left to "grab" for several hours.

Then lay out the second layer of bottles, already in a checkerboard pattern. The inside of the column can be filled with broken bricks, stones, glass, slag. When the required height is reached, laying out the rows is stopped. The column is plastered from the outside.

Basically, the algorithm for building ordinary brick houses and from plastic bottles is identical: floors are also laid, window and door frames are installed, logs are laid for ceilings and floors. Just replacing the building materials gives huge savings.

And the strength of one-story buildings, built from real rubbish, is in no way inferior to brick houses. And the thermal insulation of such houses is quite high.

By the way, Bolivia has been successfully implementing a program to turn plastic waste into cheap housing for several years.

No. 8. Palm tree from plastic bottles

Bringing a little tropical shade to your summer cottage is very simple. To make a palm tree, you will need plastic bottles of brown and green colors, a little time and effort. There are several options for creating such a plastic palm tree, they differ in the complexity of the work and how the finished result looks like a real palm tree. Let's take a look at one of the best ways.

The first step is to make the future foliage of the palm tree. Green bottles are used, in which the lower part is cut off. The remaining bottle is cut into thin longitudinal strips. In total, at least 7 branches must be made, which can consist of any required number of blanks - the length is adjusted depending on your own preferences. When the required number of bottles is prepared, they are strung on a cable with a diameter of 12-14 mm.

The barrel can be made by cutting off the bottom of the bottles and stringing the remaining parts one on top of the other, but it will look very simple. It is better to do the following. Cut off the very bottoms of brown bottles, leaving the convex parts intact. Then make longitudinal cuts to get the same petals, and string the blanks onto a metal trunk. To fix the leaves on the trunk, it is recommended to weld tubes with a diameter corresponding to that used to create cable branches to the base of the trunk.The whole composition of palm trees on the site will look especially nice.

#gallery-6 {

margin: auto;

}

#gallery-6 .gallery-item {

float: left;

margin-top: 10px;

text-align: center;

width: 33%

}

#gallery-6 img {

border: 2px solid #cfcfcf;

}

#gallery-6 .gallery-caption {

margin-left: 0;

}

/* see gallery_shortcode() in wp-includes/media.php */

insect trap

One of the most creative things you can do with plastic is to trap mosquitoes and other insects. For this, it is better to use a dark container, since in this case pests fall into it much more often.

Cut the bottle open and insert the top inside the container so that the neck is about 5 cm from the bottom

The first thing to do is cut and insert the top inside the container so that the neck is about 5 cm from the bottom. As a bait, you should use sugar-yeast syrup. To prepare it, you need to take yeast, sugar and mix them in hot water.

After the syrup has cooled, it can be poured. The neck should be at least 1 cm above the liquid. This will get rid of not only mosquitoes, but also wasps, flies or bees.

As a bait, you should use sugar-yeast syrup.

The trap should be cleaned at least once a week. To improve the effect, the bait can be hung from a window or ceiling.

DIY decor: 180+ (Photo) Getting ready for the holiday in advance (Ideas for a beautiful and fashionable New Year's miracle)

How to melt plastic waste at home

You can melt plastic waste at home using one of the devices described earlier (press, injector, extruder). However, their creation requires certain skills and time.You can resort to melting plastic using more primitive methods. For example, to obtain a plastic screw lamb, a metal syringe and a solid mold can be constructed.

Process description

Polypropylene (marking "PP") can be used as a raw material. The crushed material is put into the manufactured syringe and compacted with a metal piston. The syringe filled with plastic is placed in a conventional oven for about 30 minutes at a temperature of 220-240°C. Then the molten plastic mass is squeezed out of the syringe into the prepared mold, while for some time it is necessary to hold the material under pressure. After cooling, the finished product can be removed from the mold.

What do you need to recycle at home?

Industrial machines that process plastic are expensive and require large areas. Of course, such units are not suitable for implementing the idea of \u200b\u200brecycling plastic waste at home. In order to get new products from waste plastic in a handicraft way, you will need to independently design several special machines.

Following Precious Plastic Project

To process plastic with your own hands, you will need the following devices (or one of them, depending on the goal):

- Schroeder. Grinds polymer waste to obtain a crumb of a given size, which is then subjected to further processing. The device includes several main components: a grinding part, a loading funnel, a frame and a power source. The most time-consuming stage in the manufacture of the device is the production of a grinding element consisting of a shaft with blades "strung" on it.The loading hopper is made of sheet metal (waste can also be used here, for example, old car parts). The desired size of the resulting plastic fraction is set using a grid installed under the grinding part.

- Compression device (press). The plastic chips loaded into the apparatus are subjected to high pressure and high temperature, the result of the process is to obtain new pressed plastic products of various shapes. The main elements of the device: furnace, frame, press and electronics.

- Injector ("injector"). The principle of operation of this device is that, under the influence of high temperature, the plastic crumb melts to a fluid mass, which is then injected into any form. After the plastic mass cools, new solid objects of small dimensions are obtained.

- extruder. The heated plastic mass is pressed through the channel of the device, as a result of the process, the plastic exits the device in the form of threads. With the help of an extruder, plastic granules can be obtained.

Plastic recycling line from the Precious Plastic project. on the site. There you can also watch video instructions, which clearly and clearly talk about the technologies for creating devices, the necessary materials and the sequence of actions.

The Precious Plastic project is international. Its creator, Dave Hakkens, improved the drawings of polymer recycling devices found on the Internet and, using his knowledge, designed efficient devices that make it easy to obtain new products from plastic waste.The project helps ordinary people to create machines that process plastic, and with their help, benefit not only for themselves, but also for the environment.

We also recommend reading an interesting article about the types of equipment for processing plastics on an industrial scale. The article discusses in detail all the main types of equipment, from crushers and shredders to entire lines for processing plastic into granules. And also disclosed such an important issue as the choice of the necessary equipment to start a business on plastic waste.

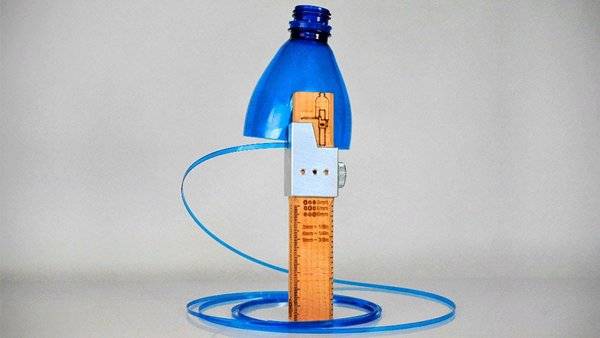

Simple mechanism for cutting plastic bottles

The essence of this cutter is that it cuts off threads of a certain thickness from the edge of a plastic bottle (along its circumference). The result is achieved thanks to a fixed blade sliding on a plastic product. The process does not require electrical energy, the device consists only of a holder and a cutter itself.

From plastic threads obtained with your own hands, you can create various interior items, baskets and other objects for which a person has enough imagination.

Moisture control in the garden

Drip irrigation and dehumidification can be done using plastic bottles.

A plastic bottle and a few dishwashing sponges can easily turn into a great drip irrigation system. You can do it yourself and not spend extra money. The system created according to this life hack is universal, because if necessary, the plant will receive the necessary moisture, and if the soil is waterlogged, then the sponge will absorb excess water.A home-made drip irrigation system allows you to water the beds less often and even leave them unattended in the summer for several days.

Manufacturing begins with the fact that holes are made in a plastic bottle in random order. Inside the bottle is filled with diced sponges. Then you just need to bury the invention in the ground next to the garden crop. In dry weather, water is poured into the bottle, which will gradually go into the soil and feed the roots. If it rains, an empty bottle will help rid the roots of rotting and waterlogging. In order for the system to work, sponges need to be changed from time to time.

Recycling PET bottles as a business idea

How can a PET bottle recycling plant (or mini-factory) be set up if the business plan is well developed. What does it take to build a plastic bottle recycling business? Let's analyze the main points.

First, the entrepreneur must register his organization. A prerequisite for starting an enterprise is obtaining a license. And, of course, you need to coordinate activities with the fire services and SES.

Next, you will need to find a suitable room, it is better that it is located outside the city. It will need to be divided into three zones, in which the storage of raw materials and the finished product, as well as the production itself, will be carried out.

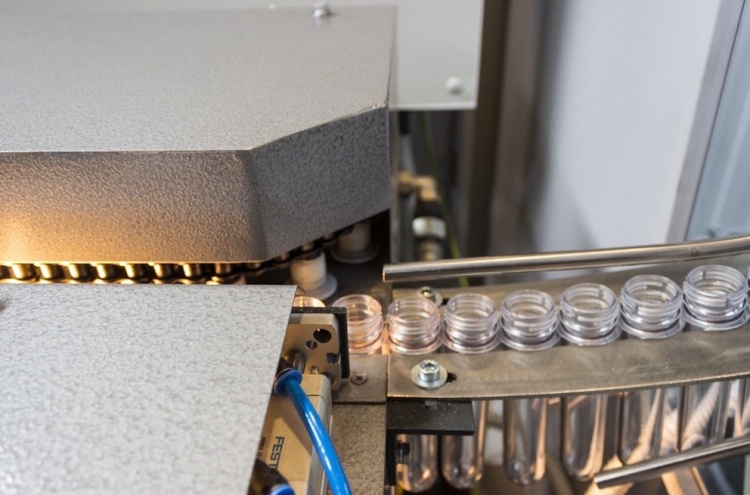

Necessary equipment for recycling PET bottles

After the premises are found, you need to start purchasing equipment for processing. An entrepreneur can choose either Russian or foreign devices for his enterprise.Imported equipment will require significantly higher costs than domestic, but its quality will be better.

A complete PET bottle recycling line includes several main machines, which are connected by means of conveyors. The line consists of:

- crushers;

- agglomerator;

- granulator.

The cost of the devices varies, the equipment of the line, its capacity and degree of automation have a significant impact on the price. The average price for a line for the complete processing of PET containers with good performance from different suppliers is approximately 3 million rubles. It is clear that for many entrepreneurs such a price will be unaffordable, even taking into account possible government subsidies. Therefore, when purchasing equipment, you can resort to some tricks. For example, it can be more profitable to buy individual devices, and then assemble a complete line from them yourself. In addition, you can buy used devices, which also allow you to save a lot.

When opening a business, you can first purchase manufacturing equipment only flex, and after the "promotion" to buy additional devices (agglomerator and granulator) that make up the line for the complete processing of bottles. Equipment required for the production of flex with a cost of approximately 500 thousand rubles. It includes the following main devices:

- crusher;

- baths for washing plastic mass;

- centrifuge.

After purchasing all the necessary equipment, you need to collect raw materials (this was discussed above in the article). Of course, to launch the enterprise, it will be necessary to find employees, the number of which at the initial stage may be relatively small. It will also be necessary to find wholesale buyers of manufactured materials.

If everything was done correctly when opening an enterprise, then this kind of business will quickly pay off and after a short period of time it will already bring good profits.

A clear example of successful business experience is the experience of Western countries in the recycling of plastic bottles. This can be confirmed by the fact that most of the plastic waste in these countries is now being recycled to create new products and materials.

How to open a PET bottle recycling business in our country and what needs to be done to make the business successful is described in the next video.

Equipment for the manufacture of plastic containers

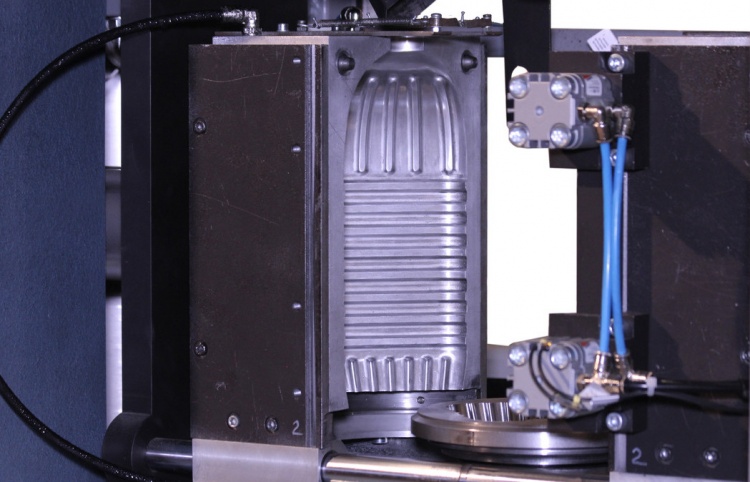

Organization of production is a simple process, the main thing is to buy the necessary equipment. Blowing PET bottles and other containers will require specialized equipment.

Preform production is carried out on injection molding machines using a matrix. The injection molding machine consists of an injection unit, a mold, a drive, a control unit. Injection molding machines are of the following types:

- Angular, horizontal, vertical;

- hydromechanical, electromechanical, electrical;

- piston, worm, worm-piston;

- with one or more plastic areas.

After the injection molding machine, the blanks are sent to the furnace for heating. But not immediately, before that they check the quality of the preform for the subsequent blowing of PET bottles. There must be no defects that affect the finished product. The electronic control system will not miss substandard material.

After the furnace, the finished workpiece in a heated form is sent to the mold. For containers of various volumes and configurations, different matrices are used. For blowing plastic containers not without a compressor. It is he who creates the pressure with which the air stream is supplied.

There are two types of plastic bottle making equipment: semi-automatic and automatic. For the first type, loading / unloading of blanks and containers is performed manually. Therefore, the performance of such systems is low. In automatic equipment, the movement of products between processes is carried out by manipulators and conveyors. They are often used for the production of PET bottles in bottling lines for beer, juices, and other liquid products.

Where to take waste PET bottles

You can hand over the waste of PET bottles to collection points organized by licensed companies that collect and recycle recyclables. Organizations can also install waste bins designed specifically for PET bottles. Such companies either only accept waste for the purpose of selling it to factories as recyclable materials, or they themselves process it. You can also dispose of large batches of plastic waste by directly contacting the company and drawing up a recycling agreement with it.

In some cases, upon acceptance, special requirements for containers may be put forward, for example:

- Bottles must be clean and dry.

- Containers must be free of paint and any debris.

- These should not be vegetable oil bottles.

Containers sorted by color are more expensive.

Different companies offer different amounts of money for raw materials. Thus, one of the Moscow companies purchases PET bottles for 18 thousand rubles. for 1 ton.

Waste management is a rational solution to many environmental problems that exist throughout the world.Recycling plastic bottles is not only beneficial from an environmental point of view, but also financially beneficial. A properly built packaging recycling business will be successful in Russia, since we have almost no competition in this industry.