- How to determine the place where to drill a well?

- Deep well drilling

- sand wells

- Advantages

- Flaws

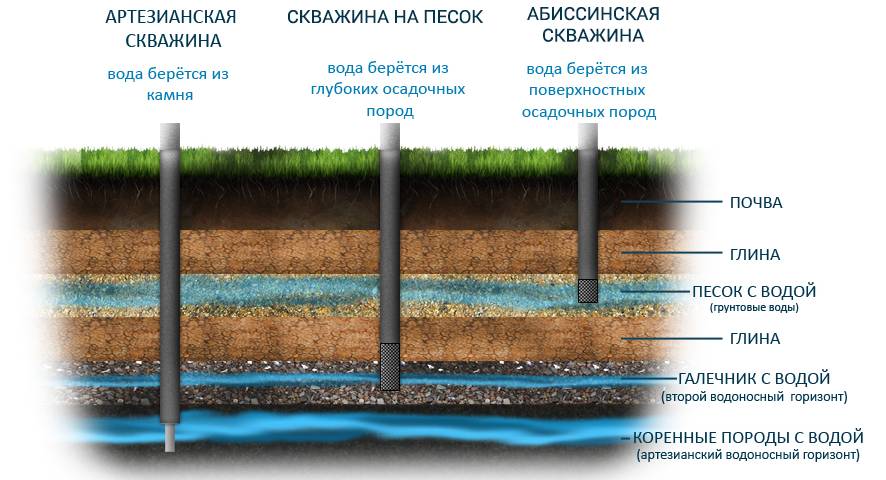

- Horizons and types of wells: accessible and not very

- Horizons have boundaries

- The whole range of wells

- Abyssinian well

- Well on the sand

- Artesian well

- Why is a well better than a well?

- Process steps

- Technological features of the process

- Technology

- Rotary

- Screw

- Other

- Hydro drilling

- What sources underground

- Verkhovodka

- Primer

- Sources between layers

- Artesian

- drilling cost

- Conclusions and useful video on the topic

How to determine the place where to drill a well?

The success of well operation depends on the correct choice of a place for drilling. The right choice is a guarantee that the water will flow constantly and will not run out at the most inopportune moment. This is the correct structure of the soil, which will not collapse under the influence of general pressure, which could lead to the collapse of the well.

All this and much more requires the right approach to choice. Therefore, the following requirements must be observed:

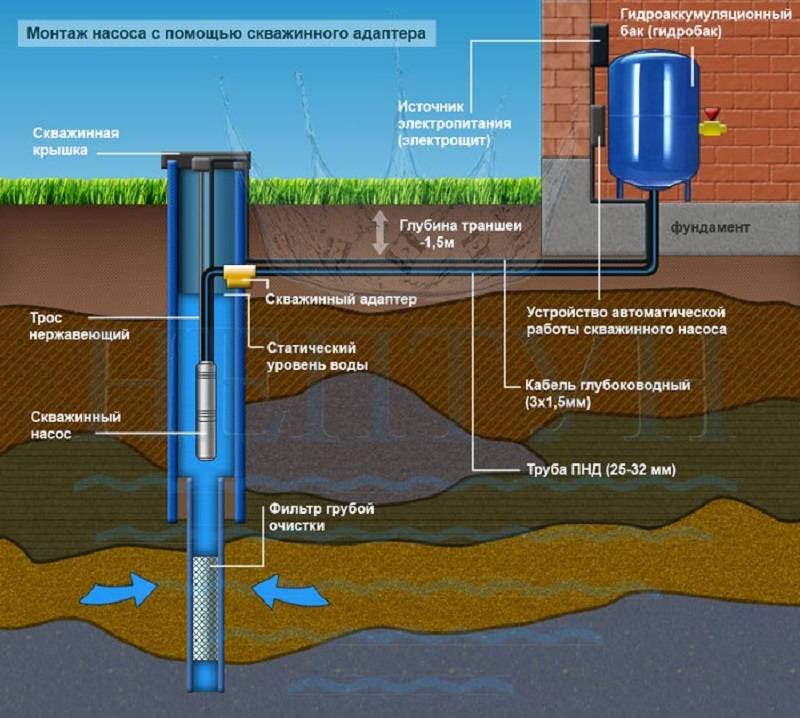

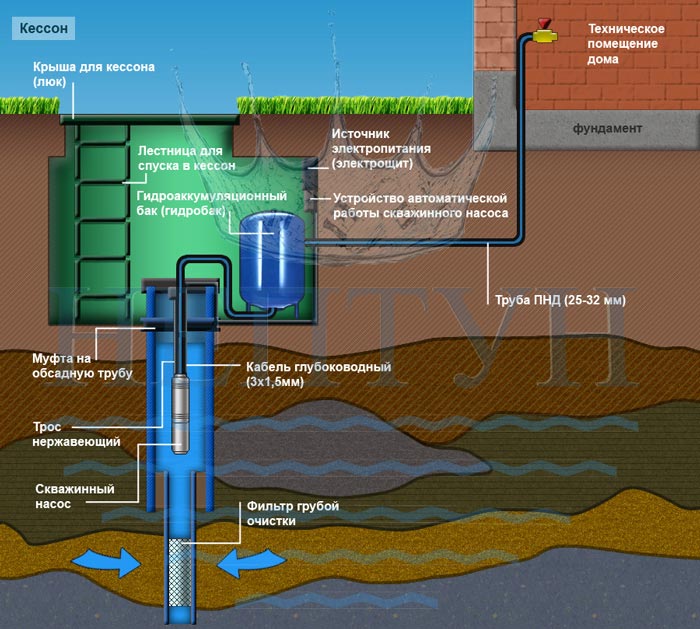

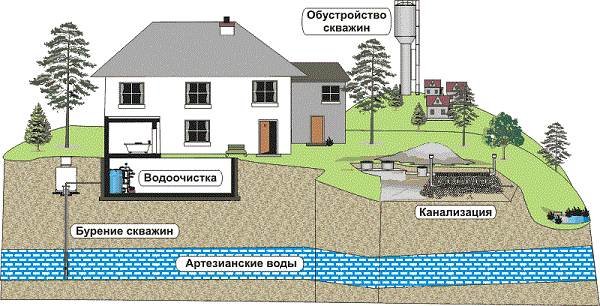

1. Localization of the area. This criterion refers to the general convenience of work, since a rig for drilling water wells must pass into the territory. In particular, this is a truck with a station placed on board.Another vehicle is often used in the work, which supplies water to the auger of the drill. The latter is used to facilitate the workflow and cool the cutting element.

2. Ease of use. Even before you start drilling, you must determine for yourself where the pumping equipment will stand. It can be a pit on the street or a boiler room of a private house or cottage. If there is a pit, then it must be buried by at least 2 meters to prevent freezing. When choosing a place, the convenience of further drying is taken into account, but access to the well is also thought out, especially to the pump, accumulator and other components.

Having determined for yourself the general principles of arrangement, you should proceed to the analysis of the area, in part to study the location of the aquifer. To do this, use the following analysis method:

Determination of a place for drilling

1. Visual inspection. This is the first thing to start with. You can understand where the water lies by the vegetation, in terms of the dense arrangement of trees, shrubs, as well as the saturation of their color and other signs.

It is important to talk to your neighbors as this can help you understand the depth of the aquifer.

It is also important to understand why you are going to extract water. As a rule, shallow water is intended for technical work, for example, for irrigation, for the needs of industry.

For drinking, a limestone well is suitable, the depth of which can be more than 60 meters.

2. Silica gel applications. This method is effective when field development is carried out for the first time, and there is simply no one to talk to, find out the depth of occurrence.Silica gel is a granule that initially has a fixed weight, size, moisture level.

They need to be buried to a depth of 1 meter, for about a day. Recesses need to be made at several proposed drilling points. The more moisture absorbed substances, the closer the water is to the surface. This applies to aquifers that are shallow and not suitable for drinking.

3. Reconnaissance of the area. This is the most efficient method since drilling allows you to get a 100% effective result. By drilling with a small diameter auger, you will not only be able to determine the depth of the drinking layer, but also be able to take water for analysis. The latter will allow you to take it to the laboratory and understand the composition.

Even though the meter of drilling is usually expensive, terrain analysts recommend that the well be placed on high ground. This will be convenient in terms of drainage, since wastewater will not enter the well directly. They, passing through the thickness of the earth, will already be cleansed and harmless to humans.

Deep well drilling

Drilling a deep well, and especially an ultra-deep one, is a complex and expensive undertaking. In world practice, deep wells are drilled with very powerful and expensive rigs with a lifting capacity of 600-800 tons.

So far, only a few pieces of such installations have been made, fewer than the fingers on one hand.

Our project involves drilling a deep well using a conventional drilling rig.

At the same time, the classical scheme is preserved destruction and removal of rock surface of the earth, but new technological methods are being applied, some new tools and, most importantly, a new approach to the problem of deep drilling.

The most important element in the complex of equipment is mud pumps, which force the drilling (clay) mud under high pressure to circulate down the drill pipes, and then up through the annular gap between the pipe string and the walls of the well.

The energy of the pumps is converted into the useful work of the turbodrill, which rotates the bit at the bottom, and ensures the rise of the drilled rock to the surface of the earth.

The solution leaving the Kola superdeep well is cleaned of rock pieces and re-injected into the drill pipes. The circulation goes on a closed cycle.

If you find yourself on the rig during the rise of the drill string, you will see vertical rows of “candles” inside the derrick – separate pipes into which the string is divided. Usually the column is made up of "candles" 36 meters high. Their diameter is about 15 centimeters.

The bit is worn out - they raise the entire string, screw on a new one and lower the “candles” into the well in the reverse order. When drilling deep wells, the bit makes several hundreds of such trips, and when driving ultra-deep wells - more than a thousand!

At the same time, it is necessary to maintain the verticality of the wellbore within certain tolerances, to fix the exposed rocks in a timely manner with casing pipes, to take rock samples from the bottom - cores, to carry out a complex of downhole geophysical surveys, and many other works.

A deep well drilling rig is, in fact, a large modern plant. The whole complex of equipment is intended to drill a narrow cylindrical passage several kilometers long in the earth's crust. This is just an injection into the bowels of the Earth. But how hard is it to do...

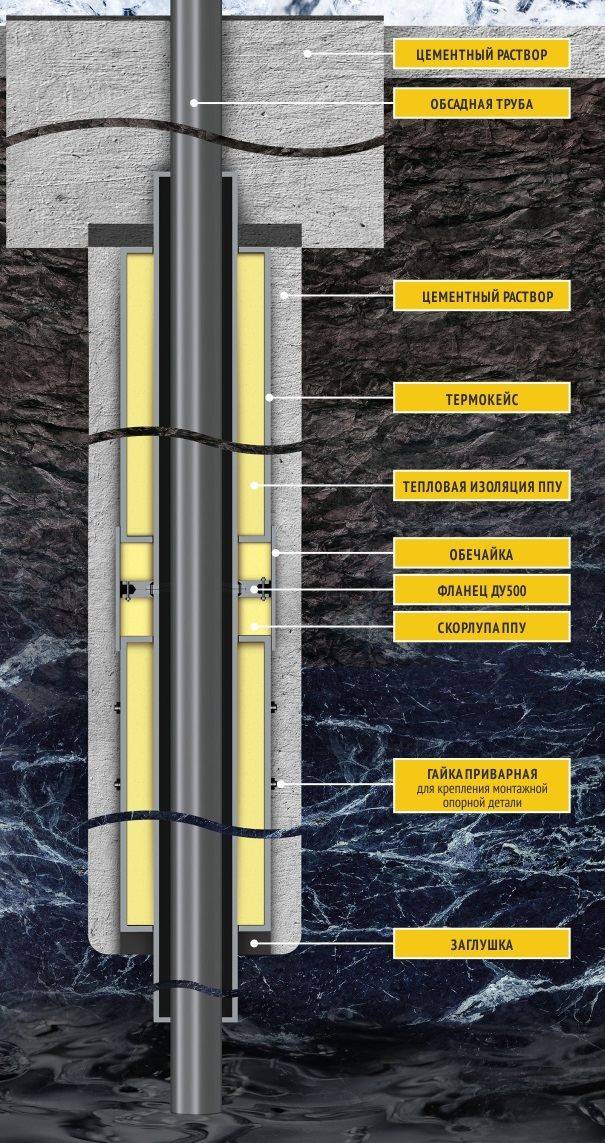

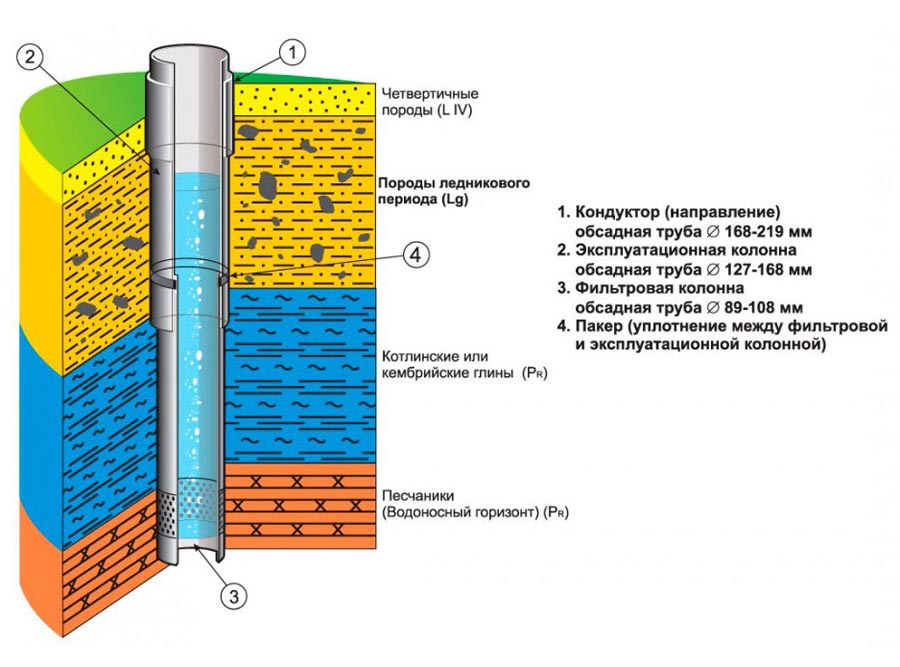

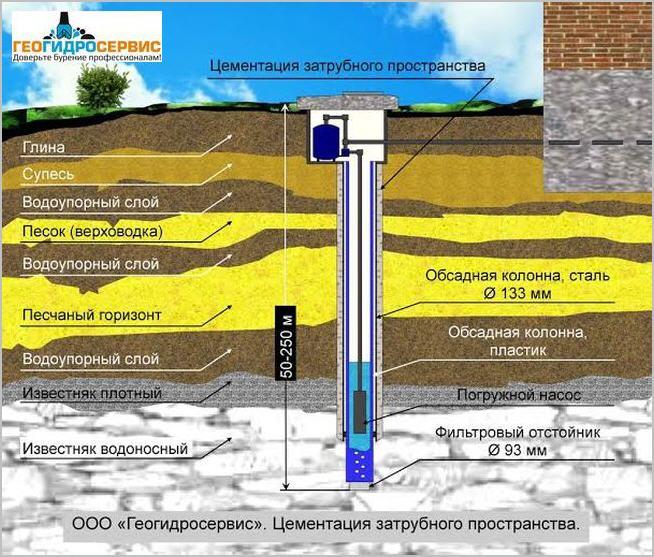

Usually a deep well is started with a large diameter bit.Drilling is carried out until any complications appear in the well (inflow of water, oil and gas, drilling mud drifts, wall collapses), making it impossible to further deepen the well.

Then special pipes are lowered into the shaft, and the space between the pipes and the walls of the well is filled with cement mortar.

Now the well is armored, and drilling can be continued (with bits of a slightly smaller diameter) until any new complications block the path of the bit.

Then another string of pipes is lowered into the well and cemented, with a smaller diameter than the first one. Such pipes are lowered into the well as many as there are zones of complications.

Each deep hole is like an underground telescope, pointing away from the stars. By the number of steps (pipes) in this telescope, the degree of complexity and high cost of drilling is judged.

It is very difficult to determine in advance the required number of telescope links and the ratio of their sizes. It is practically impossible to predict at what depth a complication will occur that will require the casing string, the next link of the telescope, to be lowered into the well.

The subsoil is very variable: literally adjacent wells can differ from each other in terms of drilling conditions. Either suddenly you will encounter a pressure aquifer, from which you should protect yourself with casing pipes, then you will come across a layer of fractured rocks, and the drilling fluid will begin to flow along them instead of carrying the destroyed rock upwards, then suddenly the walls of the well will begin to collapse, then caverns will form ...

It is impossible to foresee all the difficulties on the future underground route.Going on a trip, astronauts probably know more about their routes than drillers attacking the earth's bowels ...

After all, it is no coincidence that scientists in the laboratories of many countries are currently studying core material delivered from the Moon by Soviet and American aircraft, but not a single laboratory in the world has yet samples of terrestrial rocks extracted from a depth of at least 10 kilometers!

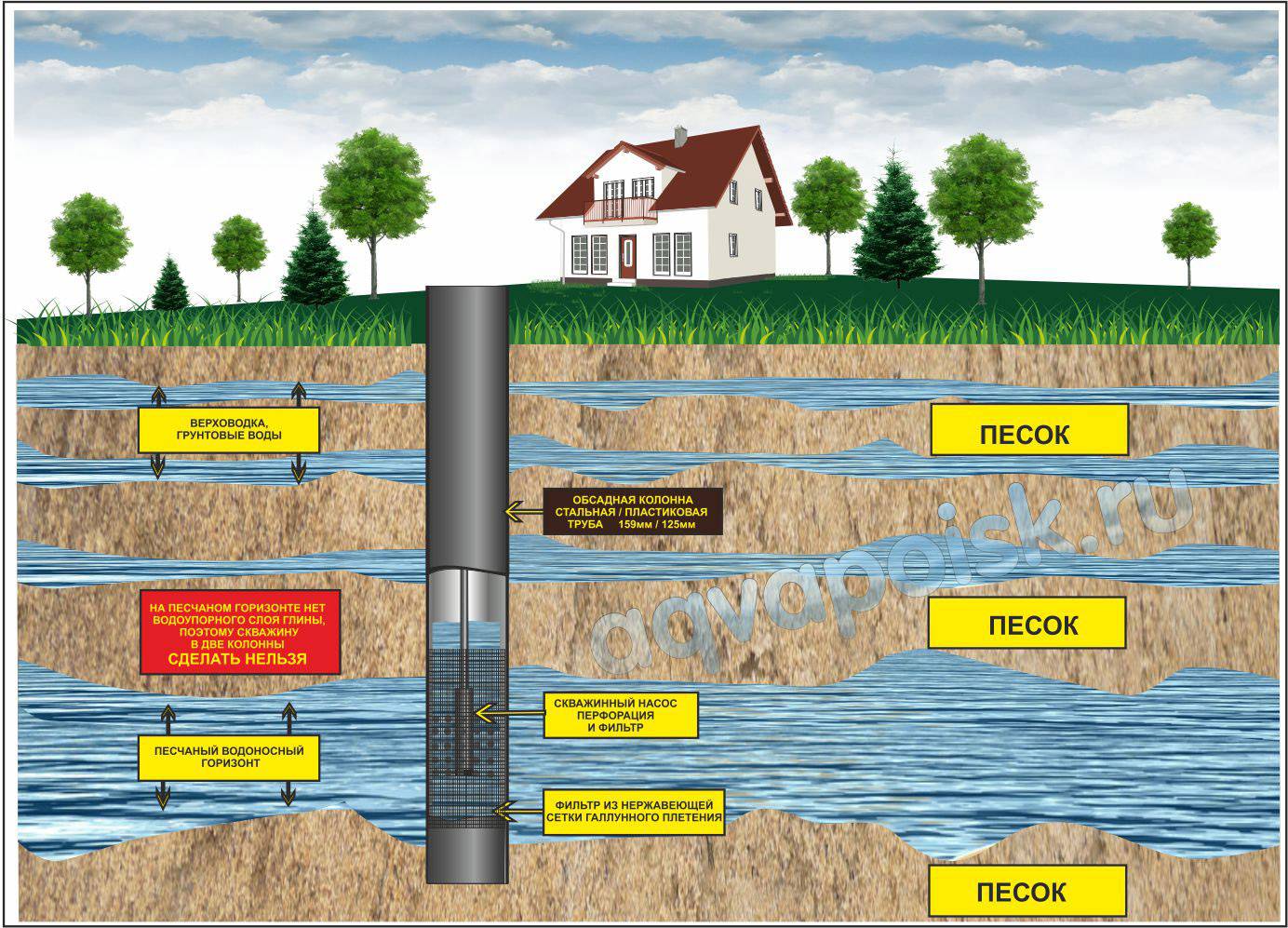

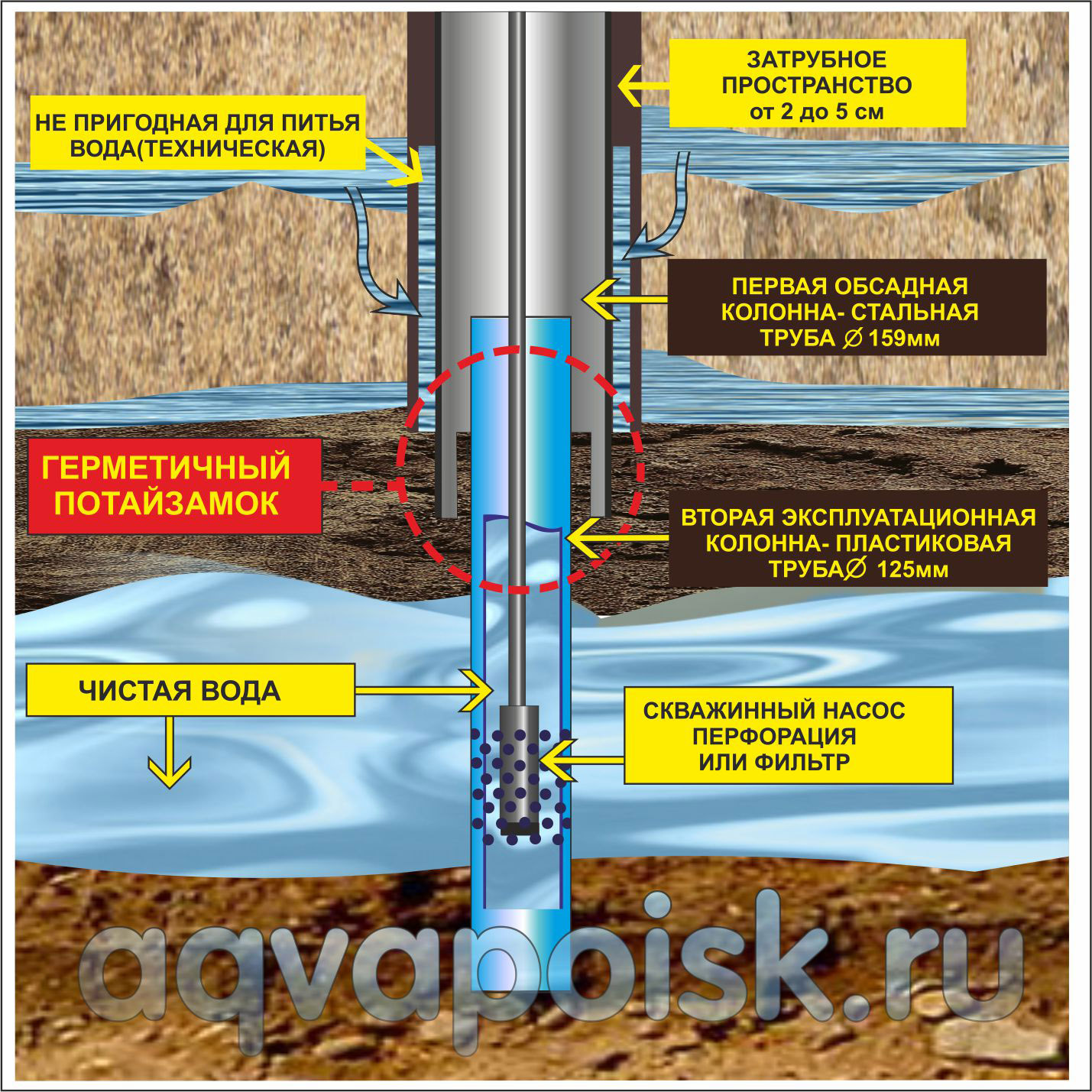

sand wells

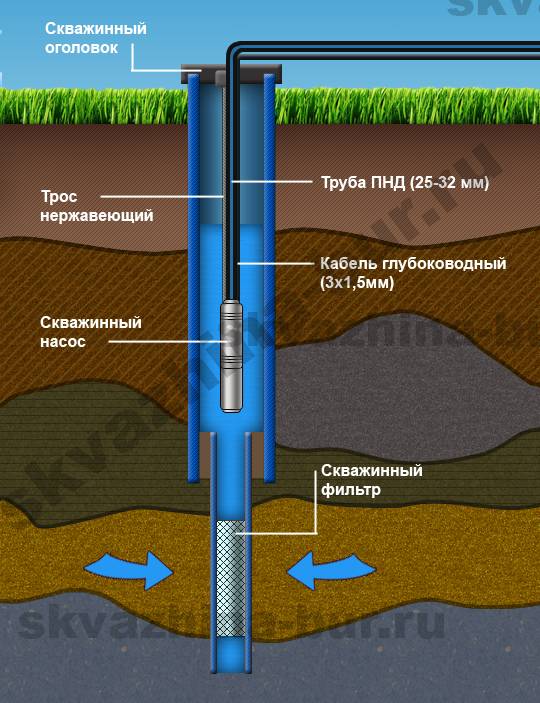

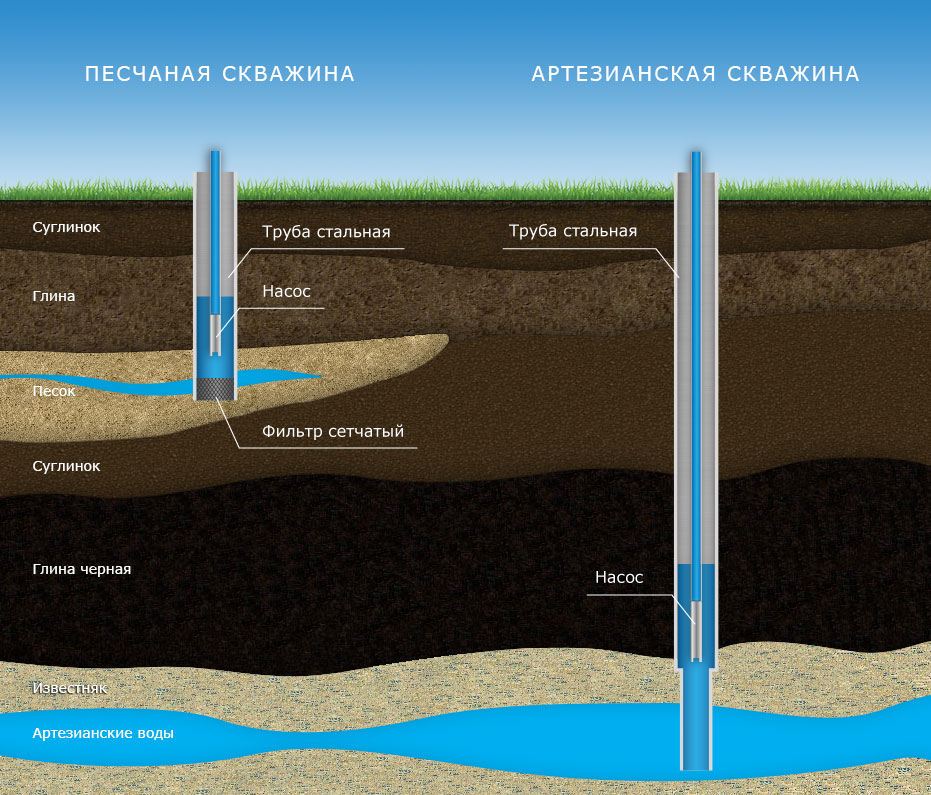

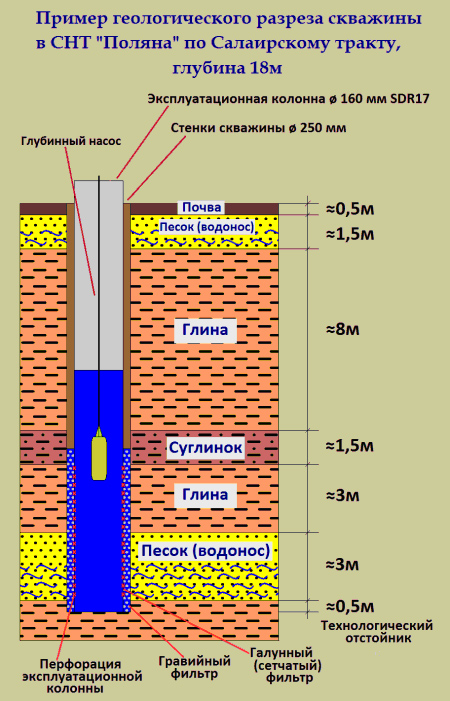

Such a source is simple in its design and does not require a long time for installation. The wells are focused on the extraction of water in loose interstratal aquifers. As a rule, it is sand, gravel, gravel. The discovered deposit is used for autonomous water supply of a country house.

Depending on the depth of the horizon, sand wells are divided into two types:

- On fine sand - up to 40 meters.

- On deep sand (sandstone) - from 40 to 90 meters.

By their design, wells, equipped on sandy horizons, are a trunk in which there is a steel or plastic casing pipe with a diameter of more than 10 cm. The lower pipe is perforated for moisture seepage, and the bottom is equipped with a filter mesh. The rock is driven by an auger drilling rig. The rise of water is carried out by means of a submersible pump.

Advantages

- Sufficient depth to obtain clean water, compared to the sources listed above.

- Deep sand wells have a stable volume.

- The chemical composition of water in sandstones fits into sanitary standards.

- High productivity from 1 to 2 m3/h.

- No permits are required to open an aquifer.

- The drilling time with the installation of the casing pipe takes no more than 2 days.

- The service life of such water wells is up to 30 years.

Flaws

- The volume of water in wells for fine sand is more dependent on the level of precipitation.

- The chemical composition of water from shallow sources is not constant and is sensitive to anthropogenic and technogenic factors.

- The presence of fine-grained sand contributes to siltation of the well.

Horizons and types of wells: accessible and not very

Before you start preparing for such a large-scale work, you need to find out where to drill, but without conducting geological exploration, you will not be able to find the exact answer.

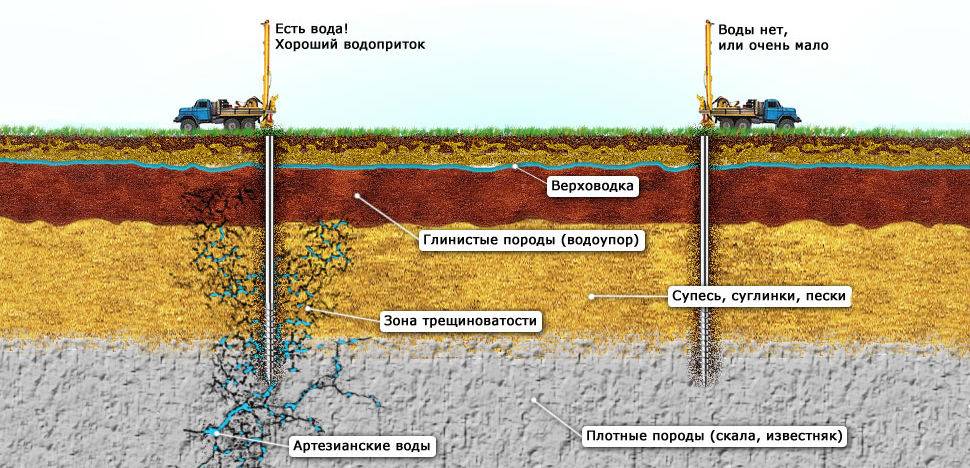

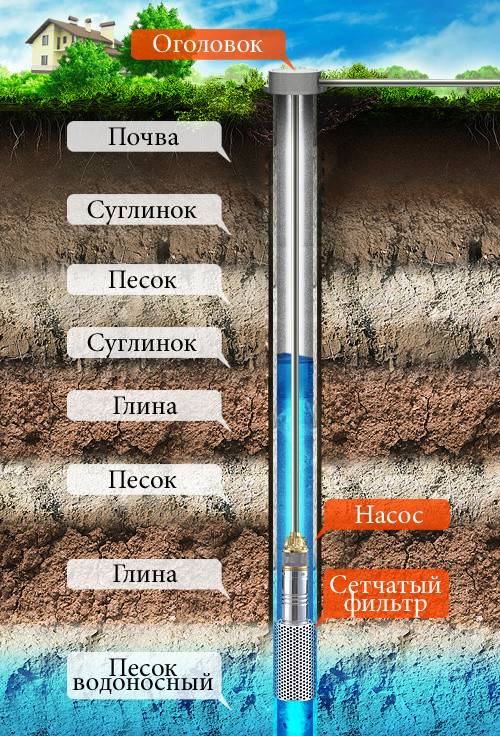

Horizons have boundaries

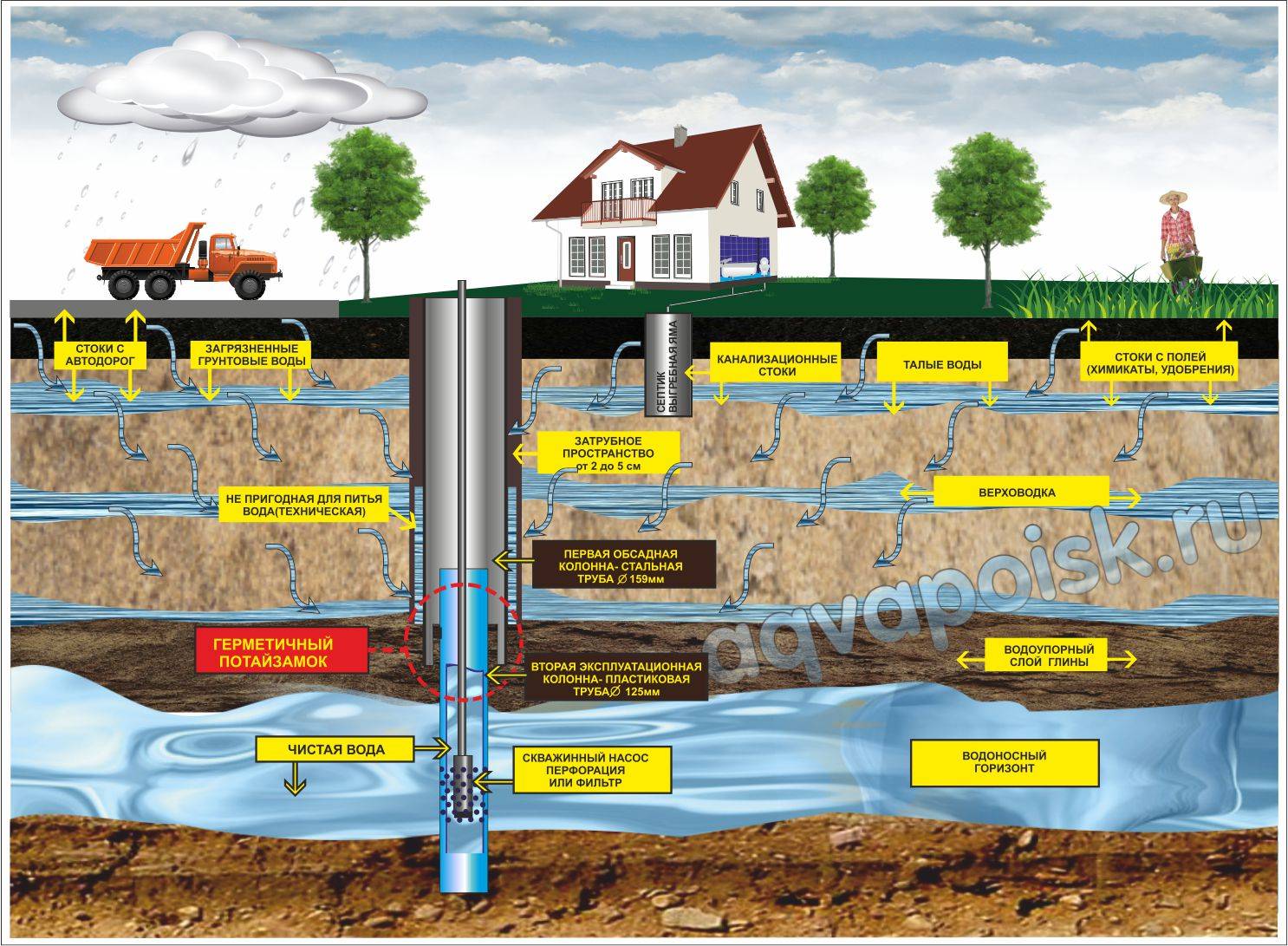

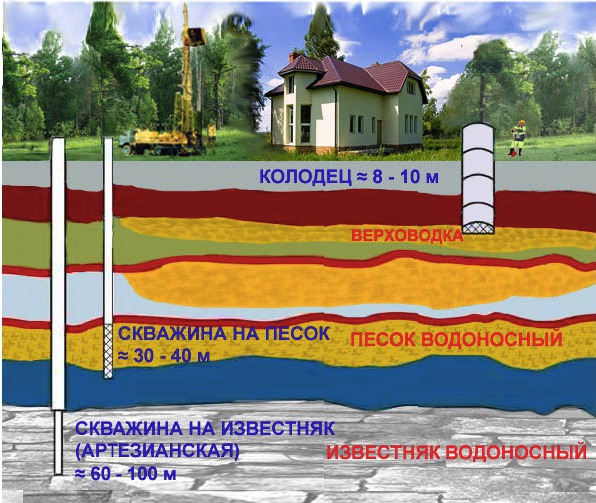

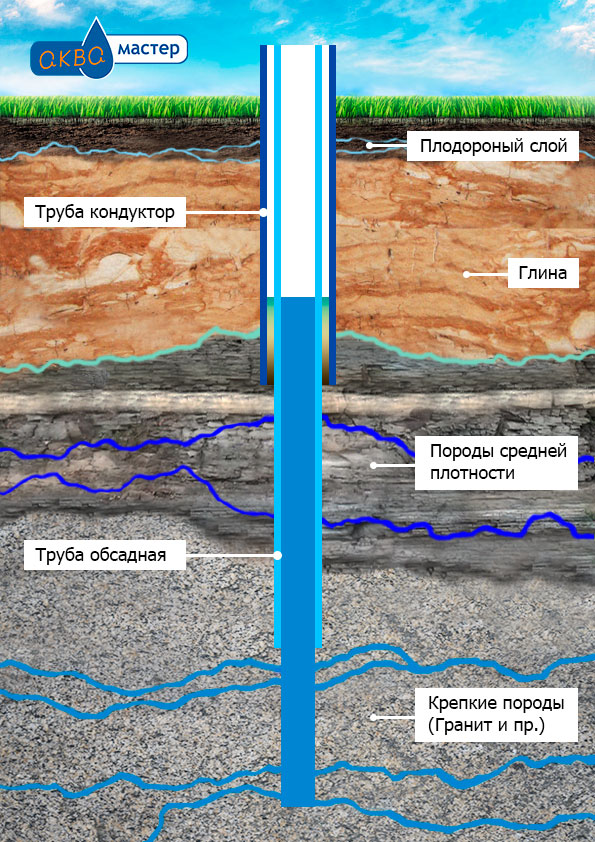

Water is located on different horizons, these sources do not communicate with each other. This is provided by layers of impermeable rocks - clay, limestone, dense loam.

- The shallowest source is perched water, which is provided by precipitation and reservoirs. It can start at a depth of 0.4 m and end at 20 m from the surface. This is the dirtiest type of water, it always has a lot of harmful impurities.

- Having drilled a well up to 30 m deep, you can “stumble” on cleaner groundwater, which is also fed by precipitation. The upper boundary of this horizon can be located at a distance of 5 to 8 m from the surface. This liquid is also recommended to be filtered.

- The underground water source, located in the sandy layer, is already filtered with high quality, therefore it is optimal for water supply. It is this horizon that must be reached by those who want to drill their own well.

- Depth from 80 to 100 m is an unattainable ideal with crystal clear water. Artisanal drilling methods do not allow you to get so deep.

Since the occurrence of horizons is influenced by relief and other factors, the boundaries of perched water and groundwater are conditional.

The whole range of wells

Drilling water wells manually depends on the type of future well. The types of structures cannot be called numerous, because there are only three of them:

- Abyssinian;

- on the sand;

- artesian.

Abyssinian well

This option is optimal when the water in the area is 10-15 m away from the surface. It does not require a lot of free space. Another advantage is the relative simplicity of work, which allows even a beginner who is just learning the science of drilling to cope with the task. This is a well-needle, which is a column constructed from thick-walled pipes. A special filter is arranged at the bottom of it, drilling holes at the end of the pipe. The Abyssinian well does not require drilling as such, since the chisel is simply hammered into the ground. But the most common way to make such a well is still called impact drilling.

Well on the sand

If the aquifer lies at a depth of 30 to 40 m, then it is possible to build a sand well, with the help of which water is extracted from sands saturated with water. Even a 50-meter distance from the surface does not guarantee the purity of drinking water, so it must be given for laboratory analysis. Since in this case there will be no insurmountable obstacles on the way - hard rocks (semi-rocky, rocky), manual drilling of water wells does not imply any special difficulties.

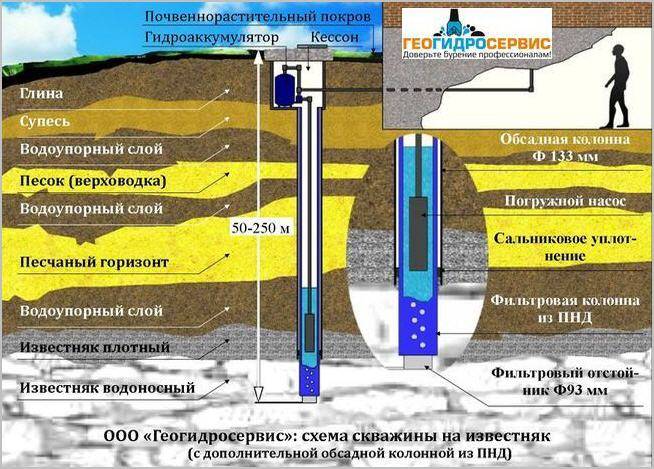

Artesian well

This aquifer can be located at a depth of 40 to 200 m, and water has to be extracted from cracks in rocks and semi-rocks, so it is inaccessible to mere mortals. Without knowledge and serious equipment for drilling, the task of building a well for limestone is an impossible mission.However, it can serve several sites at once, so drilling services ordered together promise significant savings.

Why is a well better than a well?

Previously, issues were resolved in only one way - a well was dug, water was carried into the house in buckets. Later, they began to use the simplest submersible pumps, they descended into wells and pumped water into large containers, and from them it was fed into the house by gravity. But this technology has many disadvantages.

The well has significant advantages over the well

- In winter, the containers had to be insulated very efficiently, and even such measures did not guarantee the safety of water.

- Slight pressure did not allow the use of washing machines and other household appliances that use pressurized water.

- The well contains water from shallow layers. It does not meet the existing requirements of SanPiN in many respects. Especially today, when the ecological situation has deteriorated significantly.

- During floods, heavy snowmelt, heavy rains, dirty water from the surface of the earth fell into the well, which made it impossible to use it for a long period of time not only for cooking, but also for domestic needs. I had to completely pump out the water several times and disinfect it.

- Dirt gets into the well, it silts up, it has to be cleaned periodically. This is physically very difficult work, only professionals can do it.

The main disadvantages of the well are due to its shallow depth.

Today there is a great way to solve all problems - to drill a well, and the greater its depth, the better the quality of the water.

It is interesting: Water meter - what the device is recommended for installation

Process steps

The technology is implemented in the following sequence:

- The surface is cleaned of debris and foreign objects.

- Not far from the future hole, they dig a hole two meters deep to drain the flushing fluid.

- A hole is punched in the ground to accommodate the drill, the crown is connected to the core pipe, it grows as it is driven.

- After with drill pipes - the top one is fixed in a drilling rig powered by an engine - in this way the sinking begins.

- When the pipe is completely filled, it is raised to the surface, extracting rock from it with a hammer, the blows are not applied too hard.

- The drill is again immersed in the well and drilled until the required depth is reached.

Drilling takes place with flushing, but if there is not enough water for this, the workflow is carried out dry. If specialists use diamond tools in their work, they use a special emulsion for regular washing.

In the case of sandy soil, add liquid glass to the solution, clay mass, strengthening the walls of the hole.

For soils with an unstable structure, the well, in the process of deepening, is reinforced with casing pipes. Often, instead of flushing with water, a cheaper blow with compressed air is used.

Technological features of the process

During the deepening process, it is possible speed control borax. It should be noted that the drill easily overcomes layers of sedimentary rocks at low speeds.But when passing through bedrock, an increase in the rotational speed is required. With the core drilling method, it is possible to pass layers of various composition and any hardness.

It is necessary to take into account the fact that the drilling rig must be located on a prepared leveled horizontal area. The penetration angle can be adjusted if the diameter of the developed hole does not exceed 1 meter. Then the verticality of the working is supported by the casing string.

Casing pipes can be reused if they are removed from the mine immediately after drilling. The core barrel is a reusable projectile, which cannot be said about crowns. For drilling in the sedimentary horizon, they require at least two, or even more. When constructing a well on limestone, it is impossible to predict the number of worn crowns with accuracy.

To prolong the service life of a diamond core after its installation or replacement, the bottom of the well must be processed with a chisel. This measure will significantly increase the penetration rate.

The drilling rig can be mounted on vehicles with a high carrying capacity or on caterpillar special equipment in case of work in difficult terrain. Lighter mobile equipment can be used for core drilling of water wells.

Technology

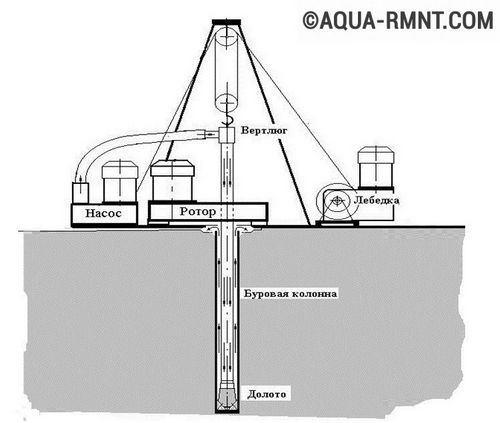

Rotary

The most common drilling method is the rotary method. It is widely applicable in areas with hard soils, namely with loamy or gravel soil types.

When working, a drill bit is used, which is a continuation of the drilling projectile. The projectile is attached to the rotor, with the help of which it starts rotation. The rotor itself moves due to the rotation of the drive shaft, powered by an electric motor.Further, the movement of the rotor is transformed into the movement of the drill, and the drill string gradually deepens vertically to the required depth.

To remove the destroyed rocks, a washing method is used, in which a clay solution is used. The prepared solution is fed into the well and takes out excess soil from the bottom, then the spent solution enters the receiving tank, from which it is then sent for further flushing of the well. The slurry also plays the role of a rig cooler. When drilling wells in a rotary way, casing strings are installed in a new well to prevent soil shedding and subsidence.

The drills used for well drilling and rock removal are somewhat different. Depending on the hardness of the soil layers, a spiral drill is chosen - for loamy layers and gravel, and for loose, for example, sandy, a drill spoon is suitable, which is a kind of cylinder with special holes.

Rotary drilling is best suited for dacha work, the single flush drilling method is usually used and this is usually sufficient. Pumping out the solution from the annulus makes it possible to better open the aquifer, but this technology is more expensive in terms of its equipment and is rarely used.

Screw

Auger drilling is suitable for rocky soils, heavy and not loose. This type of drilling allows you to lay a well of any desired width. Depending on the hardness of the soil layers and the desired depth of the well, more or less powerful equipment is used.

If necessary, the drilling rig is located on a special powerful platform.Drilling with an auger in shallow wells does not involve the participation of special equipment.

The auger screw, or "Archimedes" screw, consists of a drill with a cutter and blades accompanying it along the entire length, from the rotation of which the rock is crushed, and the blades feed the waste soil upward.

Other

The use of heavy special equipment makes it possible to achieve high quality of the produced water, as a rule, these are impact methods of water extraction, the equipment is equipped with special nozzles made of hard alloys.

To lay a well in rocks to a great depth, it can be wells up to 1000 meters, the method of drilling using diamond cores is used. At the end of the drill, which works like a chisel, there is a hardened ring-shaped nozzle. The rock is broken not into crumbs, but into pieces in the form of rings, and so it goes up. Core drilling is a relatively inexpensive method, but it all depends on the hardness of the rock.

The hydrodrilling method allows to achieve good results, but well preparation plays a leading role and is very laborious. The depth of wells can reach 120 meters. Such a well will be able to work for many years as an autonomous water supply system. During hydraulic drilling, it is necessary to dig special pits to accommodate the drilling fluid, these are pits the size of a cubic meter. Further, a specially prepared solution of clay and water is supplied from them under pressure.

This liquid cools the drilling tool, polishes the walls of the future well and strengthens them, brings the soil to the surface. At the end of the work, the well is washed with water and the necessary pump is installed.A hydrodrilling rig requires a current converter, a winch for moving pipes, a gasoline motor pump for pumping the solution, a drill can be used with a flap or exploration.

Hydro drilling

It is carried out by a powerful jet of water from a special drilling tool. The advantage of the technology is that it is possible to drill wells in rocky soil.

The jet load is provided by the weight of the rod and drilling equipment. A special solution is poured into the installation, which is then sent to the prepared pit.

Do-it-yourself hydro-drilling sequence:

- First of all, a small-sized structure or MDR for hydraulic drilling is installed.

- It is best to start work in the morning.

- If drilling takes place in sandy soil, then a large supply of fluid is needed.

- Before work, the clay is mixed into a solution in a prepared pit. The kneading is carried out by means of a construction mixer. The consistency should resemble kefir.

- Further, the solution is supplied through the hoses to the working drill.

- Gradually, the liquid polishes the walls and deepens into the soil. The solution is used in a circle.

This technology contributes to the additional strengthening of the walls of the resulting source.

What sources underground

Geological sections for land plots are not the same, but there are patterns in aquifers. With a deepening from the surface into the subsoil, underground water becomes cleaner. Water intake from the upper levels is cheaper, it is used by owners of private housing.

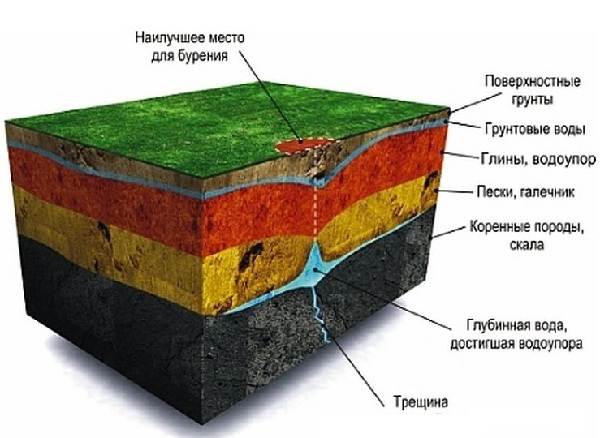

Verkhovodka

A water resource located in the ground near the surface above a water-resistant layer of rocks is called a perch.Waterproof soils are not available in all areas; it is not always possible to find a suitable site for organizing a shallow water intake. There is no filtration layer above such lenses, harmful substances, organic and mechanical impurities penetrate the soil with rain and snow and mix with the underground reservoir.

Verkhovodka is characterized by such indicators:

- Depth. On average 3-9 m depending on the region. For the middle lane - up to 25 m.

- The reservoir area is limited. Manifestations are not found in every locality.

- Replenishment of reserves is carried out due to precipitation. There is no water inflow from the underlying horizons. During dry periods, the water level in wells and boreholes drops.

- Use - for technical needs. If there are no harmful chemical contaminants in the composition, the water is improved to drinking water by the filtration system.

Verkhovodka is well suited for watering the garden. When drilling shallow wells, you can save money: sinking is available for self-execution. Option - the device of the well with the strengthening of its walls with concrete rings. It is not recommended to take water from the upper deposits, if fertilizers are used near the land plot, an industrial zone is located.

Primer

Verkhovodka is a disappearing resource, unlike the primer, which is the first permanent underground reservoir. The extraction of perched water from the bowels is carried out mainly by means of wells; wells are drilled to take the primer. These types of groundwater have similar characteristics in terms of depth −

Ground features include:

- The filter layer of rocks.Its thickness is 7-20 m, it extends directly to the layer located on the impervious platform of the rocky ground.

- Application as drinking water. Unlike top water, for which a multi-stage cleaning system is used, the removal of mechanical impurities from the primer is done by a downhole filter.

Groundwater recharge is stable in forested and temperate regions. In dry areas, moisture can disappear in summer.

Sources between layers

Groundwater scheme.

The name of the second permanent source of water is the interstratal aquifer. Sand wells are drilled at this level.

Signs of lenses interspersed with rocks:

- pressure water, because it takes on the pressure of the surrounding rocks;

- there are several productive water carriers, they are dispersed in depth in loose soils from the upper waterproof layer to the lower underlying cushion;

- Stocks of individual lenses are limited.

The quality of water in such deposits is better than in the upper levels. The depth of distribution is from 25 to 80 m. From some layers, springs make their way to the earth's surface. Groundwater exposed at great depth due to the stressed state of the liquid rises along the wellbore to its usual proximity to the surface. This allows for water intake by a centrifugal pump installed at the mouth of the mine.

The interstratal variety of groundwater is popular in the arrangement of water intakes for country houses. The flow rate of a sand well is 0.8-1.2 m³/hour.

Artesian

Other features of artesian horizons are:

- High water yield - 3-10 m³ / hour. This amount is enough to provide several country houses.

- Purity of water: penetrating into the bowels through multi-meter layers of soil, it is completely freed from mechanical and harmful organic impurities. The enclosing rocks determined the second name of water intake workings - wells for limestone. The statement refers to porous varieties of stone.

On an industrial scale, the extraction of artesian moisture is carried out for commercial purposes - for the sale of drinking water. In areas located in lowlands, it is possible to find a pressure deposit at a depth of 20 m.

drilling cost

Regardless of the type of drilling chosen, the cost will be calculated by workers based on one linear meter of soil that has to go to the desired source. You also need to consider other factors:

- A set of sleeves and the material from which they are made;

- Bore hole diameter;

- Sleeve wall thickness.

At the same time, the customer himself will not be able to choose a cheaper option, since the parameters of the diameter and thickness of the sleeves are selected solely based on the type of soil on the site, and also depend on the depth of the well. Otherwise, if you save on materials, then such a well can collapse quickly enough.

Each person must independently choose the drilling method and the complete set of finished wells, based solely on personal preferences and the type of soil in their area.

Here you can order the calculation and drilling of wells for water. Without subcontractors, on our own equipment.

Conclusions and useful video on the topic

Video 1. The initial stage of drilling a well using a core method:

Video 2. Core drilling of a well in granite rock:

The start of work on core drilling of a well should be preceded by an economic calculation.Compliance with safety standards and equipment operation rules minimizes the risk of equipment failure, thereby ensuring high work efficiency, drilling speed and reducing economic costs.

Do you want to share the intricacies of column technology known only to you? Do you have useful information on the topic of the article? Please write comments in the block form below, ask questions and publish photos on the topic of the article.