- Arrangement options

- The use of the caisson

- Adapter operation

- Head application

- How deep does an artesian well start?

- How to make a well in the country

- well drilling

- Types of wells and their features

- Abyssinian type well

- Features of sand wells

- Deep artesian well

- How to punch punch

- water wells

- Flaws

- Specific types of water wells

- Manual methods of drilling aquifers

- The highlights of the Abyssinian way

- Features of the shock-rope method

- Features of the manual rotary method

- Drilling a well with an ice drill

- Selecting a well for a site

- Exploration drilling and water analysis

- Methods for self-drilling

- Shock rope

- Auger

- Rotary

- Puncture

Arrangement options

At the moment, the following 3 methods of arranging wells are widespread - with a caisson, an adapter or a cap. The choice in favor of one or another option is carried out after drilling a well and studying the wishes of the customer.

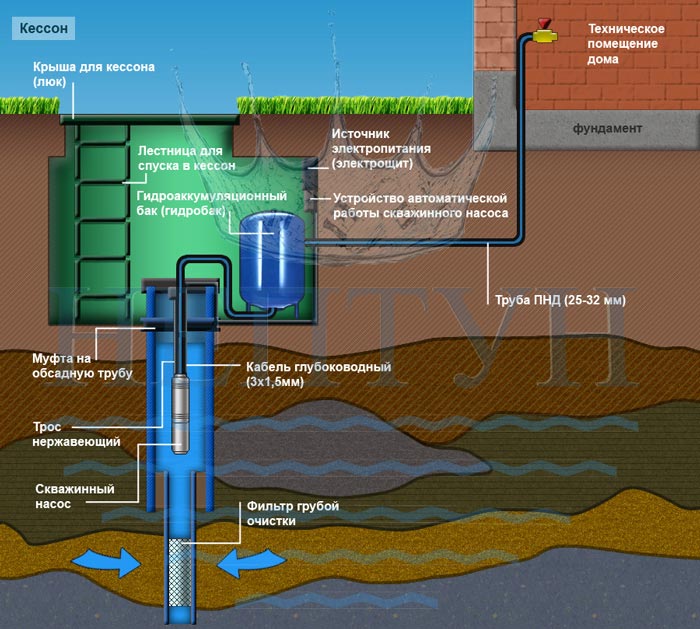

The use of the caisson

The caisson is a moisture-proof chamber, which is made of metal or durable plastic. In appearance, the container resembles an ordinary barrel. The volume is usually equivalent to a standardized RC ring of 1 m. The product is buried in the ground and is used to solve the following tasks:

- protection against water and dirt;

- ensuring that the equipment is located all year round at a positive temperature;

- freezing prevention;

- ensuring tightness;

- year-round well operation.

First, a pit is pulled out. Depth - up to 2 m. Then a hole is cut at the bottom for the casing pipe. The container is lowered into the pit and placed in the center of the well. The casing is cut off and welded to the bottom. At the end, the product is covered with soil. Only a hatch is visible on the surface.

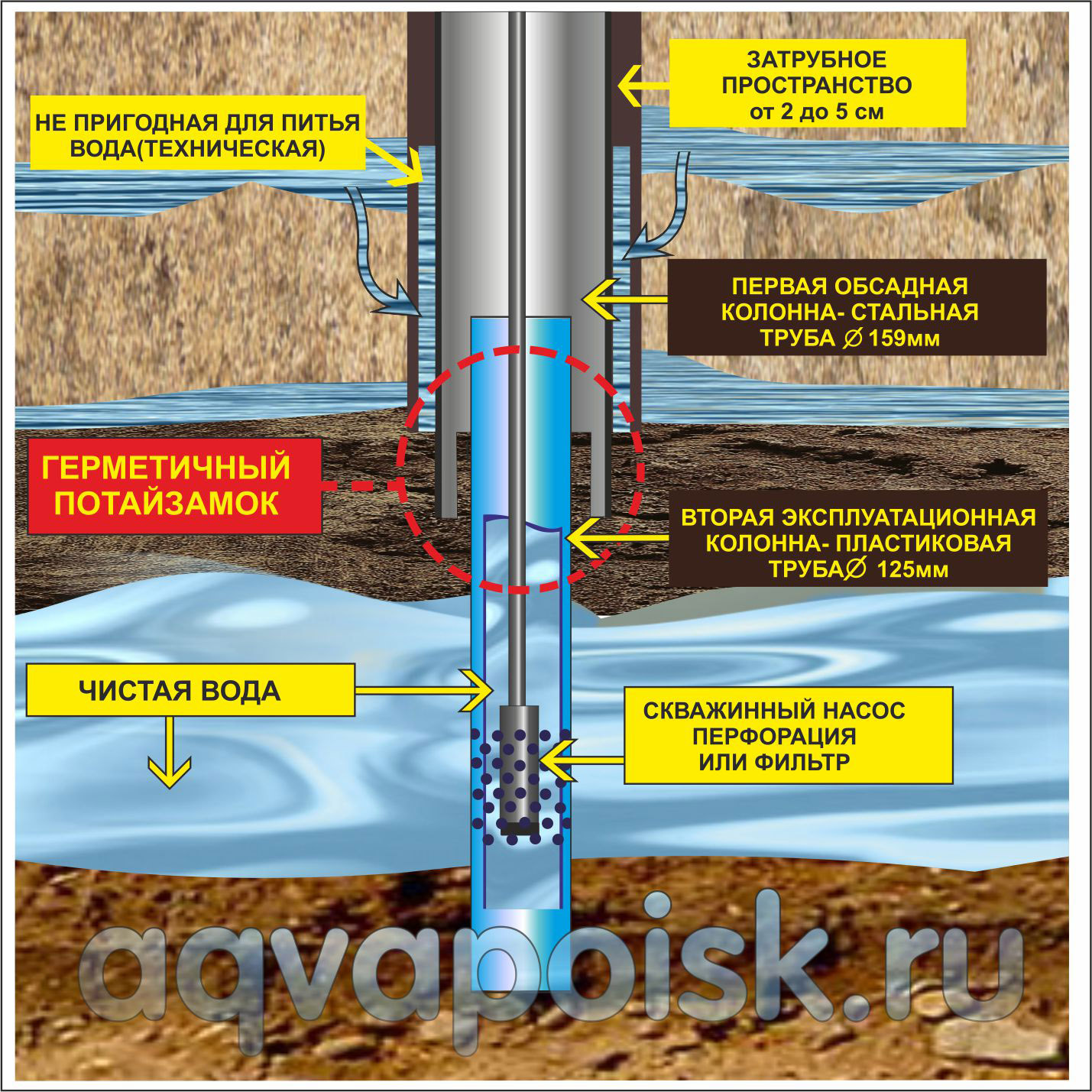

Adapter operation

The arrangement of a well for water involves the removal of a water supply directly through a cased column. The pipeline is laid below the freezing depth of the soil masses. The element itself is made in the form of a threadless type pipe connection. One end of the device is rigidly fastened to the casing, and the other is screwed into the pipe connected to the submersible pump.

Head application

Elements are either made of plastic or metal. The fixtures consist of covers, connecting flanges and rings made of rubber. Installation is not accompanied by welding.

Installation begins with trimming the casing. Then the pump is lowered and the cover is put on. The flange and rubber seal rise to its level. Fastening is carried out by tightening the bolts.

How deep does an artesian well start?

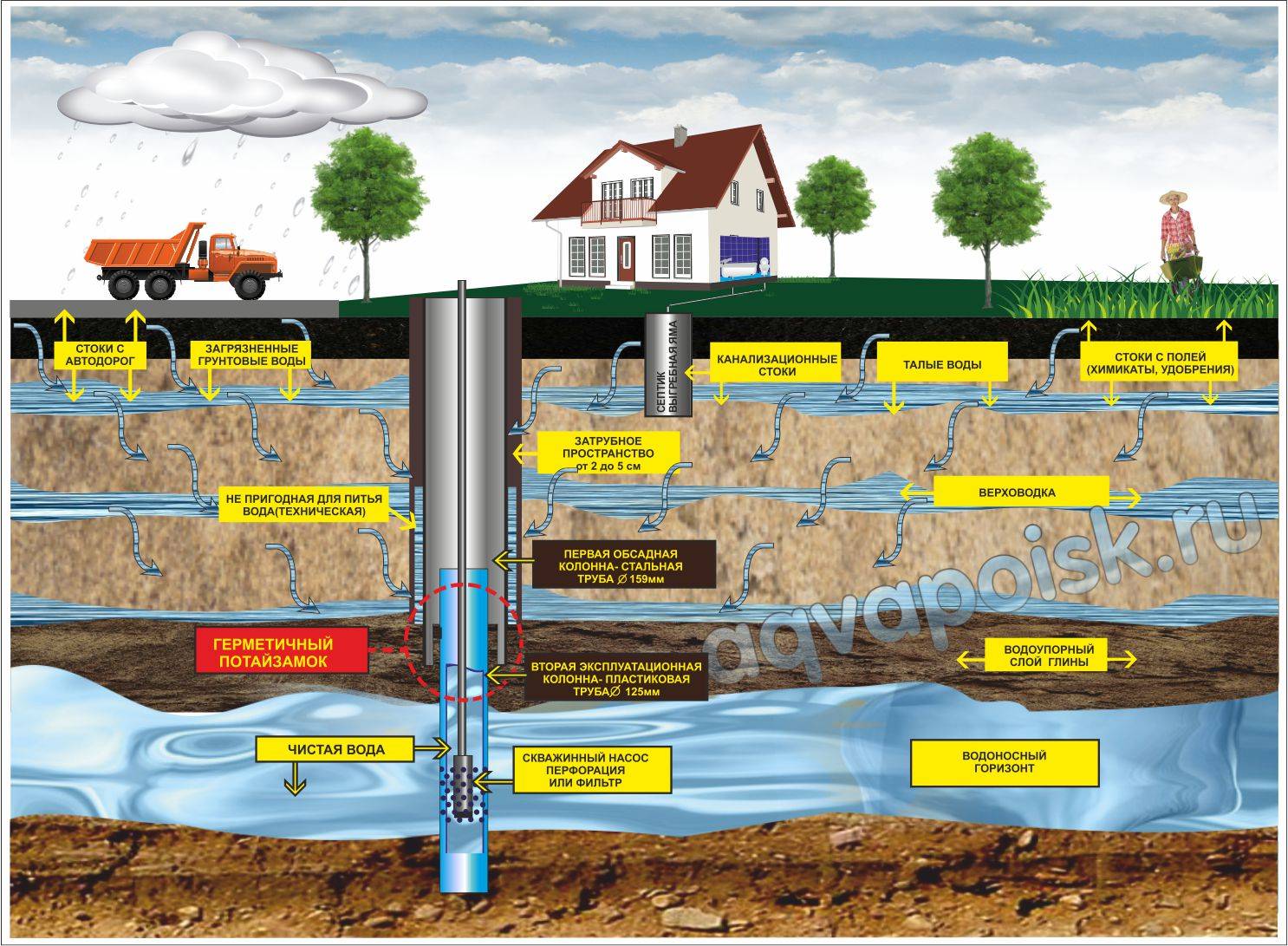

Artesian horizons lie between water-resistant rocks and are under pressure. Due to this, they are distinguished by good water loss, and the sources are able to function for 50 years or more.

The depth of an artesian well depends on the hydrogeological conditions of a particular area and can vary from 30-40 m to 200-250 m. The water level in the horizons does not change depending on the season, floods, precipitation and other natural phenomena.

Due to the great depth of the artesian well, the water is always crystal clear. It is not contaminated with pathogenic bacteria, but may contain high concentrations of dissolved chemicals and be hazardous to human health.

Among the most common water contaminants is iron, which changes the taste and properties of water. Therefore, after drilling a well for artesian water, it is necessary to take a sample for chemical analysis. If the metal concentration is too high, you will have to install a filter with iron removal cartridges.

How to make a well in the country

Almost every owner of a country house, and even a villager, wants to have a well on his site. Such a source of water from which it would be possible to constantly obtain high-quality water.

It is worth noting that if the water is at a depth of up to ten meters, then such a well can be drilled independently. This is not such a laborious process as it might seem at first glance. We need a standard pump. It will pump out water and at the same time, in a sense, drill a well.

Video-how to drill a well in the country

Let's move on to the drilling process itself. It should be noted that the pipe that we will lower into the well must be located vertically. Water will be pumped into this pipe using a pump. The teeth should be located at the bottom end of the pipe. Such teeth can be made by hand. Water, which is under pressure from the lower end, erodes the soil. Since the pipe is heavy, it sinks lower and lower, and soon reaches the aquifer.

Video-how to drill a well under water

In order to really get drilling, we need only a steel pipe.The radius of such a pipe must be at least 60 mm (preferably more). Such a pipe will serve as a casing pipe. The length of such a steel pipe must not be less than the depth of groundwater. The end of the pipe, which we close at the top with a flange and a special fitting.

To do this, we use a pass-through fitting. Through this element, water will pump through the hose. We also need to use a welding machine. With it, we will weld four "ears" with special holes. These holes should fit the M10 bolts.

As a water tank, we will take a barrel with a volume of 200 liters. In order for us to somewhat speed up the drilling process, we need to shake the pipe and turn it a little either clockwise or counterclockwise. Thus, we will wash out a large amount of soil. For the convenience of pipe rotation, we can use a gate. To do this, take two metal tubes and attach them to the pipe. For these purposes, we can use special clamps.

For drilling, several people are needed (two are possible). In the place allotted for the well, a hole is dug. The depth of such a pit must be at least 100 cm. A pipe is lowered into this pit. And the jagged end down. Next, using the collar, deepen the pipe. It is worth noting that the pipe must be in a vertical position. Next, we turn on the pump. The hole will fill with water. We scoop it out. Then it can be spilled through a sieve and poured back into the barrel. It is quite possible to drill six meters in a few hours.

Here you can read:

how to drill a well for water, how to drill a well for water video, how to drill a well, how to make a well for water, how to make a well for water on the site video

well drilling

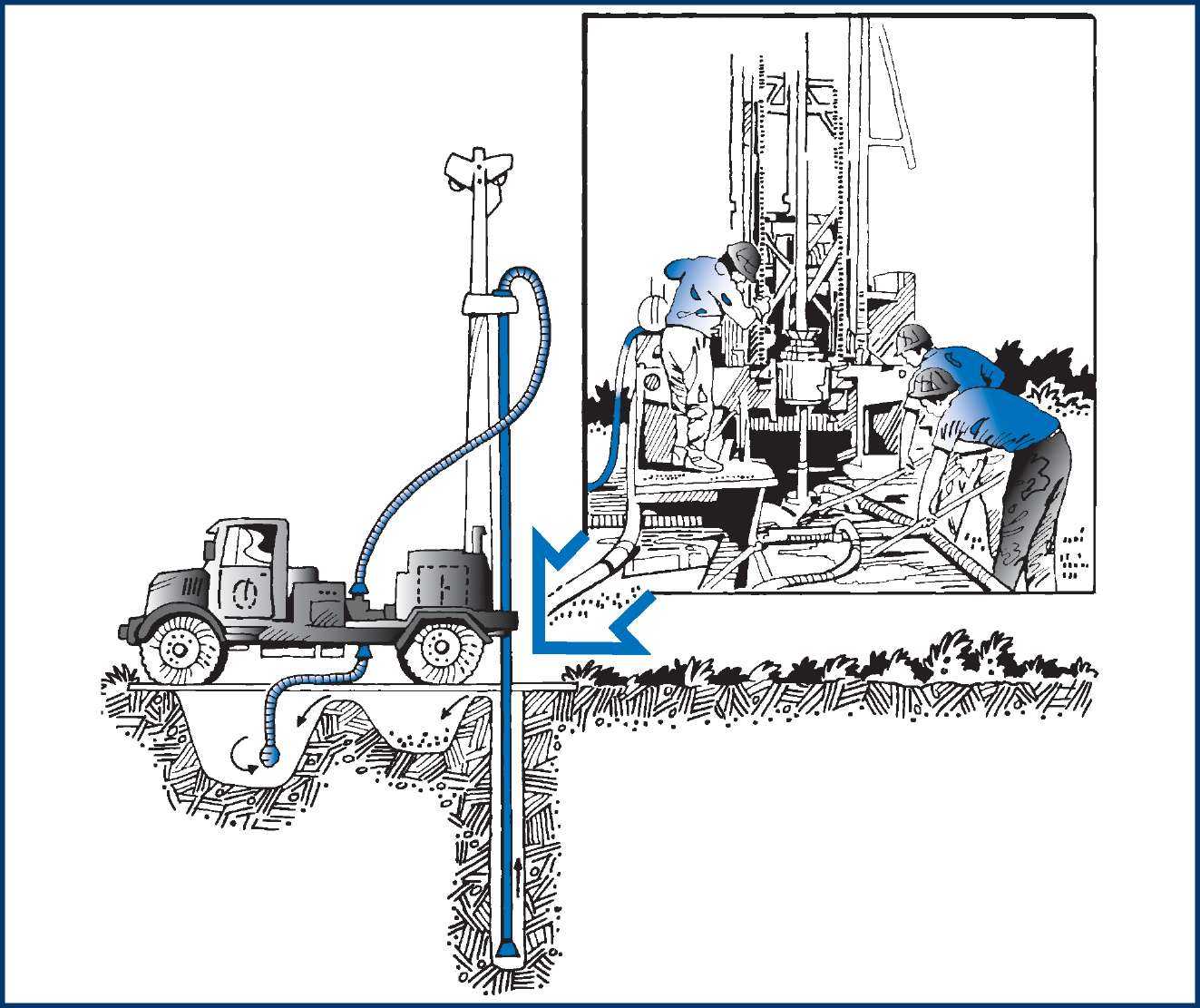

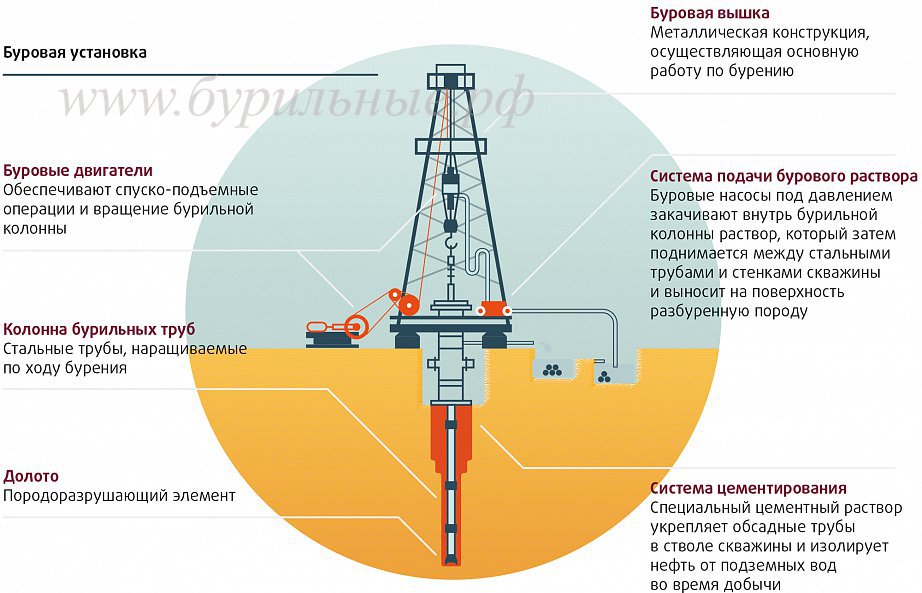

So, the most crucial moment comes - the direct drilling of the well. However, the creation of the water well itself is preceded by the process of exploratory drilling, which helps the craftsmen determine the location and the estimated productivity of the aquifer. And only after that, specialists begin to drill a production well. Then the column is cased with special pipes, a filter is installed in its lower part, and a clay lock is installed in the upper part, which protects the well from foreign water. Thanks to this technology, the well will produce clean and clear water.

Well drilling is carried out using stationary hydraulic or small-sized mobile units. After the well is drilled, it is necessary to strengthen its walls. This prevents them from shedding, and also prevents dirty water from the upper layers of the soil from getting inside the well. As a rule, the walls are strengthened by casing the column with steel or plastic pipes.

Types of wells and their features

Own source of water is a great opportunity to provide yourself and your loved ones with clean life-giving water and satisfy household needs. By drilling and arranging a well, it is possible to solve the problem of water supply for several decades ahead.

The choice of drilling method and the scope of work on well construction depends on the type of hydraulic structure.

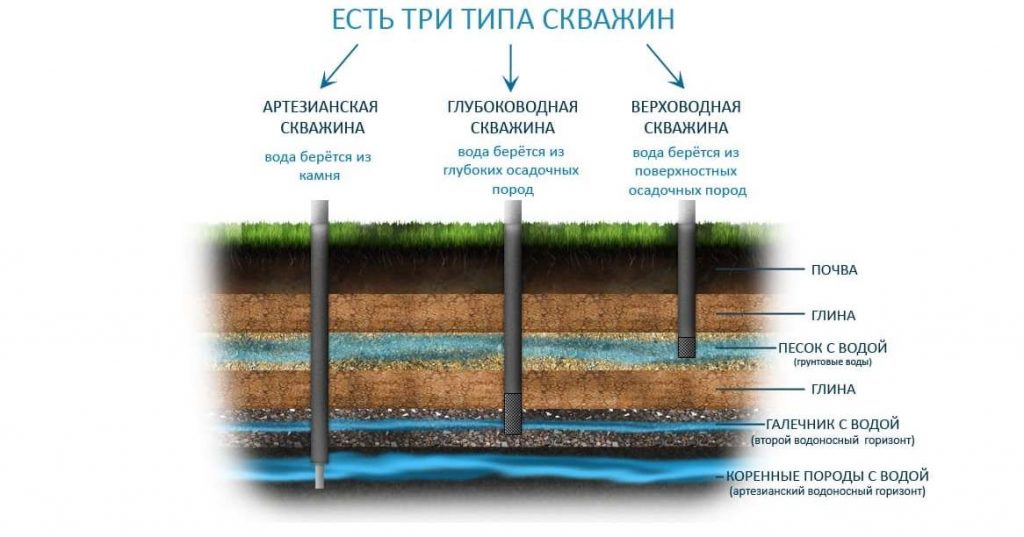

Abyssinian type well

If the water on the site is supposedly located at a depth of 10-15 meters, then it is more profitable and easier to arrange an Abyssinian well. This type of hydraulic structure uses an aquifer located above a water-impermeable clay formation. The aquifer is fed by infiltration of atmospheric precipitation and waters of nearby reservoirs.

A simple well-needle can be drilled even by a novice craftsman who is just mastering basic drilling skills

A relatively shallow narrow well is a string of thick-walled VGP pipes with a diameter of 50 - 80 mm. In the lower, very first link of the column, a special filter is arranged by drilling holes from the walls of the pipe.

The pipes perform the function of the trunk; the Abyssinian needle well does not require additional casing. It is not drilled, but immersed in the ground by driving.

The compact dimensions of the Abyssinian-type water intake make it possible to place it in almost any free space in the local area. The most common way to break through this type of hydraulic structure is percussive drilling.

Features of sand wells

With a depth of the aquifer of up to 30 - 40 meters, common in loose, incoherent deposits, a sandy aquifer is constructed. It is called so because it extracts water from water-saturated sands.

The fifty-meter depth of the source is not able to guarantee crystal clear water, and therefore the contents of the well should be checked in the laboratory for the presence of chemical compounds

The aquifer of the well on the sand is located only three to four dozen meters from the surface. And in order to reach it, one does not have to go through hard - rocky and semi-rocky rocks.Therefore, it will not be difficult to manually drill a sand well if you apply one of the methods described below.

Deep artesian well

But when planning to drill an artesian well, you can’t do it on your own. Artesian water is distributed through cracks in impenetrable rocky and semi-rocky rocks at a depth of about 40-200 meters.

The task of drilling a well for limestone can only be handled by professionals who have the necessary knowledge and have at their disposal special equipment for drilling.

To determine the depth of water, they should be guided by the data of hydraulic structures of this kind, drilled not far from the upcoming work site.

Since an artesian well is capable of providing water to several sections at once, it is convenient to order drilling services in a pool. This will significantly save on drilling and arranging a water supply source.

How to punch punch

This is the most inexpensive technology, but rather laborious. For work you will need the following devices:

- a tripod made of rolled metal with a hook and a block on top;

- winch with a cable, equipped with a handle;

- driving tool - a glass and a bailer;

- welding machine;

- manual drill.

Ground punching cup

Before drilling the soil to the required depth, prepare casing pipes. Their diameter should be such that the working tool passes freely inside, but with a minimum clearance, and the length should correspond to the height of the tripod. One condition: impact technology is not applicable on rocks or in soils with stone inclusions. To penetrate such horizons, you will need a carbide-tipped drill.

Independent drilling of a well for water is carried out in the following order:

From the first section of the casing, make a filter by drilling Ø8-10 mm holes in a checkerboard pattern with a step of 7-8 cm on a pipe section 1 meter long. From above, close the holes with a stainless steel mesh fixed with rivets.

Make a leader hole with a hand drill to a depth of 0.5-1 m

Here it is important to correctly set the tool at an angle of 90 ° to the surface so that the channel turns out to be strictly vertical.

Insert the first section of casing into the hole, correct the vertical and insert the impact tool inside.

Leaving a helper to maintain the casing, raise and lower the glass using the spool. When filling, take it out and clean out the rock

As the soil is removed, the pipe will take its place and gradually sink into the ground. To speed up the process, attach a couple of heavy weights to it.

When the edge of the first section drops to the ground, weld the second section to it, strictly controlling the vertical level. Continue in the same way until you reach the water layer.

Welding the next section in level

When the end of the pipe drops 40-50 cm below the groundwater level, stop punching the channel and proceed to "rocking" the source. To do this, lower the pipe connected to the surface pump to the bottom of the HDPE and fill the shaft with 2-3 buckets of water. Then turn on the unit and let it run for 2 hours, controlling the cleanliness and water pressure. The last step is to equip the well and connect it to the water supply at home, as described in another instruction. For more details on the drilling process, see the video:

water wells

Wells for water.

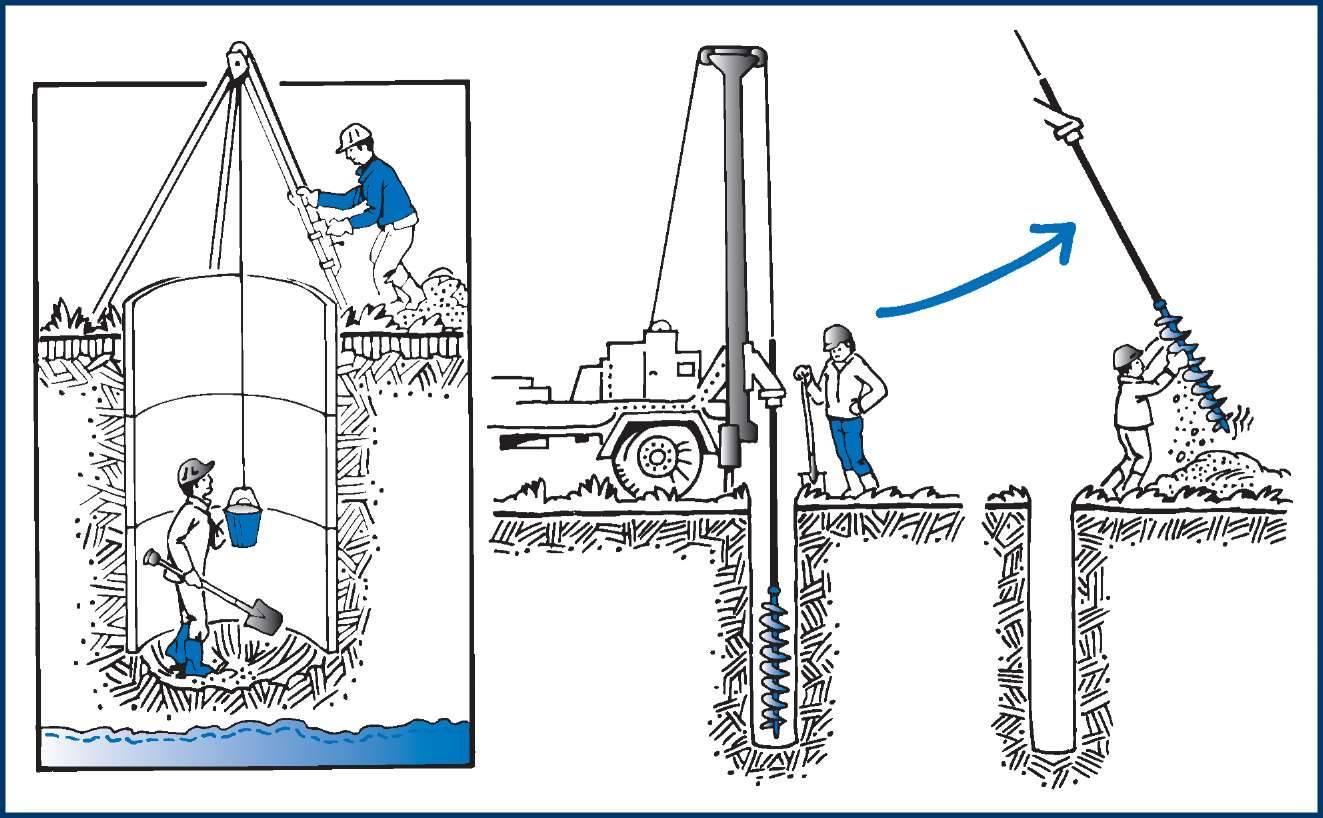

To take water from horizons located close to the earth's surface, they dig an open mine working - a pit, it is called a well.

Wood is no longer used for attaching walls: reinforced concrete rings with a diameter of 1-1.5 m have replaced oak and larch crowns from use. To get to drinking water, you need a pit up to 15 m deep.

Water intake tunneling technology:

- Choose a place under the well, lay the first ring on it.

- Excavate the soil inside the contour until the top of the concrete element is level with the soil.

- Install the second cylinder on the dug-in block, repeat the operation. Dig in subsequent links in the same order.

- Pump out the water that has appeared with a submersible pump and continue installing the rings until the intended level of the aquifer is reached.

- Attach a cap to the well shaft. The structure consists of the last concrete element, which does not need to be buried, and the first ring in the ground.

- Dig around the mouth of the pit with a ditch 60 cm wide to a depth of 1 m, fill with clay and tamp. Pour a sandy blind area over the clay castle.

- Close the head with a lid to prevent debris from entering the water intake.

If it was not possible to reach the interlayer horizon, then it is possible to use well water as drinking water after filtration and boiling. The main advantage of the well is the accumulation of moisture, which reduces the dependence of the flow rate on precipitation. The supply of water in the amount of 2-3 m³ is constantly present in the source.

Flaws

It is possible to build a concrete water source on any land plot owned by a citizen, without issuing permits. The technology for erecting a water intake is simple and available for independent execution.

The disadvantages of arranging a well include:

- the complexity of earthworks;

- the threat of being left without water during dry periods;

- the need to isolate the joints to prevent the top water from getting inside the well;

- obligatory periodic cleaning of the filtration layer at the bottom of the mine.

It is impossible to build a drinking water intake in wetlands and areas flooded during the flood period. This option carries the risk of bacteria entering the water source.

This is interesting: Mesh for reinforcing floor screed: set out point by point

Specific types of water wells

There are different types of wells:

- Designed on a quicksand, it can have a recess of 40 meters. Parallel drilling with the installation of casing pipes is used. This design allows you to get a larger volume of water, in contrast to the standard design.

- A geothermal well is drilled to extract water from an underground hot spring. It is applied to autonomous heating at heating of habitation. Hot water rises to the heat pump on its own. The bottom line is to use hot water to heat the room and drain it back into the source. Thus, the room receives free heating.

As you can see, the main types of wells differ not only in their design and depth, but also in their application.

Manual methods of drilling aquifers

The highlights of the Abyssinian way

This method of forming a water source is the simplest of all existing ones.Its technology is contained in the slaughter of a steel rod with a sharply sharpened tip into the ground. The diameter of this device, in most cases, does not exceed 3-4 cm, based on this, this method is also popularly called "drilling with a needle".

Along with such advantages as the ability to drill this type of well with your own hands, and the use of holes in the rod as a casing, the Abyssinian method has many of the following disadvantages:

- Limited well depth. This indicator should not be more than 7-8 m.

- In the case, at a time when it is not known exactly where the water lies on the site, it is possible to “riddle” its entire area with holes, along with this, without achieving the desired result.

- The small diameter of such a well does not allow the use of a submersible pump, which is why the only option is to use a surface device that cannot provide good pressure in the house's water supply system.

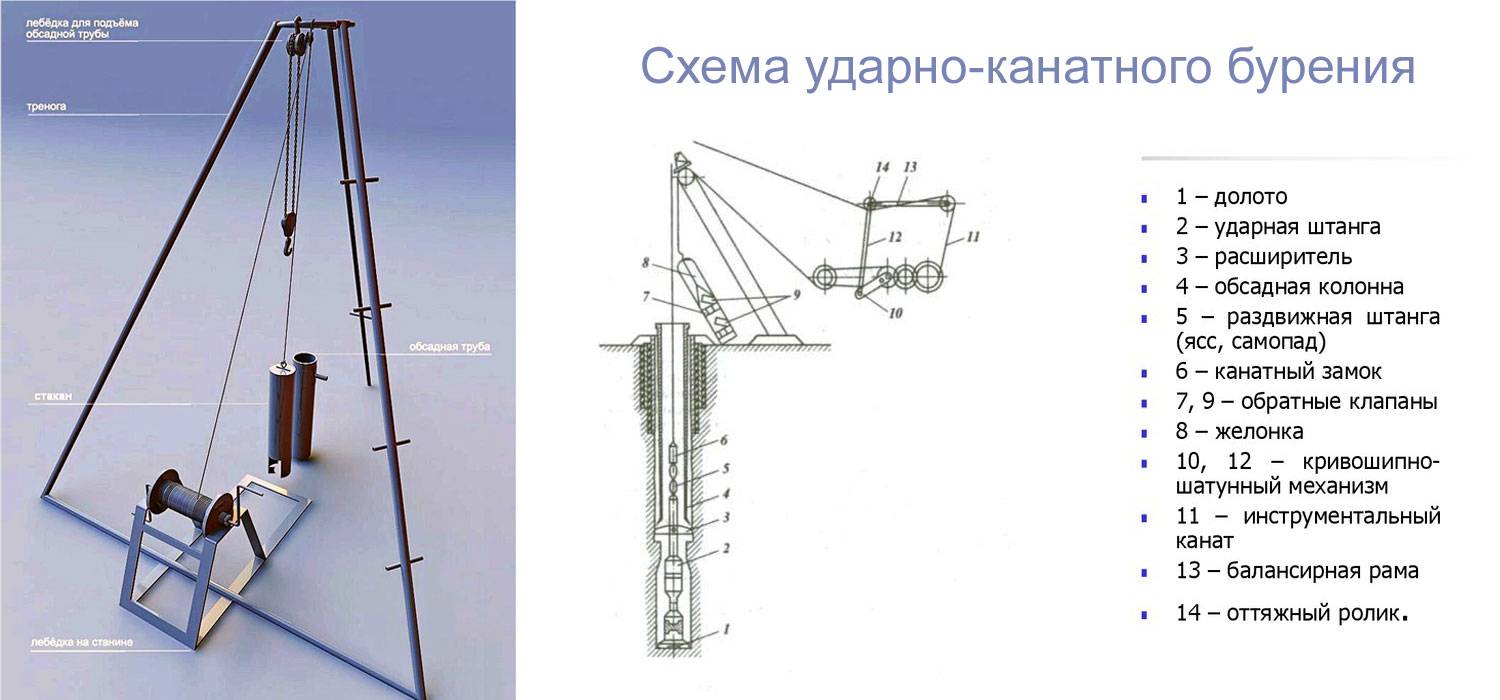

Features of the shock-rope method

The percussion-rope method is quite popular both among small companies involved in well bottoming and among private landowners, because this method can be carried out using simple equipment. To do this, it is useful to have a winch, a tripod and a driving “glass” with a sharp edge, which should look like a hollow pipe.

The technology for creating a well in this way is contained in hanging a pipe (glass) with a cable from a tripod and sharply lowering it and raising it with a winch. Along with this, the pipe will be clogged with earth from the channel, based on this, the “glass” will need to be cleaned periodically.

Such drilling is effective in the case when the site is soft and viscous soil. If it is dry and loose, then the soil will not be able to linger in the “glass”, therefore, it is more expedient to use a bailer instead of it, which can capture the earth from the wellhead, and then deliver it to the surface.

As it became clear, this type of drilling is laborious and protracted. But with the help of it, it is possible to create a fairly high-quality channel for a well, of course, provided that the technological instructions are followed.

Features of the manual rotary method

Manual rotary drilling of wells also refers to simple methods, since along with this, a simple drill in the form of a huge drill is used to form a channel. Unlike the mechanical rotary method, the drill in this case is driven not by a special mechanism, but through human efforts. This drilling option is effective when creating wells in areas with loamy and gravel soils.

At a time when loose soil is present on it, the well is clogged in this way using a drill-spoon. This device consists of a cylinder with spiral holes. be guided to take into account that this method is a laborious and lengthy undertaking.

Drilling a well with an ice drill

There is a drilling method that will require minimal financial investment. This is the drilling of wells by hand with the help of an ice drill. The tool is used as a drill, and self-made rods are used to build it.

The ice ax knife will serve as an auger, and steel pipes with a diameter of up to 25 mm can be taken as extension rods.To make the process go faster, reinforced cutters are welded to the winding edges of the improvised auger

Among other things, casing pipes will be required to form the wellbore, a shovel and a device for removing cuttings from the site.

Drilling with an auger made of an ice drill includes the following operations:

- Training. We dig a guide recess: a hole two bayonets deep.

- We lower the drill into the resulting recess and begin to screw it into the ground, using the screw tightening rule. It should be remembered that after every three or four revolutions, the tool is removed to the surface and cleaned.

- After the first meter has been passed in depth, we begin the formation of the trunk. To do this, a casing pipe is lowered into the well, its diameter should be slightly larger than the diameter of the drill. It is best to choose lightweight plastic parts equipped with threads for connection.

- When the drilling tool begins to descend into the face to its full height, we attach an extension rod to it. This can be done in two ways: screw the part if there is a thread, or extend it with a steel pin-rod if it is absent.

- In the course of work, we continue the formation of the casing string. As soon as about 10-15 cm of the pipe remains on the surface, we attach the next one to it. The connection must be strong. It is usually done by threading or soldering.

- Periodically check the verticality of the trunk. If the drill starts to beat against the walls of the casing, we level the structure with wooden wedges. They get stuck between the ground and the casing.

- After water appeared in the well and it was decided to stop work, we install a filter and carefully fill the gap between the soil and the casing with gravel.

The casing string can be installed even after completion of drilling operations. In this case, plastic pipes are introduced into the well and connected in series after the previous part is lowered down. This is not the most rational way, since you will have to clean the bottomhole from sludge again.

Plastic pipes are very light, strong enough and inexpensive, so they are most often chosen for well casing.

Experience shows that drilling a well with your own hands is quite possible, although quite labor-intensive. The case should be taken with all responsibility: correctly choose the method of drilling, select the necessary materials, study the instructions and then get to work. The result of the efforts spent will be clean water from our own well on the site.

Selecting a well for a site

When asked which well will be optimal for a particular site, it is necessary to determine the parameters of the water carrier, take into account the need for water and financial capabilities. An Abyssinian well can be equipped by any person in his area, and without any approval. It will be cheap, but the water will be technical. To turn it into drinking water, a purification plant is needed.

An artesian well provides a supply of high-quality drinking water, but is very expensive. It, as a rule, is drilled to serve several sites, or even the whole village.In addition, the arrangement of such a well requires special permission from the relevant authorities.

Sand wells are the most common. They optimally combine water quality, productivity and drilling costs. They can be equipped by one owner of the site or several owners. Drilling does not require large equipment and is carried out at any site by specialized companies. Permits are not required.

Exploration drilling and water analysis

Exploratory drilling is carried out to determine the quality of the water source at the site, as well as to analyze the produced water. Sometimes it serves as a temporary source until a final decision is made on a capital well. The reconnaissance table is called a needle.

The most accurate result will, of course, be exploratory drilling.

The most accurate result will, of course, be exploratory drilling.

To do this, you need a drill rod, drill string and casing, which will be one. The drill remains in the ground. Such a well is performed by impact technology. No special drilling tools are required for this. The penetration is up to three meters per hour, and the maximum depth is up to fifty meters.

The simplest filter will have a spear-shaped tip at its end, consist of a hole in the middle, and a ball valve at the top.

The water extracted in this way is given to any laboratory for the study of natural resources for testing for minerals, the activity of hydrogen ions, the content of metals, alkalis, dissolved acids.

Methods for self-drilling

To drill a well for water in a country house, a personal plot, a rural courtyard, it must be taken into account that there are three ranges of depths at which aquifers occur:

- Abyssinian well. Before the water will have to drill from one and a half to 10 meters.

- On the sand. To make a well of this type, you need to pierce the soil to a mark in the range from 12 to 50 m.

- Artesian source. 100-350 meters. The deepest well, but with the purest drinking water.

In this case, each time a separate type of drilling rig is used. The determining factor is the chosen method of drilling operations.

Shock rope

With such drilling of wells for water, the technology of the process involves raising the pipe with three cutters to a height. After that, being weighted with a load, it descends, and crushes the rock under its own weight. Another device necessary for extracting crushed soil is a bailer. All of the above can be bought or made with your own hands.

But before you drill a well with your own hands, you will have to use a garden or fishing drill to make the primary recess. You will also need a metal profile tripod, a cable and a system of blocks. The drummer can be lifted with a manual or automated winch. The use of an electric motor will speed up the process.

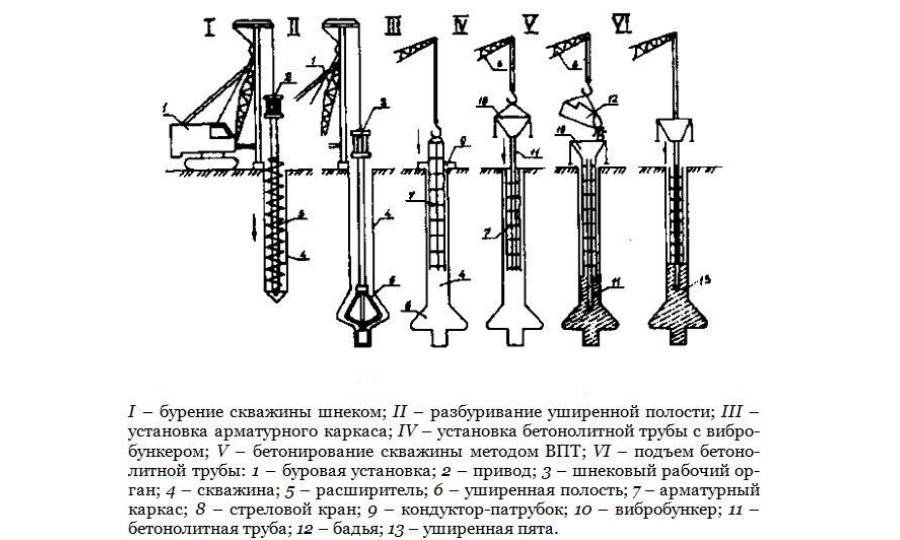

Auger

This technology of drilling wells under water involves the use of a drill, which is a rod with a helical blade. A pipe with a diameter of 10 cm is used as the first element. A blade is welded onto it, the outer edges of which form a diameter of 20 cm. To make one turn, a sheet metal circle is used.

A cut is made from the center along the radius, and a hole equal to the diameter of the pipe is cut along the axis. The design is “divorced” so that a screw is formed that needs to be welded.To drill a well in the country with your own hands using an auger, you need a device that will serve as a drive.

It could be a metal handle. The main thing is that it can be disconnected. As the drill deepens into the ground, it is increased by adding another section. The fastening is welded, reliable, so that the elements do not come apart during the work. After the procedure is completed, the entire structure is removed, and casing pipes are lowered into the shaft.

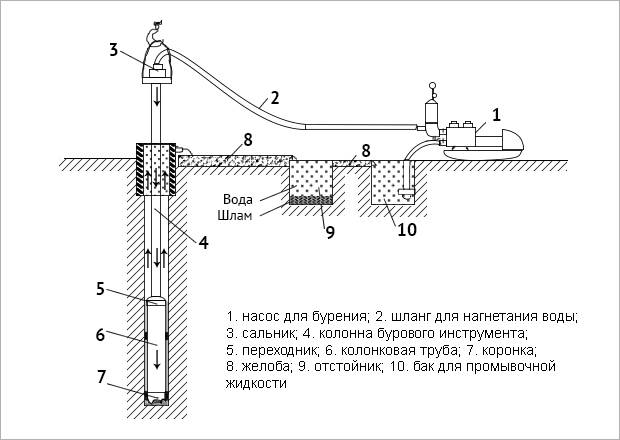

Rotary

Such drilling of a well in the country is not the cheapest option, but the most effective. The essence of the method is the combination of two technologies (shock and screw). The main element that receives the load is the crown, which is fixed on the pipe. As it sinks into the ground, sections are added.

Before you make a well, you need to take care of the water supply inside the drill. This will soften the ground, which will extend the life of the crown. This method will speed up the drilling process. You will also need a special installation that will rotate, raise and lower the drill with a crown.

Puncture

This is a separate technology that allows you to penetrate the ground horizontally. This is necessary for laying pipelines, cables and other communication systems under roads, buildings, in places where it is impossible to dig a trench. At its core, this is an auger method, but it is used for drilling horizontally.

The pit is dug, the installation is installed, the drilling process begins with periodic sampling of rock from the pit. If water in the country can be obtained from a well separated by an obstacle, a puncture is made, a horizontal casing pipe is laid, and a pipeline is pulled. Everything can be done with your own hands.