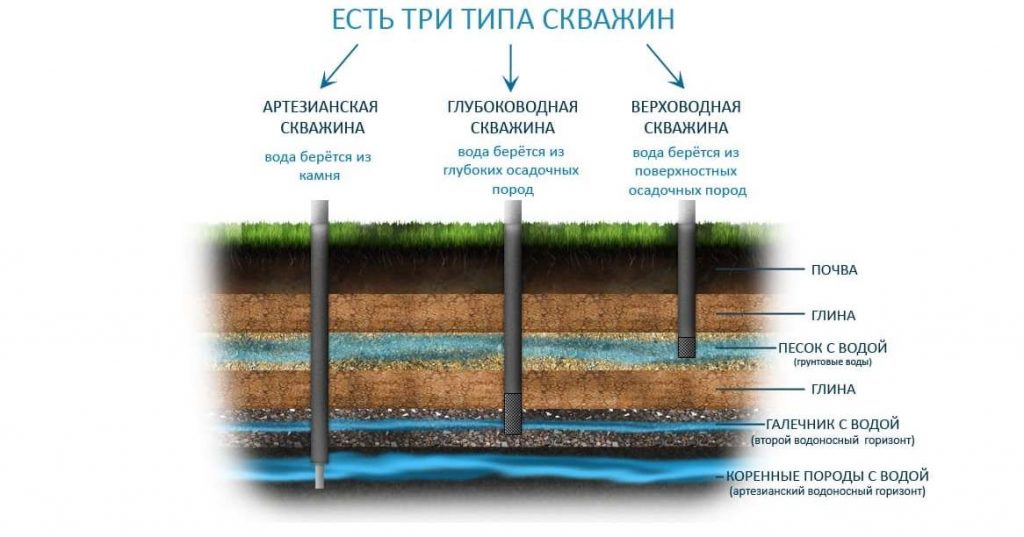

- Existing well categories

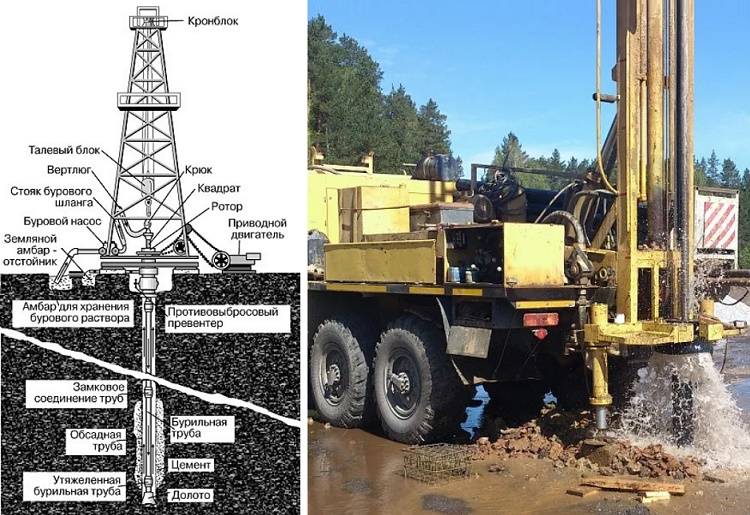

- Drilling equipment and tools

- drilling tool

- Changing the fluid to a lighter one

- Artesian well

- Advantages

- Flaws

- sand wells

- Advantages and disadvantages

- Characteristics of offshore drilling problems

- Tools and fixtures for drilling a well

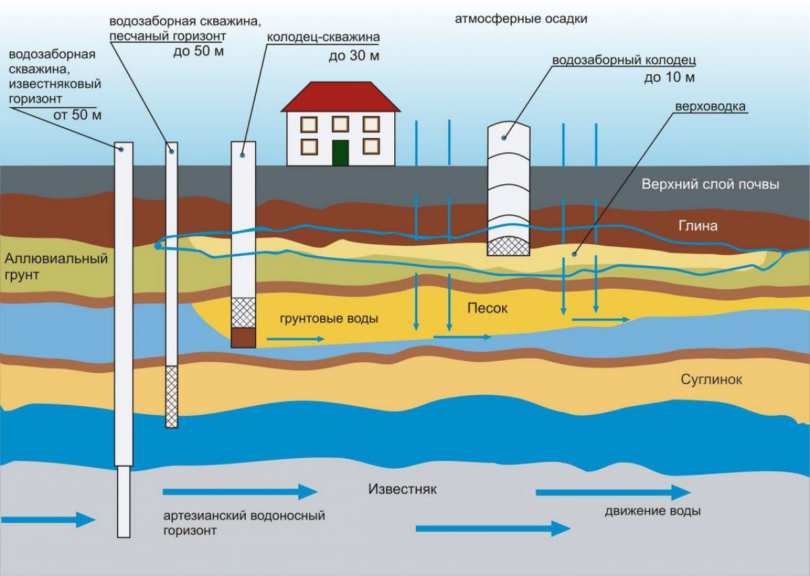

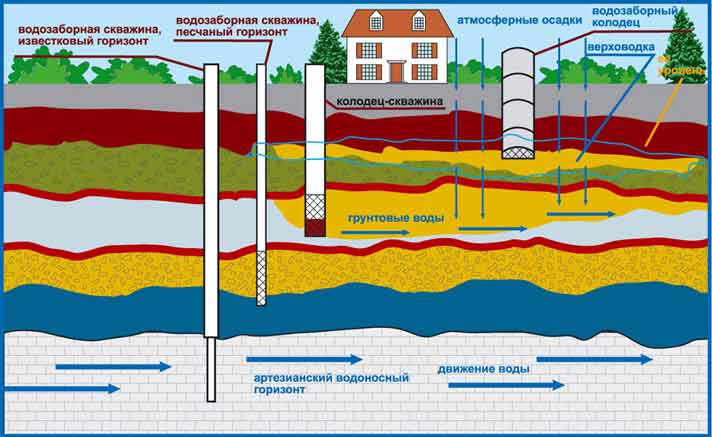

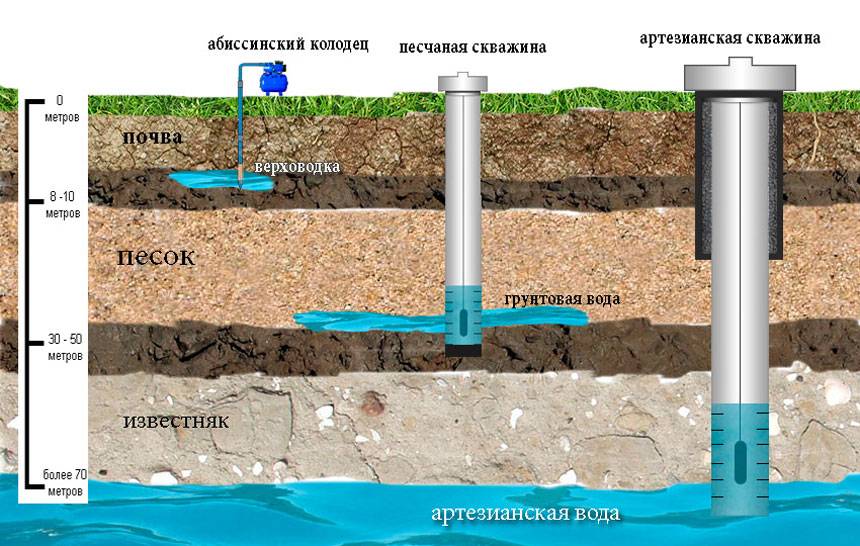

- Classification of aquifers

- Types of wells by profile

- What technology is used most often

- Afterword

- Why is a well better than a well?

- Production of drilling tools

- Option #1 - Spiral and Spoon Drill

- Option # 2 - bailer and glass

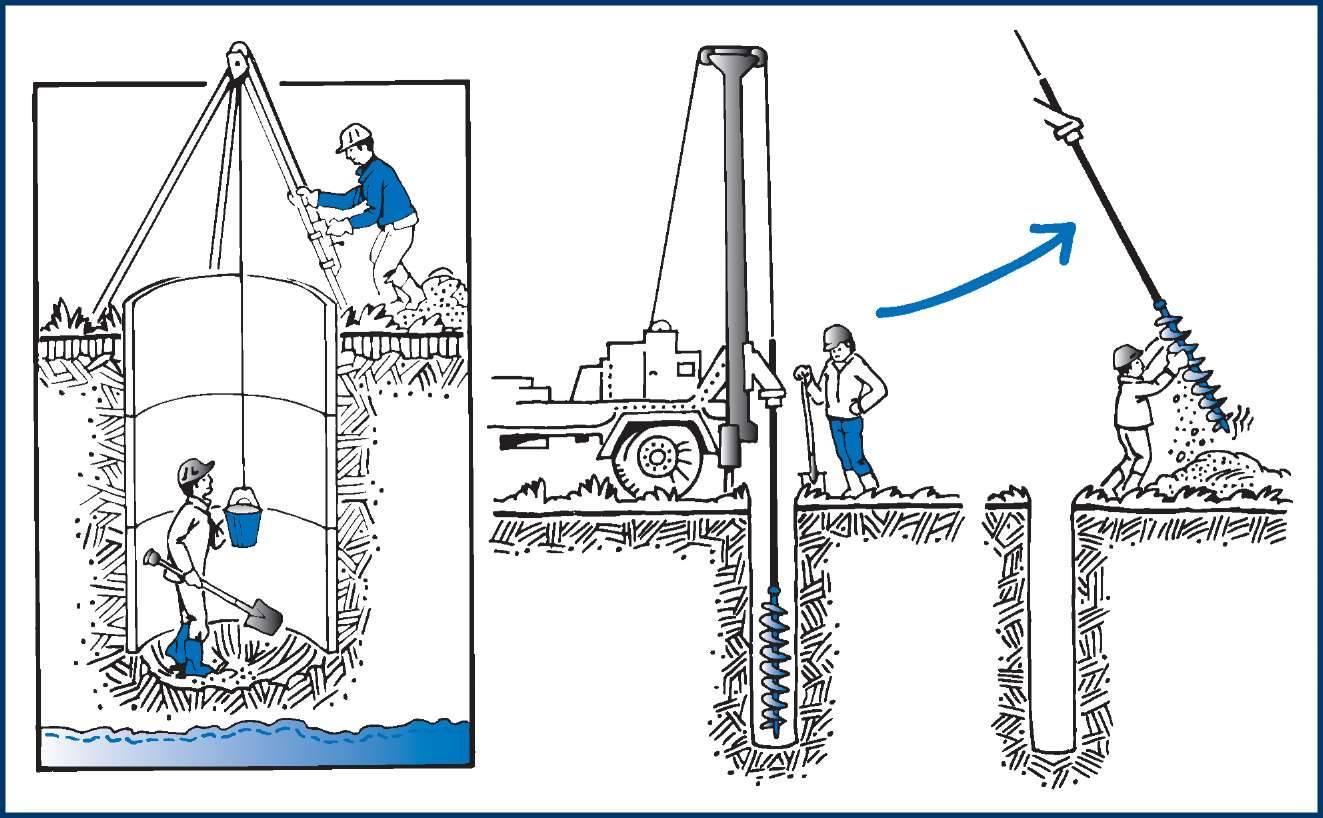

Existing well categories

According to the purpose of the well, there are the following categories:

- Parametric — allowing to define a section of a vertical layer.

- Exploration - have a small diameter, determine the prospects of drilling.

- Exploration - determine the potential of minerals.

- Operational - capable of extracting minerals from the bowels of the earth.

Wells for water production are operational, and are divided into additional types:

- producing or injection;

- specialized for technical and drinking water, including absorbing;

- for monitoring and monitoring reservoir pressure;

- understudies for production;

- estimated during operation./li>

Each of them has its own characteristics during drilling and during use.

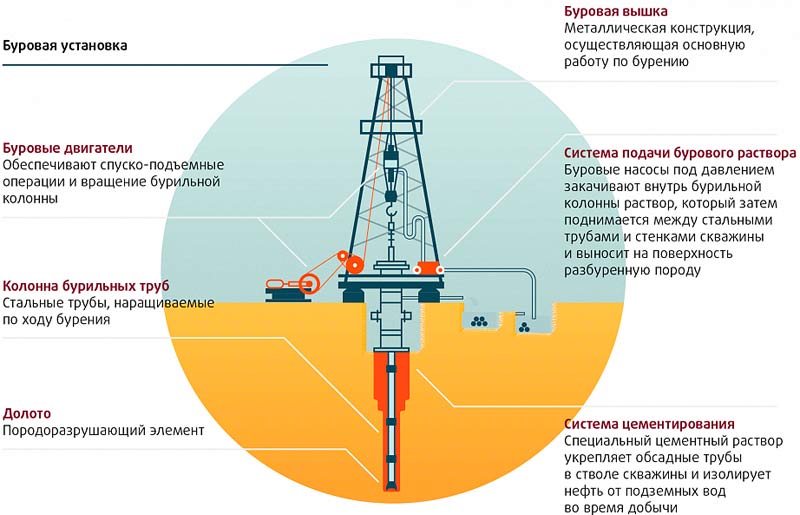

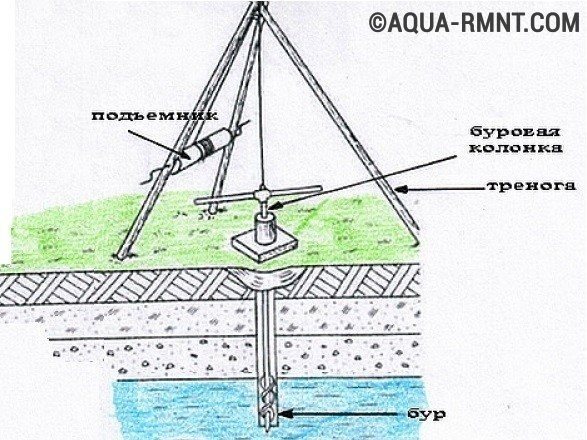

Drilling equipment and tools

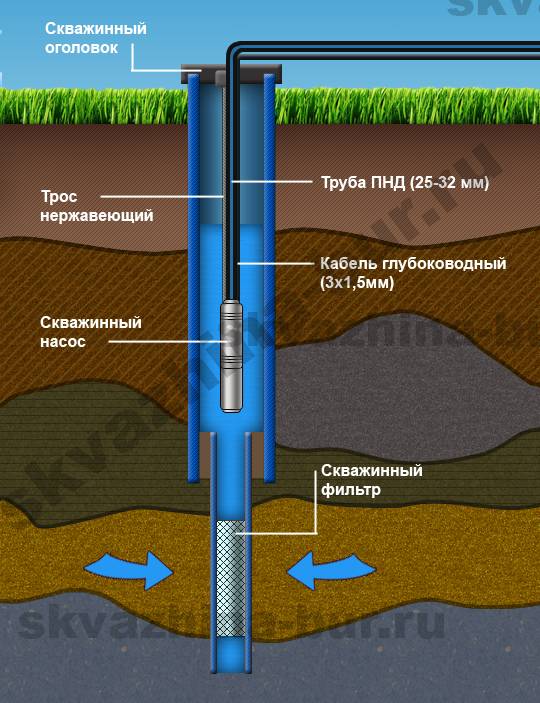

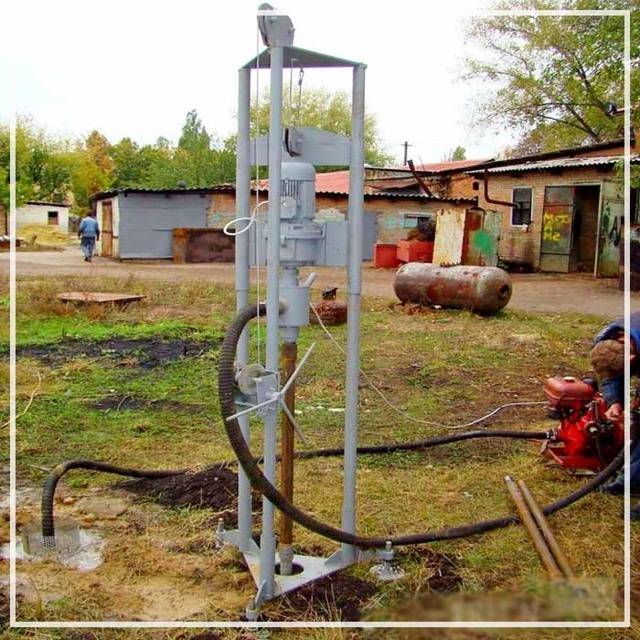

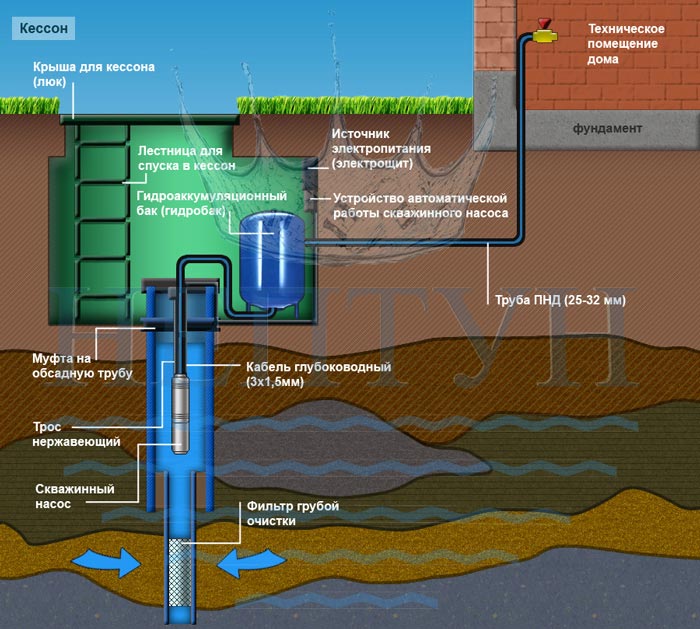

When drilling artesian wells, drilling rigs are used by professionals. For smaller wells, a conventional tripod with a winch is suitable. It will lower and raise the drilling tool, consisting of a core barrel, drill rods, a core for drilling, a drill.

Special equipment, without which it is problematic to make a well, is a drilling tool that will help to go deep into the ground (auger), a tripod and a winch. To drill a well with your own hands, you will need a metal auger. An ice drill, which is used during winter fishing, can act as an auger. The main thing is that the drill should be made of high-strength steel. This is the cheapest option for drilling a well. In addition to the tripod, you will need pipes of different diameters (water pipes, hoses, casing), valves, caisson, filters, a well pump.

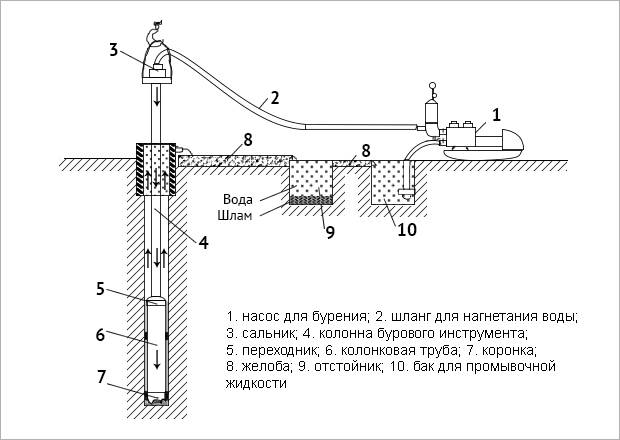

The process of drilling an artesian well

drilling tool

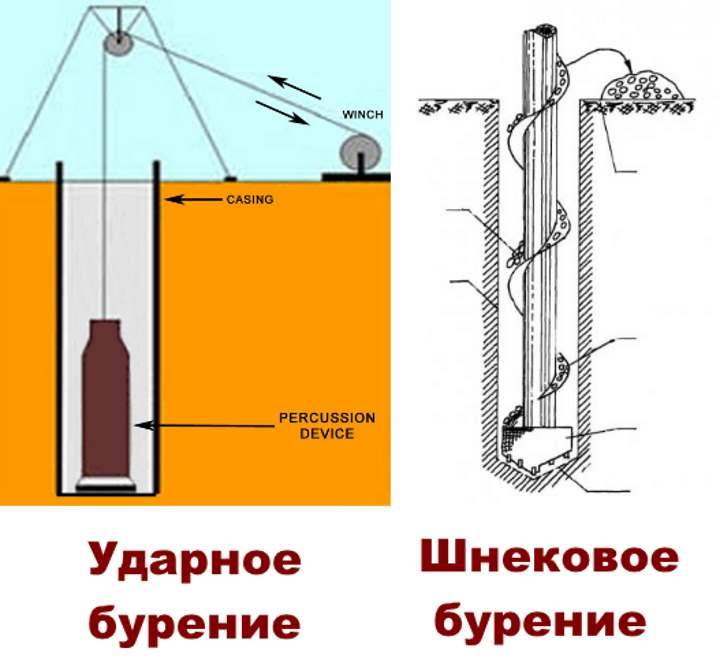

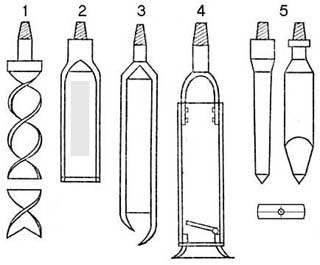

Now let's see which drill which soil and how to drill, see fig. on right:

Drilling tool for manual drilling

- Auger drill, or simply auger - for rotary drilling of cohesive homogeneous soils of normal density; simply - for the earth, loams, slightly moist sandy loams, soft clays. Unlike a garden drill, the drill auger is two-way, otherwise the asymmetry of the soil resistance force will lead the drill to the side and it will get stuck;

- Drill glass, or Schitz drilling tool - for cohesive, but viscous, highly sticky soils in which the auger gets stuck. Drilling - cable-percussion;

- Spoon drill - for loose and loose soils that do not hold in the turns of the auger and in the glass. Drilling - percussion-rotary or rotational;

- Bailer - for cleaning the trunk from crumbling soil, silt, etc. very loose or floating soft semi-liquid rock. Drilling - cable-percussion;

- As they say, pah-pah-pah over the left shoulder, and God forbid you don't need a drill bit for breaking boulders. Cross section - a plate with rounded edges. Caliber - the inner diameter of the casing minus 3-5 mm. Drilling - percussion rod.

The cutting edges of all drills are made of hardened steel. Drawings of a home-made drill glass, an analogue of a spoon drill (the cutting blades are set by a propeller at an angle of 3-10 degrees) and a bailer diagram are shown on the next. rice. on right. The outer diameters of all these drills can be changed depending on the caliber of the well.

Changing the fluid to a lighter one

The well fluid is changed by direct or reverse flushing with lowered tubing and a sealed wellhead. The slurry is replaced with formation water, formation water with fresh water or oil, and oil is replaced with various foam systems.

When changing formation water with a density of 1200 kg/m3 to oil with a density of 900 kg/m3, the maximum pressure drop will be only (1200-900)/1200 * 100% = 25% of the pressure created by the formation water column. If this method fails to induce oil inflow from the reservoir, other methods of development are used. Usually this is swabbing or compression.

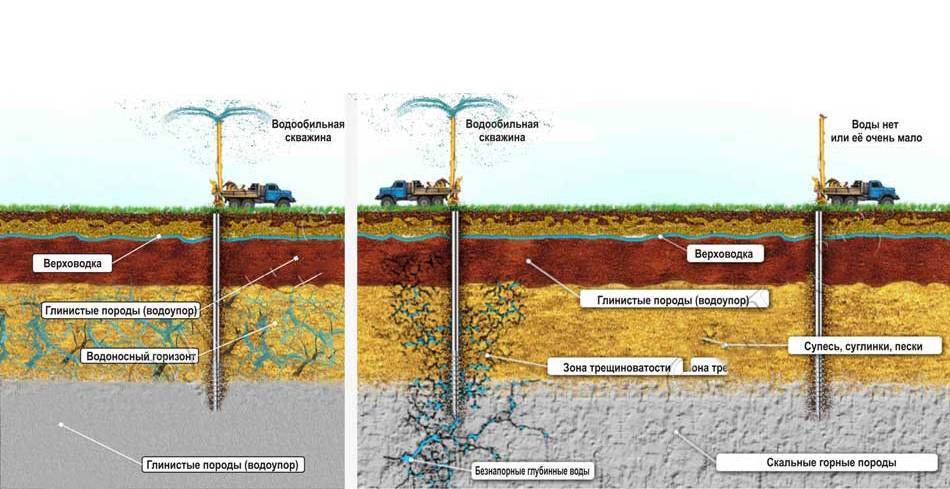

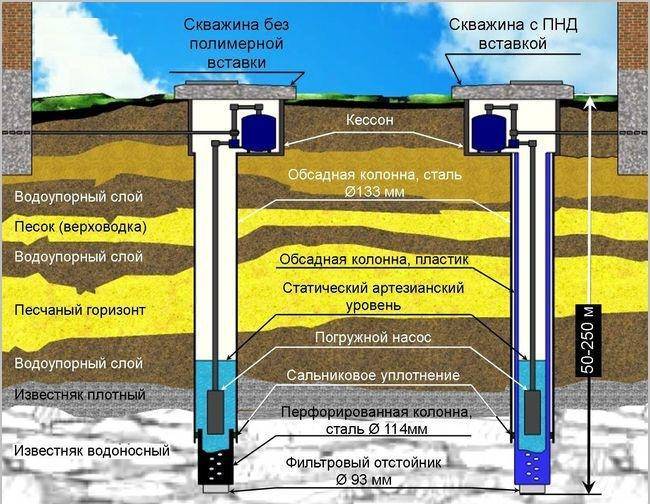

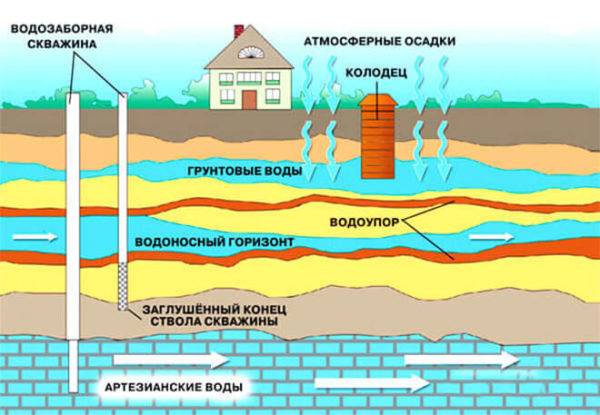

Artesian well

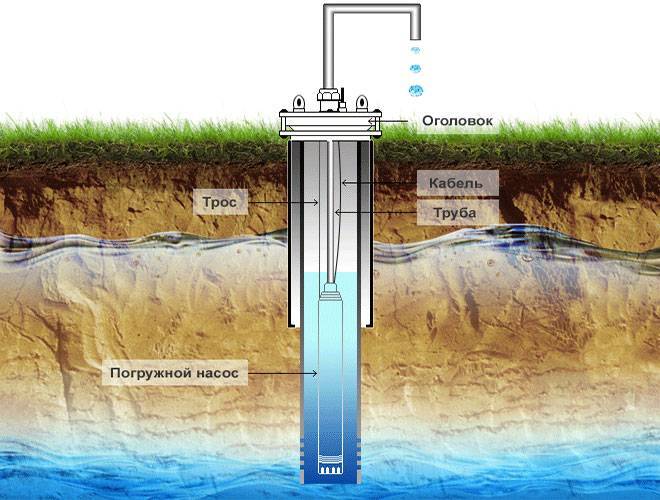

Scheme of an artesian well.

The name of this type of workings comes from the French language - from the place where the first flowing well was drilled: the province of Artois. The large length of the shaft and the solid rocks of the soil crossed on the way to the aquifer require the use of powerful drilling rigs - the auger method will not work.

The construction of the working is preceded by the stage of documentation. Drilling an artesian well is not a licensed activity, but in order to use water from it, many permits and approvals must be issued, including obtaining a license for subsoil use. The process is long and costly.

Main stages: coordination of the location of the site and the well, the project of geological surveys, issuance of a license for exploration, drilling, reporting and putting reserves on the state balance sheet.

Artesian wells are divided into 4 types:

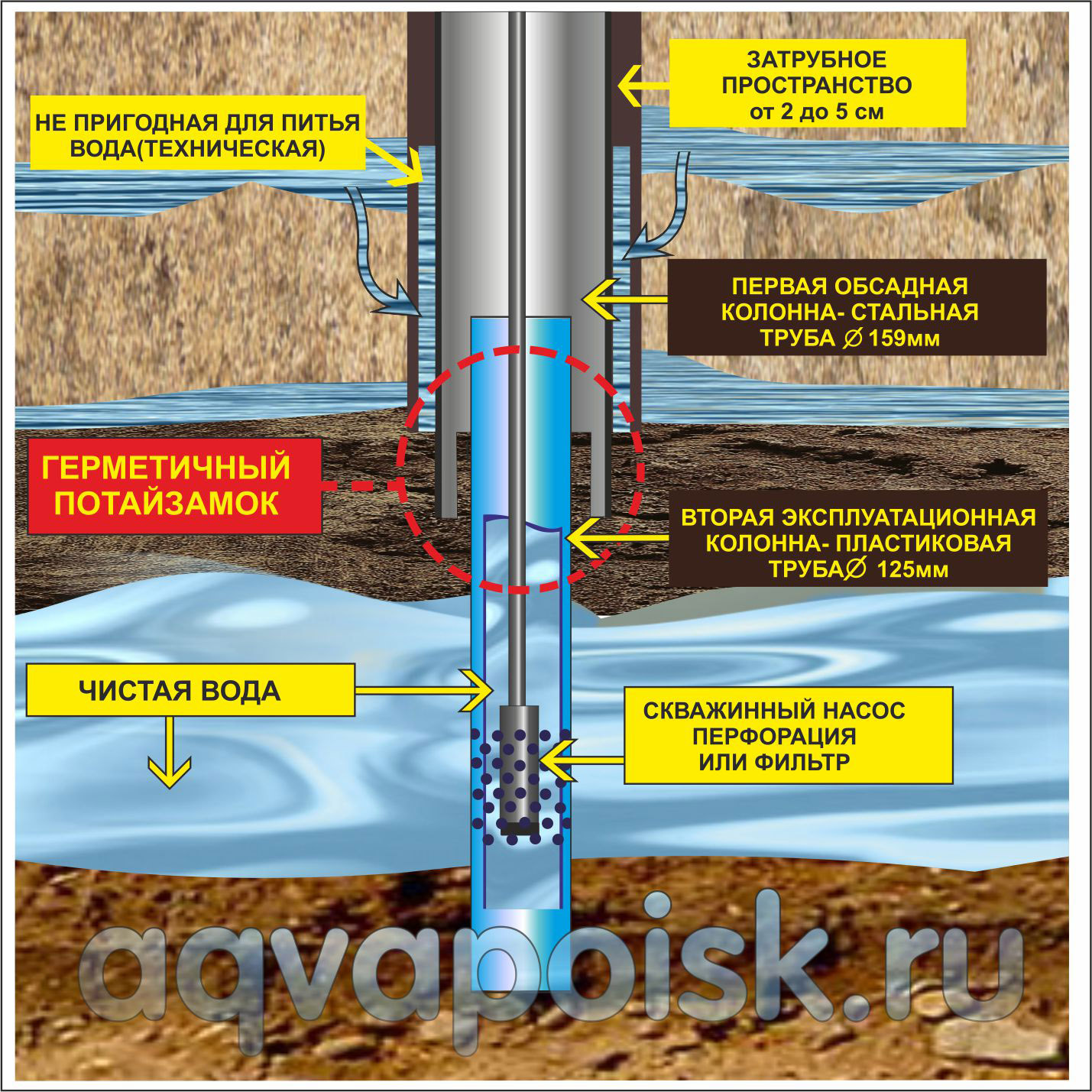

- A double-cased development - a perforated pipe is mounted in the lower part of the column in the aquifer and a pump is placed in it, the other half is installed on top, reaching the limestone layer. Through the holes in the lower link, water enters the pipe and is pumped out at the mouth with a pump. Used when reservoir pressure is low.

- A water well with a transition is arranged with a variable geological section. 3 casing pipes are mounted - large diameter in the upper part, medium - in stones and sands, small - directly in the productive layer. Used for good water supply.

- The well is classical - with one casing pipe for normal conditions.

- A barrel with a conductor - from 2 casings: in the upper and lower parts.

Drilling technology is complex. The construction of an artesian water intake is carried out by specialized organizations.

Advantages

Advantages of an artesian well.

The main advantages of an artesian well are the remoteness of the water intake from the surface and the occurrence of water in porous limestone, excluding the presence of mechanical impurities in the liquid. This allows you to pump out an underground resource without installing a strainer at the bottom.

As a result, other advantages of artesian wells appear:

- ecological purity of water;

- independence from climatic and weather conditions;

- uninterrupted water supply: groundwater reserves are confirmed by geological surveys.

The source remains inexhaustible for ≥50 years. In this case, you do not need to spend money on periodic filter cleaning: there is none.

Flaws

Associated with costs at the stage of organization of construction and drilling of deep workings. The duration of the period from design to obtaining a passport for an artesian well is 2 years.

It will not be possible to build a water intake in a limited area: the minimum area for a drilling rig is 6x9 m. The water contains mineral formations acquired during filtration through the soil, and is hard.

sand wells

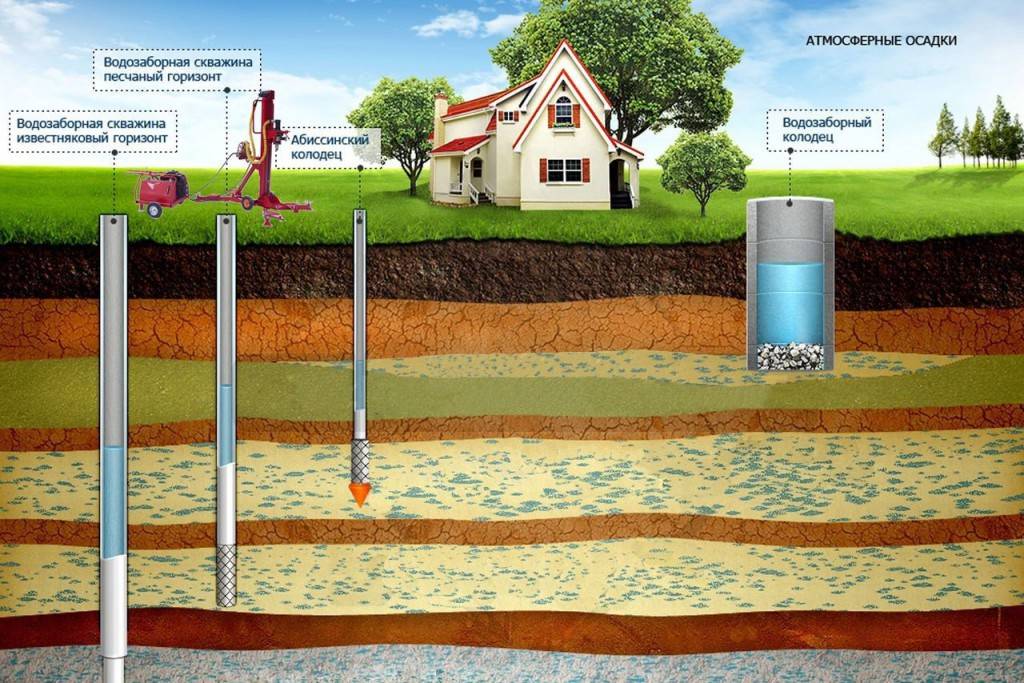

Schematic of a sand well.

They are drilled using a screw method - penetration is carried out in soft rocks: loam, sand and pebbles. Excavation diameter ≥100 mm.

There are 2 types of sand wells by depth:

- up to 40 m - on the upper layer with a flow rate of 1 m³;

- 40-90 m - deep trunks with a water flow rate 2 times greater.

A casing string made of metal or plastic pipes with a filter in the bottomhole part of the well is lowered into the drilled working. The water is lifted by a submersible pump.

Advantages and disadvantages

The main advantage is the auger drilling method, which allows you to build a well in 1-2 days without much effort. The mechanization of all operations is ensured by the design of the drilling rig on a self-propelled or mobile chassis.

Other advantages:

- water purity;

- a permit for the construction of a water intake is not required;

- service life - up to 30 years.

Disadvantages are noted in wells of shallow depth: the dependence of the flow rate on precipitation, the sensitivity of the water composition to surface contamination at the location of the mine. Another minus has already been identified - the tendency to silting of the water intake.

Characteristics of offshore drilling problems

Offshore drilling rigs face a number of problems that can significantly reduce the efficiency of the work performed.

The most basic problems include the following:

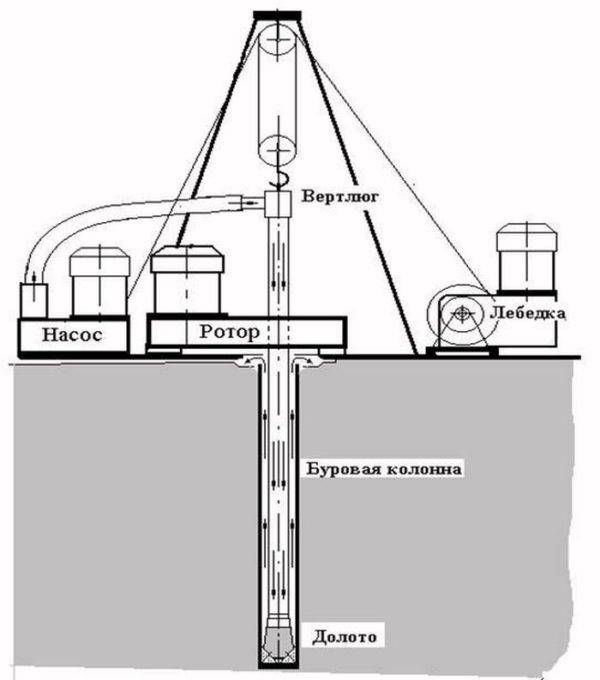

Drilling rig device

- drift and pitching of a mobile drilling rig;

- instability of loose rocks of the seabed sections at the drilling site, their strong watering;

- preservation of the cleanliness of the environment;

- the difficulty of organizing work on closed water circulation;

- the impossibility for the driller to see the near-bottom wellhead;

- premature failure of equipment, tools in an aggressive environment;

- selection of special schemes and methods of drilling, etc.

In addition, the well is filled with water to the level of the seabed. This leads to a weakening of the impact energy. Drift and undercurrents make it difficult to maintain a strict verticality of the percussion tool and weaken its immersion in the working rock.

Tools and fixtures for drilling a well

- Metal auger. The most common tool for building mines. It is applied to work on non-friable soils.The drill auger of factory production is two-way. This design will not allow you to take the tool to the side and skew it. The lower base is made with dimensions of 45-85 mm, the blade diameter is 258-290 mm.

- drill bit. Designed to work in hard rocks. With its help loosen the rock. The tip is cross and flat. It can be used with a shock bar.

- Boring spoon. It is used for digging wells in sandy soils, because. sand will not hold on a conventional auger. It is used for impact-rotary or rotational drilling.

- Drill glass (Schitz projectile). With its help, mines are created in viscous, highly sticky soils, in which a conventional rotary tool will get stuck. It is used in percussion drilling.

- Bailer. It is used for the passage of quicksand during shock-rope drilling.

- Well-needle. Used to create an Abyssinian well. In this design, the nozzle, rod and casing are a monolithic structure that remains underground after reaching the aquifer.

Often, several types of tools are used alternately for the construction of one well. For example, an auger, a bailer and a drill spoon are used to work on clay soils. For the passage of pebble layers - a bailer, a chisel and casing pipes.

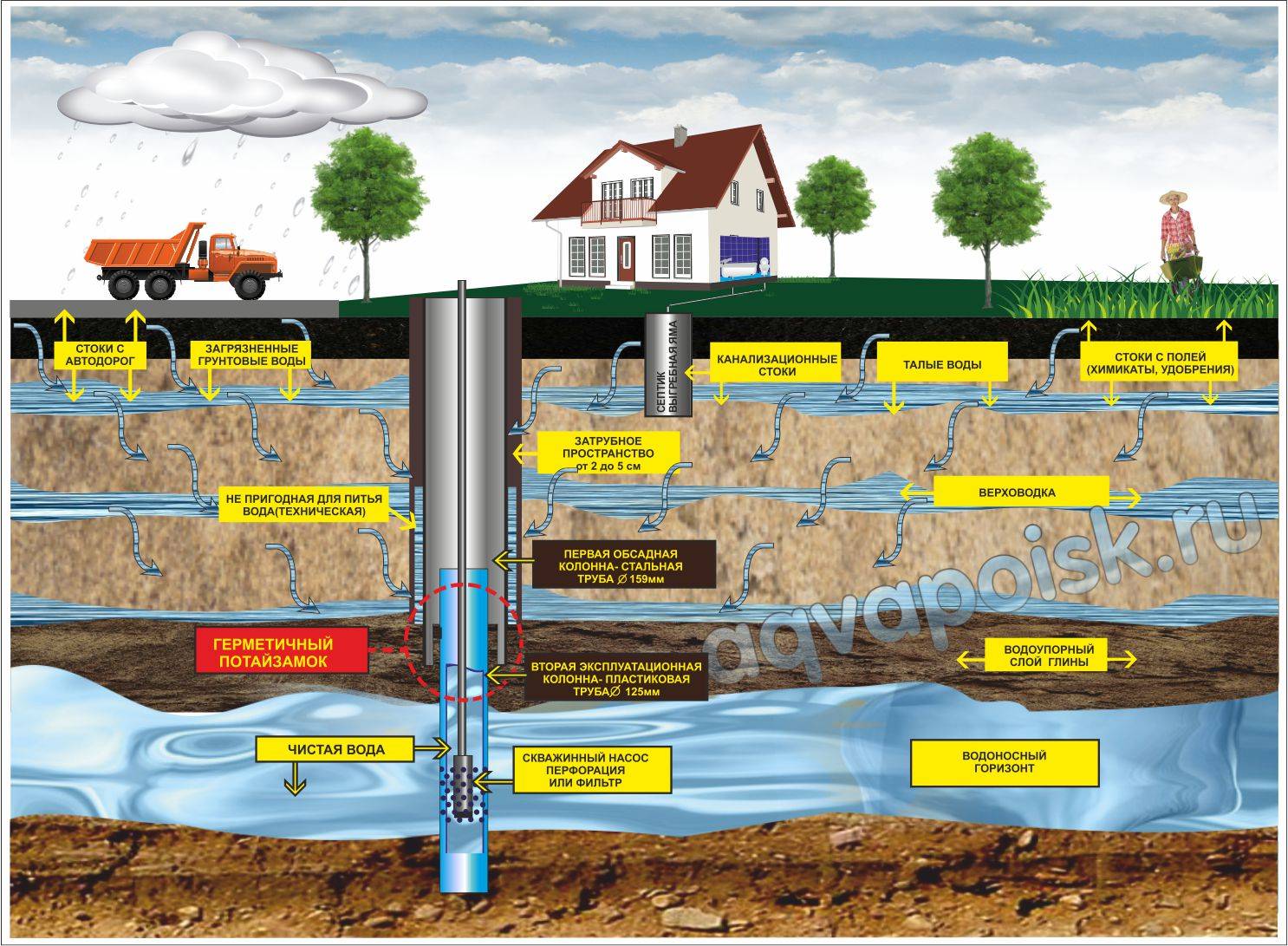

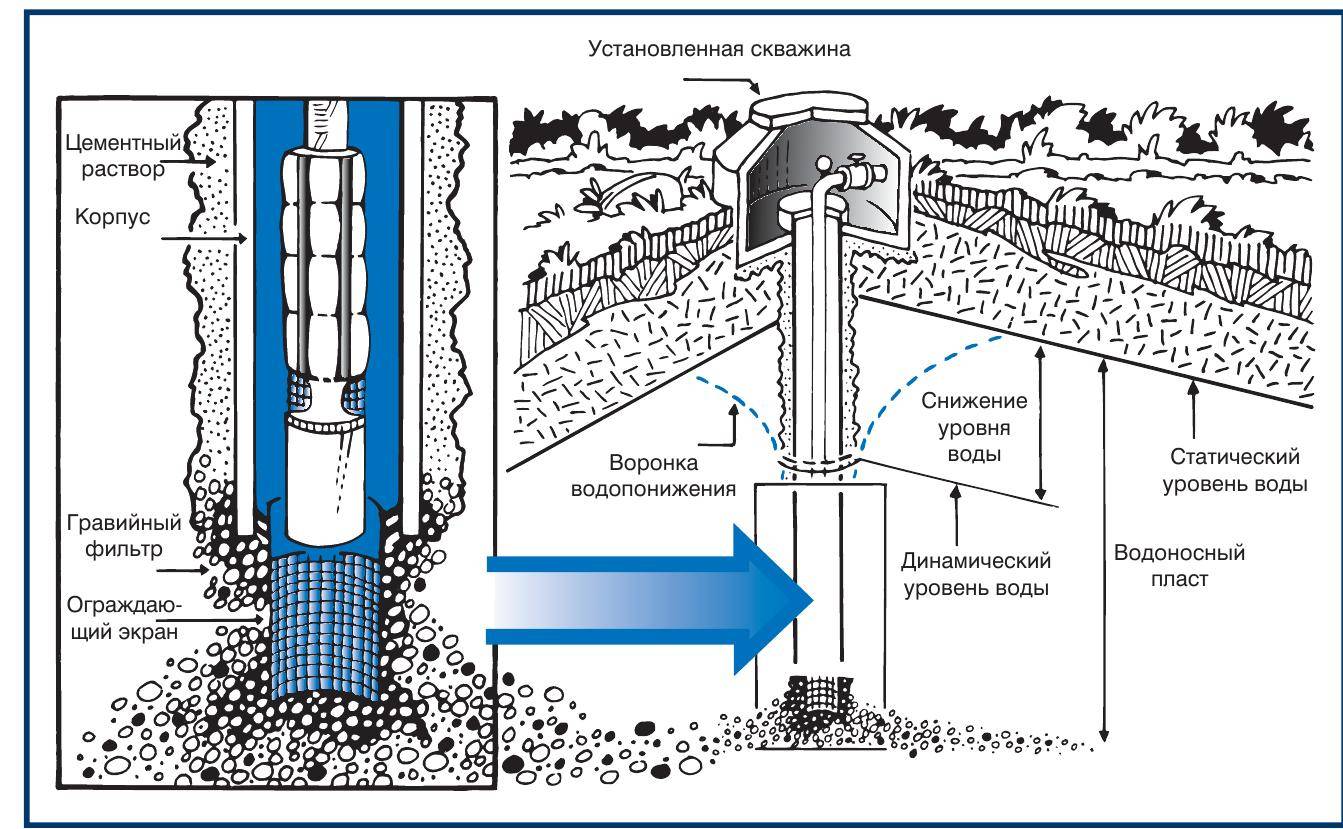

Classification of aquifers

The following main types of aquifers are distinguished:

- Verkhovodka. This is the name of water carriers located close to the surface of the earth (2-7 m). These are limited volumes of unpressurized water surrounded by water-resistant layers (eg clay). The liquid in them is, as a rule, of a precipitation and flood nature. The nature of accumulation is seasonal.The main advantages of such sources are: shallow depth, the possibility of lifting without a pump, low costs when drilling wells. The main drawback: poor water quality. The natural filter has a small thickness and is not able to completely clean the liquid. Various chemical compounds may be present in it, and therefore water is intended for technical purposes. For drinking it can be used only after additional cleaning and boiling. Another drawback is a decrease in flow rate (up to a complete cessation of water supply) in the hot season, as well as seasonal instability.

- Primer. The first permanent aquifer in the form of groundwater is located at a depth of 6-22 m. Such a layer is located between impervious layers or is limited only by the lower aquicludes and can reach significant sizes. It is formed as a result of seepage sediment and infiltration from water bodies. The water carrier can be of a pressure or non-pressure type. In the first case, the water is under pressure in it. The level of groundwater occurrence can undergo seasonal changes, decreasing in summer. Advantages: easy accessibility and ease of lifting to the surface. Water can be safely used for any household needs, but it needs to be filtered and boiled before drinking or cooking./li>

- Interstratal aquifers. These are water deposits, clogged between two water-resistant layers. They are located at a depth of 25-75 m and are always under pressure (pressure type). With an independent exit to the surface, interstratal accumulations create springs. The main advantage is the purity of the water. You can drink it. Disadvantages: deep occurrence, drilling difficulties, increased costs for well construction.Due to the presence of constant pressure, water is able to rise independently to a certain height. If it is not enough to reach the surface, then it becomes necessary to install pumping equipment.

Types of wells by profile

Before reaching the mineral, the mine can cross several layers of soil

It is important to choose the right method for drilling a well. Depending on the number of planes where the mine curves, there may be the following types of wells:

- curved in a plane;

- curved in space.

It depends on the curvature of the shaft. In this regard, the curvature in the plane can have the following varieties:

- an even pillar, ending in a slope at the bottom;

- S - shaped bend;

- J - figurative design.

These bends are formed as a result of different density of soil layers. In turn, the curvature in space can manifest itself in more complex geometric forms when drilling oil and gas wells. Water shafts are mostly made straight, bends can be used to bypass rocks.

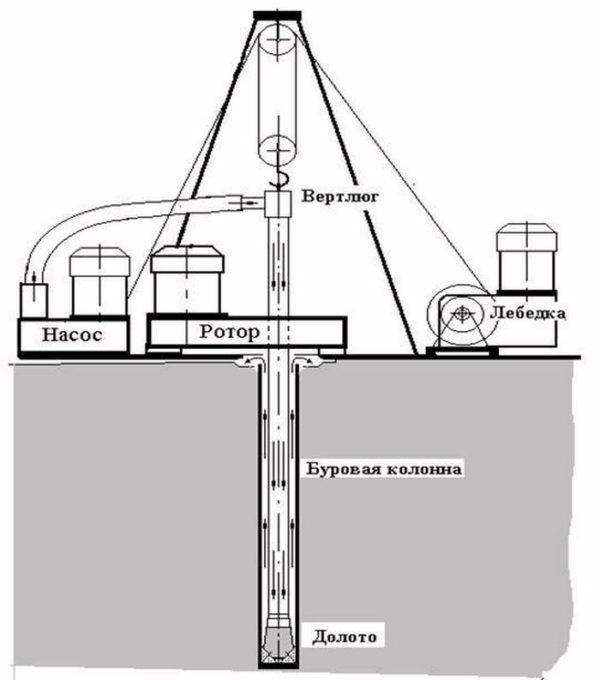

What technology is used most often

It all depends on the design depth of the well and the composition of the soil on the site. Based on the exploration data, the most optimal method is selected. You also need to understand how to find water for a well.

For drilling artesian wells, a rotary method is used. This method is the most justified economically, ecologically and gives wells of various depths and diameters in loose soils with rock inclusions.

Its essence is as follows:

- At the end of the rotor, driven by an internal combustion engine, there is a special drill. He crushes the breed.

- The well is supplied with pressurized water. It erodes the soil.

- Further, the water is discharged upward through the hollow channel of the rotor. This technology is also called "drilling with flushing"

- After installing a large diameter casing pipe, the work proceeds with a smaller drill bit.

- Upon completion of drilling work, it is necessary to produce the so-called. "declaying" of the well. This is necessary due to the fact that the water-clay solution clogs the pores through which artesian water will flow into the well.

The well gives you the opportunity to have a supply of water on your site for watering your plants in open-top polycarbonate greenhouses, information about which you can find here.

Rotary drilling is the most commonly used.

Advantages over other methods:

Afterword

The drilling masters who once mastered Tyumen and Urengoy are still alive. There were no geophysical equipment that builds a 3D picture of what is in the earth on a computer display, and there were no fully robotic drilling rigs then, but they already saw through the earth with their intuition, experience and were on “you” with all the spirits of the bowels. And the then ministers and members of the Politburo, who had more arrogance than the old Testament boyars and specific princes, addressed these aces as “you” by name and patronymic and respectfully shook hands with them.

So, any of the old bison drillers have unsuccessful wells on their account, which they are not shy about - such is the work. What then to say to beginners acting independently? Don't be discouraged by failure, if the first hole is empty, or collapses, or the drill gets stuck. Not without that in the drilling business.But annoyance and disappointment will instantly subside under a powerful pressure, as they say now, positive, as soon as your well gives water.

***

2012-2020 Question-Remont.ru

Display all materials with a tag:

Go to section:

Why is a well better than a well?

Previously, issues were resolved in only one way - a well was dug, water was carried into the house in buckets. Later, they began to use the simplest submersible pumps, they descended into wells and pumped water into large containers, and from them it was fed into the house by gravity. But this technology has many disadvantages.

The well has significant advantages over the well

The well has significant advantages over the well

- In winter, the containers had to be insulated very efficiently, and even such measures did not guarantee the safety of water.

- Slight pressure did not allow the use of washing machines and other household appliances that use pressurized water.

- The well contains water from shallow layers. It does not meet the existing requirements of SanPiN in many respects. Especially today, when the ecological situation has deteriorated significantly.

- During floods, heavy snowmelt, heavy rains, dirty water from the surface of the earth fell into the well, which made it impossible to use it for a long period of time not only for cooking, but also for domestic needs. I had to completely pump out the water several times and disinfect it.

- Dirt gets into the well, it silts up, it has to be cleaned periodically. This is physically very difficult work, only professionals can do it.

The main disadvantages of the well are due to its shallow depth.

The main disadvantages of the well are due to its shallow depth.

Today there is a great way to solve all problems - to drill a well, and the greater its depth, the better the quality of the water.

Production of drilling tools

As mentioned earlier, drilling tools can be made on your own, borrowed from friends, or purchased commercially.

Sometimes a drilling rig can be rented. However, the goal of self-drilling is usually to keep costs as low as possible. The easiest way to drill cheaply is to make tools from scrap materials.

The diagram shows the arrangement of various drilling tools. With the help of a chisel, especially hard soil can be loosened, and then it is removed with a drill, bailer or other device.

Option #1 - Spiral and Spoon Drill

Manual drilling can be done with a spiral or spoon drill. For the manufacture of a spiral model, a thick pointed rod is taken, to which knives are welded. They can be made from a steel disk cut in half. The edge of the disk is sharpened, and then the knives are welded to the base at a distance of about 200 mm from its edge.

A do-it-yourself drill for auger drilling can be of different designs. Its obligatory elements are knives with pointed edges and a chisel installed at the bottom.

Knives should be located at an angle to the horizontal. An angle of about 20 degrees is considered optimal. Both knives are placed opposite each other. Of course, the diameter of the drill should not exceed the diameter of the casing. Usually a disc with a diameter of about 100 mm is suitable. The knives of the finished drill should be sharpened sharply, this will facilitate and speed up drilling.

Another version of the spiral drill can be made from a rod and a strip of tool steel.The width of the strip can vary between 100-150 mm.

Steel should be heated and rolled into a spiral, hardened, and then welded to the base. In this case, the distance between the turns of the spiral should be equal to the width of the strip from which it is made. The edge of the spiral is carefully sharpened. It is worth noting that it is not easy to make such a drill at home.

A spiral auger for drilling can be made from a pipe and a steel strip, however, it is not always easy to roll the tape into a spiral, weld and harden the tool at home

To make a spoon drill, you need a metal cylinder. In conditions of self-manufacturing, it is easiest to use a pipe of a suitable diameter, for example, a 108 mm steel pipe.

The length of the product should be about 70 cm, it will be difficult to work with a longer device. On this case, a long and narrow slot should be made, vertical or spiral.

A homemade spoon drill is easiest to make from a piece of pipe of a suitable diameter. The lower edge is folded and sharpened, and a hole is made along the body for cleaning the drill

Two spoon-shaped knives are mounted in the lower part of the body, the cutting edge of which is sharpened. As a result, the soil is destroyed by both horizontal and vertical edges of the drill.

The loosened rock enters the cavity of the drill. Then it is taken out and cleaned through the slot. In addition to knives, a drill is welded along the axis of the device in the lower part of the drill. The diameter of the hole made by such a drill will be slightly larger than the device itself.

Option # 2 - bailer and glass

To make a bailer, it is also easiest to take a metal pipe of a suitable diameter.The wall thickness of the pipe can reach 10 mm, and the length is usually 2-3 meters. This makes the tool heavy enough so that when it hits the ground, it is effectively loosened.

A shoe with a petal valve is attached to the bottom of the bailer. The valve looks like a round plate tightly closing the lower section of the pipe and pressed by a sufficiently powerful spring.

However, a too tight spring is not needed here, otherwise the soil simply will not fall into the bailer. When the bailer is pulled out, the valve will be pressed not only by the spring, but also by the soil collected inside.

The lower edge of the bailer is sharpened inwards. Sometimes sharp pieces of reinforcement or sharpened pieces of triangular metal are welded at the edge.

A protective mesh is made from a thick wire on top and a handle is welded to which a metal cable is attached. A glass is also made in a similar way, only a valve is not needed here, and a slot should be made in the body to clean the device.