- How to make a large hole

- How to drill a hole in porcelain stoneware

- Drilling instructions win

- Core drilling tips

- Working with a ballerina

- How to drill through tiles with hole saws

- Method for wetting a diamond crown on a tile

- Why are diamond crowns moistened with water?

- Making an accessory

- Application

- Material characteristic

- Diamond technologies in construction - drilling and cutting of concrete

- Selection of crowns by parameters

- By diameter and length

- According to the method of drilling and type of fastening

- How to drill through tiles with hole saws

- What is a crown for concrete and why is it needed

- Leading manufacturers

- Models

- How to drill?

- small holes

- Large holes

- Drill all the way?

- Cooling

- Crowns for diamond drilling: varieties, features of choice

- Matrix

- Segment

- KS standard crowns

- How to choose the right high-quality and reliable diamond core bit for socket boxes

- Video - Test and comparison of diamond drill bits for socket boxes

How to make a large hole

Finally, I would like to consider in more detail the options for how to make a significantly larger diameter of the recess. Let's analyze the algorithm of work in order:

| First step | Establishing the center of a particular tile where you are going to carry out further manipulations.After the center is determined, it is worth drawing a circle of the required size. |

| Second step | Using a special drill for ceramics. On the inside of the material, along the previously drawn circle with a narrow tip, we make holes close to each other. |

| Third step | Extraction of the inner part of the circle. |

| Fourth step | This is the elimination of uneven edges, using special grinding devices. |

Remember that this must be done very carefully, trying not to damage the surface, and so that the plate does not crack.

In the end, I would like to mention tungsten heads, which, unlike diamond ones, are much cheaper, have a center drill and do not require water cooling during operation. However, the cutting quality of diamond coating is much higher.

How to drill a hole in porcelain stoneware

It should be understood that porcelain tiles cannot be processed over a canopy. That is, the method in which the workpiece is fixed on the workbench in such a way that its processed part hangs above the floor is unacceptable. Otherwise, during the drilling process, the material will split into pieces.

Instagram @grestool

The hole must be located as far as possible from the edge. The recommended minimum distance from it is 1.5 cm. If drilling through is not required, it is advisable to make a mark on the drill in advance, to which it must reach during operation.

When using a perforator, you need to turn off the impact mode in a timely manner, otherwise the finish will be hopelessly damaged.

Drilling instructions win

When using drills with a pobedite tip, it is necessary to set the rotation speed of the drill or screwdriver to 500 rpm. If we are talking about working with a diamond drill, then the optimal speed for it is 1500 rpm.In both cases, so that the tool does not slip on the surface of the tile, it is better to seal the processing area with masking tape.

Before drilling on the wall, gently tap it: if the sound gives out the presence of voids, the work will have to be abandoned, since such a finish will not withstand processing. It is undesirable to touch the seams - this is fraught with the appearance of cracks. In extreme cases, the hole must be made strictly in the middle of the joint.

As soon as the drill goes through the tile and reaches the concrete, change the drill to one that is designed specifically for this material. Unless, of course, there is a need to go deeper. The last two recommendations also apply to tiles laid as a floor finish.

When working on a workbench (or table), porcelain stoneware should be firmly fixed and make sure that there is a solid substrate (plywood or drywall) under its entire area.

The video shows the process of drilling with a win.

Core drilling tips

The formation of holes using diamond cylinders is not much different from similar operations with drills. And yet, there are some features.

Instagram @grestool

Thus, the recommended rotation speed of crowns depends on their diameter. If it is not more than 3 cm, the drill must be set to 800 rpm. A tool with a large diameter (from 6 cm) is best used at a speed of 400 rpm.

It's good if the model has a center drill - it will help hold the drill in place. In its absence, it is better to make a special template: cut a hole of the desired size in a plywood or plasterboard sheet.

Instagram @rzn_plitochnik

The finished stencil should be applied to the surface to be treated, fixed and started drilling in it.After you manage to delve into the material at least a millimeter, plywood can be removed.

Watch a video on how to properly drill a tile with a crown.

Working with a ballerina

The first step is to fix the cutter of the device at that distance from the axial stand, which will correspond to the required hole radius. The distance can vary from 15 to 45 mm. Before drilling, it is recommended to make a small indentation in the center of the circle to be cut. It will help to correctly install the ballerina and avoid its displacement in the future.

In places where processing is expected, the surface of the material should be lubricated with machine oil (excluding the hole in the center).

Having fixed the device in the drill chuck, you can start drilling at low speeds

It is very important not to apply too much force. Excessive load on the cutter can damage the tile or break the tool

In addition, you need to firmly hold the drill in your hands, avoiding its distortions, otherwise the process will go unevenly: some part of the intended circle will be cut out, and some will not. So that the working elements of the ballerina do not overheat, drilling must be carried out with periodic stops.

Instagram @plitochnik_vologda

To successfully work with the device requires some experience. If you are using this device for the first time, it would be a good idea to start with a little practice on some unnecessary workpiece.

How to drill through tiles with hole saws

Step-by-step instructions for tiles not glued to the surface:

- Take an electric drill and set it to low speed;

- Take the crown and secure it in the chuck;

- Mark the drilling site;

- Fix the tile on a flat surface;

- Stick adhesive tape on the drilling site;

- Start "drilling";

- Using even pressure, drill through the tile and drill through the entire thickness.

Step by step instructions for tiles glued to the surface:

- Take an electric drill and set it to low speed;

- Take the crown and secure it in the chuck;

- Mark the drilling site;

- Stick adhesive tape on the drilling site;

- Start "drilling";

- Using even pressure, drill through the tile and drill through the entire thickness.

When choosing a cutter for drilling material, you must first of all proceed from the density of the material, the surface of the crown must be harder than the surface of the tile itself. The work itself is not difficult, but skills are needed in marking the place of the cut, starting drilling and performing the drilling process itself.

Method for wetting a diamond crown on a tile

At present, the availability of professional power tools and various accessories has made it possible to carry out professional repairs in everyday life on their own.

This requires compliance with many non-obvious rules for working with the tool. One of these rules is the temperature regime for the use of diamond crowns.

Let's talk about how you can use a diamond crown on a tile so that it is effectively wetting.

Why are diamond crowns moistened with water?

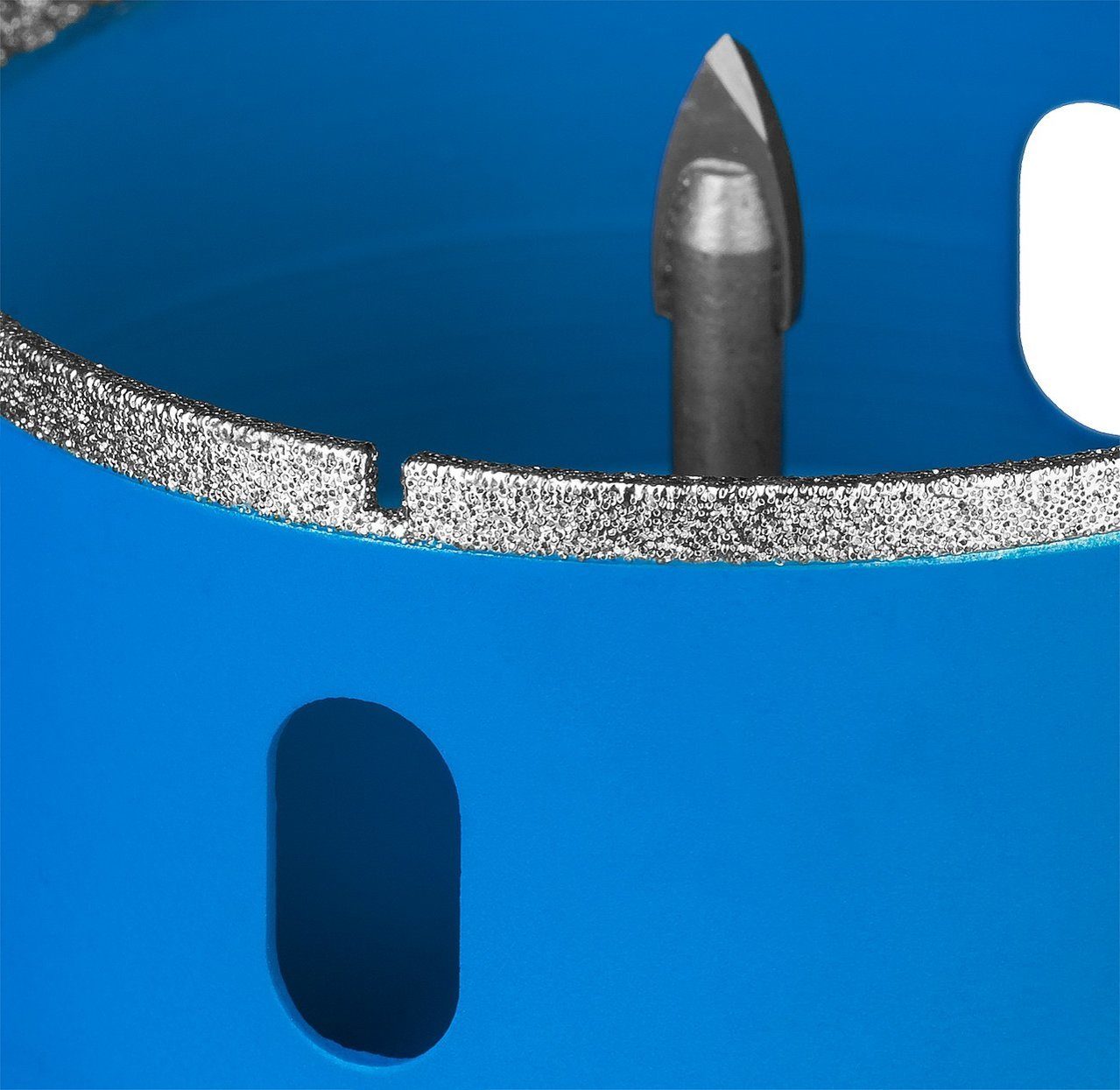

Wetting the diamond crown with water is necessary first of all to remove heat from the heated crowns. Heating occurs when drilling holes in both ceramic and porcelain tiles.Diamond grains (average size 0.15 ... 0.5 mm) are micro-cutters, which "select" the drilled material.

The matrix of the crown, consisting of hard alloys with diamond grains placed in them, wears out when in contact with the drilled material with heat generation. The harder the material is drilled, the more heat is generated.

Excessive heating leads to the destruction of both the points of attachment of the diamond segments to the body of the crown, and the matrix itself.

The welding of the diamond segments with a laser makes the diamond core bits particularly resistant to heat and allows drilling both with water and dry. Formation (sintering) of the segments directly on the body of the crown also allows dry drilling.

For some types of diamond crowns, such a type of operation as the opening of diamond segments is necessary before starting work. The opening is carried out “dry”: when drilling, for example, a brick, the matrix binder material is chipped and the diamond grains are exposed. After that, the crown is ready for work.

Currently, manufacturers indicate the purpose of crowns by materials and drilling modes, including dry and wet cutting options.

In addition, if you use "advanced" conductors with water supply, you can remove the suspension of drilling products, thereby extending the life of the crown.

Making an accessory

You can use a regular household dishwashing sponge to make this accessory. Its volume is approximately equal to (80x60x40) 190 ml. The absorbent properties of the sponge are such that the entire volume returns about 50 ml of water.

Let's estimate the internal volume of a diamond crown, for example, from the "set of diamond crowns for porcelain stoneware Enkor 9457": 20 ml for a diameter of 25mm, 64 ml for Ø44mm, 176 ml for Ø73mm.

If these volumes are filled with a sponge soaked in water, the water return will be as follows: 5 ml for Ø25mm, 16 ml for Ø44mm, 45 ml for Ø73mm. These are the volumes of the water that will fall on the matrix during drilling.

If there is a centering drill, then the sponge is simply pierced with it. The seal is necessary so that the sponge soaked in water does not fly out of the bit during the start of work with horizontal and vertical (down) drilling.

In addition, smaller capillary passages will better retain water in the sponge.

Application

Starting position: the crown looks up with the cutting part. Water is poured just below the cutting segments. When a drill, screwdriver or perforator takes the working position, some of the water will pour out.

You should not make shaking movements.

Then the usual drilling with a diamond crown of porcelain stoneware begins: without using the perforation mode (if it is a perforator), at the appropriate speeds - reduced (3-6 hundred revolutions per minute).

Water from the sponge due to centrifugal forces during the rotation of the crown will flow down the inner walls of the crown and fall into the cut zone. The presence of water, and hence the temperature of the crown in the area of the matrix, should be controlled by the absence or presence of steam. Normal thicknesses of porcelain stoneware (7mm) are passed in no more than 3 minutes with crown diameters up to 73mm.

It should be borne in mind that all passes must be made with one crown (each time adding water), otherwise there is a risk of destruction of the matrix from the geometric mismatch of the two crowns.

The use of a wet foam sponge inside the bit when drilling ceramic and porcelain tiles is quite justified, as it allows you to achieve a controlled and gentle drilling mode for the diamond bit.

- Sergey Petrov

Material characteristic

The hardness and high strength of porcelain stoneware is provided by the raw materials from which it is made and the production method itself. First, granite chips are mixed with clay, then the mixture is pressed under high pressure and fired. As a result, the plate is not afraid of overloads, has a high density and is not subject to deformation. However, despite its high strength, the material is brittle during machining, which creates difficulties during drilling and requires a delicate approach to business.

Taking into account the qualities of the material, it is often used for finishing the floor in industrial enterprises and premises where a large crowd of people is constantly observed. In everyday life, porcelain stoneware is used for facing stairs and pools, creating facades and fences, as well as for installing communication systems.

Diamond technologies in construction - drilling and cutting of concrete

Construction in the 21st century involves the creation of structures of high strength, which are designed to be used for decades. For this reason, during the construction of walls, monolithic concrete is used, which can withstand high loads without problems, and there is no doubt about its strength. But in connection with this, another problem arises - in such material it is quite difficult to make a hole for communications. There are several options for solving this problem, but the most efficient and economical is drilling concrete with diamond core bits.

For diamond drilling in concrete, you will also need:

This is interesting: What is the difference between enamel and paint - a detailed comparison of the compositions

Selection of crowns by parameters

It’s difficult to take everything into account the first time, but you can’t do without attention to the main parameters.

By diameter and length

The standard range of socket box diameters is 60, 68, 72 mm. The spread of the depths of the boxes is from 40 to 80 mm (deep socket box).

For a socket box 68 (outer diameter) by 45 (installation depth) you need a hole:

- with a diameter of 72–76 mm (with a margin for mortar) - a smaller margin for “diamond”, a maximum for Pobedit;

- 45–50 mm deep - it is better not to make a larger margin, taking into account thin walls. Adjust the depth using the mark on the body of the nozzle or extension.

If the length of the assembly is not enough to obtain the desired depth, there are two options:

- immediately select a long holder;

- complete the set with a drill bit extension for concrete or a second holder.

According to the method of drilling and type of fastening

The type of drilling is selected taking into account the recommendations in the table:

With Pobedite and carbide, everything is simple, the situation is a little more complicated with the choice of the operating mode for diamond nozzles.

The manufacturing technology and design of "wet" and "dry" diamond crowns is different. The manufacturer's recommendations regarding the mode can be found on the packaging. At the same time, nozzles for dry drilling can work in a “wet” mode, but not vice versa.

Crowns compatible with hand-held power tools are equipped with 3 types of shank holders:

hexagonal - this is more often completed with tungsten carbide crowns for concrete on a drill (regular or impact) |

SDS-plus - for household rotary hammers."Traditional" shank for concrete crowns with a diameter of up to 100 mm |

SDS-max - for powerful hammers and drill bits for concrete from 100 mm |

If necessary, you can use adapters, for example:

SDS-plus for hexagon |

SDS-max on SDS-plus |

Often, professional nozzle manufacturers indicate the recommended power of the tool on the packaging.

How to drill through tiles with hole saws

Step-by-step instructions for tiles not glued to the surface:

- Take an electric drill and set it to low speed;

- Take the crown and secure it in the chuck;

- Mark the drilling site;

- Fix the tile on a flat surface;

- Stick adhesive tape on the drilling site;

- Start "drilling";

- Using even pressure, drill through the tile and drill through the entire thickness.

Step by step instructions for tiles glued to the surface:

- Take an electric drill and set it to low speed;

- Take the crown and secure it in the chuck;

- Mark the drilling site;

- Stick adhesive tape on the drilling site;

- Start "drilling";

- Using even pressure, drill through the tile and drill through the entire thickness.

When choosing a cutter for drilling material, you must first of all proceed from the density of the material, the surface of the crown must be harder than the surface of the tile itself. The work itself is not difficult, but skills are needed in marking the place of the cut, starting drilling and performing the drilling process itself.

What is a crown for concrete and why is it needed

Nozzles for power tools for concrete are periodically required in every home. But for everyday tasks enough:

Concrete drills compatible with conventional or impact drills. The drill allows you to make a small (3–16 mm) hole up to 60 cm deep;

Perforator drills with SDS tips.In impact mode, you can drill a hole with a diameter of 4–40 mm and a depth of up to 1 m.

A crown for concrete is a highly specialized nozzle for a puncher or drill that allows you to make a hole or recess with a diameter of 40 mm to 120 mm in:

- light and heavy concrete (types);

- brick or stonework.

In general, the nozzle is used for:

- laying communications - water pipes (in the bathroom, toilet and kitchen), heating and sewerage, gas pipelines;

- making channels for entering cables and cable lines into the building - for connecting the house to electricity, communication lines (Internet) or creating a warm floor;

- installation of large fasteners (foundation anchor bolts) or fences.

During the "normal" repair, the crown is more often used in the preparation of sockets for wiring boxes (sockets).

Leading manufacturers

Of the domestic inexpensive brands worth noting:

- Bison;

- Practice;

- Anchor.

- Trio-Diamond (diamond tool).

DiStar products (Eastern Europe) can be attributed to the number of relatively inexpensive products.

Professional level tools offer:

- Keos (South Korea), the company specializes in diamond tools;

- Messer Cutting Systems is a brand of German origin with over 130 years of history;

- Makita and Bosch.

Chinese-made products (Hagwert, Matrix, Sibin, Stayer) are rated as "unpredictable". The best samples are comparable with domestic ones, and the worst ones break on the first hole.

When laying or transferring electrical wiring, the crown wins in simplicity and speed in comparison with the drill. For amateur work, a minimum experience with power tools is required, it is enough:

- know how to choose and install a nozzle;

- comply with standard safety rules.

Share

tweet

Pin it

Like

Class

whatsapp

Viber

Telegram

Models

Of all the companies selling crowns and other materials, two companies are most popular and common:

Anchor. Crowns can be purchased individually or as a whole set. The set consists of 9 diamond products, to work with them you will need a drill of the same brand. Spraying method - galvanic. Good segments for "wet" drilling provide an excellent supply of water to the cutting zone. Also in crowns there are segments for "dry" drilling. The set includes crowns with a diameter of 25, 29, 38, 44, 70 and 73 mm. In addition, crowns of this brand can be 68, 35, 32, 54, 20, 57 and 83 mm in diameter. The price of such a set is from 1500 to 2500 thousand rubles.

How to drill?

Making a hole in porcelain stoneware is much easier than it might seem at first glance. There are several rules that must be followed to obtain a quality result. They will also help to avoid early breakage of the crown:

Pay attention to the cooling of the crown during operation. The most important thing you must do is not let the crown heat up above the permissible temperature.

Be sure to use a backing

Larger plywood or chipboard can be used. Such a simple solution will protect materials from possible damage, provide additional safety during operation.

- Start making a hole from the front side and constantly make sure that the drill bit goes smoothly into the porcelain stoneware. When the crown comes out, a small chip is always formed, which is not desirable on the decorative surface.

- Using crowns with a central drill will save you from many mistakes.

- It is recommended to drill not to the end, but to 2/3 of the plate. Then it remains only to knock out the porcelain stoneware cork.

- Do not apply too much pressure on the drill as this may cause the tiles to split. Closer to the end and minimize the impact altogether.

- Carry out drilling work before installing the plate. This way you can always correct random errors.

Small holes are usually made for dowels. Large - suitable for mounting sockets, pipes or decorative elements. For drilling, it can be used as a drill, as well as a hammer drill with the percussion off.

small holes

In order to make a hole in porcelain stoneware with a diameter of up to 10 mm, get drills with a diamond tip. During operation, be sure to ensure an uninterrupted supply of fluid to the drill tip. This will cool down and the drill will stay sharp longer.

Position the drill at a 90 degree angle while drilling. To fix this position, use holders or a special machine. At the beginning of work, you need to bring an already turned on drill to the porcelain stoneware, otherwise the drill will slip and damage the decorative layer of the tile.

Large holes

The principle of drilling large diameters is no different from conventional work. Only here you will already need diamond crowns for porcelain stoneware. Also keep the drill at an even angle and do not forget about the coolant.

Drill all the way?

When working with porcelain stoneware, both through drilling and incomplete drilling are acceptable. The last option requires special attention. Make a hole 2/3 of the desired depth and knock out the remaining cork with a sharp blow.You need to strike only from the front side of the tile. In this case, a noticeable chip is formed on the back of the panel.

Once you've started drilling, don't stop. During the operation of the drill, the oil and spraying heat up, if you stop, they will harden again. Such a rash decision will adversely affect both the crown and porcelain stoneware.

Cooling

When carrying out drilling work crowns with diamond coating get very hot. Because of this, the product deteriorates. With a one-time use, you may not notice this in vain, but soon the defect will manifest itself.

Due to overheating, the characteristics of the drill first deteriorate, and then destruction occurs altogether. As a result, you will receive a new crown.

Cooling during the work will ensure a longer and better work of the crown. To do this, use one of the methods:

- Constant flow of water. For this method, you can get a tool that has a built-in water supply function. You can also be smart and supply water from outside. This is not always convenient if you are making a small hole.

- Puddle. Make a puddle in place of the future hole. Add water as needed while working. This cooling option is easier than the previous one, but also less efficient.

Evaluating all the nuances of the work, we can conclude that using diamond crowns when drilling porcelain stoneware is quite feasible at home.

Learn more about diamond crowns in the next video.

Crowns for diamond drilling: varieties, features of choice

Three types of diamond core bits are most commonly used.

Matrix

Matrix bits for diamond drilling consist of bodies, shanks and matrices coated with diamond grit. To ensure optimum drilling results and slow tool wear, the hardness of the die must match the properties of the material to be machined.

Photo No. 2: matrix diamond crown

-

For processing structures made of soft materials (limestone, etc.), masters take crowns with hard matrices based on tungsten.

-

When drilling materials of medium hardness (concrete, etc.), tools with matrices of cobalt, nickel and iron are used.

-

For processing hard materials (ceramics, natural granite, porcelain stoneware, etc.), crowns with soft matrices based on tin or bronze are taken.

Note! The harder the structure to be machined, the smaller the diamond grains should be.

Segment

Most often used. The working parts of such diamond crowns have special segments. They are made from diamond chips and metal powder (this mixture is called a binder) using sintering technology.

Photo #3: Segment type diamond crown

The ligaments used for the manufacture of segments are divided into three types.

-

Solid. The base is tungsten carbide.

-

Medium hardness. The basis is steel, cobalt or nickel.

-

Soft. The base is bronze or tin.

Segments derived from such bundles are classified in the same way.

Crowns with hard segments are used for drilling building blocks, limestone and sandstone, with medium hard segments - reinforced and unreinforced concrete structures, with soft segments - ceramics, quartz and granite.

KS standard crowns

Their cutting edges are coated with polycrystalline diamonds.They are applied using a special spraying technology that significantly extends the life of the tools.

Photo No. 4: KS standard diamond crown

These bits are designed for installation on large industrial drilling equipment.

How to choose the right high-quality and reliable diamond core bit for socket boxes

A huge number of diamond crowns of different brands are now presented in construction stores and markets, for a variety of preferences and any budget. Most people, when choosing a diamond crown, take into account, of course, the price.

But first of all, you should pay attention to:

- internal thread;

- socket size;

- what materials to work with;

- what holes are planned to be drilled.

Video - Test and comparison of diamond drill bits for socket boxes

It is better to give preference to diamond nozzles of trusted brands. For the democratic segment, these are the firms Zubr, Wolverine, Praktika, Diam. If you need a more powerful device for professional drilling of durable reinforced coatings, you should consider Bosh, Makita, Hilti.