- Gas stove in a Russian steam room

- Structural solutions for metal furnaces

- closed system

- open system

- Combined system

- Construction materials

- Who needs?

- Where to put the stove in the bath?

- The location of the stove in the bath with a separate steam room

- Stove in a bathhouse with a washing room and a steam room

- Video

- Do you always need a foundation for a furnace?

- Design features that you must observe when building a sauna stove

- metal oven

- Drawings and options for making a stove for a bath from a pipe

- vertical oven

- Related video

- Horizontal oven

- Related video

- Tips for stove-makers on how to improve the stove in a bath from a pipe

- What parameters to look for when choosing a furnace?

- Specialized classification of stoves for baths and saunas

- A simple metal stove-heater for a bath

- Do-it-yourself round stove for a bath

Gas stove in a Russian steam room

In fact, if we are talking about a brick oven, then the difference in the design of wood and gas options is small - it lies only in the presence of a gas burner where firewood would burn.

The combustion temperature of natural gas is much higher than that of firewood. However, it is easier to regulate (and even more so if the oven is equipped with control devices). Therefore, in principle, it is quite realistic to achieve the desired conditions with the help of such a unit.

IMPORTANT! Perhaps some owners will find the combined option profitable: a gas-wood stove.

In addition to brick, there are also metal gas stoves. They are also put in baths, but they are not worth mentioning for the reasons already mentioned - the material and design are more important than fuel.

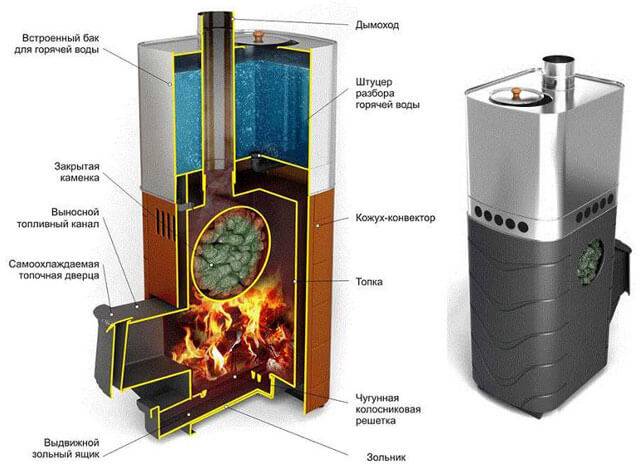

Structural solutions for metal furnaces

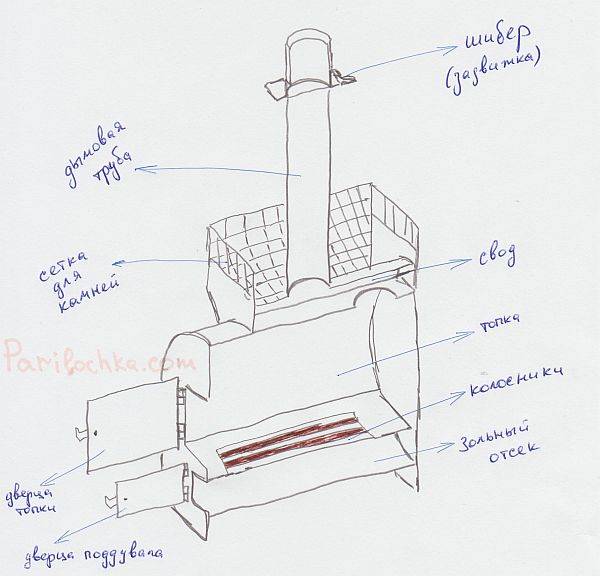

The classic device for a metal bath furnace includes the following list of nodes:

- furnace for fuel combustion;

- coil for heating water;

- pallet with stones;

- for wood-burning units - grates and an ash pan for collecting waste;

- a gas stove for a bath is equipped with a burner system and automatic control and monitoring;

- chimney for the removal of combustion products.

An electric sauna stove is much simpler - it does not have a firebox. Instead of burners or a firebox for firewood, there are several heating elements. Their heat is directly transferred to the stones and the air in the steam room. Metal units, due to the ease of processing of this sheet material, are today offered in the largest set of structural solutions.

closed system

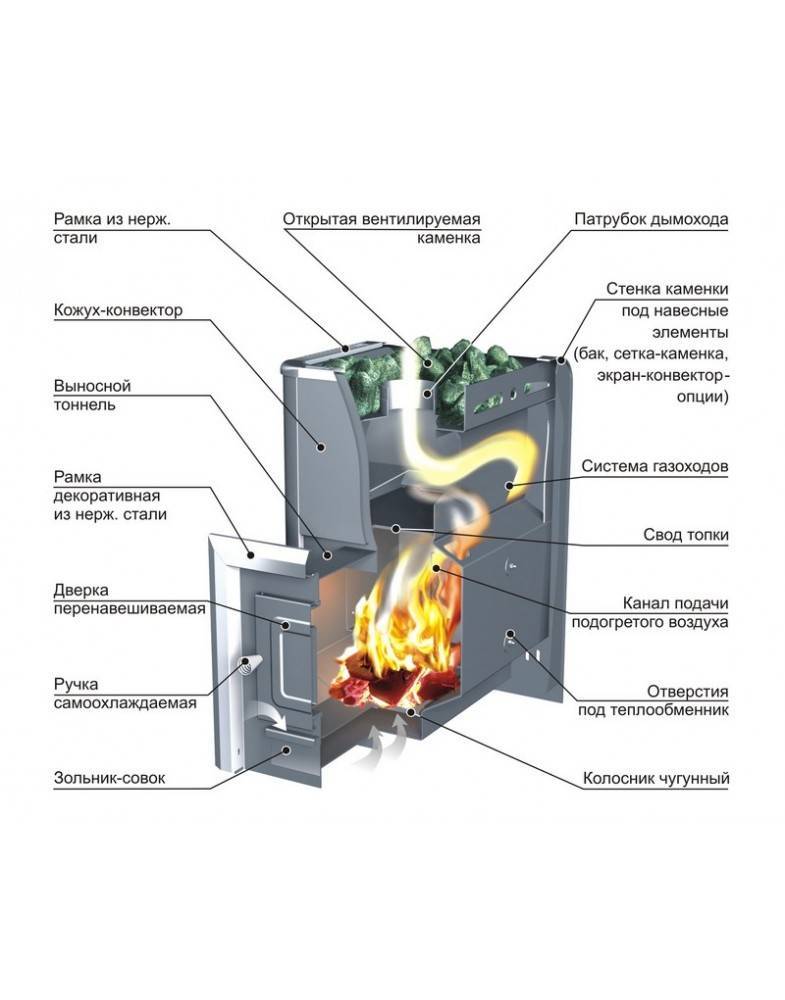

A safe metal stove is called a closed stove heater. The body of the unit is divided into three main functional areas.

- Firebox for firewood, container for collecting ashes, blower. Here the imagination of engineers knows no bounds. You can buy a stove with a cast-iron firebox or with additional devices for high-quality fuel combustion.

- Actually, a sauna heater. This is a closed compartment where stones are placed. Depending on the specific design solution, they can be heated by convection or open flame.

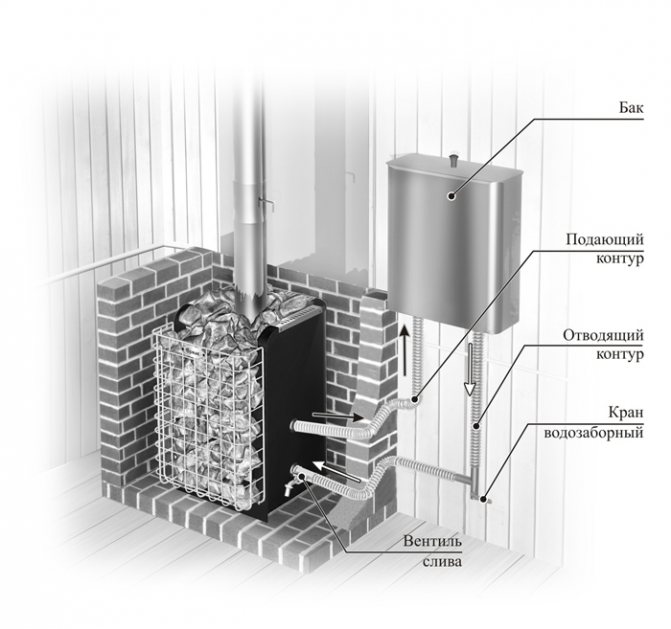

- Reservoir for heating and supplying water, as well as accessories.

The last point is worth a closer look. The so-called light steam is obtained by irrigating stones with water heated to less than 100 degrees Celsius.But to achieve a truly lively, hot, fine mist is possible only at a very high temperature. The stones are heated up to 500 degrees Celsius. When water enters, a huge amount of steam is formed. It is thrown out with great speed and carries great danger.

To avoid burns in the steam room, stoves with a closed heater are made with a heat exchanger. Its task is to supply water and release steam in a direction that is safe for visitors to the steam room.

The advantages of a closed system are many:

- security is provided;

- there is a lot of steam, it creates a lot of humidity;

- lined with bricks inside and outside the body, a closed metal furnace has good thermal inertia. Heated, it does not cool down for a long time.

Advice! This type of construction is an ideal choice if you want to create a real Russian bath. A closed stove moderately heats the air, so the steam room fulfills its main purpose. It acts on a person with hot, moist steam, with optimal comfort indicators.

open system

The open-hearth stove offers a symbiosis between a classic Russian banya and an overheated Finnish sauna. The design consists of a box for fuel or nozzles, as well as a grate for laying stones. The latter is located at the very top of the furnace.

When an open stove is operating, a lot of heat is transferred to the air in the steam room. It can warm up to temperatures over 100 degrees. This creates a feeling of dry heat and very active steam.

Advice! Such a metal stove is the perfect choice for those who like the heat more.

Combined system

As the name implies, a combined metal stove consists of several segments of a closed and open heater.Typically, the design solution is performed as follows:

- there are several chambers for fuel combustion, double valves and a blower;

- one block is a structure with a closed heater;

- the system with an open heater is implemented in the simplest way - the cobblestones are laid directly on the lid of the body, around the chimney coming out of it.

The combination oven is suitable for families with different preferences. By adjusting the rate of combustion of fuel in certain chambers, it is possible to get or moderate temperature at very humid steam, or warm up well, intensively warming the air.

Construction materials

Casting a cast-iron frame at home will not work, so steel will be the material. Several design options for steel bath furnaces have been developed:

- Welded frame made of sheet metal;

- From a pipe;

- From disks from automobile wheels.

Usually the material that is easiest to purchase is chosen.

If these are sheets, they must be at least 8 mm thick. If the pipe is about 50 - 60 cm in diameter.

You will also need:

- Grate (this can be a finished product or fittings from which the grate is manually welded)

- Door for the firebox, for the blower (you can do it yourself).

- Latch on all doors.

- Tap.

- Chimney pipe, about 2 m high, with a diameter of 12 - 15 cm.

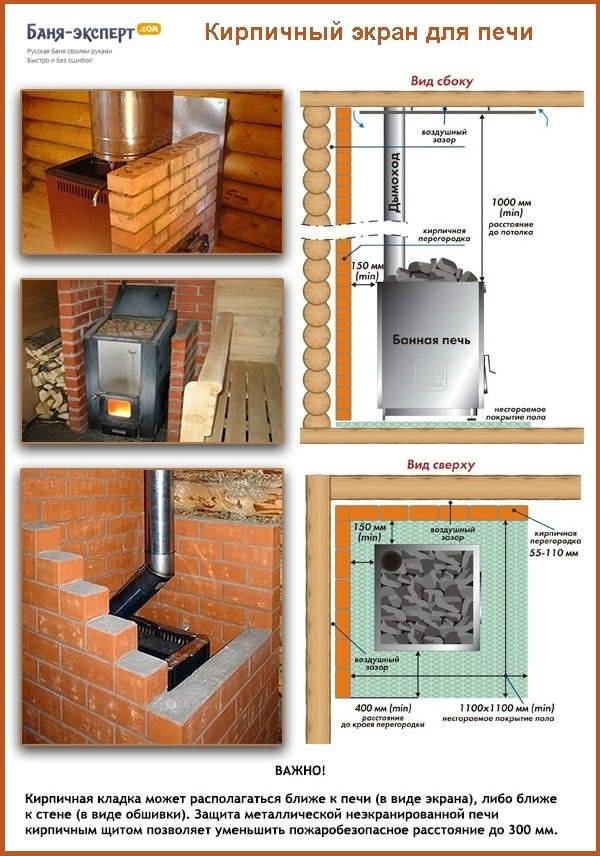

At the final stage, you will need a brick for the screen, stones for the heater and special paint.

Who needs?

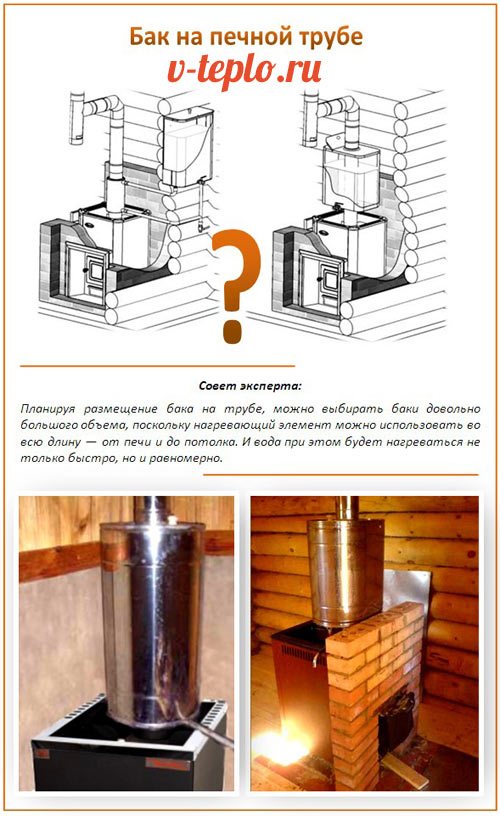

The answer is obvious: for those who do not have a connection to the hot water supply network, and this, unfortunately, is not uncommon with us.But in each case, hot water can be used for washing or for heating, or for both, therefore, under specific circumstances, ovens with water tank different types.

In addition, in the steam room itself there is also a need for hot water - it is not good to give cold water to the stones, because they cool sharply and can crack; then the temperature - it will go down from this, but for now it will pick up again - this is time. So, albeit small, but a tank for hot water in the steam room is appropriate even if there are water supply networks.

IMPORTANT! Temperature can be from 70 degrees.

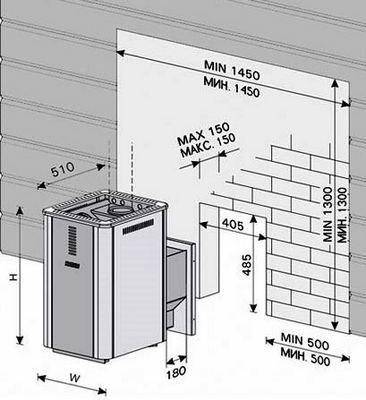

Where to put the stove in the bath?

The location of the furnace depends on many factors, in particular, on its type, as well as on the location of the furnace (in the same or in an adjacent room). In addition, fire safety matters - all fuel must be at least half a meter away.

So, those who decided to install a brick oven make a foundation for it, so the place was already determined at the sketch stage. But with a metal furnace, they sometimes pull to the last, not knowing which model to buy. Therefore, it happens that ready-made walls have to be cut, and other extra work has to be done.

IMPORTANT! The location of the supply ventilation depends on the location of the furnace, so it’s better to think in advance.

In addition to ventilation, it is worth considering fire safety, especially in a bath with combustible walls. Often, in order to ensure it, part of the wall is made of brick. Which again speaks of the need for planning.

The location of the stove in the bath with a separate steam room

There can be two options:

- either the stove, together with the firebox, is entirely in the steam room, which means it heats only it;

- or the firebox is taken out to the next room, which allows you to partially heat it too.

The location of the stove in the bath with a separate steam room: an option with a firebox from the rest room. Scheme from the article about the hood

In the first case, in the cold season, you will have to think about how and with what to heat the neighboring rooms, in the second, the same problem remains only partially.

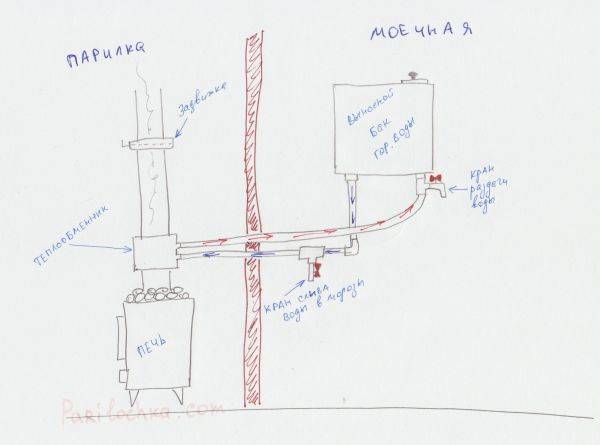

Stove in a bathhouse with a washing room and a steam room

Here, too, you can find several solutions. The firebox can be taken out not to the rest room or dressing room, but to the washing room. But this is problematic in terms of storing firewood. Therefore, there are other options.

Stove in a bathhouse with a washing room and a steam room

You can not remove the stove at all, just install a water tank at the top, which will be connected through the wall to the “samovar” on the chimney in the steam room. “Samovar” is a heat exchanger (! stoves with a heat exchanger are discussed here), which can be found on sale, it heats water for washing, and already heat comes from the tank, sufficient to maintain a normal temperature of 30-32 degrees in washing.

In some cases, the problem is solved by additional sources of heat - a warm floor or a second stove.

Video

The following video shows an explanation of the diagram shown above:

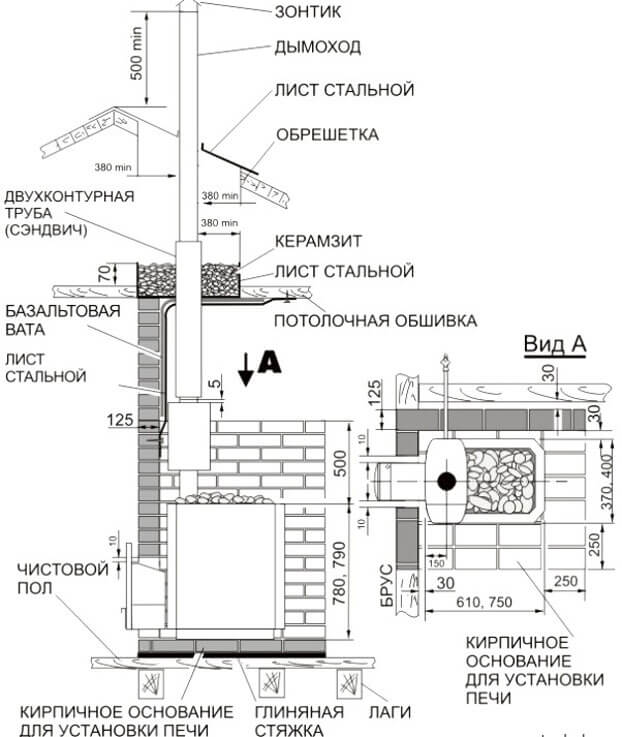

Do you always need a foundation for a furnace?

We have already said above that no, it is not always needed. The need for it arises only when the weight of the sauna stove with everything related (from the water tank to all the bricks that line the floor, stove and chimney) exceeds 700 kg. If the total weight is lower, instead of the foundation, you can simply lay out the base with bricks, put 12 mm asbestos on top, and on it - a steel sheet of any thickness (from 1 mm).The topic is discussed in detail here.

IMPORTANT! A separate foundation for a brick oven is made so that it has its own shrinkage, not related to the shrinkage of the house.

Such a foundation is made thoroughly, deepened to the bearing layer. If the stove weighs more than 700 kg, but not much, then you can make a shallow foundation.

Usually the foundation for the furnace is not brought to the height of the subfloor, because then bricks are laid and the height is compared. The area of the furnace foundation should be 15-20 cm larger on each side than the area of \u200b\u200bthe base of the stove.

The video below clearly demonstrates the process of self-pouring the foundation for a bath. The video is a bit dark, but gives an idea of the process.

Design features that you must observe when building a sauna stove

As mentioned above, furnaces can be metal and brick and their designs differ from each other. To understand which one will be more convenient for installation in a particular room, you need to consider both so that you yourself draw the right conclusion for yourself!

metal oven

Metal Sauna Stove with Water Tank

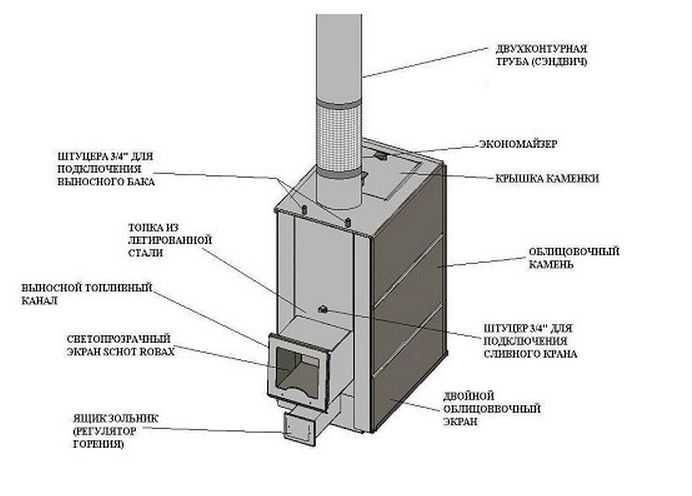

Cast iron and steel versions of wood-burning sauna stoves have the same device, and their installation can be done in two ways, depending on their design:

- the firebox is located in the dressing room, and the heater is in the steam room;

- the firebox and heater are located in the sauna room.

The first option is preferable, since in the steam room you can accidentally burn yourself on the firebox door. Together with the heater in the steam room, there is also a water tank.

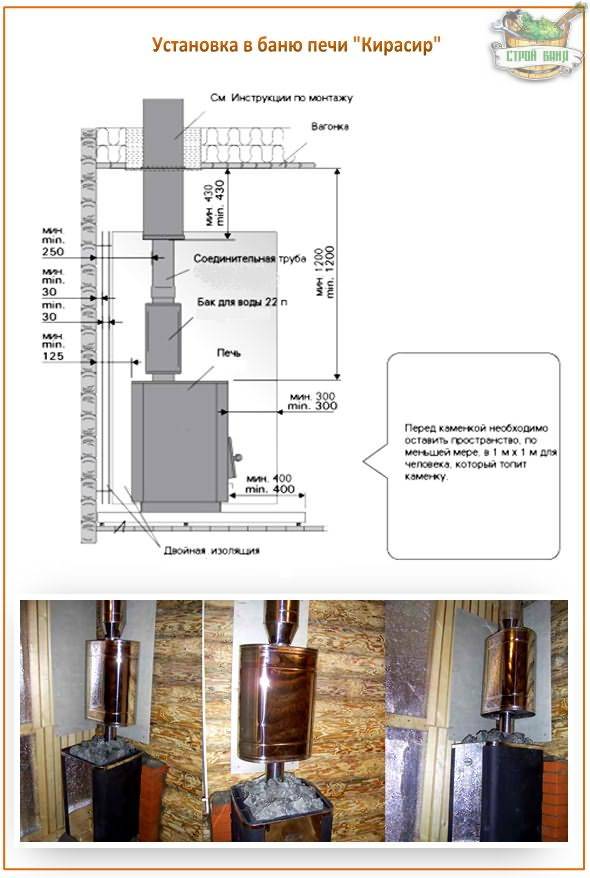

This diagram shows the design of a sauna stove model, in which the firebox goes into the dressing room.

Design wood burning metal stove for sauna

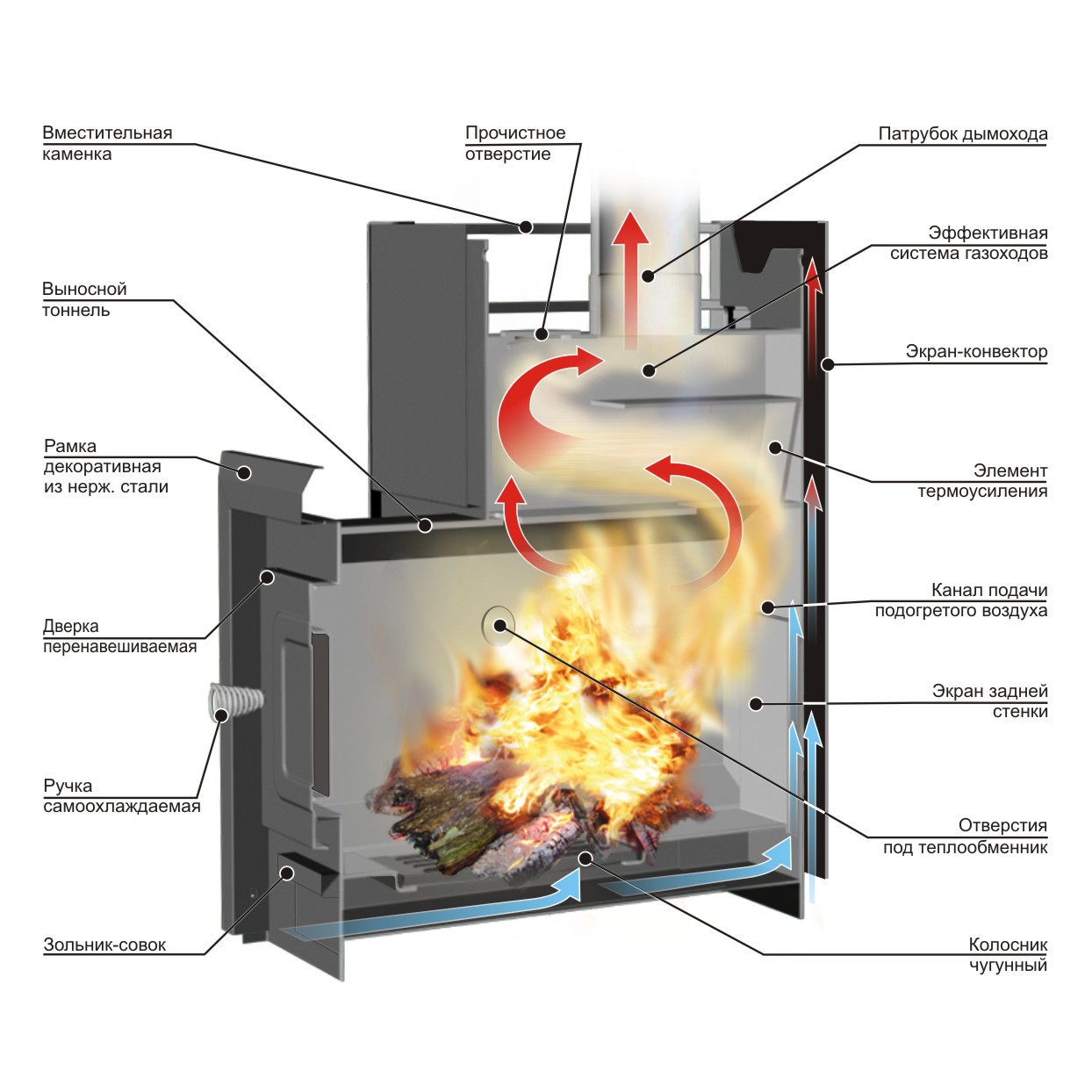

- This oven has a water dispenser. It is convenient in that you do not need to constantly add liquid to the heater - water or decoction, it will gradually come in a given amount on its own. It is shown in the diagram at number one.

- At number two in the diagram, there is a heater closed by a water dispenser, which, when heated, will give a gift for a long time. Due to the fact that the metal stove cools down quickly, a closed heater will be a good help to keep warm.

- A chimney pipe runs through the stove from the furnace. Its location also contributes to the retention of heat near the stones.

- On the other side of the pipe is the second part of the heater - already open. Water from the dispenser, passing through the closed chamber of the first heater and under the pipe, exits through the open heater in the form of dry steam.

- A deep and voluminous firebox made of heat-resistant steel has a chrome-plated finish.

- There is a cast iron grate in the furnace, which cools down for a long time, which means it also retains heat from the fuel.

- Under the firebox there is an ash chamber with a drawer. Waste from burning wood is collected there, and it must be cleaned after each heating of the stove.

- An external channel comes out of the furnace, having a certain length, calculated on the thickness of the wall through which it will pass. This model is designed to be installed in such a way that the firebox door is in the adjacent room.

- A self-cooling door is installed on the combustion channel. It cools quickly due to the fact that it is located far enough from the combustion chamber.

- From the back of the firebox, which leads to the steam room, there is a secondary air supply channel.

- From the front of the housing, from the side that will be near the wall from the side of the steam room, a convector casing is installed, which contributes to the exit of warm air upwards, and not into the wall.

- A chimney is put on the pipe that passes through the heater.

- A water tank is installed on the chimney, working on the principle of a samovar. The heated pipe inside it will serve as a good heat exchanger. The tank can be filled with water manually, or it can be connected to a tap water supply.

Convenient hot water tank

- Next, a chimney pipe riser is put on the tank pipe, which is carried out through the ceiling and roof. When passing through combustible materials of ceilings, the chimney must be insulated with non-combustible materials. The thickness of the insulator should be more than the thickness of the ceiling by 7-10 centimeters and go towards the attic. Between the ceiling and the pipe, the distance should be 10-15 centimeters, filled with non-combustible insulator. Sometimes a box is arranged for laying or backfilling the insulator.

- Waterproofing is necessarily arranged around the head of the pipe on the roof so that moisture cannot penetrate into the attic and does not damage the wooden elements of its structure.

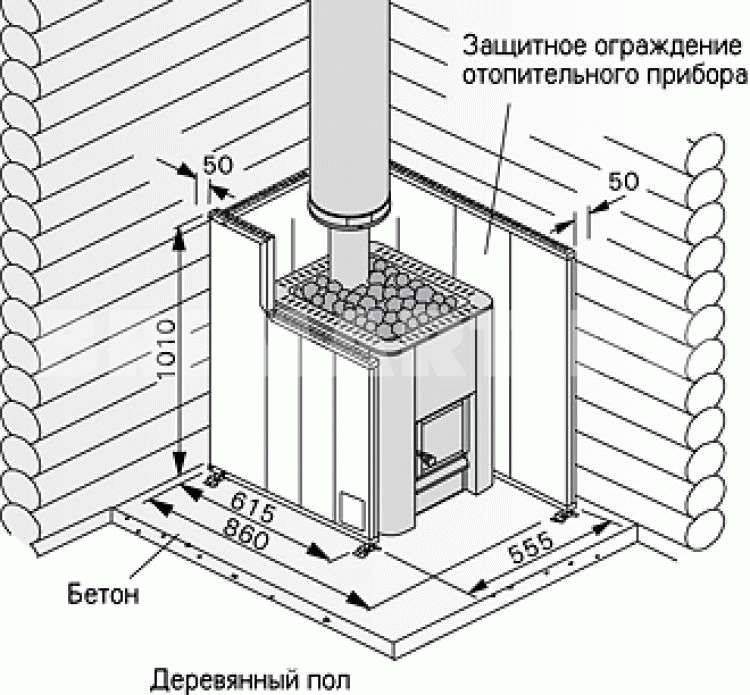

To install a metal furnace, you need to properly prepare the place - it should be a non-combustible site made of brick, concrete or ceramic tiles and a brick wall through which the combustion channel will pass.

Approximate scheme for installing a metal stove in a sauna

The installation diagram of the furnace looks something like the one shown in the figure. Minor adjustments are possible, for example, if the oven is installed on a brick or concrete podium.

Drawings and options for making a stove for a bath from a pipe

Since we decided to devote a separate article to the intricacies of making a stove for a bath from a pipe on our own, the main stages will be considered here in the most general terms. Our task is to clarify what options are available, where they are most effective.

In principle, only two ways of using the pipe are possible: either vertical or horizontal. Everything else will be solely a search for the optimal ratio between the volume of the furnace and the heater, variations in the method of heating stones - flowing or insulating stones from fire, etc.

First of all, physics speaks in favor of the horizontal placement of the pipe: when firewood burns longer, it releases more heat, burns more completely, and all together can be called briefly: higher efficiency. More information about wood burning stoves here.

However, it is believed that a horizontal oven is not suitable for small steam rooms. Well, it's a moot point. Of course, a quarter of a square meter that a vertical oven will occupy will be smaller than a horizontal oven, but only the owners of very tiny steam rooms really have no choice. But here another question arises: wouldn’t the power of a vertical stove for a miniature steam room be too big?

Another advantage of a horizontal stove is the firebox placed in the dressing room. There will be more cleanliness, but here everyone decides for himself what is more pleasant for him: to run to the dressing room or clean up the dirt in the steam room.

The vertical one is suitable for those who would like to combine the stove with a hot water tank - the easiest way to do this is on the vertical - it is enough to separate the tank from the heater with a partition, and not only the stove will heat the water, but also the chimney passing through the tank.

The main advantage of a vertical stove will be a closed heater, because horizontal ones are usually made with an open one, and this is not good for fans of the Russian bath, who should pay attention to a separate article.

vertical oven

Most often this is a three-part structure, divided inside by welded discs. It highlights:

- firebox;

- closed heater;

- water tank.

Firebox structure: ash pan, grate, combustion chamber. Grid-irons can be found on sale, you can weld it yourself by cutting a frame along the diameter of the inner circumference of the pipe, and then welding rods to it. It is better to make an ash pan retractable, in the form of a scoop - by pushing it out during the combustion process, you achieve an increase in traction. Instead, you can make a door on the blower.

The chimney is located vertically, it passes through the tank. This is good, because part of the heat of gases has time to be transferred to stones and water.

The heater, as already mentioned, can be flow-through, in which case between it and the combustion chamber there is only a grate, like a grate at the bottom of the firebox. At the same time, the stones will heat up more, become unusable faster, but the steam will be excellent.

There is an option to transversely weld a piece of pipe of a smaller diameter inside the vertical pipe and make a door. This is a closed heater, isolated from the flame. You can give in without waiting for the firewood to burn out completely (in the previous version, you will have to wait).

Above the firebox, it is worth putting a cutoff - a rectangle with rounded corners, leaving the furnace gases to pass only along the walls. The cutter is located below the heater.

Related video

A video demonstrating the manufacture of a simple vertical stove

Horizontal oven

The stove in the bath from the pipe is horizontal

The structure does not change, only the form changes. The frame for the grate is made along the wall, not across. In the simplest version, a grid for stones is made on top, which makes such a stove suitable for a sauna, but not for a Russian bath. Because there are two drawbacks in an open heater:

- strong convection overheating the bath, preventing the creation of a "steam cake";

- the impossibility of heating stones to temperatures at which finely dispersed "light steam" is formed.

In other words, the body of the pipe is purely a firebox, on which a mesh for stones and a water tank are hung from the outside. !Water tank stoves are covered in a separate article.

BY THE WAY! It is not necessary to bring the chimney through the end of the pipe - in this case, the furnace gases will leave faster, taking heat with them and lowering the efficiency of the stove.

Related video

A video demonstrating the manufacture of a fairly complex horizontal stove. You will get an idea about all the stages of work:

Tips for stove-makers on how to improve the stove in a bath from a pipe

Well, firstly, if you have no experience in creating stoves, then get ready for the fact that the first stove may turn out to be just a prototype. This also applies to those who intend to order a stove according to their sketch from the master. The optimal ratio of the parts of the stove is always specific, that is, it is your steam room where the stove will work that is taken into account. And that is why it is difficult to give universal advice.

It is especially important to choose the size of the heater and the number of stones in it. This is done by experience.

Of particular difficulty are, oddly enough, open heaters, in which it is necessary to achieve exactly such an area of \u200b\u200bcontact between the stones and the body, which will lead to the desired degree of heating of the stones. So you can't make a horizontal oven without a prototype.

+++

Well, we hope you found useful information for yourself. Otherwise, write comments, because the most popular questions will be the topic of our next article.

What parameters to look for when choosing a furnace?

In general, if there are any specific criteria for choosing a sauna stove, then the most important of them is this: the stove must have sufficient thermal power and, preferably, a wide dynamic range of regulation of this power.

But what can be called sufficient thermal power? Here it all depends on the size of the steam room. Usually, it will take about half an hour to warm up this room to 50 degrees, and adjacent rooms in summer, and about an hour in winter. In addition, the kindling time also depends on whether it is a frame bath or a log house.

Here is a simple example of calculating the required power of the stove: the cost of heating a total area of 22 sq.m. (floor, walls, ceiling) will be 4 kW. If we take into account the heating of the stove itself, its stones, a tank of water, then this figure should be multiplied by another 3, which will be 12 kW. This is for a steam room upholstered with clapboard. But if its walls are a bare log house, then you will have to multiply by another 1.5, which will result in 18 kW. If you need to warm up adjacent rooms, then another x2, which will give 26 kW. But, if you do not spare time for warming up, then this sufficient power can be completely reduced by one and a half times.

As for the dynamic range, 1:10 will be enough for a sauna stove - then it will be able to provide both 2 kW and 29 kW equally well. This is most easily implemented in gas and electric stoves, with firewood it is a little more difficult.

Further, such a moment is also important: how exactly will the sauna stove regulate the power plan? There are three options here:

- by regulating the supplied fuel for a certain period of time;

- limitation of air volume;

- release of excess heat into the environment.

As for wood stoves, the first method is difficult for them - all because of the inertia of combustion. But the second one is much more effective if you think carefully about the special designs of dampers, ash pans, etc. But with the third method, you will literally have to chill out the steam room, opening the doors to the street.

But how to find out the thermal power of the furnace if it is not indicated in the manufacturer's passport? It is easier to do this with a tape measure - calculate the internal volume of the stove. Its power is proportional to the volume of the furnace, and it can even be calculated using the following formula:

Furnace power = 0.5 x V (furnace volume in liters)

In general, a standard furnace with a furnace volume of 30 liters usually has a power of 15-18 kW.

Why is dynamic range so important? Yes, because in order for the furnace to heat up quickly enough, the thermal regime was stable, but then overheating did not happen. For wood stoves, according to experts, this range is 1:5.

Comparison of microclimate readings in various types of baths

In addition to good thermal power, the sauna stove must also meet the following standards:

The stove should have a good heat accumulator and a steam generator so that you can easily create the desired mode and turn the steam room into a dry Finnish sauna or a real Russian bath according to your mood.

- In the furnace, means of convection control must be thought out.

- There should be no significant surfaces on the oven, the temperature of which is higher than 150?C.

The size of the firebox and the furnace itself is already an individual matter, but the register-heat exchanger will definitely not hurt either.

And the best sauna stoves that are produced today have all of the above items.

Specialized classification of stoves for baths and saunas

There are a number of different criteria that have contributed to the development of a large number of types of stoves for baths and saunas. Consider the main classification types in order to understand what other sauna stoves are.

The method of space heating determines the following types of stoves:

- "Black" - stoves without a chimney, in which smoke is removed exclusively through the room and natural air openings: roof, floor, window and door openings.

- "White" - more common stoves, since their design involves the installation of a chimney.

According to the method of heating water, the following designs of furnaces are distinguished:

- with a water tank suspended above the stove or built into the body itself. A boiler or tank is usually used as a container;

- with a coil passed through the furnace, through which cold water moves and, already heated, is collected in a special container.

According to the method of placing stones in a special compartment for them:

- in the case when the heater is closed, the stones are placed directly into the chimney and this is not the best option;

- with an open type, stones are laid in special cast-iron or steel containers placed above the firebox.

By type of fuel combustion:

- periodic - allow you to start procedures in the steam room only after all the fuel has burned out;

- permanent ones are more popular, since they can maintain a constant combustion process by throwing occasionally material chosen as fuel.When using them, only the question arises of how exactly the firebox will be placed: inside the furnace or it will be taken to the right room of the bath to simplify the process of laying fuel.

Finally, stoves are divided into several categories according to the type of fuel used:

- solid fuel - on wood, peat or coal;

- liquid fuel or gas - on diesel fuel, bottled or liquefied gas (for more details: "How and which one to choose a gas stove for a sauna");

- electric - furnaces that provide high-quality heating due to heating elements powered by an electrical network.

Outcome

If you correctly use the information presented in this article, you can choose the most efficient, reliable and durable sauna stove. To do this, when buying, you need to focus on all these criteria. Also, if desired, you can entrust the choice to specialists who will take responsibility not only for the purchase, but also for the installation of the furnace with its subsequent commissioning.

A simple metal stove-heater for a bath

One of the simplest designs is a metal rectangular furnace-heater. To make it, you need to get:

- Steel sheets (more than 5 mm)

- Cutter (you can use a grinder)

- welding machine

- Pipes

- Stones and fireclay bricks

- metal corners

- Doors and accessories for them (curtains, latches)

The basis of the installation is a tank filled with water. One of its surfaces is the wall of the furnace, zonally divided into two parts: the heater and the furnace. Smoke is removed to the street through a chimney.

Such a do-it-yourself metal sauna stove is built very easily and quickly.First, you need to decide on the dimensions of the future structure and cut out the bottom, side and back walls from the prepared metal. They are securely welded together. From the inside, at a certain height, metal corners are boiled - they will serve as supports for the bottom of the heater (it is cut out from a thicker sheet).

The perimeter of the front wall is scalded with steel strips and the door is mounted. Holes must be drilled from below through which the oxygen required for combustion will flow.

So that the metal does not come into direct contact with the fire, the space inside the firebox must be lined with fireclay bricks.

In the sheet that will rest on the corners and form the bottom of the heater, it is necessary to cut a hole equal to the diameter of the chimney and weld a pipe to it.

Next, you need to think about installing a water tank. It will consist of a bottom and three walls, welded directly to one side of the finished furnace. In one of the sides (to whom it is more convenient), a hole is made from below and a pipe is welded in with a tap that drains the water.

You can mount a similar design on a base laid out of bricks (25-30 cm), or on a frame welded from metal profiles. Stones with a diameter of up to 12 cm, but not less than 5 cm, are laid on top of the heater. Basalt, porphyrite, etc. are perfect.

Then you need to finish the chimney from the pipe that was removed earlier. The tank is filled with water and closed with a lid. Firewood flares up in the firebox and it looks like all the smoke is removed to the outside.

It will not be difficult to make some changes to the built sauna stove with your own hands and equip an ash pan under the firebox. Thus, it will be possible:

- Easier to clean up from combustion products

- Increase/decrease draft with a blower door

You can install the valve directly on the chimney. With its help, it will be possible to control the combustion process no less effectively.

Video instruction

Alternative heating with a heat pump, find out how

Do-it-yourself round stove for a bath

The design of a round furnace looks simple, in which the tank is located directly above the firebox. Getting started, you need to prepare a tank or pipe with a diameter of 0.5 m and a height of about 1.5 m with a wall thickness of 1 cm, fittings, a mortise valve, a pipe with a diameter of 0.35 m, doors, hinges and curtains, steel sheets.

We begin the construction of a stove in the bath with our own hands:

- A large pipe needs to be cut into two parts - 60 and 90 cm, a water tank and a firebox, respectively

- A circle corresponding to the diameter of the firebox (50 cm) is cut out of sheet steel and welded to the pipe

- Here you can weld the frame of the legs up to 15 cm high

- Next, you need to cut one hole for the ash pan near the bottom, a little higher - for the furnace, corresponding to the dimensions of the purchased doors, hinges and a bracket for the latch are welded

A grate is welded inside, passing air into the furnace from the blower, it is located at a height of up to 15 cm from the bottom

A basket is made of reinforcing bars and connected with plastic wire - this will be a heater. It is installed at the top of the pipe, a door is made of a suitable shape for laying stones

Now you need to equip a water tank from a piece of pipe 60 cm. The bottom is welded to it, through which the chimney pipe passes, a tube with a valve is welded closer to the bottom

Both structural parts of the furnace are joined together and welded

The top has a double lid.The first part is welded to the pipe, and the second is attached to the curtains and equipped with a handle

Summing up

Building stoves in a bath with your own hands is quite simple, but you need to approach work as responsibly as possible. If the design is made of poor quality or with even minor errors at first glance, it will not produce the desired amount of high-quality steam and can be very dangerous in operation.

Getting started, it is recommended to see several ovens in the otchuyu. If there is a familiar master or stove-maker, you should not be shy to ask him for advice.