- What is a solar collector

- Types of solar collectors

- Cumulative

- flat

- liquid

- Air

- Flexible tube construction

- Solar collector - water or air

- From copper pipes

- Manufacturing of absorbers

- What is a solar collector?

- Solar collector device

- Making a device from corrugated board

- Characteristics of a vacuum solar collector for home heating in winter

- "Summer" scheme

- The process of assembling a homemade solar collector

- Flat collectors

- Rules for the location of flat collectors

- What does the price depend on

- Plastic manifolds

- Equipping systems working with solar collectors with automation

- Working principle of solar heaters

What is a solar collector

A number of designs have been developed and patented:

- Flat.

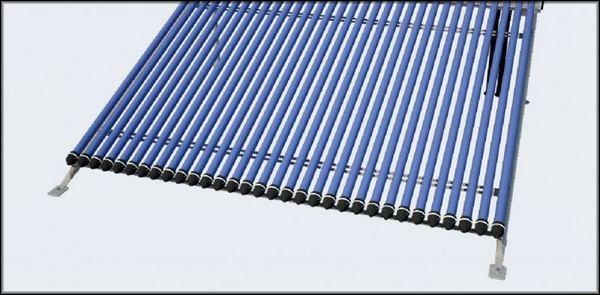

- Tubular.

- vacuum tubes.

- Thermosyphons.

A do-it-yourself solar collector is easiest to make in a flat or tubular design.

How to assemble the installation? One collector block (their number is already approximately known from the calculations performed according to the above method) consists of the following elements:

- A set of copper or aluminum tubular elements;

- absorbent plate;

- Sealed thermally insulated housing;

- Lids, which can be made from transparent heat-resistant polymer or tempered glass.

The effectiveness of the insulation determines the efficiency of the collector. It can be increased if a storage circuit is provided in the circuit, which can provide heat on cloudy days or for the operation of cooling systems.

The process of manufacturing and subsequent installation of solar collectors is possible not only for the roof, but also for the southern walls of the building. In this case, the housings are provided with perforations to facilitate the flow of air. When the heated air rises to the top of the wall, it will be directed to the ventilation ducts of the building for further distribution.

Types of solar collectors

The standard device has the form of a metal plate, which is placed in a plastic or glass case. The surface of this plate accumulates solar energy, retains heat and transfers it for various household needs: heating, water heating, etc. There are several types of integrated collectors.

Cumulative

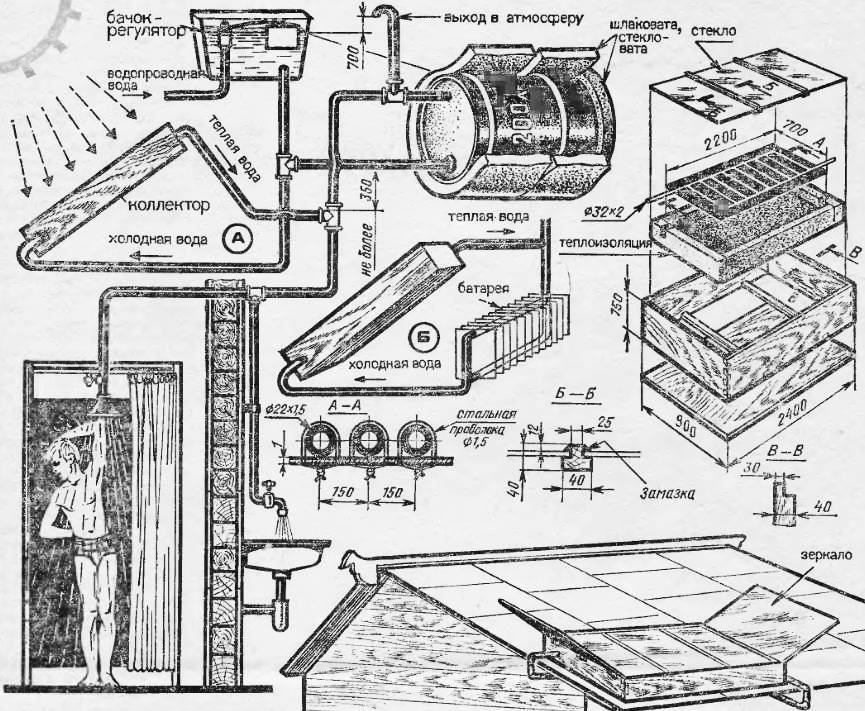

Storage collectors are also called thermosyphon. Such a do-it-yourself solar collector without a pump is the most profitable. Its capabilities allow not only to heat water, but also to maintain the temperature at the required level for some time.

Such a solar collector for heating consists of several tanks filled with water, which are located in a heat-insulating box. The tanks are covered with a glass lid, through which the sun's rays break through and heat the water. This option is the most economical, easy to operate and maintain, but its efficiency in winter is almost zero.

flat

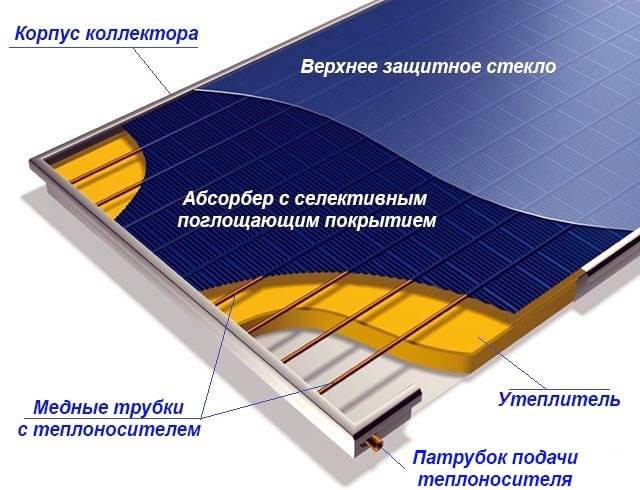

P represents a large metal plate - an absorber, which is located inside an aluminum case with a glass lid. A do-it-yourself flat solar collector will be more efficient when using a glass cover. Absorbs solar energy through hail-resistant glass, which transmits light well and practically does not reflect it.

Inside the box there is thermal insulation, which can significantly reduce heat loss. The plate itself has a low efficiency, so it is coated with an amorphous semiconductor, which significantly increases the rate of thermal energy accumulation.

When making a solar collector for a pool with your own hands, a flat integrated device is often preferred. However, it does not worse cope with other tasks, such as: heating water for domestic needs and space heating. Flat is the most widely used option. It is preferable to make a do-it-yourself absorber for a solar collector from copper.

liquid

From the name it is clear that the main coolant in them is the liquid. A do-it-yourself water solar collector is made according to the following scheme. Through a metal plate absorbing solar energy, heat is transferred through pipes attached to it into a tank with water or non-freezing liquid or directly to the consumer.

There are two pipes attached to the plate. Through one of them, cold water is supplied from the tank, and through the second, already heated liquid enters the tank. Pipes must have inlet and outlet openings. Such a heating scheme is called closed.

When heated water is directly supplied to meet the needs of the user, such a system is called open-loop.

Unglazed ones are more often used to heat water in the pool, so assembling such thermal solar collectors with your own hands does not require the purchase of expensive materials - rubber and plastic will do. Glazed ones have higher efficiency, so they are able to heat the house and provide the consumer with hot water.

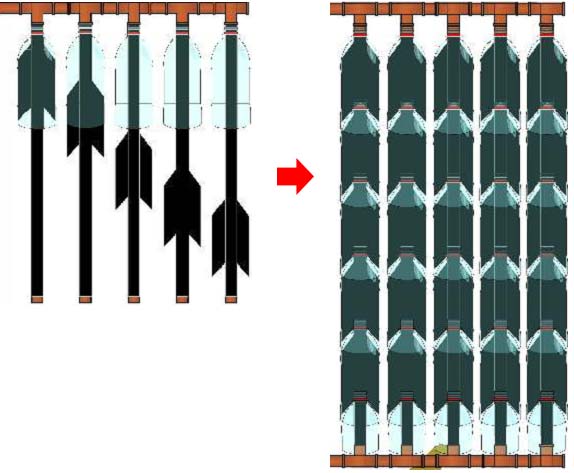

Air

Air devices are more economical than the above analogues that use water as a heat carrier. The air does not freeze, does not leak, and does not boil like water. If a leak occurs in such a system, it does not bring so many problems, but it is quite difficult to determine where it happened.

Do-it-yourself production is not expensive for the consumer. The solar panel, which is covered with glass, heats the air that is between it and the heat-insulating plate. Roughly speaking, this is a flat collector with space for air inside. Cold air enters inside and, under the influence of solar energy, warm air is supplied to the consumer.

Such options are durable and reliable and easier to maintain than devices that use liquid as a coolant. To maintain the desired air temperature in the cellar or to heat the greenhouse with a solar collector, just such an option is suitable.

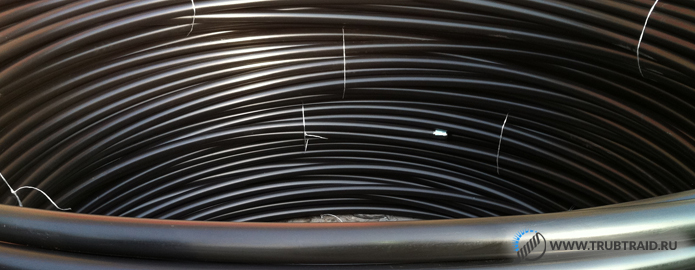

Flexible tube construction

To create a reliable solar collector, only high-quality materials are used. For this purpose, metal-plastic pipes or ordinary hoses used for irrigation are suitable. The collector can be made up of several modules. Pipes must be laid and tightly fixed in them.

This design is the simplest. Its key disadvantage is the need to use a pump.Since natural circulation is impossible in such a design. If the pipes are too long, the hydraulic resistance will be greater than the head force created by the temperature difference.

Note that installing the pump does not present any problem. Moreover, such a system pays off quite quickly.

Pool installation

The considered version of the collector can also be used to heat water in the pool. It must be connected to a filtration system with pumping equipment. The liquid circulating inside will be heated before entering the pool tank.

There are options in which it is permissible to refuse the installation of a storage tank. This approach can be implemented if the heated water is intended exclusively for use during daylight hours in a small volume. For example, the length of the circuit is one hundred and fifty meters. In this case, the indicator of the inner diameter is sixteen millimeters. In this design, thirty liters of liquid are placed. If the design consists of several compartments connected into one system, there will be much more heated water.

Solar collector - water or air

Each of the heaters is effective, only the main purpose and principle of operation differ:

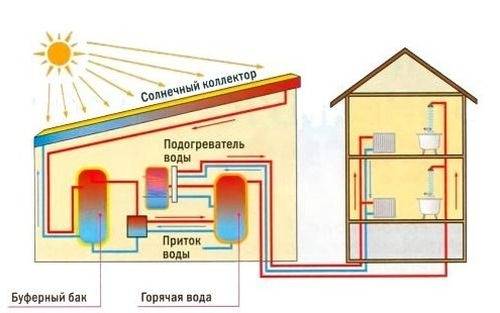

- Water collector - used to meet the needs for hot water and low-temperature underfloor heating systems. The efficiency of work in the winter period is significantly reduced. Indirectly heated vacuum and panel collectors connected to a buffer tank continue to accumulate heat throughout the year.The main disadvantage is the high cost of the solar collector, installation and piping.

- Air ventilation manifold - has a simple design and a device that, if desired, can be made independently. Main purpose: space heating. Of course, there are schemes that allow using the received heat for hot water supply, but at the same time, the efficiency of air collectors drops by almost half. Advantages: low cost of kit and installation.

Solar air heating systems only work during the day. Air heating begins even in cloudy weather, with heavy clouds and during rain. The operation of air heaters in winter does not stop.

This is interesting: What is the difference between a Russian bath and a Finnish sauna (video)

From copper pipes

A collector with a copper serpentine, upholstered on the inside with sheets of the same material, is extremely effective. Perhaps the most effective of the ones we found on the net. Tubes and strips are soldered with a special autogenous soldering iron at the seams, joints, so the copper absorber was the most time-consuming stage, which took 2 days.

Copper was blackened by placing it in a bath of potassium persulfate:

The case was insulated, foil was attached to the back wall to reflect heat. All gaps are carefully sealed:

The structure was moved into place, for this it was wrapped with ordinary cling film, and only after transportation and connection was glass installed:

Result: in a hot southern climate, under direct rays, the copper became hot, the water heated to a boil, there were even noticeable traces of melting of the polymer structural elements. It is advisable to mix cold liquid into a shower with a solar absorber of this type, for which it is necessary to provide a separate barrel with it or supply from a tap.

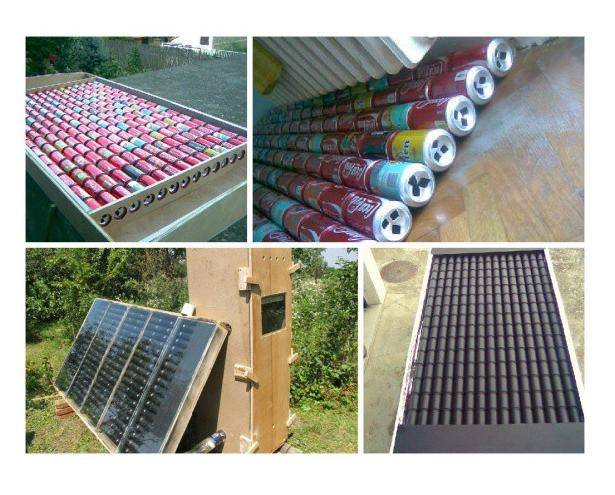

Manufacturing of absorbers

We assemble the tubes as follows:

- The wall covering the top of the jar (in which there is a hole) is cut with metal scissors into “petals”, which are bent inward. It is convenient to bend the “petals” by placing the can on a plastic pipe of the largest possible diameter (to pass inside the can).

- In the bottom of each can with a conical drill, you need to make 3 holes with a diameter of 20 mm, so that their centers are at the vertices of an equilateral triangle.

- Now you can collect tubes from cans - 8 pcs. in each. Cans should be sealed with a high temperature chimney sealant such as High Heat Mortar. This composition should be applied to a previously degreased and moistened surface. The composition is leveled with fingers, wearing rubber gloves, which should also be moistened with water.

In order for the tubes to be perfectly even, during assembly, the cans should be placed in a template knocked down from two boards and having the shape of an equal-angle corner. It is installed at a slight angle to the vertical (you can lean against the wall).

On the newly assembled tube, located in the template, a weight must be installed from above until the sealant is completely cured.

What is a solar collector?

At its core, this is climatic equipment that is used to produce hot water with its subsequent use in the plumbing and heating system. The principle of operation of such a system is to change the density of water during its heating, due to which the hot liquid is pushed up.

The main difference between such systems is that natural resources are used for heating, in particular, solar energy, which is absolutely free. And a properly designed solar collector allows you to extract this energy even on a frosty day or in cloudy weather. Therefore, the use of such a device is possible not only in summer, but even in autumn and winter.

Solar collector device

The design of a complete solar collector system necessarily includes several basic elements - these are:

- a device for extracting solar energy;

- container for accumulating hot water;

- heat exchanger;

- thermal insulation structure, which reduces the rate of cooling of the coolant.

Making a device from corrugated board

This is an even simpler solar collector design. You will build it much faster.

First stage. First, make a wooden box in the same way as in the previous version. Next, lay a bar along the perimeter of the back wall (approximately 4x4 cm), and lay mineral wool on the bottom.

Second phase. Make an exit hole in the bottom.

Third stage. Lay corrugated board on the beam and repaint the latter in black. Of course, if it was originally a different color.

Fourth stage. Make perforations over the entire area of \u200b\u200bthe corrugated board for air flow.

Fifth stage. If you wish, you can glaze the entire structure with polycarbonate - this will increase the heating temperature of the absorber. But do not forget that you also need to provide an outlet for air flow from the outside.

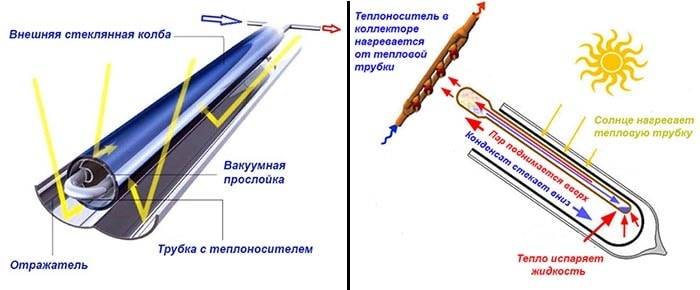

Characteristics of a vacuum solar collector for home heating in winter

Vacuum solar collector is a rather complicated device.The main working element is represented by an expensive light-absorbing bulb with a transparent surface, in which the tube is located. The basis of the work is the principle of a thermos. The vacuum flask allows sunlight to pass into the inner tube, where there is no air, which allows you to save up to 95% of heat.

Vacuum solar collectors. More expensive, but work even in winter

Vacuum solar collectors. More expensive, but work even in winter

The bottom of the inner vacuum tubes for solar collector occupies antifreeze, which passes into a gaseous state when heated. In its upper part, heat is transferred to a collector with a coolant. At the same time, the antifreeze cools and condenses, returning to its original state.

Vacuum solar collector is characterized by high efficiency in poor light conditions and temperatures below -37 °C. It has been specially designed for northern latitudes and can function in the absence of direct solar radiation. For efficient operation, the structure needs constant care, which consists in cleaning its surface from contamination.

The main disadvantage is the high cost of construction. If at least one tube fails, repair will be problematic, since all products are mounted in series.

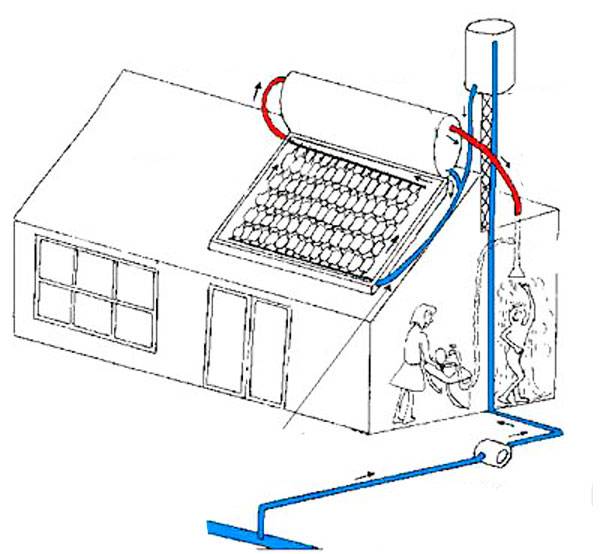

"Summer" scheme

This option is convenient for a summer shower. If it will be located on the street, then the container that accumulates hot water should be mounted there.

If we are talking about wiring inside the building, then the container with the liquid must be installed in the house.

The scheme under consideration operates on the basis of natural circulation.The collector must be mounted below the tank, where warm water will accumulate, about one meter. This is due to the different densities of cold and hot liquids. To connect the collector to the tank, it is necessary to use pipes with a cross section of 0.75 inches and above.

To effectively keep water in a warm state, the walls of the container must be insulated. For this purpose it is necessary to use mineral wool. Its thickness should be at least ten centimeters. If a roof is located above the boiler, it is necessary to additionally use polyethylene for insulation.

This scheme is not called "summer" for nothing. It is able to heat water only in the warm season. During the cold period, the liquid must be drained from the system. Otherwise, freezing it can damage the used pipeline.

The process of assembling a homemade solar collector

The beginning of the assembly of this solar energy product starts with the manufacture of the coil. If you managed to pick up a ready-made coil, the final assembly will take much less time. The selected coil should be washed very thoroughly under running water (preferably hot) in order to wash all blockages from the inside and get rid of freon residues. If you did not find suitable tubes, then you can purchase the right amount in the store. But in this case, you will have to make the coil itself. To make it, cut the tubes to the required length. Next, using corner transitions, solder them in the form of a coil structure. Further, so that the collector can be connected to the water supply system, solder ¾ plumbing transitions on the edges of the coil.There are several options for the shape and design of the coil, for example, you can solder tubes in the form of a "ladder" (if you are going to implement this option, then buy non-corner adapters, you will need tees).

Solar collector assembly

Then, on a pre-prepared sheet of metal, you apply a selective coating with black matte paint, it is advisable to do this in at least a couple of layers. Wait for the airflow to dry the paint and start soldering the coil (unpainted side). The entire coil structure must be soldered along the entire length of the tubes, by doing this, you guarantee the most efficient heat transfer and, as a result, the maximum heat transfer to the water supply system. If you do everything right, the solar collector you have assembled will work as it was intended.

Flat collectors

Flat solar collectors are a metal frame on which, when viewed from the bottom up, are fixed:

- body plate;

- thermal insulation layer;

- reflective layer (not present in all models);

- heat collector plate (heat sink or also called adsorbing plate), to which heat exchange tubes are soldered;

- transparent light-transmitting cover (tempered glass with 95% light transmittance or no less transparent polycarbonate).

Also on the body there is an outlet and an inlet pipe - the coolant circulates through them.

There are models open - without a cover. Their only advantage is their low price, but they are very inefficient and completely inoperable at low temperatures.Due to the fact that there is no cover, the absorption coating is quickly destroyed, so open collectors serve for several seasons, and due to their characteristics, they can be used to heat water in a pool or in a shower. They are useless for heating.

The principle of operation of a flat solar collector is as follows: the sun's rays pass almost completely through the top protective glass. From these rays, the heat sink heats up. Heat, of course, is radiated, but almost does not come out: the glass is transparent to the sun's rays, it does not let heat through (position "c" in the diagrams). It turns out that the thermal energy is not dissipated, but stored inside the panel. From this heat, the heat exchange tubes are heated, and from them heat is transferred to the coolant circulating through them.

Rules for the location of flat collectors

Collectors of this type must be placed at an angle of 90o with respect to the incident light rays. The more precisely this angle is set, the more heat the system collects. It is clear that it is unrealistic to constantly maintain this angle on a fixed roof, but you need to position the panel so that light falls on it for as long as possible. There are quite expensive devices that change the position of the panel in relation to the sun, maintaining the optimal angle of incidence of the sun's rays. They are called tracking systems.

What does the price depend on

The price of a flat collector largely depends on the materials used. So the body can be aluminum or galvanized steel. An aluminum body is preferred, but it costs more. There are also polymer cases. They are characterized by high strength and reliability.

The heat exchange tubes and the material of the heat collector plate have a great influence on the efficiency. They are aluminum (such panels are cheaper) and copper. Copper ones are more expensive, but also more durable, they also have a higher efficiency. For Russia, even for its southern regions, it is desirable to use them. Since insolation, even in the south, is rarely excessive, it is rather not always enough for heating.

The coating of the heat collector plate is also important: the closer it is to absolute black, the less rays will be reflected and more heat will result. Therefore, technologists are constantly working to improve this coating.

In the first models it was a regular black paint, but today it is a black nickel coating.

Plastic manifolds

In a separate type, plastic solar collectors can be distinguished. In the simplest version, these are two polycarbonate panels that are mounted on an aluminum frame. Between them, ribs are welded or welded, creating a labyrinth for the flow of water in the panel. The inlet is located at the top of the panel, and the outlet is at the bottom. Cold water is poured into the upper one, which, passing through the labyrinth, heats up and exits with a higher temperature through the lower one. The system is used to heat water in the summer. Due to the low hydraulic resistance, it functions very well in a gravity-flow system. This type of solar water heater is an ideal option for supplying hot water to a summer house during the garden season.

But sometimes full-fledged collectors for heating are called plastic solar collectors.It's just that in them the top cover is not made of glass, but of the same polycarbonate or other plastic that transmits sunlight well. Such models are less at risk: plastics are more durable than glass (even tempered).

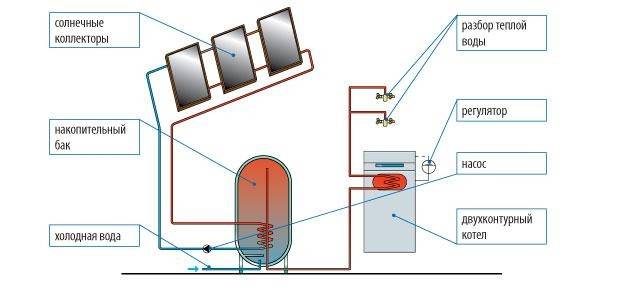

Equipping systems working with solar collectors with automation

The specifics of the operation of solar installations, constantly changing initial data (season, weather conditions, and so on) do not ensure the stability of parameters (temperature, heat carrier flow, and others), which requires the inclusion of control systems in the installation scheme.

Electronic devices such as a controller, based on the analysis of temperature in certain places of the installation diagram, give commands to open / close valves, turn on / off pumping units to select the optimal movement of the coolant along the circuit. So, for example, if the temperature of the water in the storage tank of the coolant is exceeded, the controller will stop its movement along the circuit, stopping the loss of heat that could be discharged into the environment through the collector.

Working principle of solar heaters

Before embarking on the manufacture of a home-made solar system, it is worth studying the design of factory-made solar collectors - air and water. The former are used for direct space heating, the latter are used as water heaters or non-freezing coolant - antifreeze.

The main element of the solar system is the solar collector itself, which is offered in 3 versions:

- Flat water heater. It is a sealed box, insulated from below. Inside there is a heat receiver (absorber) made of a metal sheet, on which a copper coil is fixed.From above the element is closed by strong glass.

- The design of the air-heating manifold is similar to the previous version, only the air pumped by the fan circulates through the tubes instead of the coolant.

- The device of a tubular vacuum collector is fundamentally different from flat models. The device consists of durable glass flasks, where copper tubes are placed. Their ends are connected to 2 lines - supply and return, the air is pumped out of the flasks.

Addition. There is another type of vacuum water heaters, where glass flasks are tightly sealed and filled with a special substance that evaporates at a low temperature. During evaporation, the gas absorbs a large amount of heat transferred to the water. In the process of heat exchange, the substance condenses again and flows to the bottom of the flask, as shown in the picture.

Device of a directly heated vacuum tube (left) and a flask powered by liquid evaporation/condensation

The listed types of collectors use the principle of direct transfer of the heat of solar radiation (otherwise - insolation) to a flowing liquid or air. A flat water heater works like this:

- Water or antifreeze pumped by a circulation pump moves through a copper heat exchanger at a speed of 0.3-0.8 m / s (although there are also gravity models for an outdoor shower).

- The rays of the sun heat up the absorbent sheet and the coil tube tightly connected to it. The temperature of the flowing coolant rises by 15-80 degrees depending on the season, time of day and street weather.

- To exclude heat losses, the bottom and side surfaces of the body are insulated with polyurethane foam or extruded polystyrene foam.

- The transparent top glass performs 3 functions: it protects the selective coating of the absorber, it does not allow the wind to blow over the coil, and it creates an airtight layer that retains heat.

- The hot coolant enters the heat exchanger of the storage tank - buffer tank or indirect heating boiler.

Since the temperature of the water in the circuit of the device fluctuates with the change of seasons and days, the solar collector cannot be used for heating and domestic hot water directly. The energy received from the sun is transferred to the main coolant through the coil of the tank - accumulator (boiler).

The efficiency of tubular apparatuses is increased due to the vacuum and the internal reflective wall in each flask. The rays of the sun freely pass through the airless layer and heat the copper tube with antifreeze, but the heat cannot overcome the vacuum and go outside, so the losses are minimal. Another part of the radiation enters the reflector and is focused on the water line. According to manufacturers, the efficiency of the installation reaches 80%.

When the water in the tank is heated to the right temperature, the solar heat exchangers switch to the pool using a three-way valve