- How the connection is made

- Ways

- Connection of metal-plastic pipes with metal

- How to connect plastic pipes. Metal-plastic, PVC, PPR, polyethylene

- How polypropylene pipes are connected

- Connection of metal-plastic pipes

- PVC pipes

- Connections for heating and water pipes

- Types of connection of metal pipes with plastic

- Features of threaded connections

- flange connection

- Other methods of threadless connection of metal and plastic pipes

- Mounting methods

- With flanges

- collapsible

- With weld seam

- Connection of pipes "in the socket"

- Bending technologies

- manual method

- Sand use

- Pipe bender application

- Spring application

- How to solder polypropylene pipes without a soldering iron using cold welding or adhesive bonding

How the connection is made

There are several ways to connect plastic and metal pipes:

- With the help of threaded adapters;

- Without carving.

Now many stores that sell materials for the pipeline offer their customers various adapters. These are cuffs, corrugations, plastic seals. These devices are made of polyvinyl chloride, which perfectly tolerates the effects of high and low temperatures, their differences and physical exertion.They are not used for permanent connections, they are better used as an emergency method of solving the problem of pipeline leakage.

Fittings and flanges are the most popular now.

A fitting is a part that is a plumbing adapter with a thread on one side. The smooth side is welded to the plastic pipe using welding inverters for plastic, and the threaded side is put on metal communication. It is convenient to work with fittings on a small diameter pipe with different turns or branches.

There are no threads on the flanges; they are used for large diameter pipes. They are selected according to the size of the pipeline and form a detachable mount. If necessary, you can remove the flange at any time, but this does not mean that they form a leaky clutch.

Related video:

Connecting a plastic pipe to an iron

There are several types of flanges:

- Burtovye. They are used for small structures with an internal diameter of not more than 300, while they can also be used for cast iron joints, but only with a diameter of up to 150 mm;

- Wedge. They are universal, they can be used for pipes of any diameter;

- Wedge collar. They are used for any pipes whose diameter does not exceed 200 mm.

Corrugations and cuffs are mainly needed to create strong connections between sewer pipes extending from toilets or washbasins. They are attached to the sockets, pre-treated with special sealants or adhesives.

Ways

There are several ways to connect polypropylene communications. Choosing which method to use depends on the type of PP pipes and their purpose.

Cold welding is based on gluing elements with a special adhesive composition. It is applied to the parts that need to be connected. First, the surfaces to be bonded must be degreased. After applying the glue, wait a while and connect the pipe to the desired element. After a short period of time (approximately 20 minutes), the connection will stabilize and be reliable.

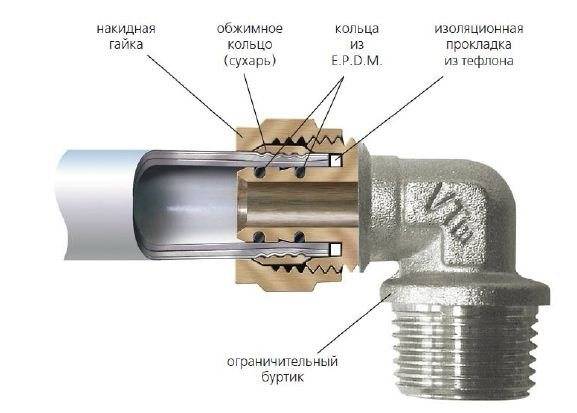

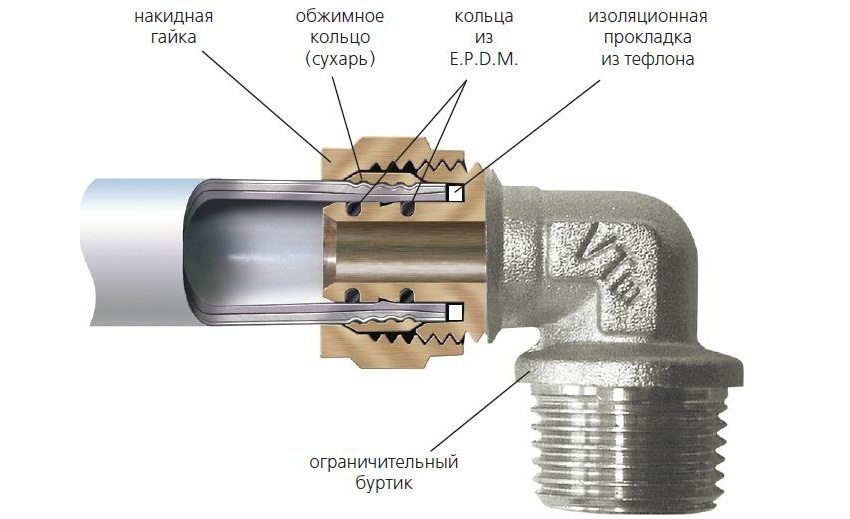

Connection using steel or cast iron fittings. This method is suitable for pipelines with a small diameter. Fittings are usually installed on bends and branchings of communications. The fitting includes such elements as a cap, a sleeve and a clamping ring, which is located in the socket of the product. The pipe is fixed with the help of a seam ring included in the design of the fitting.

When connecting with fittings, you must follow the step-by-step action plan:

- the pipe cut must be made at a right angle;

- all burrs on the surface to be joined must be eliminated;

- then you need to install the nut from the fitting on the pipe and put a clamping ring on it;

- after that, it is required to insert the pipe into the fitting and secure the connection with a clamping ring and nut.

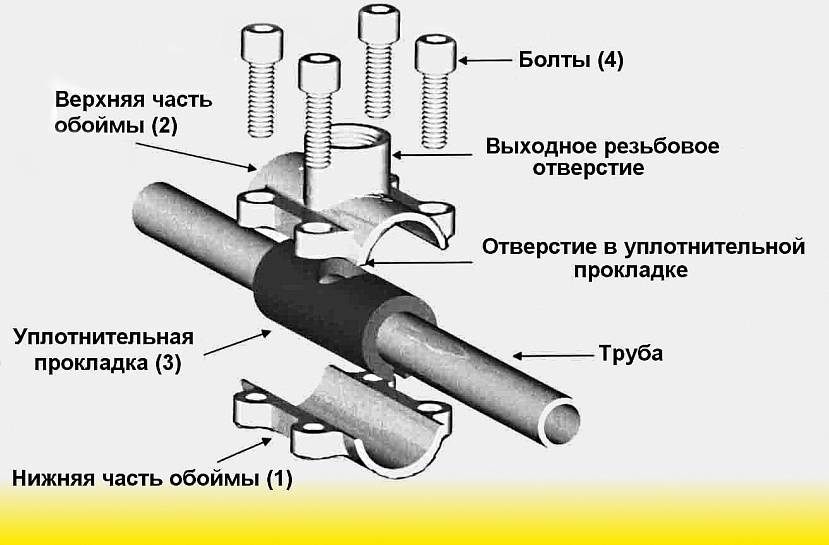

The connection using flanges is considered very reliable, withstands high temperatures and high pressures. This method is used when it is necessary to connect polypropylene pipes without resorting to welding. For connection, bolts are used that are screwed into the thread of the flange.

When connecting with flanges, the following installation rules must be observed:

- at the junction of the pipe, it is necessary to make a cut, avoiding the appearance of burrs;

- the gasket that is installed on the cut must have a protrusion of 15 cm;

- a gasket is placed on the flange and connected to another flange installed on another pipe to be connected;

- gaskets must be installed in such a way that their cross section does not touch the bolts;

- more than one gasket per flange cannot be installed, as this will reduce the tightness.

Connection using couplings. To connect with couplings on pipes, you need to make a thread for their subsequent installation and, for the tightness of the connection, wrap a little tow on it. The edges to be joined should be cut evenly and the location of the coupling should be marked with a marker. Then you need to apply grease to the coupling and install it on the pipe, at the previously marked place.

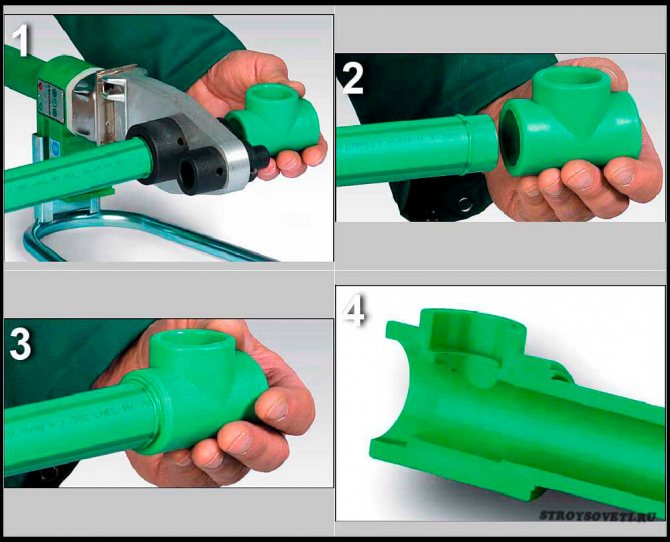

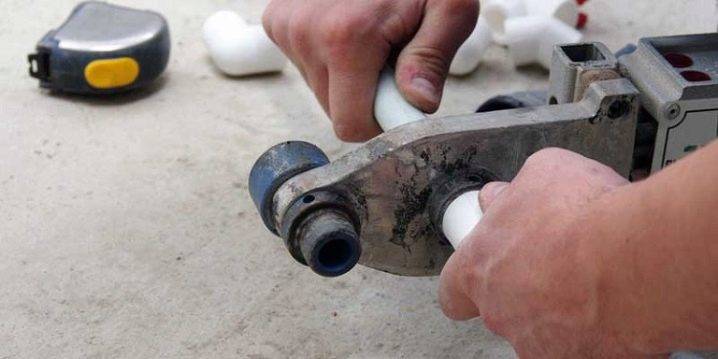

Welding refers to the hot connection method. This type of connection is one of the most reliable, and its essence lies in the melting of polypropylene with a special apparatus at a temperature of 260 C. The elements heated to the desired temperature are pressed tightly against each other, and after they cool down, a reliable connection is formed. The time after connection to the final polymerization of polypropylene will take 20 minutes.

When connecting by welding, the following sequence of actions should be observed:

- turn on the welding machine and heat it up to a temperature of 260 C;

- you need to put on the nozzles of the apparatus on the connected propylene pipes - this must be done very quickly;

- when the elements to be welded begin to melt, they are removed from the apparatus;

- connect the melted elements to each other by pressing firmly for 15 seconds;

- the connected elements must be allowed to polymerize for complete setting - this usually takes about 20 seconds.

Common mistakes when connecting by welding:

- displacement of elements during welding at the time of their heating;

- when joining the elements, they cannot be rotated - otherwise the seam will turn out to be unreliable;

- when welding the valves, the location of the valves was not taken into account, and they cannot move freely.

Connection of metal-plastic pipes with metal

Connection of metal-plastic pipes with metal

It is not always possible to assemble water supply using only metal-plastic pipes. Sometimes you have to connect them with metal ones, in cases where the plumbing is not done completely, or the riser is metal, etc.

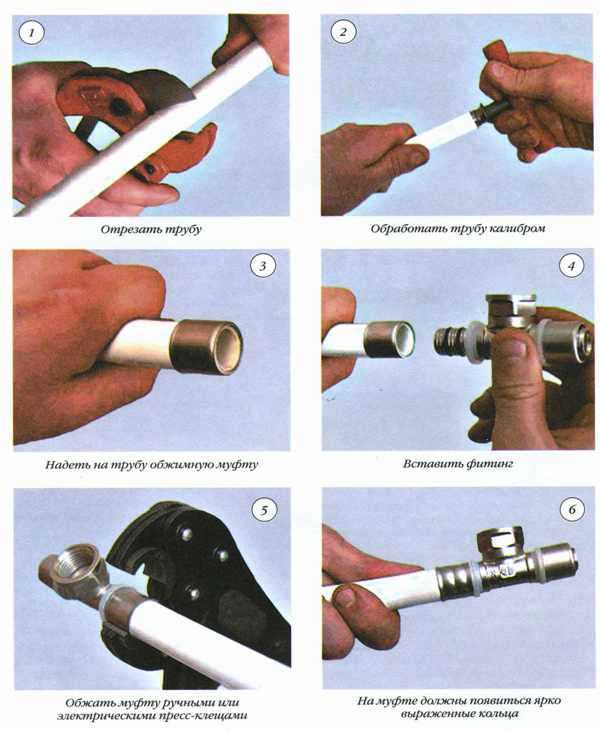

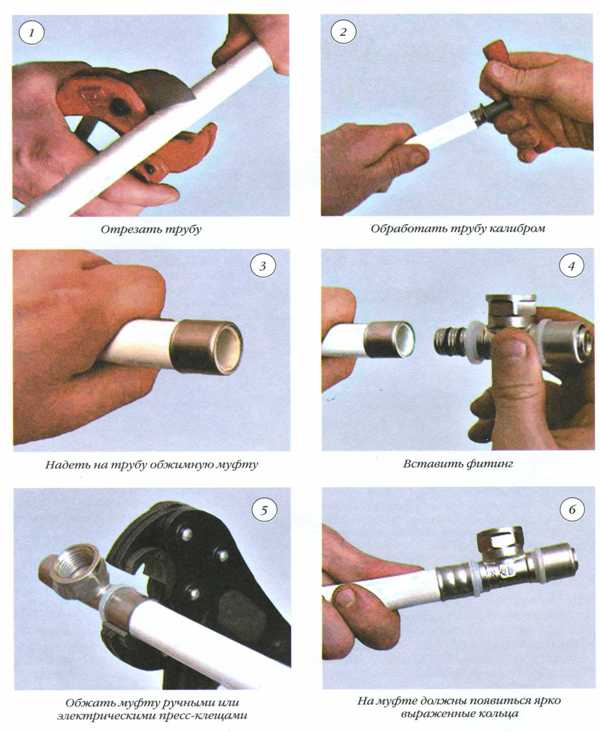

Connecting a metal pipe to a metal-plastic one is very simple. How this is done, I will consistently show a simple example. Let's say we need to connect a half-inch metal pipe with 16 mm. metal-plastic. In addition to the two pipes listed above, we also need a caliber and a compression fitting, on one side of which there will be an internal thread for a half-inch pipe, and on the other, a cone with cuffs and a compression washer with a nut for a metal-plastic pipe, respectively.

To begin with, we wind the fitting onto a metal pipe using an open-end wrench. To avoid leaks, you can use the old proven method: tow and paint. Wrap the tow soaked with paint on the pipe thread, and then screw the fitting onto it.

While the paint sets, it is necessary to deal with the metal-plastic pipe. Put a press washer with a nut on it and calibrate.

Then put the pipe on the cone, which is already screwed to the metal pipe

and using an open-end wrench, tighten the nut so that the washer compresses the metal-plastic pipe.

Everything, the pipes are connected.

How to connect plastic pipes. Metal-plastic, PVC, PPR, polyethylene

First, let's look at the confusion of a variety of materials. After all, the connection of plastic pipes with metal ones requires elementary knowledge of what other materials the pipes are made of.

Now the most popular pipes are pipes from:

- polyethylene (PE)

- polyvinyl chloride (PVC)

- polypropylene (PP)

- made of cross-linked polyethylene

- metal-plastic (composite).

Let's consider how to connect them in more detail.

How polypropylene pipes are connected

There are 2 ways to connect everything:

What are fittings? These are various couplings, bends (elbows, turns, threaded angles), plugs, transitions, tees ... In general, this is a part for connecting pipes.

Fittings for polyethylene pipes

Their main advantage is that no complicated tools are required to connect the pipes (the only thing you need is a crimp wrench, and it comes with the fittings). Manual assembly simplifies the installation process, but reduces its speed (when compared with welding).

There are also two ways of welding: butt and socket. When butt-welding, the ends of the pipes are evenly heated, melted and connected by ends. Then - cooling. When welding with a socket, the ends of the pipes are connected using a polymer fitting.

Connection of metal-plastic pipes

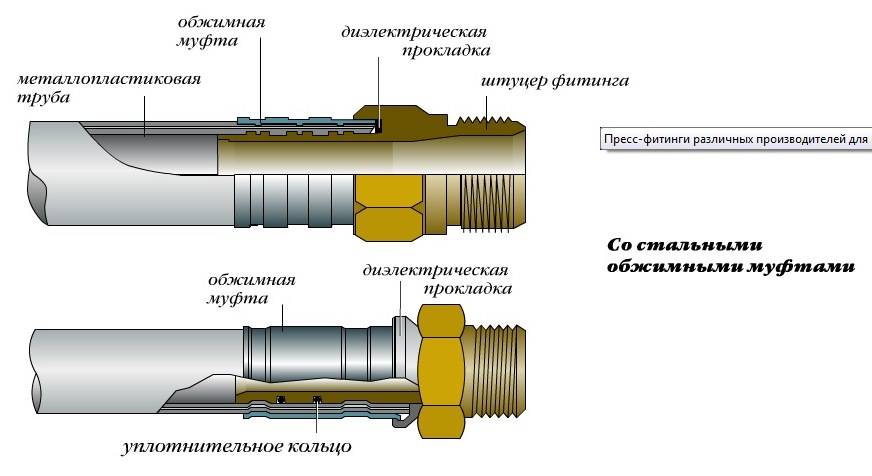

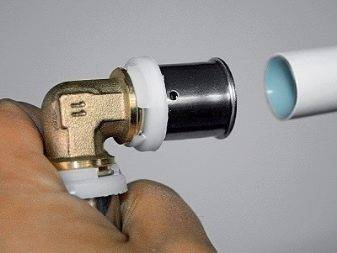

Sadly, the connection of metal-plastic pipes cannot be made by welding.

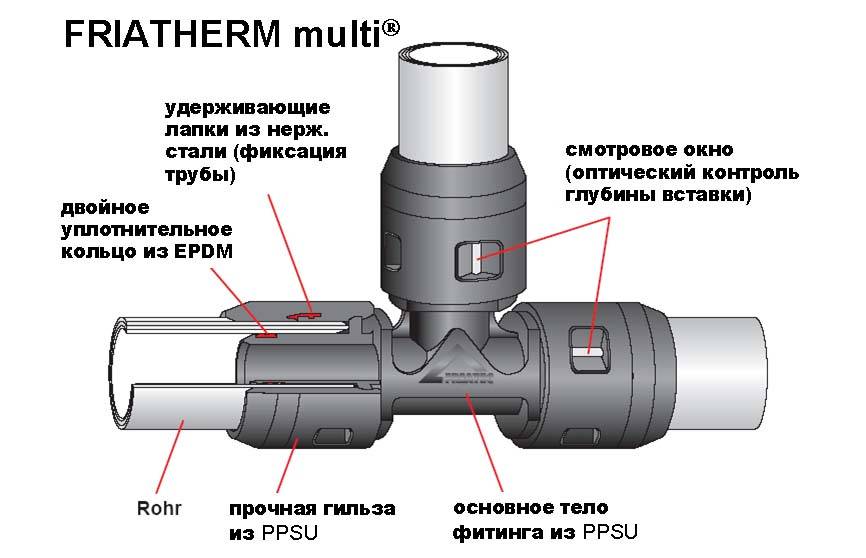

The only way out in this situation is fittings, and not simple ones, but:

Crimps praise ease of installation.

Push fittings offer a range of benefits to choose from:

- using a minimum of tools (calibrator and cutter)

- ease of installation

- fast installation (cut off, calibrated, inserted the pipe, and you're done)

- complete elimination of errors during installation

- high rate of anti-corrosion

- they can be disassembled and individual parts replaced

- seal reliability

- and (well, how could it be without it!) environmental friendliness.

Connection of metal-plastic pipes

It is also made using fittings, but there is one “trick” - welding or the so-called soldering of LDPE AND HDPE pipes. Its essence is in gluing elements under the influence of high temperatures. With full compliance with the technology, a connection is obtained that is almost eight times stronger than the surface of the pipes themselves.

But for its implementation, it is necessary to provide several conditions: sufficient free space in the area for installing plastic pipes with your own hands, the same wall thickness and brand of both pipes, and, in addition, it has limitations in use: the mobility of one of the lashes.

If it is impossible to carry out such welding, you can use electrofusion. It especially helps with a small area of \u200b\u200bthe room in which it is necessary to weld plastic pipes. In addition, couplings make it possible to connect both thin-walled pipes and those with different wall thicknesses.

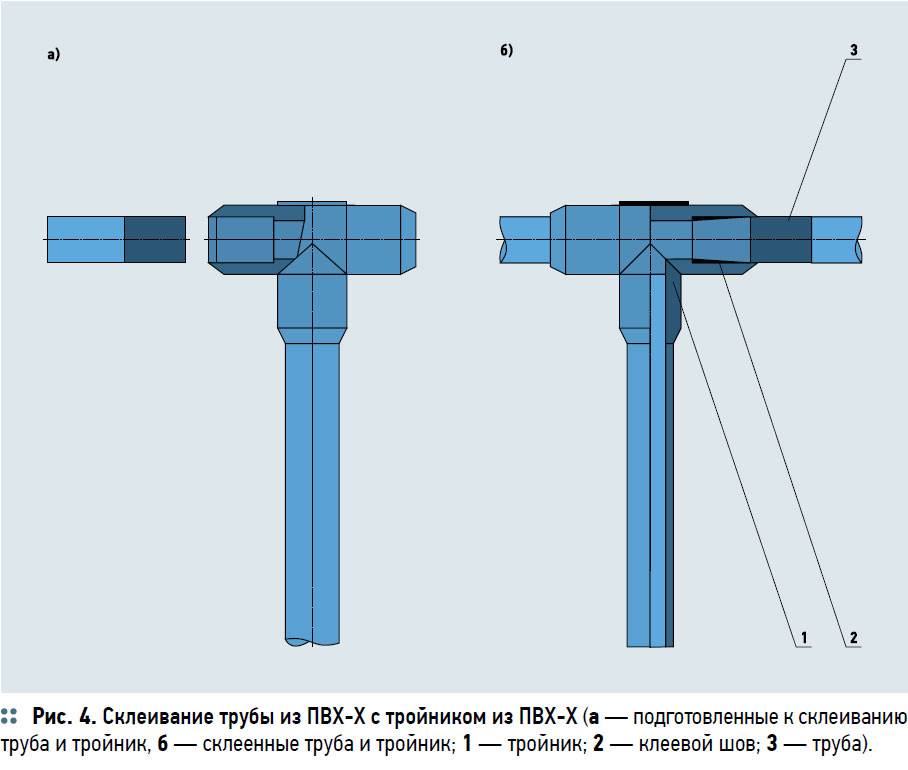

PVC pipes

They are equipped with a special socket, which is very helpful in installation.

The connection of PVC pipes is usually made by gluing.

Briefly, the installation of PVC pipes looks like this:

Installation of a PVC piping system with glue

- The outer end of one pipe and the inner surface of the socket of the other are ground with sandpaper - to give them a roughness, and, as a result, better adhesion.

- The treated edges are degreased with methylene chloride.

- Apply glue to the entire length of the calibrated end of the pipe and 2/3 of the length of the socket. Most often, GIPC-127 glue is used, it is applied by spreading it very quickly with an even layer over the surface with soft brushes three to four centimeters wide.

- On both connected elements, the pipe is quickly inserted into the coupling (bell) until it stops, then turned a quarter of a turn. It should take no more than three minutes to degrease, spread glue and connect the pipe.

- The elements to be joined are pressed and held in this state for at least a minute. If everything is done correctly, when gluing, a thin squeezed out bead of glue appears.

It will take several hours for complete and uniform bonding.

In case of an error made during the installation process, the connection should be disassembled only in the first 5-10 seconds. After that, all surfaces must be immediately cleaned with a degreaser.

Connections for heating and water pipes

This option is considered more difficult because the communication system is under pressure. In this case, you can apply several ways to connect pipes:

Threaded

For pipes whose diameter does not exceed 4 centimeters, the best option is to connect with fittings. Such convenient devices can have a different configuration and parameters, but they have a common design feature.

One end of the fitting ends with a smooth sleeve designed for a polymer element, the other has an internal or external thread at the end, designed to secure a metal pipe.

Threaded fittings, designed to create reliable connecting nodes between plastic and metal pipes, can have a wide variety of shapes and sizes.

For more complex connection options, a tee fitting is designed, using which you can join two plastic and one metal (usually steel) elements into a single system.

Flanged

For pipes of large diameters (60 cm and more), it is better to use special detachable flanges, which consist of two identical parts connected by bolts.

To connect dissimilar pipes, various types of flanges can be used (loose, figured, based on collars), which differ in size and design features

This allows you to avoid manual tightening of the thread, which is difficult to do on large parts, but at the same time create a strong reliable fastener.

Special types

Other types of fittings can also be used for joining parts, for example, a special coupling or fittings of the Gebo type. The latter option is especially recommended for fitting pipes of short lengths or systems located in difficult places (for example, close to the floor).

metal hose

To combine plastic elements with metal pipes, you can also use a special device - a metal hose, which is designed to work in extremely difficult conditions (high pressure, exposure to aggressive substances).

Typically, such a device is used when laying gas pipelines or installing systems at chemical enterprises, but it can also be used in construction.

With the help of a metal hose, you can create an elastic connection. Such a device is usually used in industry, including complex and dangerous jobs.

A metal hose, one example of which is a flexible mixer hose, is attached to a metal pipe using an ordinary thread (in the case of connecting large diameter elements, a flange of the appropriate size can be used). An additional fitting with a polymer sleeve is put on the second end of the metal hose, which is joined to the plastic product.

A special advantage of this method is the ability to create a flexible connection, thanks to which the structure is able to "bypass" various obstacles.

Below we will take a closer look at the installation of various types of connections.

Types of connection of metal pipes with plastic

Today, there are two ways to perform this procedure:

- Threaded connection. It is used when tubular products are connected, the diameter of which does not exceed 40 mm.

- Flange connection. It is optimal for a large cross-section of pipes, since tightening the threads in such cases will require considerable physical effort.

Features of threaded connections

To understand how a plastic pipe is connected to a metal pipe using a thread, you should study the fittings that are used for these purposes. In fact, such a part is an adapter. On the side to which the metal pipeline will be connected, the fitting has a thread. On the opposite side is a smooth sleeve, to which a plastic pipe is soldered. Also on sale are models with which you can connect dissimilar lines in larger quantities and fittings for making bends and turns.

The threaded coupling is selected depending on the type of plastic pipe - for soldering, with a crimp or compression connection

To connect a steel pipe to a polypropylene one, you have to perform the following sequence of actions:

- remove the coupling from the steel communication at the site of its intended connection with the plastic branch of the pipeline. You can also cut off a piece of an old pipe, apply grease or oil and make a new thread with a thread cutter;

- walk along the thread with a cloth, fasten a layer of fum-tape or tow on top, cover the surface with silicone. Wind 1-2 turns onto the thread so that the edges of the seal follow their course;

- screw on the fitting. Perform this operation with an adapter from a plastic pipe to a metal one without using a key. Otherwise, the product may crack. If, when you open the tap, a leak appears, tighten the adapter.

The convenience of the design of this part is that it simplifies the procedure for connecting metal pipes with polypropylene pipes at turns and bends. Interestingly, if necessary, the shape of the fitting can be changed. Heat it up with a building hair dryer up to +140˚С and give this part the required configuration.

flange connection

As mentioned above, metal and plastic pipes of large diameter are connected in a similar way. The final design is collapsible. The technology of such a connection of a plastic pipe with a metal one without a thread is as simple as in the case of using a threaded adapter.

carefully and evenly cut the pipe at the intended connection;

put a flange on it and install a rubber gasket

She will act as a sealant;

carefully slide the flange onto this sealing element;

do the same with the other pipe;

Bolt both flanges together.

One of the options for switching from metal to plastic is a flange connection, in which case a flange is first soldered to the polymer pipe

Advice. Tighten the bolts evenly, without moving parts and without excessive force.

Other methods of threadless connection of metal and plastic pipes

To implement this technology, in addition to flanges, the following devices are also used:

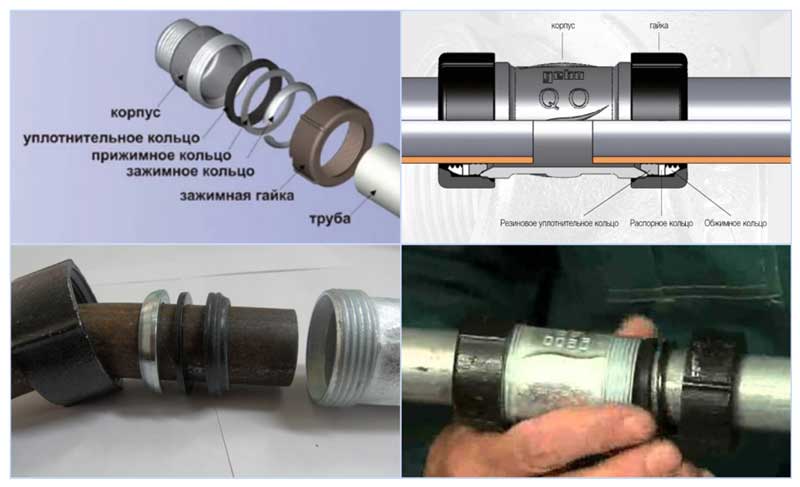

Special clutch. This part is for sale in a building materials store. However, with certain skills, you can do it yourself. This adapter consists of the following components:

- corps. It is best to make it from high-strength steel or cast iron;

- two nuts. They are located on both sides of the clutch. If you are going to make such an adapter with your own hands, use bronze or brass for the production of nuts;

- four metal washers. They are installed in the inner cavity of the coupling;

- rubber pads. They are used to seal the connection. It is impossible to specify their exact number in advance.

The diameter of gaskets, washers and nuts must correspond to the section of the pipeline elements. Connect a metal pipe with a plastic one without a thread using such a coupling in the following sequence:

- Insert the ends of the pipes through the nuts to the middle of the coupling. Also, thread the tubulars through the gaskets and washers.

- Tighten the nuts until tight. The gaskets must be compressed.

The connection is durable and strong enough.

Using a Gebo type fitting, the connection can be made quickly and effortlessly, the main thing is to choose the right diameter

Fitting Gebo. This part consists of the following elements:

- corps;

- nuts;

- clamping rings;

- clamping rings;

- sealing rings.

The connection is very simple.

- Unscrew the coupling completely.

- Put all the above elements on the ends of the pipes to be connected.

- Fix the joint with nuts.

Mounting methods

Sewer plastic pipes can be combined with each other in two ways:

Collapsible (coupling and flange).

Non-separable (connection by welding, branching, gluing, using crimps).

With flanges

In this case, the work is carried out using a cast-iron fastener and a rubber gasket.

The edges of the pipes are cut exactly at the connection points, then a free flange is put on, a rubber gasket is inserted, then the edge is attached to it again.

Only after that the whole structure is fixed with bolts.

collapsible

The edges of the pipes are sawn off at a right angle, then the coupling is put on so that its center and the border of the joint coincide.

The products are marked according to the position of the coupling. From the inside, the edges of the elements are smeared with grease.

Next - one end of the pipe is inserted into the coupling and pulled onto the other, while strictly adhering to the marks.

When installing a non-pressure sewer, it is allowed to use corrugated pipe fasteners.

Both of these methods are not expensive and do not require special tools and expensive equipment.

With weld seam

In order to connect the elements "butt" you will need professional tools - welding equipment for plastic.

To begin with, the ends of the pipes need to be heated until they begin to melt.

Then we press the softened ends against each other and wait for some time until the plastic cools completely.

At the joints, a monolithic joint is obtained, which is identical in strength to the quality of a conventional pipe section.

When arranging a small sewer system, you do not need to specifically buy a welding machine, it will not justify itself. In this case, the connection of plastic pipes can be made using fittings.

Attention! This work is not for every home master. Not everyone knows how to handle welding machines

The glue version involves the use of a special glue that is designed for this purpose.

Before starting work, you need to carefully study the recommendations of the adhesive manufacturer. Step-by-step instruction:

- we clean and degrease the surfaces that, when glued, will come into contact with each other;

- with a small brush, apply adhesive to the edges to be glued;

- we insert PVC - products one into another, fix them in a fixed position and hold it for several minutes.

During this time, the glue will set well.

The joints must be sealed again with an additional layer of adhesive to secure the result.

Thus, the design will become more durable and invulnerable to leaks at the junction points.

Connection of pipes "in the socket"

Experts consider the socket connection the simplest and most reliable.

The use of fittings makes this installation method affordable in terms of money for families with an average income.

A good tightness of this method is achieved by compressing the rubber rim on the socket and the ground end of the pipe.

The edges of the product are coated with silicone and inserted into the pipe, and the pipe itself is fixed on the bearing surface.

Do not forget that the socket must be facing away from the flow of the sewage flow.

Instead of silicone grease, you can use liquid soap or any detergent that you currently have on the farm.

You can cut plastic products with a regular hacksaw with fine teeth.

Bending technologies

Before bending metal-plastic pipes, it is necessary to decide which bending method to use. Each approach has features, advantages and disadvantages. We list the methods of bending metal-plastic products:

- Do-it-yourself bending. A simple, low cost method. The disadvantage is a high probability of deforming the part.

- Using a pipe bender. The tool allows you to bend the pipe at the required angle, eliminating the occurrence of marriage. The high cost of a pipe bender does not justify its single use. It is recommended to purchase for permanent large-scale work.

- The use of sand. Dusty, energy-intensive method that allows you to achieve accurate results.

- Spring application. Accurate method that eliminates the appearance of marriage when bending. The disadvantage is the difficulty in choosing the required diameter of the device.

Consider the bending technology of each method in detail.

manual method

When bending by hand, the main rule is not to make sudden and quick movements. The product is clamped in one hand, and the other is carefully deflected by the previously calculated radius. The first fold is recommended to be performed at 20 °, no more.Then step back 10 mm from the bend and bend with a small amplitude again. Such non-amplitude bendings should be performed 10-15 so that the metal-plastic part turns 180 °. If you need to straighten the pipe, do it in reverse order.

Sand use

This method is most often used if it was not possible to find the right size spring. Sifted sand is poured into the pipe so that there are no voids left. The ends of the pipe are closed with plugs to prevent sand from spilling out. The part is clamped with a clamp in a place that is remote from the bend.

Before bending, the required area is heated with a blowtorch. You need to heat carefully, checking the degree of incandescence of the sand with paper (smoldering paper is a sign that the sand is heated to the desired temperature). After heating, we give the product the desired shape, pour the sand.

Pipe bender application

A pipe bender is a tool with which it is possible to bend a metal-plastic product at home. The device consists of a movable roller and a template roller, a bracket, a handle and a curved pipe. The machine bends products without preheating, the maximum bend is 180°, the process is safe, the appearance of defects is excluded.

The Volnov machine is arranged simply; when using it, you do not need to have special skills. At home, crossbow or spring pipe benders are more often used. The surface that curves the tube must be oiled before using the machine. This will reduce friction and the risk of damage.

In specialized stores, there are also more advanced models of pipe benders.But the purchase of hydraulic or electromechanical machines is only advisable if a large amount of work is performed.

Spring application

Using a spring to bend metal-plastic pipes is a proven method. This process will require a suitable spring diameter. To give the product the desired shape, you need to follow a simple instruction:

- Place the fixture in the pipeline part. The spring should be located directly at the bend.

- Gently, without sudden movements, bend the part at the desired angle.

- Take out the spring.

Each of the presented methods is reliable and effective. Acting slowly, carefully, it is possible to bend a metal-plastic pipe of different diameters at the required angle. You don't have to buy expensive fixtures.

How to solder polypropylene pipes without a soldering iron using cold welding or adhesive bonding

Cold welding of plastic pipes is a process of connecting parts without heating them. You can solder plastic elements by using a special glue that hardens quickly. The composition of the adhesive usually consists of an epoxy resin and a hardener. Cold welding has black or white colors. Usually it is used for cold water supply. But some adhesives are also used for hot. This must be indicated separately on the packaging.

What is the adhesive mass:

- Fluid mixtures (the package should contain two tubes: one with a hardener, the second with an elastic substance; for example: if you are going to eliminate a hole in a polymer product, then the contents of the tubes must be combined immediately before starting work (a kind of repair); it is imperative to use a mixture for no more than 20 minutes, otherwise it will become hard).

- Plastic mass (it is a bar consisting of two layers: a hardener on top, and a plastic component inside; it resembles plasticine).

The package also indicates the maximum allowable temperature for a particular mixture (usually about 260 degrees). If you strictly follow the rules of operation, then the seam will be durable, strong and tight. There is glue for high water temperatures (about 130 degrees).

Thus, soldering polypropylene pipes is not the only way to join polymers. It is possible to connect plastic pipes with your own hands without the use of a welding machine. Do-it-yourself polypropylene pipes can be connected by cold welding or using compression fittings. The connection of polypropylene pipes without a soldering iron using fittings has features, among which the most important is the ability to assemble and disassemble structures.