- Connection methods

- Types of connection of metal pipes with plastic

- Features of threaded connections

- flange connection

- Other methods of threadless connection of metal and plastic pipes

- How to connect polypropylene pipes with metal-plastic pipes?

- Similar posts

- In what cases is connection to metal pipes required?

- What types of connections are there?

- Threaded connection with fittings

- Flanged pipe connection

- Comparative characteristics of various pipes

- Metal pipes

- Pipes made of polymeric materials

- Methods for joining pipes made of polypropylene

- Threaded fittings

- Diffusion welding

- Welding with electrical fittings

- Butt welding

- Cold welding

- Adhesive connection

- Flange application

- Soldering with solder tape

- Options for connecting metal and polypropylene

- Threaded connection: step by step instructions

- Flange connection step by step

- Plastic pipes: an advantageous connection

- Types of connection HDPE pipes

- Expert answers

- How to connect a metal pipe with polypropylene

- Threaded connection

- flange connection

- Using the Gebo coupling

Connection methods

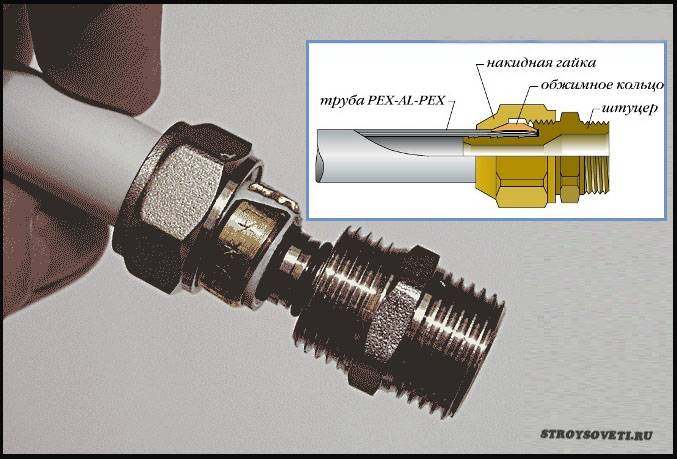

Not every person without practical experience knows how to connect metal-plastic pipes to each other. There are three effective methods for assembling pipelines from a composite material.Connections can be divided into two groups:

- one-piece - made using push fittings or crimping;

- detachable - connections are made using compression fittings.

Installation with compression fittings:

- Clean the joints from dirt, dust with a degreaser. To do this, use a rag soaked in an alcohol solution.

- Unscrew the fitting, remove the split ring, compression nut.

- Put the parts on the end of the tube.

- Insert the fitting nipple into the tube until it stops.

- Slide the split ring to the edge, clamp the joint with a compression nut.

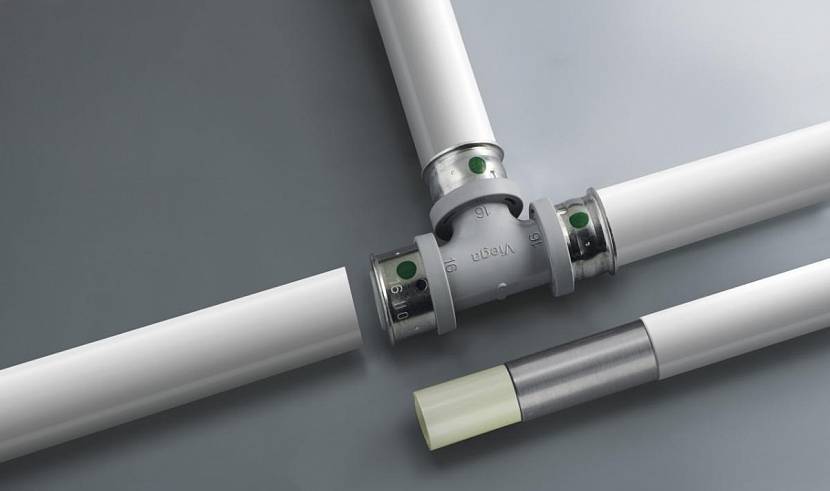

Installation with press fittings is similar to using compression parts, but instead of a clamping nut, a compression sleeve is put on the part, which is fixed with press tongs. The installation steps are identical, but the last step is to crimp the sleeve using tongs of the required diameter. It is performed once.

The process of joining individual elements with push fittings is suitable for people who have never worked with a special tool for plumbing. It is necessary to prepare the ends of the tubes in advance. After that, you need to connect the tubes to the fitting, wait 3 hours before starting the system.

Compression fittings ( / valterra_ru)

Types of connection of metal pipes with plastic

Today, there are two ways to perform this procedure:

- Threaded connection. It is used when tubular products are connected, the diameter of which does not exceed 40 mm.

- Flange connection. It is optimal for a large cross-section of pipes, since tightening the threads in such cases will require considerable physical effort.

Features of threaded connections

To understand how a plastic pipe is connected to a metal pipe using a thread, you should study the fittings that are used for these purposes. In fact, such a part is an adapter. On the side to which the metal pipeline will be connected, the fitting has a thread. On the opposite side is a smooth sleeve, to which a plastic pipe is soldered. Also on sale are models with which you can connect dissimilar lines in larger quantities and fittings for making bends and turns.

The threaded coupling is selected depending on the type of plastic pipe - for soldering, with a crimp or compression connection

For connecting steel pipes with polypropylene you have to perform the following sequence of actions:

- remove the coupling from the steel communication at the site of its intended connection with the plastic branch of the pipeline. You can also cut off a piece of an old pipe, apply grease or oil and make a new thread with a thread cutter;

- walk along the thread with a cloth, fasten a layer of fum-tape or tow on top, cover the surface with silicone. Wind 1-2 turns onto the thread so that the edges of the seal follow their course;

- screw on the fitting. Perform this operation with an adapter from a plastic pipe to a metal one without using a key. Otherwise, the product may crack. If, when you open the tap, a leak appears, tighten the adapter.

The convenience of the design of this part is that it simplifies the procedure for connecting metal pipes with polypropylene pipes at turns and bends. Interestingly, if necessary, the shape of the fitting can be changed.Heat it up with a building hair dryer up to +140˚С and give this part the required configuration.

flange connection

As mentioned above, metal and plastic pipes of large diameter are connected in a similar way. The final design is collapsible. The technology of such a connection of a plastic pipe with a metal one without a thread is as simple as in the case of using a threaded adapter.

carefully and evenly cut the pipe at the intended connection;

put a flange on it and install a rubber gasket

She will act as a sealant;

carefully slide the flange onto this sealing element;

do the same with the other pipe;

Bolt both flanges together.

One of the options for switching from metal to plastic is a flange connection, in which case a flange is first soldered to the polymer pipe

Advice. Tighten the bolts evenly, without moving parts and without excessive force.

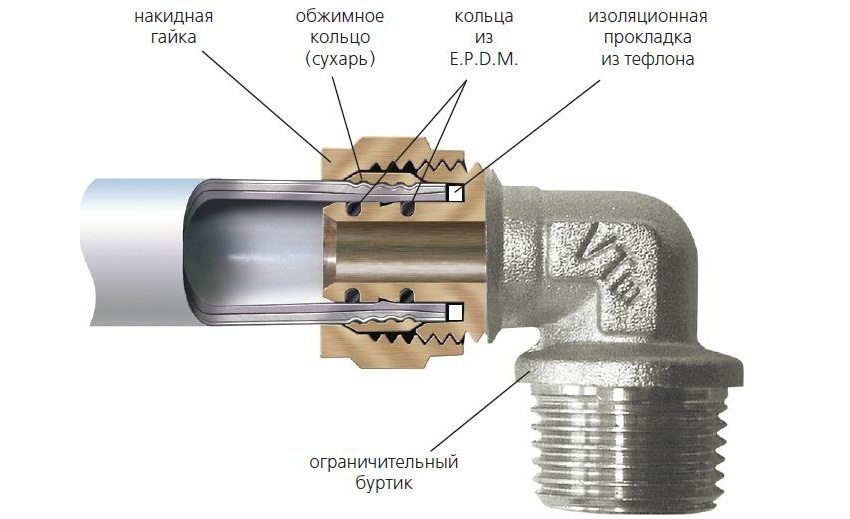

Other methods of threadless connection of metal and plastic pipes

To implement this technology, in addition to flanges, the following devices are also used:

Special clutch. This part is for sale in a building materials store. However, with certain skills, do it yourself. This adapter consists of the following components:

- corps. It is best to make it from high-strength steel or cast iron;

- two nuts. They are located on both sides of the clutch. If you are going to make such an adapter with your own hands, use bronze or brass for the production of nuts;

- four metal washers. They are installed in the inner cavity of the coupling;

- rubber pads.They are used to seal the connection. It is impossible to specify their exact number in advance.

The diameter of gaskets, washers and nuts must correspond to the section of the pipeline elements. Connect a metal pipe with a plastic one without a thread using such a coupling in the following sequence:

- Insert the ends of the pipes through the nuts to the middle of the coupling. Also, thread the tubulars through the gaskets and washers.

- Tighten the nuts until tight. The gaskets must be compressed.

The connection is durable and strong enough.

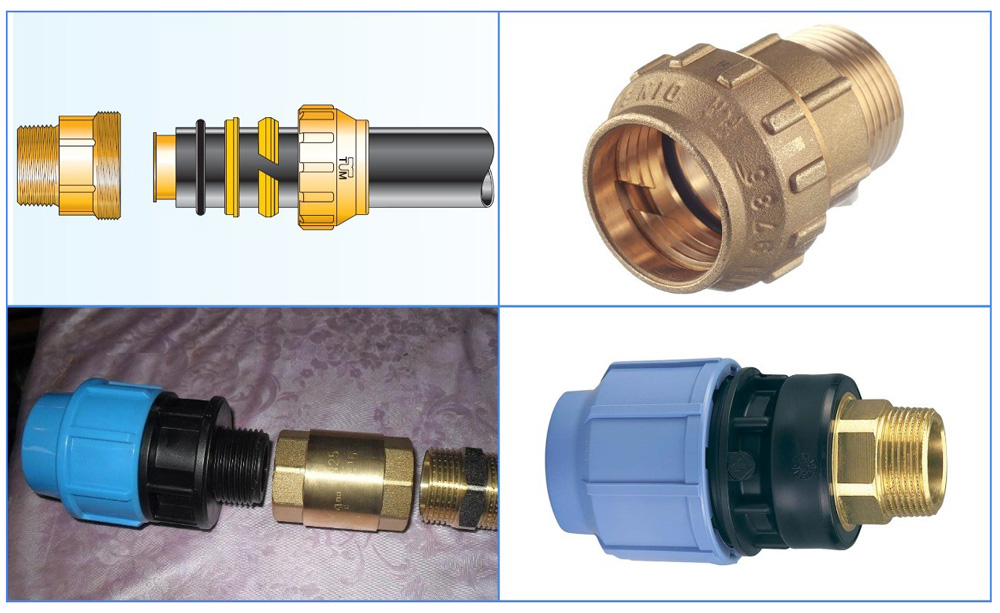

Using a Gebo type fitting, the connection can be made quickly and effortlessly, the main thing is to choose the right diameter

Fitting Gebo. This part consists of the following elements:

- corps;

- nuts;

- clamping rings;

- clamping rings;

- sealing rings.

The connection is very simple.

- Unscrew the coupling completely.

- Put all the above elements on the ends of the pipes to be connected.

- Fix the joint with nuts.

How to connect polypropylene pipes with metal-plastic pipes?

The connection principle is this - you need to find two fittings, one for a polypropylene pipe, the other for a metal-plastic pipe, but the most important thing is that these fittings have the same threads, with only one difference - one fitting must have a "mother" connection with an internal thread , and the second connection has a “male” type with an external thread, so that they can then be connected to each other.

But only in this case the pipes will stand tightly and their further separation in this place will be problematic. To prevent this from happening, it is necessary to install a compression fitting, it not only smooths out physical changes in the pipe, but can also be quickly disconnected if necessary.

They are connected with the help of fittings, they are also called PRHushki. This is a plastic product with a thread at the end, the thread can be internal ("mother") and external ("father").

PRH are not only straight, there are angular PRHushki, there are even tees with a threaded outlet.

It is on these threads that connections from metal-plastic pipes are wound.

I usually wrap not only fom tape on the thread (some people call this tape fum), but also tow, I combine it so to speak. The connection is more reliable.

There is another option, connections with the so-called "American women", "American" is almost the same as PRH, only a collapsible connection, sometimes you can't do without "American women" (the last joint, or the need to remove, periodically, the entire assembly).

add to favorites link thank you

The pipes are connected with a metapol fitting.

A fitting is a product that has a thread on the outside or inside.

There is a huge selection of these "tsatsek", there are both straight and curved, angular, with the connection of several pipes, there are different diameters:

There are connection features: for reliability, a special fum tape must be wound on the thread:

Similar posts

- steel pipe cost

- Metal-plastic pipes and their features

- Which metal-plastic pipes to choose

- Characteristics of metal-plastic pipes

- Methods for laying metal-plastic pipes

- Installation of fittings for metal-plastic pipes

some kind of tow, but you don’t need to clean the metal-plastic tube from aluminum, don’t write nonsense if you don’t know

Nikolai Dorokhov How to connect pipes made of different materials, for example, polypropylene or metal-plastic with metal? Metal pipes are gradually becoming a thing of the past. They were replaced by durable and reliable products made of polypropylene and metal-plastic. But in the process of construction, modernization or repair of existing water pipelines, it may be necessary to attach polypropylene or metal-plastic pipes to metal ones. How to connect pipes from different materials?

In what cases is connection to metal pipes required?

Situations with the joining of pipes made of different materials during construction work occur quite often. The most typical cases include:

- attaching plastic pipes to metal parts of equipment;

- implementation of various sections of communications by different organizations without agreement in the choice of one type of material;

- replacement of only a rotten section of the pipe with another, more modern material;

- repair work within the same apartment with the replacement of pipes and their connection to the old system of neighbors.

What types of connections are there?

It is possible to connect pipes that are made of different materials in only 2 ways:

threaded - using a variety of fittings, it is used for joining pipes not of large diameter, but of medium or small diameter;

flanged - this type of connection is collapsible, used for pipes of large diameter, made using flanges.

Threaded connection with fittings

Fittings are adapters, on one side of which an external or internal thread is wound, designed to be attached to a metal element. On the second side there is a coupling for connection with metal-plastic or polypropylene by crimping or soldering, depending on the material. Installation of the system is not too complicated:

- The coupling on the metal pipe at the connection point is unscrewed, and the thread is cleaned. Or a piece is cut neatly and evenly, and carved using a special tool.

- To seal the joint along the thread, a little plumbing tape or tow is wound, all this is smeared with a silicone compound.

Flanged pipe connection

Metal pipes with plastic are often interconnected using flanges. Before starting work, the required type and size of elements is selected, corresponding to the diameter of the pipes. It turns out a collapsible structure, which can be disconnected on occasion, if necessary, to access any area. Flanges before work are carefully inspected for the presence of burrs, from which damage to the plastic pipe is possible, and, if necessary, are eliminated.

The technology of this connection, like the threaded one, is also not very complicated:

- the pipe at the intended joint is neatly and evenly cut;

- the flange is put on the pipe, then a rubber gasket is installed;

a flange is carefully pushed onto this seal;

the flanges of both pipes are fastened together with bolts, which must be tightened without undue effort, evenly and without displacement of the part.

Both of these methods of connecting pipes from different materials are reliable and durable. The installation process is not too complicated.For high-quality work, you just need to carefully consider each stage, follow the instructions and act carefully.

Comparative characteristics of various pipes

Metal pipes

Separately, it is worth noting those cases when copper is used in the pipeline, which is quite exotic. The fact is that copper is too soft and ductile to be used for plumbing installations. The only option may be a copper elevator assembly made of copper with the rest of the wiring made of polypropylene pipes

Therefore, in the future, we will not take into account copper products.

As you know, the main qualities that determine the high demand for metal products are their strength to mechanical damage and hardness.

In addition, each type of metal pipe has its own individual characteristics:

- steel products - subject to overgrowth of the inner surface and corrosion;

- pipes with zinc coating - they are resistant to corrosion, however, they are quite difficult to install;

- stainless steel - such pipe products are expensive and rather difficult to process;

- cast iron pipes - earlier brands were quite brittle to impacts, but ductile iron is quite strong (for more details: “Characteristics of ductile iron pipes, production and use features”).

Pipes made of polymeric materials

In this case, it is worth separating the plastic pipes for PVC products, polypropylene and polyethylene.

The characteristics of each type of product are as follows:

- polyvinyl chloride is a rather fragile material, therefore it is used for sewer pipes, although not often enough;

- polyethylene - has a low melting point (starting from 80 ℃), a fairly plastic and soft material, so it is advisable to use them only for cold water supply;

- polypropylene is the most durable material, compared to other polymers, it is much lighter than others, so it can be successfully used for hot water pipelines.

Methods for joining pipes made of polypropylene

The choice of docking method depends on what kind of connection we want to get - detachable or not. The decision may be influenced by the presence of a special tool and work skills. Consider the most commonly used methods.

Threaded fittings

If you are thinking about how to make a detachable connection of polypropylene pipes, use threaded fittings. Working with such fittings is considered the simplest and allows you to achieve a good result.

If you are thinking about how to make a detachable connection of polypropylene pipes, use threaded fittings. Working with such fittings is considered the simplest and allows you to achieve a good result.

Threaded fittings are a combination of metal and plastic. The plastic part is attached to the polypropylene by welding or soldering through a plastic sleeve. The second end of the element is made of metal, it is threaded, through which it is attached to another piece of pipe or plumbing equipment.

For work you will need:

- Required fittings.

- gas key.

- Cap coupling and key for its installation.

- Sealant.

To prevent leaks at the points of attachment of threaded fittings, flax fiber, fum-tape are wound on the thread. Threaded fittings are installed when connecting plastic pipes with metal ones.

To prevent leaks at the points of attachment of threaded fittings, flax fiber, fum-tape are wound on the thread. Threaded fittings are installed when connecting plastic pipes with metal ones.

Diffusion welding

This type of butt welding, obtained due to the melting of the material of the parts and the diffuse mutual penetration of molecules.Suitable for joining diameters from 16 to 40 mm. Additionally, a sleeve is used, which provides a layer of plastic to obtain a seam. For thick-walled pipes, diffuse butt welding is used.

Welding with electrical fittings

An electrical fitting is a connector made of polypropylene, in its design it has a metal heater, the contacts of which are brought out.

After the fitting is put on the pipe, the metal contacts are attached to the apparatus, the element is heated, and the fitting through it.

Butt welding

Based on the occurrence of diffusion during heating of polypropylene. To work, you will need a disk unit equipped with a centering device to ensure the alignment of the pipes. Performed for welding segments with a diameter of more than 60 mm with wall from 4 mm.

The technology of work includes operations:

- The pipe joints are simultaneously heated to the required temperature with a disk soldering iron.

- Press the ends of the pipes to each other, make sure that their axes coincide, there is no skew.

- Withstand until the material cools down.

Each welding machine is supplied with an instruction, which contains tables indicating the heating and cooling times for a certain wall thickness. Thick-walled pipes produce a reliable seam. Such pipelines can be buried in the ground, immured in the wall.

Cold welding

It is carried out when the material is melted from the chemical action of the adhesive. It is applied to the joined areas, pressed, held for 10-15 minutes. After stabilization of the substance, we obtain a sealed joint. The strength of the connection is low. Used in supply pipelines cooling liquids and other connections, low liability.

Adhesive connection

A thin layer of glue is applied to the cleaned surface, the parts are pressed tightly against each other, and held for 10 seconds. The joint reaches its highest strength in a day

It is important to choose the right adhesive composition, it must be designed for polypropylene

Flange application

Flanges are used when pipes made of various materials are joined, for example, polyethylene with polypropylene. Rubber seals are used for tightness.

Soldering with solder tape

Using a soldering tape, you can connect the elements without a soldering iron, which greatly simplifies the work. The algorithm of actions is as follows:

- We clean the surfaces of parts, degrease.

- We wrap the place of soldering with tape.

- We heat the place where the tape is applied until it melts.

- We put on the joined part.

- We wait until the joint cools down.

- Remove excess solder.

We get a reliable sealed joint. This method is used for soldering small pipes.

Having some plumbing skills, you can do the installation of an internal plumbing or heating system with your own hands. To get a good result, you should read the instructions and recommendations of specialists. The choice of tool, compliance with the technology of work will serve as a guarantee of obtaining high-quality repairs.

Errors when welding polypropylene pipes:

Options for connecting metal and polypropylene

There are two technologies that allow joining steel and polymer:

- Threaded connections are used for pipes under pressure, and with a diameter of not more than 40 mm.

- The flange connection is made without thread, and will be used on pipelines with a diameter of 40 mm or more.

Each of the methods has a number of features, and involves the use of special devices.

Threaded connection: step by step instructions

To join the metal and polymer, you will need a special adapter - a fitting. On the one hand, it is a coupling with a smooth surface, on the other, there is a thread. Plastic is soldered onto the coupling, the other edge is screwed to the iron output of the route.

Step-by-step instruction:

- The riser is cut, or if there is a coupling, then it is unscrewed. If we are talking about a cut, then after that, cut a new thread with a lerk.

- FUM tape or linen sealant will help prevent water leakage. It is wound in 1-2 turns in turns (clockwise).

- The sealing ring is installed.

- The “American” fitting is screwed on very gently, as it is made of a brittle alloy.

The coupling is welded to the polypropylene pipe using a soldering iron. After that, water can be supplied.

Flange connection step by step

A flange is a non-threaded connecting device that allows the transition from iron to plastic pipes. It is a sleeve that is installed in a steel or cast iron output of the route. The flange is attached to polypropylene with a bolted connection, which eliminates axial displacement and depressurization.

The installation procedure is as follows:

The metal is cut off, the burrs are removed by the grinder

It is important that the cut is perpendicular to the axis of the pipeline. The flange is adjusted with a file if there are interfering protrusions on its surfaces

The sags on the edges are removed, because. they can damage the polypropylene. The flange with the adapter is pressed with connecting bolts. You don't need to tighten it right away. It will be possible to tighten up after the system is turned on. This is in case a leak is detected.

Plastic pipes: an advantageous connection

Recently, products made of polyvinyl chloride are at the peak of popularity, displacing metal counterparts, which are significantly inferior to plastic ones in terms of technical parameters. The main feature of plastic pipes is softening at elevated temperatures and returning to their original state at low temperatures (read: “Sewer connection options plastic pipes - advantages and disadvantages of methods).

To understand how to connect plastic sewer pipes, you need to consider the positive arguments in their favor:

- anti-corrosion properties, thanks to which PVC products can be safely laid underground without additional insulation and at the same time save significantly;

- chemical resistance to substances and aggressive environments;

- light weight of plastic pipes;

- excellent throughput due to the smooth inner surface;

- the duration of the service life, which can reach 100 years;

- easy installation, allowing you to build a drainage system of any kind.

As a minus in the operation of PVC pipes - limited throughput. Although this drawback can be completely resolved if you choose a larger pipe. Knowing the diameter and length of the product, it is easy to pick up parts for a plastic sewer network. Knowing theoretically how to connect two pipes of different diameters, you can proceed to practical steps.

Types of connection HDPE pipes

The HDPE pipe has approximately the same connection devices. The most common is a push-in connection. To connect pipes, a coupling is used, in which there is a collet on one side and a thread on the other. To fasten the coupling, the clamping nut is unscrewed and put on the HDPE pipe.The collet is inserted into the pipe, the clamping nut is put on and tightly tightened.

Note! The clamping nut must not be clamped very hard, otherwise it may burst or the collet will crush the edge of the pipe. After connecting the collet to the other end of the threaded coupling, you can wind another pipe with a thread of the same diameter

After connecting the collet to the other end of the threaded coupling, you can wind another pipe with a thread of the same diameter.

Flange connection of HDPE pipes is carried out similarly to the connection described above. A sleeve is welded to the edge of the HDPE pipe, onto which the flange is attached. And the same device with a union flange, where the connection is installed on the edges of the pipes and pressed with union nuts.

Expert answers

Michael:

Shitty plumbers tried .... but in general it was necessary not to metalloplastic, but to put plastic (cook it without threaded connections). . what is the question then? if nothing can be done, everything is sewn up and you don’t want to unzip, what are you asking? You can connect, that's all I can say ...

******:

Of course. I have so. Stand is polypropylene. And I myself redid the wiring to metal-plastic. Advice to you - let the place of the leak be more carefully wound with a fum tape (or replace the rubber gasket) and tighten it well. Something dawned on me - perhaps you have a leak not at the place of the mechanical connection, but simply the polypropylene pipe itself is soldered to the marriage. (here it oozes)

Mongolian muzzle:

it all depends on the connection, if the so-called "American" then it's just a disease due to thermal expansion, otherwise my advice is to change everything to polypropylene, less hassle,

Vladimir Yakovlev:

Of course you can and the problem is in the connection itself

Michael:

select the necessary adapters and connect, it flows due to an incorrect connection, and not because of the pipes

Nikolay Ermolovich:

It is possible but through the adapter PIPE METAL - PIPE PLASTIC this is for water, but we must remember that for hot water and for a cold pipe they are different, that is, they are marked with their markings. For sewerage, their own adapters with rubber seals, even for different diameters. for ventilation, without any problems at all, if the pipe connection is closed with gypsum, that is, so that the connection cannot be reached later, then it is better to connect it also through a special insert using clamps. if the connection is easy to reach, then it is wrapped with a wide electrical tape; if it comes off from time to time, then it can be rewound. Gutters are also like ventilation, but one must keep in mind pipes made of plastic, according to the certificate, they must have a temperature difference, for example, from -50 to + 35 degrees C and resistance to sunlight. could also answer how to lay pipes in the ground along the roof and. etc. but I think that's enough. If it's easy, rate the answer.

Vlad Ternovskiy:

if the joint is metal plastic flows, change the oring or tighten it, and if it's plastic - plastic, then you need to resolder

Grandfather Au:

you need to call a plumber if the fitting is long, let it stretch - if under pressure testing - let it change the fitting and a piece of metal-plastic pipe

Celestial slug:

So they connect. Even before the replacement of the risers, the wiring was made by metal-plastic. From the riser there is a corner-adapter, a ball into it, then a counter and up to the mixer.

Belogurov Nikolay:

when does it cool down? when does the heat stop?

Kungurtsev Andrey:

The disadvantage of metal-plastic pipes is that their connections are unreliable and the collet (metal-plastic connection) is not airtight.When using a metal-plastic in a heating system, over time, these pipes begin to flow at the junctions. What can be done? Only if you tighten the joints, drill drywall so that a hand with a key crawls through, and then putty this place. But of course you need to use polypropylene for heating systems. otopleniedoma.ucoz

Artyom Lobazin:

It is better to change the entire system or gradually in sections. Just take not junk like metal-plastic and polypropylene, but a metal-polymer pipe made of pert type 2. And it will serve for a long time and it will be easy to lay. nanopipes there and there is a video

Can't find the fire?

GEBO coupling, if you don't mind the money:

goga ivanov:

kaneshna ... insert one into the other and wrap it tightly with tape ... :)))

Dr. Zilberman:

Of course. Plasticine. If you don't plan to use

:

A piece of rubber hose and clamps.

Vladimir Petrov:

If not for a long time, then you can, as mentioned above, with the help of clamps. But it’s better to still find a soldering iron and solder and then connect with fittings. There is still pressure and a clamp somehow not reliable

Alexander:

It is possible to try for water supply with low pressure. It may be possible to put on propylene an adapter for HDPE on a water thread, then a fitting for a metal-plastic. Not suitable for reinforced polypropylene. Reliability is questionable, in an apartment building it is not worth the risk.

Cat smile:

... Look for a fitting that matches the diameter of the polypropylene. Next is a matter of technology and watch the video explanation)… s .youtube m/watch?v=cbHKD038MCM — fitting for HDPE.

How to connect a metal pipe with polypropylene

Diverse pipe products are joined in private housing, at industrial facilities.The applied technologies differ in labor intensity, used transitions and tools.

Threaded connection

The method is used when joining pipes with a maximum diameter of 40 mm. To make the connection, special adapters are used. These fittings have a thread on one side and a polypropylene tube on the other side.

Connection of a steel pipe with polypropylene

Connection of a steel pipe with polypropylene

The polymer end is connected to the PP outlet by soldering. Welding is carried out using special equipment. This is a soldering iron.

Adapters for threaded connection differ:

- diameter;

- form - crosses, squares and tees are produced;

- outlet angle - 90° and 45° elbows are produced;

- thread position - fittings are manufactured with external and internal screw threads.

When docking, a pipe cutter for polypropylene, special welding equipment and a tap or die are used. The work also uses materials to improve the tightness of the threaded joint. This is a silicone sealant or plumbing paste, fum tape or linen tow.

The threaded connection is made as follows:

- The end of the metal section is lubricated and an external or internal thread is created using a die or tap, respectively.

- A sealing material is applied to the new thread and the fitting is screwed on.

- The polymeric branch pipe of the adapter is soldered to the PP part.

At the last stage, the tightness of the connections is checked by supplying water to the system.

flange connection

The use of flanges creates a joint that can be taken apart and reassembled many times.Such a connection is distinguished by reliability, strength and the ability to perform at various temperatures.

pipeline flange

pipeline flange

Pipes made of steel and polypropylene differ from each other in different outer diameters. Flanges manage to level the difference in size.

Flange connection is performed in the following order:

- The steel pipeline is cut in the required place.

- A flange is fixed on a metal pipe.

- The flange element with the coupling is put on the PP pipe.

- Flanges are connected to each other using bolts and nuts. To increase the tightness, a gasket made of rubber or silicone is used. The bolts are tightened evenly with a torque wrench.

- After a couple of hours, the bolted connections are tightened to ensure better tightness.

Using the Gebo coupling

The basis of this method is the use of a compression fitting. The method allows to perform a reliable transition from a metal to a polypropylene pipe. At the same time, you can create the required branches and turns of engineering communications.

The use of the Gebo coupling has the following advantages:

- The high strength and tightness of the connection is ensured by the teeth that the fitting is equipped with. They crash into pipes. This allows you to get a sealed rigid joint.

- Installation is quick and does not require special knowledge.

- The connecting element does not create tension in the system. It does not cause deformation and cracks.

- The service life of the joint is more than 10 years.

Inside the metal body of the Gebo coupling there is a clamping nut, a clamping and a sealing ring. Fitting installation is carried out as follows:

- Steel pipe rolling is exactly cut in place.

- Paint, dirt, rust and other foreign inclusions are removed from the end.

- A clamping nut is fixed on the edge of the metal pipeline.

- The Gebo coupling is being assembled.

- The nut on the adapter tightens without too much effort, allowing the inner ring to compress.

- A leak test is carried out.