- How to connect a metal-plastic pipe with your own hands. Mounting Features

- Marking pipeline lines

- Types of tools

- Manual drive

- Mechanical

- hydraulic

- Electro-hydraulic option

- Pipe bending by hand

- Bending pipes with a pipe bender

- Using sand and a hair dryer to bend

- Bend Radius Calculation

- Checking, repairing leaks

- Installation of metal-plastic pipes

- Mounting with compression fittings

- Mounting with press fittings

- The device of metal-plastic pipes

- Bending of metal-plastic

- What can be bent?

- Manually

- With the use of bulk materials

- Using a spring conductor (spring pipe bender)

- Using a manual pipe bender

- Practical instruction

- Overview of fittings for the metal-plastic system

- Option #1: collet

- Option #2: compression

- Option #3: push fittings

- Option #4: press fittings

- Installation of pipes from different types of materials

- Assortment of fittings in different shapes

How to connect a metal-plastic pipe with your own hands. Mounting Features

The installation of the system is in many ways similar to the connection of polypropylene or metal pipes, with the difference that welded joints are not used in this case. It is desirable to maintain the geometry of straight lines when assembling the system, although, if necessary, metal-plastic pipes can be bent.Correctly bend the pipes and not damage their structure will help a special tool - pipe bender.

All connections of metal-plastic pipes are implemented using fittings, after the stage of preparatory work. Pipes are prepared after a careful calculation of the configuration of the future plumbing or heating system, accurately determining the required number of transition and connecting elements - fittings.

In order to properly connect pipes made of metal-plastic, a set of tools is needed. For different types of connections, you will need exactly those that best match the fittings used.

To decide how to connect metal-plastic pipes to each other, it is necessary to build on the total budget of the project and the intended purpose of the system. For a simple water circuit, the simplest methods are used: the pipes are interconnected using self-clamping fittings. For a "warm floor" type system, it is advisable to use crimp press couplings.

To connect metal-plastic pipes, it is advisable to use metal fittings

Installer's tool kit for working with different fittings:

pipe cutter - it is used by professional installers to cut pipes to the desired length. It is a special tool for cutting polypropylene, polyethylene and metal-plastic pipes.

Thanks to the wide cutting blade and the lever unit for transferring force from the tool handles, the cut is even, which is important for any method of connecting metal-plastic pipes. Do-it-yourself system installation time is significantly reduced;

a pair of ring wrenches, with their help, clamp fitting connections for metal-plastic pipes are mounted, with one key used as a retainer, and the second one is convenient to work with a clamping nut;

an open-end or adjustable wrench will be used when connecting a metal-plastic circuit to a metal pipeline

In this case, the connection is realized with special fittings, supplemented with threaded connections;

in the tool kit of a professional installer there will definitely be a so-called "caliber" - they can check the correctness of the cut of pipes of various diameters, and chamfer the inner surface of the cut pipe. Without this, a correct and reliable connection for a metal-plastic pipe cannot be achieved;

a tool called "expander" is able to expand the inner diameter of the pipe in the case of a permanent connection;

a massive, but necessary pipe bender in work, is also an indispensable attribute of a master who is used to mounting a system of metal-plastic pipes correctly and quickly;

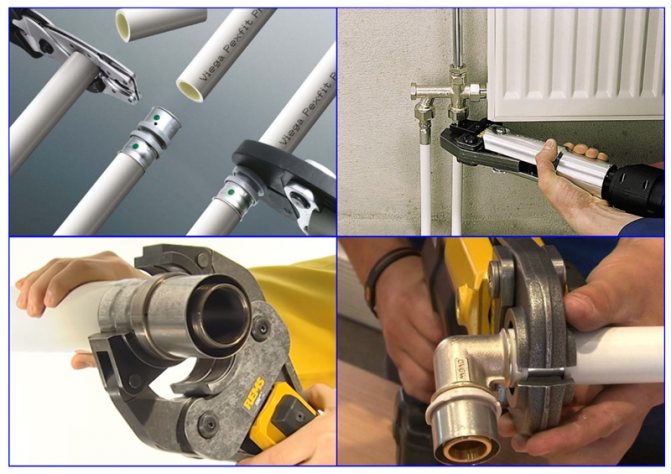

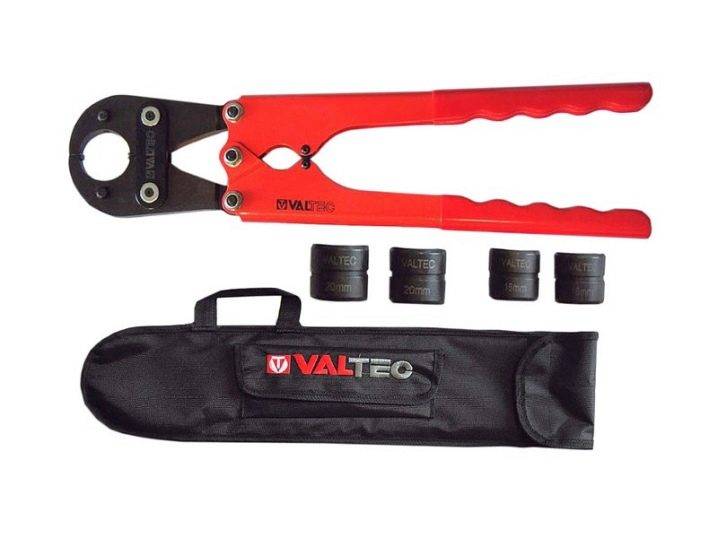

crimping pliers. An exceptionally professional and expensive tool, used for press connection of metal-plastic pipes, namely, pressing press washers on fittings. There are two types: manual and hydraulic tongs. In the delivery set there is a special template for checking the geometry and quality of the connections;

The push fitting press can also be manually or hydraulically driven.

Pipes need to be cut with special scissors so that the cut is even and without burrs

The tool used for mounting varies in quality depending on the manufacturer.It is logical that a professional tool means high-quality components for long-term use.

Important! In order to know how to properly connect metal-plastic pipes, if there is a need for self-assembly, it is necessary to study the installation rules for various fittings, and strictly follow the assembly sequence. Some craftsmen replace the pipe cutter with a conventional hacksaw

But in this case, the cut may turn out to be uneven, which will affect the quality of the connection.

Some craftsmen replace the pipe cutter with a conventional hacksaw. But in this case, the cut may turn out to be uneven, which will affect the quality of the connection.

Marking pipeline lines

Before starting work, it is important to consider how the pipes will be placed. When developing a scheme, it is desirable:

When developing a scheme, it is desirable:

- Apply pipeline lines directly on the walls of the room where it is planned to be laid, which contributes to the visualization of the structure.

- As a starting point, use the pipe connection to a faucet or radiator, which must already be installed before installation.

- Minimize the number of tees and crosses that affect head stability, and minimize the number of other fittings.

- For corner laying of metal-plastic pipes, you can use a pipe bender or corner fittings.

- All connecting elements should be freely accessible, as threaded fasteners need to be periodically tightened to avoid leaks.

The installation of the connecting elements must be carried out after the completion of the calculations and layout of the structure.

Types of tools

To facilitate the work, several variations of this equipment have been developed.

Manual drive

Crimping press pliers, which have a manual drive, are most often used as a clamp at home. Such equipment differs from other nuances in operation and affordable price. Most of such equipment has a universal crimping head, removable liners for clamping pipes with a diameter of ten, fifteen millimeters, and so on. Clamps with a diameter of forty millimeters are out of the question. The limit for a manual connector is a diameter of thirty-two millimeters. The main disadvantage of such equipment is its large size and limited capabilities, and therefore the connection process is not always convenient.

Hand tools for the installation of metal-plastic pipes are divided into several types.

Mechanical

The mechanical equipment consists of two handles connected to the head by a gear mechanism. The applied force is transferred to the head, and the coupling with the fitting is compressed.

The structure of the manual pressing machine is often made with telescopic handles to help with adjustment.

hydraulic

Making your own tool with a hydraulic connection is problematic. But a hydraulic type pipe bender is much simpler.

However, this initiative is not always reasonable. It is easier and safer to purchase Valtec factory pliers or their equivalent, of no less quality.

Among the features of hydraulic pliers, there are several.

- The tool has two handles, one of which is connected to a hydraulic cylinder.

- The output rod of the cylinder is mechanically connected to the crimp head.

- The second handle is connected to the piston of the cylinder.

- When the handles are squeezed, the piston enters the cylinder. This creates pressure that is transmitted to the head through the output stem.

- The installation of the coupling and fitting occurs with minimal effort. The price of this device is much higher than mechanical, and it needs maintenance.

Electro-hydraulic option

Electric, or rather, electro-hydraulic drive - the advantage of professional devices.

Small size electro-hydraulic pliers are very light and very easy to operate, but at the same time they are quite high-performance. This contributes to the easy connection of metal-plastic pipes, their diameter is mainly one hundred and ten millimeters.

Models of electro-hydraulic devices are divided into several types.

- Network tool. The press tongs must be plugged into a standard two hundred and twenty watt household outlet to begin operation.

- Rechargeable. This device is completely autonomous, as the operation takes place with the help of built-in batteries.

- Universal. It differs in autonomous performance or from the network, it all depends on the situation.

All high-quality electro-hydraulic pressing tongs are equipped with removable universal heads that adapt to a certain diameter of metal-plastic pipes.

In addition to the purchased pipe and the necessary fittings, you will need a few more accessories.

Pipe cutter. A scissor-like tool that ensures a correct cut - perpendicular to the pipe

Which is important at work.

Calibrator / caliber - a device designed for multilayer pipes. When cutting, the pipe is slightly flattened, and the edges are bent

The function of the calibrator is to restore the shape and level the edges of the metal-plastic pipe.

Zenker - a device designed for chamfering. A construction knife and a piece of sandpaper may well come up. Quite often, calibrators have a chamfering protrusion, so you can do without this tool.

Pipe bending by hand

The simplest and most common method of bending is done by hand. All that is required from the master is a little sleight of hand. The product modification process looks like this:

- Carefully fold so that the resulting radius is no more than 20˚.

- Step back 1 cm from the bend and bend the metal-plastic pipe a little more.

- Perform up to 15 of these mini bends to rotate the product 180.

- If necessary, straighten the pipe again, it should be leveled only in the reverse order.

The main rule in the manual method is smoothness and slowness of movements. You should not strive to bend the product in one go. Sudden movements can cause damage.

Manual bending is effective when working with products up to 20 mm thick. Thicker products are difficult to modify manually. The method is suitable for processing factory-insulated pipes. They are easy to install and do not need additional insulation.

Material of different thickness and stiffness bends differently, so it is better to practice before starting work. For training, you can use meter segments.

Bending pipes with a pipe bender

A pipe bender is a manual machine in the form of a spring, which ensures accurate and safe bending of a metal-plastic pipe to a radius of up to 180˚.It effectively works with products from 5 to 500 mm and can be used for large volumes of work.

There are four types of machines with which you can bend a metal-plastic pipe:

- hand spring (mobile, can be used at home);

- hydraulic spring (works with products up to 120 mm). It withstands mechanical shocks and heavy loads, as it has a hardened body. In combination with the pump provides high productivity;

- electric spring with program control;

- electro-hydraulic accumulator presses.

The hand spring works with metal-plastic from 5 to 125 mm. It is characterized by a minimum weight - only 10-50 kilograms. With its help, you can modify the material with just one hand.

Bending a metal-plastic pipe with a pipe bender

The procedure for bending metal-plastic:

- Insert the machine into the pipe. The external type of spring is used if you plan to work with a long pipe and make many bends along its entire length. The internal type is effective if the bend is carried out along the edge of the pipe.

- Bend the item. Bending occurs with light, gentle movements. A single bend should have a radius of no more than 20˚.

- Remove spring.

Using sand and a hair dryer to bend

Sand is a simple, affordable material that will allow you to achieve a neat bend of a metal-plastic pipe at home, without the help of bulky and expensive tools.

Working with sand includes only three stages:

- One of the openings of the pipe must be tightly closed.

- Fill the product with sifted sand.

- Slowly bend the pipe to the desired radius.

Sand is good in that it fills the entire cavity of the product evenly, so no defects should occur while working with it.

Pipe bending with a hair dryer

The hair dryer allows not only to bend a flat pipe, but also to correct the defect of the old one. Before bending the metal-plastic pipe, it is necessary to warm it up a little. The main thing is not to overheat the product so that it does not lose its shape. The basic rule when working with a hair dryer is the same as with other methods - to perform movements as smoothly as possible.

Bend Radius Calculation

The correct calculation of the radius depends on the diameter of the product. The example gives a calculation method for a section of 1.6 cm.

To make the bend even, you need to get 1/2 of the circle. If the diameter of the product is 1.6 cm, then its radius will be 80 mm. To calculate the starting points of the correct bend, you must use the formula C = 2πR / 4, in which:

- C - the size of the segment on which you want to bend;

- π is the value of pi = 3.14;

- R is the radius.

Substituting the known values, we obtain the length of the section sufficient to perform the bend 2 * 3.14 * 80 mm / 4 = 125 mm.

Then you need to transfer the resulting value to the product and select its middle, which will be equal to 62.5 mm. The center of the segment will be the middle of the bend. Then a nylon twine is taken, which measures the depth of the shipment.

To do this, tie a twine to the shipment and run it to the required distance inside the product. The string also removes the conductor after completion of work.

Next, you need to smoothly bend the product, starting from the middle of the marked segment and remove the mandrel. Both the outer and inner mandrels should be used at the same time to prevent deformation at the folds.After completing the described manipulations, the material is ready for installation.

Checking, repairing leaks

After installing the metal-plastic pipes, connect them to the faucet using the supplied hoses. Then go through all the route again, and visually check the integrity of the assembly.

Open the taps at the end of the water supply (in the kitchen and in the bathroom). And only after that, slowly, in order to avoid possible water hammer, open the water supply valve to the system. The best way to do this step is with a partner. He must control the exit of water at the final destination. As soon as the water has gone, to flush the pipes, let it drain for 2-3 minutes. Then close the outlet valves, this will raise the pressure in the system, and go along the entire path of the pipe. Check all connections. If in doubt, wipe the surface of the fittings with a paper towel (or toilet paper). Do not confuse condensate with a leak!

We guarantee that if you performed the work according to our recommendations, then in 99.9% there will be no leaks. If any connection causes you reasonable concern, then slightly tighten it.

Installation of metal-plastic pipes

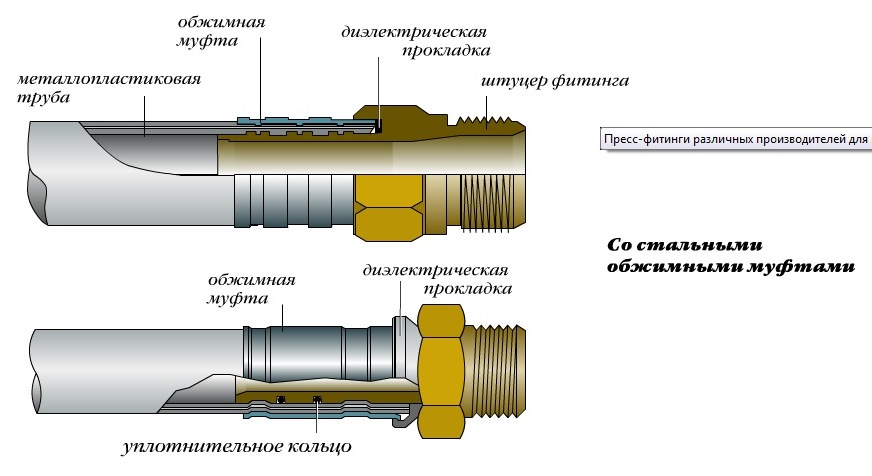

The installation of metal-polymer products is carried out using two types of fittings - compression (threaded) and press fittings; high-temperature welding is not used for their connection, since only composite pipes can be soldered together with high quality.

The main advantage of fitting connections is extremely fast and easy installation, which does not require special skills.We also note that through fittings, metal-plastic pipes can be connected to other types, including steel, copper and stainless steel.

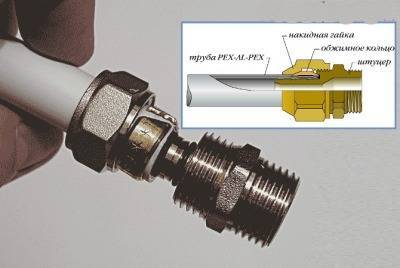

Mounting with compression fittings

A compression fitting allows you to make a collapsible connection, if necessary, to be dismantled, which is why its cost is higher than that of a press counterpart. The design of the compression fitting consists of three parts:

- fitting (metal or brass body);

- crimp ring;

- union nut.

No special tools are required to install this fitting - the union nut of the fitting is threaded, which allows it to be tightened with an Allen wrench or open end wrench. appropriate size wrench.

Compression fittings are available in a wide range of sizes, you can purchase elbows, adapters, tees, crosses and water connectors (straight couplings).

Compression fitting

Note that compression fittings need periodic repair and maintenance, because due to the tendency of metal-plastic to linear expansion, leaks may appear at the junctions of individual parts of the pipeline, which are eliminated by tightening the fitting. This imposes a limitation on the possibility of concealed installation of pipelines, which involves concreting pipes inside walls and floors.

To connect segments using compression fittings, you will need a tool:

- scissors for polymer pipes (can be replaced with a hacksaw for metal or a grinder);

- fine-grained sandpaper, file;

- calibrator.

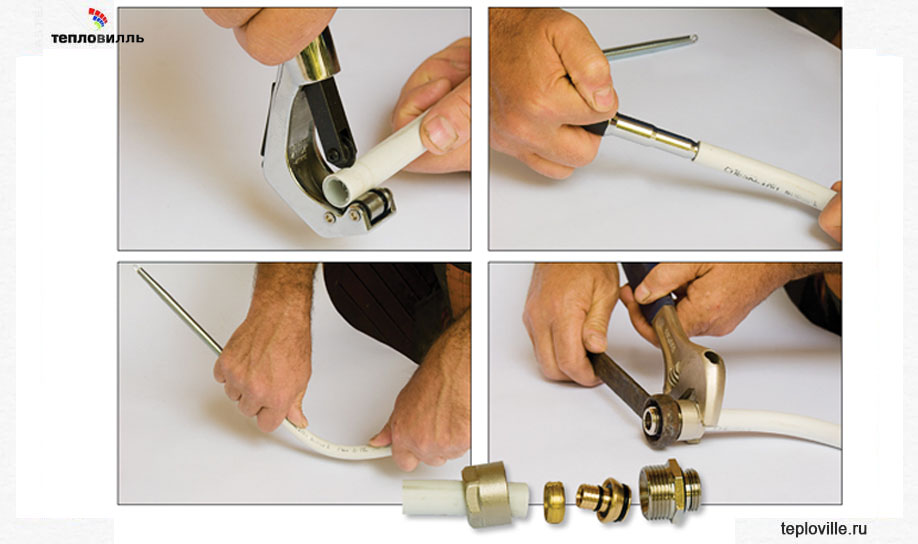

Installation of metal-plastic do-it-yourself pipes executed according to the following instructions:

- The pipe is straightened, measured and the required cut point is marked.

- According to the preliminary marking, the pipe is cut at a right angle.

- Burrs are removed from the end part of the cut using a file or sandpaper, then the product is given a rounded shape by means of a calibrator;

- A union nut and a compression ring are put on the segment, which is placed at a distance of 1 cm from the cut.

- The pipe is put on the fitting fitting, after which the cap nut is manually tightened. When the nut slows down, it reaches 3-4 turns with open-end wrenches.

When tightening the fitting, it is important not to overdo it - after assembly, the system is checked for leaks and, if necessary, problematic connections are tightened

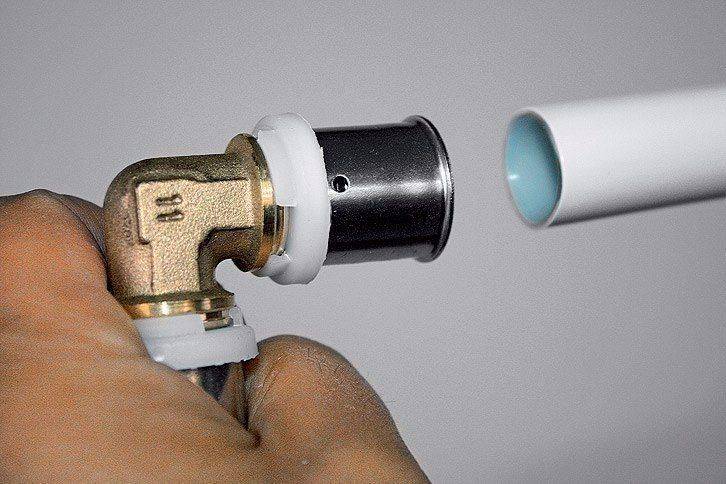

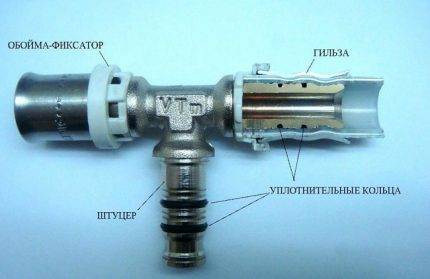

Mounting with press fittings

Press fittings provide a one-piece connection that does not require repair and maintenance, which allows for concealed laying of pipelines. Such fittings withstand a pressure of 10 bar, and their service life reaches 30 years.

To connect metal-plastic pipes using press fittings, in addition to a pipe cutter, calibrator and sandpaper, you will need press tongs. This is a tool that compresses the fitting sleeve around the pipe. The cost of pressing tongs varies between 1-3 thousand rubles, the tool is presented in the assortment of all companies selling metal-polymer products.

Press fitting

The technology of installation of metal-plastic pipelines is as follows:

- The pipe is marked and cut at a right angle into sections of the required length.

- By means of a reamer or sandpaper, the cut point is cleared of burrs.

- The calibrator eliminates the ovality that has arisen during cutting.

- The segment is inserted all the way into the fitting so that it is placed between the fitting and the crimp sleeve.

- With the help of press tongs, the sleeve is crimped to the characteristic click of the tool. If the compression is performed correctly, two rings of the same size are formed on the surface of the sleeve.

There are fittings in which the crimp sleeve and the fitting come separately. In this case, you will first need to put a sleeve on the pipe, then fix it on the fitting, move the sleeve to its extreme position and crimp it with tongs.

The device of metal-plastic pipes

Combined pipes made of metal and polymers consist of five layers. The outer and inner layers are made of cross-linked polyethylene, with an aluminum shell between them. Layers of polyethylene and aluminum are held together by bonding adhesive layers.

This design provides metal-plastic pipes with a number of advantages:

- polymer layers have high corrosion resistance, providing aluminum with protection from moisture and aggressive environments;

- the aluminum layer provides easy installation of metal-plastic pipes with your own hands, thanks to the ability to maintain the shape that was given to the pipe.

The diameters of metal-plastic pipes vary between 16-32 mm. Installation of certain types of such pipes can only be carried out using fittings of the manufacturer of the same name, and some are universal in this regard and allow the use of any fittings.

Bending of metal-plastic

The advantage of the material is the ability to give the pipeline the desired bend, which means that the number of connectors will be less. Plastic threads are bent when laying the "warm floor" system, if a turn is needed in laying the line through the living space. The bending process is carried out in 4 ways:

- manually;

- professional spring;

- building hair dryer;

- with pipe bender tool.

Only an experienced specialist can bend manually. Otherwise, you can bend too much and the plastic will burst.

A professional spring is bought for bending a metal-plastic structure. It is bought according to the parameters of the pipe, since it is inserted inside this structure. With a spring, it is easier to make a bending angle, as a result there are no defects on the surface of the pipeline.

The stream of hot air of the building hair dryer is directed to the metal-plastic. It becomes pliable and easily bends in the right direction. The warm plastic flexes easily without the use of force.

If there is little experience in working with metal-plastic pipes, then it is recommended to use a crossbow pipe bender. A product of any size is bent: the desired bending angle is set, plastic is inserted, the handles are brought together. The tool will help even an inexperienced person to cope.

The connection of metal-plastic pipes is carried out if old ones are replaced with new ones or the main is being repaired. You can handle the work yourself. Installation will be easy if metal-plastic material is chosen for laying. The advantage of this choice is obvious: the pipeline is not painted, the material does not rust, even the long structure is not heavy, the material bends in the right direction.

The water supply line or heating system will last for more than one year, provided that it is not exposed to high temperatures (its deformation occurs) or vice versa, low temperatures (the pipeline freezes at temperatures below 0).

Options for connecting pipes made of metal-plastic are easy to implement. They differ in the possibility of disassembling the structure.

What can be bent?

Although the metal-plastic is flexible in its properties, it reacts negatively to mechanical stress. If a significant deformation occurs during incorrect sharp manipulations, then subsequently it will not be possible to return the original appearance to the product. There are several options with which you can make bends on metal-plastic blanks at home:

- manually, without the use of additional devices (if you do not need many corners on the pipe and with a product diameter of up to 2 cm);

- with the use of substances to soften when bending (bulk materials, wire or spring-conductor);

- with the operation of a pipe bender.

Let us consider in more detail the main nuances of each of the methods.

Manually

The procedure is as follows:

- on the outer wall of the part, a segment of the future bend is marked from beginning to end;

- they take the pipe in their hands, placing their thumbs from below to support the structure;

- bend at an angle not exceeding 20 degrees (with a larger radius, the angle at a certain point of impact will be smaller);

- fingers are displaced along the entire length of the structure at a distance of 1-3 cm, bending further, moving to the end section of the pipe;

- if the turn turned out with a margin, it is necessary to fix the place near the bend with your hands and unbend the part to the required parameter.

It should be noted that a 90 degree angle bends in 5-10 steps, and for a 180 degree bend you need to perform 10-15 steps.

With the use of bulk materials

Work is carried out as follows:

- one end of the product is muffled;

- through the second open end, the pipe is filled with a bulk substance, without adding 1 cm to the end, and a plug is installed;

- begin to gently bend the product to the required angle, similar to the manual method;

- open the plugs, pour out the contents, wash the structure.

This method is suitable for bending products of medium rigidity in order to protect the walls of the part from high stress when creating a turn.

Using a spring conductor (spring pipe bender)

In this case, the workflow will be as follows:

- the spring is put on the structure or inserted inside into the area of the required bend;

- with a gentle movement begin to bend;

- after the formation of the bend, the conductor is removed.

Compressing the pipe in the required area and forming a frame, this device protects the part from damage to the walls during bending.

Using a manual pipe bender

Using a pipe bender, you can bend the part like this:

- choose the required turning radius on the tool body;

- insert the corresponding pipe section into the device;

- reduce the levers, producing bending.

The use of this device is the best option, contributing to the desired bending of a pipe of any diameter without damaging the structure of the material.

Practical instruction

Let's analyze the detailed instructions for self-bending a pipe made of metal-plastic.

- Before starting the installation of the pipeline, it is advisable to practice by making bends on unnecessary pieces of the product. This will allow you to understand how much force you need to apply and with what step it is easier to bend, as well as which method to use. For a test, it is worth purchasing samples of various brands and understanding which ones work better.

- In order for the finished product to keep its shape, it is better to initially bend it with a slightly larger radius, then straighten it to the required angle.

- In some cases, when bending with your hands, you can do without the use of additional devices as a stop for the structure, focusing on turning with your knee.

- Seamless pipes work well in a bent position and with an overlap seam. A seam made in a butt joint may be damaged at a turn during operation.

- If it is not possible to bend the product with your hands, it is possible to help by warming up using a building hair dryer in the fold area.

- To make it easier to insert a wire or conductor inside the cushioning structure, a rope fixed at the ends of the aids will help.

Overview of fittings for the metal-plastic system

To prepare for work, it is important to cut the pipes into sections of the required length, while all cuts must be made strictly at right angles. If the pipe is deformed during the cutting process, it must be leveled with a gauge (it will also help to remove the internal chamfer)

To connect metal-plastic pipes of different categories into a single structure, connecting elements are used - fittings that differ in design, size and fastening methods

For the installation of the structure, various types of fasteners are used, we will dwell on them separately.

Option #1: collet

Collet fittings, consisting of a body, a ferrule, a rubber gasket, have a split design, so they can be used several times. The carving of details allows to combine them with household appliances.

To connect the connecting elements to the pipe, put on a nut and a ring in series. Insert the resulting structure into the fitting, tighten the nut. To make the pipe easier to pass into the connecting element, it is desirable to moisten it.

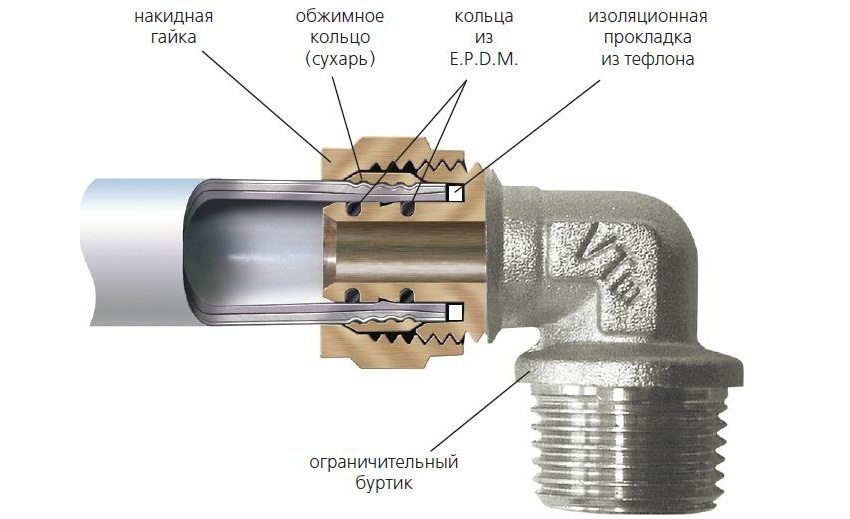

Option #2: compression

Parts widely used for connecting pipes, which can be called conditionally detachable

Before installation, it is important to make sure that the sealing rings and dielectric gaskets are present, which must be located on the shank of the part.

Compression fittings are widely used in the construction of metal-plastic structures. They allow you to easily create connections without the use of special tools.

For connection to the end of the pipe is put on nut and ferrule (if it has the shape of a cone, then the process is carried out from the narrower side of the part). After that, the shank is inserted into the pipe (for this you need to make some effort), while in order to seal the part is covered with tow, flax, sealant.

The next step is to put on the fitting body and tighten the union nut. It is convenient to do this with the help of two keys: one of them fixes the part, the other tightens the nut.

This method is quite easy and does not require the use of special equipment, however, it is undesirable to use it for hidden wiring, since it requires a connection check.

Option #3: push fittings

Convenient connecting elements for fastening of which special tools are not required. For installation, it is enough to insert the product into the connecting part, while the end of the pipe should be visible in the viewing window.

Immediately upon completion of installation, thanks to the included water jet, the wedge of the fitting is pushed forward, forming a clamp that prevents leakage.

This method allows you to quickly and easily create the necessary design, providing high-quality durable connections. Almost the only drawback of push fittings is their high cost.

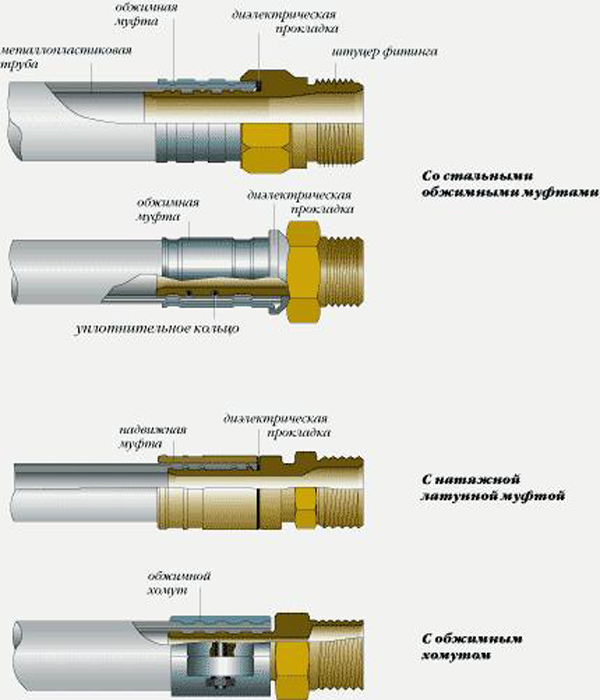

Option #4: press fittings

These elements are used to create one-piece connections using press tongs or similar devices.

Press fittings create tight, durable connections, but they can only be used once. In addition, pressing tongs are required to work with similar elements.

To connect, you need to calibrate the part by removing the fez from it, after which the sleeve is put on it and the fitting is inserted. The sleeve is captured by press tongs, after which, by bringing the handle together, the part is firmly clamped.

Such an element can only be used once, however, the fasteners mounted with it are quite tight and reliable, making them suitable for hidden wiring.

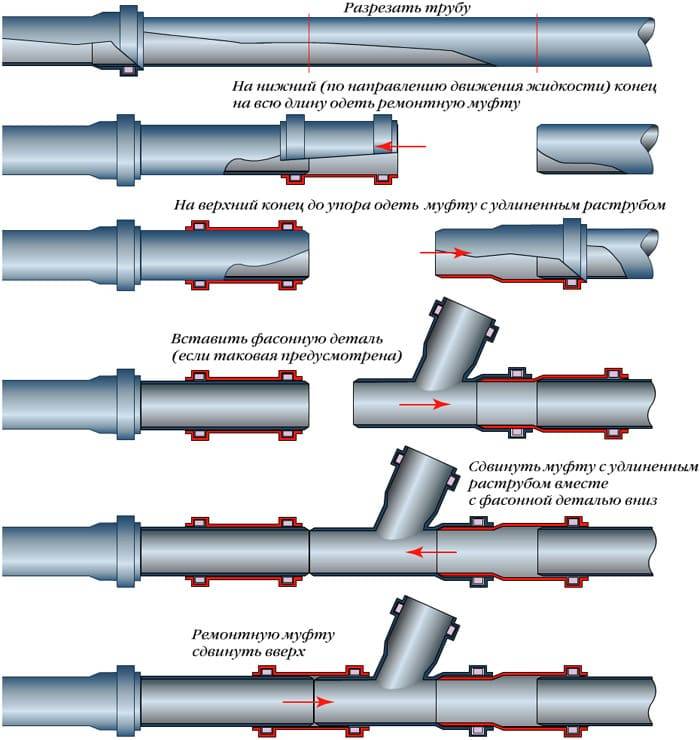

Installation of pipes from different types of materials

To connect elements, one of which is made of metal, and the second is made of metal-plastic, special fittings are designed, one end of which is equipped with a thread, and the other with a socket.

For installation, a metal pipe must be cut into threads, wrapped with tow, lubricated with soap or silicone, and then put on the fitting by hand. After its second end is connected to the plastic element, the thread is completely tightened with a key.

Assortment of fittings in different shapes

For ease of installation, the connecting elements can have a different shape. The most common are:

- adapters for connecting pipes with different diameters;

- tees providing branches from the central pipe;

- corners for changing the direction of flow;

- water outlets (installation elbows);

- crosses, allowing you to organize different directions of flow for 4 pipes.

Press fittings can have a special configuration (couplings, triangles, tees).