- Types of wells

- Abyssinian well

- sand well

- limestone wells

- Equipment

- The main methods of drilling wells

- What technology is used most often

- Equipment for horizontal drilling

- Manufacturing jobs

- Hydro drilling

- Artesian well

- Advantages

- Flaws

- Drilling stages

- Process steps

- How are bored piles constructed - the specifics of the technology

- Piling drilling using auger-type technological equipment

- Drilling wells for piles using rod technology with concreting

- Drilling for bored piles with protection of a part of the well using pipes

- Peculiarities

- Advantages of the auger method

- Stages of core drilling

- Pros and cons of core drilling

- Related video: Well drilling technology

- General recommendations

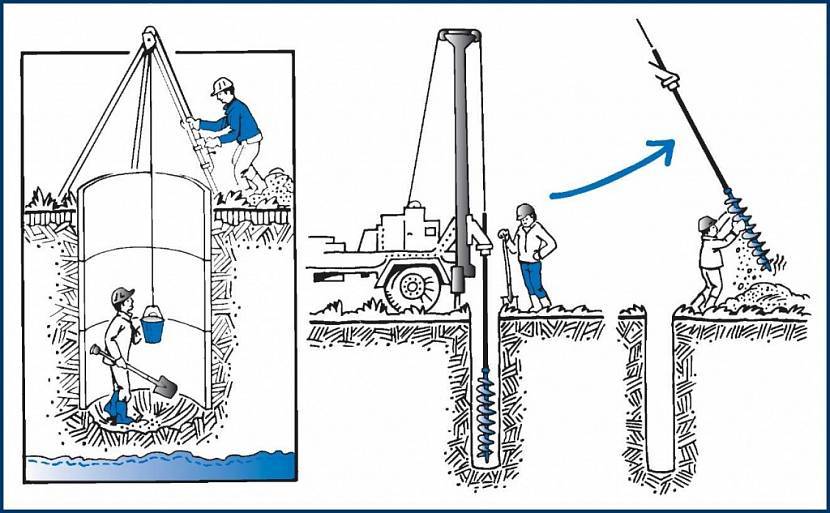

Types of wells

The task of the well is to connect the water carrier with the water consumer. An exploratory well is drilled to determine the depth of the water layer and its parameters. Reducing the cost of work is achieved by using drills of reduced diameter. When developing top water, it is enough to install a drill with a diameter of 10 cm, for deeper deposits - 20 cm. The depth is determined using special probes.

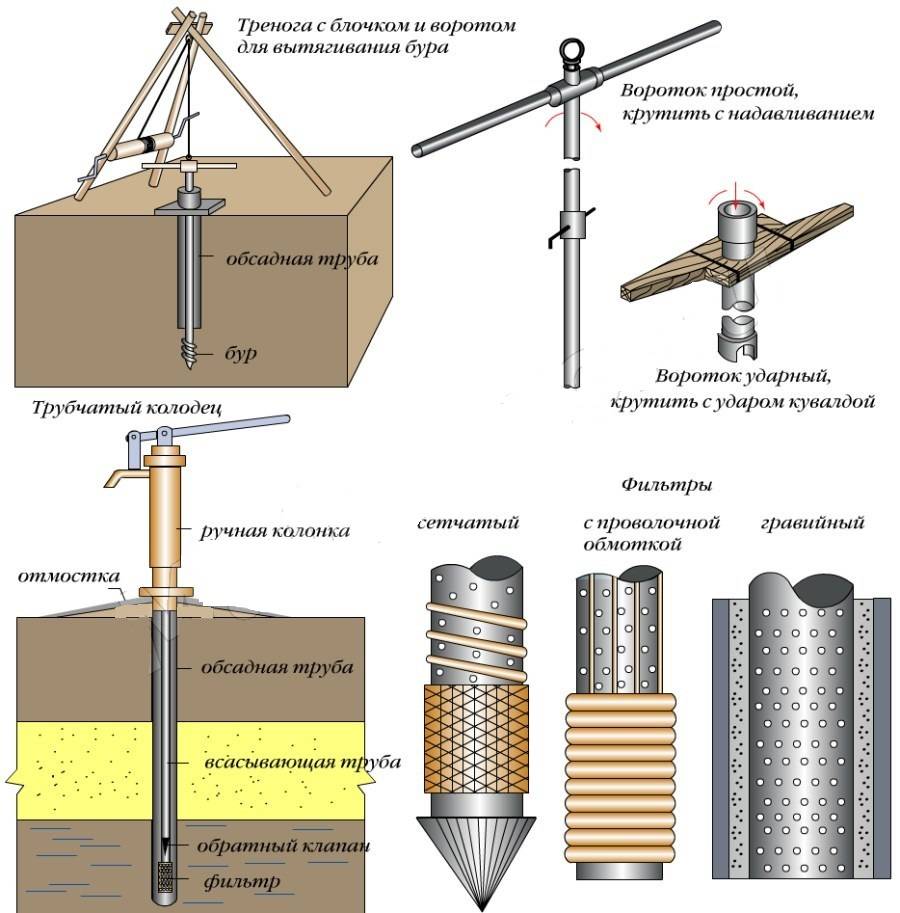

Abyssinian well

The main advantages of the wells under consideration are: low costs, the possibility of self-manufacturing, the speed of arrangement, the ability to install almost anywhere (even in the basement of a house). The service life is estimated at 25-35 years. Among the shortcomings, the following is noted: the impossibility of equipment on especially hard ground, a surface pump can only be used at a depth of no more than 6 m.

sand well

A filter well is drilled when developing a sandy aquifer located at a depth of up to 40-45 m. It is drilled using special equipment and immediately equipped with a casing string to prevent shedding of the wall. Metal, plastic or concrete pipes with a diameter of 13-20 cm are used for the column. A filter is installed at the bottom. The rise of water is provided by a submersible pump.

Advantages of a sand well: use of small-sized equipment for drilling, which reduces costs; you can install a pump of small power; a well is drilled in 1-2 days. Disadvantages: low productivity (up to 2 cubic meters per hour), dependence of water quality on many factors and its instability, dependence of the level of water occurrence on the season.

limestone wells

Advantages of artesian wells: high purity of water, constant level of occurrence of the water carrier, increased productivity (up to 9-10 cubic meters per hour), durability (more than 40 years). Disadvantages: increased costs for drilling and development, manufacturing time (5-8 days), the need for a site for the operation of large-sized equipment.

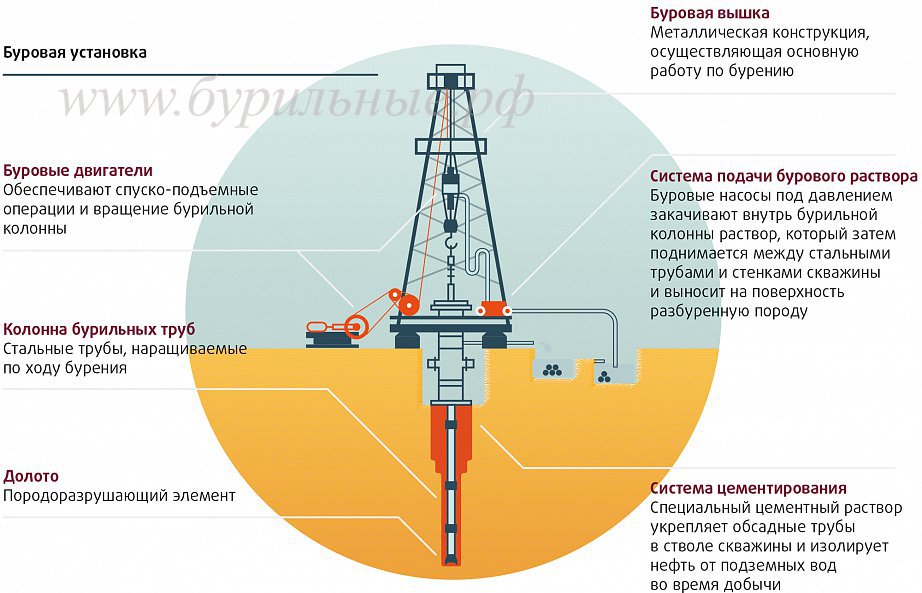

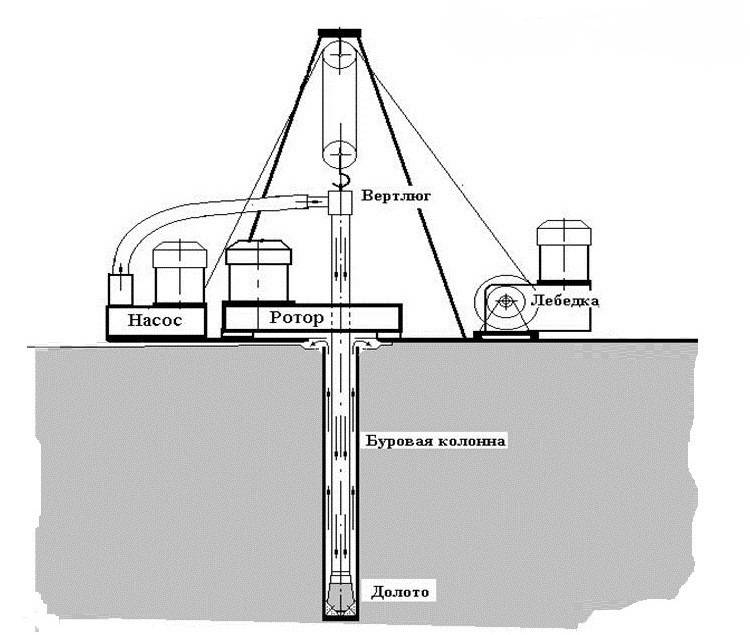

Equipment

Rotary drilling cannot be carried out without special equipment, which includes the following devices and mechanisms:

- tower;

- rotor;

- driven drilling rig;

- piston type pumping equipment;

- drilling swivel;

- mechanisms and equipment for cleaning with a washing solution;

- traveling system, consisting of a crown block;

- gutter;

- vibrating sieve;

- hydrocyclones (usually used in oil drilling).

The mobile version of the rotary drilling rig has all of the above components, except for the cleaning system with a flushing solution.

The main methods of drilling wells

Depending on the type and condition of rocks in the near-surface layer, the diameter and type of the rock cutting tool, the drilling method, the type of cleaning agent and the drill string, the following main methods of well drilling are used.

- 1. Installing the pipe-direction of the well into the hole, previously dug by hand. After installation in the pit, the pipe-direction is either cemented or buried. This method is used when drilling large-diameter wells with roller bits with mud flushing (mainly oil and gas wells) and when drilling geological exploration wells using the shock-cable method.

- 2. Drilling the well "dry", i.e. without flushing or blowing. This option is used when drilling from the surface of the earth in cases where the upper interval of the geological section is represented by sedimentary rocks using conventional projectiles (without a removable core receiver). For drilling, the core set is equipped with a SM or SA type carbide bit, and drilling is carried out with slow rotation of the column and increased loads to a depth of 2-3 m to bedrock.If the bedrock lies deeper, then “dry” drilling is carried out to the maximum possible depth, and then a directional pipe is installed and drilling is carried out to the bedrock already with flushing with a smaller tool.

It is possible to dry-drill by landing a casing string equipped with a bit or shoe into loose loose rocks with rotation and under the action of increased axial load to the maximum possible depth. After that, the casing string is not extracted, and the rock inside the string is drilled out already with flushing with a smaller core barrel set.

3. Drilling with purge air hammer or cone bit can be used on any, including hard, weathered rocks, rocks saturated with large debris and at considerable depths. This method is recommended for various drilling conditions, but only if no core is required in the drilling interval. For drilling, for example, a P-105 pneumatic hammer (bit diameter 105 mm) and a compressor providing an air pressure of 0.2-0.5 MPa can be used. For operational drilling, it is advisable to have a mobile compressor in the organization with a set of drilling tools specifically for drilling operations.

When drilling in unstable, alluvial, loose rocks, drilling with an air hammer can be carried out from the surface with advanced fastening of the wellbore, when the destruction of the rock at the bottom is accompanied by clogging of the casing string equipped with a shoe or a special bit. According to this scheme, drilling is carried out in accordance with Atlas Copco's OD, ODEX and DEPS methods.

four.Drilling with flushing with a diamond or carbide tool is carried out when drilling from underground mine workings without installing casing pipes, if the rocks are stable and not prone to swelling and collapse.

In this case, technical water is removed from the well by a spout and enters the sump along the groove.

The wellhead when drilling horizontal or rising wells drilled from underground mine workings is necessarily equipped with a special wellhead-sealing nozzle when using the SSK projectile for drilling. Then the delivery and extraction of the core receiver and overshot is carried out due to the adjustable hydraulic head in the sealed space of the wellbore.

The option of drilling with flushing is also practiced when drilling wells from the surface of the SSC. In this case, drilling is carried out with flushing with water using an SSC core set with a hard-alloy or diamond crown to the maximum depth and a core receiver with a core is removed to the surface. Technical water, at the initial stage, pours out of the well and is removed outside the drilling rig along the groove. Next, the casing pipe of a larger size left in the well and emerging on the surface of the core pipe is drilled, equipped with a reinforced shoe. After drilling with the casing pipe, drilling with the SSK projectile continues, and drilling with the casing string is carried out until the casing string enters the dense bedrock.

Drilling with flushing is also carried out when drilling with a double column of KGK (hydrotransport of the core). In this case, water circulates through the gaps in the string and enters the sump without pouring out and without contacting the well walls.

What technology is used most often

It all depends on the design depth of the well and the composition of the soil on the site. Based on the exploration data, the most optimal method is selected. You also need to understand how to find water for a well.

For drilling artesian wells, a rotary method is used. This method is the most justified economically, ecologically and gives wells of various depths and diameters in loose soils with rock inclusions.

Its essence is as follows:

- At the end of the rotor, driven by an internal combustion engine, there is a special drill. He crushes the breed.

- The well is supplied with pressurized water. It erodes the soil.

- Further, the water is discharged upward through the hollow channel of the rotor. This technology is also called "drilling with flushing"

- After installing a large diameter casing pipe, the work proceeds with a smaller drill bit.

- Upon completion of drilling work, it is necessary to produce the so-called. "declaying" of the well. This is necessary due to the fact that the water-clay solution clogs the pores through which artesian water will flow into the well.

The well gives you the opportunity to have a supply of water on your site for watering your plants in open-top polycarbonate greenhouses, information about which you can find here.

Rotary drilling is the most commonly used.

Advantages over other methods:

Equipment for horizontal drilling

Horizontal drilling machines of the PVA press-and-screw type have a simple design, apart from separate units such as a diesel generator. The unit is a frame on which a diesel generator with a block of power hydraulic cylinders is located.A carriage is attached to the frame of the drilling machine, which serves as guides for the casing or working pipe being set. Rods with a drill head for pilot drilling are attached to the shaft of the hydraulic unit. Behind the drill there is a primary transmission sensor, information from which is sent to the operator's console. Thanks to the sensor, the depth, range and angle of attack of the drill head are constantly monitored.

Additional equipment consists of a set of rods and pipes with augers, which are assembled on the rod as the earth is excavated from a horizontal well. Sometimes PVA machines are produced not in a stationary form, fastened to a prepared site with anchor bolts, but on a pneumatic course.

Manufacturing jobs

To get started with one of the drilling methods, you need:

- choose a suitable location for the well;

- mount the frame and attach the winch, engine and swivel to it;

- assemble and secure the first knee of the drill rod by pulling it up to the swivel with a winch;

- mount pipe parts on a threaded lock;

- equip containers for placing technical fluid (number of 7 pieces), for this it is necessary to dig pits 1x1m in size and connect them with shallow trenches;

- combine clay with water and place the mixture in a mini-well system;

- apply the solution to the drilling zone using a pump.

During the drilling process, the drilling fluid flows to the swivel and then to the rods. The waste material is located in a trench near the working area, then it moves to the nearest pit after it settles. As the rod deepens into the soil on the bracket, the engine, swivel and gearbox are lowered along the frame.After obtaining the required depth, the mechanism is taken out with a winch and another wheel of the rod is mounted to it.

The process is repeated until a hole of the desired depth is obtained. To set the drilling angle and adjust the inclination of the frame, it is necessary to center the rod with a calibrating bracket. With the help of a remote control, the speed of rotation of the drill changes.

There are several signs by which it is possible to determine the aquifer:

- in the first pit, light washed-out soil is visible;

- three layers of soil, two of them are denser and one is more porous;

- drilling speed drops;

- lowering the water level in the resulting well.

A small-sized drilling rig is removed after an aquifer has appeared. This is done with the help of a technical fluid that is pumped into the well, and it softens the soil, then the drill rod is pulled out with a winch. Following the dismantled equipment, a special casing string from the pipe is installed in the well (the pipe walls must be covered with perforation and wrapped with geofabric).

It is recommended to use asbestos, cast iron or polymer pipes (unplasticized polyvinyl chloride - PVC-U, polyethylene - PE, polypropylene - PP) and electrofusion couplings. The diameter of the casing pipe can be 120-150 mm, and the wall thickness is 6-7 mm. Pipes that are suitable for potable water (not sewage) are PP or PVC pipe. At the bottom of the pipe there is a filter, which is equipped with a stainless steel mesh 2-3 m long. Pipes are lowered into the well by threaded connections in parts of 3 meters. In order for it not to fail, it must be held with two pickups.

The final stage of work is the piping and arrangement of the mine.

At present, it will not be difficult to purchase a small-sized water well drilling rig, since all the necessary information can be found on the Internet. The main thing is to cooperate with large and reliable manufacturers when choosing and buying an MBU, because they can offer a more loyal price for a drilling rig.

Depending on the type of soil on which it is planned to drill a well, it is necessary to choose the right modification of the drilling mechanism, pay attention to engine power, rotational speed of drilling equipment, torque, drilling caliber, warranty period

For information on how to properly drill wells with a small-sized installation, see the following video.

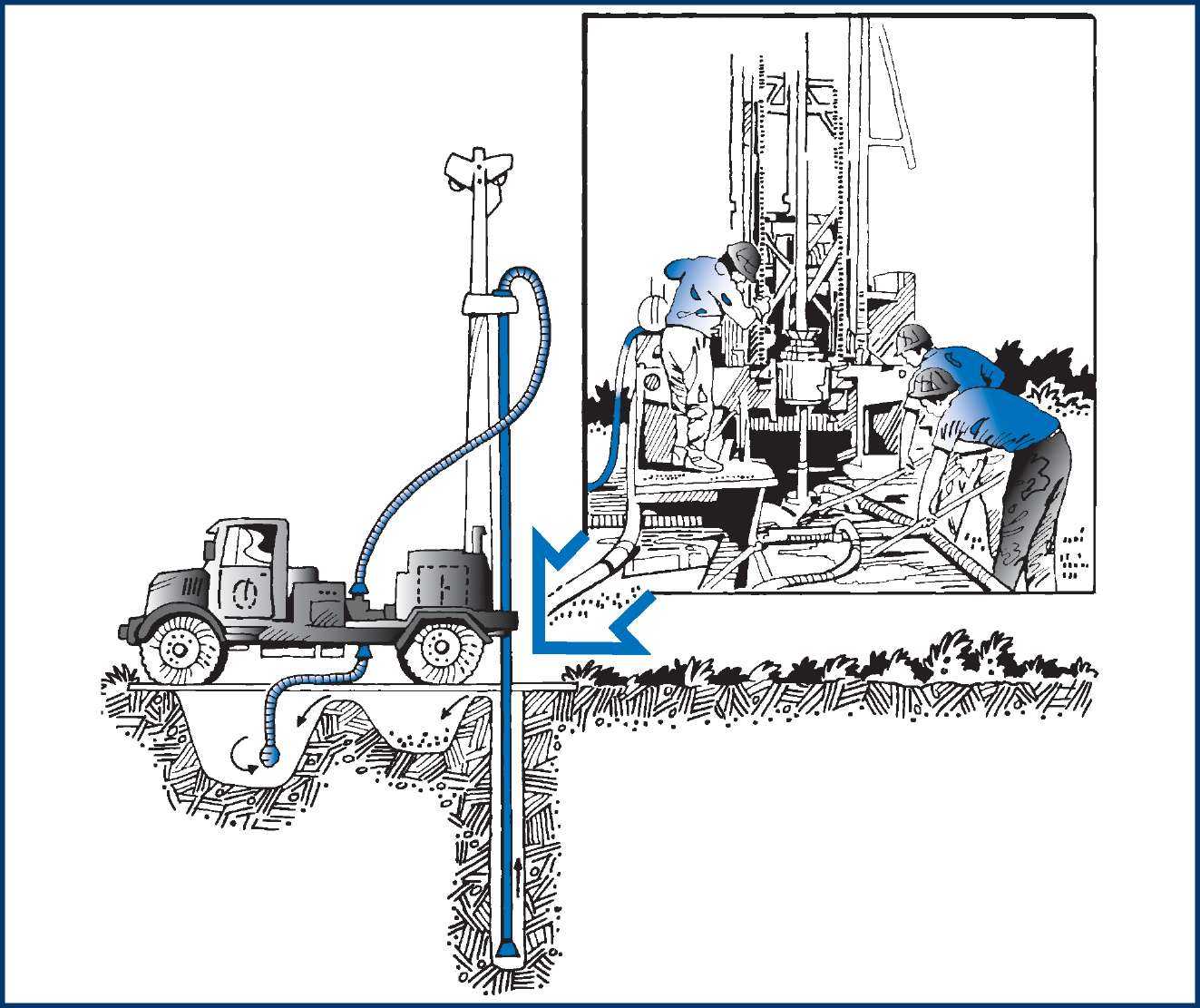

Hydro drilling

It is carried out by a powerful jet of water from a special drilling tool. The advantage of the technology is that it is possible to drill wells in rocky soil.

The jet load is provided by the weight of the rod and drilling equipment. A special solution is poured into the installation, which is then sent to the prepared pit.

Do-it-yourself hydro-drilling sequence:

- First of all, a small-sized structure or MDR for hydraulic drilling is installed.

- It is best to start work in the morning.

- If drilling takes place in sandy soil, then a large supply of fluid is needed.

- Before work, the clay is mixed into a solution in a prepared pit. The kneading is carried out by means of a construction mixer. The consistency should resemble kefir.

- Further, the solution is supplied through the hoses to the working drill.

- Gradually, the liquid polishes the walls and deepens into the soil. The solution is used in a circle.

This technology contributes to the additional strengthening of the walls of the resulting source.

Artesian well

Scheme of an artesian well.

The name of this type of workings comes from the French language - from the place where the first flowing well was drilled: the province of Artois. The large length of the shaft and the solid rocks of the soil crossed on the way to the aquifer require the use of powerful drilling rigs - the auger method will not work.

The construction of the working is preceded by the stage of documentation. Drilling an artesian well is not a licensed activity, but in order to use water from it, many permits and approvals must be issued, including obtaining a license for subsoil use. The process is long and costly.

The main stages: agreement on the location of the site and well, geological survey project, registration of a license for exploration, drilling, drawing up a report and putting reserves on the state balance sheet.

Artesian wells are divided into 4 types:

- A double-cased development - a perforated pipe is mounted in the lower part of the column in the aquifer and a pump is placed in it, the other half is installed on top, reaching the limestone layer. Through the holes in the lower link, water enters the pipe and is pumped out at the mouth with a pump. Used when reservoir pressure is low.

- A water well with a transition is arranged with a variable geological section. 3 casing pipes are mounted - large diameter in the upper part, medium - in stones and sands, small - directly in the productive layer. Used for good water supply.

- The well is classical - with one casing pipe for normal conditions.

- A barrel with a conductor - from 2 casings: in the upper and lower parts.

Drilling technology is complex.The construction of an artesian water intake is carried out by specialized organizations.

Advantages

Advantages of an artesian well.

The main advantages of an artesian well are the remoteness of the water intake from the surface and the occurrence of water in porous limestone, excluding the presence of mechanical impurities in the liquid. This allows you to pump out an underground resource without installing a strainer at the bottom.

As a result, other advantages of artesian wells appear:

- ecological purity of water;

- independence from climatic and weather conditions;

- uninterrupted water supply: groundwater reserves are confirmed by geological surveys.

The source remains inexhaustible for ≥50 years. In this case, you do not need to spend money on periodic filter cleaning: there is none.

Flaws

Associated with costs at the stage of organization of construction and drilling of deep workings. The duration of the period from design to obtaining a passport for an artesian well is 2 years.

It will not be possible to build a water intake in a limited area: the minimum area for a drilling rig is 6x9 m. The water contains mineral formations acquired during filtration through the soil, and is hard.

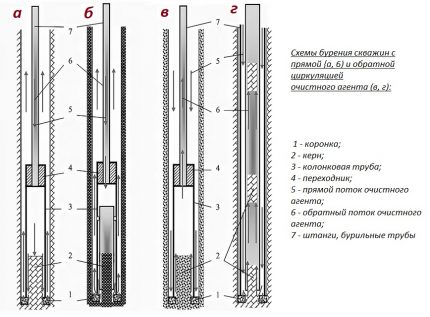

Drilling stages

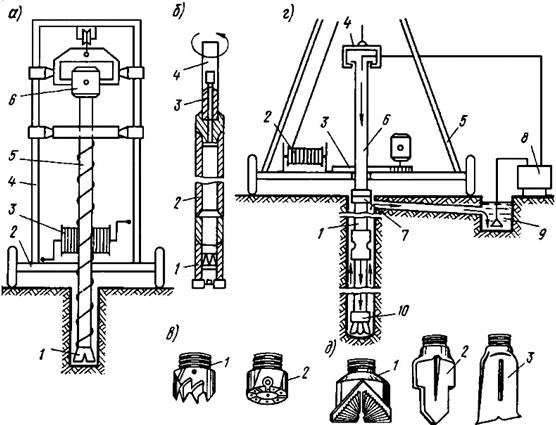

Drilling of wells by the core method is carried out with or without flushing to remove drilling cuttings. In the first type, a high-pressure pump is also added to the equipment used, which makes the process somewhat more complicated, but significantly increases its efficiency.

Consider the general scheme of drilling.

- Preparatory work at the site where the machine will be located. The selected area should be cleared of everything superfluous that may interfere with the work - debris and foreign objects. And also the site should be leveled as much as possible.

- The passage of the pit for the solution and the removal of the liquid flow. The pit should be located next to the future well. Its depth should be more than 2 meters. For these purposes, you can use welded tanks, as well as other containers.

- Installation of the drilling rig, its equipment and assembly. At this stage, the top tube is fixed in the machine rotator.

- Drilling. The projectile passes into the ground, making a rotational movement, and also due to axial pressure, which passes to the end face of the reinforced type bit. At the same time, water or flushing solution enters the bottom of the well.

- Unloading the receiver for the core. Depending on which technology is used, actions are performed either with pulling out the drill string or without it. In the second case, this will be possible if the equipment of the entire installation involves the use of a core receiver that can be dismantled. Extraction of material from the pipe to obtain a sample is performed by lightly tapping the cylinder body with a hammer.

- Return of the string or core carrier to the well and resumption of drilling with alternating actions until reaching the working depth specified in the plan.

It should be added that the composition of the flushing liquid may vary. It will depend on the condition of the rock layers as well as the category of bit that is being used. If diamond drilling is carried out, then a special emulsion is used, and in other cases, a clay-based solution.

Process steps

Horizontal auger drilling begins with the excavation of two pits - start and end (working and receiving). A drilling machine and additional equipment are installed in the working pit, in the end all the work done is completed and the pipe or case for it is accepted.

At the first stage, controlled pilot drilling is carried out, when the direction and length of the channel are set. This is how the “zeroing” is carried out with a thin drill, during which the possibility of an emergency situation is excluded, especially in urban areas with an extensive network of pipelines and underground cables.

At the second stage, a drilled well of small size is expanded by the method of punching with a casing pipe fixed on expander rods to the required diameter. The excavation of the earth is carried out by a mechanism, parts of which are assembled on the working shaft of a horizontal auger drilling machine. The augers are located in a metal pipe laid in the well and are located immediately behind the drill head.

The third stage consists in preparing the working pipe and pushing it after the casing pipe. After laying the pipes in the resulting channel, the drilling rig and other equipment are removed from the pit, the communication parts are connected to each other.

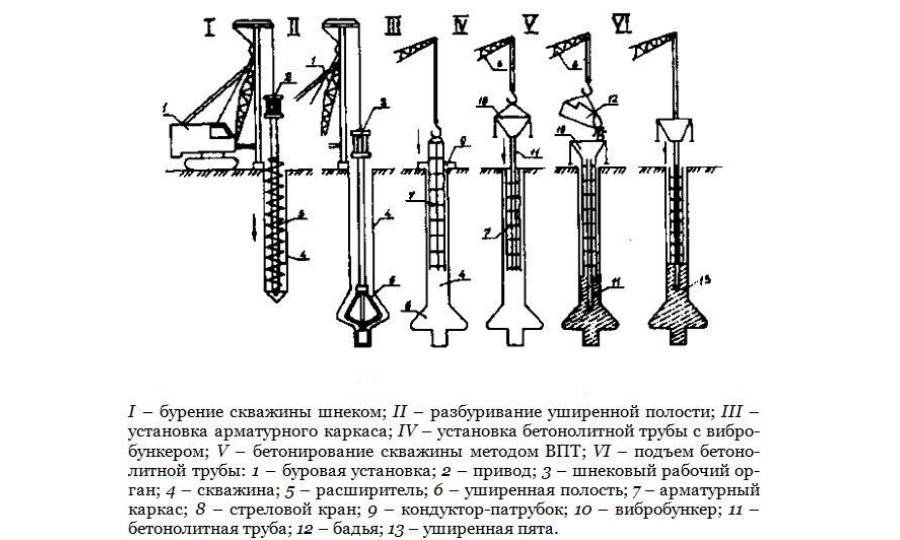

How are bored piles constructed - the specifics of the technology

Drilling wells for piles is carried out by various methods:

- using a standard paddle auger equipped with a reinforced tip;

- using a stackable inventory pipe, consisting of separate sections;

- combined method, involving auger drilling with subsequent supply of concrete into the cavity.

Each well formation method has its own characteristics.Let's consider them in more detail.

Piling drilling using auger-type technological equipment

The above method of performing drilling operations involves the use of special drilling equipment equipped with a standard auger. The working body is a longitudinal rod with blades arranged along a helix and a shank with a reinforced tip.

The main features of the operation of equipment equipped with a standard bladed auger:

- increased up to 120 cm/min the speed of penetration of the well by the working body;

- cyclic immersion and rise of the auger device with the extraction of settled soil;

- the possibility of passing in one go without lifting the bladed auger of a well with a depth of 8-10 m.

The design features of the working body and the functionality of the equipment make it possible to form a cavity in the lower part of the channel using an auger drill. The increased area of the support platform and the conical shape of the cavity are provided with the help of an expansion device, which is immersed simultaneously with the screw. At a given depth, the hinge mechanism changes the angular position of the nozzle, which forms an extension of a given shape and size in the lower part of the pit. This allows you to increase the load capacity of the bored pile.

A certain type of piles and the technology of their immersion is chosen depending on the data of geodetic and geological surveys

A certain type of piles and the technology of their immersion is chosen depending on the data of geodetic and geological surveys

Drilling wells for piles using rod technology with concreting

The used technological equipment and working tools allow:

- to form many wells per shift, the total length of which reaches 350-400 m;

- immerse the working body in the soil when performing drilling operations to a depth of 30-40 m;

- to ensure the diameter of the channel formed during the immersion of the core tool in the range of 50-100 cm and above;

- gradually increase the length of the bladed auger sections until the predetermined depth of the pit is reached;

- pump the prepared concrete mixture into the well using a special pumping unit;

- raise the working mast simultaneously with the supply of concrete mixture into the drilled cavity.

In the process of injection of concrete mortar, the walls of the well are compacted, which has a positive effect on the strength characteristics of the channel. The reinforcing cage is immersed into the well by indentation or with the help of a vibratory driver. This method of drilling can significantly reduce the construction cycle for the construction of a pile foundation by combining drilling and concreting operations.

Drilling for bored piles with protection of a part of the well using pipes

The technology for performing drilling activities provides for the possibility of using inventory pipes to protect the surface of a channel formed in the ground.

Inventory pipe is a special drilling equipment, which consists of the following components:

- individual tubular sections that are easily connected with locks. The length of each element does not exceed 6 m;

- cutting head with serrated surface. The nozzle is made of carbide material and is attached to the bottom of the pipe.

The drilling process is carried out according to the following algorithm:

- High-speed penetration of the soil mass with a drill is being carried out. When rotating and immersing the working body into the well, the soil is gradually removed from the formed channel.

- Simultaneously with drilling, an inventory pipe is pressed into the soil.The metal shell of the protective pipe makes it difficult for groundwater to penetrate into the well and prevents the walls of the pit from collapsing.

After completion of the operations for the formation of the recess, the following operations are performed:

- The auger drill is being pulled to zero.

- The water that has penetrated through the soil into the pit is pumped out.

- The reinforcing mesh is gradually lowered into the well.

The process of forming a bored pile is completed by pumping a pre-prepared concrete mixture into a cavity formed in the ground. For continuous supply of concrete solution, special equipment is used.

Peculiarities

There are certain rules and requirements that must be followed in order to build a quality autonomous water supply system. For example, one of the most popular wells with a depth of 15-30 meters can be equipped in 1-2 days, which will save a lot of time. In this case, it is required to strictly observe the technologies, to responsibly approach the choice of the location for the well and the quality of the work itself, which will increase its service life to 15 years or more, preventing its rapid clogging with groundwater.

MBU is of 2 types:

- self-propelled (drilling equipment is made on the basis of a wheeled trailer);

- stationary (prefabricated modular equipment that can be used for work inside buildings).

Depending on which aquifer is being drilled, there are 2 types of wells - limestone or artesian and sandy.Since these horizons are located at different levels, when contacting specialized organizations, the price of work varies significantly. To choose the best option for your site, you need to analyze all the pros and cons of each type of well.

Advantages of the auger method

The trench technology for laying communications is considered obsolete for economic and production reasons. The first benefit of auger horizontal drilling is the amount of work and the amount of labor required. One team of workers copes with the drilling rig, and the amount of excavated land is much less. At the same time, the construction time, depending on the length of communications, is reduced by 2-20 times.

Economic costs for horizontal directional work are reduced by 30%. At the same time, it is not necessary to interrupt traffic when laying pipes under roads or rivers, and the railway and asphalt tracks remain intact.

During drilling, the environment does not suffer, and the process itself causes a minimum of inconvenience to people. The risk of accidents on site is minimized by the use of steerable drilling heads.

The disadvantage of horizontal drilling technology is the impossibility of working on moving soils.

Stages of core drilling

Before starting work, you need to study the cadastral plan and prepare the working surface. It is necessary to ensure unhindered access to the drilling site for both the drilling rig itself and the machine with the flushing fluid.

The next step is to dig a hole with a volume of at least 2 cubic meters - this will avoid the need for an additional reservoir.The pit is designed to drain groundwater and waste washing fluid. To install the main part of the trunk, it is necessary to punch the soil.

Next, the selected bit is connected to the core barrel and the casing pipes are selected, which will be built up as they go deeper. The installation should be securely fixed, after which the drilling machine is started.

Core technology with flushing of the bottom with water allows the simplest and most efficient way to free the shaft from the destroyed rock

Core technology with flushing of the bottom with water allows the simplest and most efficient way to free the shaft from the destroyed rock

As the core drill deepens and fills, it is periodically lifted to the day surface and cleaned from the soil captured by the tool during drilling. After that, the drill freed from the core can again be immersed in the hole to continue drilling.

To rise up, the drill pipe string, consisting of a core barrel and rods, is dismantled. That is, the rod after the rod is sequentially separated until the core barrel is pulled out of the barrel.

The best option for developing a well for private traders is core drilling, accompanied by flushing. No samples need to be taken in this case. The main thing is to quickly form the shaft and clean it from sludge. At the same time, the working is being prepared for the upcoming operation.

For washing, you can use any water, it is quite suitable from a nearby pond or river. Drilling can also be done dry if a well is being developed for sand. Usually, in this case, a couple of buckets of water are enough as drilling fluid only to cool the projectile at the bottom.

According to the core technology, holes are drilled in concrete and reinforced concrete structures, foundations and brick walls

When working in loose, low-moisture sands, it is recommended to add liquid glass or clay mass to the working solution to strengthen the walls of the hole. In any case, when the drill passes through a horizon with an unstable structure, it will be justified to strengthen the walls of the well with casing pipes.

Pros and cons of core drilling

The positive aspects of the process include:

- The point action of the crown, which cuts the rock along its radius, unlike the rotary bit, destroys the soil during the passage.

- High performance method.

- Possibility by means of core drilling to study the underground structure of soils in the work area.

- Using this method, raise, multilateral, deviated wells are passed; in any layers, including basalt and granite.

- The rotational speed of the drill is adjustable: on soft ground, rather small revolutions, hard rocks require higher ones.

- Relatively high rate of penetration, which reduces the cost of the object, with a reduced energy intensity of the process.

As with any process, core drilling has some disadvantages:

- In those processes where slurry is used, there is a risk of siltation of the aquifer by the washing products.

- Rapid tool wear.

- Dry drilling is too costly.

When working with deep formations, these factors remain decisive. The cost of equipment, together with the price of ground work, is a solid figure.

The core drilling process takes place in several stages, the equipment is subject to regular inspection for damage and chips.

Masters undergo regular safety training, this precaution significantly reduces the percentage of damage

Related video: Well drilling technology

A selection of questions

- Mikhail, Lipetsk — What discs for metal cutting should be used?

- Ivan, Moscow — What is the GOST of metal-rolled sheet steel?

- Maksim, Tver — What are the best racks for storing rolled metal products?

- Vladimir, Novosibirsk — What does ultrasonic processing of metals mean without the use of abrasive substances?

- Valery, Moscow — How to forge a knife from a bearing with your own hands?

- Stanislav, Voronezh — What equipment is used for the production of galvanized steel air ducts?

General recommendations

As can be understood from the foregoing, in order to independently carry out work on drilling a well, it is necessary to do a lot of work at the preliminary stage.

Soil analysis should be performed before drilling a well

What can be included here:

- Determination of a place for a future well.

- Determining the type of soil in a given area. The quality of the water and the best type of drilling technology will depend on this.

- It should also be determined for what needs the water from the well will be used - for drinking or for household needs. This must be known in advance, preferably before the start of drilling. Otherwise, you can drill a well for drinking water in a place where it will be rich in various trace elements, minerals or metals that are life-threatening.

- You should know how deep the water source is. Based on this, it will be clear to what depth you have to drill.

- The most suitable drilling technology is then determined.For example, the presence of a layer of hard rocks or stones in the soil will automatically exclude the possibility of using an Archimedean screw for work.

After all the necessary issues have been resolved, you can choose whether to carry out the work yourself or turn to the services of the appropriate specialists.

If the decision was made in favor of self-drilling a well under water, then everything that is necessary for this should be prepared. As you can see, the level of complexity of each of the installations varies from "accessible to a beginner" to the level of a professional. In this case, it is necessary to correctly assess your strength, otherwise the consequences will be difficult to correct even for professionals.

If you listen to the advice of more experienced drillers and specialists and do everything according to the rules, the well done on the site will serve properly for a long time.