- Features of rotary drilling technology

- Water well drilling methods

- Well casing

- Equipment for rotary drilling of wells

- Features of pneumatic percussion drilling

- Advantages and Disadvantages of Hammer Drilling

- Manual drilling of a well under water

- impact method

- Rope percussion drilling

- Manual well drilling

- rotary method

- screw method

- Useful video on the topic

- Water filtration

- Other models of drilling rigs

- Drilling rig with "cartridge"

- Simple screw installation

- Drilling a well by hand

- Pump installation rules

- Conclusions and useful video on the topic

- Conclusions and useful video on the topic

Features of rotary drilling technology

The drilling process is organized in such a way that, due to the washing out of the soil layer from the mine, the drill string goes deeper with each movement. Periodically, it must be increased by adding other pipes.

The drilling process is carried out in steps:

- After passing the first loose layers of soil, the column is raised, and the casing is lowered into the shaft.

- The gap around the circle is filled with a solution of cement.

- After the cement hardens, a chisel with a smaller diameter is fed into the shaft, and work continues on.

Several similar steps can be performed, and then a production pipe perforated at the end is lowered into the shaft. Depending on the quality of the soil layer and depth, the number and weight of pipes, the type of bit, its rotation speed and edge material, and the pressure of the flushing fluid are selected. The specifics are:

- Light rock formations pass with the maximum speed and the greatest flushing.

- Rocky soils require reduced frequency and reduced fluid pressure.

Soil hard inclusions - boulders - in the path of the rotor, which can jam, or soils that actively absorb washing can interfere with work. The process is also slowed down by the lack of water at the work site and the presence of a large clay layer. Clay, mixing with water, clogs the water channel and requires additional thorough washing.

Water well drilling methods

Drilling a working well for water is carried out with a home-made drill. It also requires a means for raising and lowering it (winch), guide rods and a drilling derrick in the form of a tripod. The simplest way to drill a well is rotary, carried out by rotating a drill with cutting blades.

Working rods for drilling are made of pipes mounted in a working rod with threads at their ends. Between themselves, the pipes are additionally fixed with cotter pins. The lower rod is equipped with a drill with cutting nozzles made of hardened steel with a thickness of three millimeters. Sharpening of the cutting edges of the nozzles is carried out taking into account the direction of rotation of the drill structure in a clockwise direction.

Rotary well drilling

In the course of work, the structure is brought to the surface and cleaned every 40-50 centimeters of deepening, the accumulating earth is removed to a pre-prepared place, or natural pits and ruts are filled with it.

Auger drills

When comparing the rotating handle with the level of the soil, the structure is built up by the next link. Collapses of the walls of the well can periodically occur in sandy soil, therefore it is necessary to lower casing metal or plastic casing pipes into it simultaneously with drilling, which do not allow loose soil to crumble.

Drilling a well for water continues until the passage of the working tip of the aquifer, which is easy to determine by the state of the soil being removed. The well is considered ready when the tip enters the next layer after the aquifer - water-resistant clay. This will ensure maximum flow of water into the well. Immediately after drilling is completed, dirty water enters, which after a while becomes clean and drinkable. A submersible or manual pump is used to pump out dirty water.

If the water continues to be dirty and unfit for consumption, you should continue to deepen the well until it is cleaned.

Well casing

Some suburban areas in Moscow and the suburbs are located on loose, loose soils. The instability of the rock can lead to the collapse of the mine. Work will have to stop and move the pit to another location.

An alternative option is to carry out wall casing at the same time as drilling the well. The technology consists in strengthening the trunk with special casing pipes. Products are available in 2 versions:

- Coupling. Both sides are threaded.Fixation is carried out by threaded connection using couplings with internal threads.

- With dropped ends. Docking does not require additional fasteners or special fittings. On one of the ends, a landing is made - an increase in the cross section by the wall thickness due to broadening by heating. It is equipped with an internal thread. On the opposite side, external cutting is performed. Fragments of the column are joined by screwing.

Some owners of suburban property use PVC pipes for casing the trunk. Manufacturers equip plastic products with fasteners.

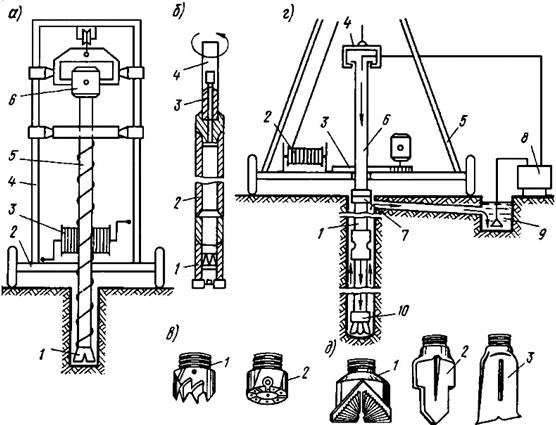

Equipment for rotary drilling of wells

The rotor is the main mechanism of the machine for the drilling method of the same name. Rotators are distinguished by power, static load, diameter of the hole for a column of pipes. By design, the rotors are stationary or moving in a vertical plane. They are designed for drilling wells with a depth of 100-1500 m, withstand a load of 10-500 tons.

In addition to the main purpose (rotation of the tool), the rotor serves as a holding device for drill and casing pipes during tripping operations. A number of other mechanisms and devices ensure the advancement of the rock-cutting projectile into the mountain range.

The composition of the rotary drilling rig includes:

- Derrick - drill pipes are placed and suspended on it. The structure is arranged in the form of a mast on 1-2 supports or a tower-type frame on 4 support points.

- Piston mud pump - is used for pumping flushing into the well. Works as part of a complex of equipment for the preparation of the solution and its purification.

- Swivel - through it, the flushing solution from the pump enters the drill string.The device is mounted on a hook at the top of the tower.

- Traveling system with a winch and pulleys - provides lowering and lifting of the column.

- Elevator - with its help, pipes are captured and held.

The equipment includes cone and diamond bits, slings for attaching the elevator to the traveling block, adapters of various types, mud pumps for pumping out the pulp. Flushing during rotary drilling - direct or reverse with the use of mud, water.

Features of pneumatic percussion drilling

Hammer drilling belongs to rotary percussion drilling technologies and is most widely used in the field of engineering and geological surveys, as well as for drilling water wells. With the help of drilling with a pneumatic tool, it is possible to carry out mine workings of vertical and directional wells in the soil up to the 10th category of drillability.

The main distinguishing feature of the technique is to destroy the rock

used simultaneously impact and rotational action performed

respectively with a pneumatic hammer and a drilling rig rotator.

The working body of the machine is a downhole hammer. With the help of a valve device, compressed air flowing through the drill rod sets the hammer in forward-and-return motion, striking the drill bit shank. At the same time, the air hammer rotates together with the rod; the rotator is located outside the well. Drill chips are removed from the well with compressed air.

Advantages and disadvantages of drilling with

hammer

The main advantages of pneumatic hammer drilling are high speed

creation of wells, effective cleaning from cuttings, the ability to work on

fractured rock and eliminate the cost of bentonite and shipping

water for washing.

We also include the following benefits:

- The drilling cycle is several times shorter than those previously considered. Hammer drilling technology makes it possible to create wells much faster than drilling with drilling fluid. The main reason is that the speed of the air flow is much higher than the speed of the washing solution;

- Associated cleaning of the well during drilling. Cuttings removal is achieved by the movement of a powerful ascending air flow in the gap between the drill string and the borehole wall;

- There is no need to use a washing solution, for the manufacture of which it is necessary to purchase bentonite and organize the transportation of water to the place of work;

- Fast and convenient change of the drilling tool.

The disadvantages of drilling by pneumatic percussion method include the need for a large volume of compressed air, it is possible to stick the drill string when drilling aquifers and rocks with increased fracturing. The stability of the borehole walls should be ensured.

Manual drilling of a well under water

Drilling a well manually only for an unprepared person will seem an extremely difficult process, requiring large physical costs. With certain knowledge and preparation, it is realistic and feasible to make a drill for a well with your own hands. Depending on the conditions of occurrence of groundwater, you can use several methods of self-drilling wells.

To carry out drilling work, specialists are usually invited, but if desired, they can be done independently.

impact method

In this way, the simplest well-needle is installed - the Abyssinian well.This method is actively used by home craftsmen, punching a well for water in the country. The design of the "drilling rig" is a shaft, consisting of pipe sections, and a tip that cuts the soil layers. A weighty woman serves as a hammer, which rises and falls with the help of ropes: when pulled, a kind of hammer rises to the top of the structure, when weakened, it falls on a podbaka - a device of clamps arranged symmetrically. After the trunk enters the ground, it is built up with a new segment, the bollard is attached to the new part, and clogging continues until the tip enters the aquifer by 2/3 of the reservoir.

The barrel-pipe serves as an opening for water to exit to the surface.

The advantage of this well is that it can be drilled in the basement or other suitable room. This creates ease of use. The price is also attractive, breaking a well for water in this way is inexpensive.

Percussion drilling can be used on any type of soil

Rope percussion drilling

The most commonly used method. This method involves breaking up the soil by lowering a heavy drilling tool from a height of two meters. The design used in this type of drilling consists of the following elements:

- tripod, which is placed above the drilling site;

- block with a winch and a cable;

- driving cup, rod;

- bailers (for passing through loose layers of soil).

The glass is a piece of steel pipe, beveled inward, having a strong lower cutting edge. On top of the driving glass is an anvil. A barbell strikes on it. The lowering and lifting of the driving glass is carried out using a winch.The rock that enters the glass is held in it due to the force of friction. In order to penetrate as deep as possible into the ground, a shock rod is used: it is thrown onto an anvil. After filling the glass with soil, it is lifted up, after which it is cleaned. The operation is repeated until the required depth is reached.

Well drilling on loose soils is carried out using a bailer. The latter is a steel pipe, at the lower end of which a delay valve is installed. After the bailer enters the soil, the valve opens, as a result of which the soil enters the pipe. When the structure is lifted, the valve closes. After being removed to the surface, the bailer is cleaned, the actions are repeated again.

Rope-impact equipment for drilling wells

The auger method described above is also effectively used for self-drilling. It does not make sense to explain how to drill a well with your own hands using an auger - the basic principle is preserved.

Advantages of manual drilling:

- economical way financially;

- repair and maintenance of a hand drill is easy;

- the equipment is not bulky, so there is no need to use heavy equipment;

- the method is applicable in hard-to-reach places;

- effective, does not require a lot of time.

The main disadvantages of manual drilling can be considered to be lowering to a shallow depth (up to 10 m), where the layers mainly pass, the water of which needs to be cleaned, and the inability to crush hard rocks.

Percussion-rope scheme with a bailer and a punching bit

Manual well drilling

Most often, summer residents are interested in how to drill a well with their own hands, and not just a well.You will need such equipment for drilling wells as a drill, a drilling rig, a winch, rods and casing pipes. The drilling tower is needed for digging a deep well, with its help, the drill with rods is immersed and lifted.

rotary method

The simplest method of arranging a well for water is rotary, carried out by rotating the drill.

Hydro-drilling of shallow wells for water can be carried out without a tower, and the drill string can be removed manually. Drill rods are made from pipes, connecting them together with dowels or threads.

The bar, which will be below all, is additionally equipped with a drill. The cutting nozzles are made of sheet 3 mm steel. When sharpening the cutting edges of the nozzle, it must be taken into account that at the moment of rotation of the drill mechanism, they must cut into the soil in a clockwise direction.

The tower is mounted above the drilling site, it must be higher than the drill rod in order to facilitate the extraction of the rod during lifting. After that, a guide hole is dug for the drill, about two spade bayonets deep.

The first turns of rotation of the drill can be done independently, but with a greater immersion of the pipe, additional forces will be required. If the drill cannot be pulled out the first time, you need to turn it counterclockwise and try to pull it out again.

The deeper the drill goes, the more difficult the movement of the pipes. To facilitate this task, the soil must be softened by watering. When moving the drill down every 50 cm, the drilling structure must be taken out to the surface and cleaned from the soil. The drilling cycle is repeated anew.At the moment the tool handle reaches the ground level, the structure is increased with an additional knee.

As the drill goes deeper, the rotation of the pipe becomes more difficult. Softening the soil with water will help facilitate the work. In the course of moving the drill down every half meter, the drilling structure should be brought to the surface and freed from the soil. The drilling cycle is repeated again. At the stage when the tool handle is level with the ground, the structure is extended with an additional knee.

Since lifting and cleaning the drill takes most of the time, you need to make the most of the design, capturing and lifting up as much of the soil as possible. This is the principle of operation of this installation.

Drilling continues until an aquifer is reached, which is easily determined by the condition of the excavated land. Having passed the aquifer, the drill should be immersed a little deeper until it reaches a layer that is located below the aquifer, waterproof. Reaching this layer will make it possible to ensure the maximum inflow of water into the well.

It is worth noting that manual drilling can only be used to dive to the nearest aquifer, usually it lies at a depth not exceeding 10-20 meters.

In order to pump out dirty liquid, you can use a hand pump or a submersible pump. After two or three buckets of dirty water are pumped out, the aquifer is usually cleared and clean water appears. If this does not happen, the well needs to be deepened by about another 1-2 meters.

screw method

For drilling, an auger rig is often used.The working part of this installation is very much like a garden drill, only much more powerful. It is made from a 100 mm pipe with a pair of screw turns welded onto it having a diameter of 200 mm. In order to make one such turn, you need a round sheet blank with a hole cut in its center, the diameter of which is slightly more than 100 mm.

Then, a cut is made at the workpiece along the radius, after which, at the place of the cut, the edges are parted in two different directions, which are perpendicular to the plane of the workpiece. As the drill sinks deep, the rod on which it is attached increases. The tool is rotated by hand with a long handle made of pipe.

The drill must be removed approximately every 50-70 cm, and due to the fact that the more it goes deep, it will become heavier, so you will need to install a tripod with a winch. Thus, it is possible to drill a well for water in a private house a little deeper than the above methods.

You can also use the manual drilling method, which is based on the use of a conventional drill and a hydraulic pump:

Useful video on the topic

Auger drilling of a water well with a depth of 20 m on the territory of a private household:

This video shows the technology horizontal auger drilling wells for laying communications under the highway:

The device of piles with a continuous auger of large diameter with a central channel. For work, a Bauer BG-30 drilling rig and a Liebherr high-performance stationary concrete pump are used:

The auger method provides high rates of well drilling.The development of the well and the supply of waste soil from the bottom to the mouth of the working occurs simultaneously and continuously, which saves both time and efforts of drillers, and the funds invested in the project. Therefore, the method of auger drilling is popular.

Please leave comments in the block form below. Tell me if you have ever used a handheld auger or drilled on a small rig using an auger. Share technological subtleties that may be useful to site visitors.

Water filtration

The first stage of water filtration occurs inside the well on the casing pipe. Such cleaning eliminates large particles of debris and increases the life of the well pump.

On sale you can find:

- Welded non-pressure filters. At a high cost, they have a number of advantages - withstand high loads, durable, reliable.

- Type-setting and ring polymeric filter. Among the advantages - low price, suitability for repair. However, they require an increased borehole diameter.

- A tubular-wire filter with a winding made of wire (profiled). The product of the middle price segment is distinguished by stable long-term operation, no risk of silting, and maintainability.

Other models of drilling rigs

In general, the assembly process of most of the existing varieties of drilling rigs remains the same. The frame and other elements of the structure under consideration are prepared in a similar way. Only the main working tool of the mechanism can change.

Read the information on the manufacture of various types of installations, make a suitable working tool, and then attach it to the support frame and connect it to other required elements using the recommendations from the instructions discussed above.

Drilling rig with "cartridge"

Drilling rig with "cartridge"

The main working element of such a unit is a cartridge (glass). You can independently make such a cartridge from a thick-walled pipe with a diameter of 100-120 mm. The optimal length of the working tool is 100-200 cm. Otherwise, be guided by the situation. When choosing the dimensions of the support frame, you will have to take into account the dimensions of the cartridge. Think over everything so that in the future it will be convenient for you to use the finished drilling rig.

The working tool should have as much weight as possible. From the bottom of the pipe section, make triangular points. Thanks to them, the soil will loosen more intensively and quickly.

Do-it-yourself drilling rig

If you wish, you can leave the bottom of the workpiece even, but it will need to be sharpened.

Poke some holes in the top of the glass for attaching the rope.

Attach the chuck to the support frame using a strong cable. Choose the length of the cable so that in the future the cartridge can freely rise and fall down. When doing this, be sure to take into account the planned depth of the source.

To increase the efficiency of excavation, you can connect the assembled unit to an electric motor. The cable with the cartridge in such a situation will be wound on the gearbox drum.

It is possible to ensure the cleaning of the bottom from the soil by including a bailer in the structure.

Using such an installation is very simple: you first manually create a recess in the drilling site with a diameter greater than the diameter of the working cartridge, and then begin to alternately raise and lower the cartridge into the hole until the required depth is reached.

Simple screw installation

Homemade auger

The main working element of such a mechanism is the drill.

Drilling auger drawingScheme of the interturn auger ring

Make a drill from a metal pipe with a diameter of 100 mm. Make a screw thread on the top of the workpiece, and equip an auger drill on the opposite side of the pipe. The optimal drill diameter for a homemade unit is about 200 mm. A couple of turns is enough.

Drill disc separation scheme

Attach a pair of metal knives to the ends of the workpiece by welding. You must fix them in such a way that at the time of the vertical placement of the installation, the knives are located at a certain angle to the soil.

Auger drill

To work with such an installation was most convenient, connect a piece of metal pipe 1.5 m long to the tee. Fix it by welding.

Inside the tee must be equipped with a screw thread. Screw the tee itself onto a piece of a collapsible one and a half meter rod.

It is most convenient to use such an installation together - each worker will be able to take on a one and a half meter pipe.

Drilling is performed in the following order:

- the working tool goes deep into the ground;

- 3 turns are made with a drill;

-

loosened soil is removed and removed.

Repeat the cycle until you reach about a meter deepening. After the bar will have to be lengthened with an additional piece of metal pipe.A coupling is used to fasten pipes.

If it is planned to build a well deeper than 800 cm, fix the structure on a tripod. At the top of such a tower there should be a hole large enough for the unhindered movement of the rod.

In the process of drilling, the rod will need to be periodically increased. With an increase in the length of the tool, the mass of the structure will also increase significantly, it will become very difficult to manage it manually. For convenient lifting of the mechanism, use a winch made of metal or durable wood.

Now you know in what order simple drilling rigs are assembled and how to use such units. The knowledge gained will help you significantly save on the services of third-party drillers.

Successful work!

Drilling a well by hand

To perform the work, the drill itself, the drilling derrick, the winch, rods and casing pipes are required. The drilling tower is necessary when digging a deep well, with the help of this design, the drill with rods is immersed and lifted.

The easiest way to drill a well for water is rotary, which is carried out by rotating the drill

When drilling shallow wells, the drill string can be removed manually, without the use of a derrick at all. Drill rods can be made of pipes, products are connected with dowels or threads. The lowest bar is additionally equipped with a drill.

The cutting attachments are made from 3 mm sheet steel. When sharpening the edges of the nozzles, it should be noted that when the drill mechanism is rotated, they must cut into the soil clockwise.

The drilling technology, familiar to most owners of household plots, is also applicable for arranging a well under water

The tower is installed above the drilling site, its height must exceed the height of the drill rod in order to facilitate the extraction of the rod when lifting. Then, a guide recess for the drill is dug on two bayonets of the shovel. The first turns of rotation of the drill can be performed by one person, but as the pipe sinks, additional help will be required. If the drill does not come out the first time, turn it counterclockwise and try again.

As the drill goes deeper, the rotation of the pipe becomes more difficult. Softening the soil with water will help facilitate the work. In the course of moving the drill down every half meter, the drilling structure should be brought to the surface and freed from the soil. The drilling cycle is repeated again. At the stage when the tool handle is level with the ground, the structure is extended with an additional knee.

Since it takes a significant part of the time to lift and clean the drill, you should make the most of the design, capturing and extracting the maximum possible portion of the soil layer to the surface.

When working on loose soils, casing pipes should be additionally installed in the well, which prevent soil from shedding from the walls of the hole and blocking the well

Drilling continues until it enters the aquifer, which is easily determined by the state of the excavated land. Passing the aquifer, the drill plunges even deeper until it reaches the next aquifer - the water-resistant layer. Immersion to the level of the water-resistant layer will ensure maximum water inflow into the well

It is important to note that manual drilling is applicable only for diving to the first aquifer, the depth of which does not exceed 10-20 meters.

To pump out dirty water, you can use a hand pump or a submersible pump. After two or three buckets of dirty water, the aquifer is washed and clean water usually appears. If this does not happen, the well should be deepened by another 1-2 meters.

You can also use a manual drilling method based on the use of a conventional drill and a hydraulic pump:

new entries

How birch leaves can be useful for the garden 6 non-obvious reasons to plant hydrangea in the garden Why soda is considered a versatile and effective tool for the garden and vegetable garden

Pump installation rules

Surface type pumps are not suitable for downhole installation. This is due to depth restrictions, which reach up to 8 years. Submersible pumps are better suited for this purpose. They can be vibrating or centrifugal. Each of these subspecies has its own set of advantages. The final choice is based on factors such as the water level in the well, the depth of the pipes, the flow rate of the well, the diameter of the casing, the water pressure, and the cost of the pump.

When all the above stages are completed, the well is put into operation. If the work was carried out with the involvement of third-party assistance, the following documents must be obtained before accepting the project:

- well passport;

- hydrogeological conclusion on the possibility of implementing the project;

- permission of the sanitary and epidemiological station;

- act of work done.

When doing all the work yourself, the only thing that is important to remember is the need to comply with the technology and the key points of the process. It is important to use quality materials

This will ensure the long-term operation of the well.

Conclusions and useful video on the topic

Video #1 A visual overview of a do-it-yourself drilling rig:

Video #2 A variant of a combined type drilling rig for percussion and auger drilling:

Video #3 Using a percussion bailer:

A home-made well drilling rig is not a very complicated unit, leaving room for engineering work. But it should be remembered that the components and mechanisms of such a device during the drilling process experience significant loads. Therefore, the materials must be durable, and the work must be done as best as possible.

Would you like to share your personal experience in assembling and putting into practice a drilling rig? Have questions about the topic of the article, want to understand unclear points? Please write comments in the block below.

Conclusions and useful video on the topic

A video demonstrating the principle of classic core drilling with water pressure core extraction:

Features of drilling a well with an auger:

core drilling with bottomhole flushing and installation of double casing, the outer part of which is made of steel pipes, the inner part is made of polymer:

Drilling an aquifer is a labor intensive process. Not only the speed of the device of an autonomous water source, but also financial costs depend on the correctness of the chosen drilling method.

The first thing you should pay attention to when choosing a drilling method is the type of soil and the depth of the aquifer.

Based on these parameters, you can choose the best option that will allow you to drill a well quickly and inexpensively.