- How is the manhole of the water supply ↑

- Design features ↑

- Standards for the manufacture of hatches ↑

- Intervals between inspection hatches ↑

- Sewer manhole device

- Types of wells

- Manholes

- Drop wells

- Filtration wells

- storage wells

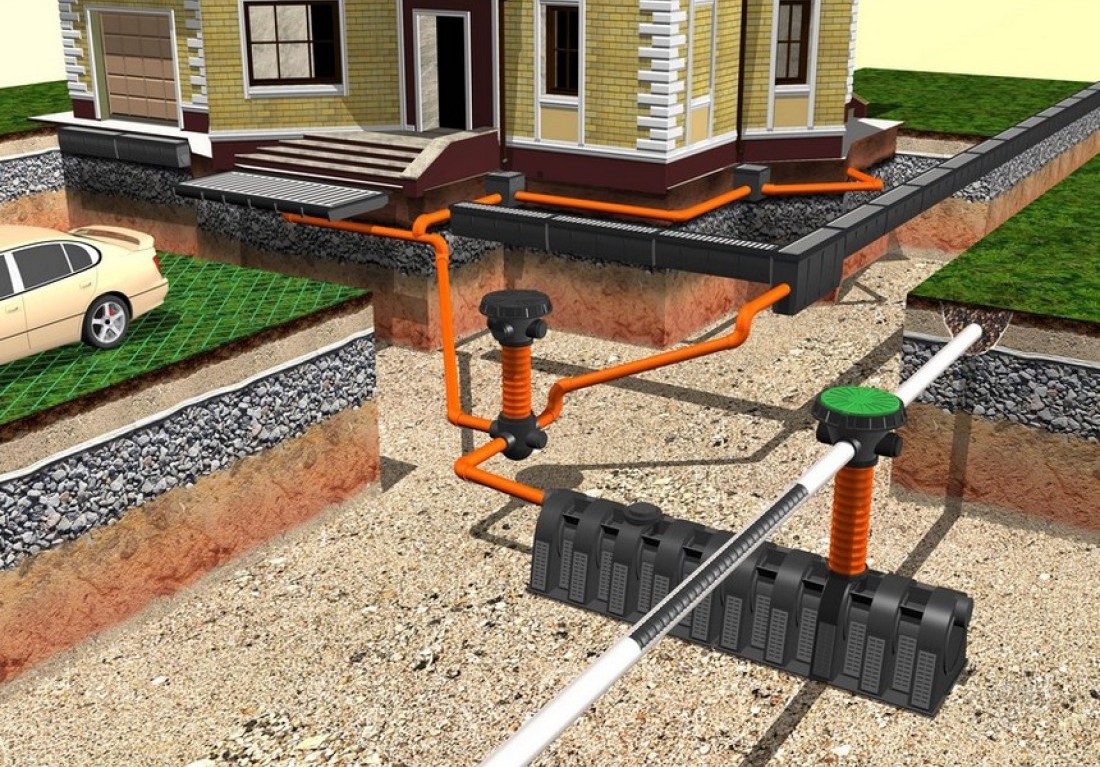

- Drainage systems for a private house: how wastewater is treated

- Design and structure of sewer wells

- As a rule, the structure of a sewer well has a typical structure:

- Insertion into the existing wastewater sewerage of a country house

- The device of sewer wells made of concrete

- Classification of sewerage wells

- Manholes

- Drop wells: types of structures

- Manhole installation technology

- Video description

- Conclusion on the topic

How is the manhole of the water supply ↑

Design features ↑

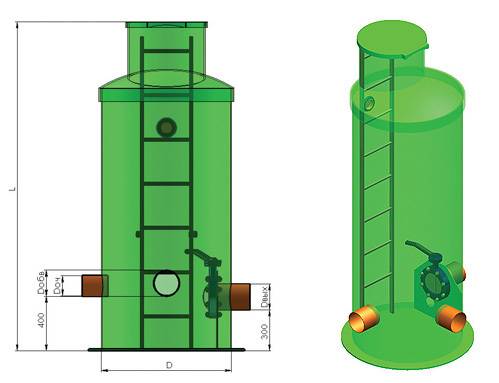

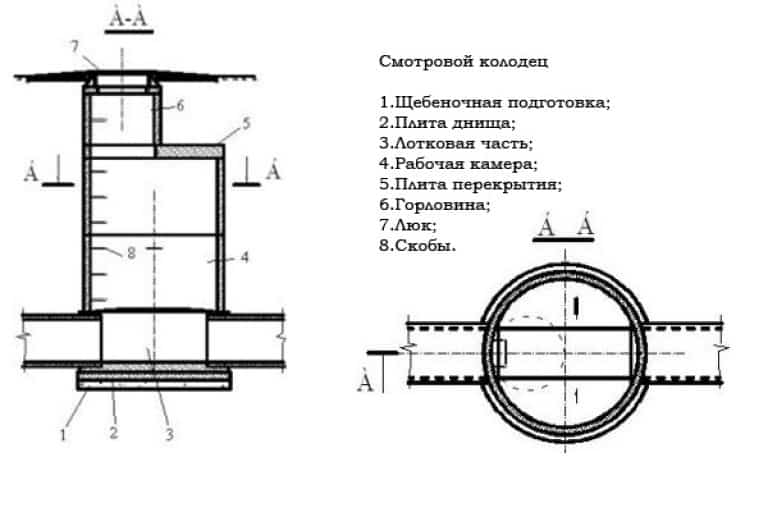

Regardless of the type of accessory, the inspection drainage well consists of a base, a tray, a working chamber, a neck and a hatch.

Wells can be made of different materials: brick, reinforced concrete blocks, rubble stone.

Manhole: construction

In the diagram (plan), manholes are round, rectangular and polygonal in shape. The base consists of a reinforced concrete slab, which is laid on crushed stone.The main technological part is the tray, which is made of monolithic concrete (M 200) using templates - formwork, followed by rubbing the surface with ironing or cementing.

The pipeline passes into the tray part, through which wastewater flows. In linear wells, the tray part is straight, and the surface in the lower part is vertical. The height of the tray is not less than the diameter of the larger pipe. On both sides of the tray, berms (shelves) are formed, which must be given a slope of 0.02 in the tray side. Shelves serve as platforms on which workers are placed during operational activities.

Well mouths are standard - 700 mm. With a pipe diameter of 600 mm, the necks must be installed so that they allow the entry of cleaning devices (cylinders and balls). The mouths and working chambers are equipped with hinged ladders or brackets for descent.

The transition to the neck is possible with the help of a conical part or a reinforced concrete floor block. At ground level, the mouths end in a hatch, which can be light or heavy.

If the well is located on an uncovered area, then a blind area should be built around the hatch to drain water.

Standards for the manufacture of hatches ↑

Plastic and cast iron hatches for manholes

At first glance, it may seem that the hatch is not such an important element of the manhole, but in fact it is not. The proof is the standards that must be observed in their manufacture. The main material is cast iron (GOST 3634-61). Cast iron hatches consist of a body with one cover for installation on necks with a diameter of 700 mm and with an opening for passage with a diameter of 620 mm.Heavy hatches are laid on the roadway and have a mass of 134 kg, while light ones, which are laid mainly on sidewalks, weigh no more than 80 kg.

Along with cast iron, polymeric materials are used for manufacturing, which are distinguished by strength, lightness, durability and environmental safety.

Intervals between inspection hatches ↑

When installing, it should be taken into account that the distance between linear-type manholes depends on the diameter of the pipe. It looks like this: d = 150 mm - 35 meters; d = 200 mm - 50 meters; d = 500 mm - 75 meters; d = 700-900 mm - 100 meters; d = 1000-1400 mm - 150 meters; d = 1500-2000 mm - 200 meters; d > 2000 - 300 meters.

The distance between adjacent manholes is strictly normalized

Inspection wells are the main component of the sewer system, not only providing unhindered inspection and monitoring of the work of urban pipelines, but also creating conditions for the implementation of important operational activities. It is noted that the process of building manholes is a costly undertaking, because it requires, in addition to time and effort, the use of large-block massive structures and specialized equipment.

Sewer manhole device

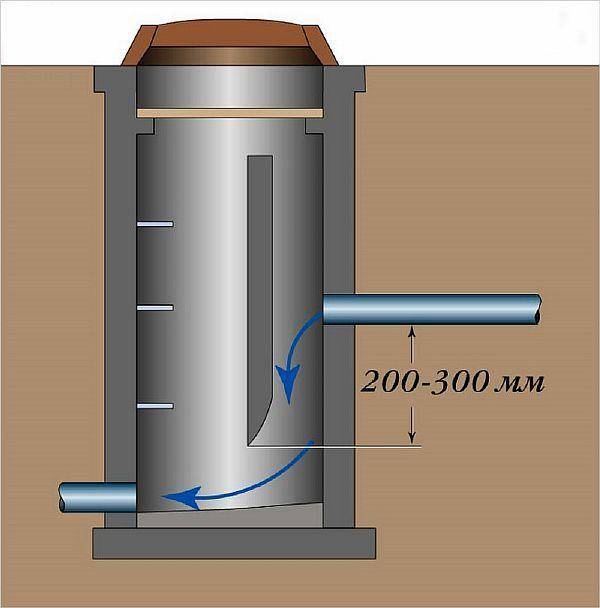

At the bottom, a concrete tray is made for the installation of a manhole (concrete of class B 7.5 is recommended) - straight or rounded along the radius (30 cm in a rotary well); the height and width of the tray are equal to the diameter of the pipe, the lower edges of the tray are rounded, the ends of the pipes are inserted into the tray.

Next, they make the working part of the well from reinforced concrete rings, with sealing and grouting with cement mortar (1: 3), or from red brick on cement mortar (1: 3); masonry seams are rubbed from the inside.In dry soils, wells are laid in half a brick, with groundwater or at a height of more than 2 m - in a brick.

The diameter of the working part, which the sewer manhole has, at a depth of up to 1.2 m is taken equal to 0.7 m, at a greater depth - 1 m. Every 0.3 m, running brackets from reinforcement with a diameter of 1-1 are embedded in the wall of the well, 5 cm

The pipe inlets into the well are sealed with a tarred strand and cement mortar, and in case of groundwater, the outer surface of the well is coated with hot bitumen.

A well with a diameter of 0.7 m is closed with a cast-iron hatch; if it is necessary to adjust the height of the well, stones or bricks on cement mortar are placed under the hatch body. You can use a cover made of tarred boards laid in two rows, with a total thickness of at least 10 cm.

With a diameter of the working part of the well 1 m, it is covered with a slab with a hole for the hatch. When constructing a working part of brick, the transition is usually made in the form of an oblique cone with a vertical section of the wall under the hatch.

If your site is not covered, the upper edge of the hatch body should be raised 10-20 cm above the ground, in this case a blind area is made around the hatch by 0.7-1.0 m. If a hard coating is laid, then the edge of the hatch is made flush with the surface. This is a basic sewer manhole device that can be upgraded with the appropriate local landscape.

Types of wells

Where and how sewer wells should be installed SNIP regulates specifically and accurately

It is also important to take into account the Building Norms and Rules because the inspecting authorities necessarily check the structures for compliance with the requirements, and if violations are found, they can issue an order to make changes to the sewerage device, which will require additional costs, and the construction time will increase significantly

Manholes

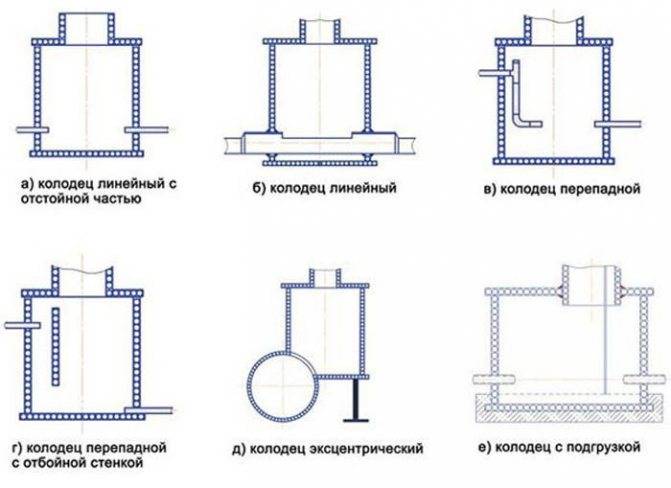

Such structures are necessary for any sewer system, regardless of its degree of complexity. Wells provide the ability to control the operation of the system and are used for its maintenance (repair, cleaning, flushing, etc.). Depending on where the observation structures are located, there are several types of them:

- linear wells are placed on straight sections of the highway at a certain interval with a significant length of communications,

- rotary wells are mounted in places where the direction of movement of wastewater changes (in order to reduce hydraulic resistance, a sharp change in the “course” should be avoided, it is necessary to connect pipes at an angle of 90 ° or more),

- nodal wells are required at the junction of the outlet pipe with several inlets (the number of the latter, according to current standards, should not exceed 3), The design of the nodal type sewer well

- control wells are installed when using a centralized sewer system and are installed where the local sewer connects to the central pipeline.

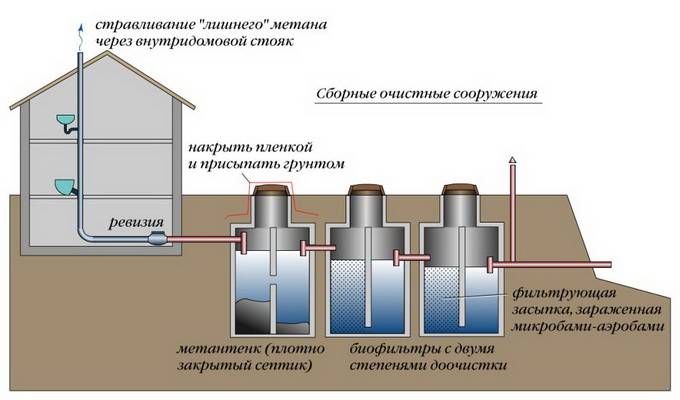

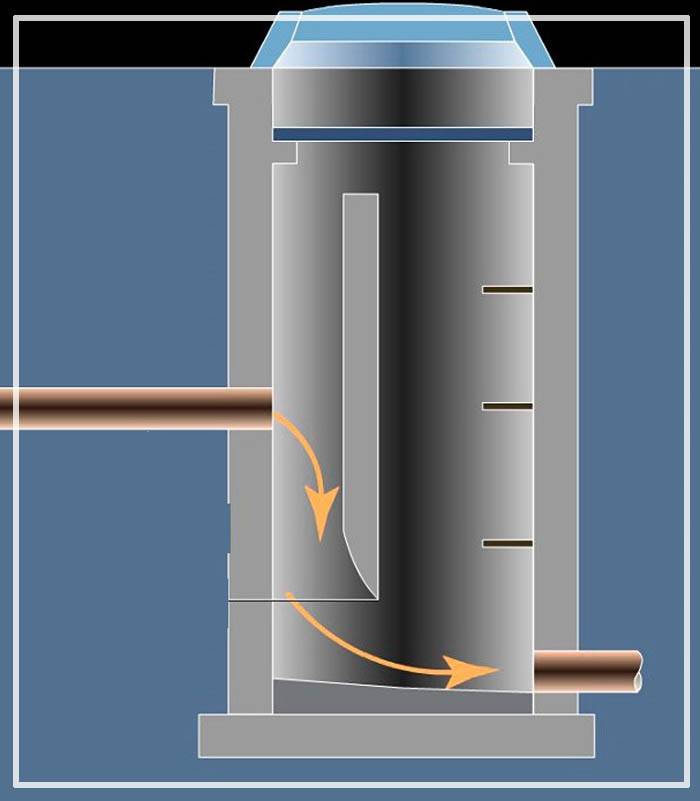

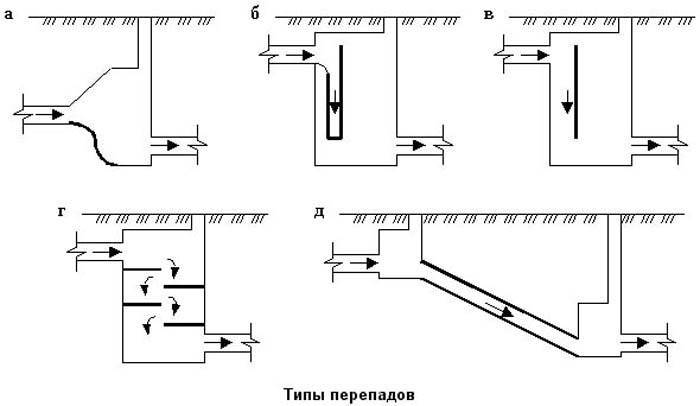

Drop wells

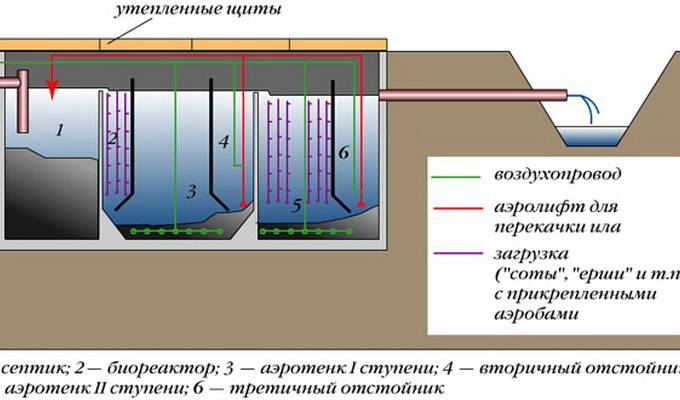

Drop wells are used to change the flow rate or the depth of pipelines. They are also used when it is necessary to bypass the sewer line of any obstacle (another pipeline, etc.). In general, such structures are a vertical shaft (reservoir) with inlet and outlet pipes. Depending on the purpose, it may be necessary to install this type of sewer wells with additional devices, for example, with steps that dampen the flow rate.

An example of a differential polymer well

An example of a differential polymer well

There are the following types of overflow wells:

- classic well design (drainage flow through the top pipe, discharge through the bottom pipe),

- models of wells with baffle and drain wall surfaces to reduce the flow rate,

- channels with a significant slope, capable, on the contrary, of “dispersing” the flow, increasing its speed,

- complex structures of multi-stage drops.

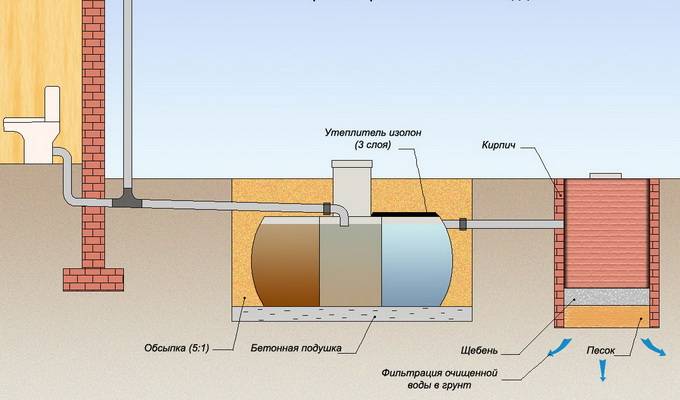

Filtration wells

Models of wells of this type are used in sewerage systems to provide soil post-treatment of effluents partially clarified in the septic tank and to drain the liquid component of the septic tank into the ground. Structurally, the filtration well differs from the others in the absence of a sealed bottom (instead of it, gravel or other filter material is backfilled). There are also options for wells with holes in the walls of the tank. Through such holes, the liquid also goes into the soil, and for its additional cleaning, filter material is also backfilled from the outside of the well at the stage of its installation.

Filtering sewer well made of concrete rings with perforation

Filtering sewer well made of concrete rings with perforation

storage wells

The principle of operation of a storage sewer well is the same as that of a cesspool - it is a place for collecting wastewater

When organizing the drive, it is important to ensure its tightness and to provide for the possibility of the access of a vacuum truck to pump out the contents.

Drainage systems for a private house: how wastewater is treated

Further on this page, you can see practical examples of how wastewater is treated. The drainage system of the house can be equipped according to one of the proposed principles. When choosing a drainage system for a private house, it is worth considering its throughput.

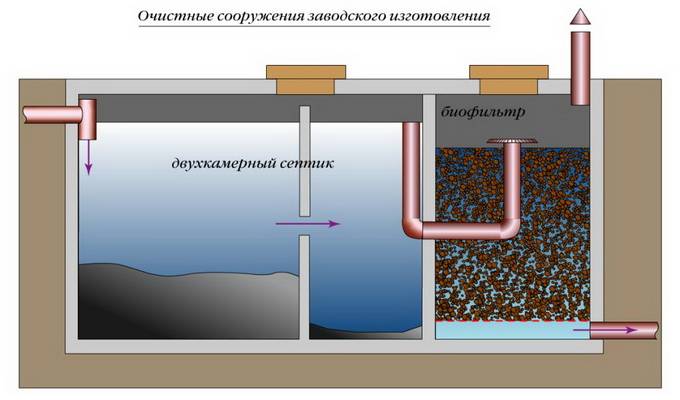

There are several options for cleaning systems:

1. Purflo septic tank + drainage - the system is designed for 2-10 people. The principle of operation is preliminary cleaning in a septic tank using bioculture and final cleaning through a soil filter. It is recommended to apply in the presence of sandy soils.

2. Purflo septic tank + biofilter - the system is designed for 2-12 people. The principle of operation of the septic tank is the same as in system 1, but the post-treatment takes place in a container filled with a special filter element. It is used for clay and loamy soils, as well as for high groundwater levels.

3. Minflo - the system is designed for 7-20 people. Principle of operation - preliminary cleaning in a Purflo septic tank; post-treatment takes place in the aeration tank.

It is possible to make a two-channel system of local sewerage: faeces from the toilet are discharged through one outlet, and wastewater from the shower, sink, bidet, etc. trench, etc.The cesspool is made of concrete rings, the bottom is waterproofed, concreted, a blind area is made and a tight cover is made. The cesspool is located in a place convenient for the entrance of a sewage truck, which periodically removes emissions. If for some reason it is impossible to place a pit in such a place, a second cesspool is made near the fence, and feces are transferred from the first to the second with a fecal pump.

The pump withstands contact with aggressive alkaline media (the chemical resistance of the device allows it to be used for pumping highly chlorinated water from pools).

The manufacturer recommends choosing a more productive model for the pool, for example, Vort 350.

Another fecal pump Wilo TMW30-02 EM (Germany) has a capacity of up to 72 l / min, a pressure of up to 30 meters, power supply 220 V, power - 700 watts. Dimensions 23 x 16.5 x 16.5 cm, weight 4.3 kg.

More powerful (and less commonly used in individual areas) are fecal pumps Ebaro DW / DW VOX (Italy) with a capacity of up to 700 l / min, a head of up to 18 m. Of course, this increases the power consumption of such pumps - up to 1.5 kW. The capabilities of the pumps are such that they allow pumping out water even with very large and solid suspensions (up to 5 cm in diameter).

The DW and DW VOX pumps are made of forged stainless steel and have a double seal with grease (silicon carbide and carbon ceramic), so that the rubbing parts of the pump are almost not subject to wear and always remain tight. Therefore, the service life of such pumps operating in sufficiently aggressive environments with large suspensions is extremely extended.

The video below shows the sewerage in a private house in a step-by-step execution with comments from experts:

Design and structure of sewer wells

As a rule, the structure of a sewer well has a typical structure:

- Manhole cover (upper part of the well);

- Neck;

- Camera;

- Mine;

- Bottom.

Depending on the material and which the well is made, there may be different sizes of products. The type of underground communications determines the shape of the underground chamber.

The dimensions and type of the well are determined based on the requirements that are presented for the communications that will be connected to the well. As a rule, the height of the working chamber of the well is 180 centimeters.

Sewer wells

The well shaft is made in the form of a round section. Most wells have a ladder so that you can comfortably descend into them. Be sure to cover each well with a lid. It is needed so that garbage, dirt does not fall into the well, and also so that someone does not fall into it.

Often on the news you can hear talk that an animal or a person has fallen into an uncovered well. That is why it is strictly forbidden to use a sewer well without a cover.

It's interesting: How to make a gate with your own hands (video)

Insertion into the existing wastewater sewerage of a country house

It’s good if there is a main sewage system running down the street - they cut an outlet into it, and, as they say now, “no problem.” But sewer lines are quite a rarity outside of cities.So it turns out that if there is a river or other body of water nearby, again “no problem” - and brownish “brooks” from individual houses flow into the river. But there are problems: brownish sewage will return to the wells, forcing homeowners who have saved on sewerage to spend money on water treatment. So put out of your mind the idea of using even the most obscure streams to receive runoff from your home.

The sewerage of a country house can be autonomous and public. In the second case, a tie-in is made into the existing sewerage of a suburban village or makes an eyeliner to it. Tapping into the public sewer can be made only after preliminary approval of the project documentation.

The device of sewer wells made of concrete

When the preparatory work is completed, the process of mounting the well begins.

In the case of a concrete or reinforced concrete structure, the arrangement of the sewer well will look like this:

- first, the base is prepared, for which a monolithic slab or a 100 mm concrete pad is used;

- further, trays are installed in sewer wells, which must be reinforced with a metal mesh;

- pipe ends are sealed with concrete and bitumen;

- the inner surface of the concrete rings must be insulated with bitumen;

- when the tray hardens enough, it is possible to lay the rings of the well itself into it and mount the floor slab, for which cement mortar is used;

- all seams between structural elements must be treated with a solution;

- after grouting with concrete, it is necessary to provide the seams with good waterproofing;

- the tray is treated with cement plaster;

- at the pipe connection points, a clay lock is equipped, which should be 300 mm wider than the outer diameter of the pipeline and 600 mm higher;

- one of the final steps is to check the design for operability, for which the entire system is completely filled with water. If no leaks appear after a day, then the system is functioning normally;

- then the walls of the well are filled up, and all this is compacted;

- a blind area of 1.5 meters wide is installed around the well;

- all visible seams are treated with bitumen.

The device of a sewer well made of concrete rings, described above, is no different from the arrangement of a brick structure, with the only difference being that in the latter, concreting is replaced by brickwork. The rest of the workflow will look the same.

There are also overflow wells, which have a somewhat more complicated structure compared to the structures described above (for more details: “Drop-off sewer wells are an important need“).

In addition to the tray, one or more conditions may be required to equip the overflow well:

- riser installation;

- water tower installation;

- arrangement of a water-breaking element;

- creation of a practical profile;

- pit arrangement.

The basic principle of installing wells does not change, with the exception of minor differences. In particular, before installing a drop well, it is necessary to lay a metal plate under its base, which prevents concrete deformation.

Thus, the composition of the differential well includes:

- riser;

- water pillow;

- metal plate at the base;

- intake funnel.

The funnel is used to neutralize the rarefaction that occurs due to the high speed of movement of effluents. The use of practical profiles is quite rare, since it is justified only on pipes with a diameter of more than 600 mm and with a drop height exceeding 3 m. As a rule, such pipelines are not used in private households, and overflow wells are a rare occurrence, but other types sewer wells are in demand.

According to regulatory enactments, the device of a well for sewerage is justified in such situations:

- if the pipeline needs to be laid at a shallower depth;

- if the main highway crosses other communication networks located underground;

- if necessary, adjust the speed of movement of effluents;

- in the last flooded well, immediately before the discharge of wastewater into the water intake.

In addition to the reasons described in SNiP, there are others that necessitate the installation of a differential sewer well on the site:

- if there is a large difference in heights between the optimal depth of the sewer at the site and the level of the wastewater discharge point into the receiver (this option is often justified, since laying the pipeline at a shallower depth allows you to perform less work);

- in the presence of engineering networks located in the underground space and crossing the sewer system;

- if there is a need to control the rate of movement of wastewater in the system.Too high speed has a bad effect on the self-cleaning of the system from deposits on the walls, as well as too low speed - in this case, deposits will accumulate too quickly, and the use of fast current is required to eliminate them. Its meaning is to increase the fluid flow rate in a small section of the pipeline.

Classification of sewerage wells

Each design has its own purpose and method of arranging a sewer well. You can distribute them according to some characteristics:

- By type of drainage network: for domestic and industrial wastewater, drainage, storm water.

- According to the material used for manufacturing: concrete, brick, polymer (plastic);

- By appointment: differential, viewing, for changing the direction of flow (rotary, nodal), direct-flow (linear, control or flushing type).

Manholes

The design is shown for installation under the following conditions:

- Changing the diameter or angle of inclination of the pipeline network;

- Change in the direction of water flow;

- When combined with side branches.

At the same time, it is obligatory to have a sewer manhole on direct-flow sections every 35-300 m.

The system has the form of a shaft with an internal chamber, where the inlet and outlet pipes are connected by means of a special tray. Each sewer well of this type has its own purpose, but it may also be that one structure performs many tasks at once. The arrangement of the structure is the same, the difference is only in the depth of the mine.Profile manufacturing parameters are standard, except that for rotary and nodal structures, the tray has a very specific shape.

Drop wells: types of structures

The function of differential structures is to change and adjust the flow of wastewater in height, as well as to delay or accelerate the total flow. It is from the practical application that the design of the structure depends. Indications for installation:

- To reduce the depth of digging in the inlet pipeline;

- With an increased risk of changing the flow rate in one direction or another;

- When crossing the highway of underground structures;

- If, in addition to the sewer well, nothing restrains the discharge of water into the reservoir in the presence of a flooded outlet.

Structural solutions also differ in several types. In particular, the following types of sewer drop wells can be distinguished:

- The presence of a practical profile and a water breaker only in the downstream;

- Tubular system based on a vertical segment;

- Equipment with a water-draining wall;

- Cascade-multistage mine type. This type is suitable for quickly extinguishing the speed and pressure of water;

- Sloping segments, called fast currents. They are mounted in areas where a slowdown in the flow rate is noticed.

Very rarely there are differential structures equipped with a water seal. The peculiarity is that the change in the water level is the opposite, that is, not to fall, but to rise. The effect is achieved through the presence of a special chamber, where there is a gradual accumulation of effluents. These types of sewer wells are used where gaseous or flammable chemicals can be released into the water.

Manhole installation technology

In principle, manholes are installed during the assembly of the entire drainage system. And for this it is necessary to dig trenches into which drainage pipes will be laid, to determine the places for installing wells: inspection and accumulation.

After that, the installation of pipes begins. Usually they start from the foundation of the house, moving to the storage well, which is installed in the lowest place of the suburban area. Pipes are brought to the installation sites of viewing devices, where the latter are mounted. It is clear that in such places extensions are made for convenient carrying out of the required work.

They try to install the drainage system during the period of the lower location of the groundwater level. But even during this period, water may appear in trenches and pits. Moreover, a pit for a manhole is usually dug below the trenches for pipes to a depth of 30-40 cm.

The bottom of the pit is covered with sand 10 cm thick, which is compacted. And after that, the well itself is installed. It is connected to drainage pipes, the connection joint must be sealed.

Installation of a drainage system with the installation of a manhole

With concrete products there are more difficulties. First, you need to create a solid foundation for them. Therefore, the bottom of the pit is leveled with a layer of sand, which is compacted. Next, a reinforcing frame is assembled from steel reinforcement in the form of a lattice. It is laid on bricks or stones, which are pre-installed on a sandy bottom. Then the concrete solution is poured. Today, many manufacturers of concrete products offer ready-made bottoms. They are simply lowered to the bottom of the excavated pit, which is pre-levelled. Here the task of the masters is to carry out a good sealing of the junction of the bottom and the installed well.

Concrete wells must be hermetically sealed, so they are covered with covers from the same concrete solution in which there is an entrance hatch. In this regard, plastic products are better and easier to use. Usually it is a pipe, which includes two roofs: lower and upper. The first is a container on which the pipe part is put on. It rests with its plane on the bottom of the pit. The second cover closes the well from above. Today, manufacturers offer plastic devices with the bottom cover already attached. That is, the well is a one-piece structure, with one top cover as a separate element.

Plastic manholes for drainage systems

And one moment. Plastic is a material that does not rot, does not rust, does not interact with many chemically active substances. Concrete cannot boast of such characteristics. Therefore, if you have chosen a concrete well, then its masters must necessarily waterproof it, preferably on both sides. Usually today, bituminous mastic is used for this, which is applied in two layers.

So, the inspection drainage well is installed and connected to the pipes. It remains to carry out its filling. If a concrete structure was installed, then there are no problems. The pit is simply covered with soil. If a plastic device was used, then it is recommended to backfill with sand, it can be interspersed with soil. Usually, layer-by-layer compaction is carried out, taking into account the layer thickness within 20 cm.

It is very important to set the hatch neck correctly in height

- If this is a roadway, then the hatch is mounted flush with it.

- If it is a lawn or a plot with green spaces, then the hatch is installed 5-7 cm above the grass.

- If the drainage is still being constructed in an undeveloped area, then the hatch of the wells should be at least 20 cm above the ground.

Video description

The video shows how to properly insert a drainage pipe into a manhole:

Conclusion on the topic

In general, there is a special relationship with manholes. They are rarely used because the gravity drainage system rarely gets dirty. But according to SNiP they must be installed without fail. With proper design and well-conducted installation work, the drainage is cleaned once every five years. And the life of the drainage itself is measured in more than a dozen years.