- How does everything work?

- Example of cyclic operation of NSU equipment

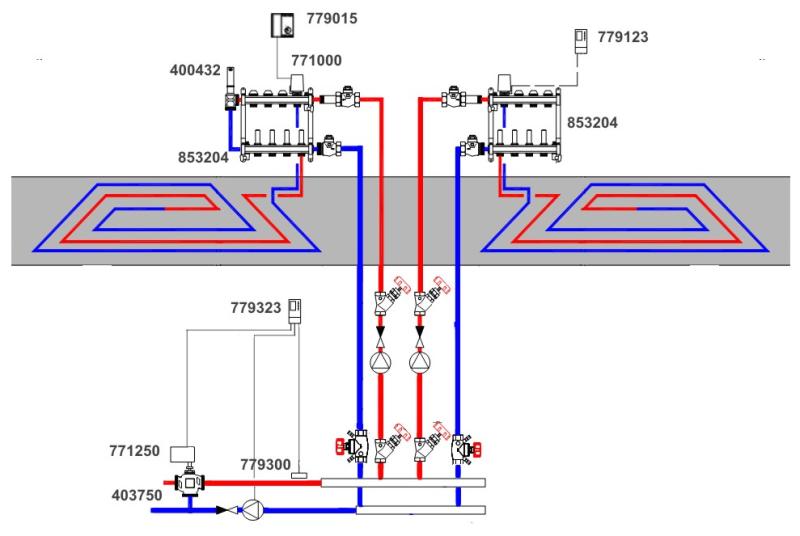

- Where can you make combined systems?

- Where can you make combined systems?

- 4 Proven schemes for connecting a water-heated floor

- Heating boiler installation

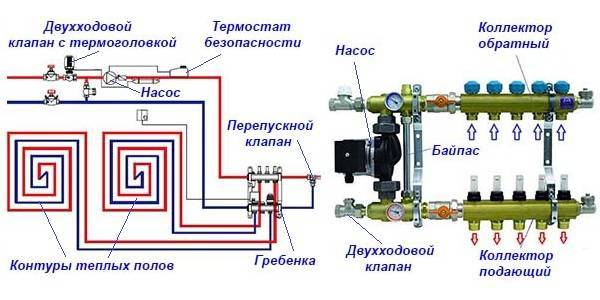

- The general concept of the mixing unit

- Why is this design important?

- How the mixing unit works

- Restrictions and regulations

- 6 Expert advice

- How to assemble a collector

- Comb made of polypropylene pipe

- Tools and materials

- Assembly process

- Direct Connection Diagram

- The Purpose of Using the Collector

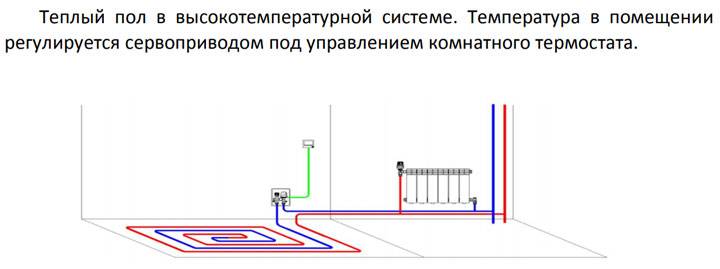

- The structure of the two-circuit system

- How it all works

- Safety valves for underfloor heating

- Scheme with a thermostatic kit for one loop

How does everything work?

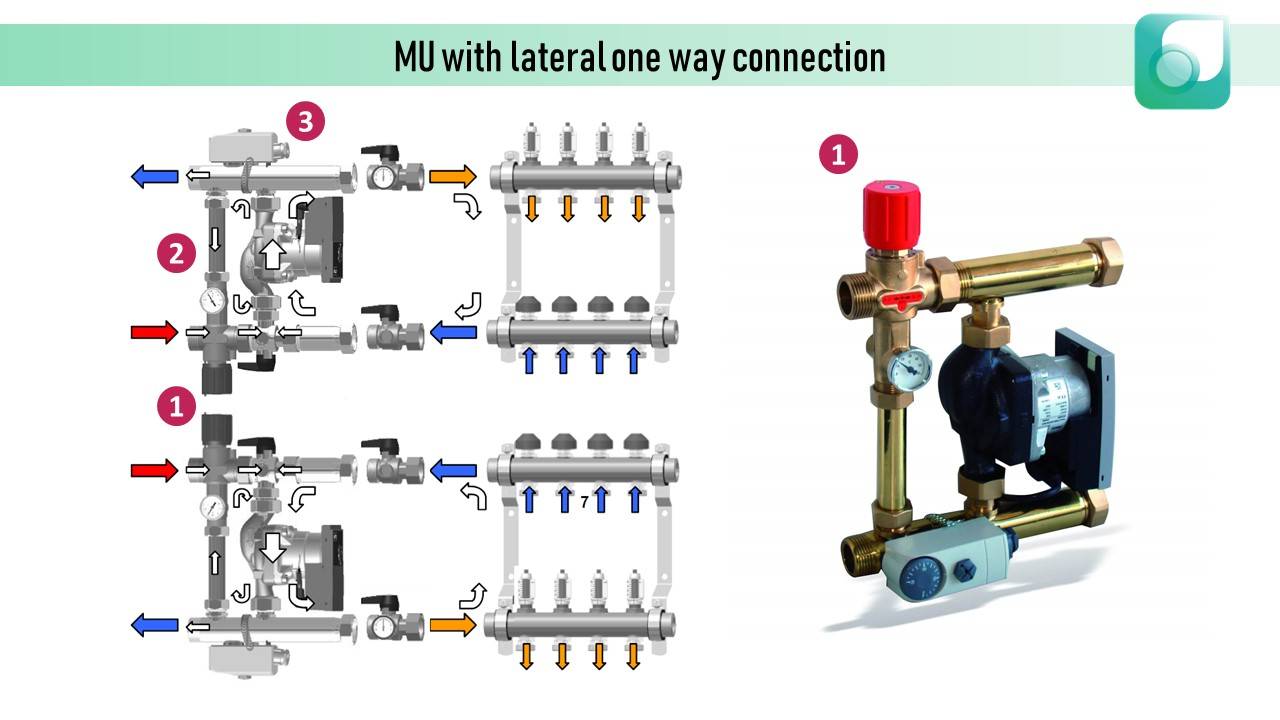

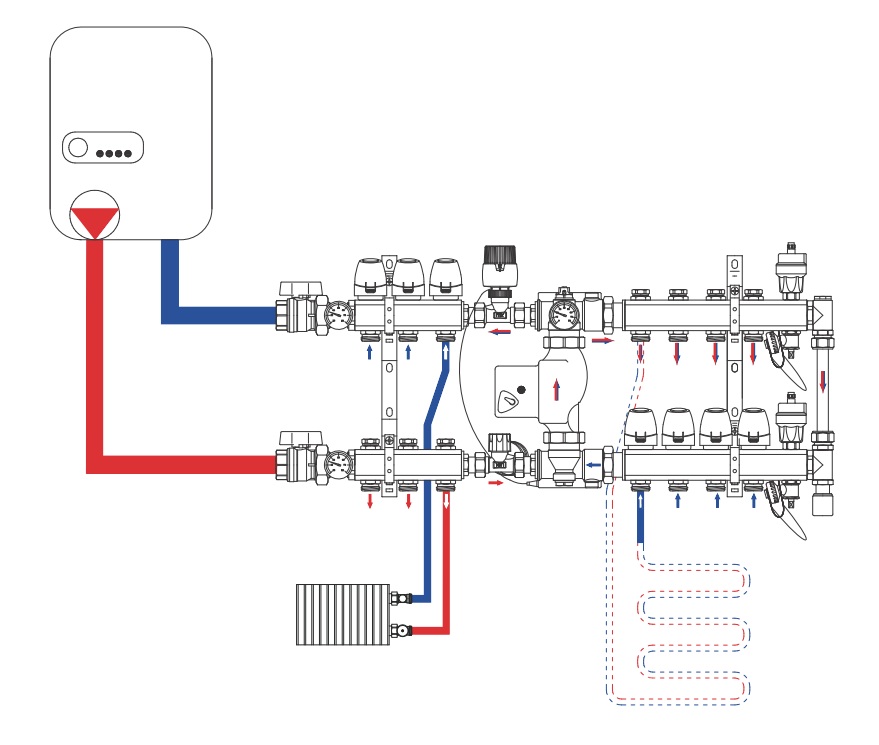

Coolant supply in a given temperature range to the underfloor heating collector provided by the mix node settings. The main fluid circulation cycle within the TP system consists of circulation cycles in each of the branches. At the same time, the NSU mixes in the hot coolant from the primary heating circuit in the volumes necessary to replenish the total heat loss for heating all rooms. That is, the more intensively the coolant is cooled in the branches of the warm floor, the greater its amount is added to the internal circulation of the entire secondary circuit.The volume of the renewed hot liquid changes automatically - from the maximum one-time setting of the balancing valve 8 (Fig. 3 and 5), to complete shutdown. In the range from maximum to minimum flow, regulation is carried out by thermostatic valve 1, which receives control impulses from its remote sensor (Fig. 5, pos. 1a), which controls the temperature of the flow T11 to the supply manifold.

Important! The control functions of the thermostatic valve 1 directly affect the operation of the heat system. In turn, the balancing valve 8 serves only to match the total pressure losses in the secondary circuits of the TP with the pressure losses in the heating devices of the primary circuit

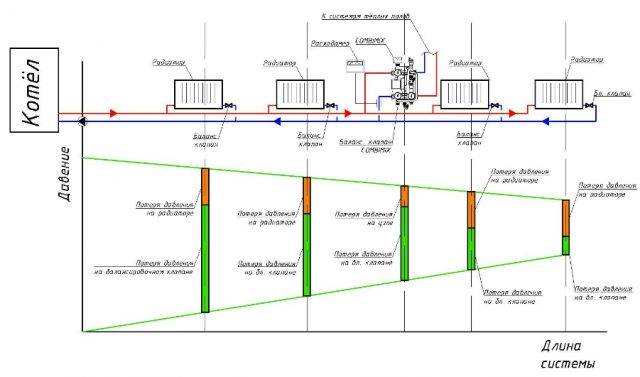

At the same time, all consumers in the primary system must be subjected to a similar adjustment in terms of pressure losses so that the distribution of thermal energy occurs in accordance with their requests, and not along the path of least hydraulic resistance. The importance and degree of such balancing is clearly shown in Figure 6.

Figure 6

Figure 6

Simultaneously with the suction of the renewable hot coolant T1 through the thermostat valve 1 (Fig. 3 and 5), the pump 3 also draws in the cooled flow T21 through the balancing valve 2 (secondary circuit). Passing through the pump, the heat carrier flows are mixed, as a result, the liquid at the temperature set by the NSU settings is already supplied to the T11 supply to the underfloor heating manifold.

Example of cyclic operation of NSU equipment

The joint operation of the pump, the balancing valve of the secondary circuit and the thermostat is as follows.For example, in the TP system there is a thermal gradient between the supply and return of the TP Δt=10С, and the calculated temperature in the supply manifold is 50С. Suppose the system operates in steady state, when the resulting coolant flow from the admixture from the primary circuit T1 and the return collector of the warm floor T21 has a temperature equal to the calculated one. With correctly set balancer 2 settings and a certain degree of thermostat 1 ajar, this is possible only if water with a temperature of 40C comes from the return T21.

If the coolant begins to flow, cooled down to 39C or lower, then the resulting flow after the pump is cooled accordingly. This imbalance is captured by a remote sensor 1a, which gives a command to open the thermostat valve 1 even more. As a result, the flow of hot water from the primary heating circuit T1 increases and the temperature in the supply manifold T11 returns to its calculated 50C.

Gradually, overheated above 40C begins to flow from the return T21, which entails reverse processes - thermostat valve 1 is covered and the volume of admixture from T1 decreases. Thus, the thermal cycles in the TP system are constantly changing in the mode of maintaining the gradient Δt=10С, with the supply t=50С.

Figure 7

Figure 7

Where can you make combined systems?

The area and number of floors in our example are very conditional. It is also necessary to coordinate their modes of operation.

It is one thing: to connect the radiator heating system to the boiler, when all the functionality for this is already installed in the boiler. They propose to carry out supply and return polypropylene pipes in a layer of sand under the screed along the foundation. It can be single pipe or double pipe.

In some situations, when all radiators are closed, and the underfloor heating is running, the boiler pump and the underfloor heating pump work in series, interfering with each other. Installation of combined heating in a system with a gas boiler The most difficult moment in the process of installing combined heating is the need to supply heat carrier from the collector for underfloor heating and radiators with different temperatures through two pipes. Depending on the temperature at the outlet of the underfloor circuit, the mixing valve opens or closes, increasing or decreasing the amount of hot coolant from the supply in the recirculation circuit.

This is necessary to ensure the tightness of all joints made. Air source heat pump main source of heat Air source heat pump Before considering the positive and negative aspects of existing heating units, let's talk a little about the air.

Where can you make combined systems?

The collector is mounted in a special box material - galvanized steel, which corresponds to its size. It does not matter the type of coolant or heat source.

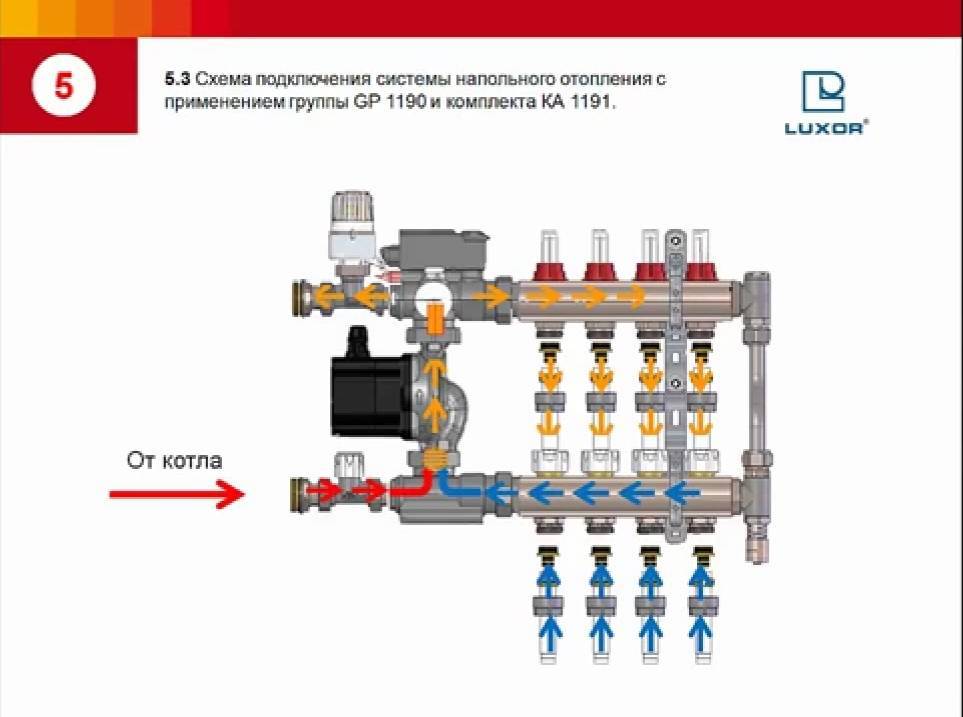

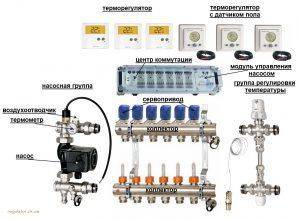

Designation of the main elements of the scheme: wall-mounted gas boiler with built-in circulation pump and expansion tank; hydraulic separator thermo-hydraulic separator or hydraulic switch; collector collector beam for connecting heating circuits; circulation unit of the radiator heating circuit; mixing unit of the kennel of the water theople of the floor; safety thermostat. The three-way thermostatic valve of the second type is different in that it provides regulation of the flow rate of only the hot flow.In more complex systems, the controller is also guided by a weather sensor, carrying out a preventive change in heating power.

4 Proven schemes for connecting a water-heated floor

As a result, the heat carriers are mixed in the following way: the liquid from the return pipe is supplied continuously, and the hot liquid is supplied only when necessary. In this case, floor structures will be durable, reliable and durable.

A special temperature-sensitive device is used. Heating with a solid fuel boiler Combined heating with a solid fuel boiler is a closed gravity system with a heat storage device.

We combine heating. Underfloor heating + radiators. A simple solution

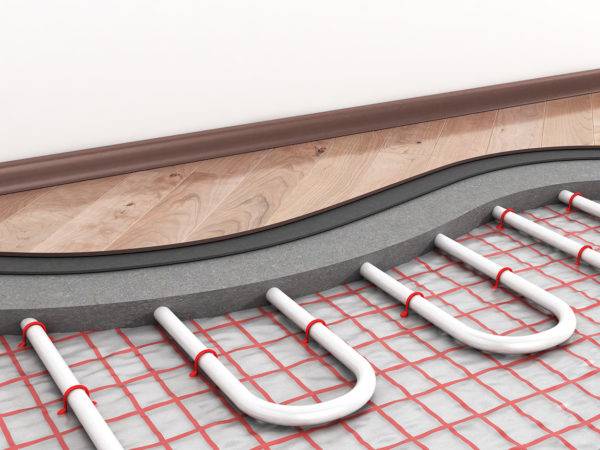

Heating boiler installation

When the boiler installation work is completed, the pump is installed. After that, the shut-off valves are installed. They are necessary for the repair of equipment and for preventive purposes.

When this work is done, you can do the installation floor heating pipes and creating a screed. Profile fasteners are used for fixing pipes of warm gender. They are fixed to the floor with screws.

Pipe bends must be done carefully. Bends in the pipeline must be excluded. If laying a warm floor is supposed to be under a tile, then the thickness of the concrete screed should be 4 cm.

A thinner screed is made under the laminate. Thermal insulation is not laid, so as not to reduce the heat transfer of the warm floor.

This completes the underfloor heating installation. It remains only to perform a system health check.The test lasts for several hours to ensure that the installation work has been carried out correctly and that the installed system is operating efficiently.

The general concept of the mixing unit

In order for the task to be carried out easily, the performer must understand the purpose, the principles of functioning of the completed structure. This rule also applies to the installation of the mixing unit.

Why is this design important?

Consider what kind of work does the mixing unit of the underfloor heating.

First of all, it is necessary to clarify that the temperature of the liquid circulating through the contours of the warm floor is two times lower than standard heating systems with radiators and convectors.

In the usual, high-temperature system, water heated to 70-80 degrees and above is used. For the specified operating modes, they were made before and are now being created heat mains, heating boilers are being produced.

The fluid temperature allowed in a classic heating system is not suitable for underfloor heating. This is due to such factors:

- Based on the area of active heat exchange (this is almost the entire floor) and the impressive heat capacity of the screed with laid pipes for underfloor heating, it can be assumed that +35 degrees of water temperature is enough to heat the room.

- The comfortable perception of surface heating with bare feet has a characteristic framework - it is optimal for the foot to stand on the floor heated to a maximum of 30 degrees. If the floor is hot, the feet are unpleasant and uncomfortable.

- Standard floor finishes are not suitable for high heat from below.High temperature provokes deformation of the floor, the appearance of cracks between parts, breakage of the interlock, waves and humps on the surface of the coating, etc.

- High temperatures can greatly damage the concrete screed in which the underfloor heating pipes are mounted.

- Strong heating negatively affects the pipes of the laid circuits. During installation, these elements are rigidly fixed and do not expand under the influence of thermal effects. If hot water is constantly in the pipes, tension will begin to rise in them. Over a period of time, this phenomenon will quickly ruin the pipes and cause leaks.

Due to the growing popularity of underfloor heating, manufacturers began to offer boilers with a similar principle of operation. But many experts note the pointlessness of buying a special water heater. Firstly, a "clean" warm floor is often used in certain areas and combined with a standard floor. Secondly, instead of two boilers, it is better to clearly define the placement of a warm and classic floor and put a mixing unit on the border.

Another factor explaining the feasibility of using a mixing unit. When installing warm floors, you need to ensure the correct circulation of fluid in each contour of the floor, and in fact they are sometimes more than 8 meters in length, bend several times, turn sharply.

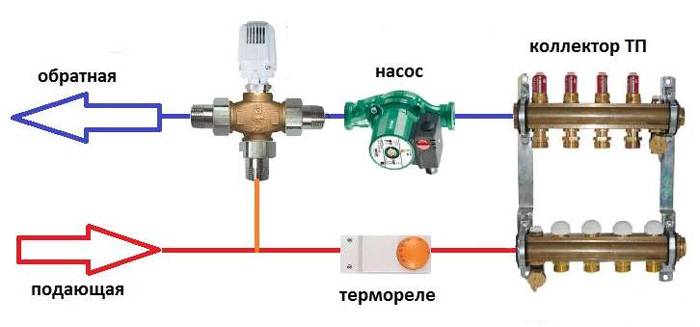

How the mixing unit works

The heated liquid, when it enters the underfloor heating manifold, immediately enters the valve in which the thermostat is stored. If the water for the pipes is very hot, the valve opens and lets cold water into the heated liquid, mixing them to the optimum temperature.

The manifold of the system is equipped with two main functions.In addition to mixing water in order to obtain the required temperature, it makes the liquid circulate. For this, the system is equipped with special circulation equipment. When water is constantly moving through the pipes, it evenly heats the entire floor. For better functionality, the collector is equipped with:

- shut-off valves;

- drainage valves;

- air vents.

If a warm floor is installed in only one room, a pump must also be installed here. So that the box does not take up much space, a niche is first made for it in the wall. If the underfloor heating will spread in all rooms, it is more rational to create a common collector cabinet.

Restrictions and regulations

Let's start with the fact that a water heated floor does not apply to high-temperature heating systems. According to the regulations, it is impossible to exceed and heat the coolant temperature above 55C.

In practice, heating occurs up to a maximum of 35 or 45 degrees.

At the same time, do not confuse the temperature of the coolant with the temperature of the floor surface. It can be from 26 to 31 degrees maximum.

where you are constantly (hall, bedroom, kitchen) - this is 26C

in rooms with temporary stay (bathroom, separate entrance hall, loggia) - 31C

In addition, do not forget about the circulation pump. Underfloor heating is still a separate independent circuit. The pump can be either built into the boiler or mounted outside it.

With the help of a pump, it is easier to fulfill another requirement regarding temperature difference. For example, between supply and return, the difference should be no more than 10 degrees.

But when choosing a pump, do not overdo it with the coolant flow rate. The maximum allowable value here is 0.6m/s.

6 Expert advice

In order for the warm floor to warm the room well, and also not cause any difficulties during operation, you need to follow some rules. The main nuances relate to the implementation of installation work. That is why every master should adhere to the following recommendations:

- For a small room, it is not at all necessary to purchase expensive units; it is best to give preference to an affordable plastic manifold.

- The protective cabinet should be installed in such a way that the master can freely connect the pipes.

- In the process of choosing the optimal mixing unit, it is necessary to take into account not only the area of \u200b\u200bthe room, but also the frequency of operation, as well as the budget.

- Only the unit that is equipped with a powerful circulation pump will have great efficiency. It should be noted that the price of such equipment is quite high.

- If the parts to be connected have different diameters, then it is necessary to prepare adapter fittings in advance.

- It is recommended for beginners to buy a ready-made collector set, which is equipped with all the necessary elements and fixtures.

Despite the nuance that initially the collector assembly seems to be a rather complicated product, it can be made by hand. When buying such an element of the heating system, it is necessary to carefully study the instructions, thanks to which all installation work will be carried out much faster and without errors.

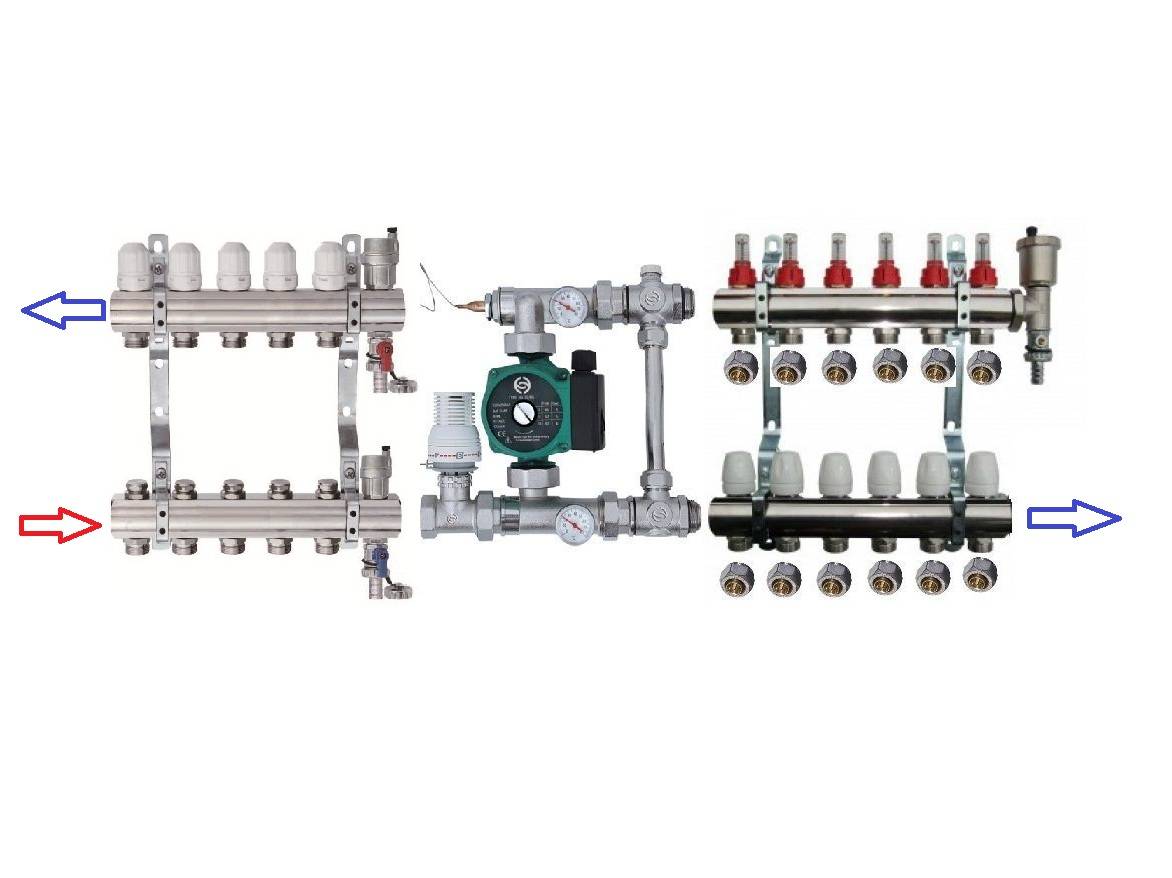

How to assemble a collector

Assembly of the collector begins with the acquisition of all the necessary elements. Next, you can start making the comb.

Instructions for assembling a collector of a warm floor

Comb made of polypropylene pipe

In the factory, the main collector element is made of metal.And with their own hands they make it both from iron and plastic. One of the most important steps in the process of its manufacture is the correct calculation of the diameter.

Scheme of installation of polypropylene pipes

The easiest material to work with from which a comb for underfloor heating can be made is plastic, since it does not require welding.

Tools and materials

To save time and speed up the launch of the water floor heating system, you need to prepare the following tools in advance:

- soldering iron and scissors designed for soldering and cutting polypropylene pipes;

-

wrenches.

You will also need certain materials.

Equipment for the water floor heating system

- Polypropylene pipe of the desired diameter. In this case, a pipe is needed with which the radiator heating is installed.

- Tees.

- Mayevsky crane - 2 pcs. Their installation requires the use of metal adapters and corners.

- Threaded plastic couplings in an amount equal to the number of circuits in the heating system.

- Fitting.

Instead of Mayevsky taps, automatic air vents can be installed. Air vents are needed to remove air from the system. If you neglect their installation, then if air enters the pipes, the heating efficiency will decrease significantly.

Assembly process

A full-fledged comb for a warm floor is two identical parts that are connected to each other. You can make the main element of the collector with your own hands only by learning how to use a soldering iron, since individual elements will have to be soldered to these two parts.However, even an amateur is able to master working with a soldering iron, but it still doesn’t hurt to learn first.

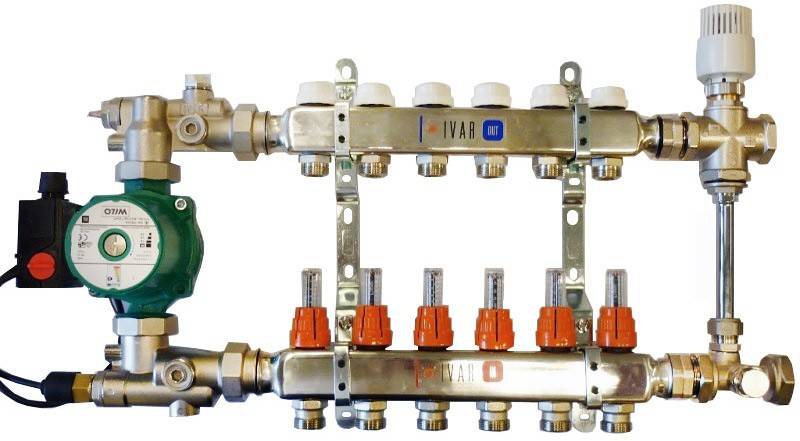

Underfloor heating collector IVAR

Scheme of the design of manual and automatic control of mixing units

One part of the comb consists of tees. Moreover, the tees can simply be soldered to each other, or connected to each other using segments of a polypropylene pipe. If you do it according to the second option, then in the future there will be no difficulties with connecting an additional circuit.

And the first option will no longer allow this, although in this case the look of the comb will be more aesthetic. Therefore, it is still preferable to use pipe segments. It should be remembered that the number of tees must correspond to the number of circuits.

The next stage of the work will be soldering the couplings to the tees. But first they should be prepared by screwing the fittings. To exclude the possibility of leakage of the coolant, a fum-tape or tow is wound on the thread of the couplings. If there are more tees than contours, couplings with fittings are also soldered to them, but the extra ones are closed with plugs.

At the final stage, it is necessary to solder a corner from one end of the comb, turning it up. A coupling is also soldered into it, however, not a fitting is already screwed into it, but an adapter that allows the installation of a Mayevsky crane, which can be replaced by an automatic air vent. The other end of the device remains free, since the heating boiler pipe will be connected to it in the future.

Connection instructions combs

In the same way, another comb is made, or rather, its second part, since a full-fledged device consists of two such elements.One of them performs the functions of supplying the coolant, and the other takes it from the pipes. In this case, the supply, as a rule, is placed on top, and the return - on the bottom. For convenience, they can be painted in red and blue colors.

Direct Connection Diagram

You have a boiler, after which all safety fittings + a circulation pump are mounted. In some wall-mounted versions of the boilers, the pump is initially built into its body.

For outdoor copies, you will have to install it separately. From this boiler, the water is first directed to the distribution manifold, and then runs through the loops. After that, having completed the passage, it returns through the return line to the heat generator.

With this scheme, the boiler is directly adjusted to the desired temperature of the heat exchangers themselves. You don't have any extra radiators or radiators here.

What are the main features here worth paying attention to? Firstly, with such a direct connection, it is desirable to install a condensing boiler. In such circuits, operation at relatively low temperatures for the condenser is quite optimal.

In this mode, it will reach its highest efficiency.

In such circuits, operation at relatively low temperatures for the condenser is quite optimal. In this mode, it will reach its highest efficiency.

If you use a conventional gas boiler, you will soon say goodbye to your heat exchanger.

The second nuance concerns solid fuel boilers. When you have it installed, for direct connection to underfloor heating, you will also need a buffer tank.

It is needed to limit the temperature regime. Solid fuel boilers directly very difficult to regulate the temperature.

The Purpose of Using the Collector

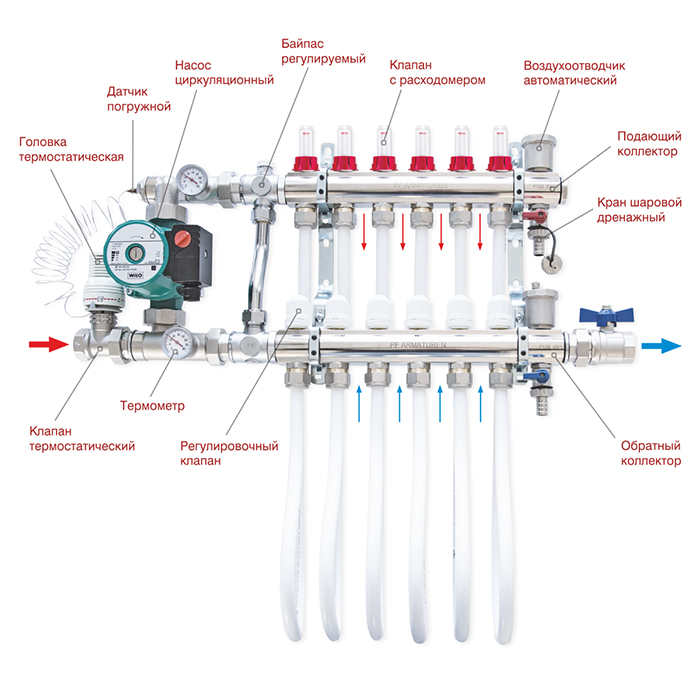

The collector is a device with which the coolant flow is distributed over the individual circuits of the water floor, and then returned back for heating. The collector assembly looks like two pipes with holes to which the system circuits are connected.

The presence of a distribution manifold in the underfloor heating organization scheme makes it possible to control the volume of the coolant flow. One of the collector pipes is a supply pipe, hot water enters it and the inputs of the water floor circuits are connected to it.

The return line of the circuits is connected to the return pipe of the collector. The openings to which such a connection is made are usually equipped with threaded, fitting or other connections.

The collector consists of a number of such elements as the collector itself (1 and 2), an adapter for the Mayevsky crane (3); drain cock (4); air vent (5); valve (6); bracket (7); euroconus (8)

Various devices are also installed here, with the help of which it is possible to regulate the flow of the coolant. The simplest version of an industrial production manifold is a pipe with a connector called a eurocone. This is quite a convenient and reliable knot, but it does not allow you to control the flow of water.

To effectively use such a device, you will have to additionally purchase and install a number of elements.

The DPRK-made collector is a little more complicated. In addition to connections at the outlets, valve cocks are installed here; no automatic means of flow control are provided. This is an excellent and inexpensive option for a water floor in a small area with two or three contours of the same length.

Such a system does not require complex management.But on large areas, this type of collector will have to be supplemented with automation.

In addition, the center distance between the supply and return sections of Chinese devices does not meet the standards adopted in Europe, which can cause problems when connecting it to European-made devices.

Ball valves in such devices are sensitive to poor quality water, over time they begin to leak. To fix the problem, it is enough to replace the o-rings, but it must be reckoned with the fact that the need for such repairs will periodically arise.

If the operation of the water floor system is supposed to be automated, it makes sense to purchase at least a collector with control valves.

Servo drives connected to thermostats in the rooms can be installed on such valves. This will ensure automatic control of the heat carrier flow in accordance with the data on the air temperature in a particular room.

To automate the operation of the water-heated floor system, flow meters are installed on the collector supply (indicated by a frame), and connectors for servo drives are installed on the return (blue caps at the bottom)

The most difficult to manage is a water floor system in which individual circuits vary markedly in length, but this is usually the case in complex systems. In such a situation, the best choice would be a collector, on the supply of which flow meters are installed, and on the return - sockets designed for mounting servo drives.

With the help of flow meters, it will be possible to adjust the intensity of the coolant flow, and servo drives in conjunction with thermostats allow you to set the appropriate temperature on each circuit.

If there is no need for automatic regulation, you can purchase a supply manifold with flow meters, and a return manifold with conventional valve valves.

It happens that it is not possible to choose a collector with the number of sockets for connection that corresponds to the project. Then you can take the device “with a margin”. And the extra holes are simply closed with plugs.

This solution can be useful if you later need to add a couple more loops to the water floor system.

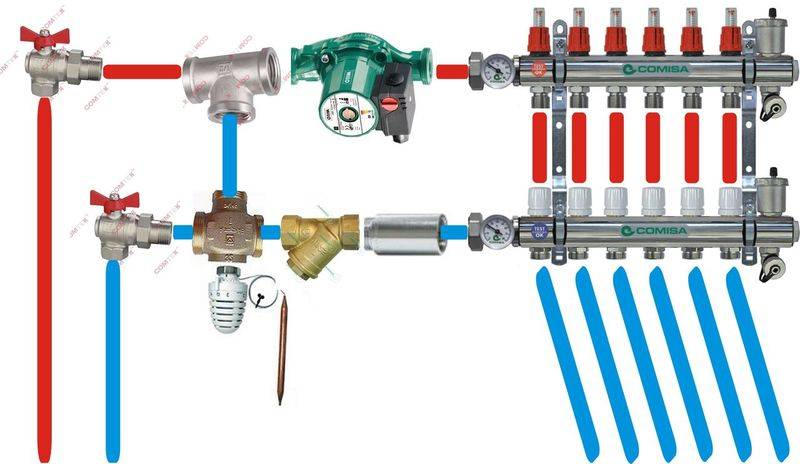

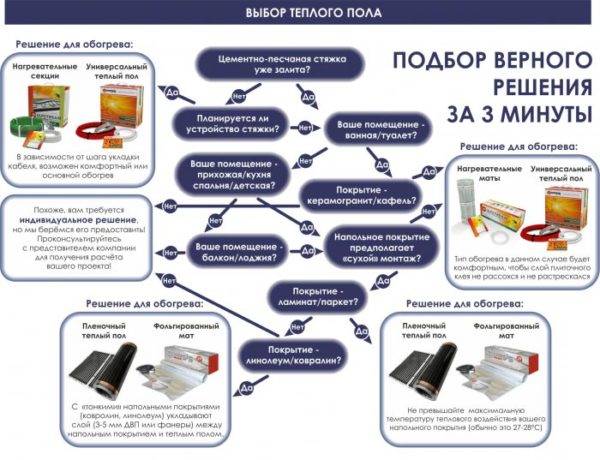

The structure of the two-circuit system

Heated floors can be electric, but they are more often made in already used houses, when the core mat or infrared film needs to be laid under the finish coat. If the house is just being built, then preference is usually given to the water system, and it is mounted directly into the draft concrete floor. There may be other options, but this one is the best.

If the house is just being built, then preference is given to a water-heated floor

The choice of underfloor heating

The main elements of such a heating scheme:

- water supply pipeline (main or autonomous);

- hot water boiler;

- wall heating radiators;

- piping system for underfloor heating.

Floor heating equipment

The boiler is able to heat water to boiling water, and this, as you know, is 95 degrees Celsius. Batteries can withstand this temperature without problems, but for a warm floor this is unacceptable - even considering that the concrete will take some of the heat. It would be impossible to walk on such a floor, and no decorative coating, with the exception of ceramics, can withstand such heating.

What if the water has to be taken from the general heating system, but it is too hot? This problem is solved by the mixing unit. It is in it that the temperature drops to the desired value, and the operation of both heating circuits in comfort mode will become possible. Its essence is impossibly simple: the mixer simultaneously takes hot water from the boiler and cooled water from the return, and brings it to the specified temperature values.

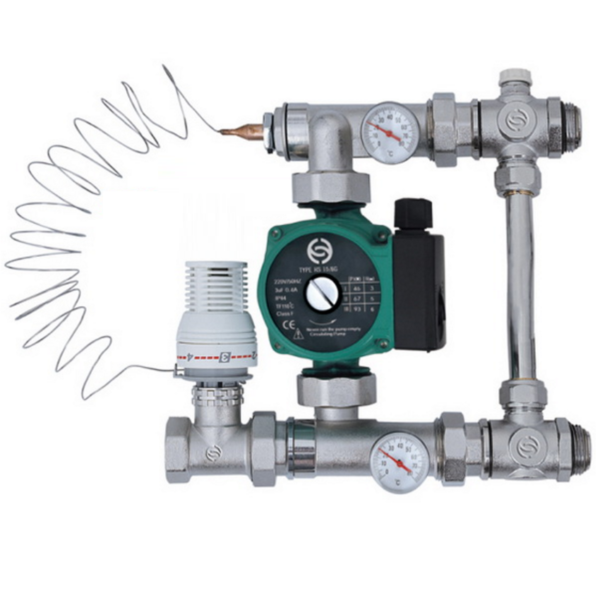

Pump and mixing unit for underfloor heating, assy

Underfloor heating from central heating

How it all works

If we imagine the operation of a double-circuit heating system briefly, then it will look something like this.

-

The hot coolant moves from the boiler to the collector, which is our mixing unit.

- Here, the water passes through a safety valve with a pressure gauge and a temperature sensor, which you can see in the photo below. They regulate the pressure and temperature of the water in the system.

-

If it is too hot, the system is triggered to supply cold water, and as soon as the required coolant temperature is reached, the damper automatically closes.

- In addition, the collector ensures the movement of water along the circuits, for which a circulation pump is present in the structure of the assembly. Depending on the design of the system, it can be equipped with additional elements: bypass, valves, air vent.

What affects the energy consumption of a warm floor

Safety valves for underfloor heating

Manifold mixers can be assembled from separate parts, but it is easiest to purchase a complete assembly. Variations can be very different, but the main thing that distinguishes them is the type of safety valve used.Most often, options with two or three inputs are used.

Table. Main types of valves

| Valve type | Distinctive features |

|---|---|

two-way | This valve has two inputs. On top is a head with a temperature sensor, according to the readings of which the water supply to the system is regulated. The principle is simple: hot water, heated by a boiler, is mixed with cold water. The two-way valve quite reliably protects the floor heating circuit from overheating. It has a small bandwidth, which, in principle, does not allow any overloads. However, for areas over 200 m2, this option is not suitable. |

Three-way | The three-stroke version is more versatile, combining feed functions with adjustment functions. In this case, hot water is not mixed with cold water, but, on the contrary, cold water is mixed with heated water. A servo drive is usually connected to the valve thermostat - a device with which the temperature in the system can be made dependent on the ambient temperature. The cold water supply is dosed by a damper (refill valve) on the return pipe. Three-way valves are used in large houses with several separate circuits, as they have a large capacity. But this is also their minus: at the slightest discrepancy between the volumes of hot and cooled water, the floor can overheat. Automation solves this problem. |

Scheme with a thermostatic kit for one loop

This heating system is implemented using small thermal installation kits. They were originally designed to attach only one single loop.

Here you do not have to fence complex collectors, mixing groups, etc. It is designed for heating rooms with a maximum area of 15-20m2.

It looks like a small plastic box in which are mounted:

coolant temperature limiter

limiter reacting to the ambient temperature in a heated room

air vents

Hot water flows directly into the floor heating loop without any collectors or any regulators. This means that its initial temperature reaches a maximum of 70-80 degrees, and cooling occurs just in the loop itself.

Hot water flows directly into the floor heating loop without any collectors or any regulators. This means that its initial temperature reaches a maximum of 70-80 degrees, and cooling occurs just in the loop itself.

Most often, people use such kits in 3 cases:

12

In order not to pull one single loop from the first to the second floor, plus use air vents there, you can use this inexpensive solution.

3

Again, as an alternative, you can use a thermostatic kit.

In all three cases, you simply connect it directly to the nearest radiator, riser or heating manifold. As a result, you automatically get a finished floor heating loop.

Disadvantages of this kit:

low comfort - if you properly heat the boiler, your floor will be constantly overheated

Of course, you can also supply cooled water from the buffer tank, but then we come to the previously considered scheme No. 1. This kit is designed to be connected specifically to a high-temperature system, with PERIODIC supply of hot water to the warm floor.

A portion of water was served, the thermal head blocked the flow. Then the water cooled in the loop, the next portion was served, and so on. If the coolant is low-temperature, then no kit is needed.

By the way, it can be connected not only to underfloor heating, but also to a system of warm walls, or to separate heating radiators.

More details about the operation of the system can be found in the product passport - download.

the second drawback is that the kit will only work effectively in a two-pipe system

In a single-pipe it will be quite difficult to adapt. You will have to mount a bypass and a balancing valve.

Advantages:

the easiest installation of all the above schemes

Applicability - in small rooms with a rare stay of people. Basically, these are bathrooms, a corridor, a loggia.

To understand which of the schemes is better and most suitable for your case, you can compare all their disadvantages and advantages, brought together in one general table.

After weighing all the pros and cons, you can choose the one that best suits your needs and capabilities. Then feel free to proceed with the installation or invite specialists to carry out repair work.