- 6 Pushbutton drive - the most common problems

- The device and operation of drain tanks

- Installation

- The most common breakdowns and how to fix them

- If the tank is leaking

- Continuous supply of water

- Leakage of water in the toilet

- Flush Button Repair

- Noise elimination

- Service

- Internal organization

- Modern models with lever drain

- With button

- Fittings for a drain barrel: types, characteristics

- Features of valves

- Side fittings for drain barrel

- Fittings for a barrel of a toilet bowl with the bottom eyeliner

- Differences flush cisterns for toilets

- Location

- Trigger type

- Material

- The way the mechanism works

- Varieties of the drain valve for the toilet bowl as a mechanism for controlling the overflow of the system

- Toilet flush valve material

6 Pushbutton drive - the most common problems

To remove the top of the tank with one button, unscrew the retaining ring around it. Do not press hard, they are often plastic and can break. In addition to the problems with the membrane and the pear, which we have already talked about, the destruction of the bolts holding the pear seat is possible. We unscrew the nut between the valve and the liner, the bolts that attract the shelf to the toilet. Slightly tilt the tank forward and take out the cuff. We change the bolts in pairs, even if one is in good condition.The material for them is brass or stainless steel.

We remove faience from under the saddle of the pear, carefully clean it, and also clean the surfaces of the shelf and tank. If we do not change the pear, we lubricate with sealant so that it sticks to the saddle. We assemble the tank and tighten it with new bolts without distortions

We check the work, paying special attention to places of possible leakage

If the buttons do not work, they either sink or the lever mechanism is disconnected. In this case, the cover is removed, and the mechanism is installed in the desired position.

The device and operation of drain tanks

All drain tanks have a similar design. The difference is only in the mechanism of starting water.

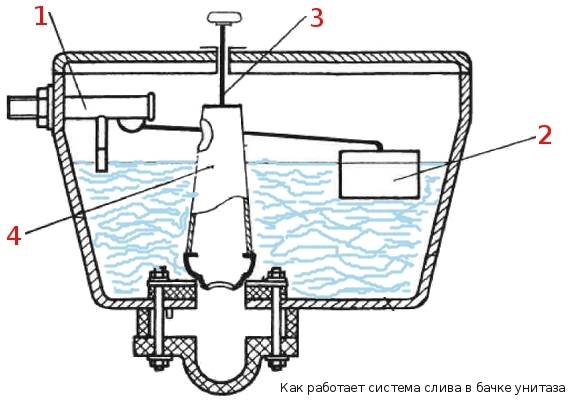

Structurally, a toilet cistern with a button or two buttons, as well as a flush lever, can be represented as a set of interacting nodes:

- Fill valve. He is responsible for maintaining the water level at a certain level. The valve is controlled by a hollow float. When the water rises to the desired level, the float closes the water supply channel to the tank;

- Plastic float attached to the filling valve. Works on the principle of a rocker, rising when filling the tank;

- Drain valve with overflow system. Modern tank options involve controlling this valve by pressing a button. With manual control of the old-style drain, it is enough to pull the lever or chain to start water into the toilet;

- Overflow is a mandatory component of the tank. It is adjustable in height, thanks to which the maximum water level is set. When this level is exceeded, water flows through the overflow pipe into the sewer without spilling out through its walls.

A tank with a mechanical drain is very simple to operate.Water enters it through the filling valve when the float is in the lowered position. After reaching a strictly defined level, the float shuts off the water supply. Drainage is controlled manually. If the tank is equipped with buttons, then the water is drained after pressing them. In this case, the drain valve partially or completely opens, passing water into the toilet. The float drops, slightly opening the filling valve.

The structure of the toilet flush tank with two buttons is a bit more complicated, but you can use such a tank more economically. If you press one of the buttons, the water is partially drained. Full drain occurs when the second button is pressed.

Increasingly, you can find new types of tanks with a lower connection to the water line. It is advisable to install them if the use of a side connection is not possible due to lack of space. The main difference of such a tank is the presence of a membrane valve. Under the influence of water pressure in the pipeline, the valve opens slightly and passes water inside. When the water rises, the float presses on the piston rod, which gradually closes the diaphragm valve. When the set level is reached, the valve closes completely.

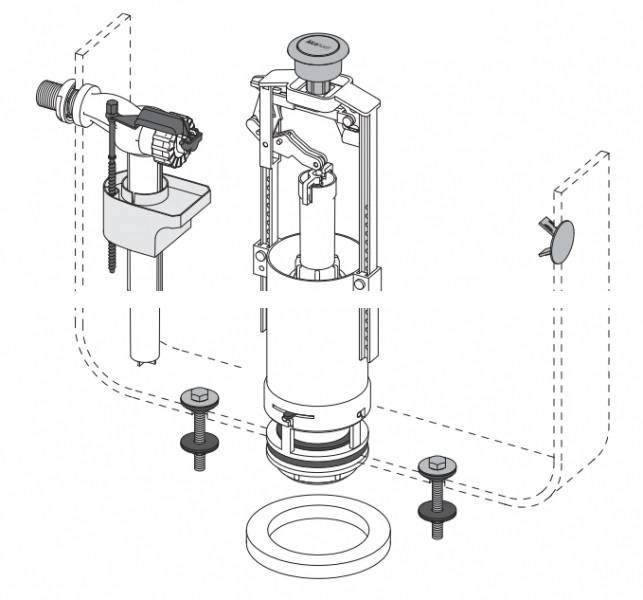

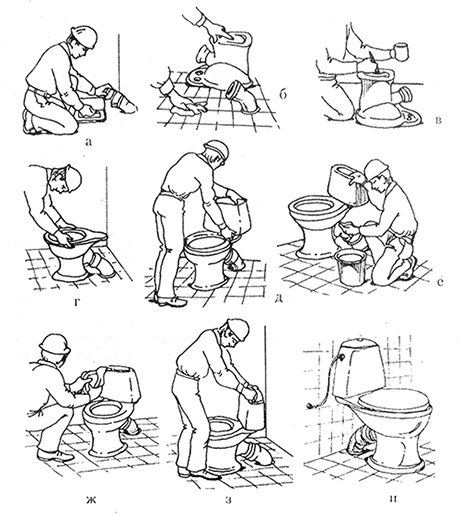

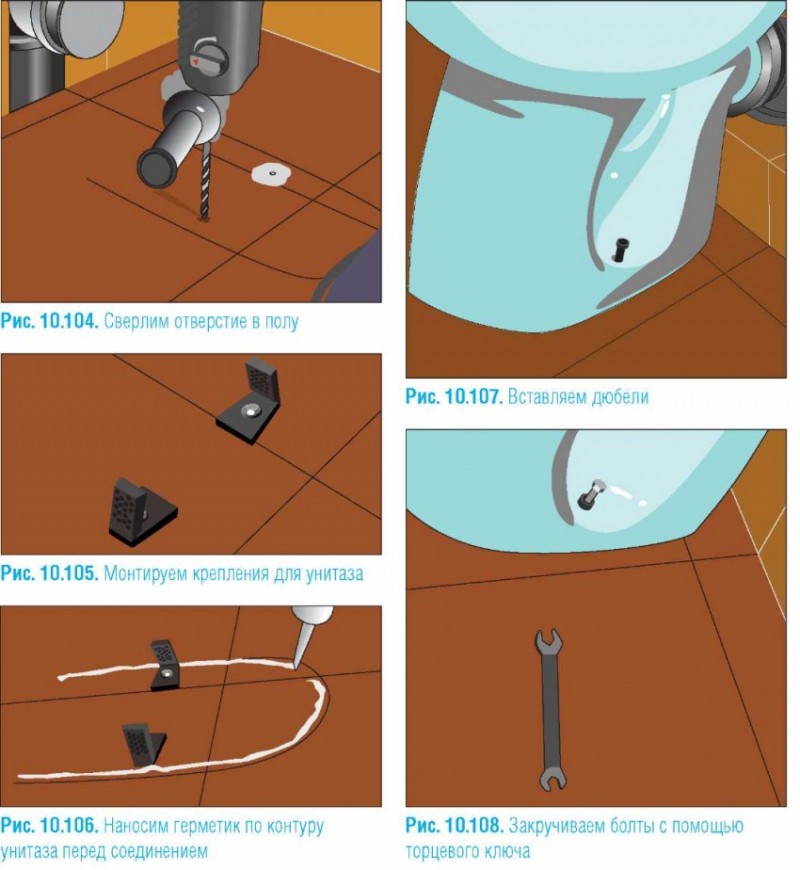

Installation

When one or another leads to the need to replace the drain fittings on your own, it is quite possible to do this.

Work should be in accordance with the algorithm.

- A filling is purchased that matches the connectors of the existing tank. A very important parameter will be where the inlets are located (top, side), their dimensions, different diameters of the drain hole and overall dimensions. It would be ideal if the names of the manufacturer of toilet bowls and the filling for the tank are the same.

- The water is shut off, all the liquid remaining in the tank is removed.

The drain button is recessed, the locking ring is carefully unscrewed. Now we can disassemble the tank cover.

The water hose is disconnected.

The nut that secures the pipe is unscrewed, and it is removed.

When the option with a vertical connection from below is implemented, it is recommended to place some kind of jar under the hole, where the residues that did not spill out when drained will drain.

- The entire "stuffing" is dismantled, it should be removed.

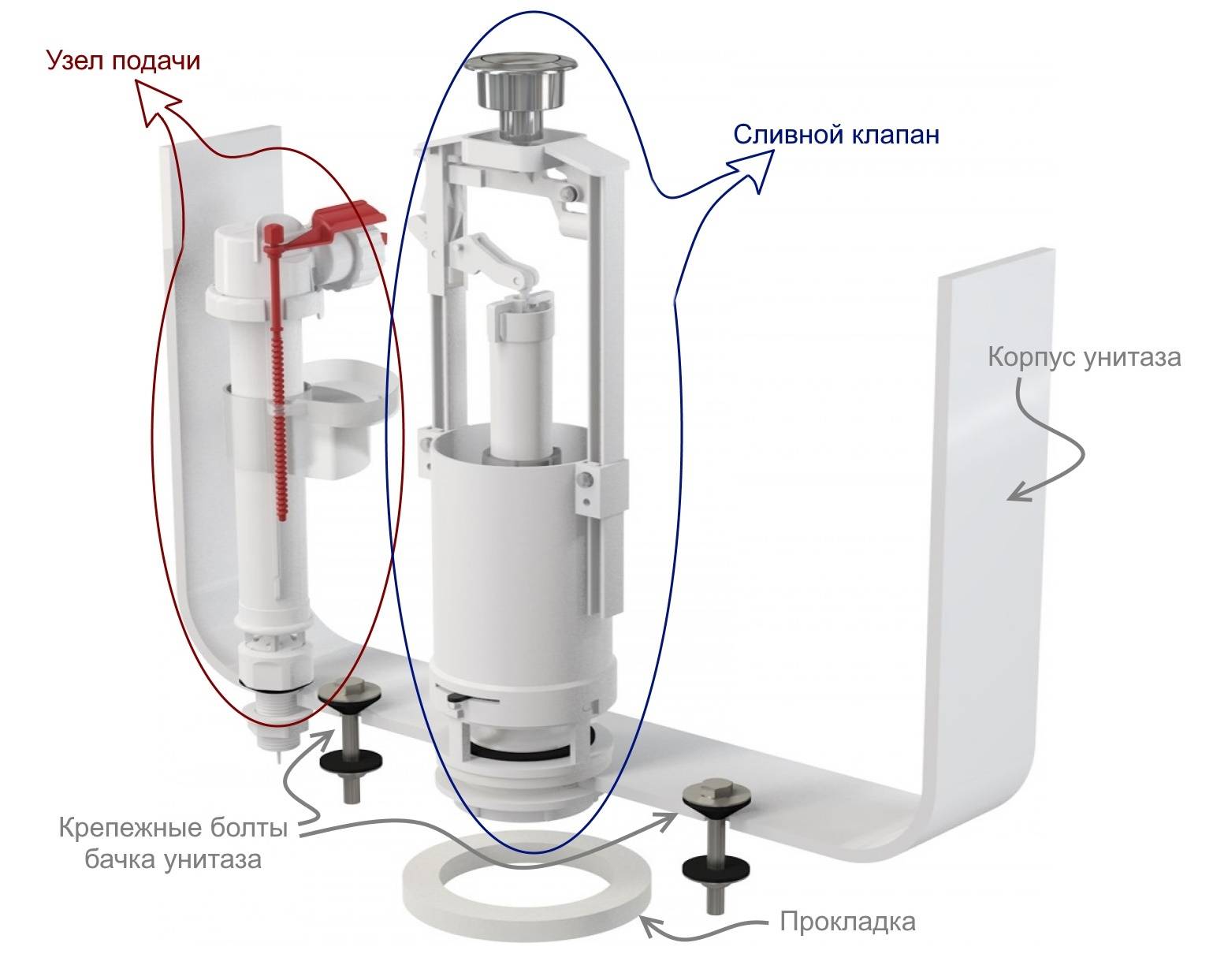

- The fasteners with which the tank was attached are unscrewed, it is dismantled. The bottom of the drain device is removed along with the gaskets that ensure the sealing of the connection.

When dismantling is completed, the internal surfaces in the tank and the bowl openings are wiped to remove plaque. At the same time, the channels of the side parts of the bowl are cleaned, which provide drainage. During operation, such places are inaccessible, but here it is quite possible to carry out prevention.

Of course, you will also have to perform the reverse sequence of actions to reinstall the mechanism:

- Install the bottom of the drain system in the hole, not forgetting the sealing gaskets.

- Reinstall the water tank, align and secure with the fixing bolts. Poor quality fasteners tend to rust, so all rusty parts are recommended.

- The installation of the "stuffing" of the drain device should be completed by fixing it in the drain hole.

- Insert the water filling valve into the wall from the side, and fix it with nuts and rubber bands.

- Connect the water supply to the outlet of the filling hydraulic valve. Turn on water to check operation.

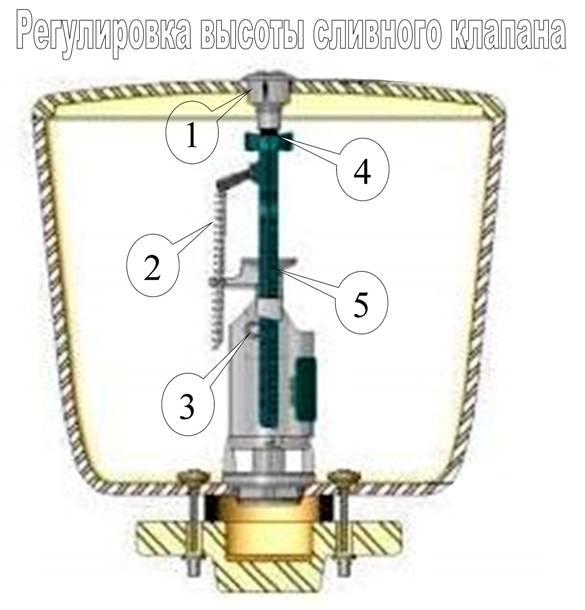

- Adjust if necessary - adjust the height of the overflow (approximately 2 cm below the level of the upper hole) and the rod that connects the drain device and buttons.

- With the correct functioning of all systems and in the absence of leaks, you can proceed to install the cover. Fix it by screwing the bezel of the buttons.

The existing design differences between the variants of tanks and their “stuffing” cause slight deviations from the algorithm, although almost all tanks are designed according to similar schemes, therefore, the tank fittings are mounted in this way.

Exceptions can be made for built-in toilet models that have a tank located inside the wall in a sliding niche.

The most common breakdowns and how to fix them

The main malfunctions of the tank are:

- leaking toilet bowl;

- water from the water pipe constantly fills the tank;

- water flows into the toilet or flushing occurs only after repeatedly pressing the button;

- the button for draining the water does not function;

- when filling the tank there is noise.

If the tank is leaking

If the toilet cistern is leaking, then the cause may be:

- formation of a crack on the body of the tank. To fix the problem, you need to completely replace the toilet tank;

- wear of the gaskets of the mounting bolts;

- wear of the gasket between the tank and the toilet bowl.

To replace gaskets:

- block the flow of water into the drain tank. For the toilet, a separate faucet is most often installed;

- drain the water;

- unscrew the fixing bolts;

Elements for fixing the toilet bowl

Fasteners equipped with O-rings

- if replacement of the bottom gasket is required, then it is necessary to completely remove the tank from the toilet;

- assemble the system in reverse order.

When starting up for the first time, it is recommended to check the tightness of all sealing elements.

Continuous supply of water

How to fix the toilet cistern if the filling of the cistern from the water supply does not stop? The causes of a malfunction of the float, which is responsible for the water level in the tank, may be:

- the formation of a crack on the float;

- shifting lever.

When a crack is formed, it is necessary:

- remove the float and pour water out of it;

The device responsible for filling the tank with water

- dry the device

- close the crack with heated plastic, for example from a bottle;

- install the device in its original place;

- check the functionality.

To temporarily eliminate the leak, you can use an ordinary plastic bag, carefully and tightly wrapping the float with it. Such a system will allow you to postpone repairs for 3 to 5 days.

If the float lever is mixed, then it is enough to simply adjust the mechanism. The optimal location is considered to be 2 - 2.5 cm lower than the underwater hose enters.

Scheme for adjusting filling fittings

Leakage of water in the toilet

If water does not linger in the toilet bowl, then the cause of the breakdown is the wear of the protective valve. mounted on the trigger. You can fix the problem yourself in the following way:

- remove the tank cover;

- install any crossbar on the tank, to which the trigger cable is fixed;

- drain the water;

- disconnect the trigger mechanism by loosening the corresponding fixing nut;

Dismantling the system responsible for draining the water

- get the membrane;

- install a new valve that is fully sized and assemble the entire system in reverse order.

Installing a new valve on the trigger

Flush Button Repair

When using a toilet with a button, the rod connecting the trigger lever to the flush mechanism often breaks. To eliminate the problem, it is necessary to replace the failed element of the system. For a short period of time, traction can be made independently from a piece of wire, but over the next 1 to 3 months it is recommended to completely replace the device.

The device of the mechanism for lowering water

In some cases, for example, when there is a lot of natural wear or breakage of individual parts, it may be necessary to completely replace the installed valve. How to do it, look at the video.

Noise elimination

The reason for the noise when collecting water is a short inlet hose. This problem can only occur on fittings provided for lateral water supply. To eliminate noise, it is necessary to extend the hose with a rubber tube of a suitable diameter. Ideally position the end of the hose at the bottom of the cistern.

Replacing the inlet hose with a longer one will eliminate noise

Knowing the structure of the fittings of the toilet cistern, all repairs can be done independently and with a small cash outlay.

- Autonomous sewerage

- Household pumps

- Gutter system

- Cesspool

- Drainage

- sewer well

- Sewer pipes

- Equipment

- Sewer connection

- The buildings

- cleaning

- Plumbing

- septic tank

- How to choose an electronic bidet

- Choosing and installing a compact bidet

- How to choose a bidet manufacturer

- How to choose, install and connect a floor bidet

- Why and how to use a bidet

- How to install and adjust toilet cistern fittings

- How to connect a dishwasher with your own hands

- How to connect a washing machine with your own hands

- Cleaning sewer pipes: household recipes and equipment

- Heating system made of polyethylene pipes: how to create your own hands

Service

The fittings for the drain tank are inexpensive. Despite this, sometimes they get by with simple repair measures instead of buying it, or they acquire some individual parts, and only then change them with their own hands.

If a malfunction occurs, open the tank, get access to the internal mechanism and see what is the cause of the breakdown. Even with a superficial acquaintance with the system, in order to understand the reasons, a few drains or sets of water in the tank are enough.

To quickly diagnose and fix a problem, read the table.

| Malfunction | Actions |

| Overflow control failure |

|

| Fill valve leaking |

|

| Breakage of the button that drains the water (does not return to its original position) |

|

| When the drain tank is full, there is a weak pressure of water |

|

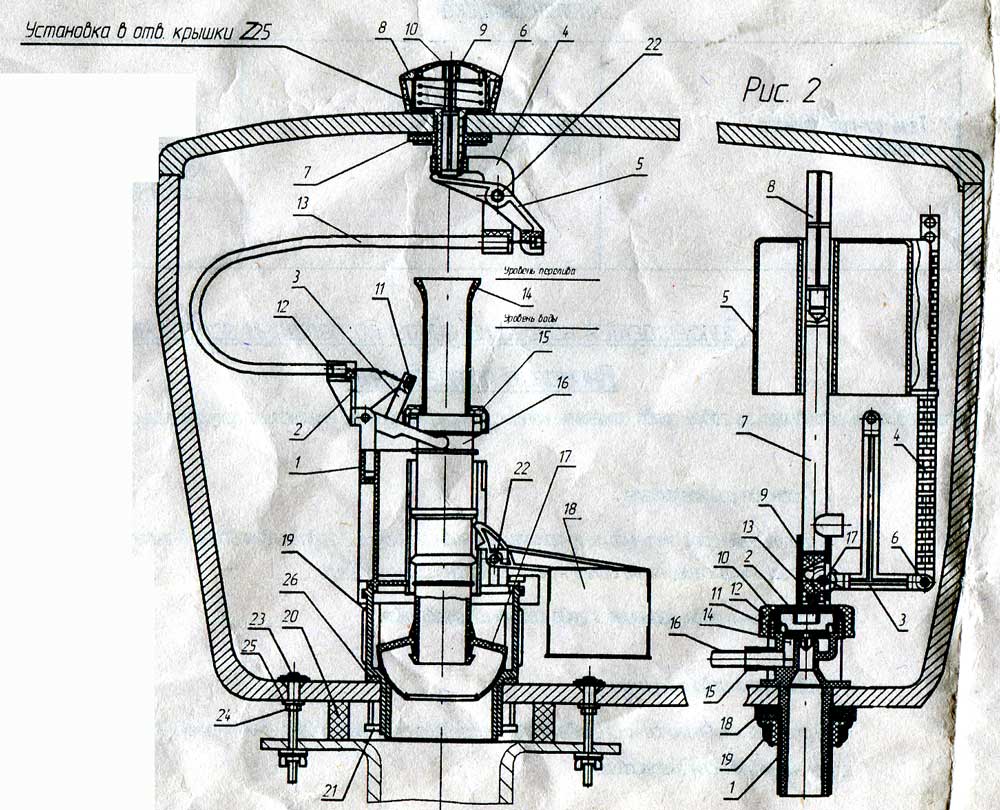

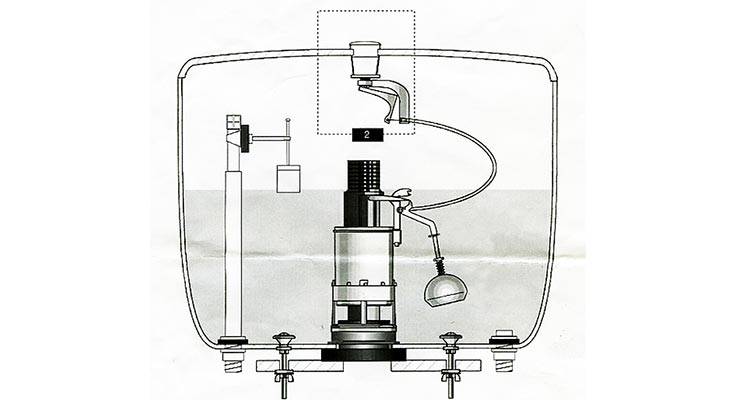

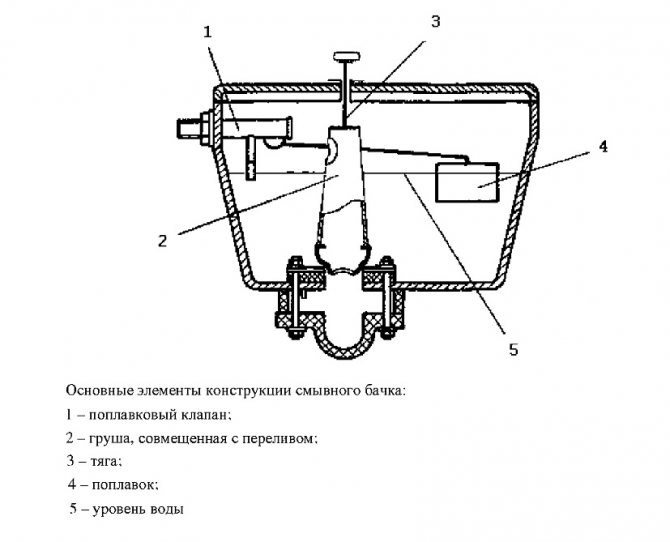

Internal organization

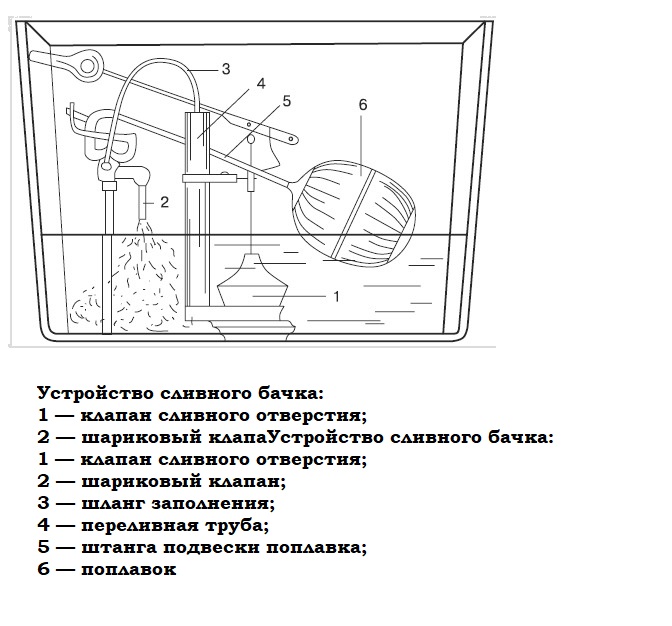

The toilet cistern consists of two simple systems: a set of water and its discharge. To troubleshoot possible problems, you need to understand how everything works and works. First, consider what parts the old-style toilet bowl consists of. Their system is more understandable and visual, and the operation of more modern devices will be clear by analogy.

The internal fittings of a tank of this type are very simple. The water supply system is an inlet valve with a float mechanism. The drain system is a lever and a pear with a drain valve inside. There is also an overflow pipe - through it excess water leaves the tank, bypassing the drain hole.

The device of the drain tank of the old design

The main thing in this design is the correct operation of the water supply system. A more detailed diagram of its device is in the figure below. The inlet valve is connected to the float using a curved lever. This lever presses on the piston, which opens / closes the water supply.

When filling the tank, the float is in the lower position. Its lever does not put pressure on the piston and it is squeezed out by water pressure, opening the outlet to the pipe. Water is gradually drawn in. As the water level rises, the float rises. Gradually, he presses the piston, blocking the water supply.

The device of the float mechanism in the toilet bowl

The system is simple and effective, the filling level of the tank can be changed by slightly bending the lever. The disadvantage of this system is a noticeable noise when filling.

Now let's look at how the drain of water in the tank works.In the variant shown in the figure above, the drain hole is blocked by a bleed valve pear. A chain is attached to the pear, which is connected to the drain lever. We press the lever, lift the pear, the water drains into the hole. When the level drops, the float goes down, opening the water supply. This is how this type of cistern works.

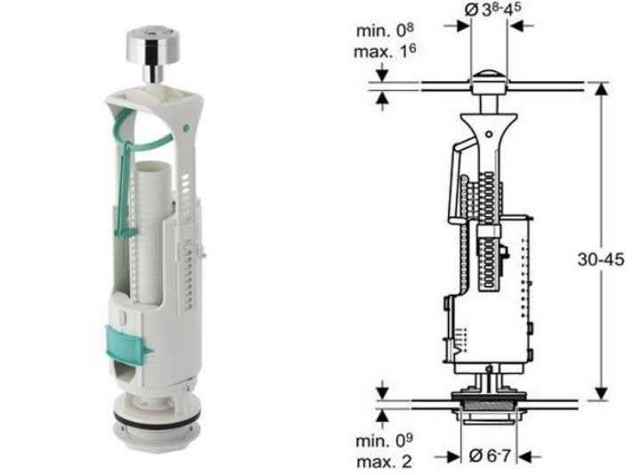

Modern models with lever drain

They make less noise when filling the cistern for toilet bowls with a lower water supply. This is a more modern version of the device described above. Here the tap / inlet valve is hidden inside the tank - in a tube (in the photo - a gray tube to which the float is connected).

Drain tank with water supply from below

The mechanism of operation is the same - the float is lowered - the valve is open, water flows. The tank was filled, the float rose, the valve turned off the water. The drain system remained almost unchanged in this version. The same valve that rises when you press the lever. The water overflow system has not changed much either. This is also a tube, but it is brought out into the same drain.

You can clearly see the operation of the drain tank of such a system in the video.

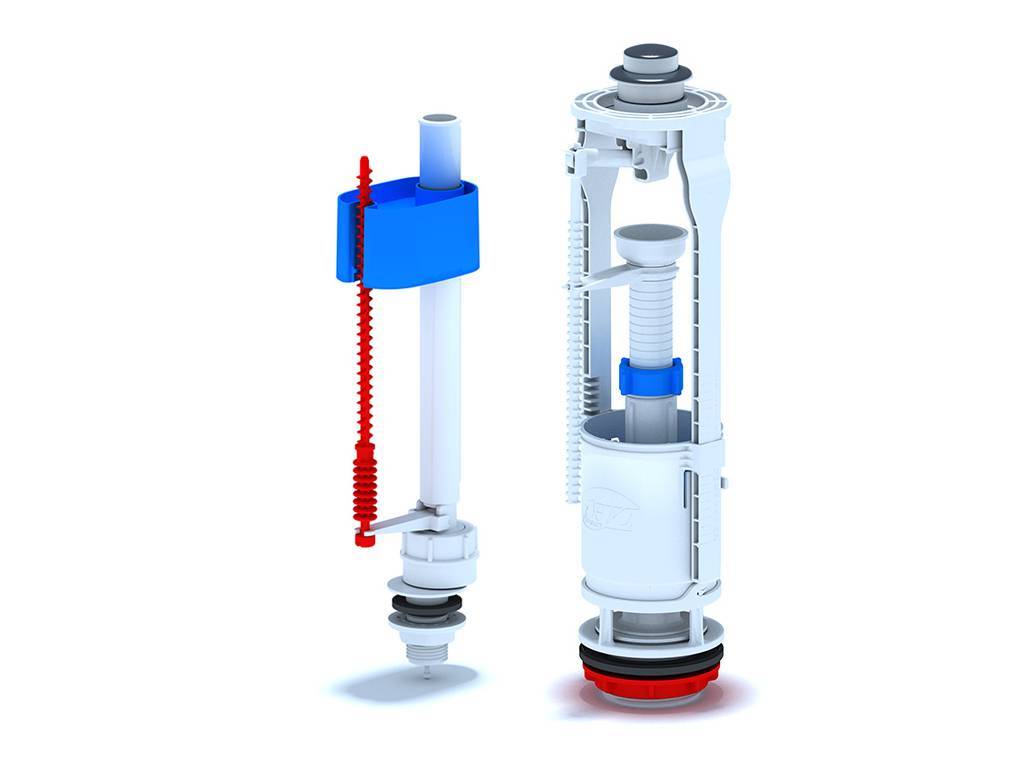

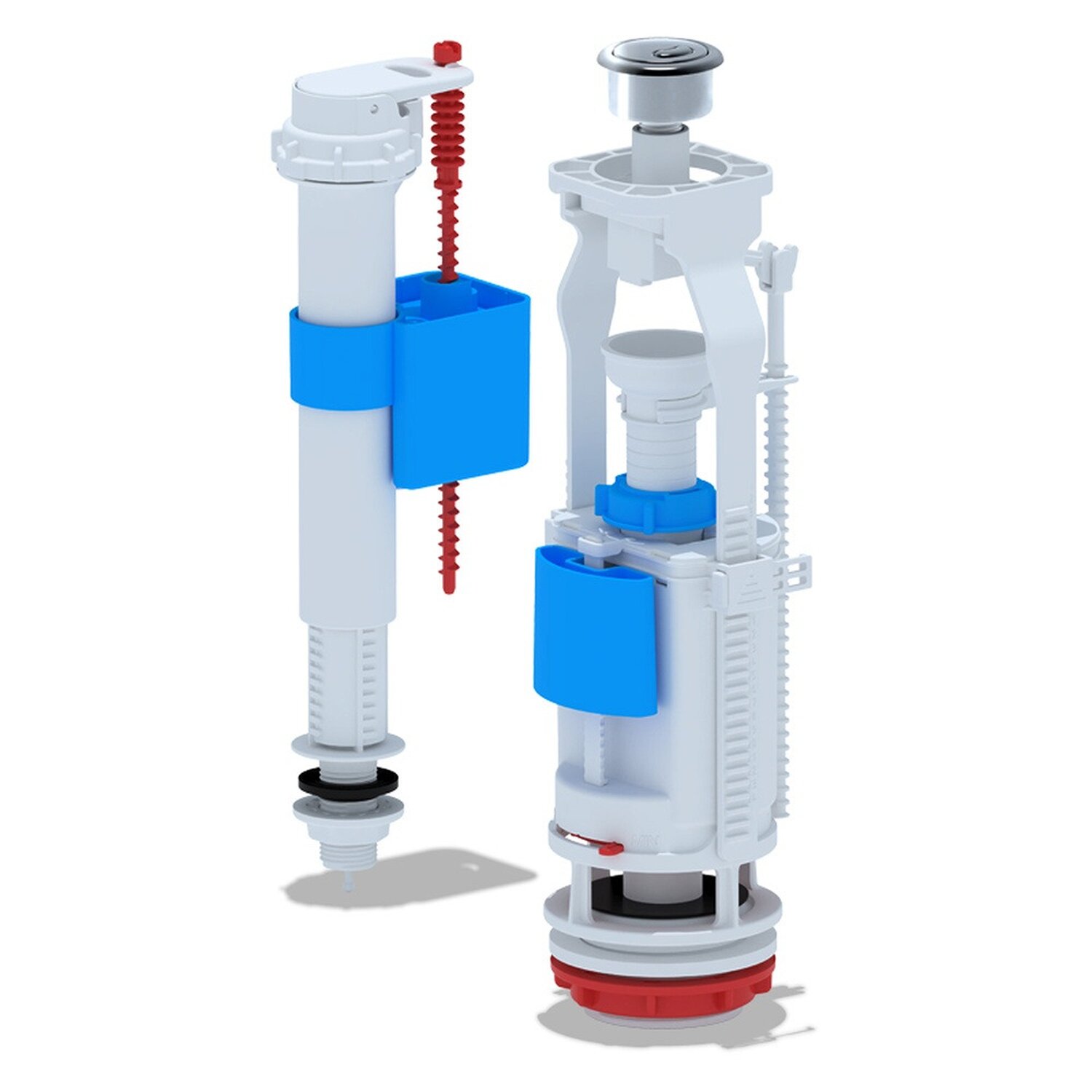

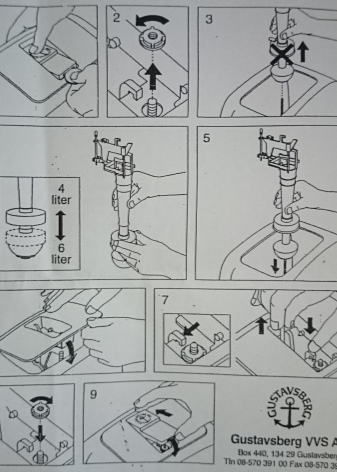

With button

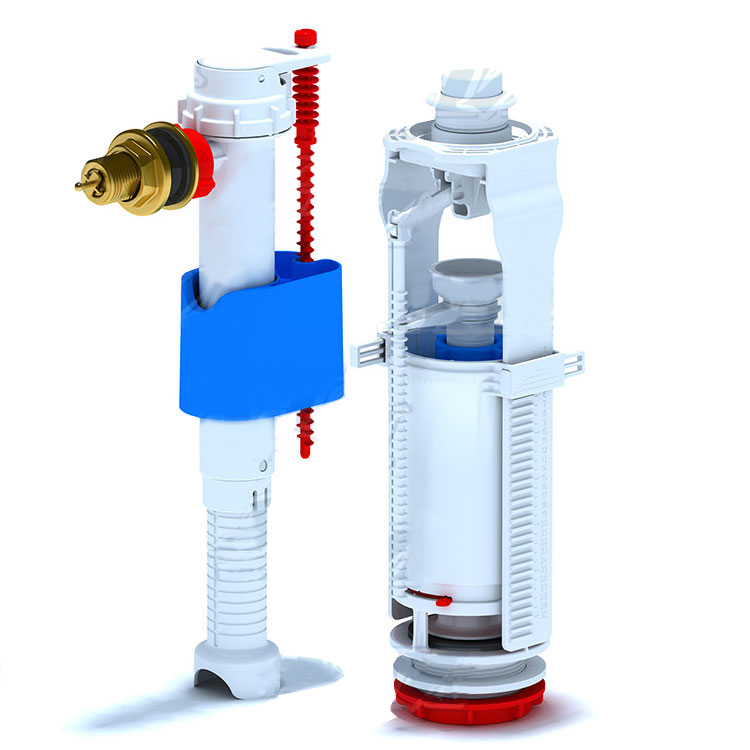

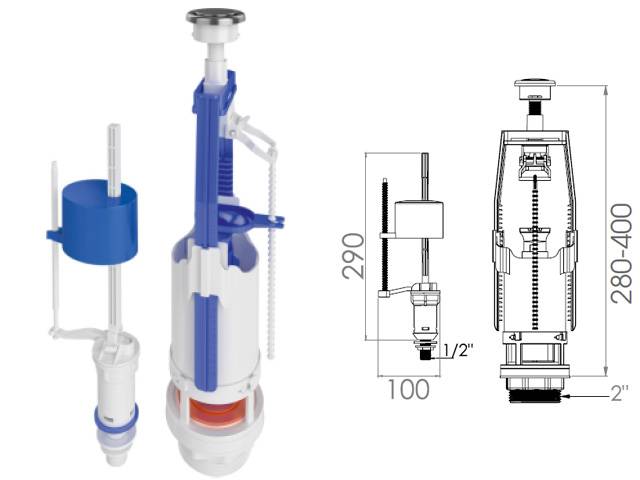

Models of toilet bowls with a button have similar water inlet fittings (there are with a side water supply, there are with a bottom one). Their drain fittings are of a different type.

Tank device with push-button drain

The system shown in the photo is most often found in toilet bowls of domestic production. It is inexpensive and reliable. The device of imported units is different. They basically have a bottom water supply and another drain-overflow device (pictured below).

Imported cistern fittings

There are different types of systems:

- with one button

- water drains as long as the button is pressed;

- draining starts when pressed, stops when pressed again;

- with two buttons that release different amounts of water.

The mechanism of work here is slightly different, although the principle remains the same. In this fitting, when you press the button, a glass rises, blocking the drain. The stand remains stationary. In short, this is the difference. The drain is adjusted using a swivel nut or a special lever.

Fittings for a drain barrel: types, characteristics

Depending on the functions performed, fittings

divided into two types:

- Shut-off. She is responsible for pouring water into the tank and blocking it after

filling. - Drain. With its help, the water is drained and the drain is closed to

tank filling.

Both of these types, despite their interconnectedness, work autonomously, but if one type of fitting fails, the result is the same - water leaks or its uncontrolled outflow.

Features of valves

The set of valves consists of:

- The drain mechanism, which, in turn, consists of a siphon with a lid and a gasket. The last part separates the drain pipe and the storage tank.

- Jet control lever. It is connected to the water pipe through a ball valve.

- A float that coordinates the filling of the tank. It is connected with the drain device by a lever.

Shut-off valves work according to the following scheme:

- water is supplied to the tank;

- the float rises to the set level;

- the lever acts on the shut-off valve and blocks the flow of fluid from the water supply.

When draining, the float takes the lower position, and the lever opens the way for water to enter the tank from the water supply. Based on the method of water input, there are side and bottom valves.

Side fittings for drain barrel

Tanks with side supply are equipped with two

holes, one of which is closed with a plug. In some models of toilet bowls, drains

carried out by means of a side lever, in others - using the upper

buttons.

The work of the side reinforcement is accompanied by quite

a lot of noise, which is eliminated by using an elongated inlet hose.

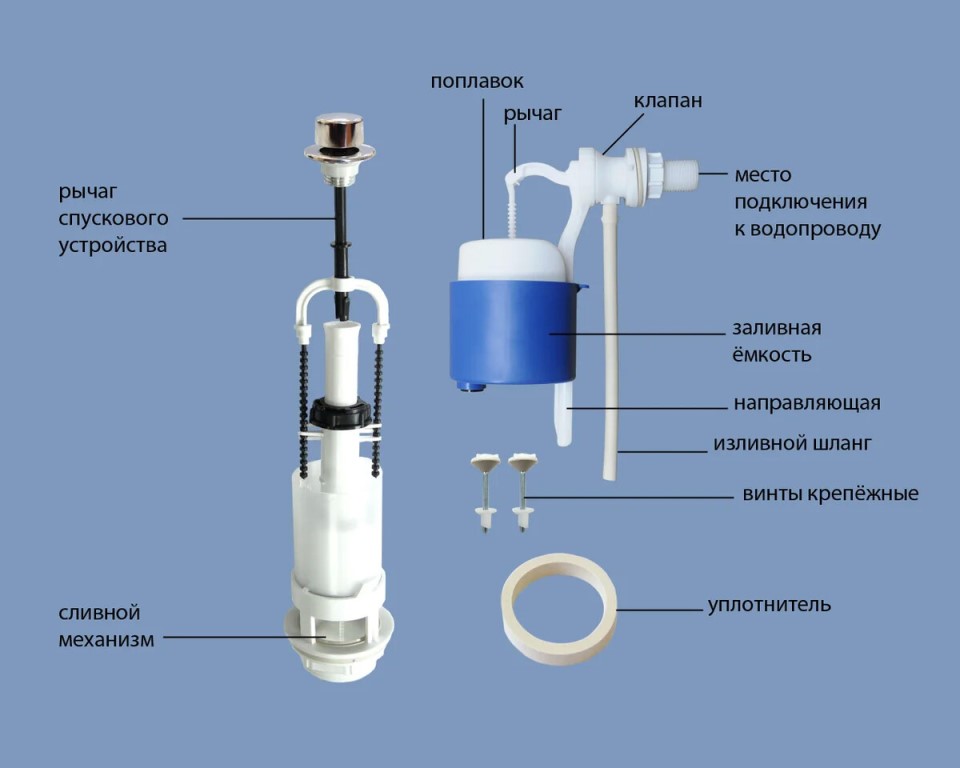

Valve components with lateral connection

Valve components with lateral connection

The drain structure consists of the following elements:

- intake valve;

- trigger device;

- float lever;

- jellied capacity;

- trigger control lever

device.

Filling capacity may be missing. Then the float moves along the guide.

Filling capacity may be missing. Then the float moves along the guide.

The advantage of fittings with side connection is the simplicity of design. It is easy to repair, there is no need to strongly seal the connection point of the inlet hose, its cost is relatively low.

The drain mechanism works as follows:

- When the button is activated, there is a pull. Under its influence, the drain valve opens.

- The entrance to the drain mechanism is blocked and draining is carried out.

- When the lowest water level is reached, the drain is blocked in the tank by closing the outlet mechanism.

- The float hole opens.

- After returning to the place of the vertical valve, the drain passage is blocked.

- The water level drops and the float drops, making way for the cistern to fill.

- When the maximum liquid level is reached and the float rises, the tap is closed, stopping the flow of water.

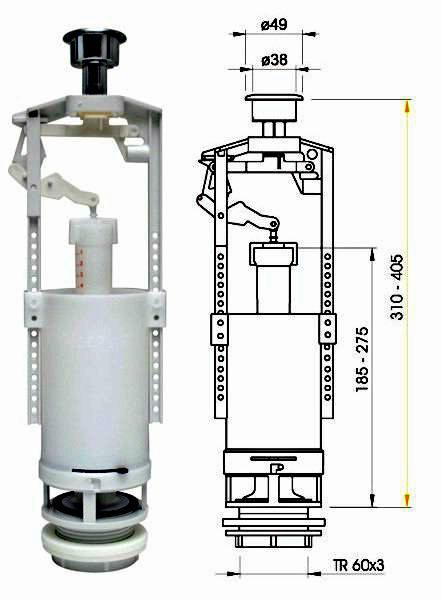

Fittings for a barrel of a toilet bowl from the bottom

eyeliner

The bottom reinforcement includes the following elements:

- Float. Its role is to limit the water level in the tank.

- Guide. A float moves along it.

- Descending device. It includes a glass, into which, when flushing the toilet bowl, a float is lowered and a rod connected at one end with the float, and at the other with an element for constipating the liquid.

- Diaphragm valve.

The advantages of fittings of this type include the absence of noise when filling the tank with water. The design of the lower reinforcement is extremely simple, therefore, it serves for a long time. Structurally, it is designed so that the inlet hose can be hidden.

The bottom fitting works according to the following scheme:

- When water is drained from the tank, the float goes down along the guide.

- The rod communicates the force that causes the valve to close. Water in

storage tank is not supplied.

A distinctive feature of this fitting is the direct dependence of the membrane valve on the quality of the water entering the tank. Ideally, it should be pre-filtered, otherwise clogging of parts is possible. In this case, it is difficult to supply water to the tank.

The aesthetics of the design is a definite plus for fittings for a toilet barrel with a lower connection, but some difficulties are encountered during its repair. They are associated with an inconvenient arrangement of reinforcement.

Locking elements fail due to

violation of the tightness of the float, resulting in its flooding.

The liquid enters the storage tank constantly and through the overflow pipe

runs down the toilet.

Leakage is possible in the connection area due to weak fixation of the nut or due to damage to the rubber gasket.

Differences flush cisterns for toilets

The modern plumbing market offers a range of drain devices of various types and types.Toilet bowls are classified according to many criteria, which are presented below.

Location

fused design with a toilet bowl.

Wall-hung toilets and hidden structures are gaining more and more popularity. In the first case, the tank is suspended at a certain height above the toilet. Such an installation contributes to a strong pressure of water, which means a good drain. The basis of the minus of the suspended structure is the excessive noise created when flushing the toilet. In general, this design is considered very convenient and practical. The appearance of such a system will fit perfectly into the interior of a retro room.

For apartments with European-quality renovation, the installation installation will be an ideal option. The tank is installed in the wall in such a way that it becomes completely invisible in the restroom. To start such a system, just press a special button on the panel.

Trigger type

The most common are flush tanks with a push-button trigger. It has proven to be a reliable and durable system. Push-button descent is located in the center or side of the drain bowl. This design is always used for closed types of cisterns.

Increasingly, they began to produce drain devices equipped with levers or chains. Typically, such a mechanism is placed on the side of the drain system. To drain the water, pull the chain or lever. This is a fairly convenient design for a hanging drain bowl. The trigger mechanism itself, regardless of the installation method, can be either manual, when the user himself sets the volume of flushed water by pressing the button for a certain time, or automatic.

Material

According to the material, drain tanks are divided into: ceramic, cast iron, plastic.

cast iron drain bowls

The most popular and affordable are faience cisterns, which are used for both continuous and hinged structures. Plastic bowls are used for drain systems built into the wall. Such tanks have a non-standard less voluminous shape.

The way the mechanism works

According to this criterion, tanks with mechanical and automatic modes are distinguished. In the first case, just press the start button. For cisterns with a mechanical lever, the principle of operation is that water flows while the user presses the button.

Varieties of the drain valve for the toilet bowl as a mechanism for controlling the overflow of the system

Let's consider in more detail toilet flush valve types mechanismand overflow control system.

The drain valve of the toilet bowl can be represented by a float or membrane locking device. The old tanks were equipped with Croydon valves, which consisted of a body, piston, axle, seat and float arm. Models of the first option may differ in structure and principle of operation. When exposed to the float lever mechanism started to function. The piston under these circumstances moved vertically.

The bulk of modern drain mechanismov are equipped with a piston valve that moves horizontally at the moment the lever is actuated. At the moment of filling the container, the inlet is blocked by a gasket, which is located at the end of the piston. The water supply is regulated by the contact between the piston and the seat.

_

Horizontal - geod. line of equal heights on the map. (GOST 22268-76)

A rubber or silicone membrane, the diaphragm valve is equipped with a non-piston gasket.The plastic piston, when exposed to the lever, begins to displace the membrane, which closes the water supply.

The drain valve can be equipped with a diaphragm or float mechanismohm

The disadvantage of this element is the high sensitivity of the product to contamination and the presence of impurities in the water. A mechanical filter will help prevent problems. The membrane valve will quickly lose its operational properties due to poor quality water in the system.

_

Filter - water intake part of a special design for the passage of water into the filter column of pipes. (SP 11-108-98)

There are floatless options for the drain system. The water supply to them is stopped due to the presence of a special chamber shaped like an inverted glass.

_

Camera - windows. profile cavity formed by its walls. The chambers are arranged sequentially along the width of the profile. The chamber may consist of a number of sub-chambers separated by partitions, usually along its height. (GOST 30673-99)

Toilet flush valve material

Expensive models of toilet drain systems are made of bronze or brass. The design can have both simple and complex designs. Reliability, corrosion resistance, ability to withstand mechanical and chemical loads, these materials are durable. The metal filling is found in expensive collectible models that are produced with a specific stylization.

Most of the drain valves are made of polymers. Easy to install, adjust, repair and allow you to replace each unit separately, in other cases, bronze and brass can be used to create only a fill valve, which makes the shut-off and drain system universal.

Many valve models are made from polymers. The more expensive the fittings, the more reliable and durable the drain system will be. The quality of the plastic and the accuracy of the production affect the cost of the product. However, there are high-quality models that have an affordable price.