- The choice of material for arranging a drain pit in the country

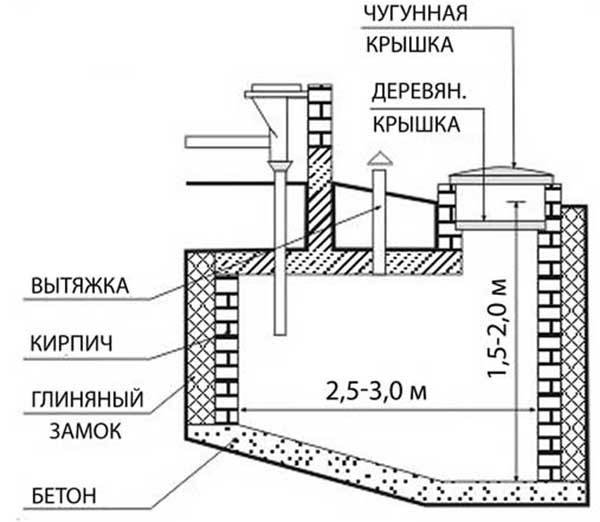

- Brick cesspool

- Stages of construction of local sewerage

- Stage 1

- Stage 2

- Stage 3

- Stage 4

- Stage number 5

- Stage 6

- Stage 7

- Stage 8

- How to make an absorbent cesspool

- Types of cesspools

- Design features

- The main types of drain pits

- Prices for septic tanks

- The principle of operation of the cesspool

The choice of material for arranging a drain pit in the country

Drainage pit

Drainage pit

Drainage pits in the country are equipped with a variety of materials, the most popular are:

- plastic;

- reinforced concrete rings;

- brick.

These materials are used to create a drain structure, and the walls of the pit are either laid out with bricks or made in the form of a container installed in the pit, such as an old case from a washing machine, a barrel with a cut bottom, etc.

It is also used such an option as a drain pit of wheels stacked on top of each other.

Most often a pit for a drain hole is being dug in the form of a cube, but it is much preferable to use a cylindrical pit, which has greater strength than a cube.

This is achieved due to the uniform distribution of loads along the walls of the cylinder, as a result, such a pit turns out to be practically indestructible, unlike a cubic drain pit, the walls of which may not be able to cope with the loads, which will lead to its destruction during operation.

Brick cesspool

long service life,

At the bottom of the pit, you can build a small foundation made of broken bricks or stones. The walls of the pit are laid out in half a brick to save material, it is desirable to leave small gaps between the ends of the bricks for filtering and exiting wastewater into the ground.

After laying several rows of bricks, it is required to carry out drainage bedding, consisting of crushed stone and pebbles between the walls of the pit and the brickwork.

Brick walls are brought to a height below ground level by about 60 cm, at this height a well is made, it is necessary to cover it with a strong cover from any available material (metal sheet, reinforced concrete slab).

In the cover, it is necessary to provide a hole for the hose of the sewage truck; a reliable cover must be made for the hole. On top of the lid, you can pour the earth remaining from earthworks and plant a flower bed on it.

Stages of construction of local sewerage

The finished sealed tank is mounted according to

special technology. A simple drive is equipped quite simply if

preliminary calculations were made without errors.

Reference! Drainage pit with a filter bottom,

intended only for gray drains. Collection of brown waste is carried out in

sealed storage.

The construction of local sewerage is carried out in

next order.

Stage 1

You need to start work on arranging a drain pit with

planning.In this case, the types of effluents are determined, and the

corresponding design. The best option is a single chamber

building with surfaces covered with waterproofing. If the gadfly is carried out

only from the kitchen, shower and bath, then the bottom part is equipped with drainage

(gravel-sand cushion 0.8-1 m thick).

Stage 2

After clearing the pit on the surface of the soil, do

markup according to plan parameters. Digging a pit is carried out with an indent from

0.5 m markings on each side. This is necessary for convenient implementation

waterproofing the outer part of the masonry during its installation. Otherwise

the task will be impossible.

Drainage pit

Drainage pit

Stage 3

Preparation of the base of the pit is carried out by backfilling

gravel-sand cushion (20-25 cm). By making a thorough compaction of the embankment

rammer, proceed to laying the surface with sheets of roofing material. Cloths are laid

overlapping, going to the previous strip by 15 cm. The joints are glued with bituminous

mastic. Waterproofing prevents seepage of cement laitance into the ground.

Arrangement of the bottom of the pit for drains

On a surface covered with waterproofing material,

install a reinforcing cage made of reinforcement 8-10 mm. Options

cells correspond to 100x150 mm. A strap is used to connect the rods.

wire. Experts do not advise welding, strength may decrease

reinforced concrete structure.

Stage 4

To obtain a solid casting of concrete at the bottom of the pit

it is recommended to choose a solution of concrete M-300 and higher. Bottom fill thickness

is about 15 cm. It will take 7-10 days to polymerize concrete. In it

work period is suspended.

Reference! Equipping the base of the drive with reinforcing

interlayer gives high strength to the structure, which experiences strong

full load. The absence of a metal mesh is fraught with

premature loss of camera specifications.

Stage number 5

Laying the vertical surfaces of the drive

made in half a brick. As a binder mixture, ordinary

cement mortar.

Drainage pit walls

Drainage pit walls

Reference! The rows are formed with a brick offset, which

corresponds to the principle of brickwork.

Stage 6

From the outside, the masonry is treated with bituminous

mastic for waterproofing. Do it as the walls rise. After

backfilling of the cavity between the masonry and the slope of the pit is carried out. As

filler used dry sand-cement mixture. It can also

add a little dropout. This solution provides additional security.

storage tank from leaks. Over time, the soil will become saturated with moisture, the mixture will harden,

forming a kind of casing of the sewage bunker.

Stage 7

The inside of the bunker is finished with plaster. AT

cement mortar, you need to add liquid glass. Suitable for potassium and sodium

formulations. They significantly increase the hydrophobicity of the walls, which makes more

long service life of a septic tank.

Finishing the interior walls of the pit

Finishing the interior walls of the pit

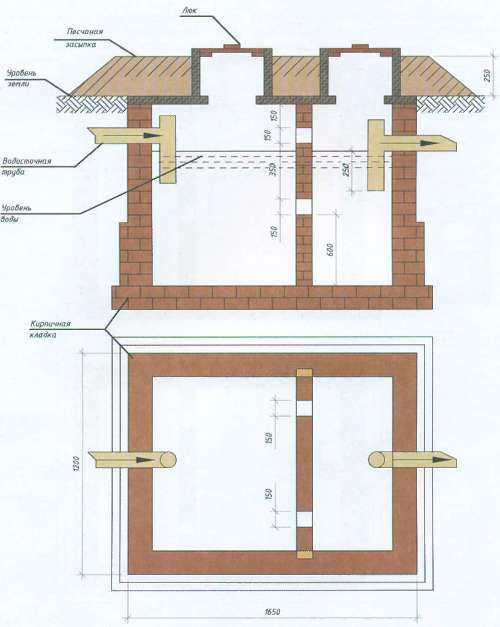

Stage 8

As a cover for an equipped pit, it is recommended

use a prefabricated concrete slab. Into surface cavity

1 or 2 hatches crash. They serve the local system.

sewerage, including waste pumping with sewers.

Drain hole cover

Drain hole cover

If with the purchase of a concrete slab there are

complexity, you can replace it with wooden shields. pre-material

being prepared:

• all sides of the shield are covered with a layer of resin;

• fix roofing material on the surface, which performs

waterproofing function.

So that in winter the contents of the drain pit do not

frozen, the ceiling should be insulated. For these purposes, it is used

polystyrene boards. They sheathe the inside of the ceiling, and

the surface is covered with soil (layer from 15 to 50 cm).

Single chamber hopper suitable according to technical data

household for up to four people. If the family is big

it is recommended to equip the storage tank with ground filtration of wastewater. Such

the design, as a rule, consists of two chambers.

How to make an absorbent cesspool

It is this type of device under consideration that is most often chosen by summer residents and residents of suburban villages - it is easy to do, and there is no need to involve specialists in the work. The stages of arranging a cesspool are very simple:

- The hole itself is being dug. It should be borne in mind that its depth should be at least 2.5 meters, and to get the best effect, it is better to go deep into the ground by at least 3 meters. The width of the private "sewerage" is selected individually.

- The walls of the pit are laid out with brick or cinder block. It is worth listening to the advice of the ancestors - the brick (cinder block) must be laid with some "glades" - earthen spaces should be traced between the rows: these will be the places where the accumulated liquid is absorbed.

- A concrete slab is poured on top, in which a hole is necessarily left for ventilation and pumping out - rarely, but it may be necessary to involve special equipment to get rid of accumulated waste.

If there is free space in a suburban area, then you can make a cesspool with overflow - this will make it much less likely to involve special equipment for pumping out accumulated wastewater. And if the soil on the site is sandy or stone-sandy, then the pumping problem may not arise at all for many years, even with the maximum use of the cesspool.

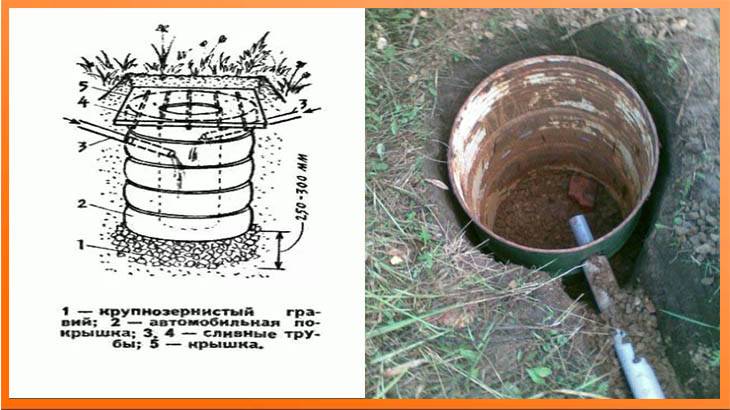

It is easier to make a cesspool from rings (concrete). To do this, follow the following step-by-step process:

- A pit is being dug (according to the principle of a mine) with the expectation that the width is 80 cm larger than the diameter of the concrete rings.

- At the bottom of the shaft well, you need to make a concrete screed - strictly along the perimeter, leaving free space inside the alleged location of the rings.

- The lower ring must be prepared: holes are made around the entire circumference every 10 cm - they will be needed to ensure that fluid flows out when there is a large accumulation of them in the pit.

- At the bottom, in the middle space of the supposed location of the concrete rings, you need to pour a “pillow” - it can be made of crushed stone and sand, broken bricks, and the height of the “pillow” should not exceed 1 meter. Before backfilling, it is necessary to carry out waterproofing - this will prevent penetration into the cesspool from the groundwater rings.

Only after carrying out the above preparatory work can concrete rings be lowered into the shaft well. Space remains around them - it is covered with earth and compacted tightly. According to the rules, it is necessary to lay a concrete slab or a concrete cover on top with the possibility of opening, but in reality everything ends with the imposition of a plastic hatch.

After installing concrete rings, it is necessary to ensure the flow of liquid waste into an equipped cesspool. To do this, they dig a ditch leading from the house to a pit, at least 2 meters deep. A sewer pipe is laid in it - it can be cast iron, but it is better to use modern materials: plastic sewer pipes will last much longer, will not suffer from too low temperatures and will withstand even strong mechanical impact from the outside.

Pay attention to important points:

- There should be three concrete rings in the cesspool.

- Before laying the rings in the prepared pit, you need to wait for the complete drying of the concrete pouring of the bottom - at least 7 days.

- In order for liquid waste to better flow into the finished pit, the sewer pipe must be installed with a slight slope.

- The point of connection of the pipe to the pit should be below the freezing level of the soil.

Types of cesspools

- Cesspool "Without a bottom" is not only one of the simplest in terms of device and operation, but also the most common to use.

The pit has a very simple design and does not require frequent cleaning, and its construction itself will not require high costs or the intervention of highly qualified specialists.

The principle of operation is somewhat reminiscent of a well, due to which a large volume of the liquid component is removed naturally, passing through the layers of soil, which in turn is very harmful to the soil and can poison groundwater.

The walls of the pit, as a rule, are made of brickwork or concrete rings. The remains of solid waste cannot seep into the soil and fill the hole over time, as a result of which it is simply buried and a new one is made.

Over time, all waste will turn into fertilizer.

One of the important points in the construction of such a pit is the correct determination of the type of soil.

Since its high permeability can affect the contamination of the soil or groundwater passing nearby, as a result of which it will be necessary to reduce the surface of the filtering part of the bottom.

If the type of soil does not allow the liquid to be removed in the required volumes, as a rule, several outlets are added or small holes are made in the wall.

Sealed cesspool, the most effective in terms of environmental safety.

The high tightness of the design does not allow bad odors to spread outside or pollute the soil with waste.

The main disadvantage of such pits is the very frequent need for cleaning. For its construction, concrete rings or ready-made plastic cesspool structures are used.

Plastic products are in great demand due to their relatively low cost, light construction, high strength of the materials used and their unpretentiousness to temperature changes.

A "septic tank" cesspool, very similar to a conventional "bottomless" cesspool, but is practically harmless.

The main advantages of such holes are:

- absence of extraneous unpleasant odors;

- cleaning is done as rarely as possible;

- high environmental friendliness.

The scheme of the device is exactly the same as in the pit "without a bottom", the walls are made of concrete or brickwork, a special layer is applied to the bottom.

As a rule, the interlayer consists of a sand mound, a crushed stone cushion and several layers of geotextile materials.

The layer serves as a filter for the initial purification of the liquid before it enters the soil, so the minimum amount of harmful substances penetrates into the soil.

A septic tank can have from one to several chambers, it all depends directly on the incoming volume of wastewater. The use of multiple cameras allows you to increase the degree of cleaning.

As a rule, manual construction of a septic tank is a very laborious undertaking, although relatively cheap.

But, in our time, the use of ready-made "septic tanks" made of plastic has become very popular, which increases the life of your cesspool for many years.

Such septic tanks, as a rule, are plastic containers with one or more chambers.

There are several types of wastewater treatment, these are ground filtration and additional biological treatment.

When using biofiltration technology, the tank is divided into many chambers, each of which undergoes cleaning processes before entering the soil, and each chamber has special compressors and pumps.

Therefore, the use of such a septic tank can be very expensive, due to the cost of the module itself and expensive installation work.

A cesspool "from tires" is the simplest and most economical option for arranging sewage in country or private houses that do not have large volumes of wastewater.

However, such a pit may have a number of disadvantages, such as: an unpleasant odor, a short service life and the lack of tightness of the structure.

However, such a pit may have a number of disadvantages, such as: an unpleasant odor, a short service life and the lack of tightness of the structure.

The arrangement of such a pit is quite simple, the tires are stacked on top of each other, forming a “well”, an embankment of crushed stone or other building material is lined at the bottom, inside it is necessary to have a drainage pipe inserted into the prepared hole in the center of the bottom of the pit.

Design features

A drain pit for a summer shower or bath consists of a drain pipe and a reservoir where water flows. A pipe for draining water must be laid before the arrangement of the foundation. It is a wide branch, for which the diameter and shape are extremely important.

-

The outlet pipe must be without bends and additional tie-ins. Its linearity directly affects the efficiency of the wastewater system. Any turns or jumpers can cause cracks and blockages;

- Its diameter is calculated based on the estimated volume of wastewater. The pipe should only be half filled with liquid, otherwise it will not be effective enough. For the calculation, you can use estimated information about the cost of water (for example, take an average value per person of 0.2 cubic meters), the distance to the drain tank, the slope and the estimated cross section. The calculation also needs to take into account that at maximum fullness between the liquid and the lid there must be a distance of at least 1 meter;

-

The floor in the bath is not insulated, but the pipe stretches in open ground. Therefore, it is necessarily covered with mineral or fiberglass, as well as waterproofing;

- To avoid problems with fluid stagnation on the floor of a summer shower or bath, it is done at a certain angle. The slope is accepted from 3% to 5%;

-

The pipe at the inlet and outlet is protected by a metal mesh filter. This will protect it from contamination by solid residues, foam, etc.

The pipe is discharged into the drain tank. This pit is located at a certain distance from the bath. Unlike a cesspool, this drain is almost always open. This approach is explained by the fact that bath water does not pose an environmental hazard.

- One of the most important factors in equipping a drain pit for a bath is groundwater. If they are located high, then there is no point in arranging the tank. With any change in the level of groundwater, the pit will involuntarily fill. In this case, it is better to simply remove the drain pipe from the bath to the site or beyond;

- The pit can be made of bricks, plastic barrels, foam blocks. In some cases, it is even equipped with wooden boards;

- A sand cushion is laid at the bottom of the tank, construction debris or fragments of bricks are placed on top of it. This is necessary to protect the pit from silting.

The junction of the pipe and the drain tank is additionally sealed and reinforced with a flexible coupling.

Metal drain tank for a bath

Metal drain tank for a bath

The main types of drain pits

The arrangement of any drain pit is a rather laborious process, since the pit will most likely have to be dug manually. At the same time, such a hydraulic structure does not differ in the complexity of the design, so any owner of the site can build and equip it on their own, without even involving assistants, of course, if there is enough strength for earthmoving.

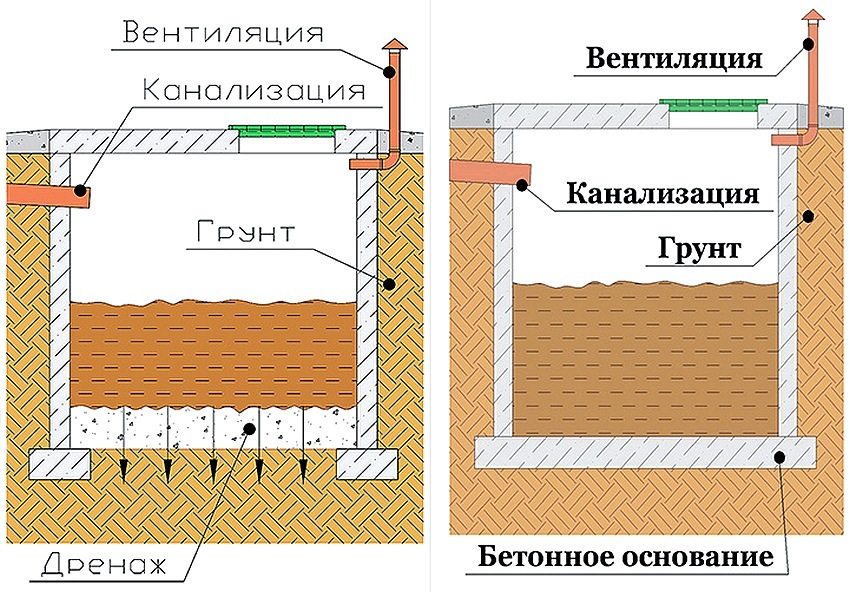

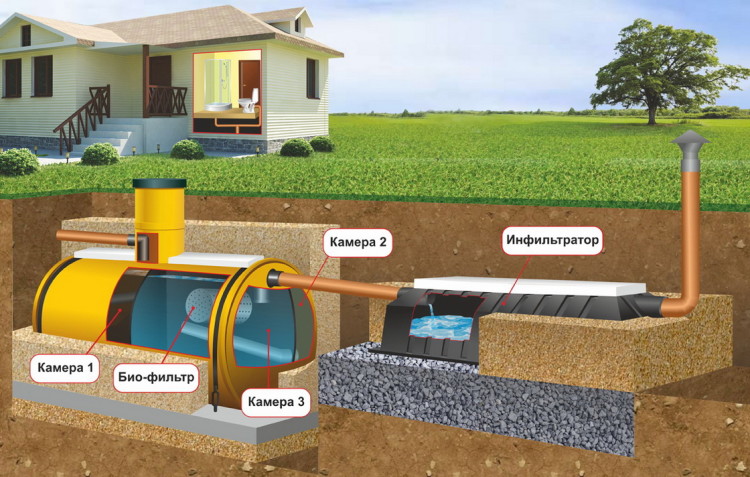

Drainage pits can be divided into three main types - a sealed container, a pit with drainage capacity, and a septic tank consisting of several chambers.

To begin with, let's figure out what each of the varieties is in principle.

A sealed drain pit is most often equipped at construction sites with shallow ground aquifers. It is often called a cesspool, that is, requiring periodic emptying of the collected volumes of dirty water.

For its construction, a pit is dug into which a container with a sufficiently large volume is installed. It will collect sewage. As the tank fills up to a certain critical level, the waste is pumped out by a sewage machine.

In the presence of a cesspool completely isolated from the external environment, it will be necessary to use the services of sewage equipment very often

This option is environmentally friendly, since no contaminants and chemical cleaning solutions enter the soil and groundwater, which can adversely affect the condition of the fertile soil on the site, as well as have a negative impact on high ground aquifers. However, this option is not convenient and cost-effective, since you will have to constantly monitor the filling level of the tank and often call specialized vehicles, and such services are not cheap.

Prices for septic tanks

septic tank

A hermetically closed bottom is not created in the drainage drain pit. As it is used a bulk layer of filter building material - most often crushed stone or gravel is chosen for this purpose.

The bottom of the drainage pit is covered with a layer of filter material - crushed stone or gravel

In addition, holes are often made in the walls of the drainage pit at a certain height through which water will be absorbed into the soil. This option is great for a bath and is perhaps the easiest to build, however, if the characteristics of the soil on the site allow it.

A septic tank is a whole system consisting of two or more chambers with different purposes.

In any of the options, the first chamber most often has a sealed design and serves to collect, primary filter and treat waste - solid components settle to the bottom, and liquid ones are clarified, undergo a biological treatment cycle due to the action of aerobic microorganisms. This container is connected to the second chamber with a special overflow pipe - the clarified liquid waste flows into the next compartment, which is already organized according to the principle of a drainage well. Water passes through the drainage, is cleaned and absorbed into the soil.

Approximate scheme of the device of the simplest septic tank

If a septic tank of three tanks is planned, then the third chamber is made drainage. The second serves for the final settling of suspensions, deeper water purification through the action of anaerobic microorganisms. And from here comes the overflow of the purified liquid into the drainage well.

A septic tank is most often equipped when it is supposed to collect the entire considerable amount of liquid waste from both a residential building and a bathhouse.

The principle of operation of the cesspool

The cesspool works on a very simple accumulative principle: all sewage from the dwelling enters one tank, which goes deep into the ground to prevent freezing and is isolated from the soil surrounding it to prevent environmentally adverse effects.

As soon as the level of sewage in the pit reaches critical values, drains are scooped out of it using sewage trucks or independently.

Also, in the design of the cesspool, it is possible to provide a drainage-filtering pad, which will allow only sufficiently purified liquid part of the waste to pass into the ground. Thus, the terms for filling the cesspool and, accordingly, the terms for its maintenance can be significantly increased.

External view of a brick pit