- The geyser burns, but does not heat the water

- Reasons for the lack of water heating

- Changing the coarse filter

- What to do?

- Repair work

- Rules for dismantling and disassembling the gearbox

- Removing the reducer from the column

- Dismantling the frog of the water heater "Neva 3208"

- The procedure for removing the gearbox "Neva-transit"

- Water Regulator Disassembly

- Frog reassembly

- Testing the repaired node

- How does a geyser work?

- We change the self-cleaning filter with a pressure gauge

- When to Clean Your Gas Boiler

- Why fell?

- Prevention of scale formation in the heat exchanger

- Error codes Neva Lux

- Code E3

- Error E7

- Error E8

The geyser burns, but does not heat the water

One of the most common breakdowns. There are several reasons why the geyser is on fire and cold water is flowing:

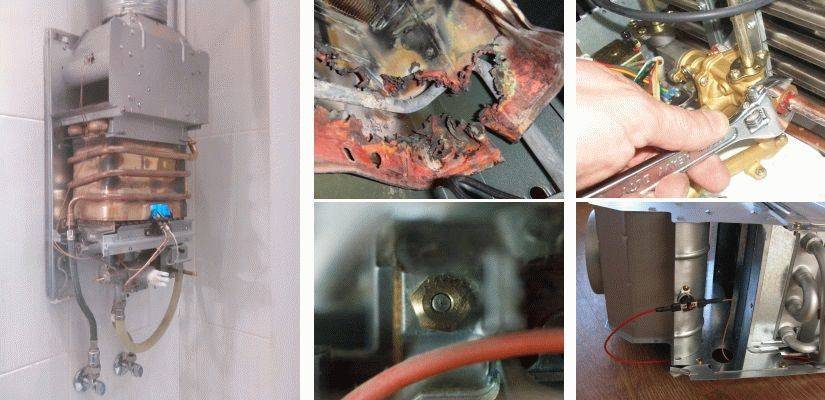

- Soot contamination of the outer part of the heat exchanger - the metal cavity is in contact with combustion products. Over time, a thick layer of soot forms on the walls. The geyser does not heat water for the reason that soot is a good heat insulator that prevents heat transfer.

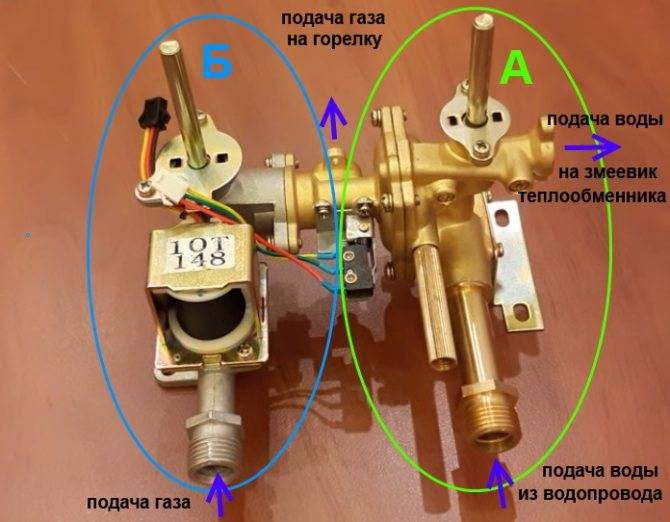

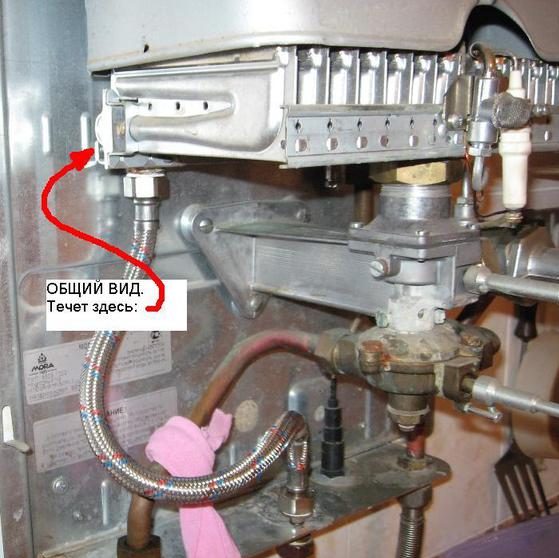

- Problems in the operation of the cold water regulator - the gas pressure is regulated using a membrane and a stem connected to the supply valve. In the "frog" there are two cavities separated by a rubber gasket.When the DHW valve is opened, the membrane bends and presses on the stem that opens the fuel supply to the burner. If the geyser does not heat water well with good water pressure, the reason is in the stem or membrane:

- Rubber Diaphragm - Gasket may break. In this case, the column turns on only with a strong pressure of water, the temperature of which is much lower than that set in the settings. Symptom: leak in the water unit.

Another reason why the water heater does not heat water, but the fire burns is that under the influence of hard water the membrane has become rigid and cannot press enough on the metal rod to completely open the gas supply. - The stem is a rod connected to the valve. When the membrane is exposed, the rod presses on the sensor, opening the supply of blue fuel to the burner. The stronger the mechanical effect on the rod, the greater the pressure of the gas. Over time, rust can form on the metal, making it difficult for the stem to move, resulting in a weak flame on the burner.

- Rubber Diaphragm - Gasket may break. In this case, the column turns on only with a strong pressure of water, the temperature of which is much lower than that set in the settings. Symptom: leak in the water unit.

- Low gas pressure - in this case, the water does not heat up in the geyser, not due to failures and malfunctions in the water heater. You can fix the problem by contacting the local branch of Gorgaz.

The causes of poor water heating by a gas column are eliminated after replacing the membrane or rod, as well as cleaning the heat exchanger. To prevent frequent breakdowns, regular maintenance of the heat generator should be carried out.

Reasons for the lack of water heating

- Dirt deposits on the outside of the heat exchanger. A heat exchanger is a kind of metal tank in which water is heated.Since it is in contact with combustion products, a thick layer of soot can form on its outer walls, which prevents the water from heating to the desired temperature.

- Insufficiently strong flame in the burner. The heating power is sometimes not enough for the water in the heat exchanger to reach the set temperature. If the flame in the burner is constantly weak, this indicates a malfunction of the membrane, which leads to insufficient stem pressure on the gas valve.

- The heat exchanger constantly overheats. This is most likely due to a manufacturing defect. In the absence of temperature control in the heat exchanger, a thick layer of scale settles on its walls, preventing its normal operation.

- Low pressure in gas pipes. This is a problem that has nothing to do with the operation of the water heater, since external factors are to blame here. If you think that the pressure in the gas pipeline is insufficient, contact the gas service.

- Neglect of preventive maintenance and maintenance. In the absence of proper care and timely repair, malfunctions inevitably occur in the operation of gas equipment. If the geyser is in poor technical condition, it will not be able to provide good pressure and the required water temperature.

Changing the coarse filter

Now you can work on filters.

A combination boiler is typically installed in your kitchen at the point where pressurized water enters your property. It controls both your hot and cold water sources as well as your central heating, giving it the name "combination".

The combi boiler system heats cold water directly from the mains when and when it is needed, when the hot tap is turned on. Because the water supply comes from the mains, at mains pressure your water will be at high pressure and will fit most most high pressure faucets if you have a good enough combination boiler. The pressure can vary from boiler to boiler, but a typical pressure expectation from a combi boiler is between 1 and 2 bar.

First, we will see what condition the coarse filter is in:

It is required to unscrew one nut. For this procedure, we need Swedes. Before that, take care of the container where you will need to drain the remaining water from the filter. The container must be taken such that it can be substituted directly under the filter (Ideally, a cropped plastic bottle is suitable, which you will see below).

With an uncontaminated water system, the master cylinder will be filled with cold water directly from the mains. Unlike a traditional gravity system, the unreliable system does not require additional storage tanks and instead offers a much simpler solution.

The water contained in the master cylinder is constantly pressurized by the incoming network water and then indirectly heated by an external source such as a boiler, solar panel, oil or electricity. These types of systems are often found in new builds and will deliver high pressure meaning you can choose any brass you require.

So, we take the Swedes and unscrew the nut:

Unscrew counterclockwise as shown in the picture. Swedes will not have to work for a long time.Next, the nut must be carefully unscrewed by hand, substituting a container to drain the water:

It is very important that you select the correct pressure taps for the water supply system you are using. Installing a faucet that requires high pressure to operate on a low pressure system will result in low flow rates or disappointing functionality

For example, installing a high pressure bath head on a low pressure system would mean it would take ages to fill the tub, and since the water would be constantly cooling, you would have to use more hot water to compensate. Dealing with water pressure reduction can be frustrating for any homeowner. The source of the problem is not always obvious and checks the entire path that water takes when entering the house. You may need the help of a local Toronto plumber to help track down and fix the pressure.

But finally, the water stopped flowing and you can examine the filter from the inside:

We see with you not a very good picture. First of all, it's full of rust inside. Secondly, there is a replaceable mesh in the filter. It needs to be extracted:

What to do next?

In a good way, it is better to replace the mesh (buy a new one). The rust inside the filter must be washed off. If there is a lot of rust, then it is worth replacing the filter itself. You ask how to wash if the water is blocked? That's right, you need to stock up on cold water in advance and dilute it with hot water, which is not turned off for you. In general, do it.

And this is what a brand new mesh for a coarse filter looks like:

install it in the filter and twist it back onto the pipe.

What to do?

| Problem | Solutions |

| Filter clogged | The mesh filter is located "at the entrance" to the heat exchanger. You can remove the blockage by pulling this part out and cleaning it with a stiff brush under running water. If during the cleaning process you notice that the filter is damaged, replace it with a new one. |

| Scale in the heat exchanger | Special tools that are designed to remove and prevent the formation of scale in gas water heaters are not recommended. They have an aggressive chemical composition that destroys metal surfaces. Much more effective and safer are "folk" remedies, for example, simple citric acid dissolved in hot water. |

| Blockage in the tubes | If a blockage has formed in the pipe through which hot water flows, you can try to eliminate it by starting the reverse flow of cold water. To do this, remove the plug, put a container under the column to collect water and open both taps. Then pinch the spout with your finger. There is a chance that cold water, moving in the opposite direction, will push the blockage forward. |

| Faucet failure | If small debris has penetrated further than the pipes of the geyser, it may well get inside the mixer. The most susceptible to clogging are the filter, crane box and thin rubber hose. You can fix the problem if you disassemble the mixer and visually inspect each part for the presence of foreign objects. Accumulations of dirt are usually easily washed out with running water. |

Repair work

What should be done if the taps are leaking or there is simply no water in them? There can be several sources of problems:

- water drips even when the faucet is closed;

- water seeps in a trickle when the valve is completely closed, while over time it only increases;

- when the valve is open, water simply does not flow through the tap;

- moisture seeps through visible damage to the equipment.

After the source of the problem is determined, it is necessary to turn off the water. It is recommended to immediately turn off not only cold, but also hot water, as you will have to remove the mixer. After that, the equipment is carefully disassembled so that repairs can be carried out.

For example, if the water just starts to leak, then the reason is a loose fit of the axle box or the complete wear of the rubber gasket. The gasket is very easy to change, it takes just a couple of minutes, including disassembly and assembly of the crane. In a ceramic faucet, a silicone gland will have to be sealed; for other models, a complete replacement should be carried out.

If the water flows in a trickle, then it also requires the replacement of a crane box, which simply has worn edges. But this problem is often caused by the fact that the mixer is not operated correctly. It is impossible to tighten the valve when closing too tightly, because of this the edges are quickly erased, and repairs are required quite often. If the mixer shows severe damage in the form of cracks, then it just needs to be replaced. Repair in this case will be a simple waste of money and time, water will flow. If only the valve is damaged, then it can still be replaced, but it’s better to buy a new case right away.

If the water from the tap simply does not flow, but at the same time it enters the mixer, then the reason may lie in a broken faucet box or a gasket that is bent and prevents water from entering the spout. This problem is solved depending on the breakdown. If the gasket is bent, then it should simply be removed and replaced with a new one. If the axle box is broken, then it must be carefully dismantled, put in serviceable, check the operation of the crane.

In rare cases, a complete valve replacement is required.This usually happens if it is completely out of order, it can no longer be repaired. Experts advise replacing if the equipment is old, leaks and other problems are often observed. It is necessary to choose taps and mixers that are most suitable for specific conditions. Today, manufacturers offer the widest range, so there should be no problems with the choice.

When water does not flow well from an installed faucet or it simply does not exist, you need to figure out what caused such a malfunction. After that, you can start the appropriate repair, the complexity of which depends on the scale of the breakdown. In rare cases, a complete replacement of the faucet may be required, but usually it does not come to this.

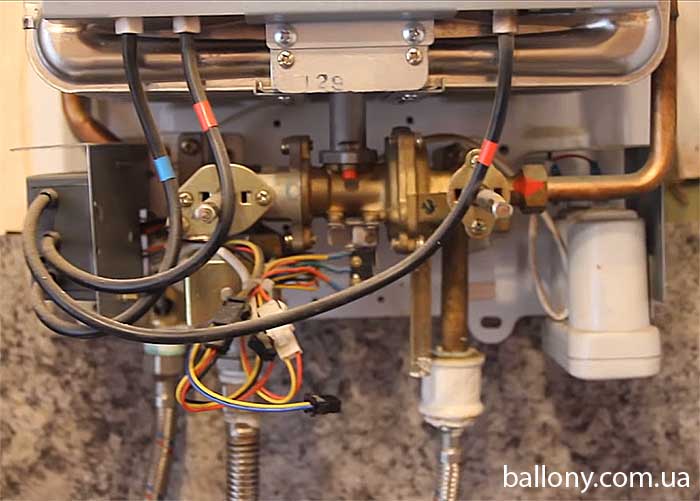

Rules for dismantling and disassembling the gearbox

Regardless of the modification of the geyser, before starting repairs or preventive maintenance, turn off the gas and cold water supply to the unit.

To drain the water from the system, open the hot water tap located below all water-folding devices powered from the column. We place a wide container (basin or bucket) under the dismantled water unit, where the remaining water from the gearbox will drain.

Removing the reducer from the column

Often the frog can be removed separately. But in some columns it is impossible to do this, so you have to dismantle both blocks together. There are models of instantaneous water heaters in which, in order to gain access to the insides of a frog, it is not at all necessary to dismantle it - just remove the cover.

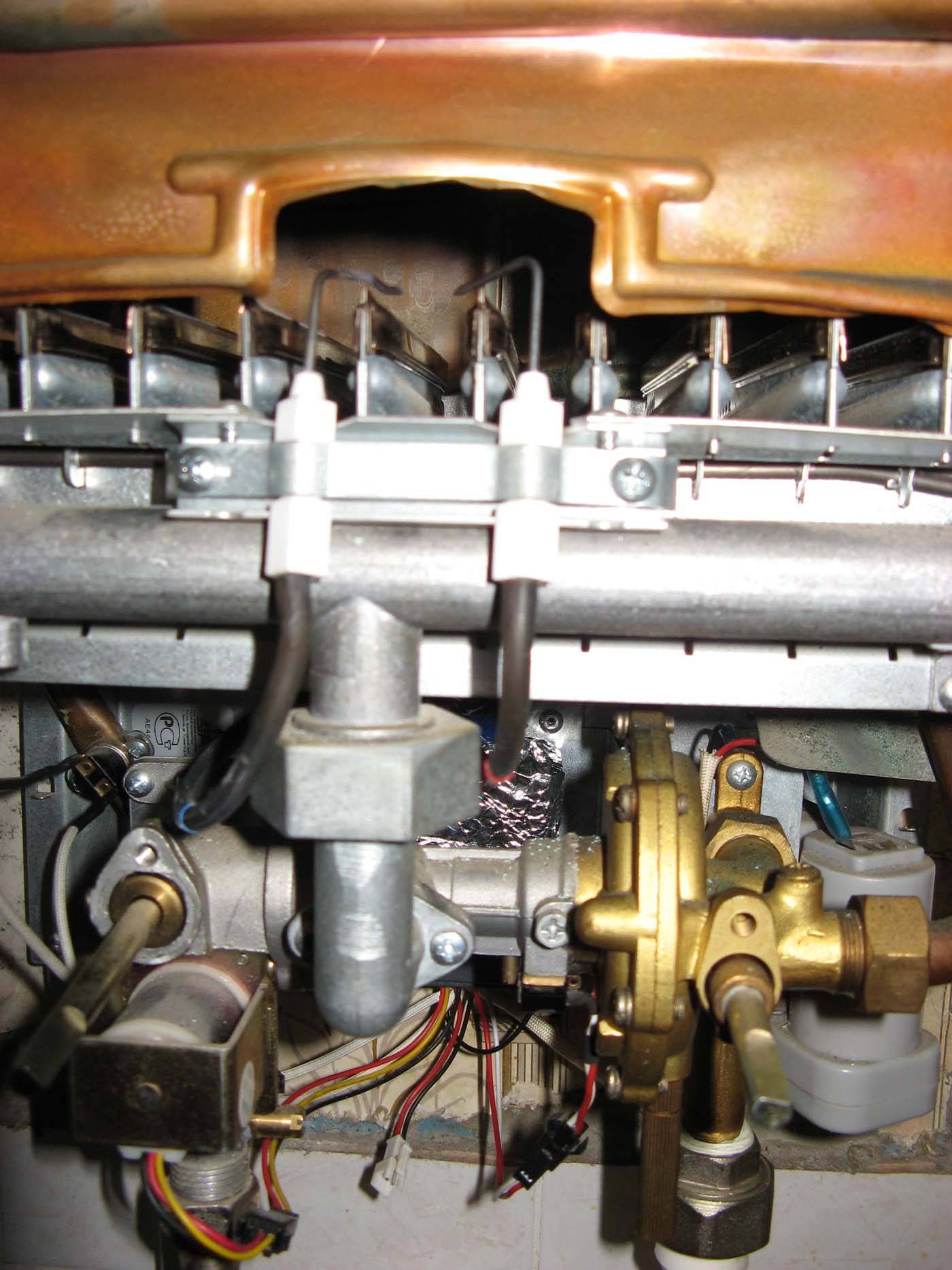

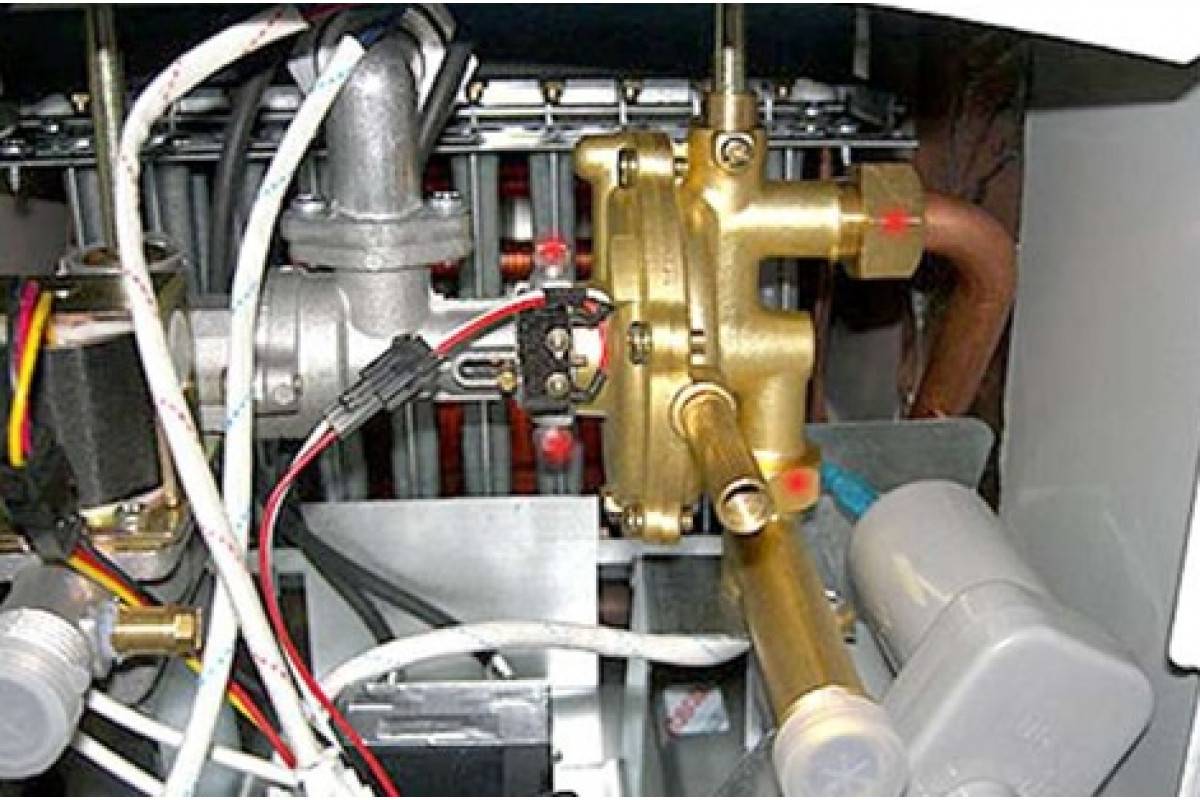

Dismantling the frog of the water heater "Neva 3208"

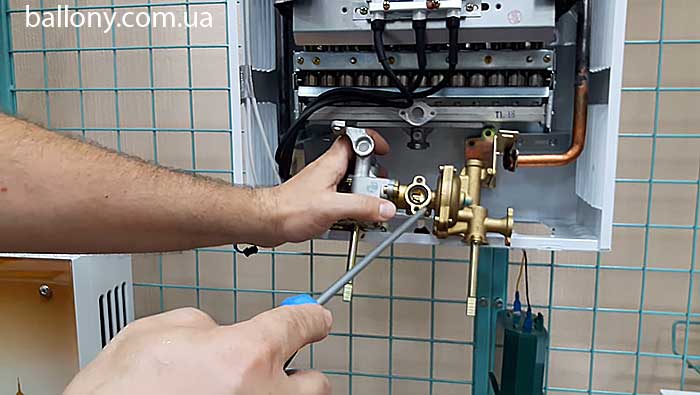

In the column "Neva 3208" it is easy to dismantle the gearbox, as in other similar devices.To do this, unscrew the union nuts on the inlet and outlet pipes of the housing, and also unscrew the three screws that secure the frog to the gas unit. When unscrewing the nuts and screws that fix the water regulator, hold the dismantled block with your hand so as not to accidentally deform the parts of the gas unit.

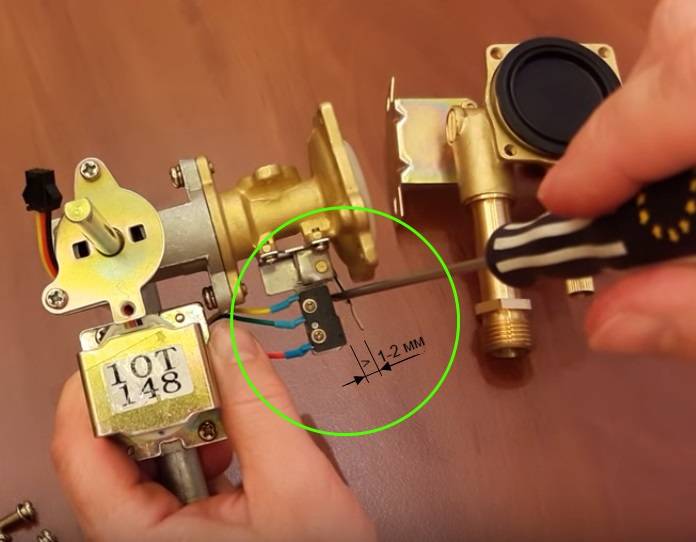

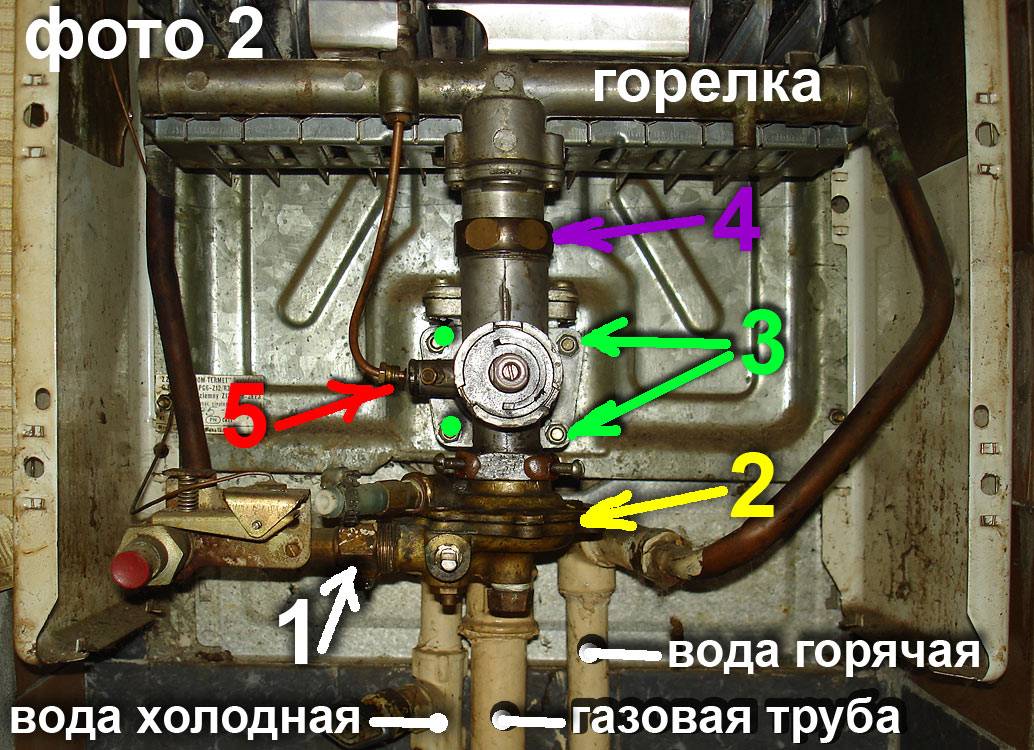

When dismantling the water regulator with a wrench, unscrew 2 union nuts of the pipes in the indicated order, then unscrew 3 screws with a screwdriver

The procedure for removing the gearbox "Neva-transit"

To repair the water reducer, it must be removed from the column housing. We will analyze how to do this using the example of dismantling the Neva-Transit column, since the fastening of gas-water units in many modern models is very similar. First, remove the adjusting knobs on the front panel. They are just dressed in stocks.

After that, unscrewing the screws, remove the front panel

Please note that the digital display on the front panel is connected with detachable terminals to the electronic devices of the speaker. Therefore, by pulling the panel towards ourselves, we disconnect the terminals and only after that we remove the panel completely

Do you have a Neva gas water heater? We recommend that you read more about typical malfunctions and how to fix them.

Water Regulator Disassembly

Having freed the frog and drained the last water from it, unscrew the lid. Often the screws are soured. To facilitate the work and in order not to disrupt the slots, we use the special tool WD-40. After unscrewing the screws, remove the cover, remove the membrane and inspect the condition inside.

We replace the parts that have become unusable, clean and wash the insides (surfaces, channels, if necessary, clean the body from the outside), install the parts in place and assemble the frog in the reverse order.

Frog reassembly

It is especially important to set the aperture correctly. The bypass hole must exactly match the holes of the same name in the cover and base.

If the channel connecting the cavities of the base and the cover is blocked, the column will not work.

After installing the cover on the base, tighten the screws. We install the assembled gearbox in place (also in the reverse order), not forgetting about the sealing gaskets on the pipes and on the connection of the water-gas unit with the platform of the gas burner leg.

Screws should be baited and finally tightened without misalignment. To do this, they are installed and baited in pairs-crosswise and similarly screwed up to the stop.

A gasket is installed in this place (between the burner and the gas unit). Be careful - the safety of the geyser is ensured by the tightness of this unit

Testing the repaired node

After installing the repaired frog, we check the operation of the water part without connecting the gas by opening the hot water tap.

Watching:

- whether drops have appeared on the connections;

- whether the flow rate is the same when hot and cold water are turned on separately;

- whether the burner igniter clicks;

- whether the stem moves normally when opening and closing the valve.

If not everything goes as it should, it is worth double-checking your work. However, sometimes the reason may lie not only in the water node.

Only after the mounted frog has passed the test can gas be supplied to the column. But do not forget about the safety rules when using the column.And if you smell gas, you should immediately shut off its supply, arrange ventilation and call the gas workers.

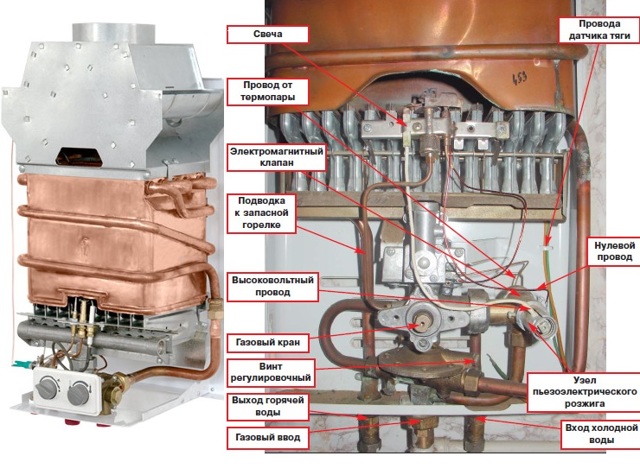

How does a geyser work?

To understand whether there is any threat from extraneous sounds emitted by the speaker, you need to consider all possible causes. If the column is old, then there will likely be more options. In addition, each model of water heating equipment may have its own characteristics. But still, the principle of their work is similar. Therefore, first you need to figure out how the gas column works and whether it is possible to fix the problem yourself.

Any modern water heater consists of a rectangular box and a supply of gas and water to it. Cold water enters the device and passes through the radiator compartment, where it is heated with a special burner.

As soon as you open a hot tap, a valve opens in the device, which is designed to supply gas to the system. It enters the combustion chamber through a special ignition burner and the process of direct heating of the heat exchange element through which the water passes begins.

Carbon monoxide, which is produced after the combustion of natural gas, is discharged to the street through the chimney. Withdrawal is carried out naturally or forcibly (turbocharged speakers).

To determine and eliminate the cause of a malfunction in a geyser, it is necessary to study its structure and the principle of operation of all elements of the device

In cases where there is no chimney, and its construction is not possible, a turbocharged type of water heater is used. The removal of combustion products is carried out using an additional fan installed in the device.All exhaust gases are forcibly removed to the street through a coaxial pipe. The design of this chimney also provides for the intake of fresh air necessary for combustion from the outside. Such water heater models are made with a closed combustion chamber.

In all geysers, emergency shutdown systems are provided. As soon as the system detects some kind of malfunction, the water heater will stop working.

Automatic protection works under the following conditions:

- weak draft in the ventilation passage or chimney;

- weak fire in the burner, which heats the heat exchanger;

- when the water pressure decreases, the system automatically shuts off;

- with excessive heating of the copper heat exchanger.

Let's take a closer look at the causes of malfunctions in the operation of a gas water heater.

We change the self-cleaning filter with a pressure gauge

Now it's time to do a self-cleaning filter with a pressure gauge. In the figure you can see where you need to unscrew the filter. But this cannot be done right away, because a drain hose is attached to the filter from below, and first you need to remove the clamp and release the hose:

For these purposes, we need a screwdriver. So, we unscrew the clamp:

We remove the hose. The water has already been drained, but small residues can still be:

Just as in the case of a coarse filter, for this filter you first unscrew it with a key and then by hand. Prepare a container for draining water. The same plastic bottle will come in handy:

It is desirable to fix the bottle so that the water drains itself, and you do not have to hold the bottle with your hands.

When the water stops flowing, you need to look at the filter itself.

Before us is a depressing picture:

The filter mesh is completely clogged.How to deal with it? I recommend installing a new grid:

The filter itself is also dirty and a good idea to clean the rust. If there is too much of it, then I recommend replacing the filter itself and installing a new mesh there.

Install the filter in place and check the water:

As you can see, everything is in order! Try it, take another look at the cold water gauge. Now he will definitely not show you zero. You breathed a sigh of relief because now the water pressure in your water supply system is back to normal!

Note that for hot water, the actions will be similar.

- In order not to bring the situation when the filters are completely clogged, it is necessary to drain cold and hot water for 3 minutes at least once every 3 weeks. The descent is made by opening the taps located directly under the self-cleaning filters. That is why it is useful to have not just taps, but hoses screwed to them on clamps that go directly into the fan pipe.

- You need to spend a little time to: unscrew your hot and cold water filters, turn off the water temporarily, go to a professional plumbing store, show your filter nets to the seller and buy them home in advance. They are not so cheap, but this must be done, because in a critical situation you will simply replace the nets. Otherwise, you will have to first turn off the water, then disassemble the entire system, and then run around the shops in search of the desired mesh. It is not a fact that you will immediately find them, while the family will be left without water, and the water supply system itself will be in a semi-disassembled state (tested on yourself).

- Never turn on the water without installed nets in the filters, even temporarily for 1 day! This day may turn out to be ill-fated.If dirt flies into the pipe, a little larger than the permissible size, then, for example, it will clog your counters, and then you really will have a lot of fuss.

- Imported mixers also sometimes fail. For example, the insides of the mixer become unusable, which it is better not to disassemble yourself (unless you are a professional in this matter). That is, when the mixer is removed, the water rushes with a powerful stream, and when the mixer is installed in hot water, the pressure is much stronger than in cold water, or vice versa. It also needs to be looked at and analysed. Sometimes a simple replacement of the faucet also brings results.

That's all. Today we learned what to do if the water pressure in your apartment suddenly began to walk.

Situations when the pressure of water coming from a tap in an apartment is weak are widespread, so the question of what to do in such cases is quite relevant. Weak water pressure in the apartment, when water from the tap flows in a thin stream, makes it impossible to use washing machines and dishwashers, and sometimes in such cases it is impossible even to take a shower. In the meantime, you can fix this problem by using one of the following methods.

When to Clean Your Gas Boiler

Information on the frequency of cleaning geysers is rather contradictory. Some sources on the Internet recommend maintenance annually, others - once every 6 months, and so on. The homeowner will correctly navigate by the quality of tap water and some signs indicating that the device is contaminated:

- the heating efficiency and pressure in the DHW line have decreased - the heat exchanger is clogged;

- the igniter burns with a yellow or red flame (should be blue);

- the color of the fire on the main burner has also changed;

- the column does not ignite and turns off on its own at normal network pressure.

The average interval between preventive cleanings of an instantaneous water heater is 1 year. But you should take into account the quality and hardness of local water. If it is saturated with salts, scale will be deposited much sooner. In such cases, it is appropriate to use softener filters, otherwise all water heating equipment will quickly become unusable.

Why fell?

The difference in pressure at the inlet and outlet of the column should be minimal. In this case, situations often arise when water barely flows from the heater. In this case, we can talk about low pressure in the network.

Here are the reasons for the drop in pressure in the column:

- Clogged pipes, filter elements. Particles of iron oxide and lime get on the filters, are deposited on the inner surfaces of the pipes. The water pressure is reduced.

- Scale on the heating radiator. Hard water provokes the formation of plaque on the water heating element. A layer of scale can appear not only on the radiator, but also on the tubes through which water exits the column. In this case, the pressure is significantly reduced.

- Clogged plumbing fixture. Occurs most often with frequent shutdowns of water. When its supply is resumed, a water hammer occurs, which “delivers” the existing contaminants from the column to the mixer.

- Unit power. When choosing a hot water supply device, you should give preference to models with a power of more than 8 kW.

- Pipes with a diameter exceeding 15 mm are installed at the outlet of the column. Or there are flexible hoses that “plant” the pressure.

- Old water pipes clogged with rust and plaque.

If the pressure has dropped to nothing, it is necessary to stop using the device.

There are several reasons that affect its work:

- Clogged water heater. Rust and scale can get into any unit of the unit, which causes a drop in hot water pressure with a stable supply of cold water.

- Scale formation in the system. Internal elements are covered with limescale. The pressure decreases, the amount of gas consumed increases.

Prevention of scale formation in the heat exchanger

The heat exchanger consists of a casing and pipes into which cold water enters and is heated there. In any case, over time, a small layer of scale appears inside. The main reasons for its occurrence are the high hardness of the water and the operation of the water heater at temperatures above 80 degrees.

You can repair the column without removing the heat exchanger. Turn off the gas and close the water valve. It is necessary to remove the casing from the device and drain the water. To do this, unscrew the union nut from the water inlet to the water heater and turn on the faucet that is the lowest in the system, usually the faucet in the bathroom. Geysers Termaxi have a special valve for draining water from the system. In this case, it is easier to drain the water into a substituted container.

After that, the nuts at the inlet and outlet of the heat exchanger are unscrewed and a special antiscale liquid is poured into it through a hose, which can be bought at hardware stores. You can also use a solution with vinegar or citric acid.

In this form, the column is left for several hours. Then everything is connected back and the water valve is turned on. Turn on the hot water faucet slowly. Dirty liquid should pour out. If after that the pressure has increased, then the heat exchanger pipes are cleaned.If necessary, you can repeat the entire cleaning procedure several times.

You can find out the whole truth about the conspiracy related to the selection, operation and maintenance of gas water heaters (instantaneous water heaters) of all manufacturers and models.

If water began to drip from the column, the reason may be that fistulas have formed on the copper pipes. In order to find a leak, you need to carefully inspect the heat exchanger with the water turned off. Some fistulas are easy to find, you will see how water comes out of these places. Small holes can be seen from the green spots and rust around.

Having previously cleaned and degreased, the place of leakage is covered with flux. After that, using a powerful soldering iron or a burner with a gas cylinder, the fistula is soldered. In this case, it is necessary to ensure that the solder covers the desired section of the pipe with a layer of 1-2 mm. If several holes are nearby, it will be effective to solder a piece of copper plate.

Use cold welding

It is important to carefully look at the instructions and make sure that it can withstand high temperatures. A piece of cold welding is pulled out of the package and kneaded with gloved hands until solidification begins.

Also, a leak can form due to the fact that the gaskets are worn out.

If water leaks from pipe connections, simply replace the gaskets there with new ones.

Also, a leak can form due to the fact that the gaskets are worn out. If water leaks from the pipe connections, simply replace the gaskets there with new ones.

In order not to suffer with the dismantling of the heat exchanger and its descaling, the geyser should be properly operated.

Any tankless water heater requires proper maintenance.Information on servicing a specific model can be found in the instructions that come with the geyser.

Preventive measures:

- Bathing should be in water with a temperature of up to 40 ° C. Such a temperature regime is good for health and does not harm the column.

- For washing dishes, a temperature of 45-50 ° C will be enough. The water will be comfortable for the hands and the fat will dissolve well.

- Washing can also take place at a temperature of 45-50 °C. For heavy soiling, an additional 5 °C can be added.

Error codes Neva Lux

The display allows the user to see the fault code. Self-diagnosis of the column gives a digital value when a malfunction occurs.

Fuel is not entering the system. Check the gas valve, the supply may have been cut off for a short time.

The control board does not receive a signal from the flame sensor. More than a minute has passed.

What could have happened:

- Air in the gas pipeline. This happens when you first turn on or when the device is turned off for a long time. Open and close the hot water several times until the burner lights up.

- The fuel supply valve is not fully open. Open the faucet.

- Insufficient pressure in the gas line.

- The tank ran out of fuel. The bottle needs to be replaced.

- Violation of the wiring between the water unit and the flame sensor, solenoid valve. Inspect the cable for insulation damage.

- The electrode has moved out of place, does not reach the burner. Return the item to its original location.

- The electrode and flame sensor are covered with soot. You can clean the parts with a brush.

- The contacts between the spark plug and the high voltage wire have come loose.

- Nozzles clogged with soot.

The burner must be removed for cleaning. Disconnect the wiring and unscrew the pipe nut.

Unscrew the two manifold bolts, then do the same with the burner mounts. After dismantling, the holes are washed with a brush and soapy water.

After rinsing and drying, reassembly is carried out.

Code E3

The solenoid valve worked before the signal from the flow sensor was received. The valve is defective.

A new element is being installed. The electronic unit is broken. Diagnosis is carried out by a specialist.

Error E7

After 7 ignition attempts, the equipment still does not light up or goes out. Open the fuel valve all the way. The ionization sensor has shifted or soot has accumulated on its electrode.

It should be in the flame zone, near the burner. Cleaning is done with a brush. The electric valves are out of order. The water or gas block has boiled. Replacing elements.

Error E8

The traction sensor has tripped. Reasons: The sensor is broken. See if the contacts are tight, change the part.

The chimney is clogged with debris or soot. If you cannot clear the passage yourself, contact the utilities.

Not enough fuel is being supplied for normal operation. What happened: Weak water pressure.

Line pressure acts on the diaphragm, which opens the valve. Wait until the supply is restored, adjust the toggle switch or descale the radiator.

Source