- The most common causes of breakdowns

- Starting the appliance and adjusting the temperature

- How to set the water temperature

- pressure problems

- Weak or no water pressure

- Weak water pressure when leaving the geyser: causes and solutions

- What to do?

- How to fix the situation?

- How to make a gas column water regulator for low water pressure?

- We service the igniter and the water intake unit

- From what the heat exchanger is clogged with scale.

- When it is necessary to flush the coil (heat exchanger) of the gas column.

- How to disassemble the column heat exchanger. Tools for work.

- Consideration by models

- What to do with poor water pressure in the water supply system of a private house

- How do you know when it's time to clean the gas column?

- Cleaning the water intake

- Cleaning the heat exchanger

- Soot and soot removal

- Causes of low water pressure

- How to increase the water pressure for a gas column?

- Installing a gas water heater in an apartment

- Turbocharged geysers

- If the gas column does not ignite

- No ignition

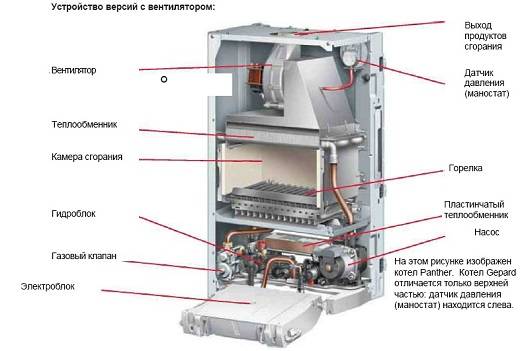

The most common causes of breakdowns

Let's start the review of breakdowns using the example of such simple gas water heaters as Oasis or Neva.These are fairly simple devices, so almost any man who knows how to work with tools and has relatively straight hands can handle their repair. Here is a short list of possible faults and causes:

- Lack of traction;

- Insufficient water pressure;

- Insufficient gas pressure;

- Inoperative ignition system;

- Clogged pipes and water supply filter;

- Burner blockage;

- Membrane or gas block malfunction;

- Inaccurate mixing of cold water in the mixer;

- Malfunction of electronics or sensors.

Now we will see how to eliminate breakdowns and the reasons for the lack of ignition.

Starting the appliance and adjusting the temperature

To properly set up hot water in the device, you must:

- Fully open the mixer for hot water supply;

- Using the water switch, select the required temperature value;

- Shut off valve.

According to the advice of professionals:

- Wait for the moment when the pressure drops in the line, but the column will still work;

- Turn the handle of the water tumbler to the maximum;

- Turn the gas regulator to the minimum value until the temperature is as you need.

For the final preparation, it is worth adjusting the gas supply. To do this, you need to look at the technical data sheet and find out the minimum value for this brand.

The toggle switch is turned to the minimum value.

Turn on the gas supply valve. U" and "Ariston" do this after joining the network. The gas water heater "Oasis", "Junkers" and "Bosch" is connected when batteries are installed.

Turn on the hot valve and the device starts to work.

How to set the water temperature

Turn on the mixer and check the temperature of the water heating.It must be twenty-five degrees larger than the original. It should be noted that the water in the gas boiler heats up gradually. The gas column is adjusted using the gas lever.

Professionals do not advise heating water over fifty-five degrees. This has a bad effect on the device, as scale is formed.

pressure problems

Setting up a geyser takes some time. Accordingly, the result will be visible later. After each stage, it is worth pouring out the water and letting it heat up again in order for the values to be correct. Reduced pressure in the device can interfere with normal operation.

If there are problems with pressure, it is worth performing the following manipulations:

- Remove the casing from the device;

- Loosen the locking bolt, use a pressure gauge to check;

- Remove the seal from the adjusting screw;

- Turn on the boiler;

- Set the values \u200b\u200bto the maximum, unscrew the hot water taps;

- Set the required pressure.

The Bosch geyser, namely its pressure in the nozzles, is regulated in the following way:

- Remove the casing;

- Attach a manometer;

- Loosen the locking screw;

- Attach a manometer to check the pressure in the nozzles to the nozzle.

Further, the Bosch geyser with maximum heat output is regulated by:

- Remove the seal from the screw;

- Turn on the device;

- Turn on hot water taps;

- Adjusting screw adjust the pressure in the nozzles;

- Put the seal in place.

There are brands where there is a special "Winter-summer" mode with temperature adjustment. On this handle made below. Adjustment geyser Oasis located on the front panel. The peculiarity of the regime is that in winter the power is higher than in summer.The force of heating the liquid in the column is directly related to the temperature of the inlet stream. In winter, the regulator is set to "maximum", the heating will be the highest. In summer, the inlet flow temperature is higher and set to the minimum position. This saves resources.

It is easy to remove bad pressure when checking.

To do this, perform the following manipulations if the device has already been in use:

Pay attention to the rubber membrane. The performance of this part is directly related to the pressure in the line

At the moment of violation of the integrity of the membrane, namely when it is produced, the gas does not flow and burner does not turn on. The problem is solved by replacing the part.

Pay attention to the mesh filter. It is located at the entrance to the water block. The water pressure becomes lower due to clogging of the part with debris. The problem is solved by cleaning.

Weak or no water pressure

Automation in all columns powered by gas is configured to turn on only if there is a certain pressure of water in the water supply. If there is no water at all, or the pressure is too weak, this will be the reason why the column does not turn on. First of all, you need to check the presence of water - for this you just need to open the valve with cold water.

The next steps will depend on the situation:

- If the water does not flow or its flow is very weak, then the problem is in the water supply. In this case, you just need to wait until they give water with normal pressure.

- If cold water flows normally, then the problem is the clogging of the column itself (read: “Why do you need to clean the gas column and how to clean it correctly“).

To clean the column, you can perform the following actions:

- Close the supply valve on the gas pipeline.

- Unscrew the pipes.

- Remove water heater.

- Turn the column upside down and place it on a flat surface.

- Using a syringe, inject the cleaning fluid into the heater. Such a special composition can be bought at specialized points of sale.

- Wait a few hours for the liquid to work. The time is indicated in the instructions.

If you do not want to do the dirty work yourself, you can invite a specialist.

Weak water pressure when leaving the geyser: causes and solutions

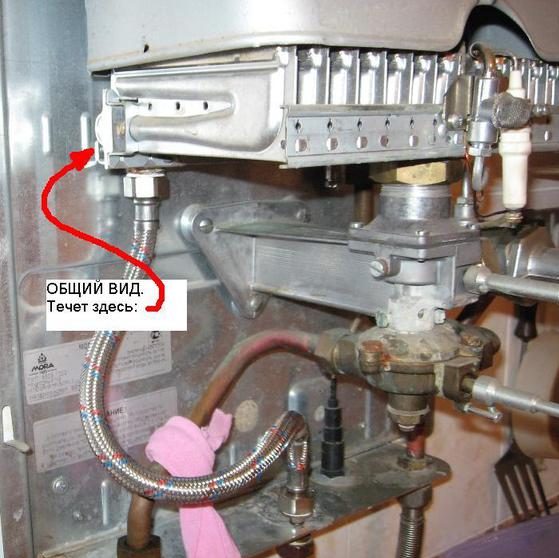

Weak water pressure when leaving the column occurs for the following reasons:

➤ the filters at the water block inlet are clogged

The problem may be caused by a clogged strainer, which is located on the inlet to the water unit. Due to the fact that it is clogged with dirt, water does not flow well from the gas column. You can check this by disconnecting the hose or pipe (when the water and gas supply is shut off) from the gas water column. ).

➤ scale in the heat exchanger and pipes leaving it

In this case, the heat exchanger must be removed and flushed from the inside with a special liquid.

But, as studies by manufacturers of gas water heaters and boilers have shown, all flushing fluids are an aggressive environment that not only gets rid of scale, but also contributes to the destruction of the walls inside copper pipes. When flushing in this way, microscopic “notches” appear on the inner walls of the tubes, in which scale will form even more, since it has where to linger.Therefore, flushing the heat exchanger is a temporary solution to the problem.

➤ blockage in faucets (faucets)

Water pipes have deposits on their walls. During the repair work, the water is turned off. At the end of the work, when the tap is opened, a water hammer occurs, which carries dirt from the pipes to the mixer. As a result of a long time of such processes, the mixer (faucet box and (or) the hose leading to the mixer) becomes clogged, which prevents the free flow of water.

➤ lack of regular maintenance of the geyser

It is necessary to regularly (at least once a year) carry out maintenance of the geyser, and it must be carried out by a qualified specialist, since your safety depends on it.

We carry out repair of geysers and, if necessary, we will be happy to help you.

Call the masterCostContactsSoldering the heat exchanger of the geyser at home

What to do?

| Problem | Solutions |

| Filter clogged | The mesh filter is located "at the entrance" to the heat exchanger. You can remove the blockage by pulling this part out and cleaning it with a stiff brush under running water. If during the cleaning process you notice that the filter is damaged, replace it with a new one. |

| Scale in the heat exchanger | Special tools that are designed to remove and prevent the formation of scale in gas water heaters are not recommended. They have an aggressive chemical composition that destroys metal surfaces. Much more effective and safer are "folk" remedies, for example, simple citric acid dissolved in hot water. |

| Blockage in the tubes | If a blockage has formed in the pipe through which hot water flows, you can try to eliminate it by starting the reverse flow of cold water. To do this, remove the plug, put a container under the column to collect water and open both taps. Then pinch the spout with your finger. There is a chance that cold water, moving in the opposite direction, will push the blockage forward. |

| Faucet failure | If small debris has penetrated further than the pipes of the geyser, it may well get inside the mixer. The most susceptible to clogging are the filter, crane box and thin rubber hose. You can fix the problem if you disassemble the mixer and visually inspect each part for the presence of foreign objects. Accumulations of dirt are usually easily washed out with running water. |

How to fix the situation?

With a decrease in the pressure of hot water in the column, you need to identify the cause and correct it.

Each problem has its own solution:

| Problem | Solution |

| Blockage in the filter | The mesh filter is installed in the heat exchanger, immediately at the “inlet”. This part can be dismantled, cleaned with an old toothbrush, rinsed under the pressure of clean water. When cleaning, you may notice damage to the filter. In this case, it is better to replace the grid with a new one. Otherwise, it will let dirt particles into the column, which will lead to its breakage. |

| Scale formation in the heat exchanger | To remove limescale, you can use aggressive industrial products. They are designed for flushing column radiators. Since such compounds are made of acid, self-cleaning is fraught with failure of the heat exchanger. Therefore, it is better to use folk remedies. For example, a solution of citric acid. |

| Clogged tubes | The difficulty of cleaning is to start the reverse flow of cold water. It is necessary to remove the plug, install a basin under the column (where the water will drain), open both taps. The spout must be clamped with a finger. With good pressure, water moving in the opposite direction will knock out the blockage. It will pour out along with water into a substituted container. |

| Failure of the mixer | Small debris that forms in the gas column can reach the mixer. In this case, the contamination enters the faucet box and the faucet filter. To fix the problem, you need to disassemble the mixer. After dismantling, you need to consider every detail. Clean or replace if necessary. In some cases, a new faucet needs to be installed. |

If the column has warranty service, it is better to entrust the cleaning work to the service master. Otherwise, the owner will lose the warranty.

If problems have arisen with a water heating boiler, then it is necessary to identify and eliminate the cause:

- blockages - clean the filters installed at the inlet to the boiler;

- scale on the heating element - clean with a solution of citric acid, or with industrial means;

- the appearance of cracks on the tank - replacement of equipment;

- malfunction of the pressure regulator and thermostat - replacement;

- clogging of the tap or its parts - cleaning of the tap box, filter.

With a significant decrease in water pressure from the boiler, it is worth stopping using it until the problems are fixed.

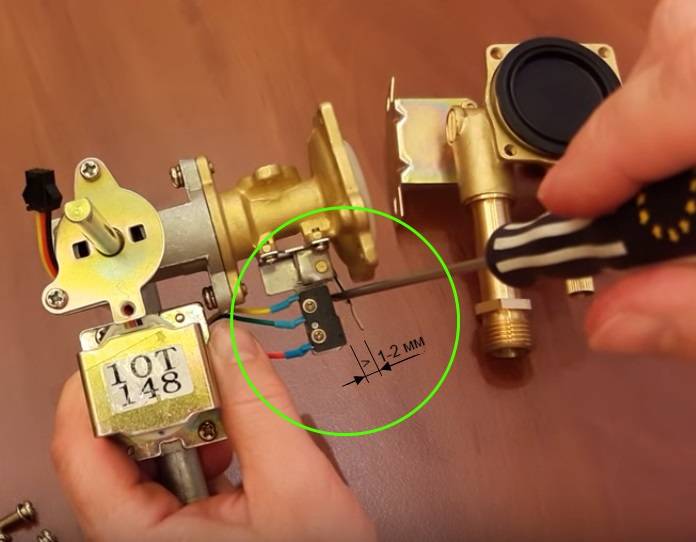

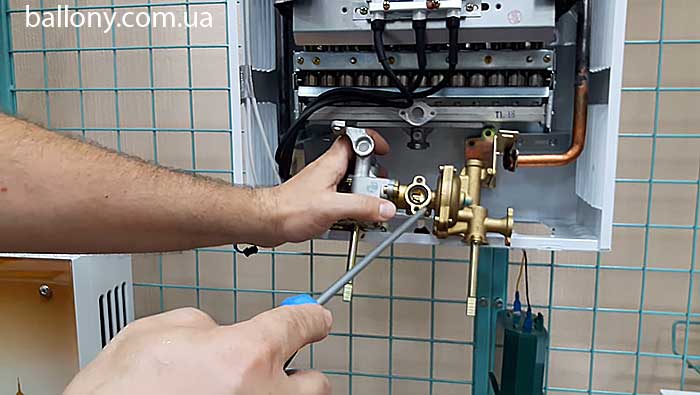

How to make a gas column water regulator for low water pressure?

At the beginning, turn the right knob on the front panel of the column to the left until it stops, this is the adjustment of the water supply.

Left vice versa to the minimum level (this is the gas supply).

Of course, you can try to “manipulate” the water regulator of the gas water heater, but all these tips can lead to a breakdown of the water heater, this is at best.

On modern columns, a low water pressure sensor is installed, I advise you not to “test his patience”, if the pressure is weak, the sensor works, then so be it, safety is paramount.

If you still insist, then there are options (I emphasize that the options are not useful for the column).

AT clean up first mesh filter, it prevents the free flow of water.

Further, on the right side of the water regulator, there is a plug, unscrew the plug, there will be a screw inside, tightening the screw, you can turn on the column even at low pressure, but pops and other unpleasantness are possible.

If you want to remove the retarder ball altogether, for this you need to remove the water assembly, unscrew 8 bolts, disconnect the assembly, remove the membrane, in the area of \u200b\u200bthe adjusting screw, you will see this very ball.

The ball partially blocks the channel, by the way, the channel can also be “treated” with a round needle file, increasing its diameter, increasing the flow of water.

But I repeat, all these tips are from the "harmful" series. And it’s not clear what you will do when the pressure in the system returns to normal, disassemble the water unit every time? Remove and replace the retarder ball?

The right options are either to buy a boiler, or a column that is designed for low water pressure, or install a pump that increases the water pressure in the system,

By the way, the pump is not a bad option, it works in auto mode, the installation is not complicated, it is not expensive.

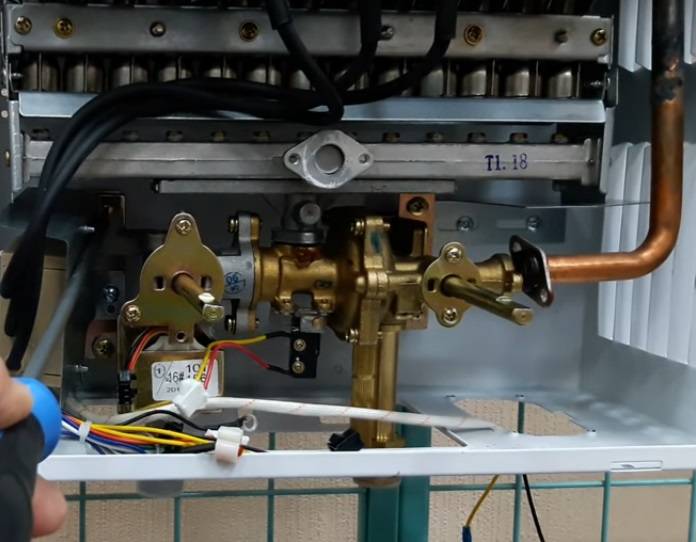

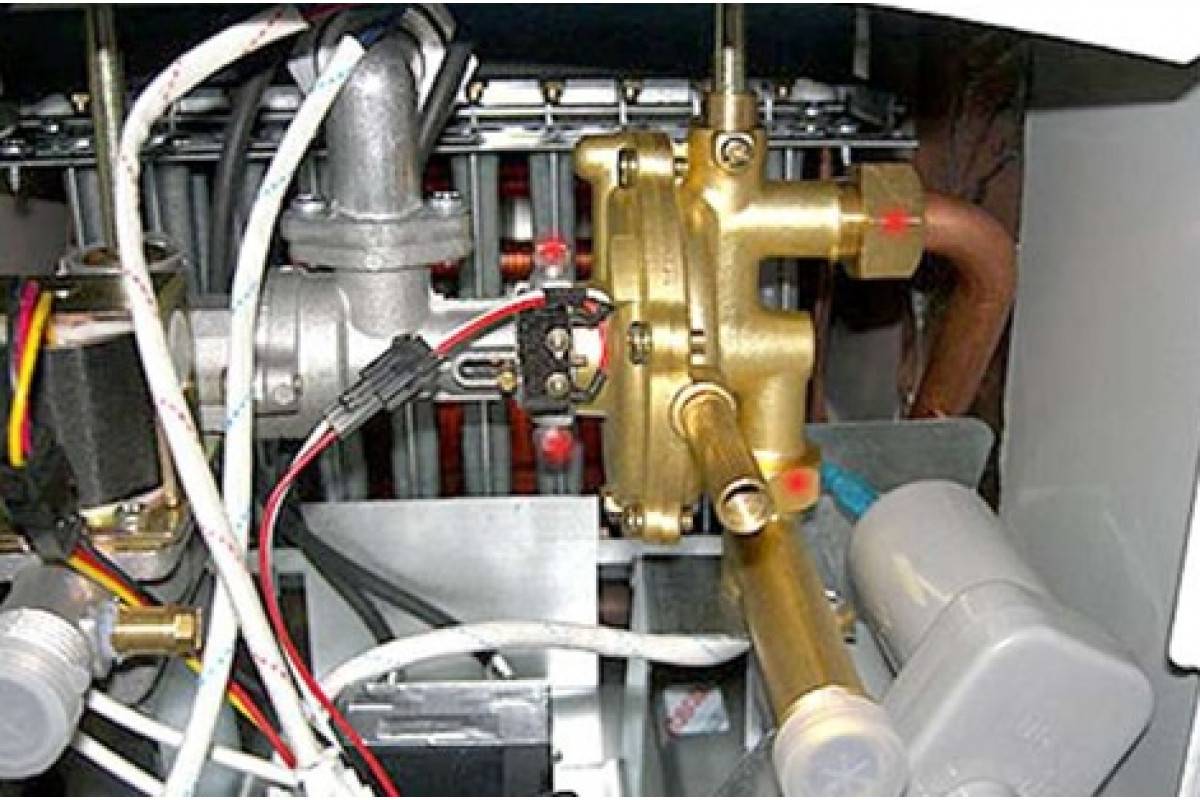

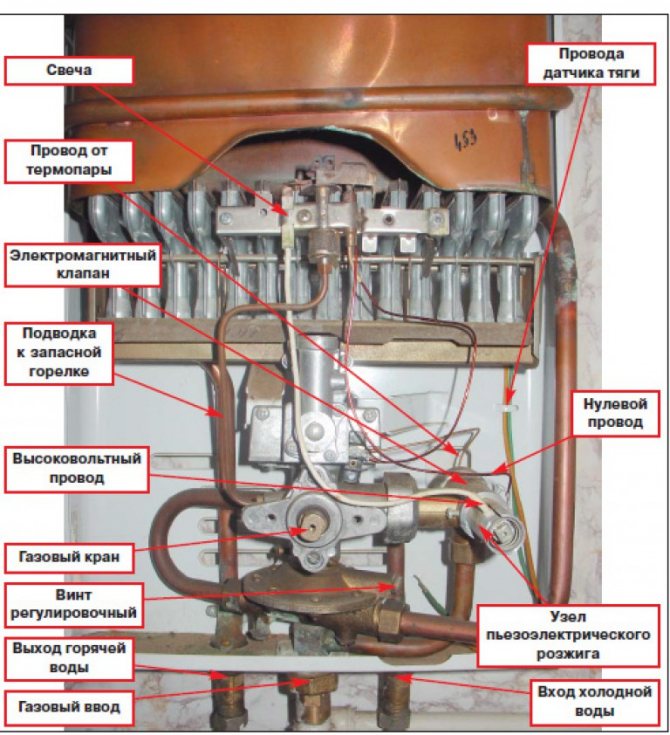

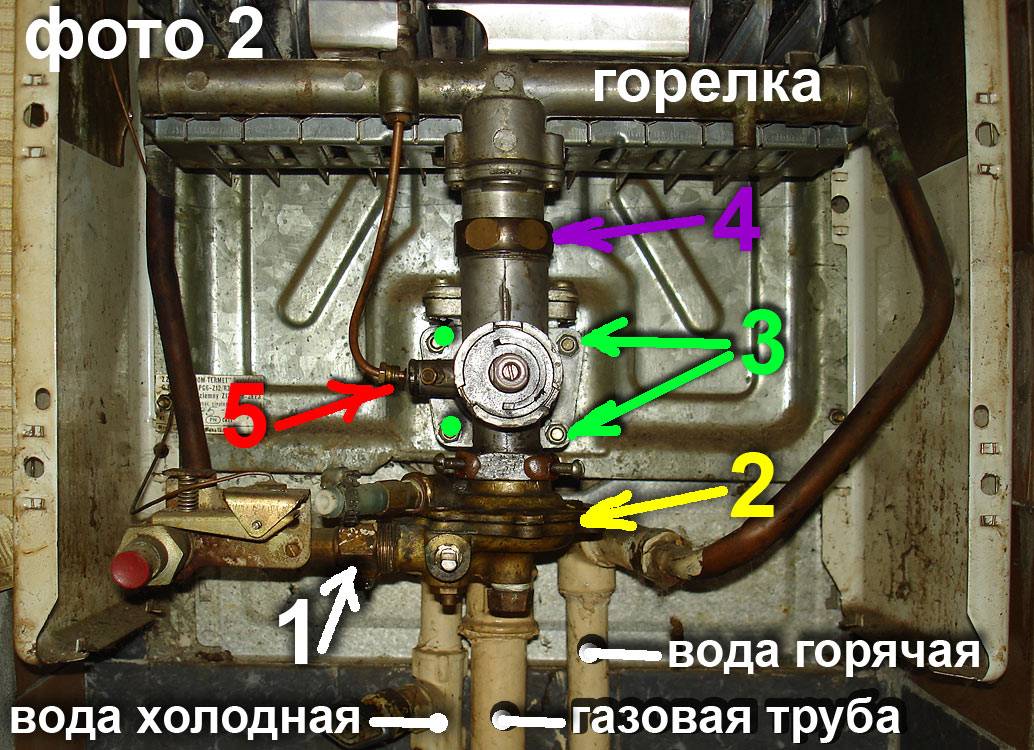

We service the igniter and the water intake unit

If it becomes necessary to clean the water unit, do not rush to disassemble the entire apparatus.Look at the instruction manual for the water heater, find the “frog” on the diagram and follow the following algorithm:

- Remove the control knobs and front cover.

- Dismantle the water unit by disconnecting the nozzles.

- Unscrew the screws holding the cover, remove it and get to the membrane.

- Clean the filter - mesh and water holes in the body of the "frog" using a wooden stick or soft copper wire. Remove scale with a brush.

- Rinse the parts with water and assemble the assembly. Replace damaged or cracked membrane immediately.

Clean the pilot burner jet (wick) with a thin copper wire or a toothpick moistened with alcohol. Wipe the ignition electrodes and the flask of the flame sensor (thermocouple) thoroughly from soot, otherwise, over time, the column will spontaneously turn off.

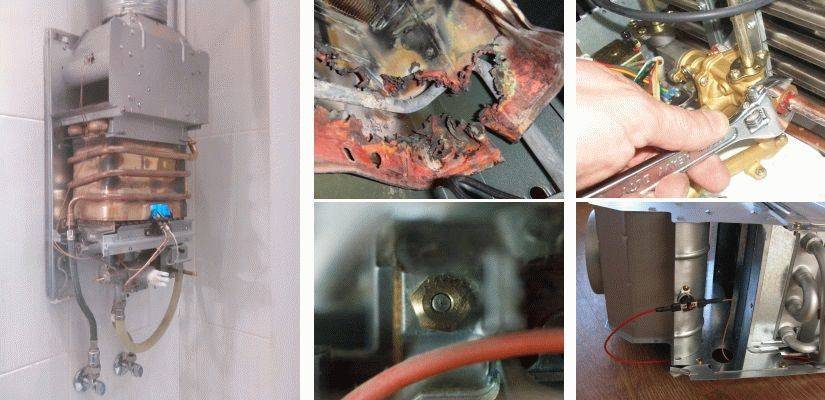

From what the heat exchanger is clogged with scale.

How to understand whether you need to clean the heat exchanger or not, and why it clogs. As a rule, you yourself and only partly hard water are to blame for the overgrowing of tubes of a flowing water heater with scale. Why you yourself, because everyone around them only does what they scold hard water. The whole point is that scaling starts when the water temperature is over 80 degrees. To be precise, there are still no deposits at 78 degrees, and at 82 intensive scale deposits begin. Why are you asking this temperature? For bathing, a temperature above 42 degrees is not needed, 45 degrees is enough to remove fat, fat removers cope with it in cold water. For washing more than 60 degrees is not necessary, but now mostly washing washing machines - automatics.

Draw your own conclusions. A lot of people leave work a gas column on the igniter, undoubtedly, it is convenient, there is no need to kindle and adjust it every time, the flame on the igniter is small, but if you drilled it out for reliability, then it takes an hour for the temperature in the heater heat exchanger to rise to 90 degrees, here you have scale. And our third mistake is geyser operation with low water flow - read low water pressure in the water supply. Of course, an instantaneous water heater cannot operate at low pressure in normal mode. But Russian craftsmen and "the devil on Shrovetide will make pancakes bake." We twist it where necessary, drill the igniter, put a washer and a voila at the outlet of the gearbox, the water barely flows, and the column burns and at the same time it even throws out boiling water with steam. Here's to you your scum.

Conclusions:

So that scale does not form in the column, do not be lazy to turn it off and on as needed, if you do not want to, use an electric instantaneous heater or a double-circuit boiler designed to produce hot water. And it’s not true that boilers heat water worse, I personally have the most ordinary, cheap Zhytomyr double-circuit boiler that provides two bathrooms and a shower with hot water without problems.

Do not redo the automation of the flow heater, if you have a weak pressure, it is better install booster pump, there are a lot of them now, you can always choose the right one for you.

When turning on the gas water heater, adjust the water flow according to temperature, boiling water is not needed, tell me why dilute hot water with cold water, if we are now paying the same for both.

When it is necessary to flush the coil (heat exchanger) of the gas column.

Gas column heat exchanger.

Well, now, if we have already had trouble, let's get down to flushing the heat exchanger. And you can understand that the heat exchanger of the geyser is clogged by the following symptoms:

— low pressure at the hot water faucet with good pressure in the tap with cold water, while the column either does not turn on at all, or turns on and then turns off.

Of course, the tap at the entrance to the column may still break, so first check it, and only then disassemble the gas column.

We made sure that the faucet is working, you can start disassembling the water heater.

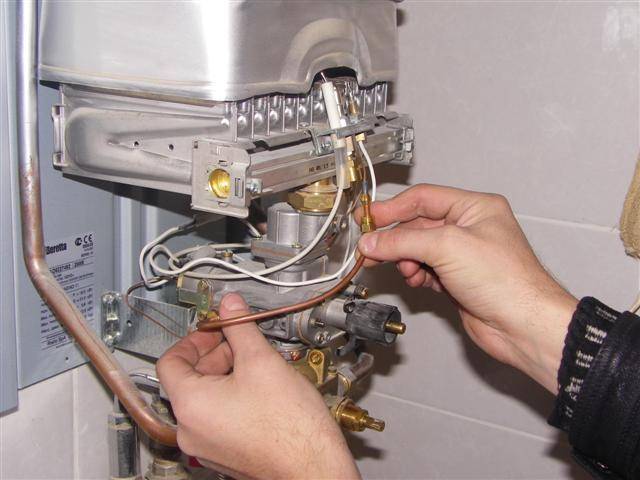

How to disassemble the column heat exchanger. Tools for work.

I don't think it's worth describing the whole disassembly process. The main thing is to make sure that you have the necessary tools. This is in the minimum set the key "Bako" or pipe No. 1, the wrench is adjustable, screwdrivers - Phillips and flat at least No. 5, set of spare paranitic gaskets. Do you also need 60 centimeters of rubber hose? inches with a metal collar. In some columns, the tube may be larger, so check its thickness yourself. And of course, buy in advance at the hardware store antiscale, sold as a dry powder, diluted with hot water. If you're lucky, you can find it in the same place, in a plastic bottle. Better take 2 pieces so that it is enough for two times.

Antinakipin

To begin with, we remove the fittings from the boiler - handles, etc. Then the casing. Removed the cover decide on water pipesso as not to accidentally touch the gas.

Usually, then everyone recommends removing the heat exchanger and washing it outside the column. We will do otherwise.

Consideration by models

The problems mentioned above can be models of different brands and capacities.Although modern modifications are equipped with special technology that controls water flows.

However, columns from different companies may have their own prerequisites for a weak flow of water or its absence.

The following is an overview of the models of some companies and the main reasons for the weakened pressure in them.

The first modification is from the Neva brand.

If hot water does not come from the Neva gas column, the most common answers to this are:

- Pressure drop in the pipeline. To solve it, you need to involve specialists.

- Lack of gas in the main. You need to contact the appropriate service.

- The hot water valve in front of the appliance is not open enough. You need to check it and, if necessary, close it properly.

- Illiterate choice of water consumption mode. Adjust the unit settings in the special menu on the display.

- Filter contamination, TO. Carry out the previously mentioned cleaning operations.

- Breakage of the membrane in the water mechanism.

The greatest problems arise with the labeled membrane.

If it is deformed and does not give any reactions to water pressure, replace it.

A device with a damaged membrane cannot work stably. And it is possible that it will not turn on at all.

The second unit is Zanussi.

This is where dilemmas often arise:

- The water is weakly heated. And a cold stream comes out. In such a situation, it is necessary to reduce the water pressure by applying the control system on the device panel. The maximum fuel supply to it is set.

- The same spectrum of pollution (TO, filters). The solution methods are identical.

The third example is Bosch.

In practice, for models of this brand, the reasons for a weak hot flow or its absence are:

- Errors in the water supply settings.

- Clogged components.

- Installation flaws.

What to do with poor water pressure in the water supply system of a private house

Low water pressure in a private house served by an autonomous water supply system is also a common problem. In private houses, a weak pressure of cold water supplied by a pump from a well or a well can not only cause a deterioration in living conditions, but also exclude the possibility of watering green spaces in the garden.

In most cases, the problem of low water pressure in private houses and cottages is solved by installing storage tanks of various capacities, in which the liquid supplied by the pumping station will be collected in the required amount, providing stable pressure in the autonomous water supply system. To ensure that the water level in the storage tanks always remains constant, they place float switches for the liquid level, which automatically turn on and off the pumping equipment.

How do you know when it's time to clean the gas column?

Gas column cleaning is necessary if:

- The column does not turn on, or turns off after working for a while. At the same time, it is precisely known that gas and water enter the column.

- The column thermal protection sensors are constantly triggered. The scale layer has a porous structure and has heat-insulating properties, which interferes with the normal cooling of the column.

- The efficiency of the column has noticeably decreased: during normal operation of the burner, the water heats up much weaker.

- Weak head at the outlet of the column with a normal head at the inlet. Water cannot get through the channels covered with scale.

Cleaning the water intake

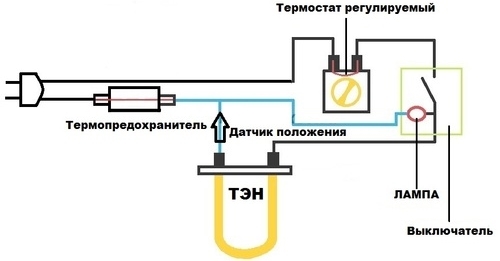

The water intake unit is installed at the inlet of the water supply system of the column, it has a mesh filter to prevent clogging of the heat exchanger tubes with large particles of rust and sediment, as well as a membrane for automatic gas supply when the water tap is turned on.

- We remove the water intake unit from the column body.

- Having unscrewed the connecting screws, we open the case.

- We clean the filter and rinse it with a strong pressure of water.

- We check the membrane. The membrane should be flat, if the membrane has a pronounced concavity, then it has exhausted its resource and must be replaced. You can replace the "native" membrane of the old column with a modern silicone one, which has a much longer service life.

- We close the cover of the water intake unit, “bait” the screws and tighten alternately diametrically opposite pairs of screws. Thus, a uniform tension of the membrane is ensured.

Cleaning the heat exchanger

- Disconnect the water inlet and outlet pipes to the heat exchanger. If the heat exchanger is not cleaned regularly, the fastening nuts may be clogged with scale, preventing them from detaching. In this case, we recommend using a special VD-40 fluid, which can be purchased at any car dealership. It is necessary to drip liquid into the junctions of the nuts using an oiler. You can also use "Silit" from scale. After 15-30 minutes, the nuts can be unscrewed. If that doesn't work, try tapping on the nut from all sides.

- After disconnecting the heat exchanger, using a funnel, pour the descaling agent into it. As such a tool, a solution of 100 g of citric acid per 0.5 l of hot water is perfect.You can also clean the heat exchanger with nine percent table vinegar, diluted with water in a ratio of one to three. But the use of hydrochloric acid is not recommended, as it can react with the metal from which the heat exchanger is made, which will only aggravate the situation. Leave the solution inside the heat exchanger overnight.

- Drain the solution, thoroughly rinse the heat exchanger. If the scale that has left the walls is not removed, it can clog the tubes of the heat exchanger, so we wash the heat exchanger with a strong stream of water from the tap. To do this, you can adapt the tubes of the appropriate diameter.

- We put the washed heat exchanger in place, tighten the fastening nuts, after changing the seals.

Soot and soot removal

Unlike the water supply, it is impossible to disassemble the gas part of the column on your own; only a master from the city gas service should do this. The only thing we can do to eliminate soot is to remove carbon deposits from the burner jets.

- The jets are cleaned with thin copper wire.

- The soot is swept away with a metal brush.

- It is advisable to immediately check the column for gas leakage. To do this, it is necessary to prepare a soap solution, which is applied to all joints of gas pipes and units. A gas leak will be indicated by the formation of characteristic bubbles at the junction. If you find a leak, turn off the gas and call 104.

Preventive maintenance can minimize the need for column cleaning. Longer operation of the column without failures and cleanings is facilitated by the use of filters and devices to reduce water hardness.

Causes of low water pressure

To find out exactly why there is a weak pressure of cold or hot water in the taps of an apartment, you should first of all interview your neighbors above and below, whose apartments are connected to the same water supply as yours. If only you have encountered the problem of low pressure, this means that the reasons for its occurrence lie in the pipeline water supply system of your apartment.

We list the most typical of these reasons:

- Clogged pipes are the most common cause of poor water pressure. Most often, old steel pipes become clogged in apartments, the inner walls are highly rough. It is better to replace such pipes with new ones in order to solve the problem of low water pressure.

- Another common cause of low water pressure in the taps of a single apartment is a clogged coarse filter, which must be installed in front of the water meters. Such a filtering device, also called a mud collector or an oblique filter, is periodically clogged with sand, rust and other debris, so it must be cleaned.

- Clogging of the aerator, a special filter mesh that is installed in the spout, can also lead to a decrease in water pressure in the tap. To raise the pressure in the tap in this case, it is enough to unscrew the aerator and clean it.

If, however, not only you, but also your neighbors in an apartment building faced a weak pressure of water in the taps, then the reason may lie both in a separate riser of the house, and in the clogging of the entire house pipeline. In addition, the power of the pumping station seriously affects the water pressure in the water supply system.

How to increase the water pressure for a gas column?

Question

The AEG gas water heater does not ignite, apparently due to a lack of water pressure. Is it possible to put some kind of not very powerful pump to increase the water pressure?

Is it possible to call a wizard from your company to fix this problem?

Vitaly.

Answer

Hello Vitaly!

It is possible to increase the pressure of tap water at the inlet to the gas column if a circulation pump is installed on the section of the water movement path from the water pipe to the gas column, which is called “water pressure increase pump”.

There are many modifications of such pumps from different manufacturers with different technical characteristics. You can purchase and install a pump that will increase the pressure only in your apartment, but there are also those that are designed to increase the pressure throughout the house. There are low power pumps with a capacity of 1.1 cubic meters. m per hour, and there are with a capacity of more than 2 cubic meters. m per hour.

They can create pressure from 8 to 18 meters. Some models are equipped with an automatic shutdown system when the column is turned off. Among the most popular at the moment are the following models: GL15GR-9 Taifu; GL15GRS-10 Taifu; GL15GRS-15; UPA 15–90 Grundfost; Sprut GPD 15-9A; 15WBX-12 and many others.

They can provide an increase in water pressure at the inlet to the geyser up to 30% compared to the water pressure in the plumbing system.

Regarding the second part of your question, unfortunately I can't be of any help to you. I do not represent any company, but I provide visitors to my site only with information about construction, and also provide free consultations.

Also interesting

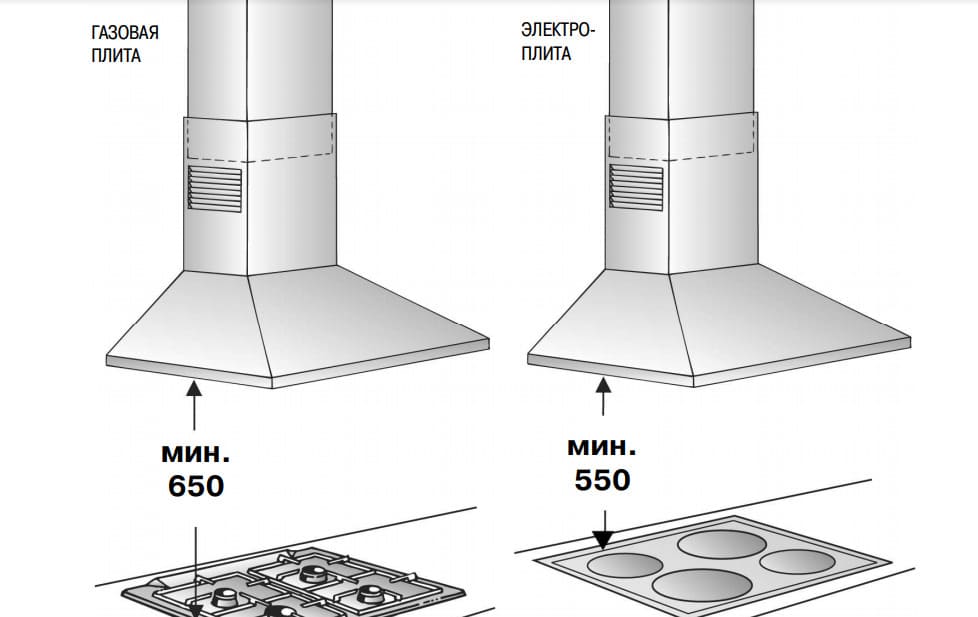

Installing a gas water heater in an apartment

It must be said right away that if there is no experience in work of medium complexity and an understanding of what needs to be done and what to connect where, it is better to call a gas water heater installation specialist.

Turbocharged geysers

Turbocharged geysers are flow type water heaters. Turbocharged water heaters have a significant difference from traditional gas water heaters - their operation does not depend on draft in the chimney.

If the gas column does not ignite

A geyser is a fairly reliable water heating installation. In principle, the column is quite unpretentious in operation and, with proper handling, works without interruption for a long period.

Fields marked * required. HTML tags are disabled.

No ignition

If for some reason the column does not ignite at all, the first thing to check is the battery that powers all the electronics (including the piezo ignition system).

When the water heater is powered by a built-in generator, you should make sure that the piezoelectric element is in good condition, as well as that there is no break in the supply wires. In addition, it is necessary to inspect the electrode (wick) for damage.

The same actions are performed when the power supply is working. If it turns out that the battery has run down or leaked, you just need to replace it. In the absence of clearly visible external damage, check the condition of the ignition elements with a multimeter. With it, you should ring the lead wires and the start button. If they are in good condition, an audible signal will sound, if there is an open circuit, the device will show an infinitely large resistance.

The same device, included in the voltage measurement mode, checks its presence at the input contacts of the ignition element. The presence of a certain potential on them indicates that all parts are in good order, except for the piezoelectric element.