- What could be the causes of breakdowns

- How to protect submersible pumps in a private system

- Automation for deep pumps and its types

- Press control

- Pressure support block

- Repair and cleaning

- Selection and installation of the pump

- Marking and popular models

- Self-assembly

- Start-up and maintenance

- Cleaning and repairing minor faults

- The principle of operation of the submersible apparatus

- Main advantages of pumps

- Pump features

- The device and principle of operation of the Aquarius pump

- Pump "Aquarius" for giving

- Advantages of Aquarius pumping stations

- Disadvantages of the lineup

- What is

- How the machine works

- Accessories

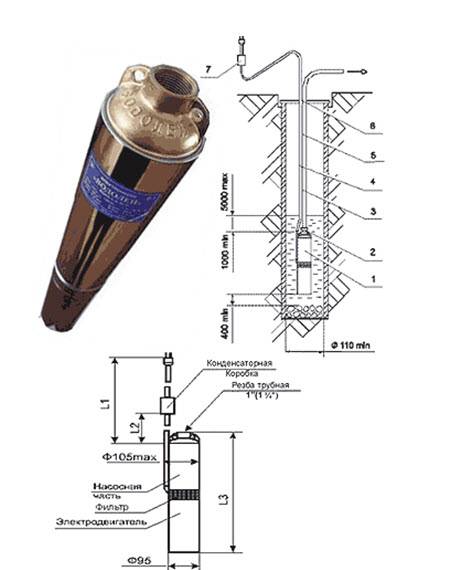

- The principle of operation and constructive device of the electric pump Aquarius

What could be the causes of breakdowns

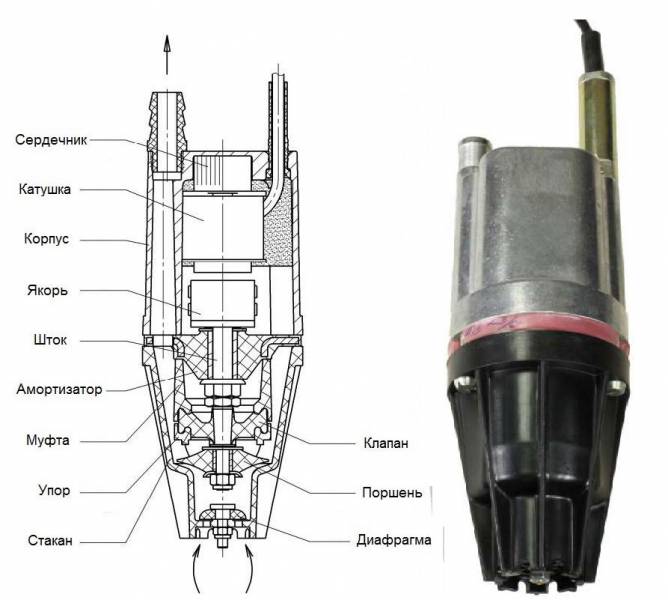

Submersible vibration pump device

The failure of the unit can occur for several reasons. When the pump is located directly near the water, many negative factors act on it. When carrying out repairs, the price will be significantly lower than the purchase of a new unit. The reasons for the failure of the device may be:

Output and building of the magnet. In this case, ordinary repairs will not help, you need the help of specialists.

Mechanical failure is characterized by extraneous sounds emitted by the pump. You can try to fix such a malfunction of the product yourself.

In case of mechanical failure, the cause may be too dirty water clogging the pump. Sometimes the device works in dry mode, with no oil, which must be present.

The unit may fail when the working fluid is heated to a temperature of more than 40 ° C. There can be many reasons for unit breakdowns, both in the mechanical part and in the electrical part, consisting of the engine and the automation system. Here are located:

- Time relay.

- Automatic elements that protect pumps from short circuits.

From time to time, all this can become unusable.

An incorrectly fixed underwater cable for submersible pumps can lead to breakage.

How to protect submersible pumps in a private system

Like any device, deep pumps require careful handling. Most often, manufacturers of units provide for the occurrence of possible dangerous situations during operation and produce additional devices that look like an external unit for automation and control of the product.

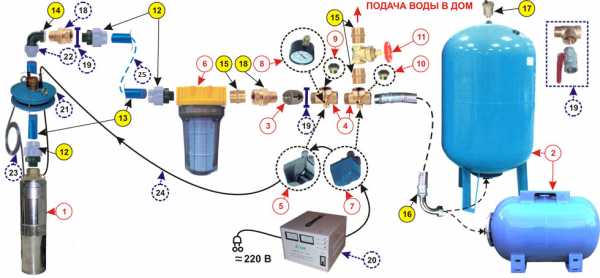

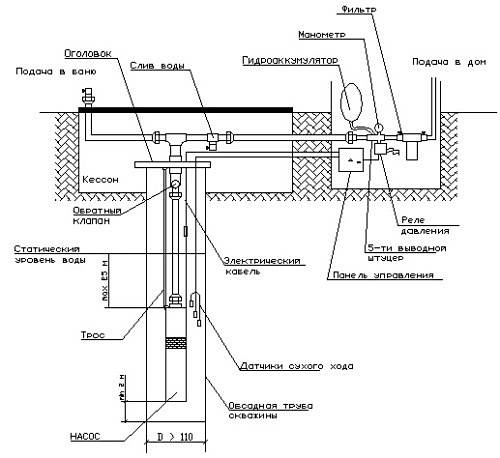

Deep pump connection diagram

Dry move. Occurs when the water drops below the critical level, and the unit nozzle is above it. As a result, the device fails. You can prevent this from happening:

- installation of a float system;

- lower into the water two special electrodes or level sensors that are connected to a protective device. When the lower electrode is located above the water level, the pump turns off, and when the level of the upper electrode is reached, it turns on;

- installation of a device that controls the passage of water through the pump.In its absence, this element stops the pump.

Water hammer. Occurs when the “dry pump” is turned on or when the unit is turned off. At this point, the liquid hits the impeller blades hard, which can severely damage them and lead to pump failure. You can solve the problem:

- a check valve device made of high-strength materials, which can reduce the weight of the water column acting on the impeller;

- equipment of hydraulic accumulators with pressure switches and sensors that can turn the pump on and off when there is an excess of pressure in the system.

Unstable parameters in the electrical network.

- Freezing water. Such a phenomenon in the pump housing is unacceptable. When the temperature drops below zero, the water must be drained. With year-round use of the device, it is installed in caissons.

- Turbidity of pumped liquid. The presence of abrasive particles can lead not only to jamming of the downhole pump, but also to damage to the entire tract.

Automation for deep pumps and its types

Automation for submersible devices is divided into three categories:

- automatic control unit in the form of a remote control;

- press control;

- control unit equipped with a mechanism to maintain stable water pressure in the system.

block protects the pump from power surges

block protects the pump from power surges

- pressure switch;

- level switch;

- float switch.

The average cost of such a control unit is about 4000 rubles, but remember that this control device will not work without additional devices, in particular, the same pressure switch or additional protection of the device against dry running.

Of course, some models of such control units are already equipped with all the necessary systems for full-fledged work, but their cost will already be about 10 thousand rubles. You can install such a control device yourself without consulting a professional.

Press control

The next version of the automatic control device is a press control. It is equipped built-in systems for automatic operation of the pump and passively protects against dry running. The control in this case is determined depending on the orientation to some parameters, in particular, the pressure level and water flow. For example, if its consumption in the device is more than 50 liters per minute, then it will work continuously. And if the water flow decreases or the pressure increases, then the press control will turn off the pump, and this will be protection against the dry running of the pump.

If the liquid in the system does not reach 50 liters per minute, then the device starts when the pressure drops to 1.5 atmospheres

, this is very important in conditions when the pressure rises sharply and the number of on-off switches needs to be reduced. It also provides for automatic shutdown of the device in conditions of a sharp and powerful increase in water pressure. The most common press control devices on the market for control:

The most common press control devices on the market for control:

- BRIO-2000M (cost - up to 4 thousand rubles);

- "Aquarius" (4-10 thousand rubles).

The cost of a backup accumulator for both devices most often ranges from 4 thousand rubles. And remember that when purchasing a control unit of this type, it will be more difficult to install it yourself than the previous one.

Pressure support block

The last version of automation for submersible pumps is a control unit, which includes a mechanism, maintaining stable water pressure throughout the system. Such a mechanism is indispensable in those places where it is impossible to sharply increase the pressure, because if it constantly rises, this will increase energy consumption and reduce the efficiency of the pump itself.

All this is achieved due to the rotation of the rotor of the electric motor of the control unit, but the regulation of the rotational speed occurs in automatic mode. The most famous models of such control units:

- "Aquarius";

- grundfos.

It should be noted that the brand "Aquarius" - the most popular in Russia and neighboring countries in the market of control units for pumps. Devices of this brand attract buyers for the following reasons:

- relatively affordable price;

- good quality blocks;

- ease of installation.

The cost of different models can vary significantly, of course, devices equipped with subsystems and additional functionality will cost much less than conventional ones.

Repair and cleaning

One of the reasons for stopping the rotation of the pump may be damage or clogging of its impellers. A small blockage can be eliminated on its own. This is done as follows:

- The protective mesh is removed. On new generation models, for this you need to open the clamp that fixes the grid, hooking it with a screwdriver and pressing it down in the middle. In older models, the mesh is held on by two unscrewing screws.

- On wide pumps, it is necessary to additionally remove the cable channel, which looks like a small metal groove.

- We separate the engine from its pumping part.To do this, unscrew the four bolts that fix it, and remove the plastic couplings connecting the engine and the pump part.

- We lay out the disassembled structure on a flat surface.

- Using a 12 head or socket wrench, turn the pump shaft, holding its upper part with your hand. When it moves, we wash the pump part with a jet of water, trying to remove debris from there that clogged the device. If this attempt was successful, and the shaft moves again without difficulty, we flush the pump and assemble it again, proceeding in the reverse order.

If the impellers are damaged, the pump part of the unit must be dismantled. However, due to the complexity of this operation, it must be done in specialized services, where worn parts will be replaced professionally and quickly.

In case of self-repair of the device, the following operations are performed:

- The pump housing is pressed with force from the upper and lower sides, with an emphasis on the brass element located in its lower part.

- Narrow-nose pliers carefully remove the stopper ring installed in a special recess, which should expand after the pump housing is compressed.

- The impellers and the thrust cover with the bearing are removed one by one.

- After the jam is removed, the pump is reassembled. (Sequence of actions: in reverse order).

When starting this work, it is necessary to understand that it will be very difficult to carry out these manipulations on your own due to the need to use special equipment (press).

Thus, we can conclude that deep well pumps for wells, the technical characteristics and cost of which made them very popular with consumers, are really effective and convenient for domestic needs. Subject to compliance with the rules of operation and regular and timely care, they will serve for a long time without requiring the cost of repairs and reinstallation.

How to repair the Aquarius pump with your own hands is shown in the video.

Selection and installation of the pump

The Kharkov plant "Promelektro" under the brand name "Aquarius" produces units:

- ground-based;

- deep drainage pumps (for dirty water);

- borehole pumps for drinking water.

You can distinguish them in the catalog by marking.

Submersible pumps can provide water for both one house and an entire neighborhood.

Marking and popular models

We are interested in pumps Aquarius BTsPE (household centrifugal submersible electric pumps). It is easy to understand the marking, for example, let's take the Aquarius BTsPE 0.5-100U 60/150 pump:

- 0.5 - means productivity, the number of liters per second (l / s);

- 100 is the height of the water column during normal operation, measured in meters;

- 60 is also a performance characteristic, but already when operating in overload mode, it is measured in liters per minute (l / m);

- 150 is the height of the water column in overload mode.

picking up Borehole pump Aquariusyou can use the chart.

Aquarius BTsPE pumps are divided into 4 areas in terms of performance:

- BTsPE-0.32 l/s,

- BTsPE-0.5 l/s,

- BTsPE-1.2 l/s,

- BTsPE-1.6 l/s.

Plus, each direction has its own lineup. On average, the price of household units ranges from 7,400 rubles to 27,000 rubles. (prices are current for spring 2017)

Often, in a country house or in a country house, a well is drilled for sand, such wells have a limited flow rate (productivity), so it is better to take Aquarius BTsPE-0.32 here. In this niche, 9 models with different technical characteristics are presented.

Technical characteristics of the BTsPE-0.32 model range.

Units of the Aquarius BTsPE-0.5 series can also be used for sand wells, but the productivity of such wells must exceed 3 m³ per hour. There are 8 models in the line.

Technical characteristics of the BTsPE-0.5 model range.

Units of the Aquarius BTsPE-1.2 series are not suitable for wells with low productivity. These units are installed on artesian wells - they are placed on several houses at once. The line includes 8 models.

Technical characteristics of the BTsPE-1,2 model range.

Aquarius BTsPE-1.6 pumps are closer to the industrial version. If we talk about private houses or cottages, then these borehole pumps are installed on 1 powerful artesian well and provide water to a whole garden partnership or a small area.

Technical characteristics of the BTsPE-1.6 model range.

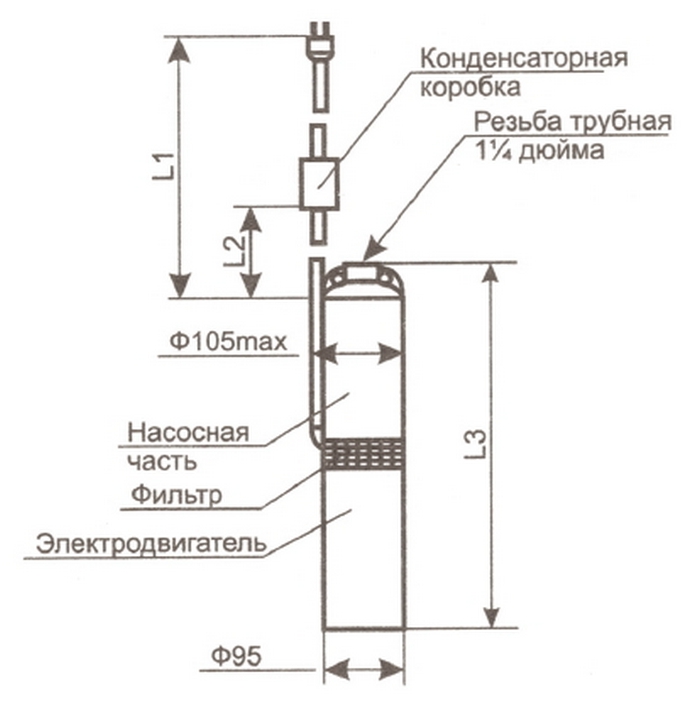

Self-assembly

Calling a specialist to install such a pump in a country house, firstly, will cost a pretty penny, and secondly, it makes no sense, you can do everything yourself.

The instructions are quite accessible.

Illustrations

Recommendations

Tools:

A pair of adjustable gas wrenches;

Open-end wrench set;

Hacksaw for metal;

Knife.

Materials:

fum tape;

Brass check valve;

Brass adapter for check valve;

HDPE pipe;

Plastic tightening clamps;

Head or downhole adapter;

Metal cable with anti-corrosion coating and 4 clips to it.

Aquarius well pump kit:

Box;

Nylon rope;

Capacitor group;

Electrical cable;

Pump for wells Aquarius.

We assemble the adapter on the pump.

Brass adapter;

check valve;

Adapter for HDPE pipe.

We connect the pipe.

We have a HDPE pipe with a cross section of 32 mm. It is connected to the adapter using sealing gaskets, they come with the adapter.

We tie up the cable.

Fix the pump better

In the photo, the electrical cable is fastened with electrical tape, but in general it is better to do this with plastic clamps.

We fasten the steel cablePay attention: the steel cable is threaded into both ears on the pump;.

Now we take the clamps for the steel cable, thread the cable into them and tighten the clamps with keys. You need to fix in two places;

We make exactly the same loop on the opposite side of the cable, it will cling to the carabiner mounted on the head;

Head mounting:

Then we disassemble the head, put a pipe into it and clamp it;

After that, through a carabiner we hook a safety cable to the head;

The head is attached with gaskets and clamping screws.

Missing parts.

The pump comes in a budget package, so I recommend purchasing:

Dry running sensor, as in the photo (in case the water in the well runs out);

Voltage stabilizer with surge protection.

Start-up and maintenance

After the pump is in the well, the first start is made:

- it is necessary to close the valve on the pipeline,

- supply power to the pump (1 phase, 220 V, 50 Hz),

- slowly open the valve.

If the water from the pressure pipe has gone clean, then it is advisable to leave the pump in operation for a while, and then turn it off. Then you need to connect the pump to the existing water supply system at home.

If the pump began to supply muddy or silty water, the following measures must be taken:

- leaving it on, close the valve and leave the pump in operation for a while;

- wait for clean water.

Otherwise, all mechanical impurities that have been preserved in the discharge pipe and the pump structure may jam the hydraulic part or the check valve.

If it is necessary to remove the pump from the well and send it for long-term storage, it is recommended to rinse with water and then dry thoroughly. At the time of the secondary immersion, the pump should be left in the well for a while, and then run according to the above scheme.

Cleaning and repairing minor faults

In the case when the deep pump began to work unsatisfactorily, and its hydraulic part does not rotate, it means that the impellers or the internal mesh of the pump are clogged with fine sand or silt.

There is no internal filter-sump in the pump configuration!

To clean the wheels or mesh, you must disassemble the pump:

- Dismantle the protective mesh. On recent models, pry off the clamp with a screwdriver and press on its middle; on older models, unscrew the screw connections.

- Remove cable gland.

- Using a wrench, unscrew the bolted connections and detach the motor from the hydraulic part of the pump.

- Remove couplings.

- Turning the shaft with a key, flush the pump part, removing mechanical impurities.

In the case when the shaft began to turn easily, it is necessary to assemble the pump in the reverse order.

If the impellers are jammed or damaged, it is necessary to disassemble the pump part. But only specialists of an authorized service center can perform such work while maintaining the warranty.

Procedure for repairing minor faults:

- clamp the pump housing from above and below, rest against the brass part;

- remove the stopper ring;

- remove impellers;

- remove the stop cover with the bearing;

- try to eliminate jamming;

- reassemble in reverse order.

However, service centers use a press machine when assembling / disassembling the pump, so self-repair of the pump can be difficult.

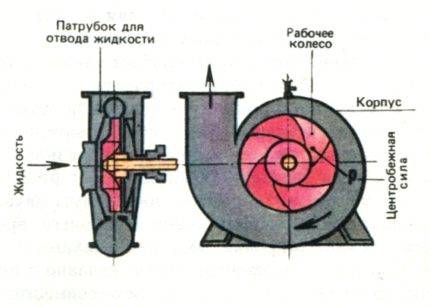

The principle of operation of the submersible apparatus

To supply water up and move it to the required distance, it is necessary to create pressure. The centrifugal type of pumps produces the required pressure by rotating the wheel (or several wheels), which is fixed on the working rod (shaft) and connected to the engine.

When the wheel is started, kinetic energy arises, which is transmitted to the blades, and from them to the liquid. As a result, water is scattered to the walls, then it moves from the receiver to the adjacent (upper) chamber, and another portion of water from the well enters its place under pressure.

A suction pipe is designed to take liquid, and a filter is provided to protect the internal parts of the device from clogging and rapid wear. The device is simple, but so effective that it makes no sense to look for a device with a different principle of operation. All elements of the mechanism are placed in a fairly compact elongated "sleeve", the design of which is ideal for running into a narrow wellbore.

Unlike vibrating analogs, centrifugal ones work evenly and carefully, thanks to which they do not lift sand from the bottom and do not destroy the walls of the well.

Main advantages of pumps

In recent years, Aquarius pumps have become quite popular on the Russian market, and Ukrainian production no longer bothers anyone. The fear has long passed and more and more installers recommend these pumps for installation in private homes.

Let's highlight the main advantages of Aquarius pumps:

- Excellent price. Spending a little money on a good thing is not at all as often as we would like. In this case, Aquarius will be a good example.

- Equipment. The best part is the included power cable. For any submersible pump, this is a very serious argument in favor of buying a ready-made solution.

- Maintainability. All pumps are repairable and the cost of spare parts is low. However, it is extremely difficult to repair it yourself (without a special tool).

- Wide range of equipment. Submersible pumps Aquarius have more than 40 models. Pumps for narrow wells, for marginal wells and natural sources of water supply.

Quality that is not inferior to European brands. 100% quality control and a proven design will not cause trouble with breakdowns for many years. At all.

Pump features

Aquarius pumps of the BTsPE 0.5 series have a nominal flow rate of 1.8 m³/h (maximum 3.6 m³/h). This is more than enough for a family of 3-4 people. At the same time, the nominal pressure of pumps of this series reaches 100 meters. These pumps are designed for wells and wells with an internal diameter of 110 mm.

The nominal flow rate of Aquarius pumps of the BTsPE 1.2 series is 4.3 m³/h (maximum 9.6 m³/h).Pumps of this series can be used for water supply of several houses, industries, filling water towers or large tanks. At the same time, the nominal pressure of pumps of this series reaches 80 meters. The inner diameter of the well must also be at least 110 mm.

Aquarius pumps of the BTsPE 0.32 series have a nominal flow of 1.15 m³ / h (maximum 3 m³ / h), and the nominal head is a record 140 meters. There are two main advantages at once - the ability to work at low costs, and on the other hand, the provision of very high pressures. They are chosen with a low flow rate of a well or well or low water consumption. The diameter of the well must be at least 110 mm.

If you are just starting to build a house, then try to imagine the entire future water supply system as fully as possible. This is necessary for the optimal selection of the Aquarius submersible pump specifically for your conditions.

For example, if you are going to take water from a shallow (5-10 meters) well or well and use the Aquarius pump only for watering or filling containers, i.e. do not set the task of creating an automatic pumping station, then the smallest pumps manufactured by Promelectro will suit you: Aquarius BTsPE 0.5-16 U or Aquarius BTsPE 0.5-25 U. And if the pump is needed to create an automatic pumping station, t .e. to work in conjunction with a hydraulic accumulator and a pressure switch, then the choice of the pump must be carried out in accordance with all the rules.

The device and principle of operation of the Aquarius pump

Deep pump "Aquarius" is a device consisting of 2 compartments:

- Motor.

- Pumping.

The composition of the electric motor includes:

- Stator.

- Rotor.

- Ball bearings.

A single-phase AC motor converts electrical energy into mechanical energy and sets the unit in motion. The motor is filled with clean oil and is located at the bottom behind the pump unit to prevent oil from entering the pumped medium.

The pump unit includes:

- Drive shaft.

- Radial impellers attached to the drive.

- Vane outlets are diffuser channels surrounding the impellers.

- Guide rings.

All mechanisms of the pump unit are located in one housing. There is a filter between the compartments. On top of the pump there is a clamping cover with 2 holes for attaching a cable, on the bottom - an internal G1 ”pipe thread. An external condenser box with a power cord is attached to the device.

The principle of operation of BCPE is simple. When the system is activated, the drive wheels are set in motion. They create a centrifugal force, which is aimed at pumping water under pressure and then filling it with the inside of the apparatus. A suction pipe is used for water intake, and a filter is used to protect against clogging and siltation of the system. After filling the unit, the liquid moves smoothly into the storage tank. The next portion of water enters the pump from the well.

Pump "Aquarius" for giving

The Aquarius pumping station gained particular popularity among summer residents only a few decades ago, when a new Ukrainian company, Promelectro, entered the market for septic tanks, drainage systems and pumping stations.

Due to the decent build quality and relatively low cost, Promelectro managed to get the positive attention of millions of summer residents not only in Ukraine and Russia, but also in the neighboring CIS countries

Aquarius deep pumps are capable of taking water at a distance of 20 to 200 m from the surface of the earth. At the same time, the company offers budget options for 1 plot, as well as more powerful ones - up to 3-4 plots, depending on their total total area.

Model range of submersible pumps Aquarius

Advantages of Aquarius pumping stations

Why users prefer this particular brand:

- The depth of water rise - unlike most models of the budget class (for example, the same Belamos, the maximum level of water rise does not exceed 30 m), while the Aquarius water pump is able to get water from the bottom of the well, the depth of which is about 180 m ;

- The Aquarius well pump belongs to fully submersible models with reliable electrical insulation, for which water is a cooling medium;

- Despite the comparative cheapness, it is in no way inferior to more expensive foreign pumps;

- Depending on the technical characteristics of the Aquarius pump, the price range is in the range of 5-25 thousand rubles with small errors in both directions;

- The range of Aquarius centrifugal pumps is distinguished by the most powerful devices in its price category. Even the smallest and least powerful pump for a well and a well, Aquarius, is capable of delivering a maximum head of a column of water of 70-80 m, capable of providing water to a small family of 2-3 people;

- When purchased from an official supplier, submersible pumps are supplied complete;

- With impressive power and high performance, the Aquarius deep pump does not have a high level of electrical energy consumption, which also allows it to remain in the top of sales among domestic analogues;

- When purchased from an authorized supplier, warranty service is included. However, problems with self-repair of the device should also not arise.

Disadvantages of the lineup

Unlike European analogues, the electric pump cannot boast of full automation and absolute noiselessness in operation, and it is not equipped with all kinds of protective options, such as protection against overheating of the device. Therefore, you will have to systematically monitor how the device works, and whether it has overheated.

What is

What does the design of an electric pump look like in a section

The structure of submersible well models of pumping stations from different manufacturers is approximately the same and includes:

- multi-stage sector for increasing fluid pressure;

- electric motor;

- filter;

- condenser box.

The pumping unit, or rather the impeller, is responsible for the performance of the station: the larger it is, the more water flows at a time.

How the machine works

Features of the device:

- To transport water up the well shaft, a sufficient level of pressure in the tunnel is required. In the submersible apparatus, pressure is created due to the operation of the paddle wheels, which are connected to the engine through the rod shaft;

- The filter provided in the water station does not allow small debris and sand to pass along with the liquid. Its installation is necessary in two cases: firstly, the filter field protects the pump itself from rapid wear, and secondly, it supplies water without impurities;

- Submersible pumps do not create vibrations, unlike vibration stations, therefore, they do not scoop sand from the bottom along with water. As practice shows, even with timely care of the device, the average operating life of a centrifugal pump exceeds the mark of 10 years, while vibration models barely survive the warranty.

Accessories

For the first time equipping a well for transporting water for domestic needs, it is necessary to purchase the following equipment:

- Hydraulic accumulator. Depending on the number of regular consumers, a model of 100-120 liters will be enough for a family of several people;

- Underwater cable;

- Upper bearing part of the well;

- pressure gauge;

- Pipe for outdoor use (connects the pump and tank);

- Pressure switch.

Pressure gauge for pumping station

Often, users additionally purchase another cable with clamps, noting some fragility of the one already supplied with the pump.

The principle of operation and constructive device of the electric pump Aquarius

The electric pump is classified as a centrifugal model, in which water is taken through an inlet located in the center of the impeller axis. The liquid entering inside is discarded by curved blades to the edge of the working chamber, and due to centrifugal force it is pushed out through the outlet pipe in the side of the housing.

The pump works due to the rotation of the electric motor and is structurally made of two parts: electric and pumping. The first has an asynchronous electric motor and an external control unit mounted on a cord with a plug.

The electric motor includes a stator and a rotor mounted on end bearings and bathed in environmentally friendly oil.

The pump part includes a strainer in the middle part of the device, a block of stages with centrifugal impellers, cylindrical rings and petal outlets driven by the motor shaft, and an outlet pipe.

Rice. 3 BPTSE 0.32, BPTSE 0.5 deep pump for a well Aquarius characteristic