- Drill pipe connection methods

- Do-it-yourself drilling of water wells

- DIY drilling methods

- What sources underground

- Verkhovodka

- Primer

- Sources between layers

- Artesian

- How to equip a punched well

- Drilling Options

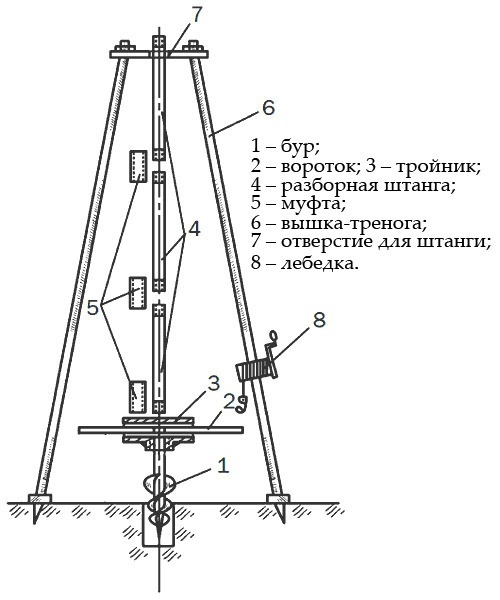

- Tripod

- Drill and casing

- Distinctive features of the method

- buildup

- Video: cleaning (buildup) of the well with a homemade bailer

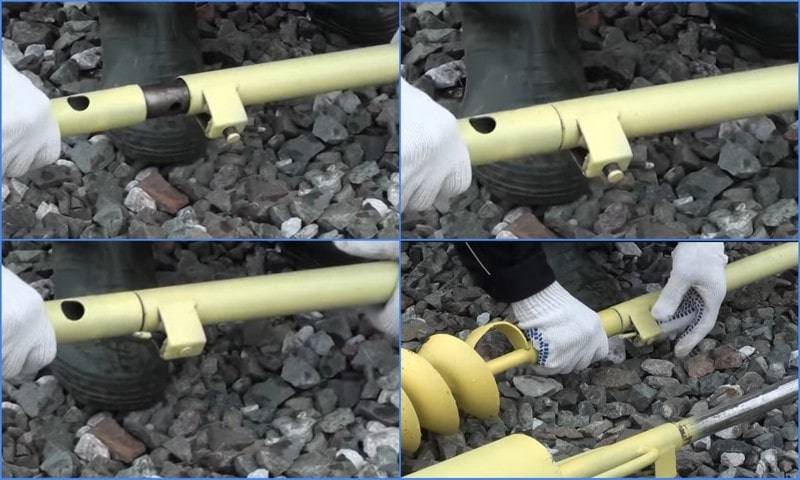

Drill pipe connection methods

For driving long distances, the drill under water is extended using hollow steel pipes of standard diameter 21.3, 26.8 and 33.5 mm in length from 1500 to 2000 mm, which are interconnected in the following ways:

Threaded. In this technology, for connection, an external thread is used, which is cut at one pipe end, and an internal thread on adapter sleeves, which are short cylindrical segments with a diameter corresponding to the lower point of the pipe threaded notch. Cutting is carried out manually with dies using die holders according to the old Soviet method or modern, more convenient devices - krupps. After applying the thread to the inner side of the transition sleeves and the outer shell of the pipes from one end, a sleeve is welded to their other edge, the extension is made by winding subsequent pipes into the previous sleeves.

Bolt and threaded socket.With this method, a large-diameter bolt is welded to one end of the pipe, and a long nut in the form of a coupling with an internal thread corresponding to the external thread of the bolt is welded to the other, when connecting the pipe elements, they are screwed onto each other until they stop. The technology resembles the docking of factory-produced drill rods, factory connecting heads can be welded or screwed to the threads instead of bolts and couplings.

pin. Docking pipes with a pin is the most optimal method, providing a high speed of connection and disassembly of extension rods, for its implementation, an inner sleeve is welded to one side of each of the pipes, the next pipe is put on it and holes are drilled in them at some distance from the edge. Then a pin is inserted into the through channel of two joined pipes, preventing their separation.

The disadvantage of pin fastening is the possibility of falling out of the holes, the easiest way to eliminate this disadvantage is to use a threaded bolt with a nut for fastening. True, this solution is inefficient for quick connection, moreover, when used in the ground, the thread is constantly clogged with dirt, which significantly slows down the assembly and disassembly of the extension pipeline.

The best way to solve the problems associated with the shortcomings of pin connections is to use a special design in which a U-shaped plate with an inserted pin is welded to the pipe opposite the through hole, and a restrictive pin is inserted into its body through the through radial channel.The limiter prevents the loss of the pin with its falling out of the assembly, and is also an element with which the pin is moved along the through hole, connecting and opening the pipeline. Also, the outer U-shaped steel plate protects the pin and stop from damage when rotating in the ground.

If the above design seems too complicated to manufacture at home, a good option is to purchase a factory-made pin for attaching soil drills, which is a bolt with smooth walls, a hole is drilled in the head and a rigid wire stopper is inserted that wraps around the pipe and is worn on the other side on the end of a smooth-walled bolt.

Do-it-yourself drilling of water wells

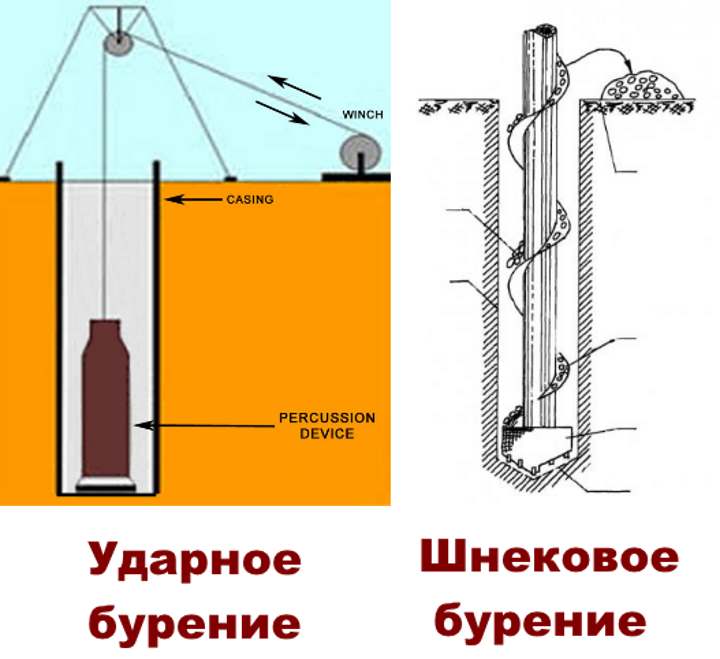

Do-it-yourself water well drilling methods are manual, but differ little from mechanical ones. The main differences are performance and depth. However, they drill even with flushing. Often they use a garden drill, use the auger method, other types of drills, less often the shock-rope method.

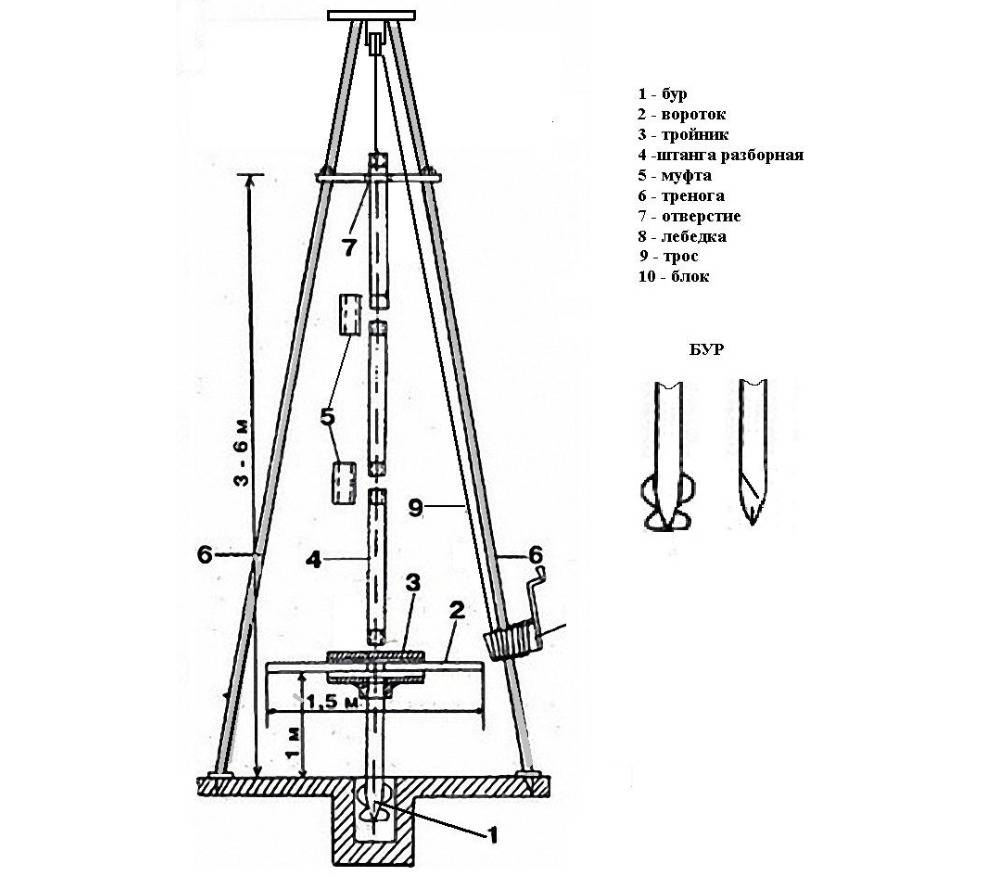

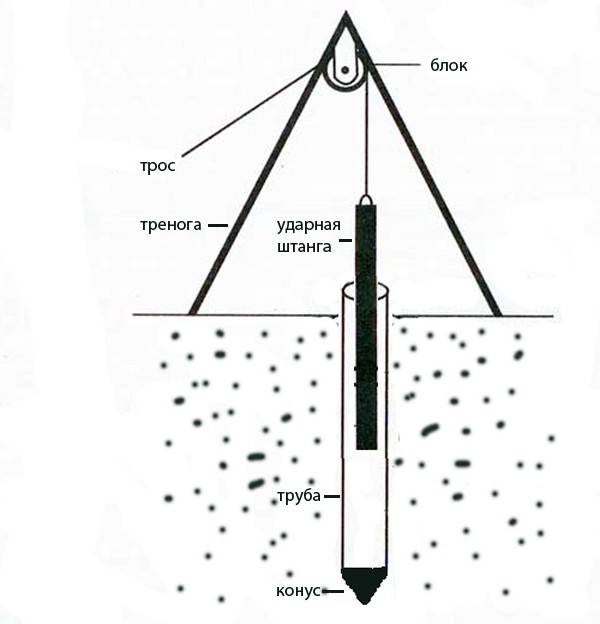

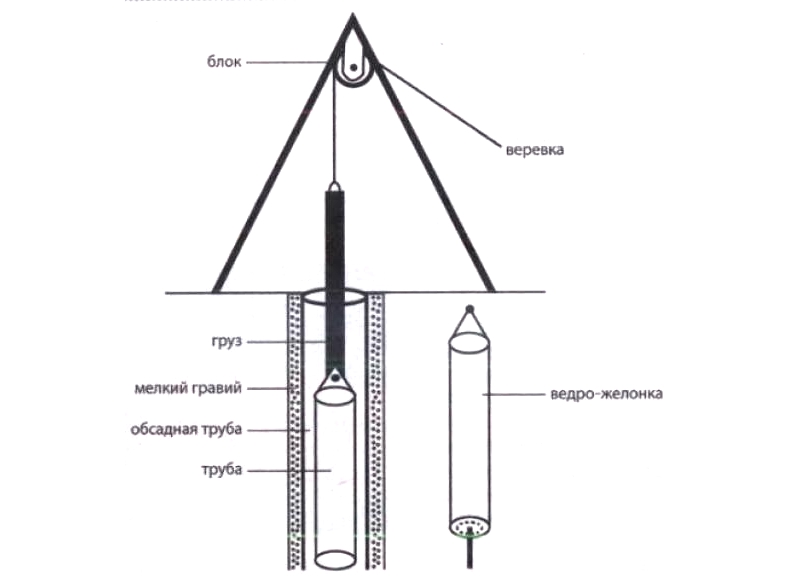

The shock-rope method is the simplest. They drill without the help of heavy equipment, using a special installation, consisting of:

- frame,

- shock bar,

- driving glass,

- cable, winch and block.

The installation is simple - a tripod with a driving glass; the glass is connected by a cable to the winch. The glass is lifted up with a winch, and then released: the projectile cuts the ground with a sharp edge. The glass is removed, the soil is removed from it and the process is continued. If the soil is loose, a bailer is used (a simple glass is not suitable in this case, as it loses everything collected on the way) with a damper in the lower part, which closes when the projectile is filled.On stony soils, you need to work first with a chisel, and then with a bailer to extract the crushed rock, but it is more expedient to use another method.

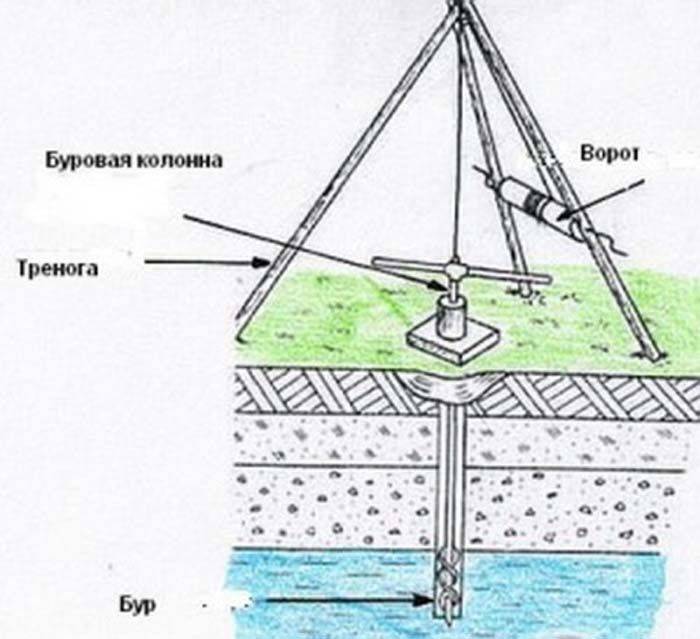

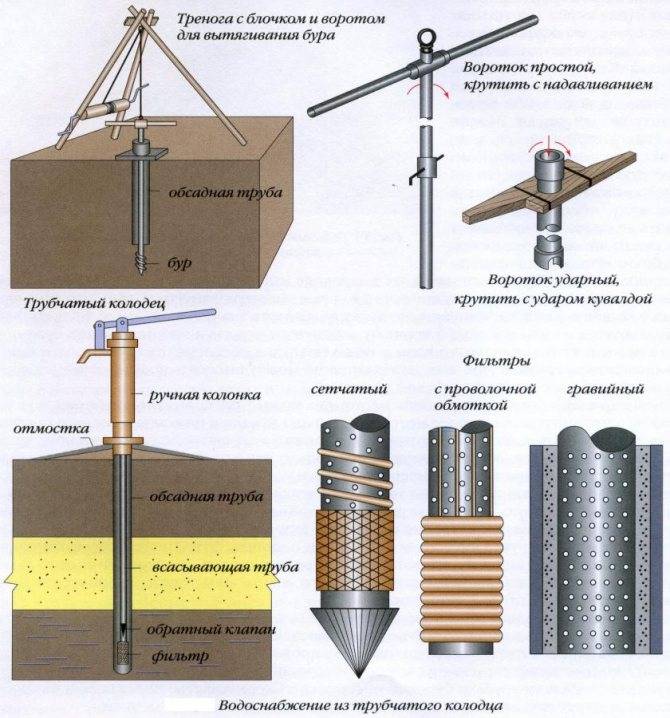

In manual rotary drilling, the following equipment is used:

- drilling rig,

- winch

- drill rods,

- casing pipes and the drill itself.

The tower and the winch provide lifting of the drill and its descent together with the rods (drill string). Here you can also use a tripod as a tower. Pipes are connected to each other - they form drill rods; the drill is attached to the bottom. When using a spoon drill, the casing is installed in the process; such a drill freely passes through it. When using a spiral drill, it is periodically removed and freed from the soil, disassembling the drill string, and then reassembling it. The occupation is not easy, but it is possible to pass through clay or gravel layers only with a spiral drill (“spoon” will not take gravel).

Another manual method is drilling with a garden drill, which is built up along the way with the same drills. The crushed rock is brought to the surface by an auger (a drill of a special design: the cutter destroys the rock, the blades feed it up). With this method, a tower is not required, and a garden drill is powered by a simple engine, greatly facilitating penetration by reducing the proportion of manual labor. At the end of drilling, a 10-meter pipe (several connected) is placed in the well and driven into the sand. When using the mechanical method, exploratory wells are drilled with an auger, obtaining a core directly in the process of passage.

DIY drilling methods

There are several ways in which you can get to the aquifer:

- auger drill - as it deepens into the earth, it is built up with new sections of a metal pipe;

- bailer - a device with sharp teeth at the end and a valve that prevents the earth from spilling back into the mine;

- using soil erosion - hydraulic method;

- "needle";

- percussion method.

Using auger drilling technology, it is possible to dig a well up to 100 meters deep. It is difficult to do this manually, therefore, stationary electrical installations are used, and the drill is built up with new sections as it deepens. Periodically it is raised to pour out the soil. To prevent the walls from crumbling, a casing pipe is laid after the drill.

If the drill cannot be built up, a bailer with sharp edges is attached to its base and the drill screws it in a few meters deeper. Next, the pipe is lifted and the accumulated soil is poured out.

The work with the auger can be done on soft ground. Rocky terrain, clay deposits and club mosses are not suitable for this method.

The bailer is a metal pipe with solid steel teeth soldered at the end. A little higher in the pipe there is a valve that blocks the exit to the ground when the device is lifted from a depth. The principle of operation is simple - the bailer is installed in the right place and manually turned, gradually deepening into the soil. The method takes more time than using electrical equipment, but it is economical.

The device needs to be periodically lifted and poured out of the earth from the pipe. The deeper the pipe goes, the harder it is to lift it. In addition, scrolling requires the use of brute force. Most often there are several people working. To make the soil easier to drill, it is washed out with water, pouring it from above into the pipe using a hose and a pump.

Percussion drilling is the oldest method still in use today. The principle is to lower the metal cup into the casing and gradually deepen the well. For drilling, you need a frame with a fixed cable. The method requires time and frequent lifting of the working pipe to pour the soil. To facilitate the work, use a hose with water to erode the soil.

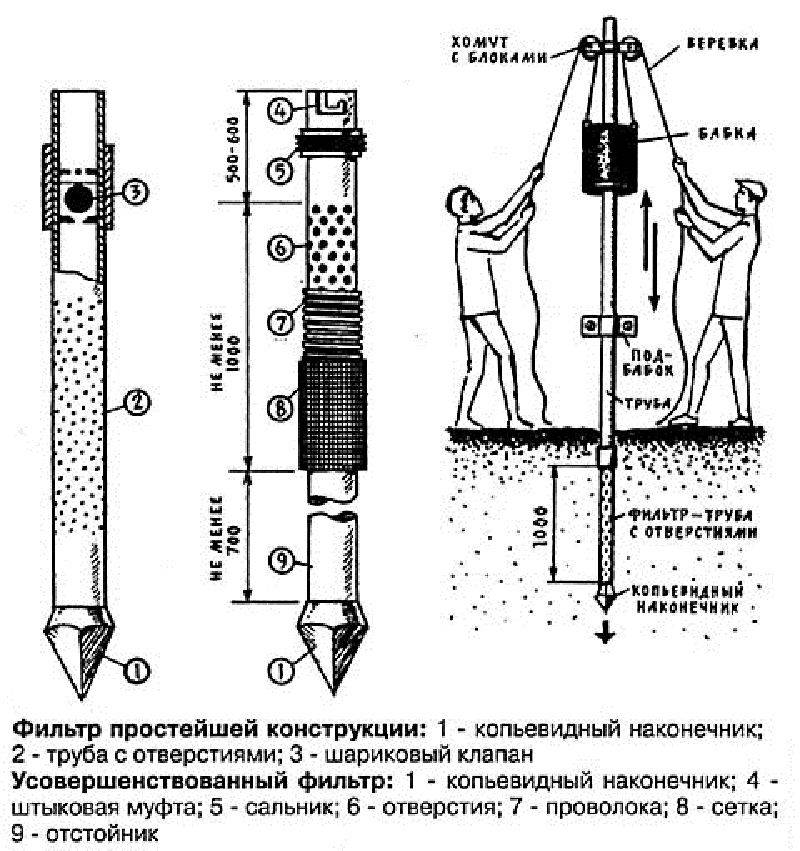

The "needle" method for the Abyssinian well: when the pipe is lowered, the soil is compacted, so it is not thrown to the surface. To penetrate the soil, a sharp tip made of ferroalloy materials is needed. You can make such a device at home if the aquifer is shallow.

The method is cheap and time consuming. The disadvantage is that such a well will not be enough to provide a private house with water.

What sources underground

Geological sections for land plots are not the same, but there are patterns in aquifers. With a deepening from the surface into the subsoil, underground water becomes cleaner. Water intake from the upper levels is cheaper, it is used by owners of private housing.

Verkhovodka

A water resource located in the ground near the surface above a water-resistant layer of rocks is called a perch. Waterproof soils are not available in all areas; it is not always possible to find a suitable site for organizing a shallow water intake. There is no filtration layer above such lenses, harmful substances, organic and mechanical impurities penetrate the soil with rain and snow and mix with the underground reservoir.

Verkhovodka is characterized by such indicators:

- Depth.On average 3-9 m depending on the region. For the middle lane - up to 25 m.

- The reservoir area is limited. Manifestations are not found in every locality.

- Replenishment of reserves is carried out due to precipitation. There is no water inflow from the underlying horizons. During dry periods, the water level in wells and boreholes drops.

- Use - for technical needs. If there are no harmful chemical contaminants in the composition, the water is improved to drinking water by the filtration system.

Verkhovodka is well suited for watering the garden. When drilling shallow wells, you can save money: sinking is available for self-execution. Option - the device of the well with the strengthening of its walls with concrete rings. It is not recommended to take water from the upper deposits, if fertilizers are used near the land plot, an industrial zone is located.

Primer

Verkhovodka is a disappearing resource, unlike the primer, which is the first permanent underground reservoir. The extraction of perched water from the bowels is carried out mainly by means of wells; wells are drilled to take the primer. These types of groundwater have similar characteristics in terms of depth −

Ground features include:

- The filter layer of rocks. Its thickness is 7-20 m, it extends directly to the layer located on the impervious platform of the rocky ground.

- Application as drinking water. Unlike top water, for which a multi-stage cleaning system is used, the removal of mechanical impurities from the primer is done by a downhole filter.

Groundwater recharge is stable in forested and temperate regions.In dry areas, moisture can disappear in summer.

Sources between layers

Groundwater scheme.

The name of the second permanent source of water is the interstratal aquifer. Sand wells are drilled at this level.

Signs of lenses interspersed with rocks:

- pressure water, because it takes on the pressure of the surrounding rocks;

- there are several productive water carriers, they are dispersed in depth in loose soils from the upper waterproof layer to the lower underlying cushion;

- Stocks of individual lenses are limited.

The quality of water in such deposits is better than in the upper levels. The depth of distribution is from 25 to 80 m. From some layers, springs make their way to the earth's surface. Groundwater exposed at great depth due to the stressed state of the liquid rises along the wellbore to its usual proximity to the surface. This allows for water intake by a centrifugal pump installed at the mouth of the mine.

The interstratal variety of groundwater is popular in the arrangement of water intakes for country houses. The flow rate of a sand well is 0.8-1.2 m³/hour.

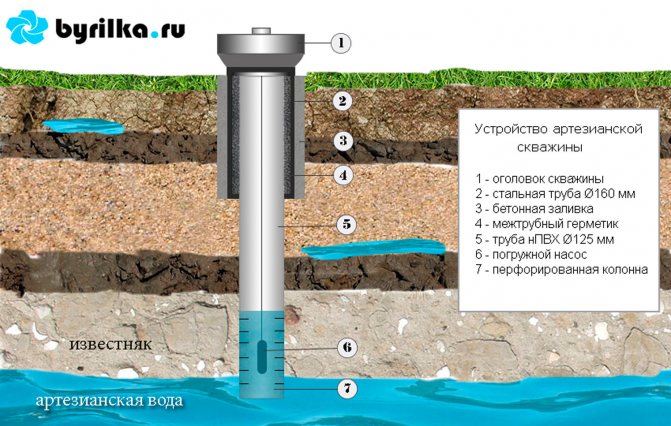

Artesian

Other features of artesian horizons are:

- High water yield - 3-10 m³ / hour. This amount is enough to provide several country houses.

- Purity of water: penetrating into the bowels through multi-meter layers of soil, it is completely freed from mechanical and harmful organic impurities. The enclosing rocks determined the second name of water intake workings - wells for limestone. The statement refers to porous varieties of stone.

On an industrial scale, the extraction of artesian moisture is carried out for commercial purposes - for the sale of drinking water. In areas located in lowlands, it is possible to find a pressure deposit at a depth of 20 m.

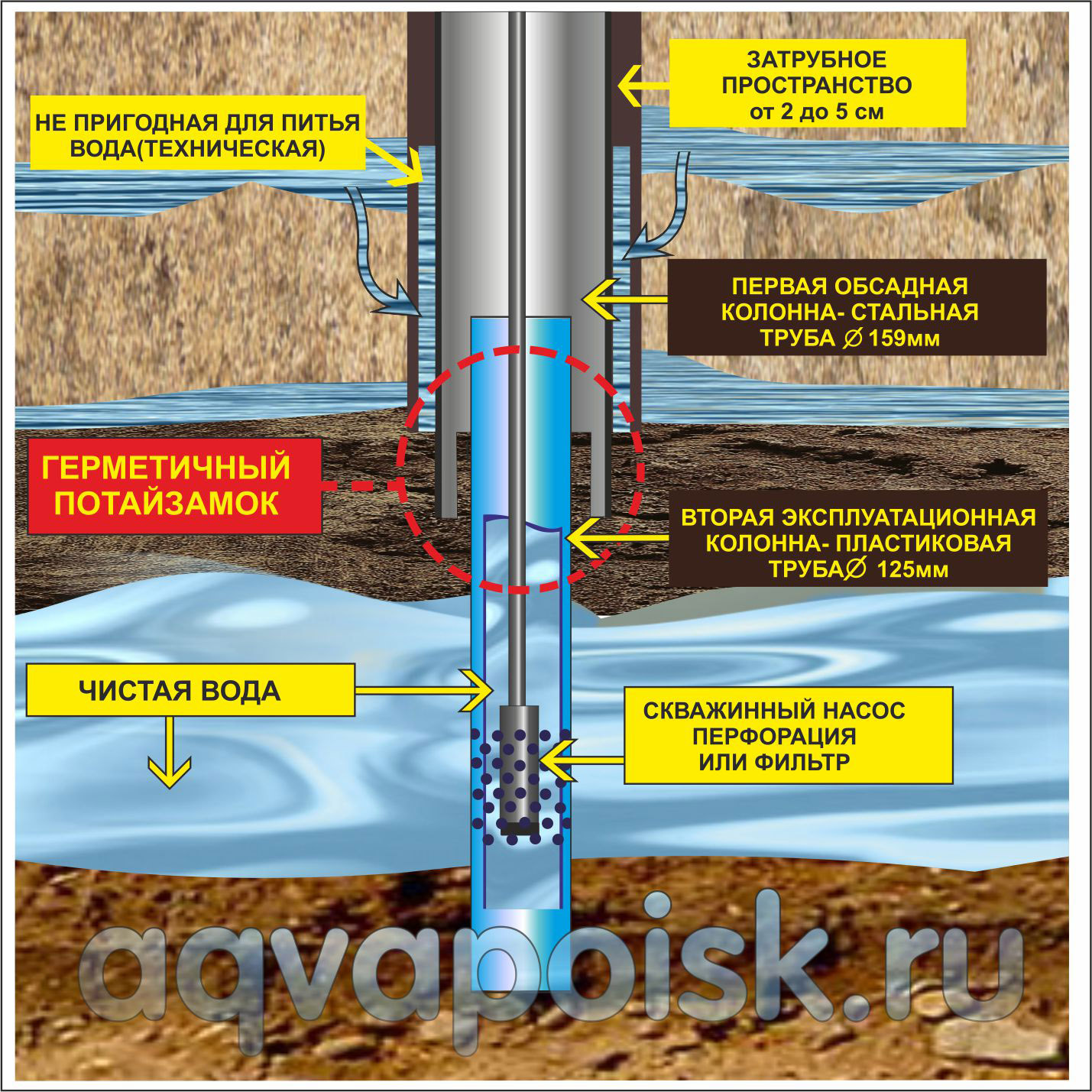

How to equip a punched well

For seasonal water supply in the country, you can get by with a more modest set:

- vibration pump;

- check valve, which is installed in front of the pump;

- water container;

- watering hose;

- taps, etc.

Please note that the check valve is installed in front of the pump, and not at the end of the hose submerged into the well. Just like that, this very hose will not break during frosts. Another plus of such a device is that it is easier to dismantle for the winter.

Another plus of such a device is that it is easier to dismantle for the winter.

Another tip: the well must be closed with something. In permanent residences, a caisson is made - a concrete or plastic bunker, which is located below the freezing depth. It contains all the equipment. When using water only periodically, the caisson is too expensive. But something needs to close the well. Firstly, some kind of living creature may fall into it, which will not please you in any way. Secondly, "good" neighbors can drop something. A more budgetary way out is to build a house like a well. An even cheaper option is to dig a pit, beat it with a board, and make a wooden cover. Key point: all this should be locked.

Drilling Options

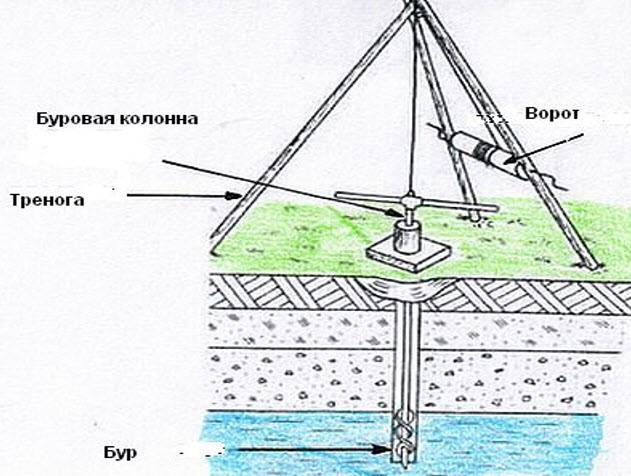

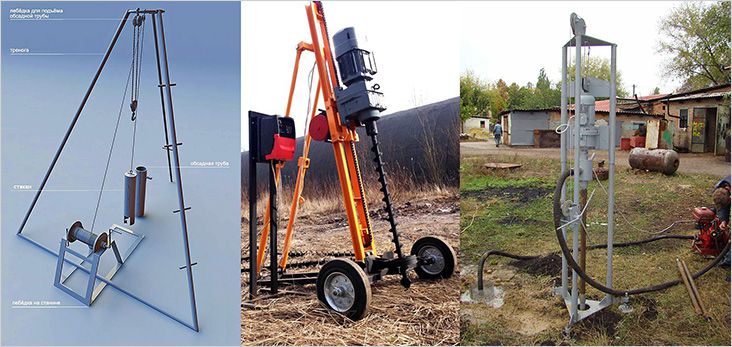

Tripod

new entries

Chainsaw or electric saw - what to choose for the garden? 4 mistakes when growing tomatoes in pots that almost all housewives makeSecrets of growing seedlings from the Japanese, who are very sensitive to the land

The tripod can be made of wood (knots are not allowed) or a profile pipe. The length of the pipe or beam should be about 4.5-5.5 m.

Then a mechanical winch with a cable is fixed to the tripod, where the drill glass is attached.

This drilling rig is quite small and has a sufficient margin of safety. The principle of operation of the mechanism is quite simple: the glass, sinking into the ground, absorbs the soil. Taking into account the composition of the soil in one blow, you can get 0.30-1.2 m of land. You can simplify the work by pouring water into the drilling site. Periodically, the drill glass must be cleaned of stuffed earth.

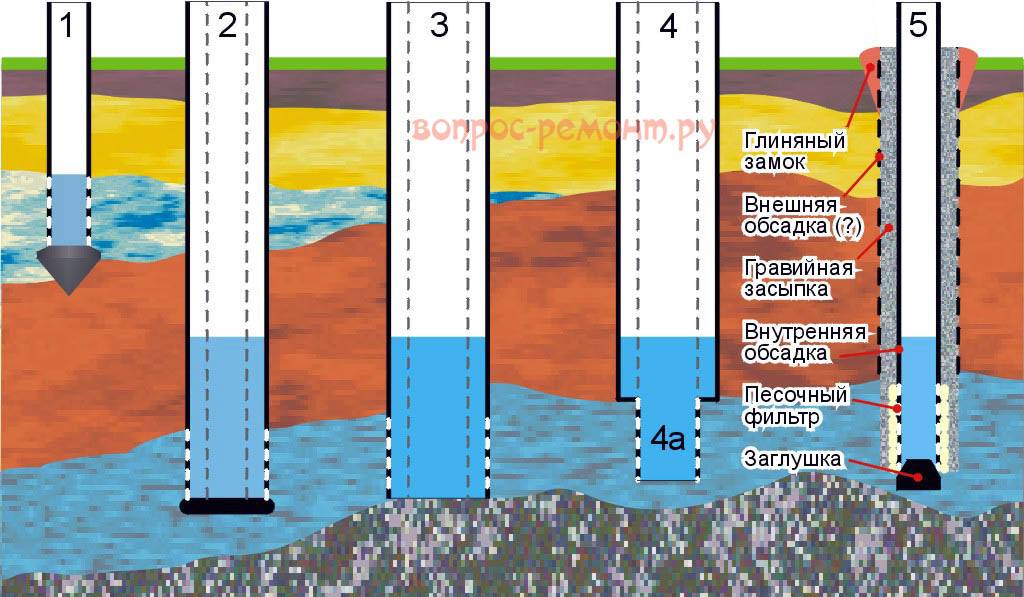

The casing pipe can be installed simultaneously with the passage to the depth or after all the work done.

Drill and casing

its diameter must be greater than the size of the drill

When doing work, it is necessary to constantly monitor the humidity of the earth being removed so as not to miss the aquifer (otherwise it can simply be closed with a pipe).

Then, when an aquifer is found, the dirty water must be pumped out to determine if there is enough water in that layer. What is a manual or submersible pump used for? If, after pumping out several buckets of dirty water, clean still has not gone, then it is necessary to drill further to a more capacious core.

Distinctive features of the method

The use of wells as an autonomous source of drinking water is quite an old and proven method. Along with traditional, sometimes expensive technologies, the hydrodrilling method can be deservedly called economical and versatile.

Popular well drilling methods are discussed in our other article.

This fairly simple way to drill a well has some nuances, ignoring which can nullify all your efforts.Its essence lies in an integrated approach.

from A specific feature of hydraulic drilling is that the destroyed rock is removed not with a drilling tool, but with a pressure jet of water. Simultaneously with the drilling process, the working is flushed, which reduces the stages of work before putting it into operation drilling tool Water from the mine is drained through a hose into a sump. After settling in a container and settling to the bottom of the soil particles, the water is used again. A high drilling rig is not needed for hydraulic drilling. A mini machine is quite suitable, because. there is no need to extract from the bore of the drill string. In self-made machines, water is supplied to the drill through the cavity of the rod column. A weighty disadvantage of hydraulic drilling is the dirt and slush that accompanies the work. In order not to dilute it, you should prepare a couple of containers for water or dig deepenings. Water should be supplied to the pit with good pressure, therefore, before starting drilling, you should stock up on sufficiently powerful equipment. workHomemade drilling rigPerceptible disadvantages of hydrodrillingEquipment for water injection

Two main processes are combined here - this is the direct destruction of rocks by a drilling tool and the washing out of drilled soil fragments with a working fluid. That is, the rock is affected by the drill and water pressure.

The load required for immersion in the ground is given by the weight of the drill rod string and special drilling equipment that pumps flushing fluid into the body of the well being formed.

The washing solution is a mixture of the smallest particles of clay and water. Close it in a consistency slightly thicker than pure water. A motor-pump takes the drilling fluid from the pit and sends it under pressure to the wellbore.

The simplicity of the hydraulic drilling method, the availability of technology and the speed of execution have made it so popular among independent owners of suburban areas.

Water in the hydrodrilling scheme performs several functions simultaneously:

washes out drilled particles of destroyed soil;

brings the dump to the surface along with the current;

cools the working surfaces of the drilling tool;

when moving, it grinds the inner surface of the well;

strengthens the walls of the well that are not fixed by casing, reducing the risk of collapse and filling with a moldboard.

As the drill string is deepened, it is increased with rods - sections of the VGP pipe 1.2 - 1.5 m long, Ø 50 - 80 mm. The number of extended rods depends on the depth of the water carrier. It can be determined in advance during the farrowing of neighbors in order to mark the water mirror in their wells or wells.

The estimated depth of the future well is divided by the length of one rod to calculate how many pieces need to be prepared for work. On both ends of each rod, it is necessary to make a thread for making up the working string.

One side must be equipped with a coupling, which is desirable to be welded to the rod so that it does not unscrew in the barrel.

Hydrodrilling technology allows you to arrange a source of technical water in the country without the involvement of a drilling team

In practice, hydrodrilling in its pure form is rarely used, because a large pressure of water is needed. It is also difficult to drill dense clay layers. More often produce hydrodrilling with a burner.

This method is somewhat similar to rotary drilling, but without a rotor. For better centering of the well and easy overcoming of tight areas, a petal or cone-shaped drill is used.

Hydrodrilling is not suitable for driving through rocky and semi-rocky soils. If sedimentary rocks in the drilling region are crushed stone, pebbles, sands with a large inclusion of boulders, this method will also have to be abandoned.

It is technically impossible to wash and lift heavy stones and fragments of heavy rocks from the well with water.

The addition of an abrasive to the working fluid increases the rate of penetration by increasing the destructive effect

buildup

A drilled well will not yet give water in the required quantity and quality. To do this, it is necessary either to open the aquifer, or to shake the well. Opening the reservoir allows you to get drinking water during the day. It requires a large amount of clean water, complex and expensive equipment. For your information: opening is carried out by direct and reverse methods. In the direct case, water is pumped under pressure into the casing and the drilling fluid is pumped out of the annulus. In the reverse, water is fed by gravity "by the pipe" and the solution is pumped out of the barrel. Direct opening is faster, but it disrupts the reservoir structure more and the well serves less. The opposite is the opposite.Keep in mind when negotiating with drillers if you order a well.

The buildup of the well takes several days, but can be done with a conventional household submersible centrifugal pump; vibrating is not suitable for the reasons indicated above. For buildup, first, the silt is removed from the well with a bailer; how to work with a bailer, you can see in the video below:

Video: cleaning (buildup) of the well with a homemade bailer

The rest is easy: the water is completely pumped out each time it is enough to cover the pump. It is useful to raise and lower it several times on the cable before turning it on in order to stir up the residual sludge. The buildup can be done with a manner, but you can scoop up, and it will take about two weeks.

The buildup of the well is considered complete when the transparency of the water rises to 70 cm. clean barrel. When the edges of the disk begin to blur during immersion - stop, already opacity. You need to look at the disk strictly vertically. Upon reaching transparency, the water sample is handed over for analysis and, if everything is OK, the annular space is concreted or closed with clay, and a filter is installed.