- What sources underground

- Verkhovodka

- Primer

- Sources between layers

- Artesian

- Types of wells

- Determining the quality of water

- How to drill a well

- What to drill

- Types of wells

- 3 Drilling by hand - how and with what tool

- Drilling methods

- Casing installation

- Options for autonomous water supply from a well

- How to make a filter well

- DIY drilling methods

- We select pipes

What sources underground

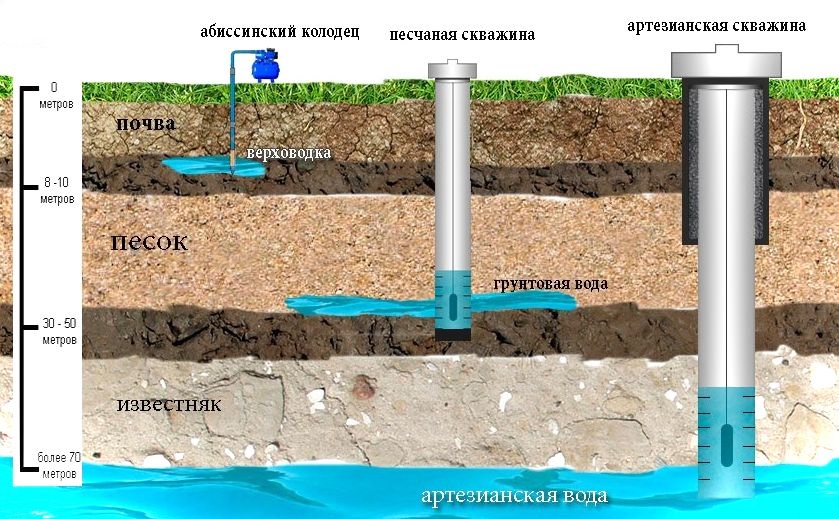

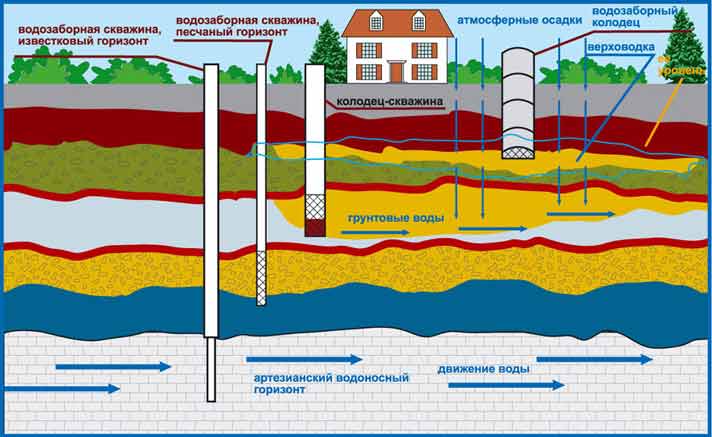

Geological sections for land plots are not the same, but there are patterns in aquifers. With a deepening from the surface into the subsoil, underground water becomes cleaner. Water intake from the upper levels is cheaper, it is used by owners of private housing.

Verkhovodka

A water resource located in the ground near the surface above a water-resistant layer of rocks is called a perch. Waterproof soils are not available in all areas; it is not always possible to find a suitable site for organizing a shallow water intake. There is no filtration layer above such lenses, harmful substances, organic and mechanical impurities penetrate the soil with rain and snow and mix with the underground reservoir.

Verkhovodka is characterized by such indicators:

- Depth. On average 3-9 m depending on the region.For the middle lane - up to 25 m.

- The reservoir area is limited. Manifestations are not found in every locality.

- Replenishment of reserves is carried out due to precipitation. There is no water inflow from the underlying horizons. During dry periods, the water level in wells and boreholes drops.

- Use - for technical needs. If there are no harmful chemical contaminants in the composition, the water is improved to drinking water by the filtration system.

Verkhovodka is well suited for watering the garden. When drilling shallow wells, you can save money: sinking is available for self-execution. Option - the device of the well with the strengthening of its walls with concrete rings. It is not recommended to take water from the upper deposits, if fertilizers are used near the land plot, an industrial zone is located.

Primer

Verkhovodka is a disappearing resource, unlike the primer, which is the first permanent underground reservoir. The extraction of perched water from the bowels is carried out mainly by means of wells; wells are drilled to take the primer. These types of groundwater have similar characteristics in terms of depth −

Ground features include:

- The filter layer of rocks. Its thickness is 7-20 m, it extends directly to the layer located on the impervious platform of the rocky ground.

- Application as drinking water. Unlike top water, for which a multi-stage cleaning system is used, the removal of mechanical impurities from the primer is done by a downhole filter.

Groundwater recharge is stable in forested and temperate regions. In dry areas, moisture can disappear in summer.

Sources between layers

Groundwater scheme.

The name of the second permanent source of water is the interstratal aquifer. Sand wells are drilled at this level.

Signs of lenses interspersed with rocks:

- pressure water, because it takes on the pressure of the surrounding rocks;

- there are several productive water carriers, they are dispersed in depth in loose soils from the upper waterproof layer to the lower underlying cushion;

- Stocks of individual lenses are limited.

The quality of water in such deposits is better than in the upper levels. The depth of distribution is from 25 to 80 m. From some layers, springs make their way to the earth's surface. Groundwater exposed at great depth due to the stressed state of the liquid rises along the wellbore to its usual proximity to the surface. This allows for water intake by a centrifugal pump installed at the mouth of the mine.

The interstratal variety of groundwater is popular in the arrangement of water intakes for country houses. The flow rate of a sand well is 0.8-1.2 m³/hour.

Artesian

Other features of artesian horizons are:

- High water yield - 3-10 m³ / hour. This amount is enough to provide several country houses.

- Purity of water: penetrating into the bowels through multi-meter layers of soil, it is completely freed from mechanical and harmful organic impurities. The enclosing rocks determined the second name of water intake workings - wells for limestone. The statement refers to porous varieties of stone.

On an industrial scale, the extraction of artesian moisture is carried out for commercial purposes - for the sale of drinking water. In areas located in lowlands, it is possible to find a pressure deposit at a depth of 20 m.

Types of wells

Drilling a well in the country is not so difficult. Its price will depend on the depth of the water. A sand well will be much cheaper than an artesian well, and this should also be taken into account.

Well on the sand

Done to a great depth. Therefore, it is quite possible to do all the work with your own hands and this will significantly reduce the cost of your venture. Before starting work, you should find out what quality the water is at a shallow depth. To do this, it is best to take a sample from the neighbors and take it for examination and check the quality. We will give the parameters below.

Suitable for the place where you live permanently. This water is of better quality. But the work will cost more. Here it would be better to hire a specialized organization. And immediately it will be necessary to provide for its cleaning. It is located in lime layers and therefore has a high iron content. Immediately provide for proper filtering.

Attention: If you do not live permanently in the country and you only need water for irrigation, then you can safely make such a design

Determining the quality of water

Water in a well or well is considered drinking water in the following cases:

- When the water is clear thirty centimeters deep;

- When nitrate impurities do not exceed 10 mg/l;

- When one liter of water contains no more than 10 Escherichia coli;

- When the taste and smell on a five-point scale, water is estimated at least three points.

To determine these indicators, water must be subjected to laboratory analysis in the sanitary and epidemic service.

How to drill a well

Let's analyze this process from a theoretical point of view:

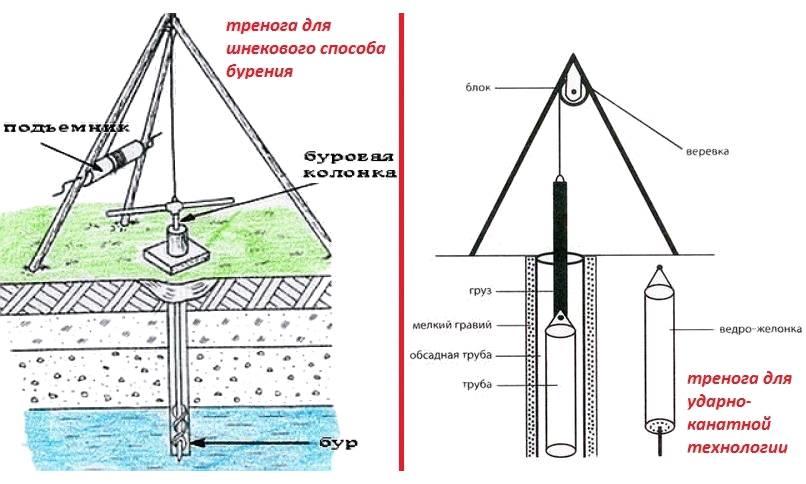

- Work begins with digging a hole, whose depth and diameter must be at least two meters, or a side of one and a half meters.This measure prevents further shedding of the soil of the upper layer.

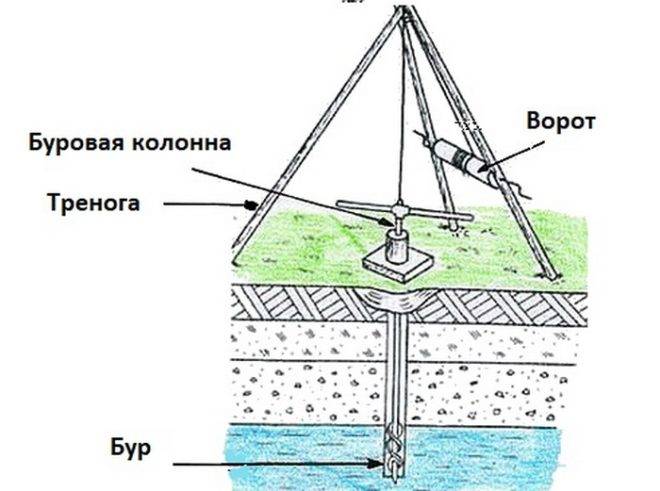

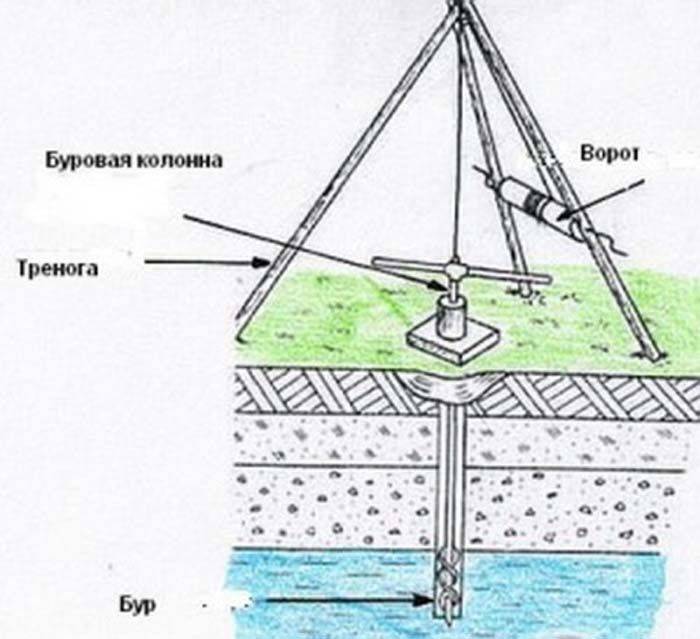

- The pit is strengthened with plank shields. Further, with the help of a column and a drilling rig, a well is drilled. The drill column is suspended on a tower at the central point of the future well.

- The drill string consists of several rods, which, with the help of adapter sleeves, are lengthened during the drilling process. The drill head is mounted at the end of the column.

- The tower is mounted from logs, steel pipes, a channel or a corner, which are made into a tripod, at the top of which a winch is attached.

Attention: If the water is shallow, drilling can be done without a tower. In this case, special shortened rods one and a half meters long are used. If you cannot do without a tower during drilling, the length of the rods in this case should be at least three meters

If you cannot do without a tower during drilling, the length of the rods in this case should be at least three meters.

What to drill

The equipment and method of drilling is selected based on the type of soil. The tool used must be made of carbon steel.

We select tools and materials

Drilling is carried out using the following drill heads:

- For drilling in clay soils, a drill is used in the form of a spiral with a base of 45-85 mm and a blade 258-290 mm long.

- In percussion drilling, a drill bit is used. The drill can have a flat, cruciform and other shapes.

- Drilling in loam, sandy clay or clayey sand is carried out using a spoon drill made in the form of a spoon and having a spiral or longitudinal slot.This drill has a diameter of 70-200 mm and a length of 700 mm and deepens for a passage of 30-40 cm.

- Extraction of loose soil is carried out with the help of a drill-bailer using the impact method. The bailers are made from a three-meter pipe and have a piston and ordinary appearance. Inside the bailer should have a diameter of 25-96 mm, outside 95-219 mm, its weight should be 89-225 kg.

Drilling is a cyclic process, periodically accompanied by cleaning of the drilling tool from the soil. Cleaning is carried out with the complete extraction of the drill from the soil. Accordingly, the difficulty of extracting them from the well depends on the length of the hose.

Types of wells

Before you start work, you need to choose the appropriate type of well. In accordance with how deep the water layer lies, there are three main types of penetrations:

- Abyssinian well.

- Filter well.

- Artesian well.

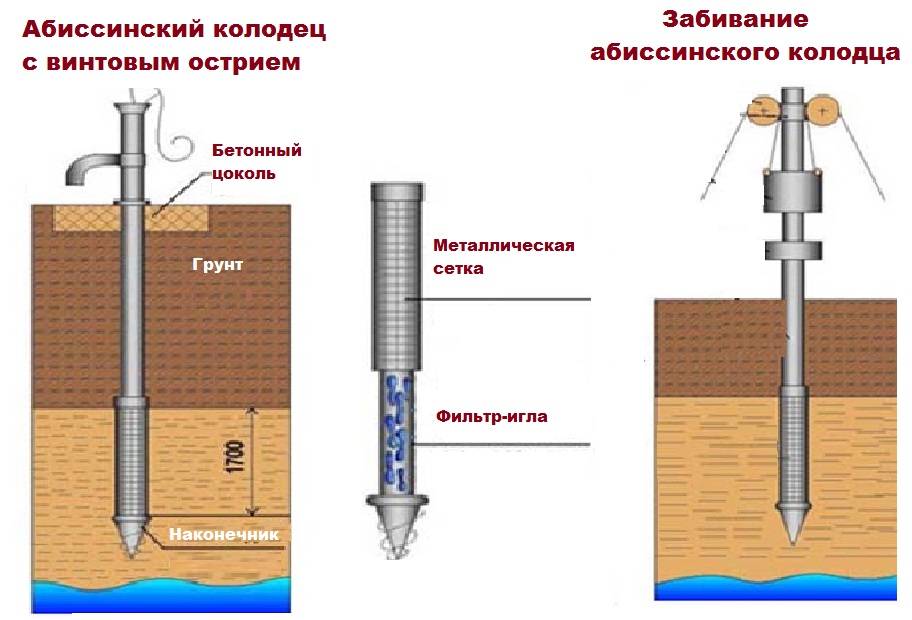

Now let's look at the features of each development. The Abyssinian well is a simplified version of penetration, which can be drilled almost anywhere. A significant disadvantage of such a well is the relatively low quality of the water. Most often it is used for irrigation or other similar needs. Such water is not suitable for consumption or can be used only after multi-level purification. This is due to the fact that waters lying at shallow depths are fed by precipitation and contain harmful impurities.

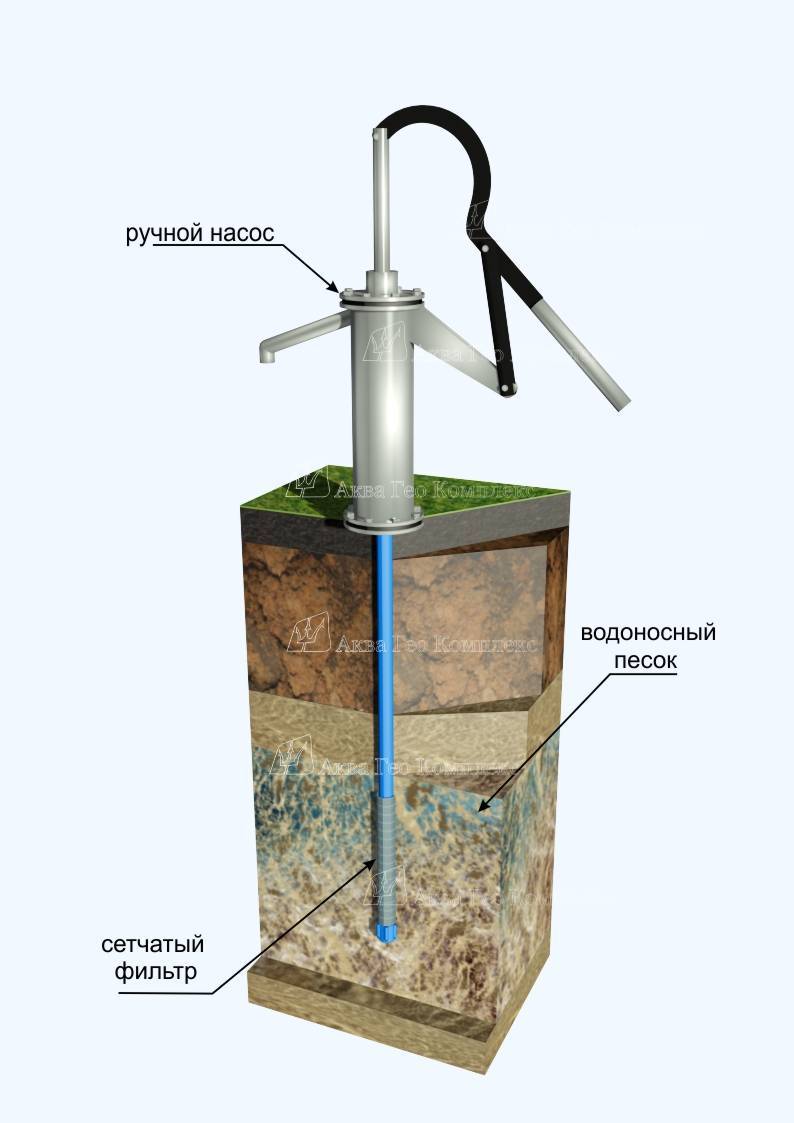

Regardless of the type of well, a pump is mandatory

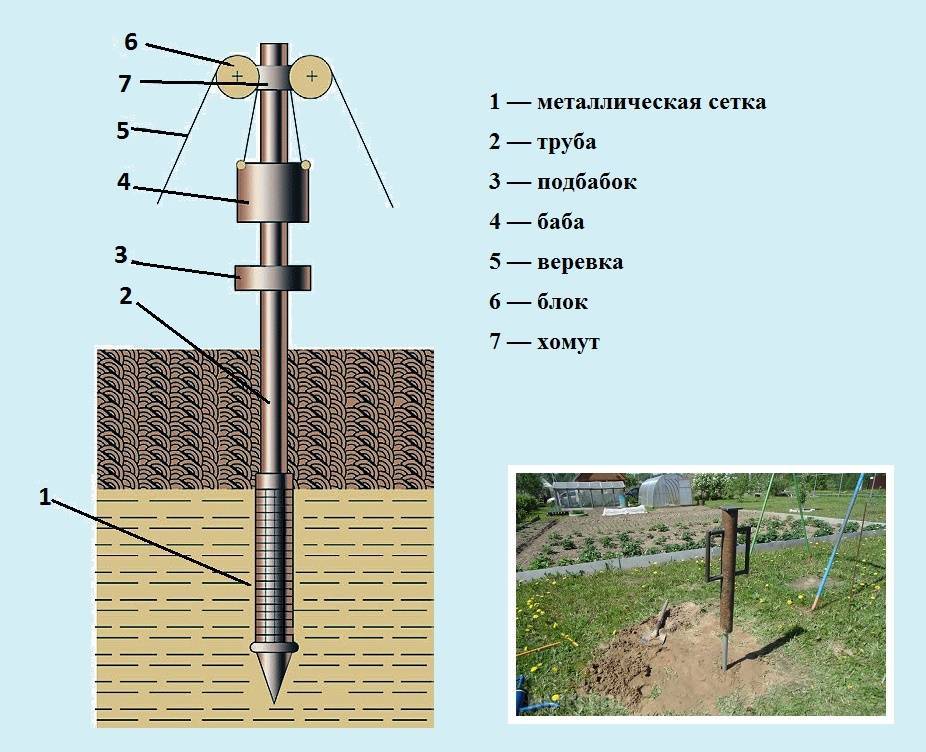

To prepare the Abyssinian well, which is often referred to as a well-needle, the driving technology is more often used, which cannot be used to work on other types of penetrations.If you have the necessary equipment and assistants, you can complete the work on the manufacture of such a well within one day.

Before you drill a well with your own hands, it is recommended to calculate in advance what kind of water supply is needed. For example, if you need to provide a house, a bathhouse, or other outbuildings, it is better to opt for a filter well - its flow rate is sufficient, and drilling such a penetration is relatively simple. The depth of the water layers in this case is from 20 to 30 meters.

Artesian springs are called the best option - they do not silt up, since the water is contained in rock crevices, does not contain harmful impurities, does not need to be filtered and is completely drinkable. Its only drawback is the depth of water, which can range from 30 to 100 or more meters. Probably, almost everyone is now thinking about how to drill a well under water with their own hands, given such a significant depth. Unfortunately, in no way, this type of well is given here only as an example; it is impossible to get to artesian waters through artisanal methods.

Artesian well

3 Drilling by hand - how and with what tool

For self-drilling, the following methods are used:

- rotary - a tool in the form of an auger bites into the ground during rotation;

- percussion - they strike the bar, deepening it into the rock;

- percussive rotational - the pipe with a drill at the end is lifted and lowered with force, achieving loosening of the soil, rotated, gaining rock;

- rope-impact - on the rope they raise and lower the tool several times, which takes the rock.

The development of wells by all of the above methods is carried out dry, but sometimes water is used, pouring it into the well to increase the permeability of the rock. Only in percussion drilling is the process continuous, since the entire tool remains in the hole and begins to play the role of a well. Other methods require constant lowering and raising in order to select the rock from the projectile. At one time it is impossible to go more than the length of the drill, otherwise it will not be possible to pull it out. Even drilling with an auger does not allow you to go more than one and a half meters at a time, otherwise you will have to leave it in the ground.

The auger is used for rotary drilling of common rocks: earth, slightly wet sandy loam, soft clay, loam. You can make it yourself. We weld a sharp tip to a thick-walled pipe from one end. We cut the disk of circular heat in half, sharpening at the place of the cut on each half. After 125 mm from the tip, we weld the halves of the disk opposite each other to the pipe, maintaining an angle of 70 ° with respect to the longitudinal axis of the rod. At the top of the rod for its extension, we install a threaded sleeve.

The drill nozzle is used to pass through sticky, cohesive rock in a cable-impact way where the auger tool gets stuck. It is straight and conical, extended downwards. The conical expansion increases the diameter of the trunk. For the manufacture of a drill glass, we take a pipe with walls of 2 mm. The diameter is selected based on the required size of the well. From above we weld a blind cover, to it - a connecting element for fastening the rod. We sharpen the lower part, directing the sharpening inward. Instead of solid sharpening, you can cut the teeth and sharpen. In the side wall we make holes for excavation of the rock.

Also, a bailer is used for cable-percussion drilling of loose and loose rocks with water. This is a two-meter pipe with a valve at the bottom, and at the top with a mount for the rod. The fastening is performed so that the bailer can be rotated to remove the rock. The valve is usually flat steel plate with a rubber seal. Upon impact, it opens and passes the rock into the glass. When lifting, it keeps it inside the bailer, through which the projectile is cleared of the contents.

For rocks made of clay or sand that do not crumble, a drill-spoon was invented. The movement of the drill is rotational or shock-rotational. The soil is cut with two cutting edges - bottom and side, is collected in a cylinder. We take a thick-walled pipe, in which we make cuts along the axis on both sides. We bend them to form cutting side edges, and bend the lower part inward so that a semblance of an auger comes out. Weld down the center drill diameter up to 36 mm. The vertical bar is welded on top with a 15 mm offset from the center of the longitudinal axis.

A drill is used for percussive drilling.-needle. It is possible to use in sandy and loose rocks for the arrangement of the Abyssinian well. We weld a sharp tip to a thick-walled pipe from one end. After 30 cm up to a length of 1 m throughout the pipe, we drill holes with a diameter of 5 mm with a step in a row and between rows of 5 cm. We wind and fasten a fine mesh over the holes and fix it - we got a device for filtering. To build up the rod, we provide a threaded fastening using a coupling.

Drilling methods

You can drill wells on your own in the following ways:

- Rotary, or rotary - the drilling tool rotates, biting into the rock;

- Percussion - they hit the drill rod, deepening the drill projectile into the rock, so needle wells are drilled;

- Percussion-rotational - the rod with the drilling projectile is lifted several times and lowered with force, loosening the rock, and then rotated, taking it into the cavity of the projectile, see below;

- Rope-percussion - a special drilling projectile is raised and lowered on a rope, taking the rock with it.

All these methods refer to dry drilling. During hydraulic drilling, the working process takes place in a layer of water or a special drilling fluid that increases the compliance of the rock. Hydrodrilling is not environmentally friendly, requires expensive special equipment and high water consumption. In amateur conditions, it is used in exceptional cases, in an extremely simplified and limited form, see below.

Dry drilling, except for impact drilling without casing, is only intermittent, i.e. the drill has to be lowered into the trunk, then removed from it in order to select the rock from the drill. In professional hydro-drilling, the crushed rock is carried out by the used drilling fluid, but the amateur needs to know for sure: it is impossible to go through the trunk to a depth greater than the length of the working part of the tool in 1 drilling cycle. Even if you drill with an auger (see below), you need to lift it and shake out the rock from the coils after a maximum of 1-1.5 m of penetration, otherwise the expensive tool will have to be given to the ground.

Casing installation

Holding the casing pipe from spontaneous upsetting

An attentive reader may already have a question: how do they put a casing in the barrel? Or, how do they raise / lower the drill, which, in theory, should be wider than it? In professional drilling - in different ways. The oldest is illustrated in Fig.on the right: the axis of rotation of the tool is shifted relative to its longitudinal axis (circled in red), and the cutting part is made asymmetrical. The neck of the drill is made conical. All this, of course, is carefully calculated. Then, in the work, the drill describes a circle that extends beyond the casing, and when lifting, its neck slides along its edge and the drill slips into the pipe. This requires a powerful, precise drive of the drill string and its reliable centering in the casing. As the depth increases, the casing is increased from above. Complex special equipment is not available to amateurs, so they can install casing pipes in the following ways:

- A “bare”, without casing, hole is drilled to the full depth with a drill larger than the casing diameter, and then the casing pipes are lowered into it. So that the whole column does not fall down, they use 2 drilling gates: one is holding the pipe that has already gone into the well, see fig. on the right, and the second is installed on a new one before removing the first. Only then is the column thrown into the trunk, if it itself is no longer moving. This method is often used by amateurs on fairly dense, adhesive (sticky) and cohesive (not loose) soils to a depth of 10 m, but there are no statistics on how many wells collapsed, how many drills and casing were lost.

- The drill is taken with a smaller diameter, and the lower casing pipe is made with divergent sharpened teeth (crown) or equipped with a cutting skirt. Having drilled for 1 cycle, the drill is lifted, and the pipe is forcibly upset; crown or skirt cut off excess soil. This method slows down drilling, because before starting a new cycle, you need a bailer (see.below) to choose crumbled soil, but more reliable, facilitates gravel backfilling of the annulus and allows the use of an external sand filter, see below.

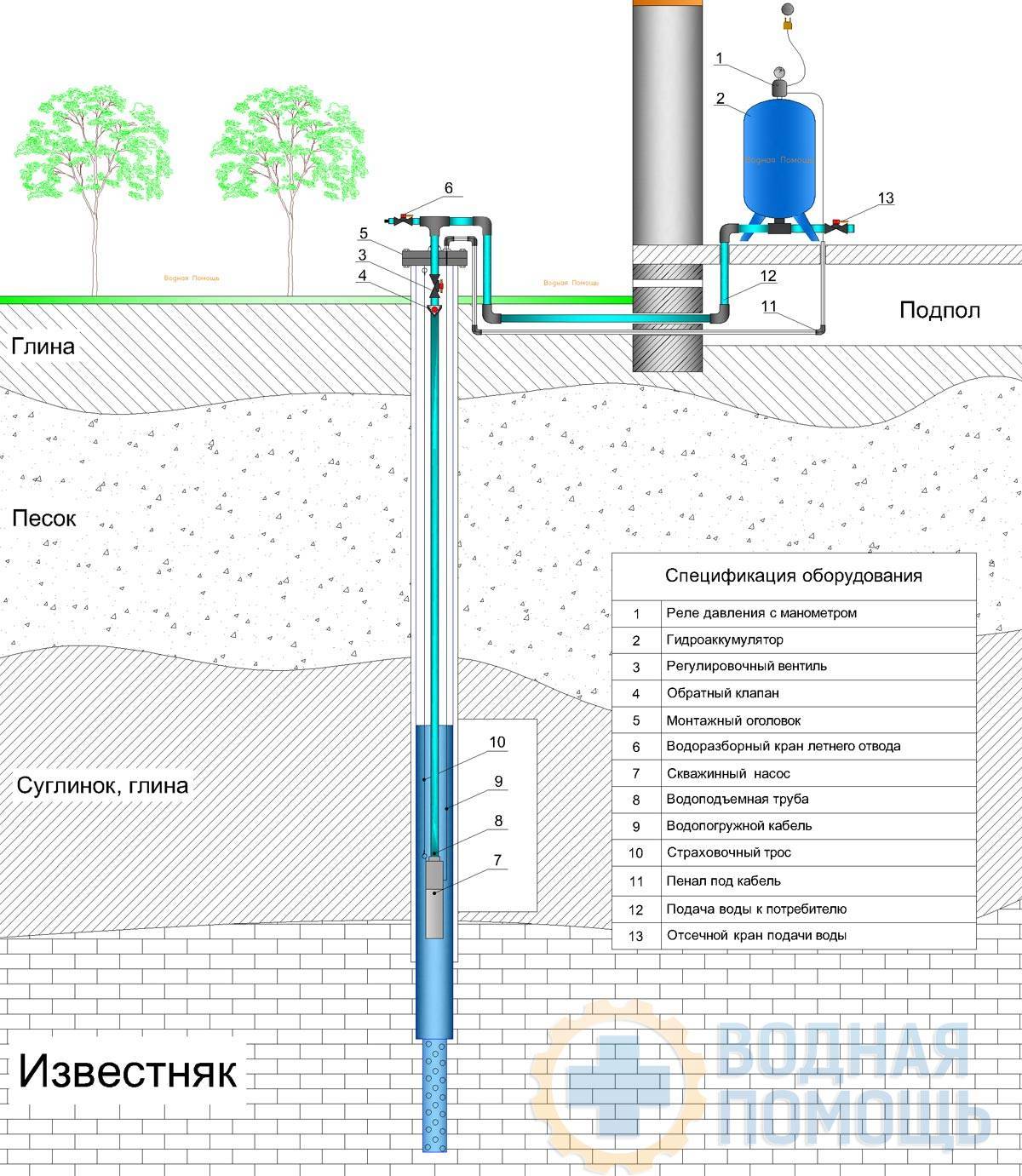

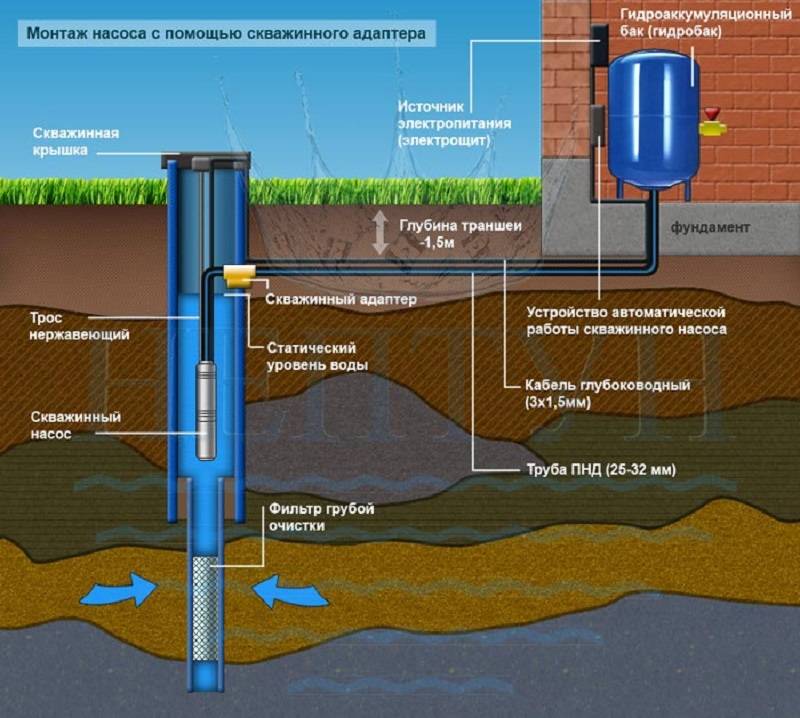

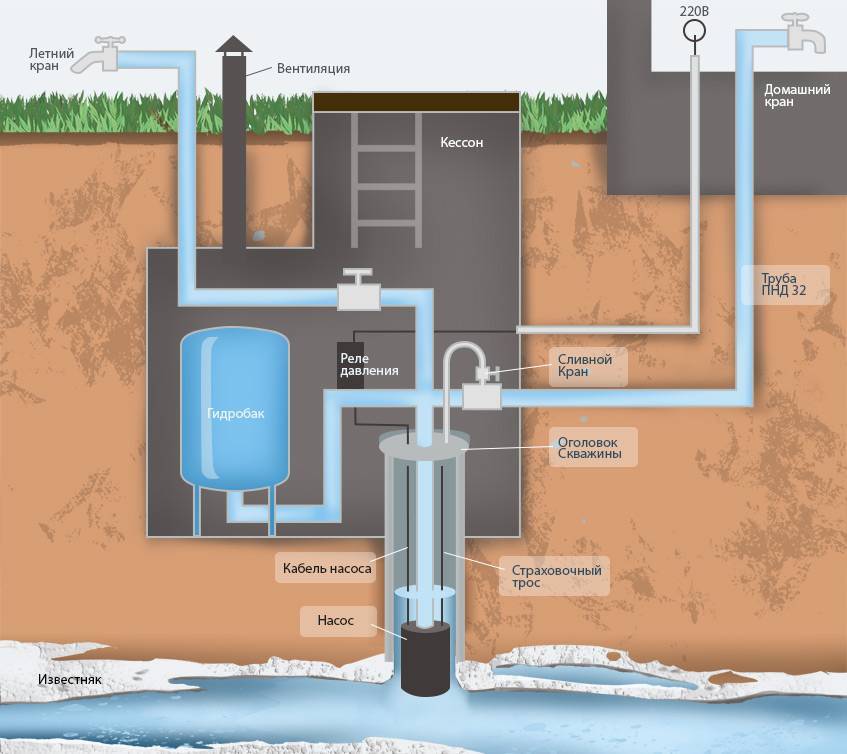

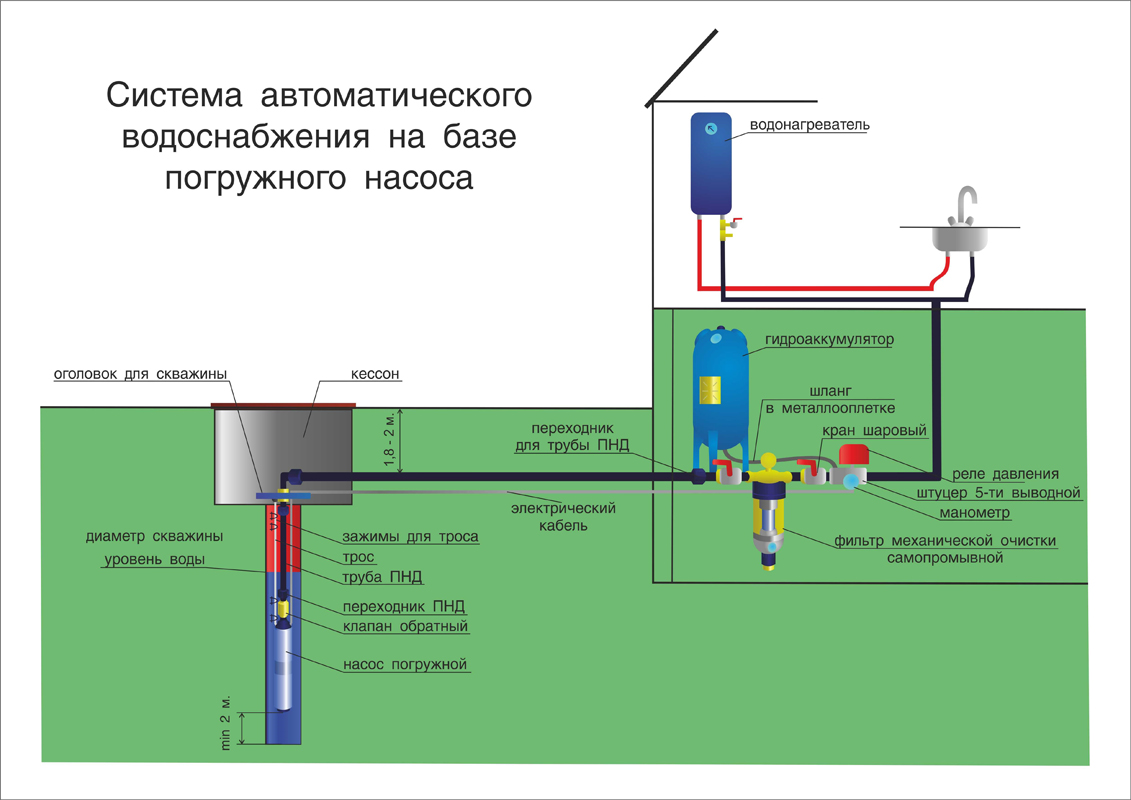

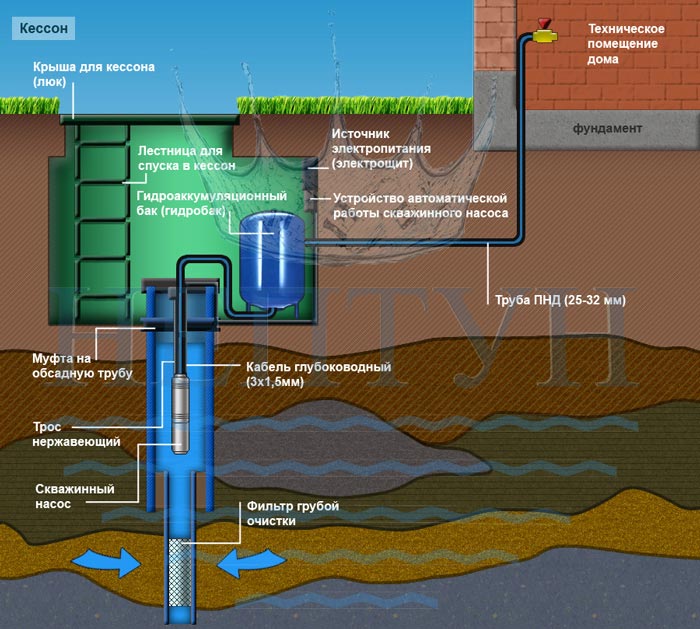

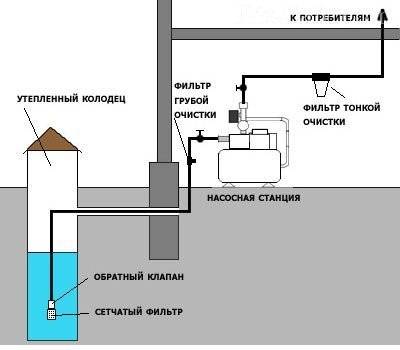

Options for autonomous water supply from a well

Having a shallow well on the site, if the water level in the source allows, a pumping station or a hand pump is installed. The essence of the automated system is that, under the action of a submersible pump, water is pumped into a hydropneumatic tank, the capacity of which can vary from 100 to 500 liters.

When working with a shallow sand well, the best option is to equip an automated water supply system that will ensure uninterrupted water supply to the house.

The water storage tank itself is separated by a rubber membrane and a relay, thanks to which the water pressure in the tank is regulated. When the tank is full, the pump is turned off, if water is consumed, a signal is sent to turn on the pump and pump out water. This means that the pump can work both directly, supplying water to the system, and after reducing the pressure in the system to a certain level, in order to replenish the “reserves” of water in the hydropneumatic tank. The receiver itself (hydraulic tank) is placed in any convenient place at home, most often in the utility room.

From the caisson to the place where the pipe enters the house, a trench is laid, on the bottom of which a water pipe and an electric cable are laid to power the pump. If possible, it is better to purchase a heating electric cable, which, in addition to its direct purpose, will protect the water pipe from freezing.

With this method of water supply, a deep pump pumps water from a well into a storage tank, which is placed on an elevated point in the house.

Most often, a place for arranging a storage tank is allocated in one of second floor premises at home or in the attic. When placing a container in the attic, to prevent freezing of water in the winter months, the walls of the tank must be insulated

Due to the placement of the tank on a hill, the effect of a water tower is created, in which, due to the height difference between the hydraulic tank and the connection points, pressure arises when 1 m of water column is equal to 0.1 atmospheres. The tank can be made of stainless steel or food grade plastic. Capacity - from 500 to 1500 liters. The larger the volume of the tank, the greater the supply of water: in the event of a power outage, it will automatically flow into the tap.

Installing a limit float switch will ensure that the pump is automatically turned on when the water level in the tank drops.

Deep well pumps are used in cases where the distance to the water level in the well exceeds 9 meters or more

When choosing a pump, well productivity should be taken into account. Despite the fact that the power of the unit will only affect the rate of filling the water storage tank, when choosing a unit is better start from the mark of the maximum water flow in the house.

The deep-well pump, together with the electric cable and pipe, is lowered into the well, suspended on a galvanized cable using a winch, which is installed inside the caisson. To maintain the necessary pressure in the system and prevent pumping water back into the well, a check valve is placed above the pump.

After installing all the elements of the system, it remains only to check the internal wiring to the connection points and connect the equipment to the control panel.

The total cost of an automatic water supply system is about $3,000-$5,000. It depends on the depth of the source, the type of pump and the number of water intake points inside the house. From 30% to 50% of this amount goes to the engineering arrangement of the system, the rest of the expenses go to the elements that determine the level of living comfort.

How to make a filter well

The first thing to do before drilling a filter well is to ask nearby neighbors if they have a similar water source. The main thing is to find out from what depth they extract water. If you have to drill more than two dozen meters, you will have to hire a team of professionals or rent special equipment.

In the case of a layer with water at a shallower depth you can use hand tools.

Having chosen a convenient place, remote from heaps of garbage, cesspools and other pollutants, dig a hole 150x150x150 cm. It is recommended to strengthen its walls with sheets of wood or metal.

Winch and tripod for impact driving

Now you need to build a tripod, on which the winch will subsequently be fixed. Below is an instruction on how to build this structure necessary to lift the drill.

Drilling Rig, Well Drilling, Rotary Type

Step 1. At the ends of three bars with a twenty-centimeter cross section, holes are cut out for a tube that will connect these tripod supports.

Step 2. The tripod is placed above the drilling site, fixing the supports to protect them from being buried in the ground during operation.

Step 3. Attach a winch to the tripod: electric on top, mechanical on the bottom.

Step 4A drill is attached to the winch.

You can start drilling, which is a cycle that repeats until an aquifer is reached, and includes the following steps:

- a handle is attached to a strictly vertical drill;

- two workers move clockwise, screwing the drill into the soil;

- about every half meter, the drill is raised to shake off the soil from it;

-

upon reaching the aquifer, a pump is lowered into the drilled well to pump out dirty water.

As soon as clean water begins to flow, it is possible to proceed with the arrangement of the well, which includes backfilling the bottom filter, installing casing, pumping equipment, head and caisson.

Slit filters

Casing

Well sealing

Thus, you can drill a well in the sand or an Abyssinian well on your own, using improvised equipment. If you need a larger debit of water, you will have to allocate a significant amount of funds and hire an organization whose activities are related to the drilling of artesian wells.

When choosing drillers, it is better to choose a company that has several drilling rigs and does not offer plastic casing. In addition, this firm must have a hydrologist.

Well cleaning

Well restoration

DIY drilling methods

There are several ways in which you can get to the aquifer:

- auger drill - as it deepens into the earth, it is built up with new sections of a metal pipe;

- bailer - a device with sharp teeth at the end and a valve that prevents the earth from spilling back into the mine;

- using soil erosion - hydraulic method;

- "needle";

- percussion method.

Using auger drilling technology, it is possible to dig a well up to 100 meters deep. It is difficult to do this manually, therefore, stationary electrical installations are used, and the drill is built up with new sections as it deepens. Raise it periodically to excavate the soil. To prevent the walls from crumbling, a casing pipe is laid after the drill.

If the drill cannot be built up, a bailer with sharp edges is attached to its base and the drill screws it in a few meters deeper. Next, the pipe is lifted and the accumulated soil is poured out.

The work with the auger can be done on soft ground. Rocky terrain, clay deposits and club mosses are not suitable for this method.

The bailer is a metal pipe with solid steel teeth soldered at the end. A little higher in the pipe there is a valve that blocks the exit to the ground when the device is lifted from a depth. The principle of operation is simple - the bailer is installed in the right place and manually turned, gradually deepening into the soil. The method takes more time than using electrical equipment, but it is economical.

The device needs to be periodically lifted and poured out of the earth from the pipe. The deeper the pipe goes, the harder it is to lift it. In addition, scrolling requires the use of brute force. Most often there are several people working. To make the soil easier to drill, it is washed out with water, pouring it from above into the pipe using a hose and a pump.

Percussion drilling is the oldest method still in use today. The principle is to lower the metal cup into the casing and gradually deepen the well. For drilling, you need a frame with a fixed cable. The method requires time and frequent lifting of the working pipe to pour the soil.To facilitate the work, use a hose with water to erode the soil.

The "needle" method for the Abyssinian well: when the pipe is lowered, the soil is compacted, so it is not thrown to the surface. To penetrate the soil, a sharp tip made of ferroalloy materials is needed. You can make such a device at home if the aquifer is shallow.

The method is cheap and time consuming. The disadvantage is that such a well will not be enough to provide a private house with water.

We select pipes

Here you need to correctly calculate the required amount. Take note of the slope and number of turns.

Having correctly identified, you can take them in the desired manufacture, they differ in the angle of rotation and this will greatly facilitate the work:

The diameter of any pipes made of different materials (steel, polypropylene, metal-plastic) must be from 32 mm.

When choosing pipes, you should pay attention that the material of their manufacture is food grade, not technical.

Check it out for sure;

We need to supply pipes to the premises, the trenches from the well to the foundation of the building must be at least a meter deep

It is important that the level of laying the pipes in the trench is below the freezing ground in your area. It is necessary to provide reliable protection by covering the pipeline with insulation (see How to insulate a well correctly)

For this, mineral wool is used.

Even better, if you still lay a special electric cable for heating, which will provide heating and prevent the pipe from freezing;

An above ground piping option is also available. In this case, measures to insulate the external water supply must be carried out.Pipes are laid directly on the ground, or in a preliminary recess. In parallel, a heating cable is laid, but in this embodiment it should already be mandatory.