- Some Helpful Tips

- Rotary drilling tool

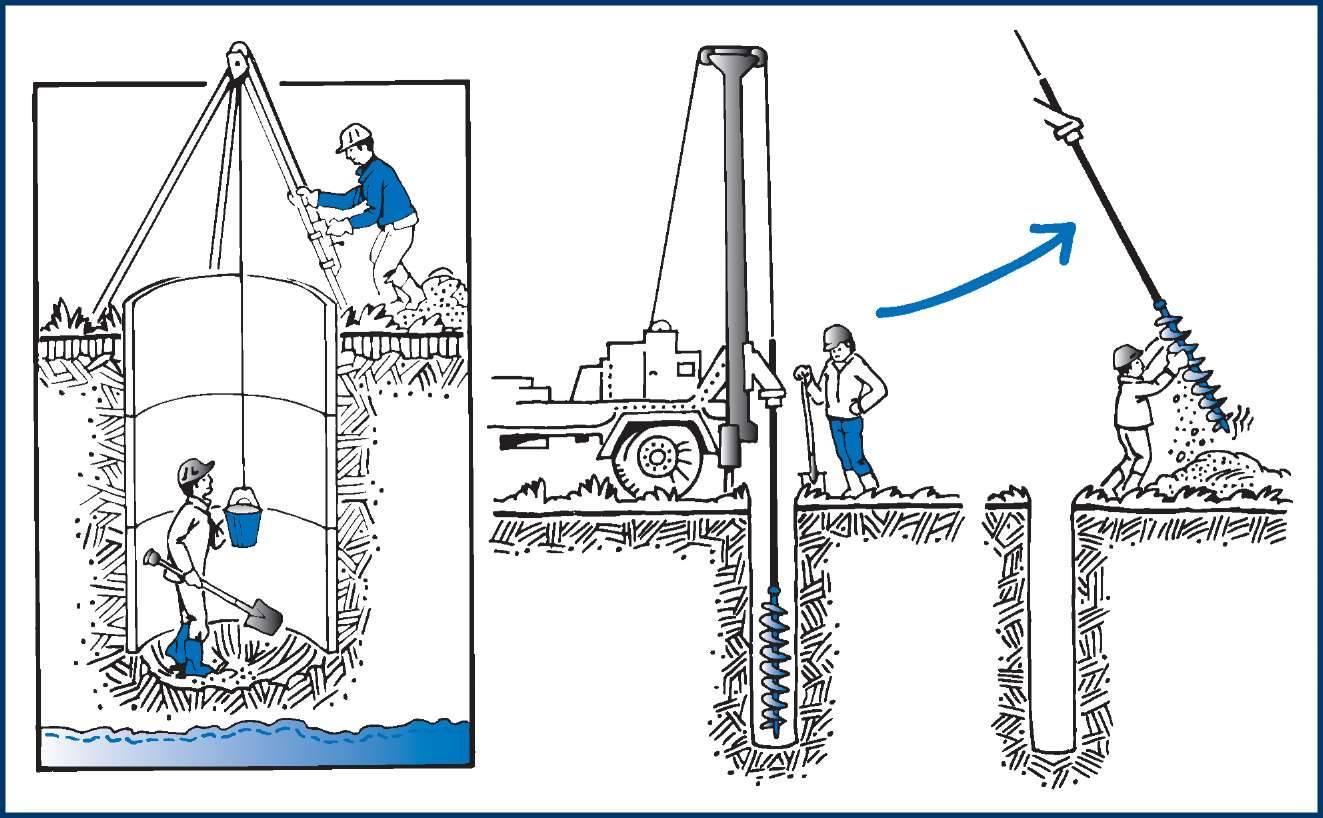

- Do-it-yourself sand well in the country

- Work order

- Do-it-yourself drilling of a shallow well

- The buildup of a homemade well

- Production of drilling tools

- Option #1 - Spiral and Spoon Drill

- Option # 2 - bailer and glass

- The main types of water wells

- Abyssinian tubular well

- Sand well (filter)

- Artesian well without filter

- Advantages and disadvantages

- Installation of equipment

- When to drill a well

- Important nuances

- How to drill a well on sand: instructions

- The order of the device head

- Drilling process: sequence of actions

- Filter

Some Helpful Tips

After the well is ready, you should pay attention to a number of important nuances. For example, in order to keep the water in the well fresh, it is necessary to ensure the flow of fresh air into the casing string.

To do this, make several ventilation holes. The upper part of the well should not be walled up, it is closed with a hinged lid so that, if necessary, you can get the pump, inspect the column, etc.

Upon completion of work, it is necessary to return for analysis of water from a wellto test for various impurities.Any problems with the condition of the water are usually solved by selecting the right filters.

Water is not taken for analysis immediately after drilling, but after some time, so that the pollution caused by drilling is removed from it.

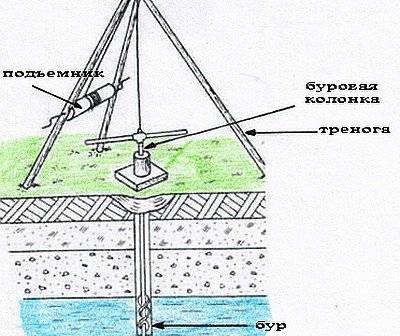

Rotary drilling tool

This method implies certain difficulties, but the technique itself is the most reliable for well formation. In this case, the drill is driven by a rotor. On your own, you can only build a frame, and the rest of the elements must be purchased from a reliable manufacturer:

- drill rod;

- swivel;

- paddle drill;

- motor pump;

- gear motor.

Through such an installation, it is possible to perform drilling with flushing, as well as to perform rotational, percussion and other work. In addition, it is possible to supply a solution that will erode the soil in order to facilitate its excavation. In addition, the process itself is much faster.

Do-it-yourself sand well in the country

Taking directly to the execution of work, you need to start with drawing up plans and schemes. First of all, think about where the well will be located in your yard. Consider all the buildings on the site to understand how convenient the location you have chosen. Do not forget about what you planned to build at your dacha in the future. Remember that a well is built once, and it will not be easy to move it to another place.

Work order

Having settled all the issues of location, creating work plans, it is necessary to proceed with their implementation:

- Carefully mark up for future work. Make sure that the accuracy is maximum.

- Prepare a hole for the entry of the drilling tool.

- Install the drilling equipment at the required position.

- Start drilling.

- Assemble the filter column from the pipe, sump, and filter, and lower it into the pit.

- Take a closer look and find the space between the soil and the walls of the casing from the outside. It must be covered with gravel or sand, your choice. If you choose crushed stone, be extremely careful not to damage the casing from the outside.

- Rinse the filter by pumping water into the pipe with a pump. This way you can seal the top of it.

- Using a screw pump, as well as a bailer, pump water out of the well.

- Make sure the well water is clean.

- Gently and slowly lower the submersible pump into the well. This procedure is performed using a safety type cable.

- Connect the water pipe or hose to the pump.

- In order for the water supply to be regulated, install a special valve on the pipe.

- A casing pipe that protrudes above the surface must not allow water to pass through in undesirable places. For this purpose, perform waterproofing.

- Equip the wellhead with a caisson, then carefully fix it on the head with a welding machine.

- If you were planning to bring pipes to the house, at this stage it's time to lay them in trenches.

- Sprinkle the caisson with soil, and also make a concrete blind area.

And so, in less than 20 steps, a well can be made in the country. Of course, everything is not so simple, but doing the work as accurately as possible, you will succeed.

Do-it-yourself drilling of a shallow well

You can also drill a well manually, but this, of course, requires special equipment. We list it below:

- Boer;

- drilling rig;

- winch;

- casing;

- rods.

By the way, it is not necessary to take a drilling rig, but only if the well is not deep. For shallow holes, you can pull out the drill string by hand.

As for the drill rods, they are made from ordinary pipes, and are connected using threads or dowels. The lower of the rods should not be forgotten, because it is she who must be equipped with a special drill.

For the manufacture of cutting nozzles, you will need sheet steel with a width of 3 millimeters. And another very important point concerns the sharpening of the edges of the nozzles. They need to be sharpened in such a way that as a result they enter the soil underground in a clockwise direction.

Now you should set up a tower in the area where drilling will be carried out. Make sure that the height of the derrick exceeds the dimensions of the drilling rod so that lifting and retrieving the rod is completely unimpeded.

To create a well, you will probably need an assistant. You can start the rotation yourself, but after a while, when the drill goes underground, the efforts of one person will not be enough to continue drilling.

If, together with an assistant, you stumble upon problems or simply get stuck, try pouring water into the soil, as it will soften it somewhat.

When the drill reaches ground level, an additional bed is attached to it. Continue drilling until the very moment when you notice on the ground that you have finally reached the aquifer. After that, you need to clear the well from the ground and plunge the drill even deeper, trying to reach a layer called water-resistant. Having reached this layer, an abundant influx of water will begin in the well.

Pump out the dirty water with the help of a pump and soon you will find clean water. If suddenly you notice that the water is not getting clearer, you need to deepen the drill a few more meters.

The buildup of a homemade well

A drilled well is not everything. It will not give water of the required quality in the right quantity. To do this, it is necessary to open the aquifer or "shake" the well. If you open the reservoir (directly or reversely - no difference), water can be obtained within a day, but complex expensive equipment will be required. And the buildup of the well will last several days, but for it it is enough to have the most ordinary household submersible pump (only centrifugal, because vibration will not work).

To swing a drilled well, silt is first removed from it with a bailer, and then they begin to pump water - completely, as soon as the volume covering the involved pump is reached.

You can build up with the help of a manner, but then you will have to draw water for a long time - 2 weeks, no less.

Important: The buildup of the well can be considered complete when the transparency of the water reaches 70 cm. You can check this in an opaque vessel (for example, in a clean barrel), using a white enameled or faience disk, the diameter of which is about 15 cm (take, say, a saucer or saucepan lid)

You should look at the immersed disk strictly vertically, and as soon as the liquid begins to spread along its edges, blurring the contours - this is already opacity, you need to stop. As soon as transparency is achieved, a water sample must be taken and submitted to the laboratory for analysis.If the regulatory authority confirms the quality of production, the annulus of the well is concreted or sealed with clay, and then a filter is installed.

Production of drilling tools

As mentioned earlier, drilling tools can be made on your own, borrowed from friends, or purchased commercially.

Sometimes a drilling rig can be rented. However, the goal of self-drilling is usually to keep costs as low as possible. The easiest way to drill cheaply is to make tools from scrap materials.

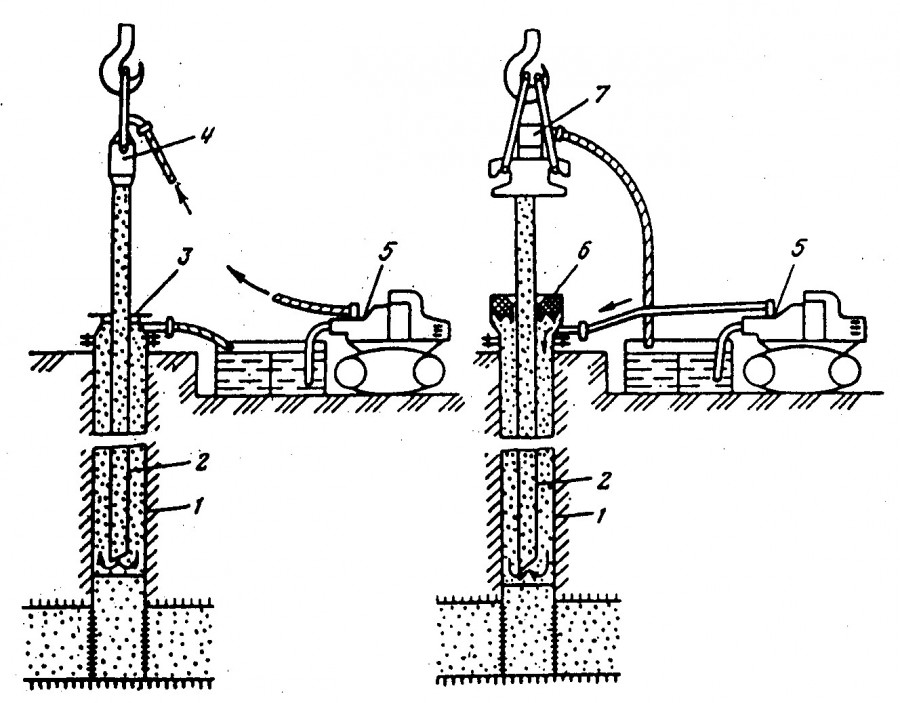

The diagram shows the arrangement of various drilling tools. With the help of a chisel, especially hard soil can be loosened, and then it is removed with a drill, bailer or other device.

Option #1 - Spiral and Spoon Drill

Manual drilling can be done with a spiral or spoon drill. For the manufacture of a spiral model, a thick pointed rod is taken, to which knives are welded. They can be made from a steel disk cut in half. The edge of the disk is sharpened, and then the knives are welded to the base at a distance of about 200 mm from its edge.

A do-it-yourself drill for auger drilling can be of different designs. Its obligatory elements are knives with pointed edges and a chisel installed at the bottom.

Knives should be located at an angle to the horizontal. An angle of about 20 degrees is considered optimal. Both knives are placed opposite each other. Of course, the diameter of the drill should not exceed the diameter of the casing. Usually a disc with a diameter of about 100 mm is suitable.The knives of the finished drill should be sharpened sharply, this will facilitate and speed up drilling.

Another version of the spiral drill can be made from a rod and a strip of tool steel. The width of the strip can vary between 100-150 mm.

Steel should be heated and rolled into a spiral, hardened, and then welded to the base. In this case, the distance between the turns of the spiral should be equal to the width of the strip from which it is made. The edge of the spiral is carefully sharpened. It is worth noting that it is not easy to make such a drill at home.

A spiral auger for drilling can be made from a pipe and a steel strip, however, it is not always easy to roll the tape into a spiral, weld and harden the tool at home

To make a spoon drill, you need a metal cylinder. In conditions of self-manufacturing, it is easiest to use a pipe of a suitable diameter, for example, a 108 mm steel pipe.

The length of the product should be about 70 cm, it will be difficult to work with a longer device. On this case, a long and narrow slot should be made, vertical or spiral.

A homemade spoon drill is easiest to make from a piece of pipe of a suitable diameter. The lower edge is folded and sharpened, and a hole is made along the body for cleaning the drill

Two spoon-shaped knives are mounted in the lower part of the body, the cutting edge of which is sharpened. As a result, the soil is destroyed by both horizontal and vertical edges of the drill.

The loosened rock enters the cavity of the drill. Then it is taken out and cleaned through the slot. In addition to knives, a drill is welded along the axis of the device in the lower part of the drill. The diameter of the hole made by such a drill will be slightly larger than the device itself.

Option # 2 - bailer and glass

To make a bailer, it is also easiest to take a metal pipe of a suitable diameter. The wall thickness of the pipe can reach 10 mm, and the length is usually 2-3 meters. This makes the tool heavy enough so that when it hits the ground, it is effectively loosened.

A shoe with a petal valve is attached to the bottom of the bailer. The valve looks like a round plate tightly closing the lower section of the pipe and pressed by a sufficiently powerful spring.

However, a too tight spring is not needed here, otherwise the soil simply will not fall into the bailer. When the bailer is pulled out, the valve will be pressed not only by the spring, but also by the soil collected inside.

The lower edge of the bailer is sharpened inwards. Sometimes sharp pieces of reinforcement or sharpened pieces of triangular metal are welded at the edge.

A protective mesh is made from a thick wire on top and a handle is welded to which a metal cable is attached. A glass is also made in a similar way, only a valve is not needed here, and a slot should be made in the body to clean the device.

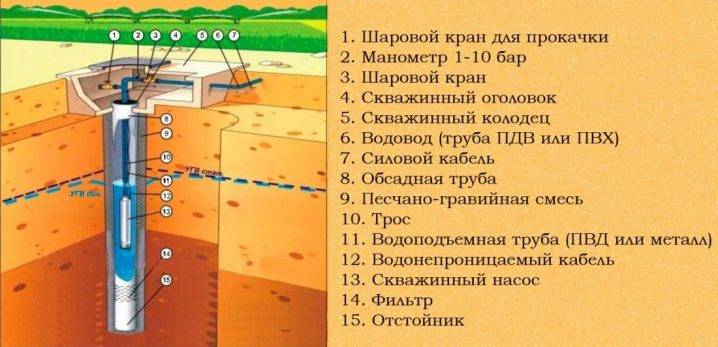

The main types of water wells

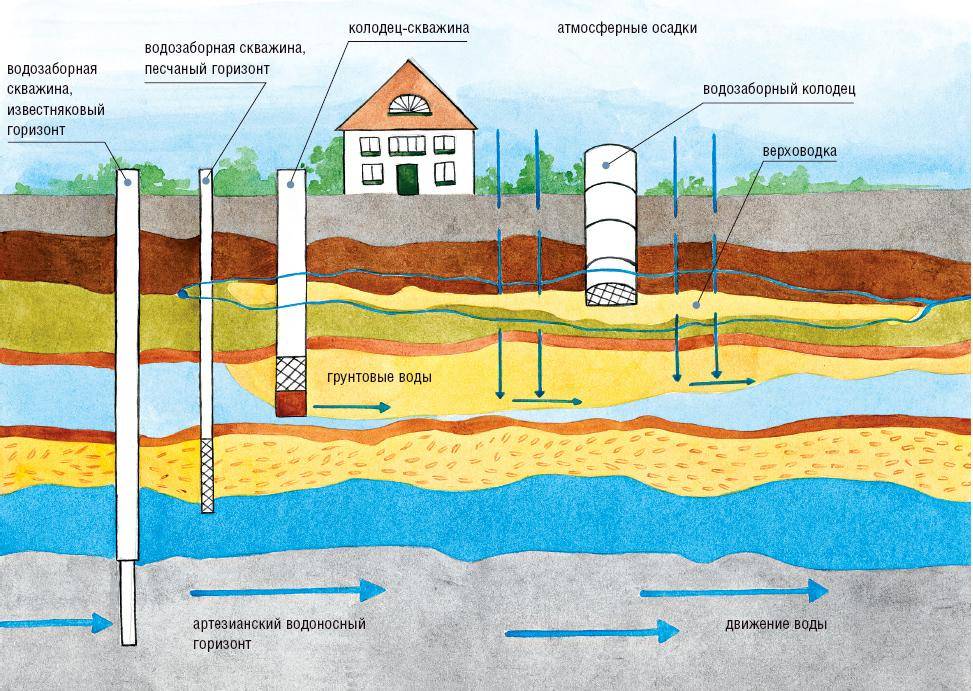

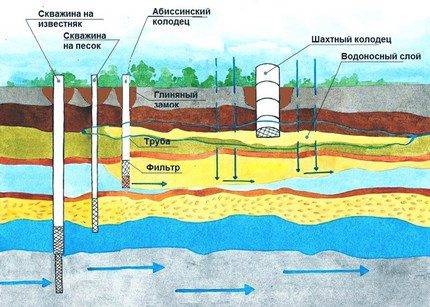

There are several real ways to get life-giving moisture, which we will tell you about. There are several technologies that can be used to independently extract water in a suburban area.

You will have to choose the appropriate option yourself, since it depends on the landscape of the area, as well as on the technical equipment, finances and skills that you possess. Let's consider the main borehole structures.

It is difficult to give preference to any one design: each has its own advantages and disadvantages, so the choice depends on the landscape of the area and on the capabilities of the site owner

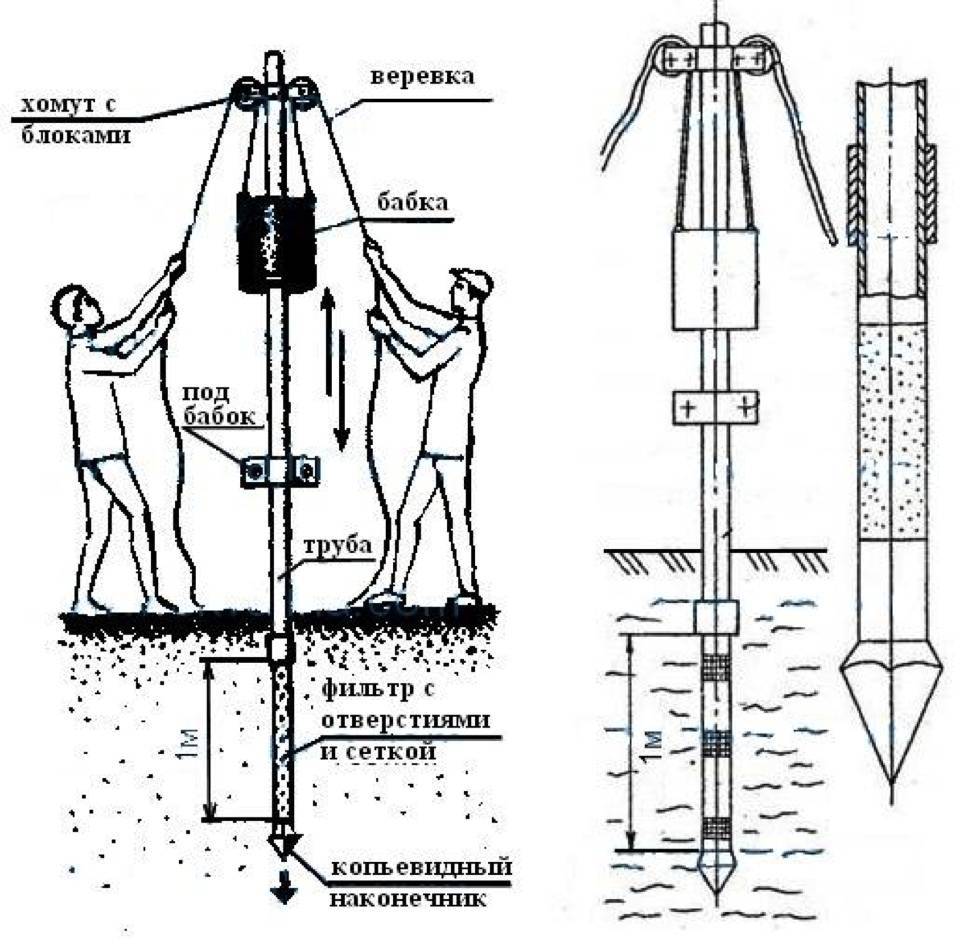

Abyssinian tubular well

If there is a spring on your site, then arranging a well is a great option for extracting water. The shaft of this structure will play the role of a fluid storage tank. If the source is active enough, up to 2 cubic meters of water will always be at your disposal.

The Abyssinian well is, in fact, the same well, but narrow and long. Due to the fact that its length can be approximately 8-12 meters, pollution from the soil surface does not get into the water that fills it.

The Abyssinian well is often called a needle well, because the pipe driven into the ground during the creation of this structure really resembles a needle

The following video will introduce the technology of punching and arranging a well-needle, otherwise called the Abyssinian well:

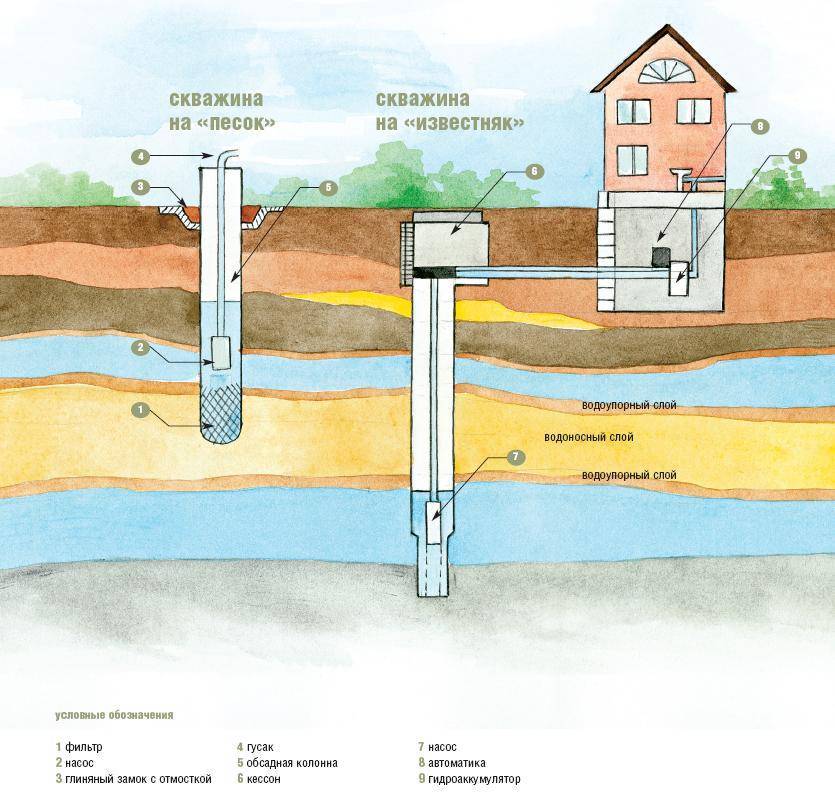

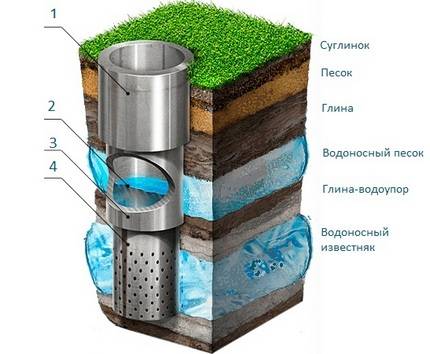

Sand well (filter)

The deepening of this structure by 15-30 meters is carried out by any method: auger, shock-rope, core. The walls of the well are formed using a pipe with an average diameter of 100 - 180 mm.

The deep end of the wellbore is equipped with a filter. As a filter, a stainless steel mesh is used, which is welded or soldered to the first link of the pipe string before it is immersed in coarse sand mixed with pebbles.

So you can schematically represent the design of the well “on the sand”, where number 1 will be the casing, number 2 is the statistical water level, and number 3 is the strainer

This design is able to satisfy the need for water in a small country house with two water points. If the operation of the structure is seasonal, it will last about five years.With constant use, you can count on 15 years of water supply.

When the well is still silted up, it will be possible to try to flush it. If resuscitation measures do not give the desired effect, a new shaft will have to be drilled. Place it next to the previous one.

Artesian well without filter

This building does not need a filter. Such a well can reach a depth of 100 meters or more. The water produced by such a facility is contained in limestone cracks. The liquid accumulated in them due to condensation can be not only crystal clear, but also mineralized.

A little mineralization is acceptable for everyday use. If the extracted water in its composition is among the mineral waters, then it cannot be used for domestic purposes.

Scheme of an artesian well: 1 - conductor, 2 - statistical water level, 3 - intermediate column, 4 - production string with perforation

It is difficult to determine in advance the depth of the well that will have to be drilled in search of water. You can only roughly orient yourself by talking with your neighbors in the area and finding out from them what parameters similar structures have in their territories.

The ground layers lie unevenly, so the information obtained still cannot be considered accurate for your site. For this reason, casing pipes are purchased taking into account the correction of the data obtained.

Advantages and disadvantages

The use of caissons for a long time was a classic option for the implementation of autonomous sources of water supply. That is why the arrangement of a well without a caisson using an adapter is still far from being perceived unambiguously.Although several years of using this technology in various climatic zones of Russia have proven its effectiveness and right to life.

This method has a number of advantages:

- Installation of this product frees the owner of the well from the need to perform earthworks in such volumes as would be required by installing a caisson. And this is a very significant savings for the family budget.

- There is no need to purchase such an expensive device as a caisson.

- Using an adapter makes it possible to conduct water supply close enough to a gas pipeline or sewer.

- Repair of downhole equipment is greatly simplified.

- Protection of the well from vandalism, since it is not conspicuous in the specified design. And it is possible to dismantle the pump installed in it only using a special device.

well arrangement scheme with adapter

Disadvantages to consider when making a decision - "caisson or adapter for a well", include:

- It is not recommended to use the product if a well of great depth is to be equipped.

- If there is no place to install water supply equipment in the house.

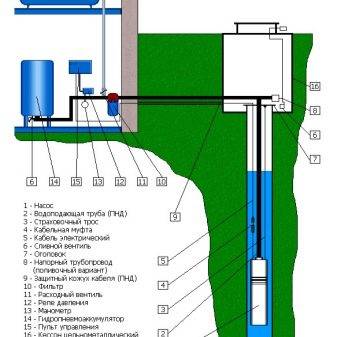

Installation of equipment

The equipment must ensure the stability of the water supply. For uninterrupted supply, there are various types of pumps, and their operation requires electrical power. The simplest option for arranging a place for well equipment is a pit. The undeniable advantage of such a site is that it can be made from improvised materials.

Due to the fact that moisture can get into the pit, experts recommend this type of platform for equipment as an adapter. Methods for arranging sites with an adapter imply that the role of the caisson is played by the casing string. It is possible to apply the method if the arrangement of the casing string is made in one container and the tightness of the pipes is ensured. For such a case, pipes are usually selected from steel. Plastic is not recommended for the adapter design, as the pump is fixed to the water pipe and not suspended from a cable.

Another option for a site for arranging equipment, the caisson mentioned above. This is a sealed container, which is considered reliable and durable. The container can be equipped ready-made or made by hand. Caissons are either plastic or steel. Plastic sealed, weigh a little, easy to install. Steel options are airtight, reliable, but need to be treated with anti-corrosion compounds, they have a higher price

The equipment is mounted after the site is mounted, while it is important to take into account some of the nuances

When to drill a well

Those readers who, for some reason, did not have time to acquire their own water source in the country in the fall, or they are not satisfied with the existing water source, and they decided to arrange a water source now.

The right decision: a reasonable owner thinks about this not on May 1, but on March 1. However, it is worth noting that the most successful time for drilling a well is the time after the end of the season (October, November, even December). March is also a good period: in frost on hard ground, it is much easier to drive 15-ton vehicles to the site than in warm weather on soft ground.Although drilling a well when it is warm is easier for both equipment and people. Now the snow will begin to melt, and it will become more and more difficult to drill a well: even three-axle drilling machines get stuck in the snow, and when they start digging the ground, they generally “sit down”.

Among other things, you need to know that some dacha villages, cottages, where the shareholders themselves laid roads on their own, simply close the entrance to any equipment, except for personal vehicles. Persuade do not persuade, threaten, pay - it's useless. A decision was made by the general meeting - no drilling rig will enter there. In this case, you will have to wait for the end of the flood, and maybe even until the end of May.

And another very important point when drilling a well. The price of drilling a well is not constant within the annual cycle. Pipe complexes roll pipes all the time, in summer there is demand, in winter there is no demand. Therefore, the price of pipe products in summer is higher. Serious companies that bought pipes before the new year for all their profits can drill for some time using cheaper pipes. The dynamics of prices for fuel and lubricants also affects the overall cost. A good well takes up to one and a half to two tons of gasoline. The lowest prices for drilling are from mid-October to March. At the end of March, they begin to grow. For example, for the arrangement of an artesian well, if we talk about the region of the Moscow region, you can order drilling a well for water here.

A shallow well in the sand is usually drilled for one light day. A deep well is drilled from two to five days. If you have a drilling rig and have been drilling a well for two weeks, you can immediately drive it. Artesian wells, in principle, no matter when to drill, these wells cannot be dug during a flood, it is clear why (they will be shallow with water, and then the water will run out).Wells on sandy horizons too.

For many years I have not been convinced that they are somehow actively seasonally filled with water. If the horizon is normal, it never dries up in summer. Just do not confuse perched water and ground horizons. Verkhovodka is a seasonal aquifer that occurs after snowmelt and stays at the top for some time, and then goes down. And the well is built on a permanent reservoir that never dries up.

Drill auger while drilling a well on a sandy aquifer

Important nuances

If the land on the site is fertile, and in case of destruction the surface layer will have to be restored, it is preferable to use cluster drilling. Pad drilling reduces backfilling and reduces the cost of resource extraction. Any work on the site can be started only after studying the level of groundwater. If this level is high, it is better to place the protective room on the surface, rather than deepen it underground.

It is extremely important to choose and fix the pump correctly. The role of equipment is extremely important for an autonomous water supply system

For wells, it is customary to choose submersible pumps, as they have better performance. But when choosing, it is important not to overdo it, since the size of the hydraulic structure itself will be an important parameter. The length of the drains is also taken into account. For example, with a water intake structure height of 33 meters, the pressure in the system should be from 1.4 to 3 atmospheres.

For constant support and the possibility of changing the working pressure, a hydraulic accumulator is needed. The tank will provide storage of the minimum water reserve.Modern equipment of this type is a single design, the main distinguishing feature of which is capacity. For example, for summer cottages, a capacity of up to 55 liters is sufficient, and for hotels and boarding houses, devices from 100 to 950 liters are selected.

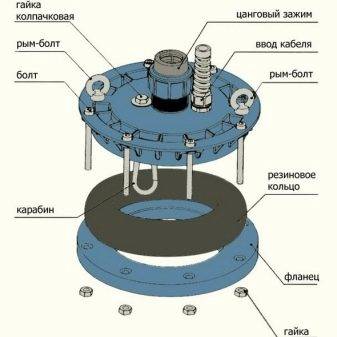

An important protective device of the well is the head. Usually the device is equipped with holes for installing water pipes, as well as power cables.

The cap protects the structure from biological and other contamination.

The design of the head includes such parts as:

- carabiner, flange;

- rubber rings;

- fasteners;

- covers.

If the well is equipped with a cap, then the column is cut off during installation. The cut is cleaned and treated with anti-corrosion agents.

- The supply cable of the pump is inserted through the inlet cover of the water pipe.

- The pump is connected to the pipe, and the hanging end of the cable is fixed with a carabiner.

- The flange is fixed to the column, and a sealing ring is installed on top.

- Next, the pump is immersed to the bottom of the well, and the head cover is fixed with bolts.

How to drill a well on sand: instructions

How to drill a well for drinking water if aquifer lies at a depth of up to 40 m? Sand holes can be punched by hand, but this will require too much time and hard physical labor. The best way is to use small-sized equipment and select a drill according to the type and density of the soil.

Unlike wells that can be drilled by hand, sand springs require careful preparation. It is difficult to find a place for slaughter on your own.Specialists who are engaged in the arrangement of water intakes usually have accurate information about the depth and saturation of water-bearing sands and use special maps.

At the selected site, the installation is assembled. Before assembly in the ground, three holes are dug on the site:

Pit, which must be sheathed from the inside with rough boards, or tighten the bottom and walls with a strong plastic film.

Two slurry wells connected by a liquid overflow trench. The first tank is a filter in which the clay solution settles. From the second, water is fed under pressure into the barrel during drilling.

Hoses are being prepared: one for water supply, the other for outlet. After the assembly of the installation, they begin to clog the well.

You can drill such a well under water with your own hands in different ways: in soft rocks, a spiral drill, a glass are attached to the installation. In hard stony soils, a rotary method is used: they are drilled with a chisel and the mine is flushed with a clay solution.

In the course of work, the verticality of the projectile entry and depth are constantly monitored. As you deepen, lengthen the bar. MDRs are equipped with collapsible rods of sufficient length to work at a depth of up to 80 m. Signs of water-bearing sand:

- Washing out of the trunk of a large amount of sand.

- Easy entry of the drill into the rock.

Casing starts after drilling is completed.

Regardless of whether the drilling of a well for water was used manually, or the slaughter was performed using an MBU, it is necessary to equip the source. It is also worth equipping surface wells with a pump.

Arrangement technology:

A caisson (pit) is equipped in the pit for piping the well. The walls are sealed.

Assemble and install the pump group.Submersible devices are lowered into the barrel, a safety cable is fixed on the head. Surface mounted on an elevation, connecting the inlet pipe to the supply hose or pipe.

Perform piping, connect watering hoses.

Drilling wells manually is difficult, long and without guarantees. The price of a mistake is lost time, money invested in the purchase of equipment and its rental. The video shows an example of how faster and more accurately the work is carried out by specialists.

It is important to get qualified help from specialists even before the source is arranged: traditional search methods do not guarantee that there will be water at the planned depth and that it will be enough to provide the site in summer. Masters can accurately predict both the depth and flow rate of the well. A water intake equipped by professionals is guaranteed to serve for decades

A water intake equipped by professionals is guaranteed to serve for decades.

The order of the device head

Header provides:

- Protection of the well from floods and melt water.

- Protection from third-party debris and groundwater.

- Protection against theft of equipment and well wells.

- Frost protection during cold weather.

- It makes the cable attachment more secure.

- Contributes to facilitating the use of a well well for water.

- Makes submersion of the pump as convenient as possible thanks to the winch.

Mounting diagram well head.

This device consists of several parts, namely:

- Carbine and flange.

- Rubber rings.

- Special fasteners.

- Protective cover.

The inner side of the cover is equipped with one eyebolt, the outer side with two.A metal product can withstand a weight of up to 0.5 tons, and a plastic one - no more than 200 kg.

During the installation of the head, it will be necessary to cut the casing, clean it and cover it with an anti-corrosion compound. Lead the pump cable and water pipe through the head cover. Connect the pump to the pipe. Attach the free end of the rope to the carabiner. This should be done through the eyebolt on the inside of the protective cover. Place the flange and rubber ring on the casing.

Place the pump in the well and install the head cover. This is done very simply: you just need to lift the flange and the rubber ring for the cover and compress all these parts with bolts. On this, the installation of the head is considered completely completed.

Drilling process: sequence of actions

If you prepare the necessary equipment and follow the sequence of stages, there will be no questions about how to make a well. The finished drilling rig is equipped with a head and a mechanism in the form of a winch. The bar is passed through both holes down, if necessary, it is increased and the collar is fixed. The gate is usually rotated by two, and a third person is needed to correct the position of the bar.

If the well is shallow, then only the drill column is used, directing it down strictly vertically. A tripod with a lift is necessary for deep wells

A mark is placed on the column, retreating from the upper flooring 60-70 cm. Having lowered the column to a designated distance, it is removed back, removing the rock raised along with the drill. In the same way, the purified column is immersed several times. Greater depth requires extension of the rod. To do this, with the help of a coupling, another pipe is attached.

Depending on the stability of the soil, a drilling method is chosen - with or without casing pipes. With stable, dense soil, it is possible to drill the entire well without using casing pipes. The crumbling rocks indicate that after 2-3 meters a pipe equipped with a shoe should be installed. The diameter of the pipe is wider than the diameter of the couplings, so the pipe enters the shaft with difficulty. Sometimes screwing or a sledgehammer is used to place it there.

As casing pipes, products for laying water pipes are used - metal or polypropylene pipes of the required diameter for outdoor work

If the rocks crumble, collapse should be avoided. To this end, the drill is not lowered too low - below the end of the casing pipe for a certain distance. Usually it is equal to half the length of the drill. Thus, the process consists in alternating drilling and installation of casing pipes, which are built up as they go down.

Filter

A well filter is the main device that ensures the quality of water from it. And at the same time, its node is the most subject to wear, therefore, the choice of a well filter must be taken with all responsibility.

Artesian water is taken without filtration. For a limestone well, a simple screen filter in the form of a perforation on the lower casing bend is most often sufficient; it will also serve as the basis for the well filter on sand. Perforation requirements are as follows:

Hole diameter - 15-20 mm, up to 30 mm depending on the ground.

The duty cycle of the filter (the ratio of the total area of the holes to the area they occupy) is 0.25-0.30, for which the distance between the centers of the holes is taken 2-3 times their diameter.

The location of the holes is in transverse rows in a checkerboard pattern.

The total area of all holes is not less than the cross-sectional area of the casing pipe clearance.

The device of filters of wells on sand

For a sand well, firstly, gravel backfilling is also necessary; in this case, it is she who ensures the long-term quality of water, as in the well. In view of this, downhole filters are commercially available with a layer of gravel included in the design. There is no harm from them, but the wellbore needs a larger diameter, which makes it difficult to drill, and without external backfilling, the well still quickly silts up.

Further, if you follow the flow of water, the same perforated pipe goes, but now it will be a bearing element that perceives the pressure of the rock. So that the sand, which gravel does not hold well, does not spoil the entire waterway, you also need a sand filter. It can be external or external (on the left in the figure) or internal (on the right in the same place). External filters have three advantages: the minimum diameter and siltation of the well and the installation depth of the pump. But they are easily damaged during the installation of the casing, they are not repairable and expensive, because. due to the latter circumstance, they must be made of very high quality materials: alloys for the mesh and wire of external well filters are more expensive than silver.

When installing a pump in a well with an internal filter, its bottom is considered to be its upper edge, so the volume of a single water withdrawal is seriously reduced. The disease of all internal filters is increased silting of the well due to water seepage into the gap between the filter and the casing. Also, as a result, the service life of the filter is reduced, and the wear of the pump increases, because. sand gets into it.Often, therefore, the pump is placed in a separate pipe, mounted on the filter outlet, which again requires an increase in the diameter of the well.

Homemade sand filter

The best option is to connect the pump directly to the filter outlet, then both silting and sanding stop. But this requires a centrifugal pump with an intake pipe on the bottom, which makes it much more complicated and expensive, and the pressure of the vibration pumps is often small for sand wells.

The filter elements of sand filters are sometimes made independently from PVC pipes, stainless springs and a polymer mesh, see fig. on the left, but they filter poorly and do not last long. It is better to take a good purchased filter, the working conditions are too difficult, and taking it out, as they say, is a whole thing. In this case, basically 3 options are possible, see Fig.:

Modern borehole filters

- Polymer stacked-ring filter. Cheaper than others, but it serves less and is prone to silting, but it is maintainable: you can pick it up and sort it out, replacing bad rings. Requires increased borehole diameter;

- Tubular-wire with profiled wire winding. A little more expensive than polymer, but it lasts a long time and does not silt. For repair, a bulkhead is not needed, it is enough to flush at the top. It would be optimal, if not for one “but”: cases of scams by manufacturers, traders, and drillers have been repeatedly noted - how completely stainless filters are supplied, in which the longitudinal rods are made of ordinary galvanized wire. It is impossible to check without breaking the filter, but harmful impurities soon appear in the water, and then the rods completely rust, the winding slips, and the entire filter has to be changed.

- Supportless welded filters, wire and slotted. They would be ideal (the latter also withstand draft into the barrel outside on the pipe), if not for the price: they are made from the same profiled stainless wire that costs about the same as silver.