- Brief overview of popular models

- SHUN Grundfos Control MP204

- SUN from NGO STOIK

- Cabinets from the Grantor brand

- Wardrobes Wilo SK

- How to choose a pump control cabinet

- Control cabinet for one pump (SHUN-1)

- Control cabinets for several pumps (SHUN-2, SHUN-3, SHUN-4)

- Uponor Base X25.

- Completeness of the automation system of the pumping station.

- Two separate items.

- Block-modular approach.

- Benefits of professional installation

- Maintenance and repair

- Types and their features

- Pump control cabinets (SHUN)

- Valve control cabinets (SHZ)

- Ventilation control cabinets (SHUV)

- Lighting control cabinets (SHUO)

- Valve control cabinets (SHUK)

- Criteria for choosing the right cabinet

- Overview of popular models

- Conclusion

Brief overview of popular models

SHUN Grundfos Control MP204

Grundfos Control MP204 control cabinets are designed for automatic operation and protection of one pump.

The parameters in Grundfos Control MP204 can be adjusted manually and automatically, and there are two thresholds: the first is a warning, the second is an emergency shutdown. A trip log listing the reasons for the response is stored in memory

Specifications:

- Voltage - 380 V, 50 Hz

- Motor power of connected equipment - from 1.1 to 110 kW

- Temperature range – from -30°C to +40°C

- Degree of protection: IP54

The advantage is the ability to transfer CIU data and adjust parameters via Grundfos GO.

SUN from NGO STOIK

Control stations for pumping units (SUN) from NPO STOIK. Designed for automatic control of submersible water intake and drainage pumps, capable of serving from 1 to 8 connections.

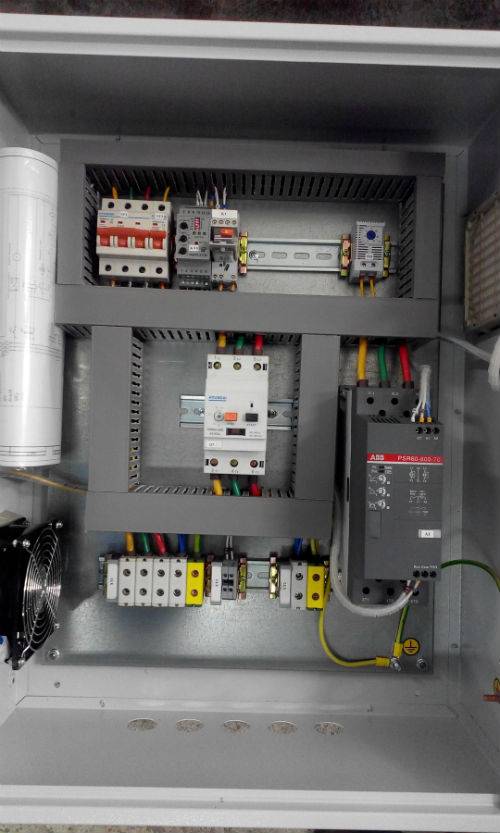

A sample of the SUN 30 kW in a metal hinged case with an Aucom soft starter and a Delta frequency converter

Specifications:

- Voltage - 380 V, 50 Hz

- Motor power of connected equipment – from 0.75 to 220 kW

- Temperature range – from -10°C to +35°C

- Degree of protection: IP54

Among the basic functions is the automatic activation of ventilation if the temperature inside the cabinet rises above the norm.

Cabinets from the Grantor brand

Multifunctional cabinets of the Grantor brand are designed for maintenance of circulation and drainage systems.

Possible modes of operation: circulation and drainage by an analog sensor or by a pressure switch. Two options for the operation algorithm involve joint or sequential switching on of pumps

Specifications:

- Voltage - 1x220 V or 3x380 V, 50 Hz

- Motor power of the connected equipment - up to 7.5 kW for each motor

- Temperature range - from 0°С to +40 °С

- Degree of protection: IP65

In the event of an emergency and a breakdown of the pump motor (due to a short circuit, overload, overheating), the equipment is automatically turned off and a backup option is connected.

Wardrobes Wilo SK

The SK-712, SK-FC, SK-FFS ranges from the Wilo brand are designed to control several pumps - from 1 to 6 pieces.

Several automatic circuits at the Wilo SK-712 cabinet greatly simplify the operation of pumping stations

Specifications:

- Voltage -380 V, 50 Hz

- Motor power of connected equipment - from 0.37 to 450 kW

- Temperature range – from +1°C to +40°C

- Degree of protection: IP54

During operation, all technological parameters are displayed on the display. In the event of an emergency, an error code is displayed.

How to choose a pump control cabinet

The vast majority of modern domestic and foreign manufacturers produce equipment that is completely ready for operation.

In order not to make a mistake when buying a pump control cabinet, you need to pay attention to the following parameters:

- Year of issue. Ideally, it should match the production date of the connected equipment.

- Parameters and number of supported aggregates. In this case, it is necessary to take into account the power of the device, the current and the operating voltage of the motor.

- Control type. It can be manual, automatic and remote.

- Operating conditions. This includes such important indicators as temperature and humidity.

In addition, when buying a SHUN, pay attention to its performance, build quality and compatibility with plug-in pumps. Following these simple rules will help you avoid mistakes and acquire durable and productive equipment. Following these simple rules will help you avoid mistakes and purchase durable and productive equipment.

Following these simple rules will help you avoid mistakes and acquire durable and productive equipment.

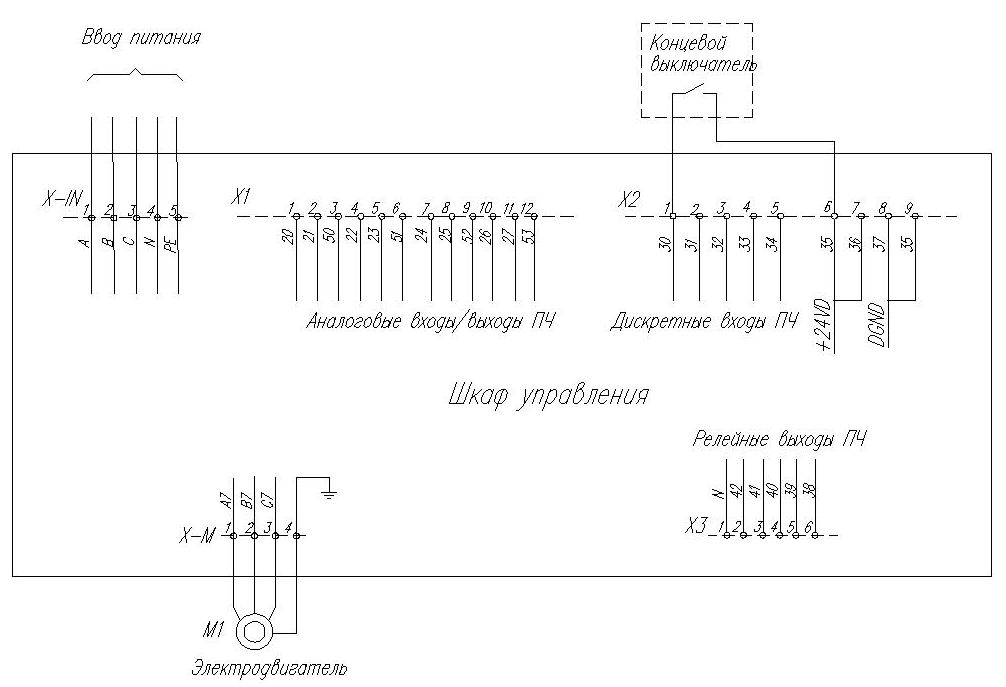

Control cabinet for one pump (SHUN-1)

The simplest control cabinets are control cabinets for one pump (SHUN-1). For its operation, it is enough to install one control element - a contactor, a soft starter or a frequency converter. The logic of operation is the simplest - turn on / off the pump on a signal or from the "Start", "Stop" buttons. ShUN-1 is advisable to use in household water supply systems, in systems for pumping liquid, irrigation, circulation, etc.

|

|  |  |

| Control cabinet for 1 pump 75 kW with frequency converter ATV 630 based on Schneider Electric equipment | Control cabinet for 1 pump 30 kW (soft start) based on PSR soft starter, Schneider Electric equipment | Control cabinet for 1 pump 4 kW with frequency converter ATV 212 based on Schneider Electric equipment |

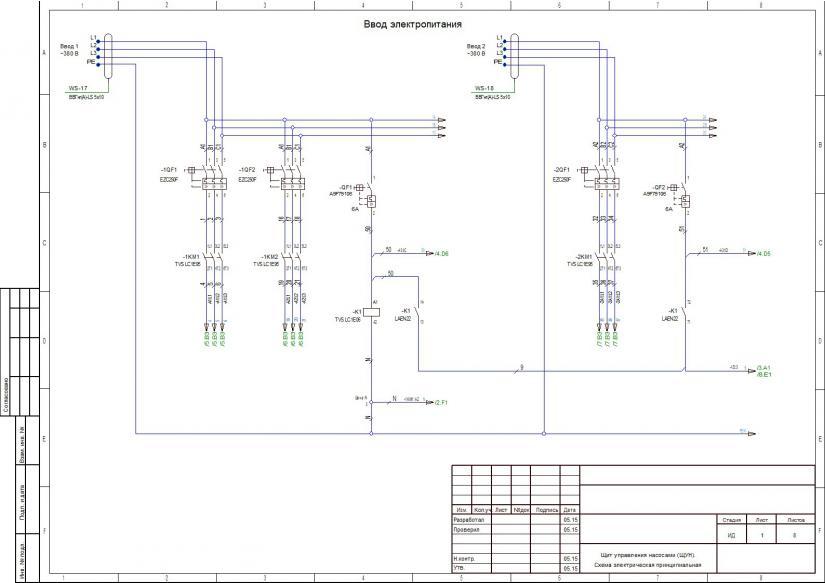

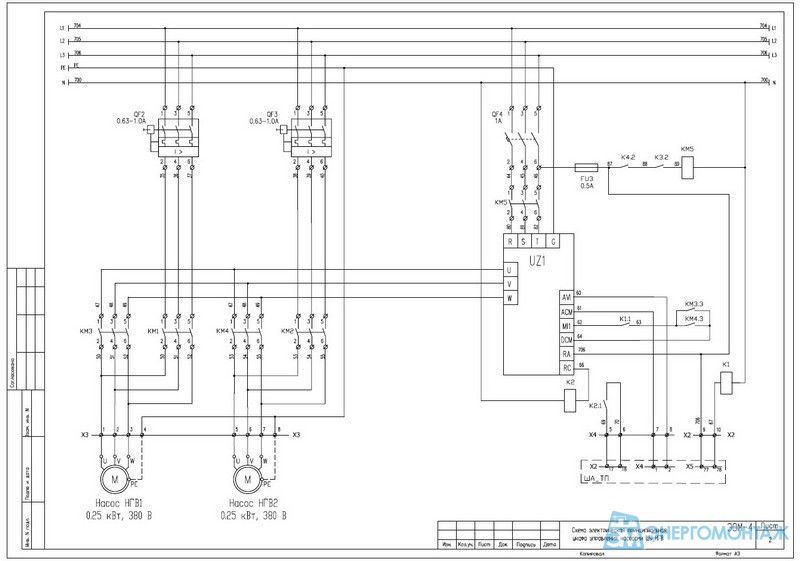

Control cabinets for several pumps (SHUN-2, SHUN-3, SHUN-4)

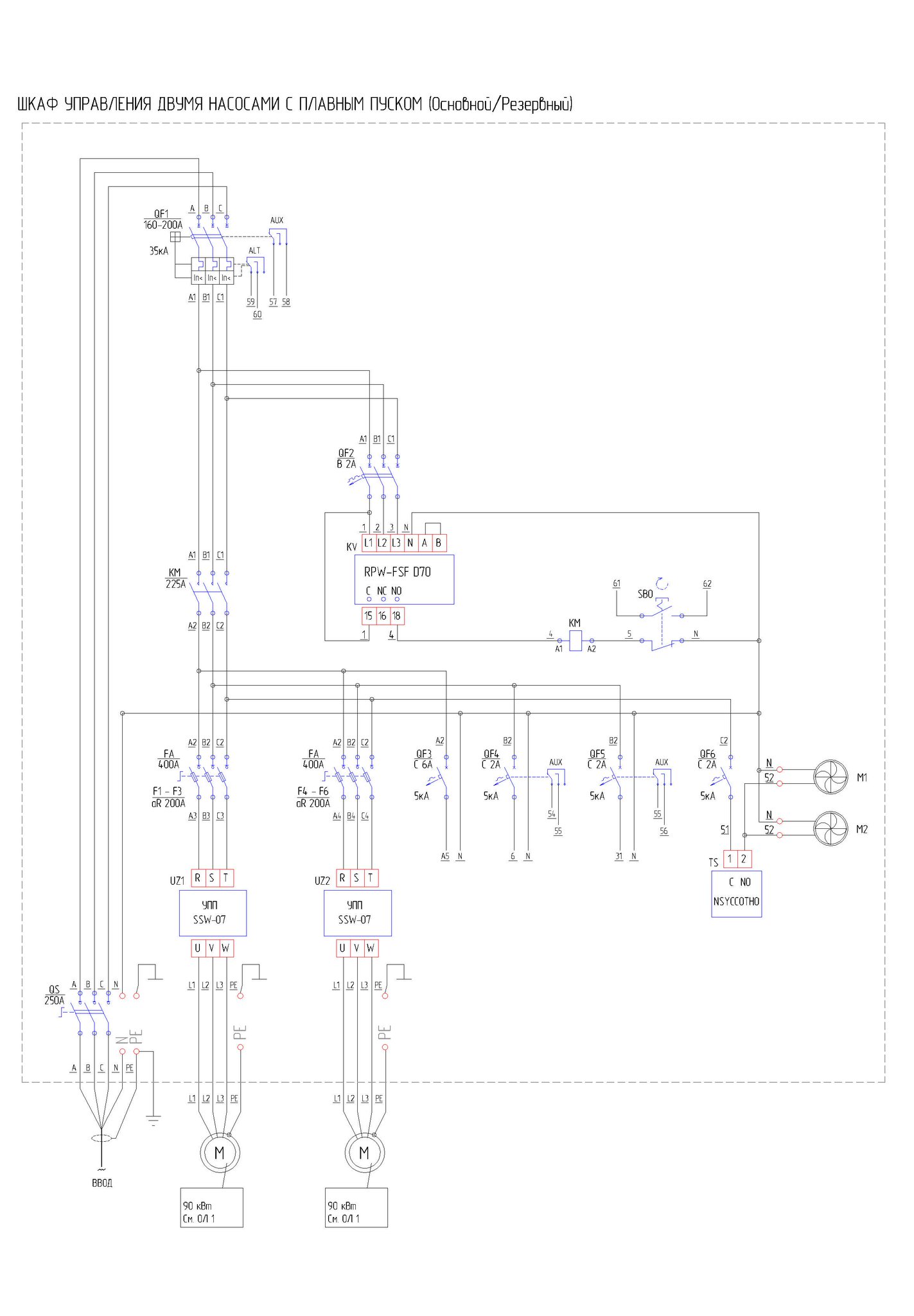

If a more complex logic of operation is required, or redundancy for pumps, control cabinets are used simultaneously for 2-, 3-, 4 or more pumps (usually they are called simply, SHUN-2, SHUN-3, SHUN-4).

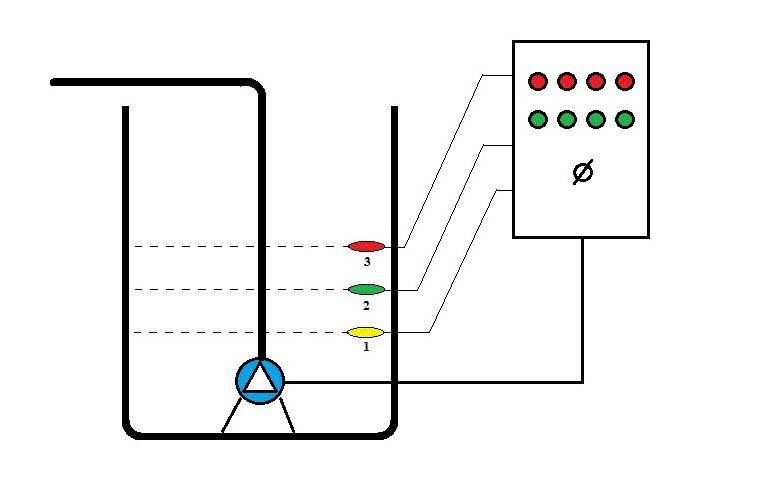

Such systems are usually used in control cabinets for circulation pumps, borehole (submersible) pumps in water supply and sanitation systems. But the most common use of control cabinets for several pumps can be found in sewerage systems of residential buildings (KNS control cabinets), sewage treatment plants or storm water sewers, where it is necessary to ensure the pumping of liquid to prevent the level from rising above a certain level.

|  |  |  |

| SPS control cabinet with ATS, 2 pumps (soft start), Siemens Simatic S7-1200 controller based on ABB equipment | Control cabinet for 2 pumps with a Segnetics controller based on Schneider Electric equipment | SHUDN - 2, 18.5 kW, 2 pumps (soft start), Modicon M172 controller, based on ABB and Schneider Electric equipment |

By default, in the control cabinets for several pumps of our production, a cascade start-up scheme is implemented, where all pumps are working. The principle of operation of such a start is quite simple: according to a given algorithm, the control cabinet, if necessary, changes the lead pump, during operation, the operating time of each pump is counted. The pump with the longest run time is always switched off first, the one with the shortest run time is always switched on first. In the event of a malfunction of the lead pump, it switches to the backup pump. Like ShUN - 1, control cabinets for several pumps have automatic and manual modes of operation.

In automatic mode, start and stop signals come from external level control devices (see diagram).

| 1 pump control

|

| 2 pump control

|

| 3 pump control

|

Uponor Base X25.

Modular surface heating control systems Uponor deserves attention - this is one of the options for an ideal underfloor heating control system. Consider the simplest wired Uponor Base X25 controller with a pump relay

Consider the simplest wired Uponor Base X25 controller with a pump relay.

This device costs more than 9400r.

Functionality:

- Rotary channel selector for easy registration of actuators;

- Pump relay 2A;

- Overload protection;

- Power LED;

— 6 channels (thermostats);

- 12 actuators.

Datasheet Uponor Base X25 in pdf: installation-manual-uponor-base-4.pdf.

An expensive device, but Uponor's range of devices is worth exploring.

Completeness of the automation system of the pumping station.

There are three approaches to completing equipment and building a system.

- Two separate items.

- Block-modular approach.

- One finished device.

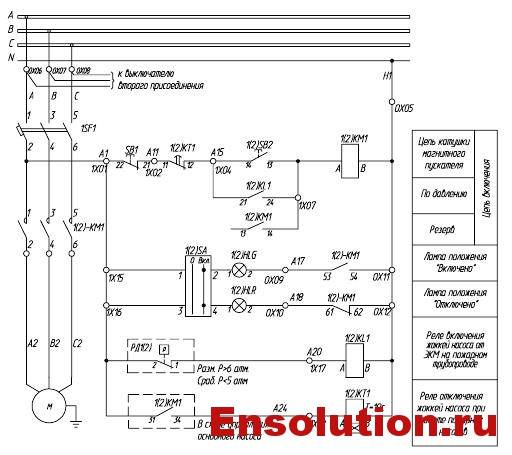

Two separate items.

The system consists of two devices: PU and SHAK.

This approach is clearly expressed, for example, in the equipment of the Sprut-2 set.

There is a control device specialized for control of fire pumping stations. The control device is made as a separate product, sharpened for use in water fire extinguishing systems. Modern control devices have all the goodies: RS-485 interface, indication and remote control devices, expansion devices, etc.

The entire power section is contained in one switching equipment cabinet, which is completed by prior order and is also delivered as a finished product.

Depending on the number and power of units and actuators, as well as other parameters of a particular pumping station, one cabinet with switching equipment is manufactured and delivered as a finished product.

Block-modular approach.

This approach is implemented in addressable fire alarm systems, for example, in the Bolid address system and the Rubezh address system.

The control system of the fire extinguishing pumping station is distributed over several devices.

There is a specialized dedicated device for implementing the control logic of the pumping station as part of the system. Everything else is distributed over several devices. There is no single cabinet with all power equipment.

Each power unit has its own control cabinet. For example, if the pumping station has a jockey pump, two fire pumps, a bypass valve and a fire tank filling valve, then we need 5 power control cabinets.

The control device can directly control a small number of power units and actuators. Such a control device can also receive a small number of status signals.

To organize the collection of information from a sufficient number of sensors and control the required number of actuators and power units, it is necessary to expand the basic functionality.

Something else is also required for scheduling and status signaling as well as scheduling.

Expanding the functionality is not a problem - it's an address system.

Only this requires the use of a network controller, under the control of which the elements of a distributed system interact with each other.

The cost of equipment with this approach is less due to the use of more unified devices.

But less reliability and ease of operation. you will also have to spend time to set it all up and run.

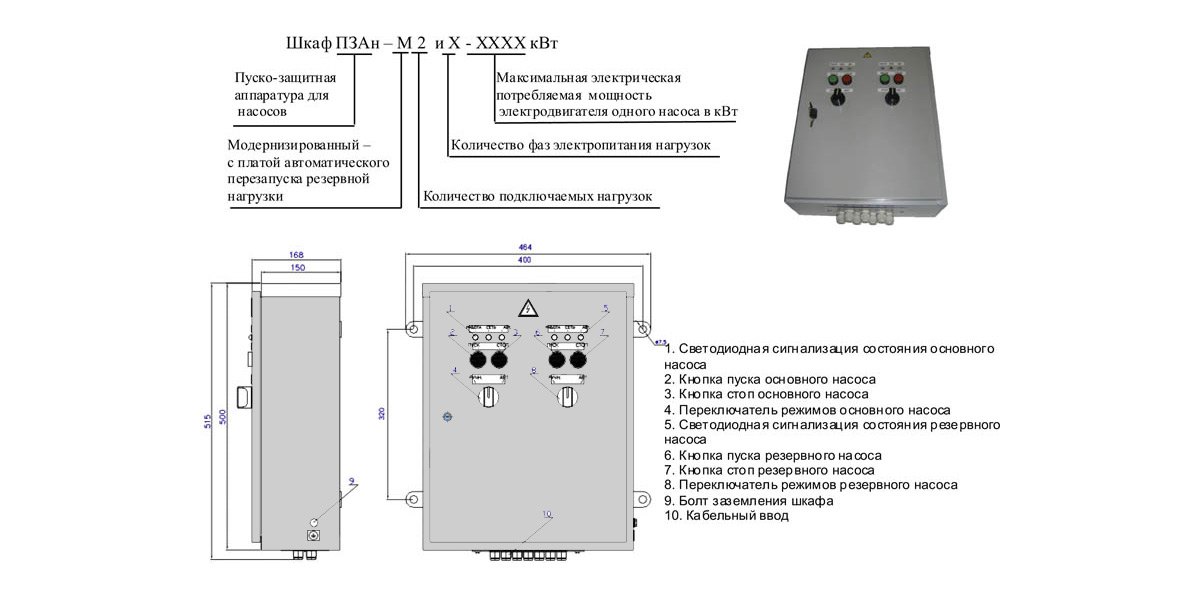

One device.

For foreign manufacturers and their localizations in Russia, control devices and control cabinets are not divided into separate boxes, but are made in the form of one red box.It is probably more profitable to buy a ready-made device there than to design and pay engineers to assemble a bicycle.

The box contains both low-current and power parts. The low-current part is made in the form of a PLC board (programmable logic controller) or a PLC built into the cabinet door.

All operation logic is already programmed - the user only needs to select the necessary operation parameters.

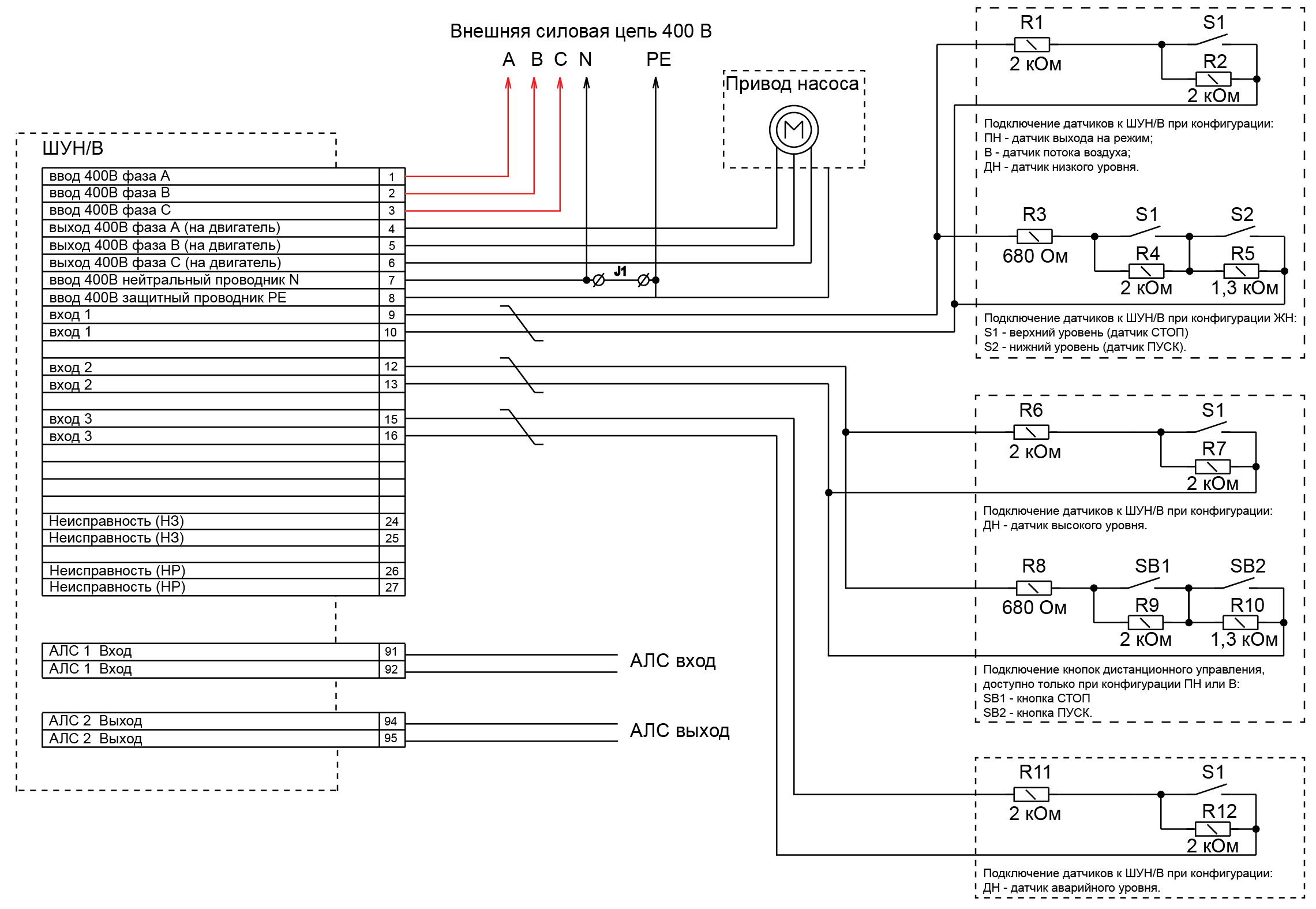

The controller outputs are connected to the control circuits of the power section, and the inputs are routed to the cabinet terminals, which are signed and it is clear what to connect to them.

The box is ordered with the required configuration, depending on the number and power of power units.

But the box is not a piece product: the volume of production allows you to maintain a sufficient range of basic configurations in the form of finished products.

The control box of the water fire extinguishing station is one product, completely ready for operation.

Naturally, if the fire extinguishing system is complex, this approach is not applicable, due to the limited basic configurations. If you have a 3-phase valve, and the box was ordered with a 1-phase valve control channel, then it’s also a disaster.

Of course, such a box is more expensive than a team of several system devices.

The difference is as if you bought an MP3 player or its components from an Arduino shield kit. But, unlike an MP3 player, the box is operated not by the buyer of the box, but by the attendants or no one at all.

Benefits of professional installation

According to the rules, installation and maintenance of ventilation systems, as well as control rooms, should be carried out by specialists with an engineering education.They are also fully responsible for the wrong choice, installation, connection of devices, as well as for the maintenance of technical devices in an improper or emergency condition.

In order to correctly determine the filling of the shield or cabinet, installers make a complete monitoring of the ventilation network.

Then you need to do the following:

- analyze the load;

- choose the optimal scheme;

- determine the operating modes of devices in order to increase efficiency;

- pick up equipment.

The assembly itself takes a little time: all devices are mounted in turn in several rows, the wires are carefully attached to the terminal blocks and laid along the lines in organized bundles, then they are brought out.

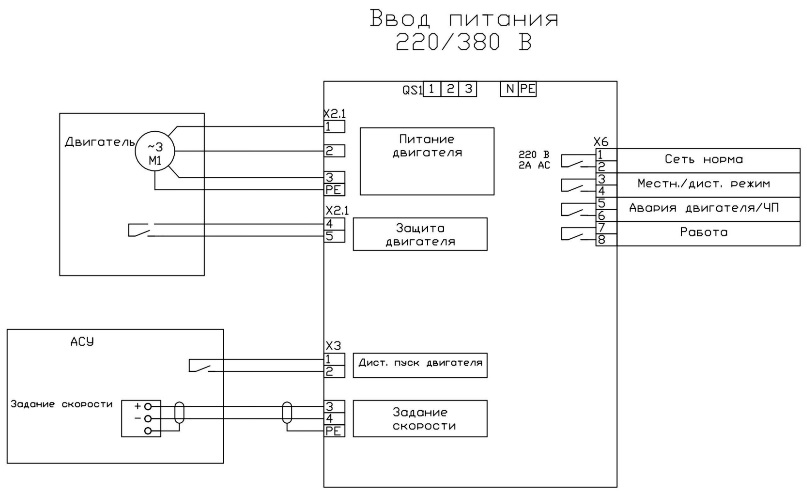

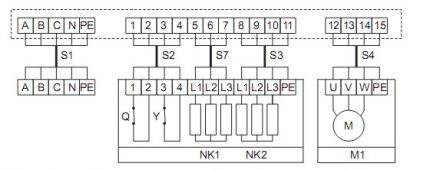

One of the connection options, where NK1 and NK2 are channel-type heating devices; M1 - 3-phase fan; A, B, C - network connection, N - neutral, PE - earth; Q - protective thermostat against overheating; Y - ignition protection thermostat

Professional installers have experience in the installation and operation of the control panel, so they are unlikely to make a mistake with choice of model and nuances connection of devices. Besides, they well versed in system diagrams ventilation of apartments and country houses and can quickly determine the presence of an error in the drawing.

If you don’t figure it out in time and connect the devices according to an illiterate scheme - and this also happens - you can create an emergency.

Many companies that manufacture or sell ventilation, refrigeration and heating equipment are engaged in the sale and sale of shields and cabinets. For example, in Moscow, this can be done in the companies "Ruklimat", "Roven", "AV-avtomatika", "Galvent", etc.

Maintenance and repair

Maintenance of control cabinets does not differ from similar procedures carried out with other electrical devices. That is, all manipulations come down to the timely replacement of failed blocks, cleaning filters, tightening contacts and other things.

Repair of control cabinets is carried out by replacing the failed unit with a new, efficient device. Moreover, after each installation of a new element, the operation of the cabinet should be adjusted.

If you are the owner of a country house or a dacha with autonomous water supply, then you probably at least once wondered how to make pumping equipment work more efficiently and for a long time, and also have several convenient operating modes. In addition, sometimes two pumps are used at once to provide the house with water and water the garden, so it is necessary to coordinate and automate their work. You will receive an answer to all questions when you find out what a pump control cabinet is, and also why it is needed.

The main purpose of switch cabinets is to control the electric motor of one or several pumping units at once. The type of pump does not matter. This can be submersible type equipment or a borehole or drainage pump.

Moreover, the purpose of pumping equipment may be different. For example, a submersible type unit is needed for the efficient operation of the heating system, arranging the water supply of a country house, or creating a fire extinguishing system. But the drainage pump, together with the control cabinet, is useful for pumping liquid.

If you install a control cabinet to coordinate the operation of the borehole pump, then you will finally find the long-awaited peace and rest, because from now on you do not need to monitor the operation of the equipment, all this will be done by the automation located in the cabinet. In this case, this device will be able to perform the following functions:

the equipment will ensure safe and smooth start of the engine of the pumping unit;

automation will be able to regulate the operation of the frequency converter;

in addition, the device will monitor the pressure in the system, the water level, as well as its temperature, which is very important for the timely switching on and off of pumping equipment.

The functions of control cabinets for two or more pumps are even more extensive:

- if the unit notices that one of the pumps is operating in emergency mode, it will immediately connect the second pump to work;

- since the automation of the control cabinet will regulate the alternate operation of each of the pumps, the general wear of the pump units will come later;

- if one of the pumps is idle for a long time, the equipment will be able to protect it from silting;

- thanks to such a device, you can manually block the operation of one of the pumps;

- cabinet automation has different control programs for several pumps;

- if necessary, you can get complete data on the operation of each unit separately.

Types and their features

There are several main types of control cabinets.

Pump control cabinets (SHUN)

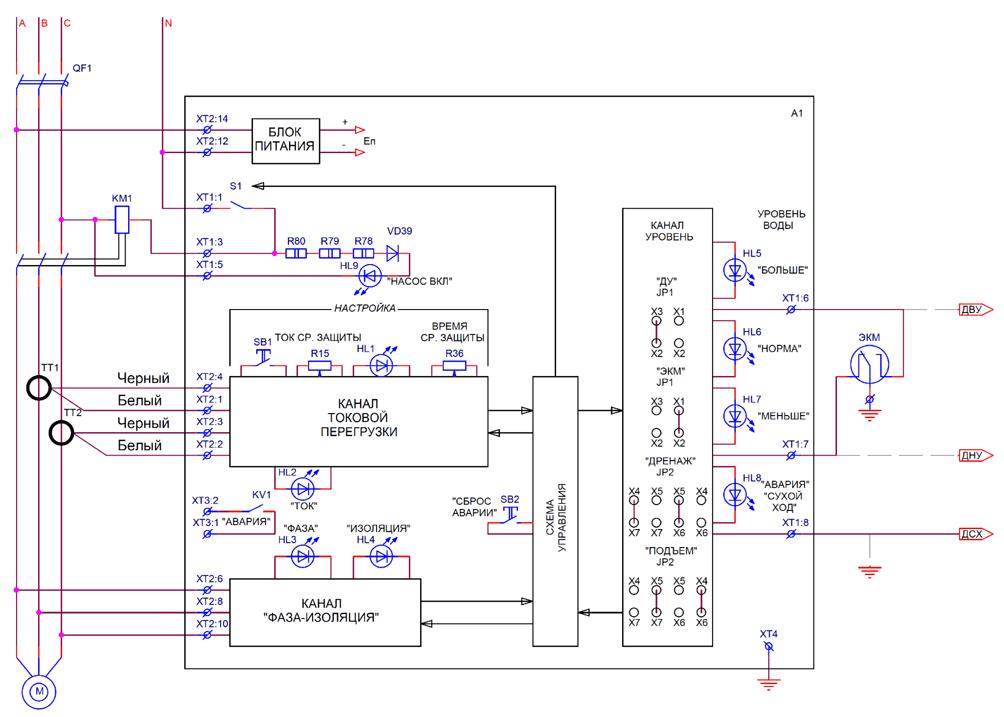

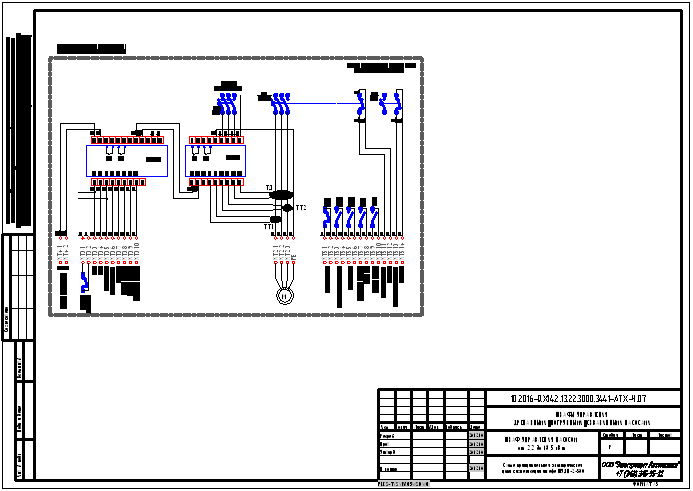

SHUN is a distribution station in which pumping equipment is located. One control system (remote control, computer) is capable of regulating various types of motors (drainage, submersible, downhole, etc.).This station is convenient to use when the distance between the control object and the control object is large. Any number of devices can be added to such a system. For minimal work, only two pumps will be enough. The first pump (submersible or borehole) is required to supply water to the system. The second pump (drainage) will operate in emergency situations to quickly pump water out of the system. Usually the SHUN consists of the following elements:

- rectangular metal case

- fuses and protection elements

- control unit

- switches

- frequency converter

- automatic adjustment unit

- a set of sensors and bulbs (used for protection)

- thermal relay

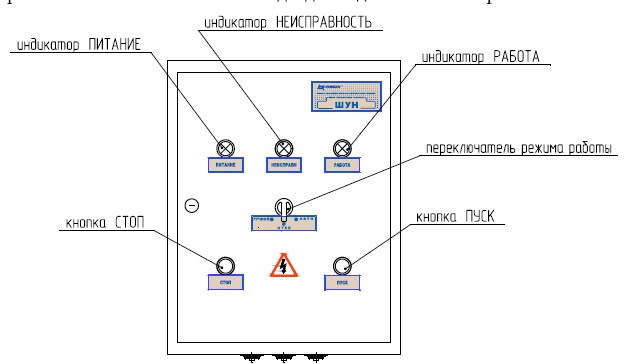

The configuration of the SHUN may vary depending on its purpose. The switches can be used to manually turn the pump on or off. Sensors are needed to control water pressure and temperature. The control unit regulates the three-phase voltage. On the front side of the SHUN there is a panel, which may differ from manufacturer to manufacturer. However, each model must have "Start" and "Stop" buttons to enable manual start and stop.

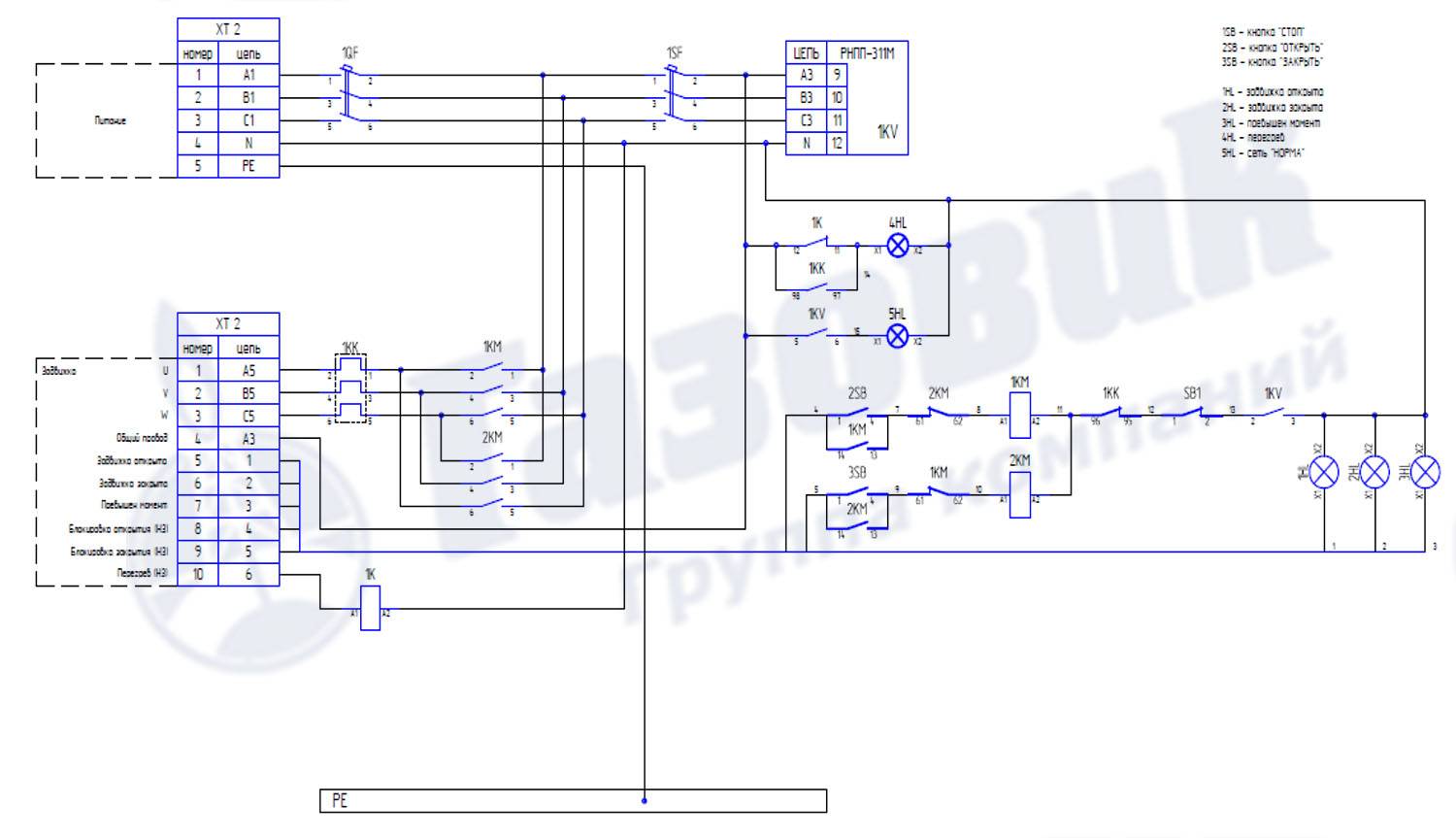

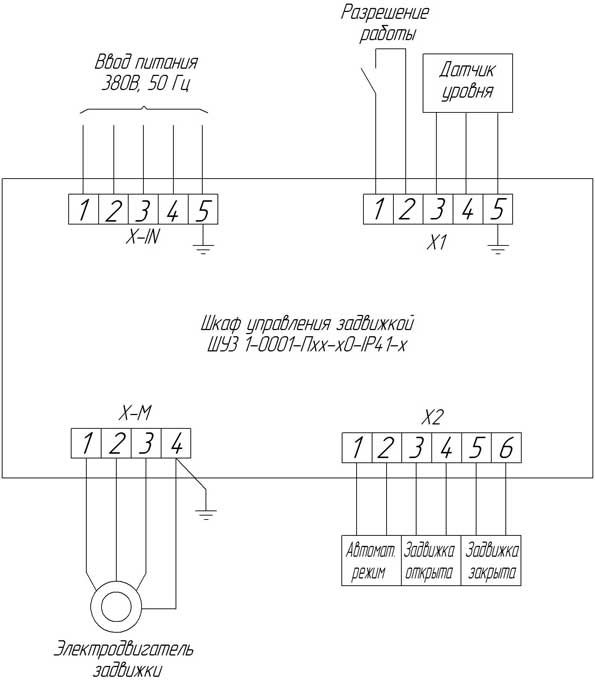

Valve control cabinets (SHZ)

SHUZ - a station that works with single-phase or three-phase electric gate valves. Working with them depends on the signals that come from the modules. A system has been thought out in the cabinet so that the valves can be controlled both manually (from the panel) and remotely (using special equipment, such as a computer). There is a light alarm in the SHZ. It shows the state of the valves, performs operations that protect against prolonged operation (more than 1 second), and blocks overloads.

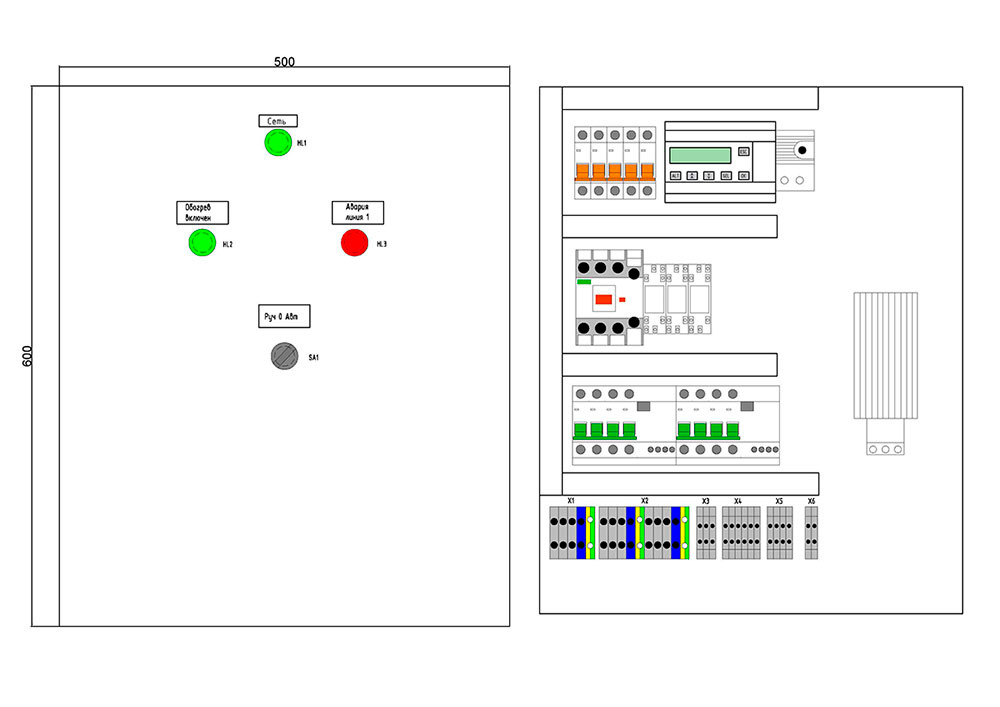

Ventilation control cabinets (SHUV)

Shuv - a station that maintains the desired temperature and humidity in the room, and also sets new parameters, if necessary. The station is adjusted using a special remote control or a computer network. The standard package of SHV includes:

- defense mechanisms

- circuit breakers

- indicator lights

- contactors, starters, switches

- frequency converter

- relay

- microprocessor controller

Heat exchangers (mainly water) or air heaters are used to protect the SHUV from low temperatures, freezing, and ice formation.

Lighting control cabinets (SHUO)

SHUO is a station that controls all lighting elements. The lighting algorithm can be completely different depending on the requirements of the project. SHOO consists of the following elements:

- manual lighting trigger

- electronic load switch

- backup battery

- switches

- electrical fuse

- overcurrent protection circuit breaker

- external cable channel

The convenience of working with SHUO is achieved by an additional switch. With it, you can select one of three operating modes: manual, timer, photorelay. With built-in blocks, you can set the on and off times.

Valve control cabinets (SHUK)

SUK is a station that regulates smoke and fire dampers. At the same time, the light signaling shows the current position of each of the valves, and the dispatcher can receive the necessary information. The position of the valves varies depending on three modes: remote, manual and automatic.In automatic mode, standard protection is activated (the fire alarm is turned on and the fire extinguishing system is started). In remote mode, a notification is sent to the process operator. Manual mode is used if the previous two do not work. To use it, you must independently press the button to start the fire extinguishing system and turn on the alarm.

Criteria for choosing the right cabinet

Since in water supply, fire extinguishing and other systems there are often requirements for the synchronous connection of several devices, a SHUN will be required to solve this problem. When purchasing it, it is necessary to take into account both the level of quality of the product and the performance of the loads for which it is designed.

But choosing a well-equipped drainage pump control panel is not all

It is important that the control system is compatible with the equipment being serviced. For example, if you are going to use a SPS control cabinet in combination with new generation pumps, then you need to stop at a modern model. Usually the system is chosen so that its year of manufacture is the same as that of the equipment.

Typically, the system is selected so that its year of manufacture is the same as that of the equipment.

In order to achieve efficient operation, quick payback and long service life of the fire pump control cabinet, it is necessary to purchase it in accordance with the hydraulic system diagram. With a competent solution of this problem, it is possible to achieve not only high reliability, but also resource saving.

Components for the KNS control cabinet should be selected taking into account the available pumping equipment.

KNS control board

For the smooth operation of the system, you will need:

- Pressure Sensors;

- Converters;

- Electromagnetic starters;

- Network chokes;

- Controllers.

In addition to quality indicators, buyers often pay attention to the cost of equipment.

Here it is important not to try to choose the cheapest model of SHUN pump control cabinet. Since such devices are usually not very reliable and are not designed for long periods of operation. Since such devices are usually not very reliable and are not designed for long service life.

Since such devices are usually not very reliable and are not designed for long periods of operation.

Overview of popular models

Among the SHUN presented on the domestic market, there are brands that have already managed to prove themselves from the best side. These products include ShUN Grundfos. The equipment of this manufacturer is designed to control the operation of drainage and fecal pumps of the following types:

- SEG;

- SEV;

- A.P.

In this case, the cabinet plays the role of a switching device. It connects the pump to the system and floats using cables. Grundfos drain pump control cabinets can be connected to a 220V and 380V network. If the marking of the model you have chosen contains the Latin letter D, this means that the product is designed to control 2 pumps.

Grundfos model

The range of Grundfos products is presented quite widely. It includes SHUN differing in configuration and technical characteristics. However, all of them are capable of performing the following functions:

- Pump control;

- Automatic start during long periods of inactivity;

- Liquid level control with data output to the display panel;

- adjustment.

Operation of pump control cabinets included in OKOF is possible at temperatures from minus 20 to plus 40°C.

Most Grundfos models are equipped with an electronic engine protection unit against:

- dry run;

- Voltage drops;

- phase missing.

KNS cabinets Alpha Control KNS are no less popular brand. They are designed to organize the work of sewer stations and provide automatic control of their equipment. Cabinets of this brand protect pumps from factors leading to failure and are able to control any models of units.

Thanks to the use of such equipment, it is possible to achieve a uniform development of the resource of pumps. The basic SHUN scheme allows you to control two or more devices on the principle of main and backup.

Conclusion

Analyzing the above information, we can conclude that the use of SHUN allows not only to achieve efficient operation of the equipment, but also to save electricity. Therefore, they are widely used in various fields of human activity.