- Models

- Standard equipment

- Technical support and service

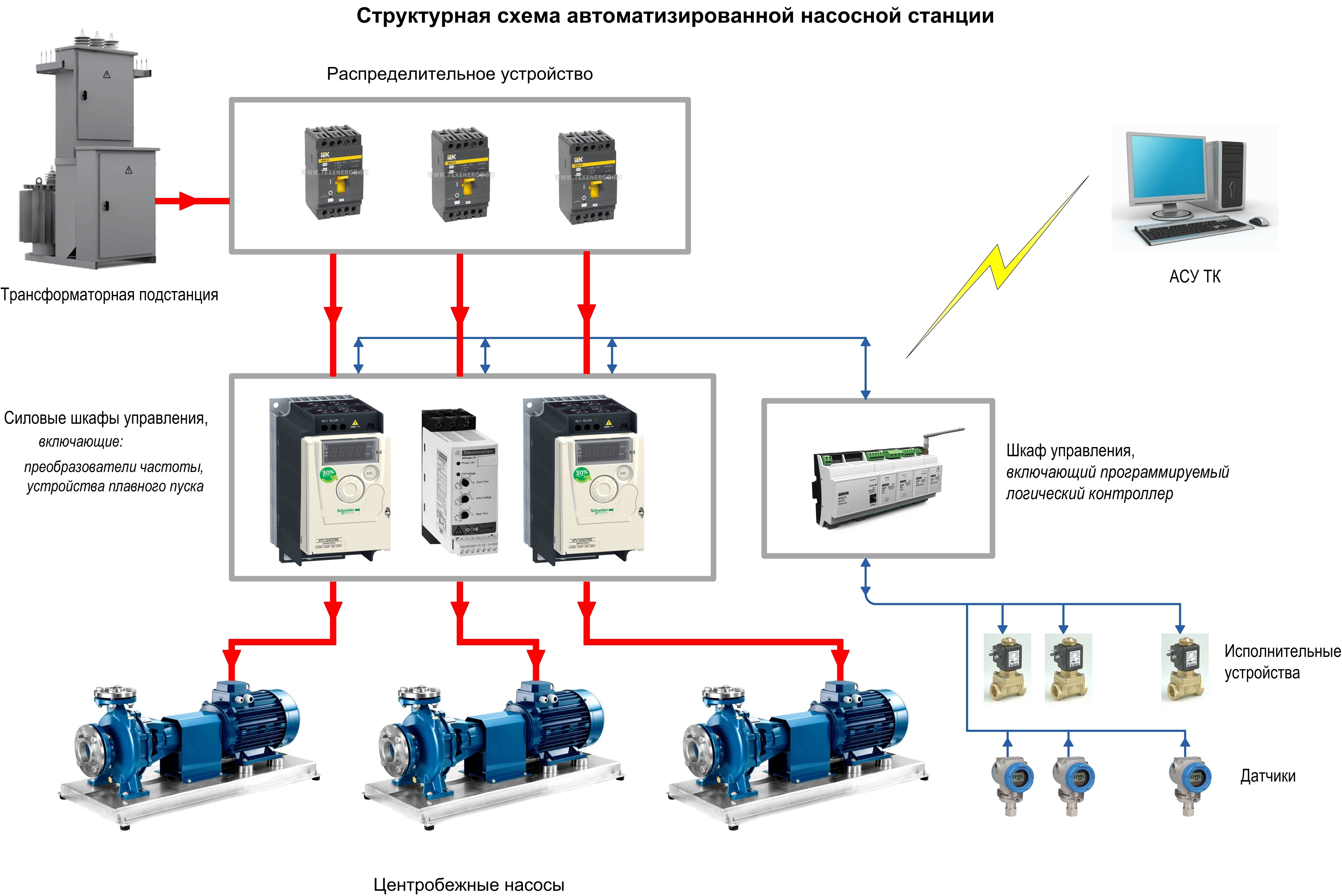

- Status signals and actuators.

- Control signals - states.

- Executive devices - power units.

- Samples of electronic technical connection diagrams

- Borehole pump control cabinet

- The main schemes for managing the operation of the SHUDN

- Standard equipment of borehole pump control cabinets

- Additional options to the standard SHUSN

- Basic rules of operation

- Operating principle

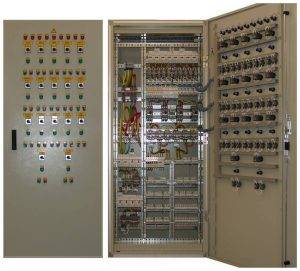

- Typical control cabinets for drainage pumps, sewage pumping station, filling systems, own production.

- Pressure control

- What is the requirement?

- For what tasks is it used

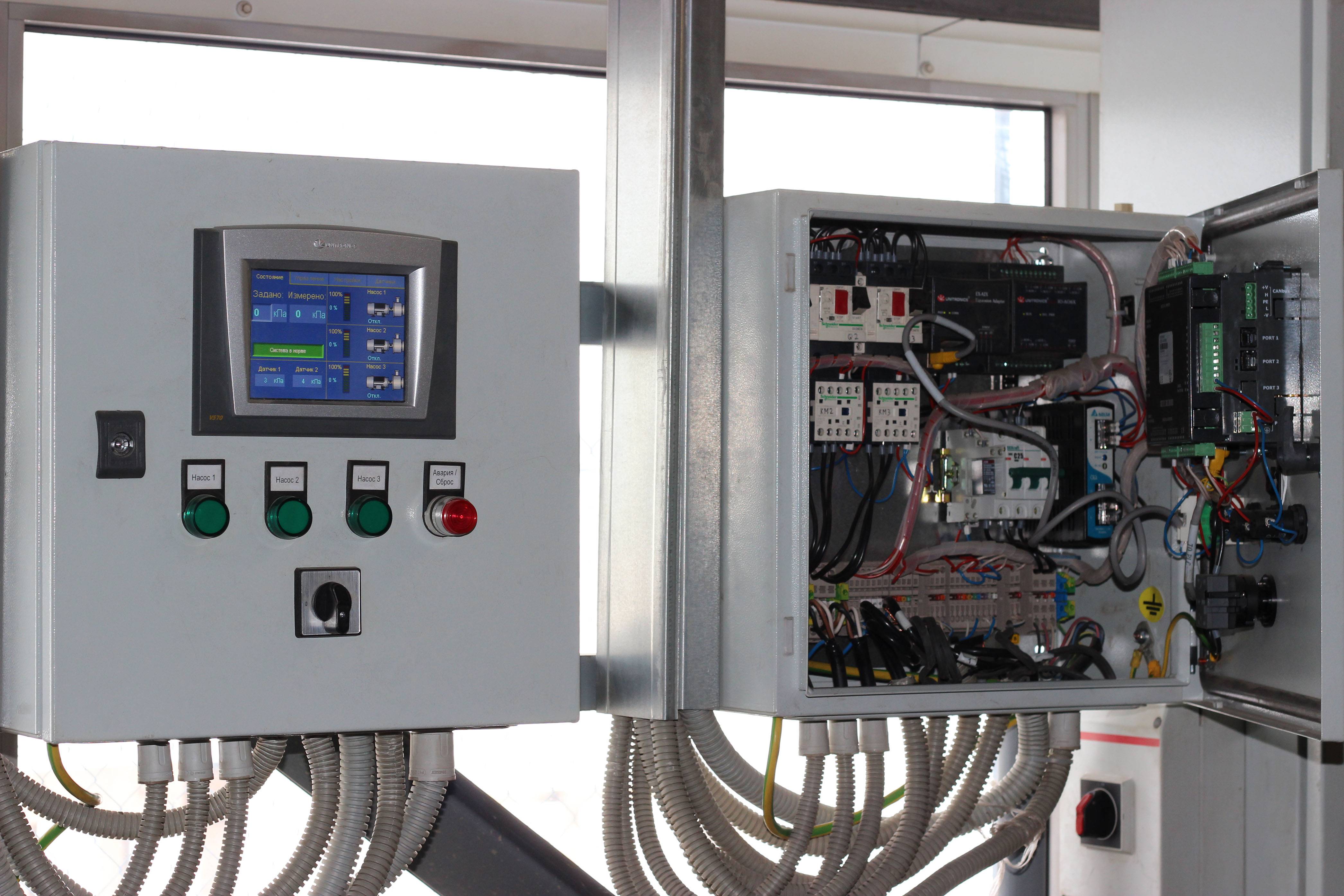

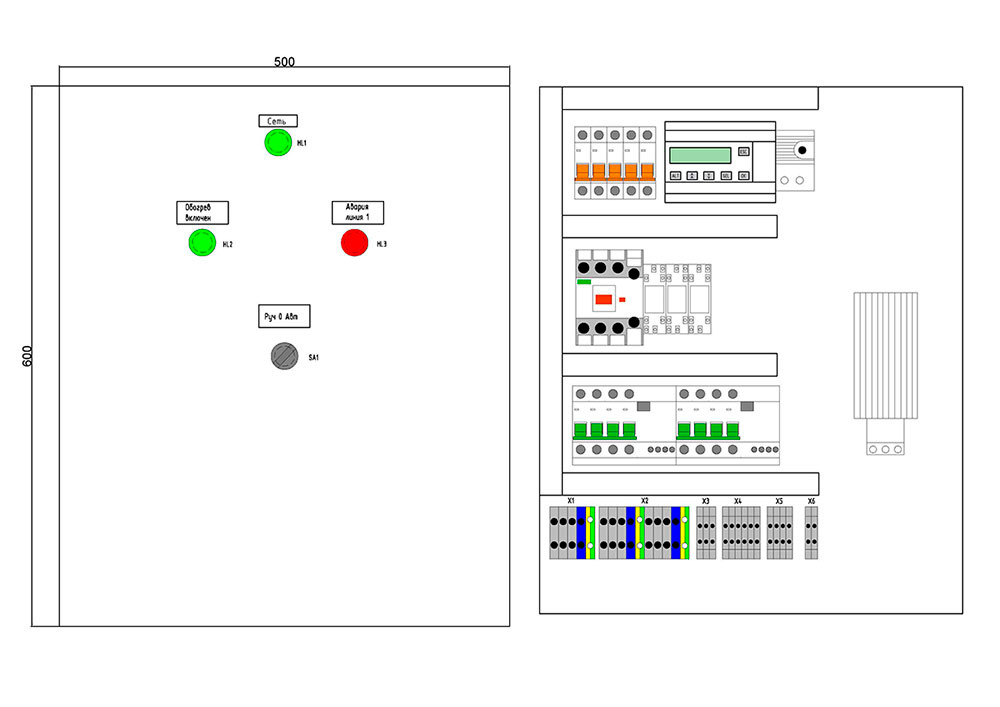

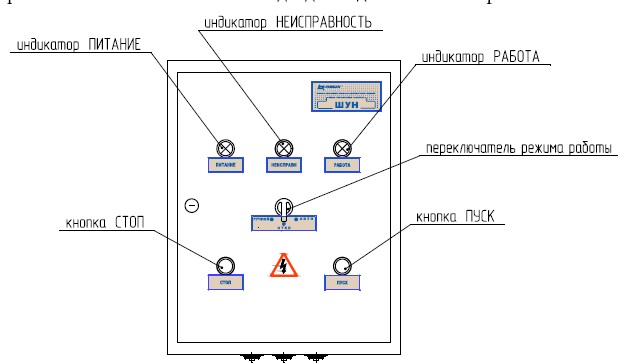

- Control cabinet layout

- Criteria for choosing the right cabinet

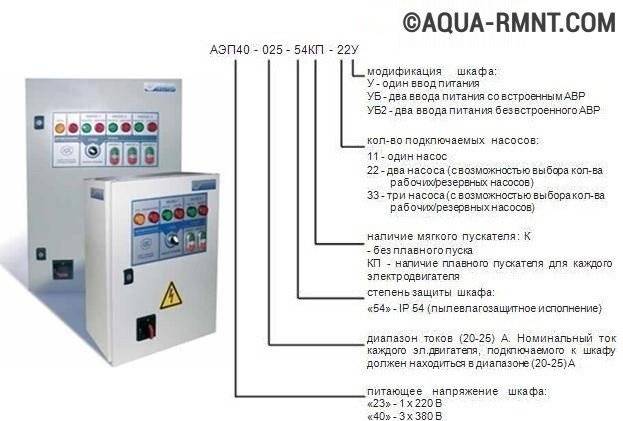

- Overview of popular models

- Conclusion

Models

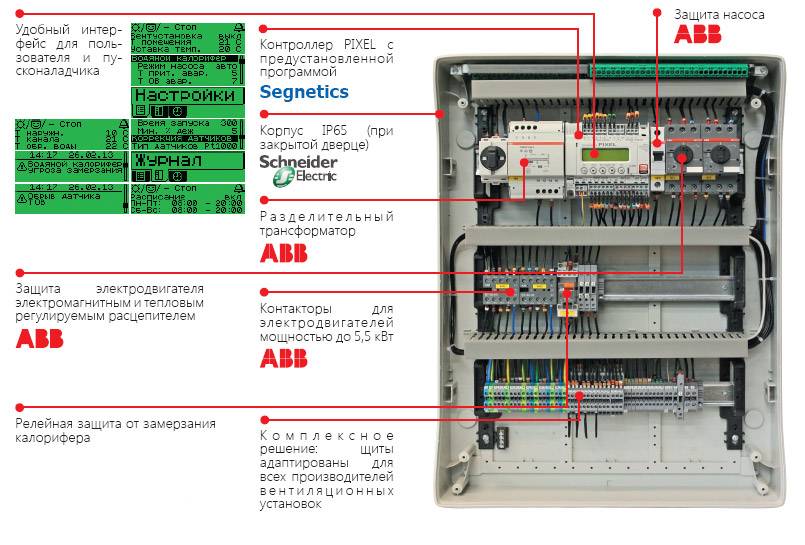

The design of smoke exhaust control cabinets is quite simple - these are hinged metal cases with lockable doors.

On the outside of the product there are indicator light panels that signal the presence of power, the inclusion of automatic mode, the start of smoke exhaust / air supply fans, fire dampers; other actuators, mechanisms that are part of the control cabinet.

In addition, a push button / toggle switch for manually starting the equipment is mounted on the body of the product, duplicating the automatic / remote start mode.

Among the well-known trademarks from manufacturing companies that manufacture control cabinets that are in demand and popular with specialists in design, installation and commissioning organizations, maintenance services of facilities, several models of products should be distinguished:

- Fire control devices of the Shkval-200 series, manufactured by the VEZA company from Moscow, are designed for exhaust, supply installations of smoke protection systems for objects.

- Shkval-200 cabinets control up to 4 fans up to 11 kW each, up to 4 normally closed fire dampers, continuously monitoring the continuity of communication lines between the control cabinet, fan motors, fire dampers, alarm / fire extinguishing devices.

- The Shkval-200 product line includes seven models numbered from 211 to 234, with different configurations of control units, which allow using this equipment for all modern design solutions for building smoke ventilation schemes for protected objects.

- The eminent company "Bolid", which produces almost the entire range of equipment for security systems, produces models of standard control and launch cabinets with a line from ShKP-4 to ShKP-250, where the figure indicates the power of the controlled electric motor in kW.

- Wall-mounted cabinets are intended for operation as part of smoke exhaust systems, water fire extinguishing installations for controlling 1 electric motor of fans, fire pumps, actuator drives.

- Cabinet dimensions - from 400x400x170 to 1000x500x350 mm, product weight - from 20 to 70 kg. Degree of protection - from IP 30 to IP

- The inertia of turning on after the command signal is no more than 1 s. Operating temperature of cabinets is from -30 to 50℃, with humidity up to 98% at 25℃.

- Smoke protection control cabinets / smoke exhaust automation panels from the Efficient Ventilation manufacturing company from Moscow, whose purpose is to control in automatic / manual mode asynchronous electric motors of smoke exhaust and / or air supply fans, as well as fire dampers, after receiving a command from alarm devices , quenching.

- Typical products of the company are a hinged smoke exhaust control panel, made in a metal case, with a lockable door, with a lower supply of power cable, 12/24 V switching wires. Control of 1 fan of one kind or another with a power of 5.5 to 45 kW, valve.

- Voltage ~ 380/220 V, 50 Hz; degree of protection - from IP 33 to IP 66, depending on the upcoming operating conditions, including in damp, dusty rooms. Operating temperature range - from 0 to 50℃, with the option of heating inside the product body - from -40 to 50℃.

- The company custom-produces control cabinets for groups of smoke exhaust / supply fans, groups of fire dampers, ensuring smooth start of electric motors with a power of more than 11 kW, including those allowing control over several smoke zones at the protected object.

All leading manufacturing companies do the same, manufacturing according to technical specifications and design solutions almost any set of control units for fans, valves, hatches, transoms, smoke exhaust skylights, cabinets / boards that control the start-up, reliable operation of smoke exhaust systems and air supply.

Standard equipment

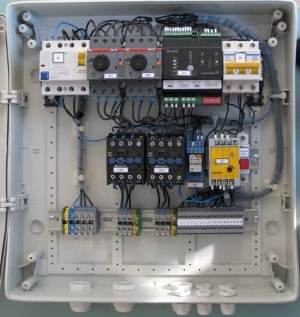

The control cabinet for a submersible pump of any type - drainage, fire, water - consists of the following elements:

Control cabinet for 2 sewage (drainage) pumps

- Cases - a standard metal box designed for the installation of electrical equipment.

- Front panel - it is created on the basis of the cover (door) of the case, into which the "Start" and "Stop" buttons are built. In addition, on the front side there are indicators of operation (pumps and sensors) and a relay for switching between manual and automatic operation.

- Phase control unit - it is connected at the "entrance" to the cabinet hardware. It consists of three sensors that monitor the load on the phases.

- Contactor - a switch that supplies energy to the pump terminals and disconnects the unit from the mains.

- Fuse - a special relay with a fusible element, leveling the effects of a short circuit. In the event of a short circuit or “breakdown”, the fusible element will burn out, and not the contents of the cabinet and the motor winding.

- Control unit - it controls the operating modes of the pump. Moreover, the mandatory elements of this block are: a pump shutdown sensor, a pump on sensor, an overflow sensor. Moreover, the outputs (terminals) of the sensors are introduced both into the well and into the hydraulic tank. After all, it is the control unit that controls the operation of the contactor that turns the pump on and off.Moreover, when the tank overflows or the water level in the well decreases, the pump turns off, and when the water level in the tank decreases, it turns on. However, as a result, these blocks automate the operation of the entire autonomous water supply system. And according to this automation scheme, both the control cabinet for the drainage pump and the control cabinet for the operation of the water supply unit work. After all, the role of the tank in the drainage system is played by the same septic tank or drain well.

- Frequency converter - it controls the speed of the shaft of an asynchronous electric motor, increasing or decreasing the speed at the time of starting or stopping the unit.

- Temperature and pressure sensors - they are connected to the contactor and prevent an attempt to start the unit in unacceptable operating conditions (at elevated pressure or icing of the pipe)

Such a configuration of control cabinets is adopted as a basis by most manufacturers of such equipment. However, each company seeks to introduce its own design solution into the standard scheme, which increases the competitiveness of the product.

Control cabinet for sewage and drainage pumps Grundfos LC LCD 108

So, the Grundfos pump control cabinet is equipped with shaft speed control sensors - a kind of speed box that involves the choice of one of the operating modes, including the low-noise "night". In addition, Grundfos cabinets have special blocks - thermal relays, with the help of which they also control the flow temperature inside the pipe, which is very much in demand in heating systems. And some models of Grundfos cabinets are controlled remotely, including via the Internet.

In turn, the Wilo pump control cabinet is also equipped with modern remote control units. However, in addition to this option, Wilo cabinets also have completely special control relays, with which you can “program” the operation of the entire system with a 24-hour cycle. In addition, products from Wilo are famous for their frequency controllers, which reduce the energy consumption of pressure equipment.

There are no such blocks, agreed and approved by all regulatory authorities of the federal level, in any pump control device.

Technical support and service

Some control cabinet companies claim that no maintenance is required. This is true, but the control unit must be checked regularly by the operator. There is a frequency set by the manufacturer, and for the correct operation of all devices, it must be adhered to without fail.

Before inspecting or replacing any parts, disconnect power and secure the equipment from being restarted. You can independently check the reliability of the connections. A list of potential faults, as well as possible solutions, is usually also indicated by the manufacturer.

ShUN to orderA control cabinet for a borehole or submersible pump with a frequency converter for use in industrial boiler houses, utilities or private homes, made to order according to an individual specification.

For example, the simplest malfunction - the light does not light up, indicating that the system is connected to an electrical cable.There are three possible reasons: there is no voltage in the network, the circuit breaker has broken, or the lamp has burned out. Accordingly, the solution to the problem will be to supply voltage, replace the switch or lamp.

If a malfunction occurs that cannot be eliminated on your own, you must contact the specialists at the service center.

Status signals and actuators.

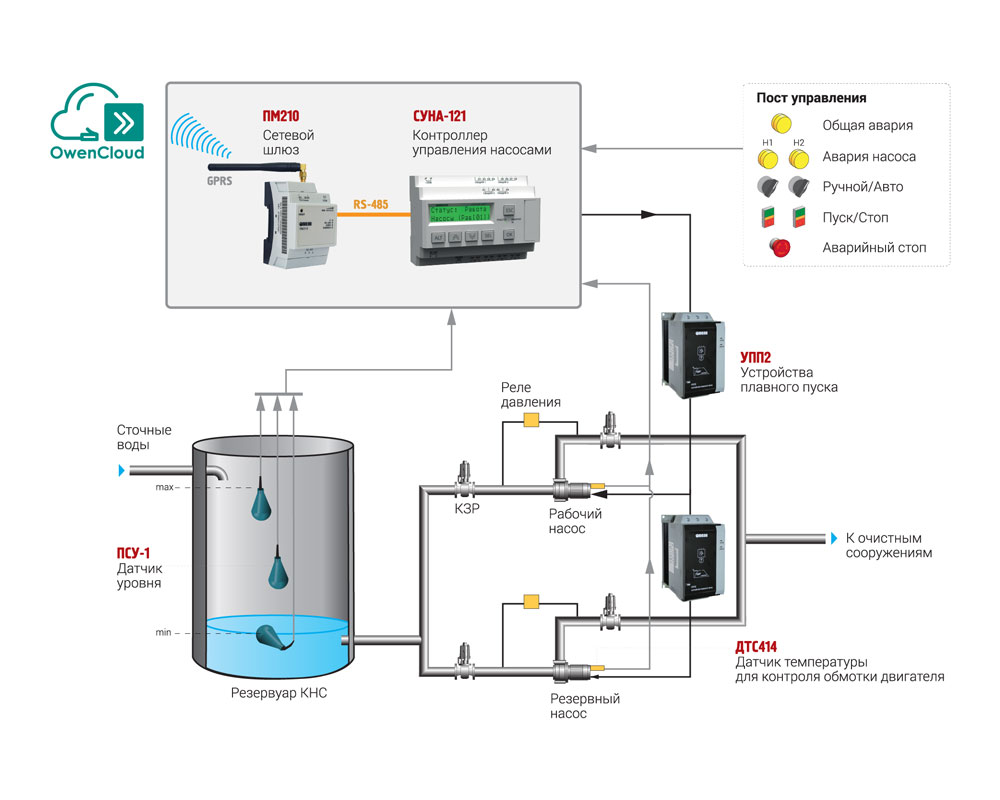

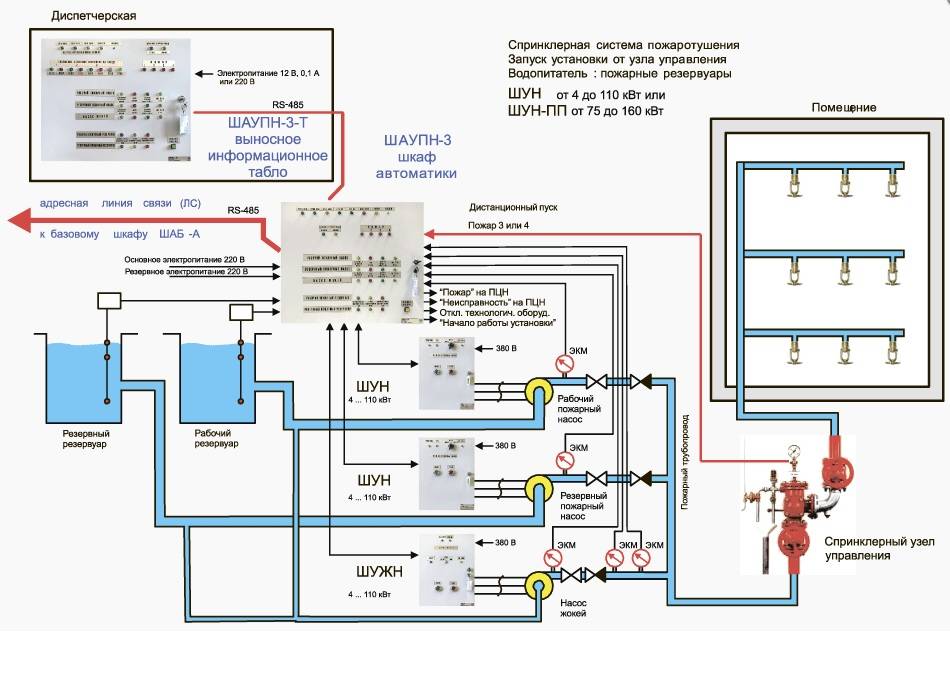

In a fire extinguishing pumping station, and indeed in a water fire extinguishing system, a limited number of signals and several types of actuators are possible.

Control signals - states.

- The pressure in the fire extinguishing system is necessary for making a decision on automatic start.

- Pressure in the fire extinguishing pump manifold - informs about the output of the fire extinguishing pump to the mode.

- Jockey Pump Trim Pressure - To start/stop jockey pump on low/high level.

- Water levels in the tank - to open / close the valve filling the tank.

- Fluid flow switch - for start confirmation and start signaling.

- Gate valve status “Open/Closed” – to stop the gate valve movement.

- Start / stop from a push-button station in the room on duty - for manual remote unconditional control.

- Start from buttons in fire cabinets - for manual remote conditional control.

- Direction control node status signal for deluge and sprinkler systems.

- Signal to start the direction control node for the deluge system.

- Emergency high pressure in the system - for signaling to duty personnel.

- Automation mode "Enabled / Disabled" - for continuous monitoring of the readiness of the pumping station for start-up.

- Low inlet pressure - to prevent dry running.

- The position of the fittings (faucet, butterfly valve ...) - so that the fire extinguishing direction does not accidentally turn out to be blocked.

- Power input failure - to switch to the backup power input.

- Circuit failure - to ensure the requirement of monitoring the integrity of the circuits.

Damn, you can write a whole article about how you need to receive all these signals and how to use them.

For executive devices, everything is simpler.

Executive devices - power units.

- Fire pumps - at least two: main and backup.

- Jockey pump if automatic start of the pumping station by pressure is used.

- Control node - in a deluge system, a special control node must be used to start.

- Gate valve - to open the bypass section around the meter or to fill the fire tank.

- Drainage pump - for emptying the drainage pit (common household device).

Samples of electronic technical connection diagrams

The assembly of equipment takes place in a production environment, and schematic diagrams of the pump control cabinet are also drawn up there. The simplest are the connection diagrams for a single pump, although a set of additional devices can complicate the installation.

As an example, let's take ShUN-0.18-15 (Rubezh company), designed for manual and automatic control of electric drives of a pumping station. The control scheme looks like this:

Control circuit On the housing cover there are on / off buttons, a toggle switch responsible for selecting the operating mode, a set of indicators indicating that the system is working (+)

The manufacturer sells 19 basic versions, which differ in the power of the electric motor of the pumping station - from 0.18 kW to 55-110 kW.

Inside the metal case are the following elements:

1. automatic switch; 2. protection relay; 3. contactor; 4. backup power supply; 5. controller.

For connection, a cable with a cross section of 0.35-0.4 mm² is required.

Drainage pump connection Sample connection of model SHUN-0.18-15 (for drainage or fire pump) from the manufacturer Frontier with one drive and a controller that regulates the operation of the equipment (+)

Grantor SHUNs, designed for drainage work, control asynchronous motors and have two control options: manual and automatic. Manual adjustment is carried out from the front panel of the housing, automatic adjustment operates from external relay signals (electrode or float).

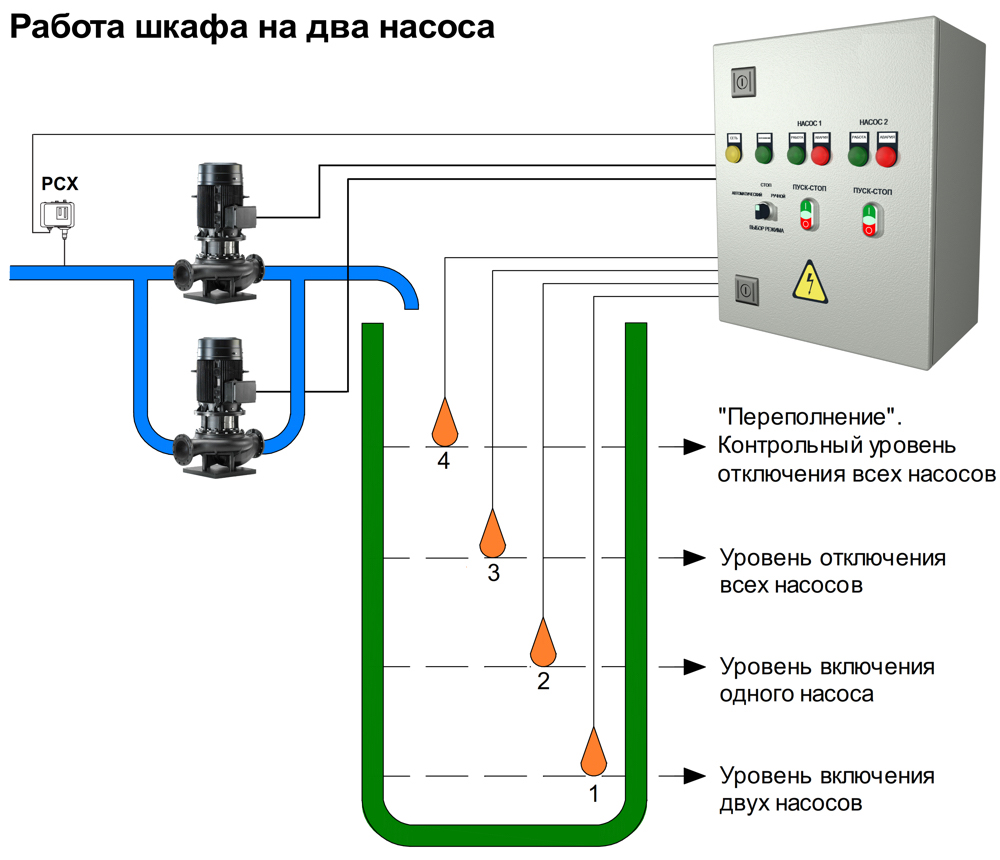

Scheme of float automaticsTriple diagram showing the operation of the cabinet for 1, 2 and 3 pumps with float automatics. In the presence of 2 or more pumps, it is proposed to distribute the load between the working and standby equipment.

The principle of operation of the SHUN in automatic mode: with a critical drop in the water level in the water well and the operation of float No. 1, the operation of all pumps stops. In the normal state of the liquid level, float No. 2 is activated and one of the pumps starts. When other floats are triggered, which are at higher levels, the remaining units are introduced.

Borehole pump control cabinet

Water supply to a country house or cottage can be provided in various ways. But if it is not possible to connect to the central water supply, then the most correct solution is water intake from a well or well, the depth of which can reach several tens of meters.

And in order for water from it to enter the pipes, it is necessary to install a special water-lifting mechanism.Installation of a borehole pump control cabinet (SHUSN) will provide an uninterrupted supply of clean drinking water all year round.

The main tasks of borehole pump control cabinets are:

- protection of pumps from undesirable factors that can disable it, namely from:

1. voltage drops; 2. overcurrent; 3. overheating; 4. from a decrease in the number of revolutions; 5. from dry running; 6. providing soft start (for protection against inrush currents and hydraulic shocks).

– implementation of automatic start and stop of the electric motor of pumps at a certain water level;

- control of the main parameters of the system, such as mains voltage, pump power, electricity consumption, pump motor rotor speed and its operation time.

The main schemes for managing the operation of the SHUDN

It is possible to connect one or more pumps (main and backup) to the borehole pump control cabinet, as well as in the SHUDN cabinets. There are two main schemes for controlling the operation of well pumps:

- pressure in the pipeline. In this case, the relay is installed on the pipeline near the accumulator (membrane tank). The hydraulic accumulator is designed to maintain a certain pressure in the system when the pump is off and to protect against water hammer. Two parameters are set on the pressure switch:

1. Pmin - the minimum pressure value at which the relay contacts close, the pump starts and fills the membrane tank with water.

2. Pmax - the maximum pressure value, upon reaching which the relay contacts open and the pump stops.

- according to the water level in the tank.In automatic mode, pumps are turned on/off, standby pumps are connected and extra pumps are turned off using installed sensors (floats, electrode, ultrasonic or laser). The number of sensors depends on the number of pumps connected to the SHUSN and the depth of the well.

Standard equipment of borehole pump control cabinets

1. a metal case with a front panel on which light indicators and start buttons are located; 2. control unit SHUSN; 3. protective equipment of pumping units; 4. switching equipment; 5. control and indication system.

Additional options to the standard SHUSN

1. ATS system (automatic transfer of reserve) is installed to ensure the uninterrupted operation of the pumping station; 2. additional insulation and an increased degree of protection of the body is especially important for SHUSN installed outdoors. Contribute to additional protection of equipment from low temperatures and high humidity. 3. soft start system provides engine protection from abrupt start; 4. SHUSN dispatching allows you to control the station at a distance using a radio modem, the Internet or GPRS; 5. installation of light alarms and sirens.

Instructions: /article/show/shkaf-upravleniya-skvagin-nasos

Basic rules of operation

The safety of the serviced pumps depends entirely on the correct operation of the distribution plant. Be sure to carefully read the instructions and technical data sheet of the unit before using it in work.

Before inspecting the switch cabinet, be sure to turn off the power supply.Some malfunctions can be eliminated independently, all of them are indicated in the instructions (replace a burned-out lamp or circuit breaker).

It is impossible to repair the cabinet for operation with pumps in the event of a breakdown without the appropriate qualification

Proper operation:

Pay special attention to the front panel;

Regularly clean the fan and regulator for cooling;

Mounting bolts are carefully checked.

The scheduled inspection provided by the service should be carried out regularly. The specialist must check all connection interfaces and compare them with the work instructions.

The use of switch cabinets is very popular today. Thanks to such a control system, you can not only monitor the quality of the pumps in the water supply system, but also use electricity carefully.

Operating principle

The principle of operation in automatic mode looks like this:

- When the automatic mode is activated, the frequency converter performs a soft start of the submersible pump motor.

- It keeps it on until the water pressure in the system reaches the set maximum.

- After that, the equipment turns off the pump.

- The same thing happens during active water analysis - the pump runs until peak water consumption stops and the pressure rises. As a result, the frequency decreases and the unit turns off.

The body of the equipment is made of metal. There are cabinets made for wall mounting, while other units are installed only on the floor. The main purpose of any product is to control system parameters and select the most appropriate mode of operation of the electric motor.Thanks to their use, it is possible to achieve a reduction in energy consumption and prevent damage to the electric motor.

Typical control cabinets for drainage pumps, sewage pumping station, filling systems, own production.

ECOTECHNOLOGIES LLC offers typical control cabinets for TSHUN pumps (submersible, drainage, etc.) of its own design based on EATON (Moeller) equipment, Germany.

Typical products are serial and do not require large financial and time costs for development and logistics. The advantage of ordering standard products is that the client receives a solution that has been tested and proven in its field without additional costs for engineering development, issuance of project documentation, and programming. This factor provides a reduction in the cost, and, accordingly, a reduction in the final price for the customer and significantly reduces the time it takes to receive the equipment. As a rule, the warehouse keeps a stock of ready-made TSHUN, and even if at the time of ordering the device you need is not available, the production time is at least 1-2 days.

Control cabinet "ECOTECHNOLOGIES" (3x380 V), 2 pumps, direct start, one power input, plastic housing. Indication: network, overflow, "emergency" of each pump. Controls: "Auto-O-Manual" operating mode switch for each pump.

| Cabinet brand | Power of each pump, (kW) | In, (A) | Overall dimensions, mm. (WxHxD) |

| SHUN2-340-0040-PP-A-54P economy series | 4 | 6,3-10 | 372x409x138 |

Control cabinet "ECOTECHNOLOGIES" (3x380 V), 2 pumps, direct start, one power input, plastic case. Indication: "Network", "Operation" and "Emergency" of each pump, "Overflow", "Dry running".Controls: "Auto-O-Manual" mode switch for each pump "Start", "Stop" buttons for each pump. Protection against: dry running, short circuit, thermal current overload, overheating of the motor windings. Dispatching.

| Cabinet brand | Power of each pump, (kW) | In, (A) | Overall dimensions, mm. (WxHxD) |

| SHUN2-340-0040-PP-A-54P | 4 | 6,3-10 | 372x559x138 |

Control cabinet "ECOTECHNOLOGIES" (3x380 V), 2 pumps, direct start, one power input, metal case. Indication: "Network", "Operation" and "Emergency" of each pump, "Overflow". Controls: "Auto-O-Manual" mode switch for each pump with operation indication, "Start", "Stop" buttons for each pump with indication. Protection against: dry running, short circuit, thermal current overload, overheating of the motor windings. Dispatching.

| Cabinet brand | Power of each pump, (kW) | In, (A) | Overall dimensions, mm. (WxHxD) |

| SHUN2-340-0004-PP-A-65M | 3-7 | 6,3-10 |

Control cabinet "ECOTECHNOLOGIES" (3x380 V), 3 pumps, "star-delta", one power supply, metal case. Indication: "Network", "Operation" and "Emergency" of each pump, "Overflow". Controls: "Auto-O-Manual" mode switch for each pump with operation indication, "Start", "Stop" buttons for each pump with indication. Protection against: dry running, short circuit, thermal current overload, overheating of the motor windings. Dispatching.

| Cabinet brand | Power of each pump, (kW) | In, (A) | Overall dimensions, mm. (WxHxD) |

| SHUN3-340-0055-ZT-A-65M | 5,5 | 16 | 800x1000x250 |

| SHUN3-340-0075-ZT-A-65M | 7,5 | 16-20 | |

| SHUN3-340-0110-ZT-A-65M | 11 | 20-25 | |

| SHUN3-340-0150-ZT-A-65M | 15 | 25-31 |

Pressure control

The result of the correct connection of automation to the water intake system will be reliable protection of the equipment. To do this, you need to install a relay on the pipeline.

It is impossible to do without an automatic control unit for a pumping station, especially for individual water supply, which has a membrane tank.

The advantage of automation is that the pressure is applied strictly according to the specified parameters.

The advantage of automation is that the pressure is applied strictly according to the specified parameters.

The principle of operation of an automatic device for downhole equipment is characterized by functioning in a certain pressure range.

Features of the downhole tool automation:

- Pressure supply is carried out strictly according to the specified parameters (from the minimum to the maximum level);

- The motor is turned on automatically if the pressure drops to the lower indicator;

- The engine switch is activated if the upper limit value is reached during operation.

It is better to use a relay with spring adjustment. In this case, the limit value settings are made manually. If you plan to set up automation yourself, it may be difficult to set up budget devices. Even with a pressure gauge, it is impossible to achieve high accuracy in adjustment.

Another thing is industrial devices with provided pressure gauges. They have special controls that allow you to achieve high accuracy in setting the desired parameters.

This is interesting: Ondulin laying technology

What is the requirement?

Everything is quite simple. When operating a small unit that is responsible for any one function, the requirements for the very quality of engine operation may not be so high.But if the electric motor works in a hydraulic installation system or an autonomous heating system of a large multi-storey building, then special requirements are imposed on the stability and uniformity of the pump.

Consider the operation of a pumping station based on the example of a power hydraulic installation of a high-rise building heating system.

As you know, the latest heating systems for high-rise buildings are built on the basis of double-circuit systems. This means that the hot water supplied to the technical room of the house does not run through all the floors, but enters the primary circuit of the heat exchanger system. But the water that is contained in the secondary circuit is pumped through all floors with the help of a pumping station.

If the heat supplier is responsible for the pressure and water flow in the primary circuit, then the pump is responsible for the second circuit. Therefore, high demands are placed on maintaining the same and uniform pressure in the system. If the pump does not work evenly, and even more so, allows abrupt starts, then a strong water hammer will occur in the system, which can lead to a rupture of the heat main or failure of the taps.

This is where the chastotnik-based hydraulic pump control cabinet comes to the rescue. It is he who provides smooth and timely regulation of the speed of the electric motor, which in turn allows you to equalize the pressure in the system in time. When the pressure drops, the speed of the electric motor increases in proportion to the pressure drop, and when the pressure stabilizes, the speed drops to the set value.

The system works automatically due to the operation of pressure sensors and a frequency converter with programmable control.

Among other things, if the electric motor is used in a water supply system or works with another conductive liquid, then the cabinet is necessarily equipped with power cutters and an RCD system. Thus, this unit becomes absolutely safe for humans.

For what tasks is it used

Regardless of the intended purpose of the installation (water intake or drainage systems), for normal and, most importantly, efficient operation, it is necessary to use one or more devices for supplying or draining water to / from the object

For industrial purposes, pumping stations are used, and it is important to ensure the highest possible degree of efficiency in order to reach a certain level of system performance.

We watch the video, the purpose and arrangement of the cabinet:

To solve this complex task, the human factor will not be enough, since it is necessary to control the operation of the equipment around the clock. Therefore, automatic control of the pumping station is the only right solution in such cases.

In addition, special equipment provides protection against short circuits, overloads, and in addition, it allows you to monitor the performance of the main parameters. Similar installations are used in sewer and drainage systems for various purposes, in particular, at production facilities.

Control cabinet layout

One of the most common and modern options for controlling a pumping station is a control cabinet. The device is equipped with all necessary devices that simplify the operation of a submersible pump.

There are many advantages to this control system. The cabinet has devices for automatically starting the engine, which allow you to do this safely and smoothly. The system also monitors pressure, water temperature and fluid level in the well. There are models that can simultaneously ensure the smooth operation of several types of pumps, which allows you to solve even more problems.

There is a standard set of accessories for automatic pump control.

Cabinet diagram:

- Frame. It is a steel box with doors.

- Front panel with built-in start and stop buttons. There are also indicators that monitor the operation of the pump and sensors, and a relay where you can select the operating mode (automatic or manual).

- Phase control device. It is installed at the entrance to the equipment compartment of the cabinet.

- The device for supplying current is a contactor. It conducts current to the pump terminals and turns off the equipment.

- Safety relay. Protects the pump motor and cabinet instruments from short circuits.

- Control block. Performs many functions - from monitoring the overflow of the tank to the level of water pressure.

- Frequency converter. This device controls the rotation of the motor shaft.

- Fluid temperature and pressure sensors. They are needed to fill the tank with water.

It is not recommended to carry out repair work on the pump control system yourself.

Such a cabinet allows you to improve the quality of the pumping station. It is able to work automatically, does not require constant user intervention.

Criteria for choosing the right cabinet

Since in water supply, fire extinguishing and other systems there are often requirements for the synchronous connection of several devices, a SHUN will be required to solve this problem. When purchasing it, it is necessary to take into account both the level of quality of the product and the performance of the loads for which it is designed.

But choosing a well-equipped drainage pump control panel is not all

It is important that the control system is compatible with the equipment being serviced. For example, if you are going to use a SPS control cabinet in combination with new generation pumps, then you need to stop at a modern model. Usually the system is chosen so that its year of manufacture is the same as that of the equipment.

Typically, the system is selected so that its year of manufacture is the same as that of the equipment.

In order to achieve efficient operation, quick payback and long service life of the fire pump control cabinet, it is necessary to purchase it in accordance with the hydraulic system diagram. With a competent solution of this problem, it is possible to achieve not only high reliability, but also resource saving.

Components for the KNS control cabinet should be selected taking into account the available pumping equipment.

KNS control board

For the smooth operation of the system, you will need:

- Pressure Sensors;

- Converters;

- Electromagnetic starters;

- Network chokes;

- Controllers.

In addition to quality indicators, buyers often pay attention to the cost of equipment.

Here it is important not to try to choose the cheapest model of SHUN pump control cabinet. Since such devices are usually not very reliable and are not designed for long periods of operation.Since such devices are usually not very reliable and are not designed for long service life.

Since such devices are usually not very reliable and are not designed for long periods of operation.

Overview of popular models

Among the SHUN presented on the domestic market, there are brands that have already managed to prove themselves from the best side. These products include ShUN Grundfos. The equipment of this manufacturer is designed to control the operation of drainage and fecal pumps of the following types:

- SEG;

- SEV;

- A.P.

In this case, the cabinet plays the role of a switching device. It connects the pump to the system and floats using cables. Grundfos drain pump control cabinets can be connected to a 220V and 380V network. If the marking of the model you have chosen contains the Latin letter D, this means that the product is designed to control 2 pumps.

Grundfos model

The range of Grundfos products is presented quite widely. It includes SHUN differing in configuration and technical characteristics. However, all of them are capable of performing the following functions:

- Pump control;

- Automatic start during long periods of inactivity;

- Liquid level control with data output to the display panel;

- adjustment.

Operation of pump control cabinets included in OKOF is possible at temperatures from minus 20 to plus 40°C.

Most Grundfos models are equipped with an electronic engine protection unit against:

- dry run;

- Voltage drops;

- phase missing.

KNS cabinets Alpha Control KNS are no less popular brand. They are designed to organize the work of sewer stations and provide automatic control of their equipment.Cabinets of this brand protect pumps from factors leading to failure and are able to control any models of units.

Thanks to the use of such equipment, it is possible to achieve a uniform development of the resource of pumps. The basic SHUN scheme allows you to control two or more devices on the principle of main and backup.

Conclusion

Analyzing the above information, we can conclude that the use of SHUN allows not only to achieve efficient operation of the equipment, but also to save electricity. Therefore, they are widely used in various fields of human activity.