- Criteria for choosing the right cabinet

- Overview of popular models

- Conclusion

- Dryer design

- What parts does the automatic block consist of

- First generation

- Second generation control units

- third generation

- Modular well automation - advantages and disadvantages

- Varieties of the proposed equipment

- Design features

- Functions performed

- Tips for selection and application

- Video description

- Briefly about the main

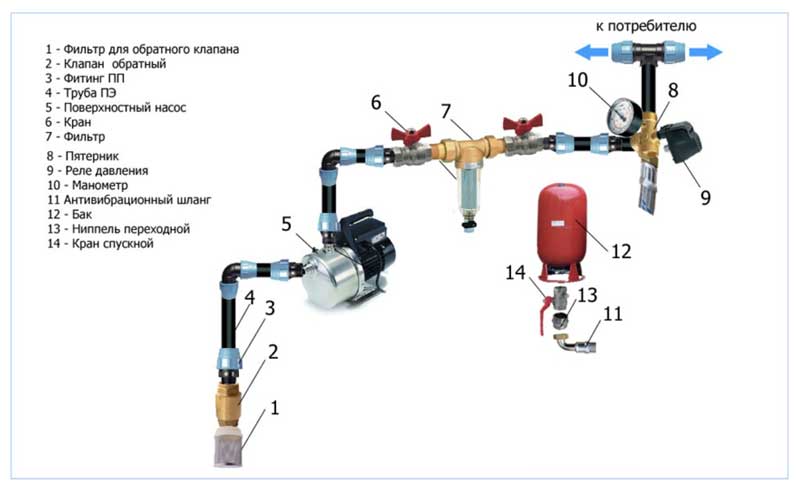

- Completeness of the automation system of the pumping station.

- Two separate items.

- Block-modular approach.

- Dryer operation

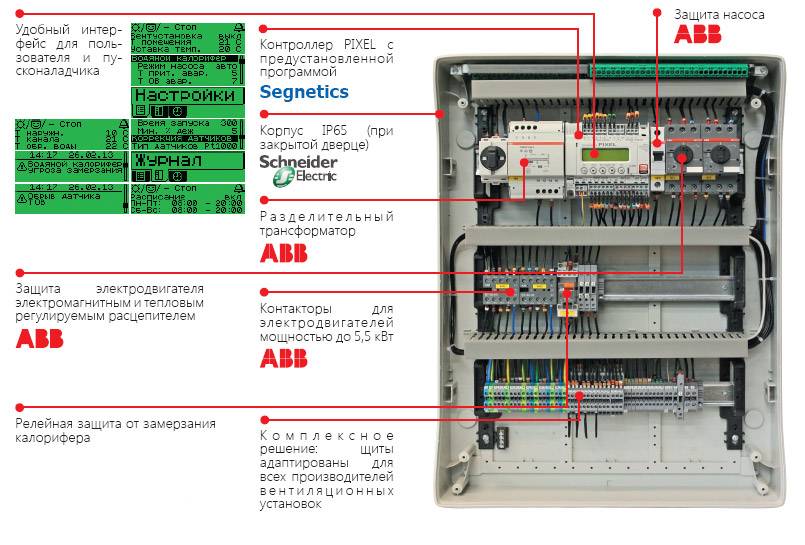

- The purpose of the ventilation control panel

- The principle of operation of the device

- What is pump automation and why is it needed

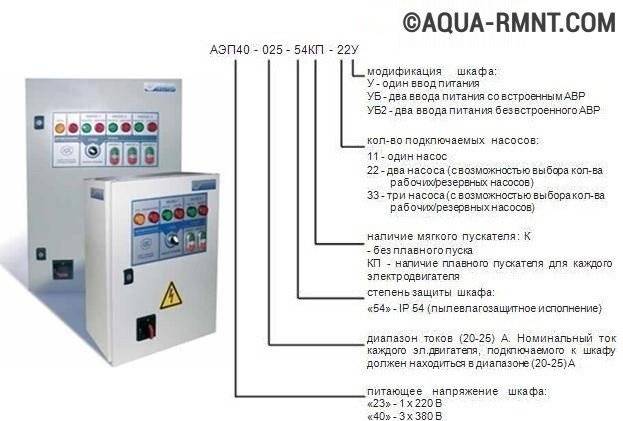

Criteria for choosing the right cabinet

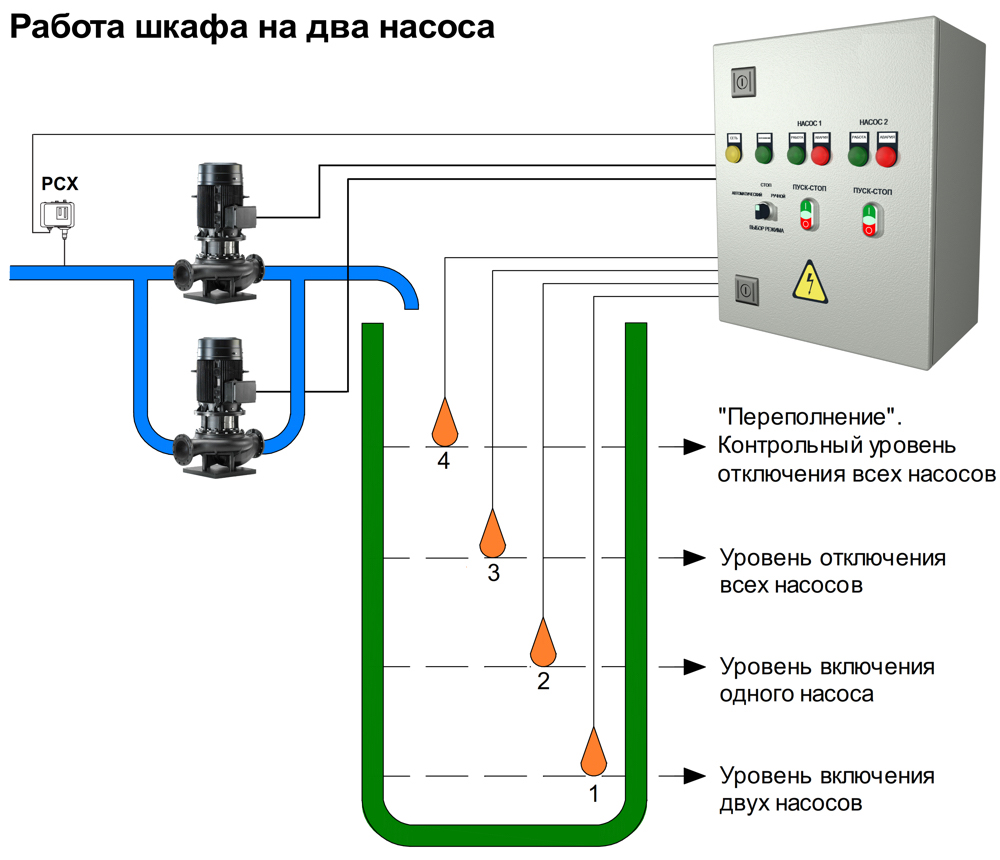

Since in water supply, fire extinguishing and other systems there are often requirements for the synchronous connection of several devices, a SHUN will be required to solve this problem. When purchasing it, it is necessary to take into account both the level of quality of the product and the performance of the loads for which it is designed.

But choosing a well-equipped drainage pump control panel is not all

It is important that the control system is compatible with the equipment being serviced.For example, if you are going to use a SPS control cabinet in combination with new generation pumps, then you need to stop at a modern model. Usually the system is chosen so that its year of manufacture is the same as that of the equipment.

Typically, the system is selected so that its year of manufacture is the same as that of the equipment.

In order to achieve efficient operation, quick payback and long service life of the fire pump control cabinet, it is necessary to purchase it in accordance with the hydraulic system diagram. With a competent solution of this problem, it is possible to achieve not only high reliability, but also resource saving.

Components for the KNS control cabinet should be selected taking into account the available pumping equipment.

KNS control board

For the smooth operation of the system, you will need:

- Pressure Sensors;

- Converters;

- Electromagnetic starters;

- Network chokes;

- Controllers.

In addition to quality indicators, buyers often pay attention to the cost of equipment.

It is important here not to try to choose the cheapest SHUN model. pump control cabinet. Since such devices are usually not very reliable and are not designed for long periods of operation. Since such devices are usually not very reliable and are not designed for long service life.

Since such devices are usually not very reliable and are not designed for long periods of operation.

Overview of popular models

Among the SHUN presented on the domestic market, there are brands that have already managed to prove themselves from the best side. These products include ShUN Grundfos.The equipment of this manufacturer is designed to control the operation of drainage and fecal pumps of the following types:

- SEG;

- SEV;

- A.P.

In this case, the cabinet plays the role of a switching device. It connects the pump to the system and floats using cables. Grundfos drain pump control cabinets can be connected to a 220V and 380V network. If the marking of the model you have chosen contains the Latin letter D, this means that the product is designed to control 2 pumps.

Grundfos model

The range of Grundfos products is presented quite widely. It includes SHUN differing in configuration and technical characteristics. However, all of them are capable of performing the following functions:

- Pump control;

- Automatic start during long periods of inactivity;

- Liquid level control with data output to the display panel;

- adjustment.

Operation of pump control cabinets included in OKOF is possible at temperatures from minus 20 to plus 40°C.

Most Grundfos models are equipped with an electronic engine protection unit against:

- dry run;

- Voltage drops;

- phase missing.

KNS cabinets Alpha Control KNS are no less popular brand. They are designed to organize the work of sewer stations and provide automatic control of their equipment. Cabinets of this brand protect pumps from factors leading to failure and are able to control any models of units.

Thanks to the use of such equipment, it is possible to achieve a uniform development of the resource of pumps. The basic SHUN scheme allows you to control two or more devices on the principle of main and backup.

Conclusion

Analyzing the above information, we can conclude that the use of SHUN allows not only to achieve efficient operation of the equipment, but also to save electricity. Therefore, they are widely used in various fields of human activity.

Dryer design

Dryer drums for clothes have a fairly simple design. We will tell you what most condenser dryers look like.

- Control Panel. It contains an electronic display, a program selector, depending on the type of clothing, buttons for additional functions.

- Drive belt connecting the motor to the tank.

- Dryer drum. This is the main element of the dryer, in which the process of drying things takes place.

- Electric motor.

- Heat exchanger. In it, cold and hot air flows move along two channels at once. However, they do not mix with each other. This is how air is cooled and condensation is further formed.

- Heating element (TEN). It heats up the air before it enters the drum directly into the clothes.

- Fan. It helps to capture cold air and sets its correct direction.

- Container for collecting condensate. It can be located at the bottom of the front panel or where the powder receiver is located in the washer. From it it is necessary to periodically drain the water so that there is somewhere to go to the new condensate.

- Air intakes with fluff filters. They collect dust, particles of debris coming with air currents. Filters should be cleaned at least once a month.

What parts does the automatic block consist of

Currently, there are various types of automation, ranging from the simplest discrete devices to small-sized units with pulse width modulation. All its types can be divided into three groups depending on the technological developments used and the range of functions performed.

First generation

In this case, automatic control is carried out using the simplest nodes, which include:

- Pressure and idle switch. Their functioning is described in detail above, it is easy to install and configure the devices with your own hands in the pipeline.

- Hydraulic accumulator. It is a container for collecting water, the volume of which can vary significantly, the main purpose is to support pressure and compensate for water hammer in the system.

- Pressure gauge. An element necessary to control pressure and adjust the hydraulic switch.

Rice. 9 1st generation pump automation

Second generation control units

Modules of this class differ significantly from the first type due to the following parameters:

- all discrete parts, including a volumetric hydraulic accumulator, are mounted in one module;

- the functions performed have been significantly expanded;

- parameter setting is done electronically;

- many modules are designed to work with specific models of electric pumps and have preset settings.

Automation of pump control by modules of the second generation allows you to implement the following functions:

- The pump turns off after a few seconds when the pressure rises above the permissible parameters or there is no liquid in the line.

- Winding protection against idling.

- Possibility of fine adjustment of adjustable parameters.

- Electronic indication reflecting the hydraulic performance and the condition of the equipment.

- Damping of hydraulic shocks due to the installation of a small volume hydraulic accumulator.

- Soft start, increasing the service life of the pump unit.

- Anti-cycling to prevent repeated power-on in the event of a leak in the pipeline.

Rice. 10 2nd generation modules

third generation

The third generation of automation has all the listed functions of the second with the additional ability to adjust the speed of rotation of the motor shaft. This feature provides the following benefits:

- The pump motor works with water intake in mind, turning on high speeds with a large amount of consumption and slowing down its speed with a small flow.

- There is no hydraulic accumulator in the module - there is no need for it, since water supply occurs smoothly without jumps.

- A constant pressure is always maintained in the water supply.

- Electricity is saved by 30 - 40% when the engine operates in economy mode at low speeds.

Modular well automation - advantages and disadvantages

The advantages of using automation in 2nd and 3rd generation modules are the following features:

- All nodes are assembled in one block, which takes up little space and is easily connected to the water supply.

- Devices have wide functionality for management.

Rice. 11 Automation units of the 3rd generation

- When used, the service life of the electric pump and other components of the water main increases, and energy is saved.

- The procedure of control, diagnostics, adjustment and management is simplified.

- Due to the constant pressure in the system, the comfort of using the water supply system increases.

The disadvantages include the following features:

- The high cost of third-generation modules, which is several times higher than the second and an order of magnitude higher than the first.

- The performance of the devices is highly dependent on the voltage in the network.

- Many systems are designed to work only with a certain brand of electric pump, have fixed settings and are not suitable for use with other devices.

Rice. 12 Surface pump installation diagram

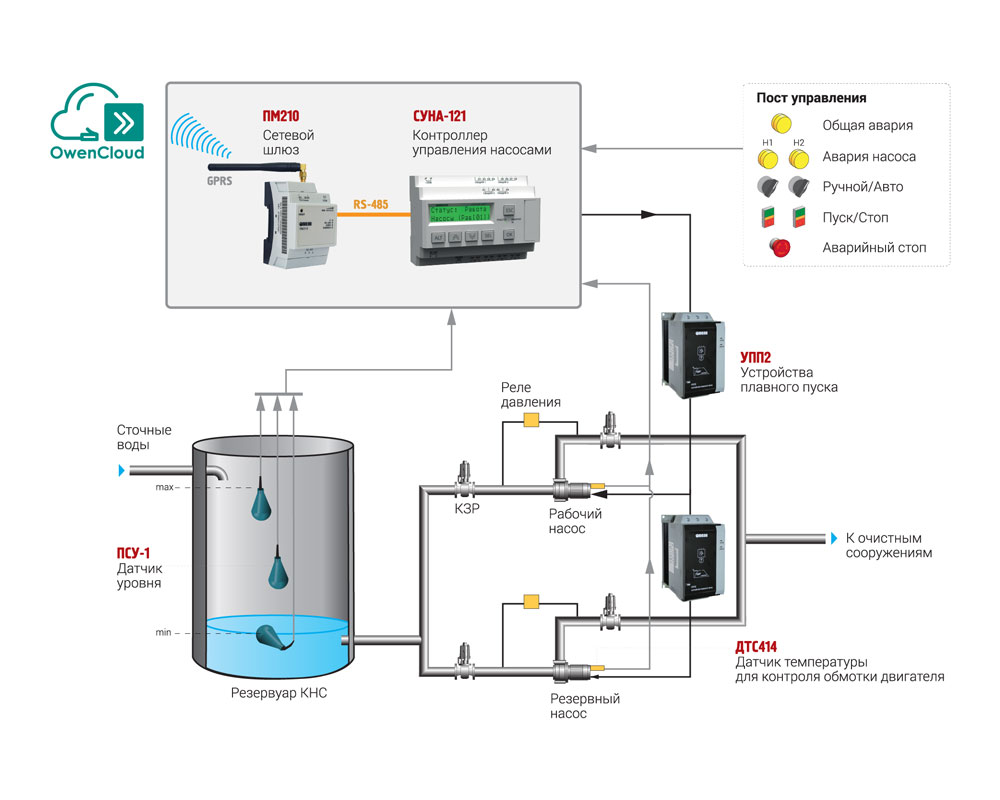

Varieties of the proposed equipment

On the page "production of cabinets and panels of automation and control" there are cabinets for process control and automation panels:

On the page "production of cabinets and panels of automation and control" there are cabinets for process control and automation panels:

- distributed control system DCS;

- technological processes;

- emergency protection PAZ;

- pumping stations and pumps;

- dispatching systems;

- energy accounting ASTUE, ASKUE;

- gas pollution control;

- ventilation systems, heating points, fans for air overpressure, smoke removal;

- fire pumps, valves, channels;

- power supply and lighting systems;

- telecommunications;

- cross cabinets;

- server rooms;

- Main switchboard, RP, ATS, ASU.

It is possible to purchase a standard control cabinet for standard configuration, according to the completed questionnaire, or non-standard according to individual requirements.

ACU series cabinets are made of high quality European components.

Design features

ShU cabinets differ in that they include power circuits and control circuits. Control cabinet diagrams include the following elements:

ShU cabinets differ in that they include power circuits and control circuits. Control cabinet diagrams include the following elements:

- Power supplies;

- controllers, modules for input and output of discrete and analog signals;

- automatic switches;

- network communication modules;

- touch panels (optional);

- contactors;

- electromagnetic relays;

- two and three position switches;

- buttons;

- indication signal lamps;

- terminals.

Functions performed

The principle of operation of control cabinets (control panels) is based on:

- constant monitoring of changes in the technical characteristics of the system, recorded by sensors;

- mathematical processing of the received data by the software installed in the controller;

- generating control signals to turn on and off equipment (pumps, compressors, valves, etc.) and set their operating mode;

- implementation of visual monitoring of the state of technological processes.

The main functions of SHU control cabinets and SHA automation cabinets include:

- equipment diagnostics and protection;

- automatic equipment control;

- switching between manual, semi-automatic or automatic operating mode;

- implementation of dispatcher's and operator's commands;

- precise adjustment of technical indicators of engineering systems or technical processes (temperature, pressure, etc.);

- transmission of telemetric data to the operator's panel or to the operator's monitors in the control room;

- visual and remote monitoring of changes in the values of monitored parameters;

- light and sound signaling (working, warning, information, emergency);

- automatic protection in case of an accident;

- blocking the activation of equipment in case of recurrence of the emergency.

Tips for selection and application

Before choosing a pressure regulator, you should understand how high you need to supply water, since the standard pressure is from 1.5 to 3 atm., And to supply water for every 5 m, you need to add another 0.5 atm to this indicator. Therefore, for the 2nd floor, the minimum pressure will be from 2 to 3.5 atm.

You should also install a block on the pump that prevents damage from voltage surges. It also acts as a current power stabilizer that is supplied to the system. At critical values, the protection will turn off the power, and if the indicators are slightly different, but not limiting, then it equalizes the voltage.

Before you start using the automation and the pump, it is recommended to carefully configure all the parameters, since they may be different for each well. Also, the settings depend on the presence of a hydraulic accumulator and its volume.

Video description

This video shows how to properly set up the pressure switch:

Automation should be installed only if it is necessary. For example, for an autonomous heating system. For watering the site in the summer seasons, automation is not needed. A simple pump is enough for this. A pump that has a capacity higher than the flow rate of the well (recoil) will supply water in jerks, which can lead to breakage.

The automation control unit should be placed in a dry place so that the contacts inside the system do not oxidize and a short circuit does not occur. Also, the place should be easily accessible to whom, since in the event of a failure or when changing settings, it will be inconvenient to approach the unit if it is blocked.

It is necessary to carry out periodic maintenance of the automation unit (setting, checking for operability, replacing parts). This is required because if the motor does not work properly and is not turned on in time, the contacts in the pump burn out and it stops working.

Service maintenance of the automation unit

The installation of electronic automation should be carried out only with experience. If it is not there, then it is better to turn to specialists, since an improperly mounted system will quickly fail or will not start working at all.

If an external pump is used, which is connected to the well, then a storage tank (if not available) and a pressure regulator should be installed for it. There are external pumps that come with these modules or are initially connected to its housing. You should also put a liquid flow switch in the form of electrolytic sensors. This will prevent air from entering the motor.

Expensive systems are best installed if frequent use of water in different volumes is required, as they will be able to regulate its flow.

Well automation control unit

Briefly about the main

Automation for wells is needed if frequent switching on and off of the pumping station is required, as well as to maintain a constant pressure in the system.

There are three generations of automation for pump control.

The first generation of automation is most often mechanical, which is why it has a low cost.

The second generation has an electronic control system, due to which the water supply occurs offline.

The most reliable automatic water supply control systems belong to the third generation, as they are equipped with an electronic control unit with a frequency converter. It extends the service life and also reduces electricity consumption.

Source

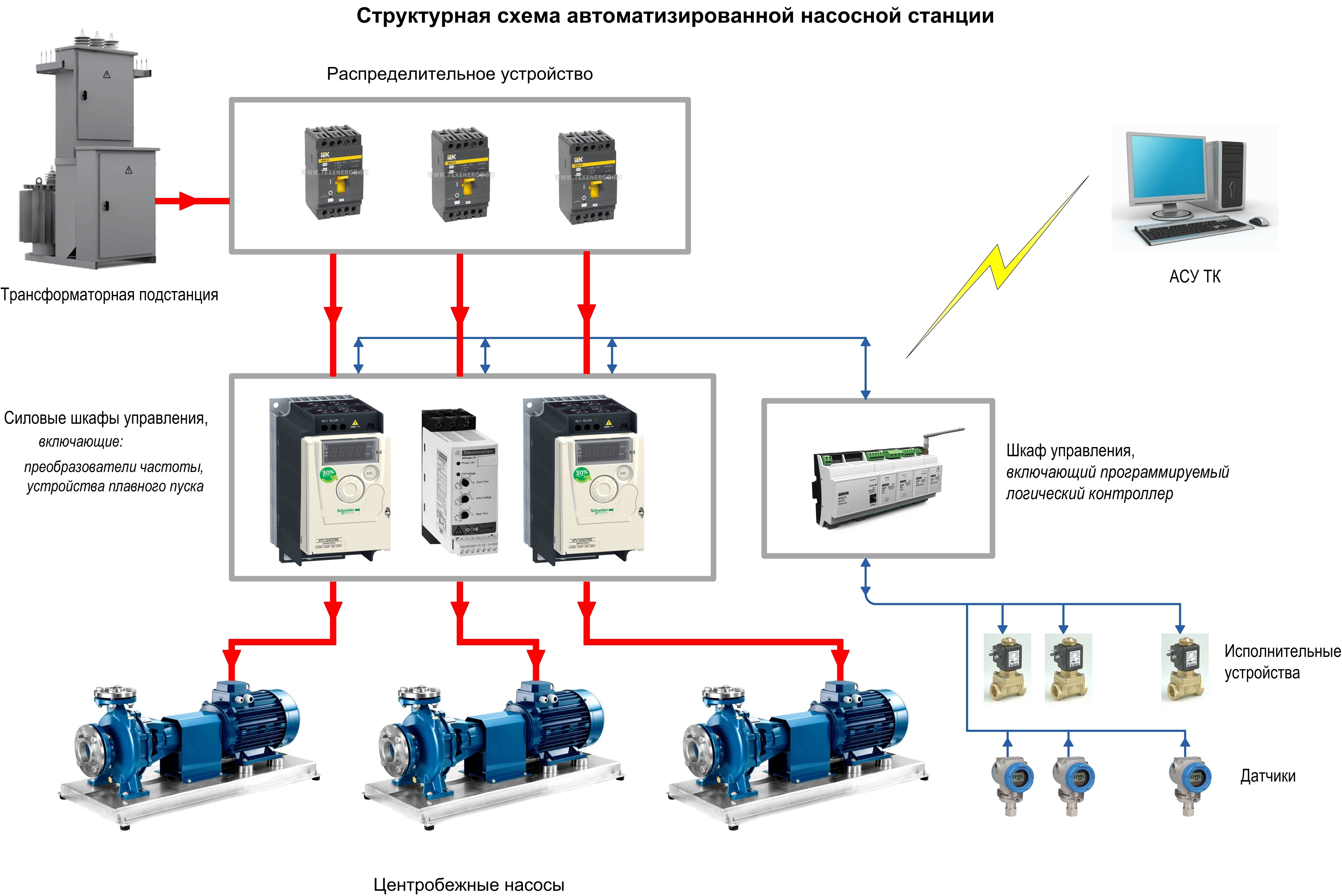

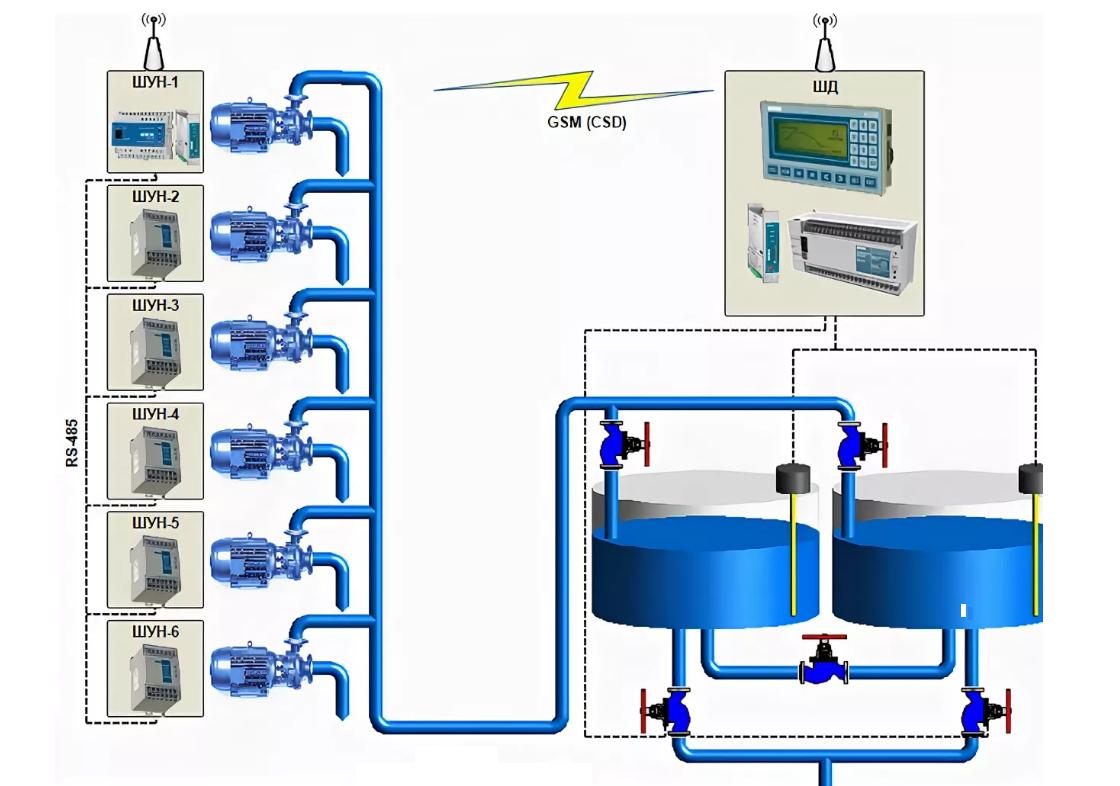

Completeness of the automation system of the pumping station.

There are three approaches to completing equipment and building a system.

- Two separate items.

- Block-modular approach.

- One finished device.

Two separate items.

The system consists of two devices: PU and SHAK.

This approach is clearly expressed, for example, in the equipment of the Sprut-2 set.

There is a control device specialized for control of fire pumping stations. The control device is made as a separate product, sharpened for use in water fire extinguishing systems. Modern control devices have all the goodies: RS-485 interface, indication and remote control devices, expansion devices, etc.

The entire power section is contained in one switching equipment cabinet, which is completed by prior order and is also delivered as a finished product.

Depending on the number and power of units and actuators, as well as other parameters of a particular pumping station, one cabinet with switching equipment is manufactured and delivered as a finished product.

Block-modular approach.

This approach is implemented in targeted fire alarm systems, for example, in the Bolid address system and the Rubezh address system.

The control system of the fire extinguishing pumping station is distributed over several devices.

There is a specialized dedicated device for implementing the control logic of the pumping station as part of the system. Everything else is distributed over several devices. There is no single cabinet with all power equipment.

Each power unit has its own control cabinet. For example, if the pumping station has a jockey pump, two fire pumps, a bypass valve and a fire tank filling valve, then we need 5 power control cabinets.

The control device can directly control a small number of power units and actuators. Such a control device can also receive a small number of status signals.

To organize the collection of information from a sufficient number of sensors and control the required number of actuators and power units, it is necessary to expand the basic functionality.

Something else is also required for scheduling and status signaling as well as scheduling.

Expanding the functionality is not a problem - it's an address system.

Only this requires the use of a network controller, under the control of which the elements of a distributed system interact with each other.

The cost of equipment with this approach is less due to the use of more unified devices.

But less reliability and ease of operation. you will also have to spend time to set it all up and run.

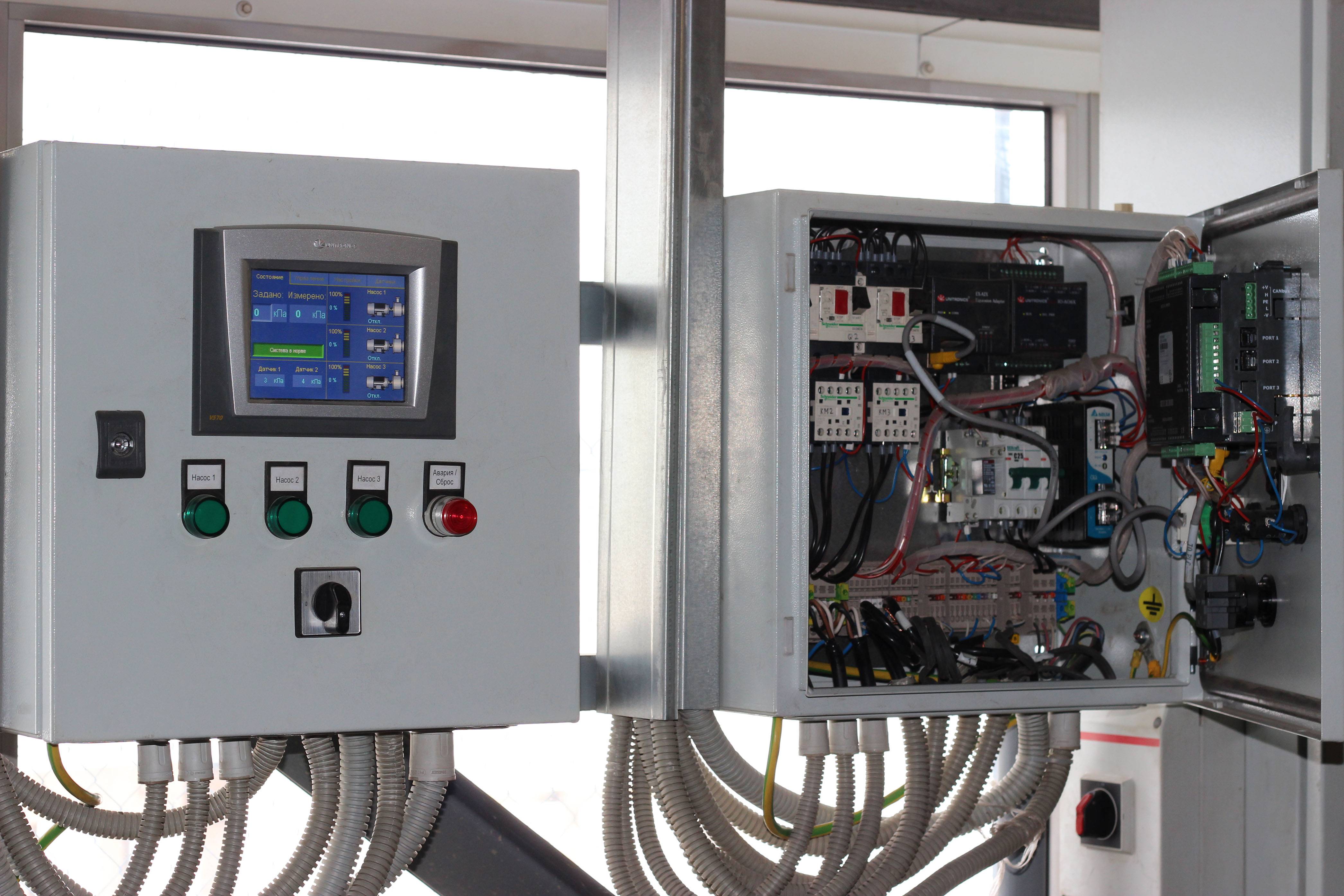

One device.

For foreign manufacturers and their localizations in Russia, control devices and control cabinets are not divided into separate boxes, but are made in the form of one red box. It is probably more profitable to buy a ready-made device there than to design and pay engineers to assemble a bicycle.

The box contains both low-current and power parts. The low-current part is made in the form of a PLC board (programmable logic controller) or a PLC built into the cabinet door.

All operation logic is already programmed - the user only needs to select the necessary operation parameters.

The controller outputs are connected to the control circuits of the power section, and the inputs are routed to the cabinet terminals, which are signed and it is clear what to connect to them.

The box is ordered with the required configuration, depending on the number and power of power units.

But the box is not a piece product: the volume of production allows you to maintain a sufficient range of basic configurations in the form of finished products.

The control box of the water fire extinguishing station is one product, completely ready for operation.

Naturally, if the fire extinguishing system is complex, this approach is not applicable, due to the limited basic configurations. If you have a 3-phase valve, and the box was ordered with a 1-phase valve control channel, then it’s also a disaster.

Of course, such a box is more expensive than a team of several system devices.

The difference is as if you bought an MP3 player or its components from an Arduino shield kit. But, unlike an MP3 player, the box is operated not by the buyer of the box, but by the attendants or no one at all.

Dryer operation

There is nothing difficult in using machines for drying clothes. To know how to use them, read the brief information below.

Loading laundry. Its quantity should not exceed the capacity of the equipment.

- Cycle completion. Dried linen, taking into account the degree of its humidity, is sent to the closet or ironed.

- Removing fluff from fluff filters. The procedure is mandatory and cannot be ignored. Because filters clogged with dust will not be able to pass air properly. As a result, the technique will not dry things well.

- Getting rid of condensate. After the end of each cycle, you need to remove the condensate container and pour out the collected moisture.

Now you know how dryers work and for what do they need. And as it turned out, using them, in some moments, is even easier than using washing devices.

There is no doubt about the practicality and usefulness of dryers. After all, household appliances that facilitate the housework of the hostess simply cannot be useless.

The purpose of the ventilation control panel

If you want to enable or configure the home split system or supply air devices ventilation, fixed in the opening of the ventilation duct, then no control units are required - each device is adjusted manually or from the remote control.

But if the length of the networks is large, and the devices are installed in inaccessible places: in shafts, on the roof or attic, in specially designed niches inside the walls, then it becomes necessary to install a remote control unit.

All information about the operation of heaters, convectors, individual fans is sent to a single center - SHUV. There are also automatic machines responsible for the functioning and adjustment of devices.

Modern SHUV are panels with indicator control devices or metal cabinets that are installed on the floor or hung from the wall. To protect the internal filling, hinged doors are provided that are locked with a lock. In addition to the abbreviation SHUV, you can find SHUV (cabinet).

Main functions of SCHUV:

- control over the equipment included in the ventilation and air conditioning systems;

- protection of units against overheating, incorrect installation and connection, short circuit;

- adjustment of the most important parameters of the equipment, such as productivity or power;

- programming the operation of the entire system or individual units for a given time period - day, week, month;

- providing an indication that facilitates control and adjustment;

- maintaining a certain temperature in various rooms, the ability to quickly change its parameters;

- control over the internal walls of the air ducts and the degree of contamination of the filters;

- prevention of failures in the operation of seasonally dependent equipment, for example, water heaters, which can freeze at too low a temperature.

Installing an electrical panel in an enterprise or in a residential building allows maintenance personnel to monitor the operation of the equipment from one place and quickly respond to breakdowns and stops of individual devices. Devices that regulate fire extinguishing devices and partially heating can also be placed in the same cabinet.

Scheme of the installation of SHUPVV. Cabinets can be common, uniting all devices in the building, and serving a separate floor, wing, workshop, section, etc.

In the event of an emergency, for example, a fire in one of the rooms, the ventilation equipment is stopped automatically or manually - from the control panel.

The principle of operation of the device

The electric dryer in operation resembles an automatic machine. The main element is a rotating drum. But unlike a washing machine, it is not water that enters the drum, but warm air, which dries things. In this case, the rotation of the drum does not exceed 100 revolutions per minute.

Before entering the laundry tub, the air masses pass through fluff filters. Then the fan directs them to the heating element. The air is heated by the heating element to a temperature of 50–70 degrees, and only then, with the help of an additional fan, does it move into the drum.

After removing moisture from wet clothes, the air descends to the heat exchanger.There he gets rid of excess moisture and cools down, after which he again goes to the heating element. Thus, continuous circular circulation of air flows and drying of wet things is ensured.

Maximum drying power input per cycle - 4 kW. But in most dryers, it is 1500-2300 watts.

What is pump automation and why is it needed

In areas where it is not possible to connect to a common water supply system, a well is often drilled, which becomes a source of water. But to create a full-fledged plumbing system, you need a pump. With its help, water will be pumped into the pipes, and in order not to start it manually, automation for the well is used. This is a device for automatically starting a pump or monitoring the presence of water.

If there is automation, then the pump can independently pump fluid into the system or supply it to the upper floors. Also, if you have automation and a heating boiler, you can make a heating system that will pump water to create pressure and drive it through pipes not only to radiators, but also to a shower or sink. With the help of automation, you can prevent overheating of the motor and avoid idle column operation (when there is no water in it).

Example of a control unit with a tank