Selection of welding equipment

We will weld the cabinet for cylinders at a direct current of direct polarity, therefore we choose a VD-306 brand rectifier as a power source for the welding arc (GOST 13821-77). Single-station arc rectifier with a rated welding current of 315A, modification number 1. The rectifier is designed to power one welding station for manual arc welding, cutting and surfacing of metals with direct current. It is manufactured with mechanical transformer regulation and is widely used due to its simple design, reliability and ease of maintenance. The change in the strength of the welding current in this rectifier is provided using a "range switch". Smooth regulation within the range is carried out by moving the coils of the secondary winding with a lead screw. The bridge rectifier consists of six B200 silicon valves. Ventilation for cooling valves - air, forced.The normal operation of the ventilation is controlled by a wind relay. Welding equipment must be completed in accordance with the passports, adjusted and installed according to the instructions of the manufacturer. Voltage fluctuations of the mains supply to which the welding equipment is connected are allowed no more than ± 5% of the nominal value. Power sources must be in good condition and equipped with serviceable control and measuring instruments, an ammeter, a voltmeter. Electrical cables (high and low voltage) must be properly insulated and must be provided with terminals or sleeves to securely connect them to the power source, holder and ground.

Cutting equipment

For cutting, we choose an oxygen-propane cutter RZP-02 with an increased size of the injector and output slots to significantly increase the stability of the cutter. Reducer For oxygen, we choose a single-stage oxygen cylinder reducer BKO-50-12.5. It is designed to lower and regulate the pressure of gas - oxygen coming from the cylinder, and automatically maintain a constant set working gas pressure. For propane, select propane balloon reducer single-stage BPO-5-3. It is designed to reduce and regulate the pressure of gas - propane coming from the cylinder, and automatically maintain a constant set working gas pressure.

Sleeves

- for oxygen - inner diameter 9.0 mm, the sleeve is designed to supply oxygen to the gas-plasma metal processing equipment. Corresponds to GOST 9356-75. — for propane — an acetylene hose with an inner diameter of 9.0 mm, the hose is designed to supply acetylene/propane to gas-plasma metal processing equipment.Complies with GOST 9356-75

- for propane - an acetylene hose with an inner diameter of 9.0 mm, the hose is designed to supply acetylene / propane to the gas-plasma metal processing equipment. Corresponds to GOST 9356-75.

Acetylene cylinders

The power supply of gas welding and cutting posts with acetylene from acetylene generators is associated with a number of inconveniences, therefore, at present, the power of posts directly from acetylene cylinders has become widespread. They have the same dimensions as oxygen. An acetylene cylinder is filled with a porous mass of activated charcoal (290-320 g per 1 dm3 of cylinder capacity) or a mixture of coal, pumice and diatomaceous earth. The mass in the balloon is impregnated with acetone (225-300 g per 1 dm3 of balloon capacity), in which it dissolves well. Acetylene, dissolving in acetone and being in the pores of the porous mass, becomes explosion-proof and can be stored in a cylinder under a pressure of 2.5-3 MPa. The porous mass should have maximum porosity, be inert with respect to the cylinder metal, acetylene and acetone, and not give off during operation. Currently, activated charcoal crushed (GOST 6217-74) with a grain size of 1 to 3.5 mm is used as a porous mass. Acetone (chemical formula CH3SOSN3) is one of the best solvents for acetylene, it impregnates the porous mass and dissolves it when filling cylinders with acetylene. Acetylene delivered to consumers in cylinders is called dissolved acetylene.

Figure 2 - Acetylene cylinder

The maximum pressure of acetylene in the cylinder is 3 MPa.The pressure of acetylene in a fully filled cylinder changes with temperature:

| Temperature, °C | -5 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | |

| Pressure, MPa | 1,34 | 1,4 | 1,5 | 1,65 | 1,8 | 1,9 | 2,15 | 2,35 | 2,6 | 3,0 |

The pressure of filled cylinders should not exceed 1.9 MPa at 20°C.

When the cylinder valve is opened, acetylene is released from acetone and enters as a gas through the reducer and hose into the torch or cutter. Acetone remains in the pores of the porous mass and dissolves new portions of acetylene during subsequent fillings of the balloon with gas. To reduce the loss of acetone during operation, it is necessary to keep acetylene cylinders in a vertical position. At normal atmospheric pressure and 20 ° C, 28 kg (l) of acetylene dissolves in 1 kg (l) of acetone. The solubility of acetylene in acetone increases approximately in direct proportion with increasing pressure and decreases with decreasing temperature.

To fully utilize the capacity of the cylinder, it is recommended to store empty acetylene cylinders in a horizontal position, as this contributes to an even distribution of acetone throughout the volume, and with tightly closed valves. When taking acetylene from a cylinder, it carries away part of the acetone in the form of vapors. This reduces the amount of acetylene in the cylinder during the next fillings. To reduce the loss of acetone from the cylinder, acetylene must be taken at a rate of no more than 1700 dm3/h.

To determine the amount of acetylene, the cylinder is weighed before and after filling with gas, and the amount of acetylene in kg is determined from the difference.

Weight of empty acetylene cylinder consists of the mass of the cylinder itself, the porous mass and acetone. When taking acetylene from a cylinder, 30-40 g of acetone per 1 m3 of acetylene is consumed together with gas.When taking acetylene from a cylinder, it is necessary to ensure that the residual pressure in the cylinder is at least 0.05-0.1 MPa.

The use of acetylene cylinders instead of acetylene generators provides a number of advantages: compactness and ease of maintenance of the welding unit, safety and improvement of working conditions, and increased productivity of gas welders. In addition, dissolved acetylene contains less impurities than acetylene obtained from acetylene generators.

The reasons for the explosion of acetylene cylinders can be sharp shocks and blows, strong heating (over 40 ° C).

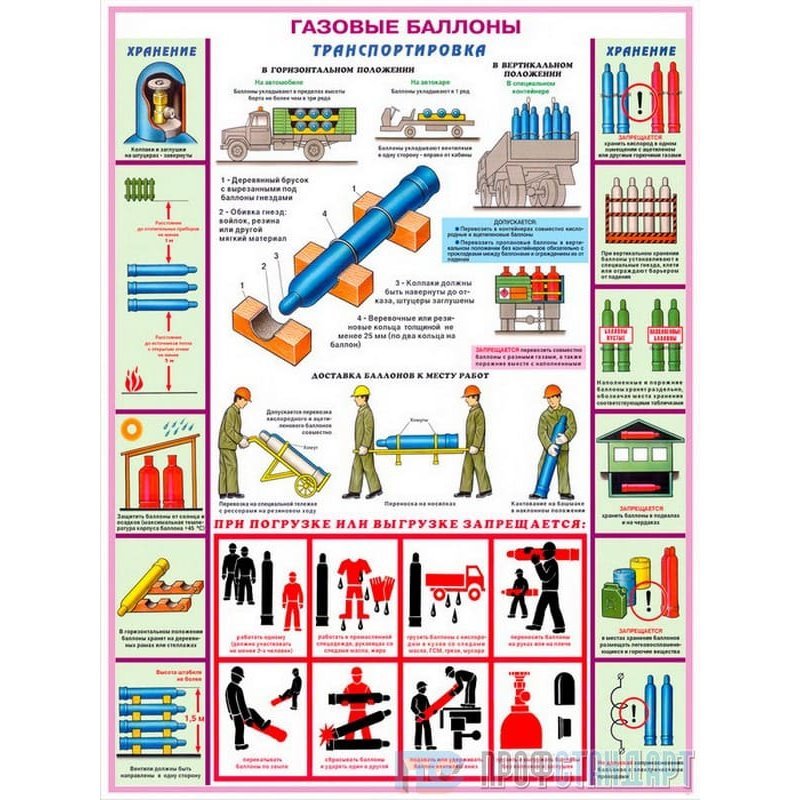

Rules for storing gas cylinders at home

Gas cylinders are used not only in large enterprises, they can also be used for domestic purposes. Often, such containers are installed for gas stoves and water heaters.

Rules for domestic storage of gas containers:

- gas vessels cannot be stored in residential premises;

- you need to install near a blank wall, five meters from the front door of the house;

- the place should be well ventilated, have opening windows;

- at the entrance to the house it is necessary to install a sign that there are gas cylinders here;

- do not use the container if there is a sharp smell of gas;

- it is forbidden to check the strength of gas seams by fire.

Organization of the workplace of the welder

The organization of the workplace at the enterprise is a set of organizational, technological and sanitary and hygienic measures that ensure the most appropriate use of working time, production skills and creative abilities of each member of the team, contributing to the elimination of heavy manual labor, adverse environmental effects on the body of the worker, and reducing injuries. Proper organization of the welder's workplace contributes not only to increasing labor productivity and welding quality, but also to ensuring safe working conditions, reducing injuries and accidents. Depending on the dimensions of the products to be welded and the nature of the production, the welder's workplace can be located either in a special cabin, or in a workshop or directly at the assembly facility. The dimensions of the cabin must be at least 2x2 m. The walls of the cabin are made 1.8-2 m high. For better ventilation, a gap of 150-200 mm is left between the floor to the bottom edge of the wall. The cabin wall material can be thin iron, as well as plywood, tarpaulin, read with a fire retardant compound, or other fire retardant materials. The cabin frame is made of metal pipes or angle steel. The doorway of the cab is usually closed with a canvas curtain mounted on rings. As mentioned above, it is recommended to use zinc white, crown yellow, titanium white, which absorb ultraviolet rays well, for painting the cabin walls. Painting welding shops and booths in dark colors is not recommended, as this worsens the overall illumination of the welding site.In cases where welding work has to be performed in open areas of the workshop, the welding places must be enclosed on all sides with shields or screens. The outer sides of such fencing devices are recommended to be painted in bright colors (preferably in the form of a “zebra”) so that they are better viewed.

To warn unauthorized persons about the danger, on such shields it is necessary to make inscriptions in large letters: “Caution, welding is in progress!”

In the organization of welding work, the correct placement of equipment is important. Multi-station units and installations, consisting of several welding units, are located in a separate room or on an area of \u200b\u200ba common production room, fenced with permanent partitions with a height of at least 1.7 m. Welding converters during operation create noise that has a harmful effect on the human nervous system, causing a decrease in attention and decreased performance. For this reason, all welding converters must be isolated in the workshop room or taken out of the production room, fenced off from all sides and covered from atmospheric precipitation.

For this reason, all welding converters must be isolated in the workshop room or taken out of the production room, fenced off from all sides and covered from atmospheric precipitation.

Popular manufacturers of gas cylinders

Among the many manufacturers of cylinders, the Russian brand Sledopyt should be singled out. Here they offer two types of gas cylinders with threaded and collet connections - for all-weather mixture and winter.The American company Jetboil supplies the market with cartridges filled with propane and isobutane, which can be used in winter.

Mobile gas cylinders are produced by Tramp, a South Korean brand. They are filled with all-weather gas. Connection - threaded and collet

The French company Campingaz produces all kinds of devices equipped with gas cylinders. The type of connection they have is collet, valve or puncture. Primus - produces several types of gas cartridges. Connection in all carving.

Good quality composite vessels are supplied by the Czech brand Research. The package includes special valves that protect the container from overfilling. All of these cylinders are explosion-proof.

At the enterprise

When operating gas cylinders on the territory, in workshops of industrial facilities, public / private institutions / organizations, enterprises, they often contain containers with the following substances in a compressed / liquefied state:

- Cylinders with LPG, combustible gases, also used in everyday life.

- Tanks with a volume of 10 to 50 liters with technical gases - nitrogen, helium, argon, hydrogen, carbon dioxide, acetylene, oxygen.

Required explanation:

- There is no difference between LPG cylinders used at enterprises, organizations, in everyday life - these are the same tanks.

- Terms of operation, re-examination are the same.

- The requirements for safe technical operation for them do not differ; safety regulations - different due to other conditions of placement, storage, the presence of a much larger number of hazardous factors that contribute to the occurrence of an explosion / fire.

- The difference is that at enterprises, in organizations, cylinders of a larger capacity are in demand than in everyday life, although this statement is rather controversial.

All this applies to cylinders with combustible gases, because. reservoirs with technical gases are not in demand in everyday life, with the exception of a pair of acetylene + oxygen when carrying out repair work on water supply systems, including fire-fighting water supply.

PCGB requirements, PB standards on the territory, in the buildings of the enterprise / organization:

- If it is necessary to equip a permanent workplace equipped with gas cylinders, whether it is a welding post or a scientific laboratory, the individual installation should contain no more than two cylinders (working + reserve) at a distance of: at least 1 m - from any heating devices, at least 5 m - from sources of open flame.

- LPG cylinders must be protected from direct sunlight.

- In case of temporary use of gas cylinders during the working day (shift), it is forbidden to install them on the evacuation routes, the movement of goods, the passage of vehicles.

It is also forbidden to install cylinders with light combustible gases in shopping centers to fill balloons or for other purposes; store oxygen cylinders in the buildings of medical institutions.

Before performing hot work using gas welding / cutting at temporary places on the territory of settlements, in buildings / structures for any purpose, except for construction sites and private houses, the head of the enterprise / organization or the person responsible for the fire-fighting condition of the object / building is issued a work permit in the form of appendix .No. 4 to PPR-2012; which disciplines, placing responsibility on all participants in this extremely fire hazardous event.

Detailed video about storage, transportation and operation

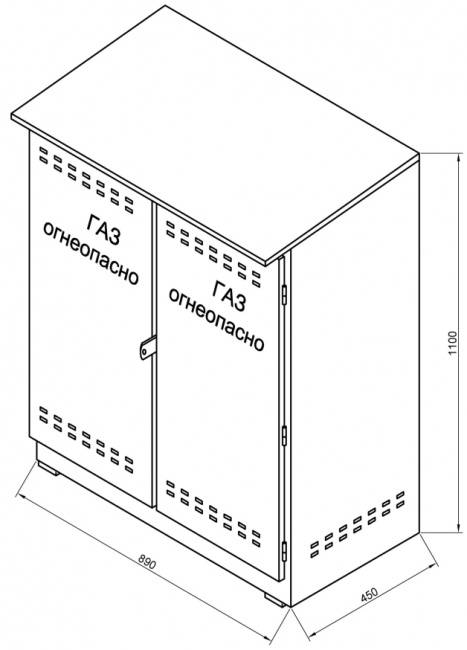

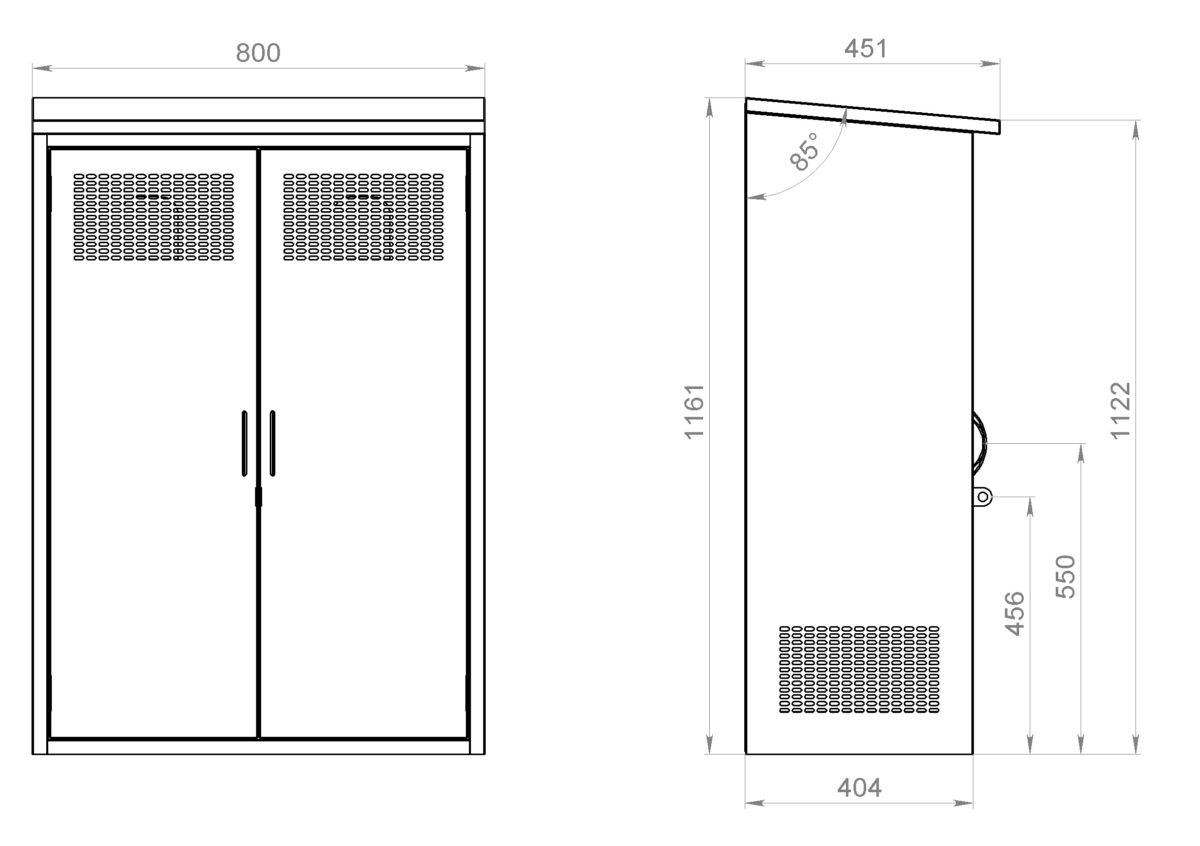

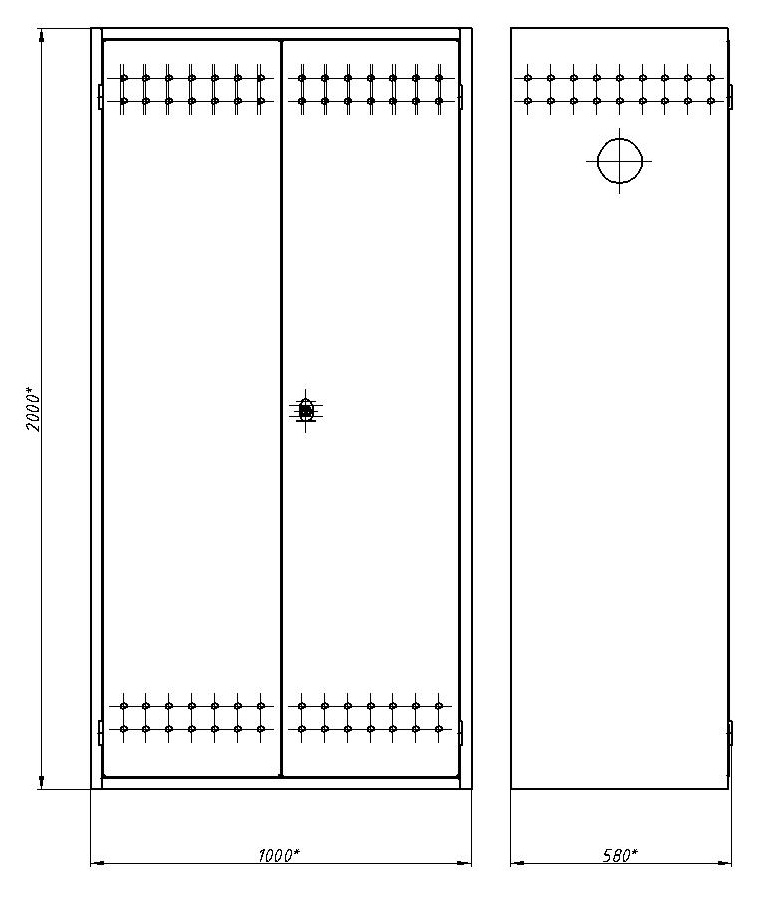

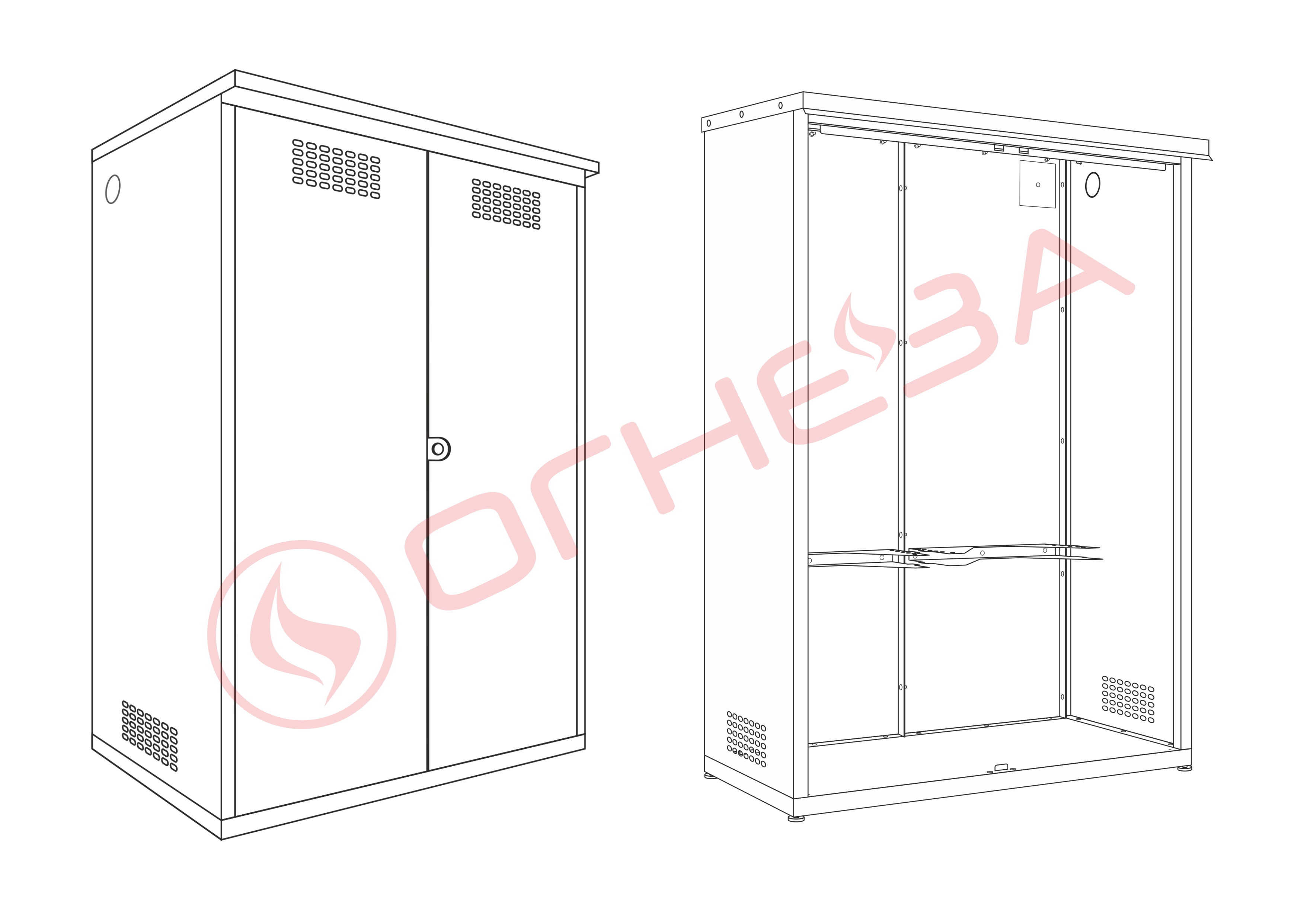

The device of a metal cabinet for cylinders

In accordance with the legislation of the Russian Federation, the operation of gas cylinders is possible only if there is a cabinet in which they are located.

There are a number of mandatory requirements for such products:

- the material of manufacture of all parts of the structure must be fire resistant;

- the design must have a locking device;

- must have holes for ventilation;

- have the information inscription “Flammable. Gas".

The materials used for the production of such cabinets do not burn or smolder themselves, being a barrier to the spread of fire in the event of a fire. Thus, they increase the fire safety of the building in the event of a possible ignition or explosion.

Locks limit unauthorized access inside. The information plate is made in accordance with GOST and is necessarily located on the front of the product. It can be supplemented with any structural signs.

One of the most reliable and safe materials in case of fire is metal. Most of the structures for household gas are made from it. Special metal cabinets for cylinders are designed to store working gas containers there, taking into account all possible conditions.

Components of household gas cylinders:

- product body - made of steel with a thickness of ≥ 0.1 cm;

- doors - one or two, depending on the number of stored containers;

- the pallet on which the cylinders stand inside the product is a lattice or solid;

- fasteners - a holding device with which the container is securely fastened inside;

- openings for hoses in the rear wall of the metal cabinet;

- blinds for ventilation - are made mandatory, the shape of the pallet (lattice or solid) does not affect their presence;

- metal product opening system (handles, latches, etc.);

- eyelets for a padlock.

The material for the manufacture of handles and valves must also be non-combustible. Plastic must not be allowed.

Most often, metal cabinets are a one-piece structure. However, prefabricated specimens are also possible. The box is covered with polymer paint - a substance consisting of polyester and epoxy resins. This paint is also called powder. The advantages of this coating are resistance to fire and protection of the product from corrosion.