- Benefits of professional installation

- Scheme of ventilation control cabinets

- 3 Manufacturing features

- Purpose and equipment of the pump control cabinet

- Brief description of standard equipment

- What is a control cabinet for?

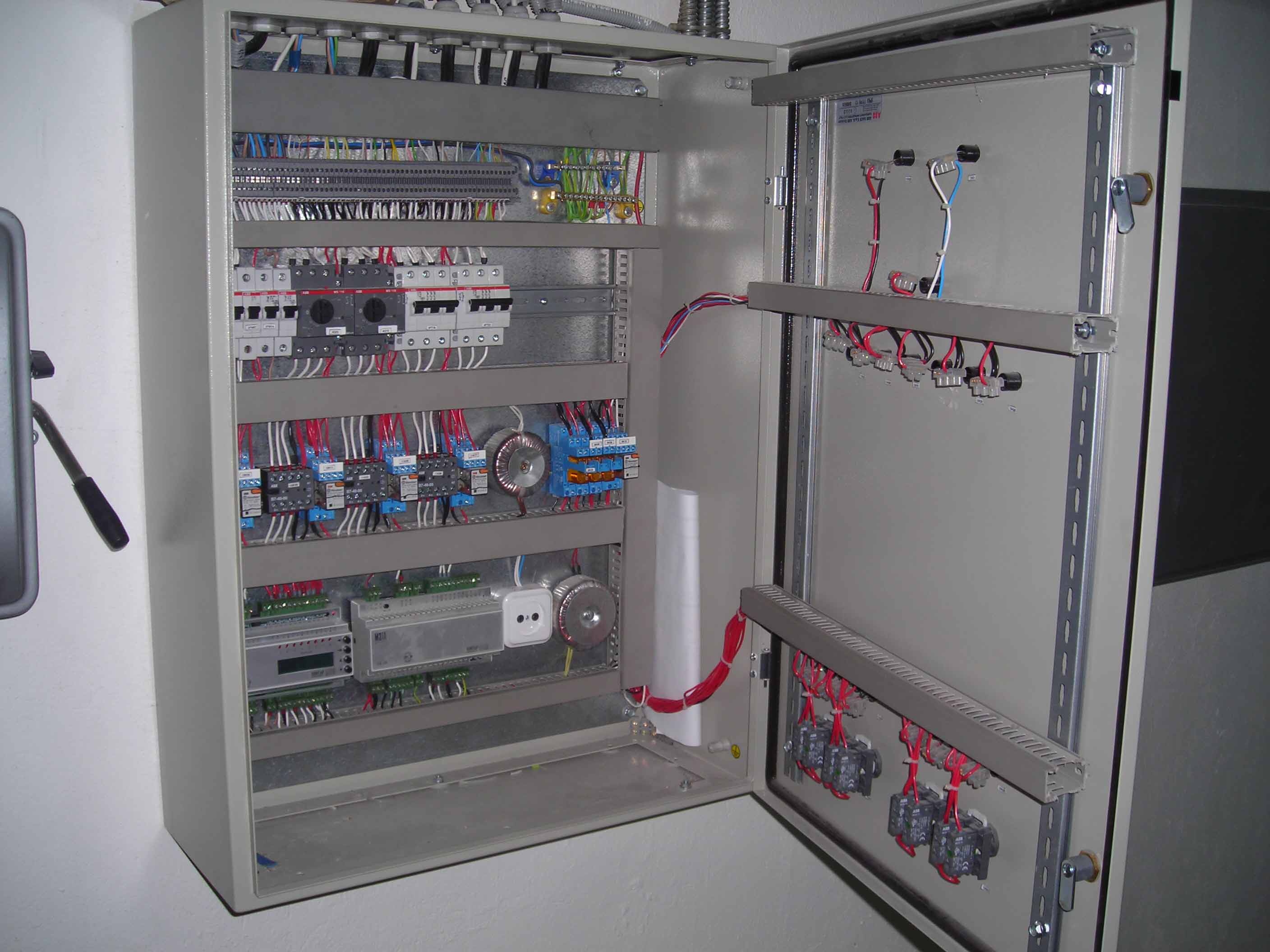

- 4 Internal arrangement

- Popular Models

- Protective system

- Model overview

- SHUPN-2

- SHUN

- SHKANS-0055

- Operating modes of the exhaust unit

- 1 Purpose of the cabinet

- Fire fan control cabinets that comply with the regulations.

- Bolide.

- Plasma-T.

- Frontier.

- Operating ventilation controls

- Ventilation control sensors

- Controllers

- The principle of operation of automated ventilation systems

- Control cabinets with automatic transfer switch (automatic transfer)

- Appointment of ATS

- Application area

- Main functions of ATS

- Description of ATS operation modes

- Marking of automation and control panels

- Installation of ventilation systems

Benefits of professional installation

According to the rules, installation and maintenance of ventilation systems, as well as control rooms, should be carried out by specialists with an engineering education. They are also fully responsible for the wrong choice, installation, connection of devices, as well as for the maintenance of technical devices in an improper or emergency condition.

In order to correctly determine the filling of the shield or cabinet, installers make a complete monitoring of the ventilation network.

Then you need to do the following:

- analyze the load;

- choose the optimal scheme;

- determine the operating modes of devices in order to increase efficiency;

- pick up equipment.

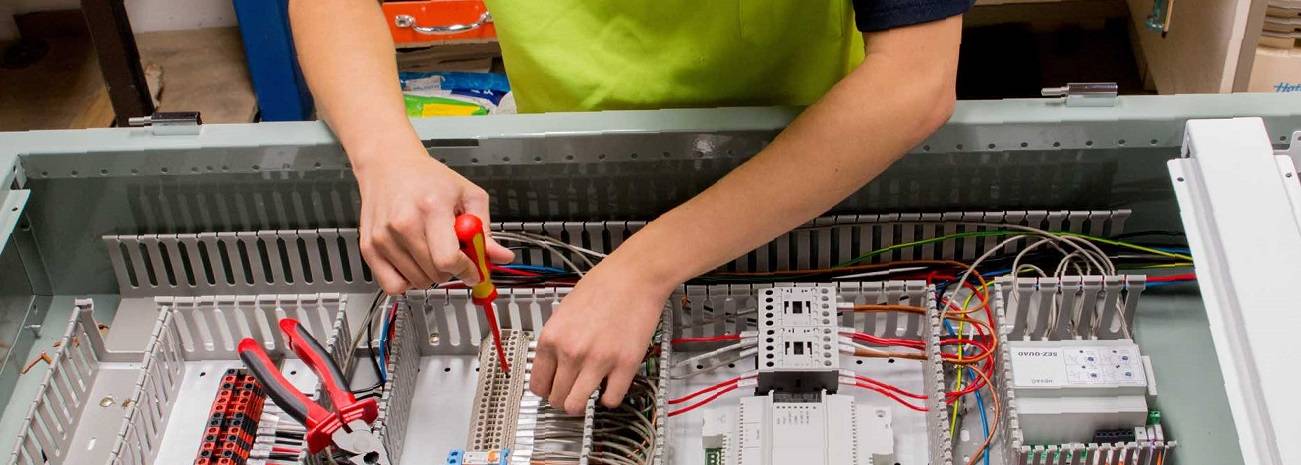

The assembly itself takes a little time: all devices are mounted in turn in several rows, the wires are carefully attached to the terminal blocks and laid along the lines in organized bundles, then they are brought out.

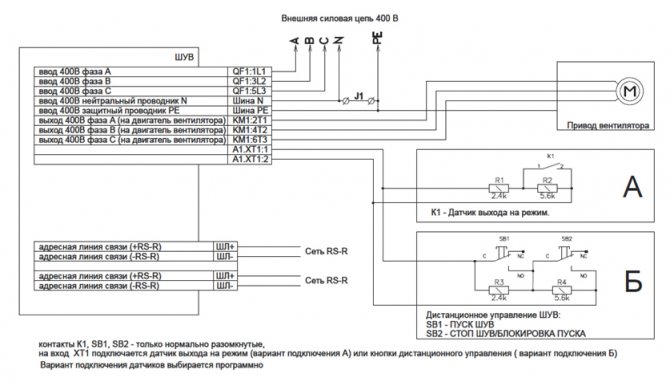

One of the connection options, where NK1 and NK2 are channel-type heating devices; M1 - 3-phase fan; A, B, C - network connection, N - neutral, PE - earth; Q - protective thermostat against overheating; Y - ignition protection thermostat

Professional installers have experience in the installation and operation of SCHUV, so they are unlikely to make a mistake with the choice of model and the nuances of connecting devices. In addition, they are well versed in the schemes of ventilation systems for apartments and country houses and can quickly determine if there is an error in the drawing.

If you don’t figure it out in time and connect the devices according to an illiterate scheme - and this also happens - you can create an emergency.

Many companies that manufacture or sell ventilation, refrigeration and heating equipment are engaged in the sale and sale of shields and cabinets. For example, in Moscow, this can be done in the companies "Ruklimat", "Roven", "AV-avtomatika", "Galvent", etc.

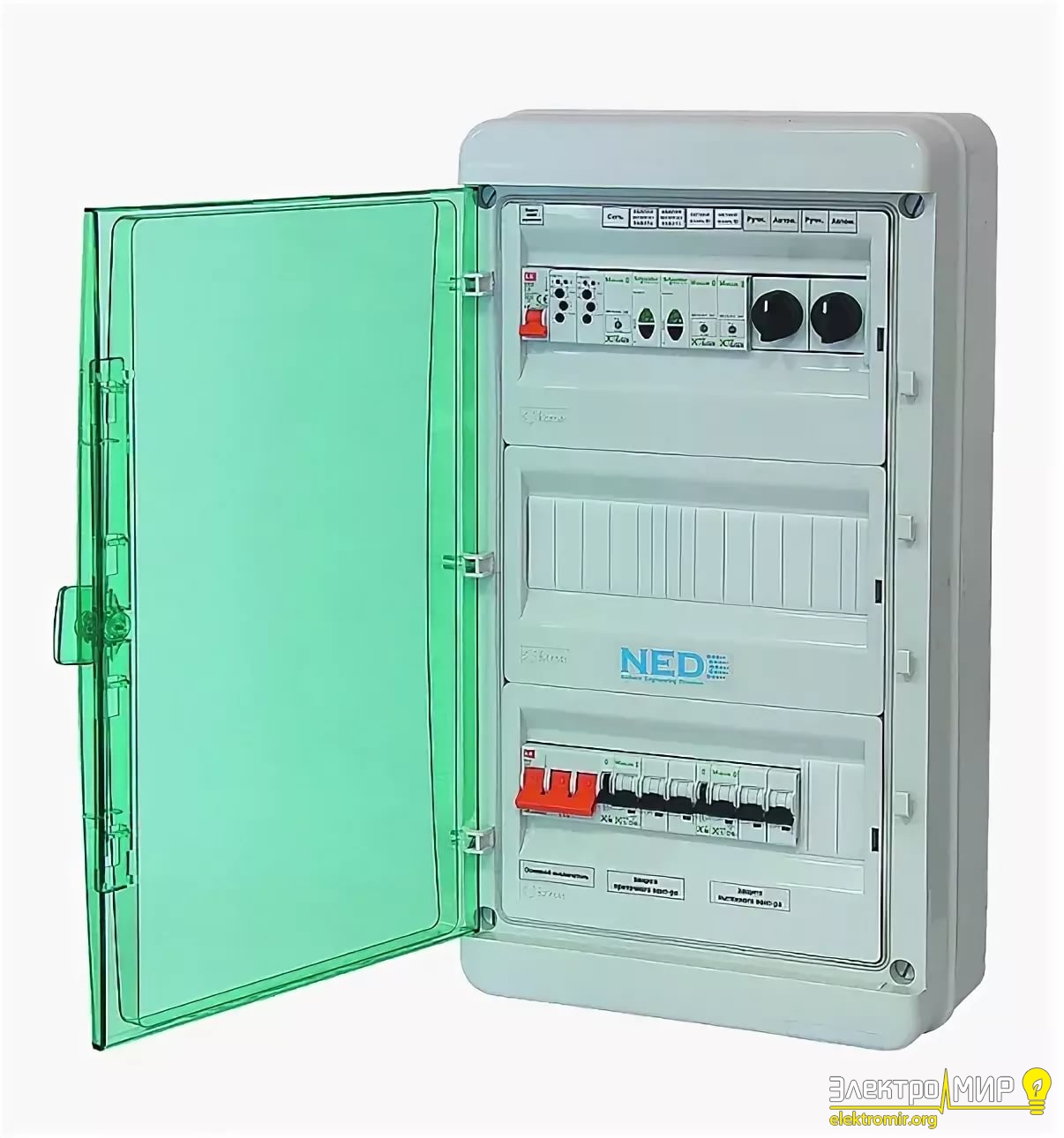

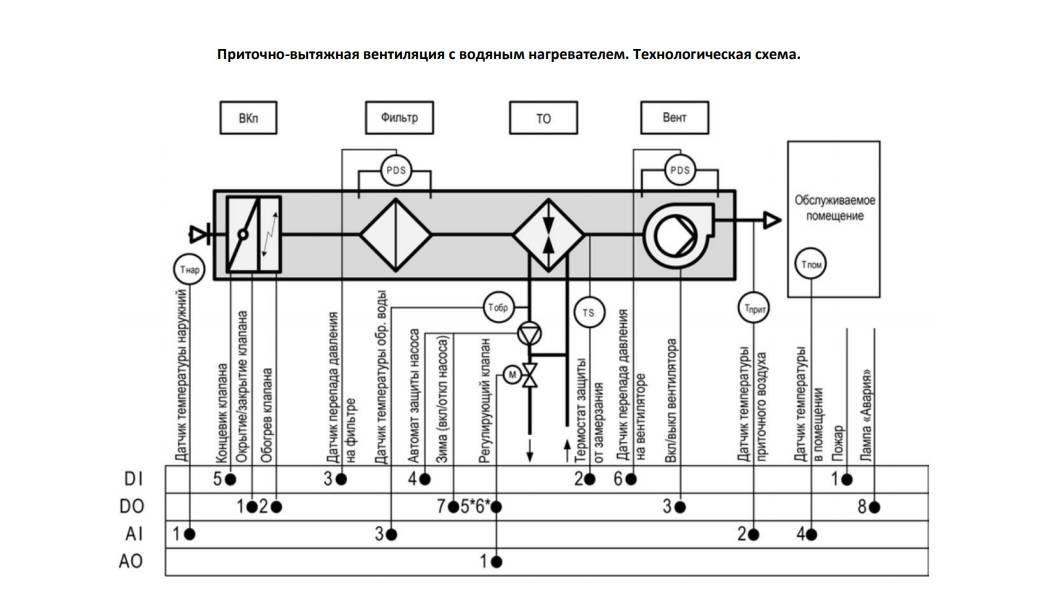

Scheme of ventilation control cabinets

scheme of the supply ventilation control unit with water heating

The standard layout of the ventilation control cabinet includes:

- frequency converter;

- microprocessor controller;

- starters, knife switches;

- automatic switches;

- contactors;

- protective mechanisms;

- relay;

- mode indicators.

scheme of the control unit for supply and exhaust ventilation with water heating

Frequency converters are needed to change the speed of rotation of the fan blades and the asynchronous motor, start the mechanisms without jerks, providing a more favorable operating mode. Frequency control provides speed control in both manual and automatic modes, prevents engine overloads. Reducing energy costs, and increasing system safety, extending the life of the system.

One of the important elements of the ventilation cabinet control circuit is the controller.

Controller types:

- discrete;

- analog.

Models presented on the Russian market contain a programming menu in Russian. The capabilities of the controller are sufficient to solve any problems that arise during the operation of ventilation systems. The most practical controllers are free programming, which allow you to organize the control of the ventilation system of any scheme.

The reliable and uncomplicated scheme of the ventilation control cabinet makes it possible not to carry out its service and maintenance. Once every 6 months, the integrity of cables and insulation, the state of grounding are checked. In addition, you must adhere to the rules for operating the equipment.

3 Manufacturing features

Since the uninterrupted functioning of the entire system depends on the ventilation cabinet, in its manufacture it is important to select materials that can ensure regular operation under the specified conditions. Here are some important factors to consider when developing a ventilation plan:

- 1. What is the ambient temperature.Each material is designed for certain conditions, and if they are not observed, the device will function worse. The outer shell may melt, which will require the entire device to be replaced.

- 2. The height of the building relative to sea level. With its change, atmospheric pressure also changes, and this affects the operation of ventilation. Heat transfer deteriorates, and this must be taken into account in advance.

- 3. Humidity level. If it is too high, the risk of short circuits increases in the system.

To take into account all this and more, preliminary measurements are sometimes made, but more often pre-set standards are used that are suitable for most premises. However, it is still desirable to know how high above sea level the system will be, within what limits the temperature in the rooms can fluctuate, and also what is the power of the equipment. In addition, it is worth considering that the conditions inside the cabinet and outside will be different, and find out in advance the temperature of the shield and the surrounding atmosphere.

Having collected all the necessary data, you can select or order a cabinet that is suitable in all respects.

Purpose and equipment of the pump control cabinet

The technical filling of different models is different, since the control points have an individual functional focus.

Brief description of standard equipment

The presence of certain elements depends on the number and category of pumps, narrow or wider technical capabilities, and the availability of additional functions.

The basic equipment for most of the models for sale is as follows:

- Rectangular metal case with a control panel located on the front side.The design of the panel may differ, but it necessarily contains indicators and buttons such as "Start" or "Stop".

- Switch (one or more) that allows you to turn on / off the pump in manual mode.

- Fuses and protection elements.

- Control unit that regulates the voltage of three phases.

- Frequency converter needed to control an asynchronous motor.

- Automatic control unit responsible for planned and emergency shutdown of equipment.

- A set of sensors showing water pressure and temperature.

- Thermal relay.

- A set of light bulbs - light signaling.

The main functions embedded in the control unit depend on several factors. For example, if there are 2 pumps, the main and additional (backup), a program is installed that allows you to turn on both mechanisms in turn.

Control panel for two pumps operating in standby mode. The advantage of interval switching is a uniform distribution of the load and an increase in the planned resource.

The temperature sensor protects the equipment from overheating and running dry (the likelihood of such a situation often occurs in wells with insufficient flow rate). Automation stops the operation of the equipment, and when favorable conditions for water intake occur, it again turns on the engine of the connected pump.

- The pumping equipment control station will reduce energy consumption and guarantee an extension of the working life

- The control cabinet for one or more (up to 9) submersible pumps automatically starts them when water is taken from the system and the pressure in it decreases

- The SHUN of the submersible pump is equipped with a relay-type fuse to prevent short circuits from affecting the equipment and the brewing of emergencies

- The pump control station can be powered from a centralized network or from an autonomous power generator

Protection devices against power surges, phase failure, incorrect connection protect the mechanisms and do not allow them to work in emergency mode. They adjust the network parameters, and only after equalizing the indicators automatically connect the equipment.

Overload protection works in much the same way. For example, there is a ban on the simultaneous activation of two pumps, which leads to unnecessary costs and irrational use of equipment.

What is a control cabinet for?

The control cabinet is designed to control and coordinate the operation of all devices included in the supply, exhaust, supply and exhaust, emergency ventilation system, in automatic or manual mode. In addition, the control units can successfully work with ventilation systems equipped with electric or water heaters and coolers, recovery and recirculation of air flows. The main tasks that are solved using the control cabinet:

- Monitoring the condition and performance of equipment included in the ventilation system.

- Ensuring the necessary modes of operation of devices.

- Timely notification of equipment failures, contamination of air ducts and filter elements.

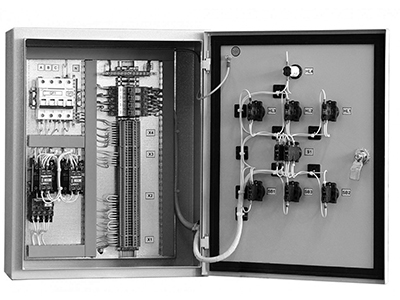

4 Internal arrangement

Although ventilation control cabinets can perform different tasks and have different designs, there are a few basic elements that are present almost everywhere. They are necessary to control any such system:

- 1. The frequency converter is used so that the speed of the fan blades changes smoothly and the motor is not overloaded immediately after the start of work.

- 2. Starter and knife switch - elements for turning equipment on and off.

- 3. The controller controls the whole system, its functions can be freely changed to set all the necessary parameters. It is analog and discrete.

- 4. Contactor - a mechanism for remotely turning on or off devices.

- 5. Automatic devices are used for emergency connection or disconnection of current in case of an emergency, such as a short circuit.

- 6. Protective mechanisms protect against various emergency situations.

- 7. Relays open or close a circuit while the system is running.

- 8. Light indicators. By their glow, you can get information about the functioning of the equipment.

Popular Models

In the domestic market, products of the following brands have proven themselves very well:

- The range of Grundfos brand cabinets is quite extensive. It has products with different configurations and technical characteristics. Some models have protection against dry operation, undervoltage and phase failure. However, all of them can:

- manage pumping equipment;

- automatically start the unit after a long period of inactivity;

- control the water level and display data on the display panel;

- regulate the operation of the equipment;

- such products can be used in the temperature range from -20 to +40°C;

- All equipment of this brand is given a two-year warranty.

- Alpha Control cabinets reliably protect pumping equipment from negative factors that cause units to fail. They can work with any models of pumps. These products are designed to be connected to a network of 220 and 380 V. The marking “D” in the designation will indicate that the model can be used to control two pumps.

Protective system

Automatic air ventilation control, like any other, has no right to exist without proper security. Protective mechanisms in the shield can be triggered in the event of one of the following circumstances:

- A failure in the mode of operation of the constituent element.

- Failure of any of the devices or devices.

- The inability to control certain parameters of the air in the room - in case of loss of communication with some kind of sensor.

To solve these problems in the operation of the automatic ventilation mechanism, the control controller is designed. The use of controllers allows you to quickly respond to the most insignificant deviations from the normal state during the operation of each of the devices and, at the same time, quickly eliminate them.

Thus, the control of the ventilation of the room, if you have a special shield, becomes fast, simple, as convenient and safe as possible.

Model overview

SHUPN-2

Typical control cabinet for two pumps (including standby). It is used to interact with submersible units used in fire extinguishing systems and agricultural irrigation. Power up to 55 kW, operating temperature from -10 to +50 degrees. The manufacturer puts forward special requirements for the environment.The air must not contain aggressive gases and not be saturated with conductive dust. Relative humidity up to 80% is allowed. The cabinet is designed for a service life of ten years. Retail price 31,600 rubles.

SHUN

Produced by the Ecotechnologies company, which has been presenting goods on the domestic market since 2005. The hardware warranty is two years. Cabinets are designed to work with drainage pumps and sewage pumping stations. Can operate fire tanks. The unit is controlled in two modes - automatic and manual.

Cabinets are designed to work with drainage pumps and sewage pumping stations. Can operate fire tanks. The unit is controlled in two modes - automatic and manual.

It is possible to connect two pumps - reserve and main. In the event of a failure of the main pump, the backup pump will be activated automatically. Automatic alternation of pumps is provided to ensure uniform running time and prevent overheating of the winding. At the request of the customer, the unit is modernized. For example, a GPRS module is installed, which ensures the forwarding of SMS messages in case of an accident. Permissible power of each pump is from 4 to 11 kW, depending on the cabinet model. The average cost of a budget model is from 10,900 rubles.

SHKANS-0055

If you are the owner of a country house or a dacha with autonomous water supply, then you probably at least once wondered how to make pumping equipment work more efficiently and for a long time, and also have several convenient operating modes. In addition, sometimes two pumps are used at once to provide the house with water and water the garden, so it is necessary to coordinate and automate their work. You will get the answer to all questions when you find out what is pump control cabinetand also why it is needed.

The main purpose of switch cabinets is to control the electric motor of one or several pumping units at once. The type of pump does not matter. This can be submersible type equipment or a borehole or drainage pump.

Moreover, the purpose of pumping equipment may be different. For example, a submersible type unit is needed for the efficient operation of the heating system, arranging the water supply of a country house, or creating a fire extinguishing system. But the drainage pump, together with the control cabinet, is useful for pumping liquid.

If you install a control cabinet to coordinate the operation of the borehole pump, then you will finally find the long-awaited peace and rest, because from now on you do not need to monitor the operation of the equipment, all this will be done by the automation located in the cabinet. In this case, this device will be able to perform the following functions:

the equipment will ensure safe and smooth start of the engine of the pumping unit;

automation will be able to regulate the operation of the frequency converter;

in addition, the device will monitor the pressure in the system, the water level, as well as its temperature, which is very important for the timely switching on and off of pumping equipment.

The functions of control cabinets for two or more pumps are even more extensive:

- if the unit notices that one of the pumps is operating in emergency mode, it will immediately connect the second pump to work;

- since the automation of the control cabinet will regulate the alternate operation of each of the pumps, the general wear of the pump units will come later;

- if one of the pumps is idle for a long time, the equipment will be able to protect it from silting;

- thanks to such a device, you can manually block the operation of one of the pumps;

- cabinet automation has different control programs for several pumps;

- if necessary, you can get complete data on the operation of each unit separately.

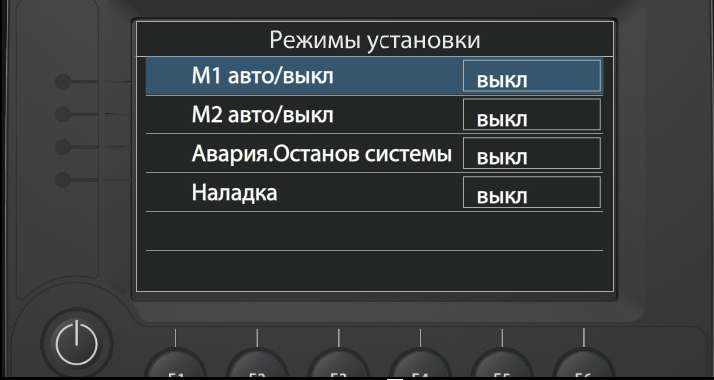

Operating modes of the exhaust unit

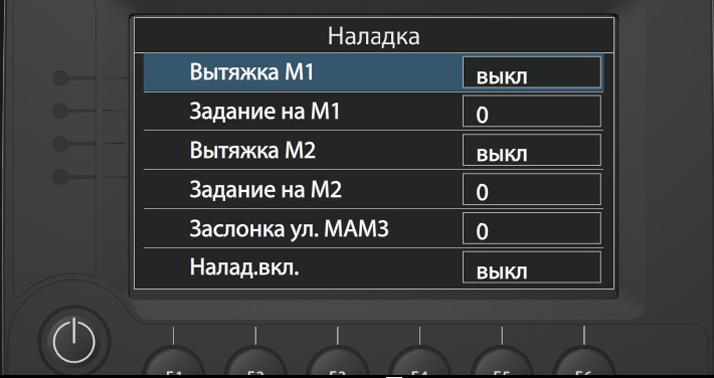

Screen Setting Modes

M1 - auto / off - Fan 1 - on - off

M2 - auto/off - Fan 2 - on - off

If we first turn on the switch SA1 in auto, then the fan M1 becomes the main one. When the SA2 switch is turned on in the auto, the M2 fan becomes a backup. If we turn on SA2 first, then the main fan will be M2, and M1 will be the backup. If one of the fans fails, the system automatically switches to the backup one.

Accident. System shutdown

This mode is activated when a fire alarm is triggered, a malfunction of the outdoor air intake damper or a malfunction of the inlet temperature sensor.

Adjustment

In the setup mode, you can turn on all the mechanisms separately. When this mode is enabled, the green indicator on the PLC is lit.

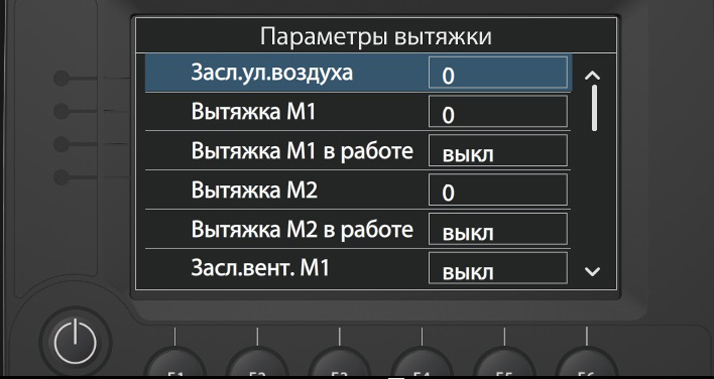

Hood settings screen

Set point. Honored St. Vozd. — Setpoint for outdoor air damper MAM3 is the setpoint for the PID controller to control the damper according to the inlet temperature sensor.

Setpoint T min - setting the minimum temperature according to the temperature sensor

Setpoint Tmax - setting the maximum temperature according to the temperature sensor

When the Tmin and Tmax settings are exceeded, it switches to the Emergency mode. Stop the system.

Dead zone MAM3 - Dead zone of the damper MAM3. The outdoor air damper MAM3 is always monitored. We give the task \ get a return signal.Dead zone - a zone in which the damper has no sensitivity. You can set 2-5 degrees.

Coefficient prop.R (MAM3) – coefficient of proportionality of the PID controller

Integ.factor I (MAM3) – integration factor of the PID controller

The proportional and integration coefficients are the coefficients for the outdoor damper PID controller. Selected by experience.

Setpoint min M1 – Minimum fan control range M1

Setpoint max M1 – Maximum fan control range M1

Setpoint min M2 — Minimum fan control range M2

Set point max M2 – Maximum fan control range M2

Fans M1 and M2 operate in direct proportion to the output from the damper PID controller. Min and max sets the range of fan regulation. (min- 15, max- 1015). 15 - 0 hertz, 1015 - 50 hertz.

Setpoint Motor hour M1, Setpoint Motor hour M2 – set the time in hours after which the main fan will turn off and the backup fan will start working.

Screen Exhaust Options

The screen displays various parameters of the installation - the position of the outdoor air damper, the state of the M1 and M2 exhaust, the position of the dampers MAM1 and MAM2, the operating time of the fans M1 and M2.

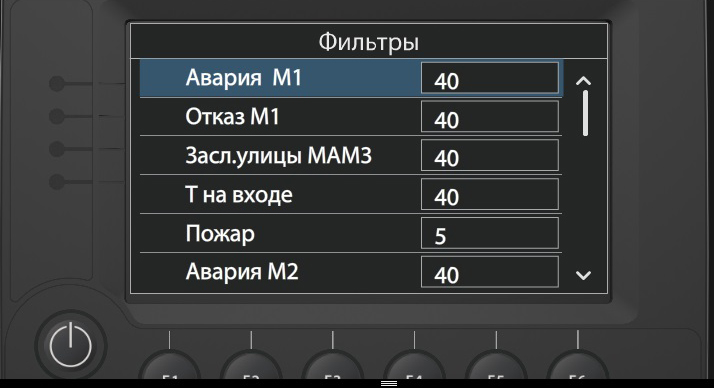

Screen Filters

Filters - response delay. The exposure time in seconds for a particular accident, or for turning on fans or shutters, is set.

Reset system alarms - switches SA1 and SA2 are set to the off position. Press the F1 button on the PLC.

1 Purpose of the cabinet

As a rule, the ventilation system in an apartment or a small room does not require complex management of many parameters, but in large enterprises, things are different.This is especially true for industries where natural air supply is impossible - due to the peculiarities of the building or because of the need to constantly maintain a certain indoor climate.

There are various models of such equipment, designed for certain operating conditions:

- exhaust, supply or supply and exhaust;

- ensuring the removal of smoke emitted during production;

- purifying the air for later use or using recirculation;

- minimizing the content of hazardous substances in the air or involving recovery;

- heated by water or electricity.

Such devices have several standard modes that can be switched manually or automatically depending on external conditions.

Fire fan control cabinets that comply with the regulations.

These cabinets have everything you need to comply with the regulations:

1. Cabinets have the ability to start, voltage 24V, which eliminates problems with integrity control.

2. Have operating modes Manual / automatic

3. Cabinets issue exhaustive dispatching signals: Work, Automation, Emergency.

4. All circuits are monitored, including power circuits.

5. There is a possibility of external manual control and control from the cabinet panel.

6. And most importantly - a certificate of compliance with federal law No. FZ-123.

Bolide.

ShKP-10 14925₽.

Control cabinet. There are no valve control circuits and it is necessary to use the S2000-SP4 smoke exhaust module, costing 2200 rubles, as part of the address system.

Plasma-T.

SHUV 11kW 15332₽.

Control cabinet for a three-phase pump / fan motor with a power of up to 11 kW with direct start, DEK equipment, IP31.There are no valve control circuits - something must also be done.

Frontier.

SHUN/V-15-00 project R3 29000₽.

Comparison of this cabinet with others is not entirely correct, since this cabinet itself is an addressable device, that is, only one wire of the addressable communication line needs to be connected to it, and a device or module for control loops and start lines is not needed.

Management and dispatching takes place over the address network.

There are no valve control circuits and it is necessary to use the MDU-1 smoke exhaust module, costing 2280 rubles, as part of the address system.

Operating ventilation controls

Ventilation control sensors

These elements play the role of receptors that collect all the necessary information about the system (temperature, pollution level, gas concentration, air mass movement speed, etc.) and transmit it to the “brain” of the ventilation complex. Based on the received parameters, the control system issues appropriate commands to the actuators.

There are a great many varieties of sensors, therefore, for convenience, they use a kind of classification.

By appointment:

- temperature sensors (analog and digital) record the temperature of air flows and individual working elements, providing information about both the "outboard environment" and the state of the system itself;

- humidity sensors automatically determine the percentage of moisture content in the ambient air, choosing the most comfortable operating mode based on this;

- speed and pressure sensors allow you to control the operation of fans by the intensity of the working flows inside the air ducts.

By location:

- indoor collect information about changes in temperature in the room itself;

- atmospheric are installed outside buildings and, thanks to the information they collect, make it possible to change the operating mode in advance in accordance with the indicators of the external environment.

At the place of direct installation (mainly these are sensors that are responsible for controlling the speed of air flow and the operation of the ventilation devices themselves):

- duct sensors record data on the speed of the air flow and the force of its pressure, pressure and other necessary characteristics (they are installed inside the air ducts directly on the walls or with the removal of the section across the air flow);

- outdoor sensors are responsible for collecting the external parameters of ventilating devices - the speed of rotation of the blades, the temperature of the windings, etc. (they are installed directly on the surface of the controlled element)

Proper installation of sensors should take into account both the manufacturer's recommendations for their installation and operation, and the requirements of the project itself. Otherwise, the system not only risks losing its security, but also becomes unreasonably energy-intensive.

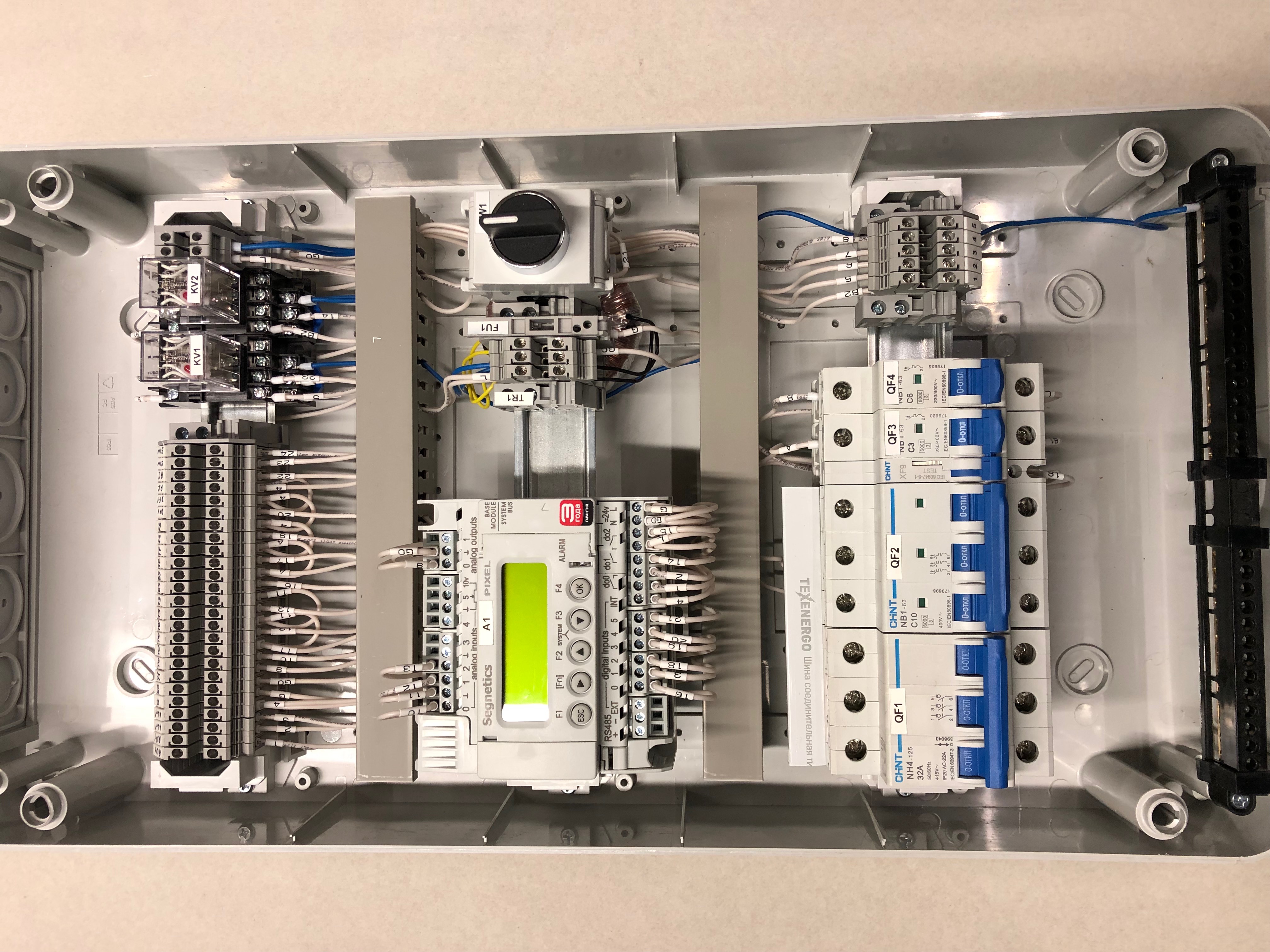

Controllers

They are means of processing information from numerous sensors. Having processed the received signal, they give commands to the actuators, thereby changing the mode of operation of the ventilation system.

The most popular are microprocessor controllers, the compact dimensions of which allow them to be installed in control cabinets of standard sizes. An example of such a controller can be a multifunctional Pixel controller capable of working with information from various types of communication networks, including heating and water supply lines.

The principle of operation of automated ventilation systems

So what is the basic principle of operation of automated ventilation devices?

Like many modern technologies of this kind, this one is aimed at minimal operator involvement in the process of controlling air freshening processes. In the truest sense of the word, the devices themselves calmly cope with the tasks.

Smart operating systems allow you to develop an algorithm that is necessary specifically for your premises or premises, according to which at a certain time of the day the system will operate in a special mode. Organizing this system with your own hands is not easy, but with some diligence you will succeed.

For example, at lunchtime, the sun shines brightly clearly on the back of the building, where it usually does not reach during the day. So, at this moment, the exhaust unit system in this part should work hard.

But, since this side is not exposed to sunlight for most of the day, it is not economical to leave strongly working ventilation units for the whole day.

But there is no way to completely get rid of the problem either. This means that the system itself must control the situation and switch the ventilation level depending on the conditions and situation.

This computer will be assisted by a whole bunch of sensors that determine the main indicators of air. By transmitting data to the system control center, they start an almost instantaneous decision-making process by artificial intelligence.

The fans will be accelerated, the inlet valves will be opened wider, the temperature will be lowered below the desired average. But only at the right time!

After that, all sensors will transmit new measurements, which will testify to the normal temperature regime. The operation of the ventilation shafts will return to normal.

Ventilation switch

That is, in addition to the initial functions of competently providing fresh air to the premises, the system plays the role of a saving device that will allow you not to waste electricity.

to the menu

The most important thing is quality!

When choosing any devices or fully automated exhaust and intake ventilation systems, you should pay attention to their consumer power. Some devices, despite the good ones, are not extremely economical (especially when extracting work) and will seriously bite your wallet due to electricity tariffs

Especially in this perspective, the automatic supply ventilation will tighten

Some devices, despite the good ones, are not extremely economical (especially when exhausting) and will seriously bite your wallet due to electricity tariffs. Especially in this perspective, the automatic supply ventilation will tighten.

The country of origin also plays a role. The exhaust ventilation scheme is quite complicated and it is worth working with it only when buying appliances from good manufacturers.

Shield of the ventilation system

European manufacturers are considered to be of the highest quality, they honor their reputation and do their work accurately. Chinese appliances are no less high quality, but energy-intensive. This means they may not always fit you.

The importance of the quality of the automated part of your ventilation helps office workers to endure the summer heat more calmly. In turn, this increases the return and activity

And ventilation systems do not have such a detrimental effect on your health as other cooling devices.

to the menu

Control cabinets with automatic transfer switch (automatic transfer)

Appointment of ATS

The transfer switch is designed to provide power to the load from two independent sources: it controls power circuit breakers that protect two independent inputs and supply current to the busbar. ATS can also be used to automatically turn on backup equipment when the identical main equipment is turned off. The use of ATS allows you to avoid equipment downtime, disruption of technological processes resulting from the loss of the network or if its main characteristics go beyond the permissible values.

Application area

ATS is used: in systems and devices of uninterruptible power supply; to provide power to critical loads; in systems of parallel redundancy of power supplies.

Main functions of ATS

The main function is automatic switching to a backup power source when the main source voltage fails or its parameters go beyond normal values.

- Motorized switching;

- Built-in control relay;

- Dual power supply;

- Switching under load;

- Manual failover, setting range 5-15s.

- Control of increase or decrease in voltage and frequency;

- Accounting and monitoring of electrical energy of the ATS output voltage.

Description of ATS operation modes

ATS can work in automatic and manual mode.

Work in automatic mode:

Restores power to consumers when the main power source is turned off, by connecting a backup power source. In case of loss of voltage at the main source, the machine will turn off the automatic switch of the main source, and will turn off this source after the time set by the timer. After the timed delay has elapsed, the backup source circuit breaker will turn on. When power is restored to the main source, the timer will turn off the circuit breaker of the backup source after a set time and reconnect the main power source using the circuit breaker. To control the automatic transfer switch, a programmable control relay is used, in which all the logic of the operation of the ATS circuit is programmed. The programmable control relay is equipped with a liquid-crystal display, which displays information (in the form of display texts in Russian) about the current state, switching and emergency situations in the power supply circuit, has a non-volatile memory, so even if the auxiliary power supply of the ATS circuit is completely de-energized, the program is saved even when power is restored, the circuit continues to operate based on the current state of the power circuit.

Manual operation:

When the ATS operation mode switch is switched to the "MANUAL" position, only the output control commands of the programmable control relay are disabled, all signaling in the form of display text messages continues to work. Control of circuit breakers: input 1 (QF1) and input 2 (QF2) is carried out using the buttons on the front panel of the ATS cabinet.

ATS scheme with two inputs (working and reserve) and one output.

Automatic transfer of a reserve can be made with a different algorithm of operation at the choice of the customer:

ATS with first input priority:

In normal mode, power is supplied only from the first input. If the voltage on it disappears, the machine switches to the second input, when the supply is restored at the first input, the ATS shield immediately returns power to it.

AVR with equivalent inputs:

Able to work for a long time both from the first and from the second input. When the voltage is turned off at the first input, the second input is automatically connected, from which the voltage supply continues. Automated return to the first input when the power supply is restored on it is not provided, this happens only when the power is interrupted at the second input. In ATS cabinets of this type, it is possible to manually switch from one input to another.

AVR no refund:

When the power supply is interrupted at the first input, AVR of this type automatically switches to the second input. Returning to the first entry is only possible in manual mode.

Some AVRs provide for the mode of independent operation of each input for different groups of consumers. If one input fails, all consumers join the serviceable input.

Marking of automation and control panels

The classic marking of shields is clear from the abbreviation of the first letters:

- SCHU is a control panel;

- SHA is an automation shield;

- SHAU is a control and automation panel;

- NKU is a generalized designation of low-voltage complete devices (SchU, SCHA, SCHAU, SHR, VRU, MSB) up to 0.4 kV.

Separately, we can highlight:

- SCHO - lighting boards;

- SHUV ─ ventilation control panels;

- OSCHV ─ hinged lighting boards;

- UOSCHV ─ built-in lighting boards.

ShchAU assembly features

Automation panels, more often, are assembled for a specific task, a specific technological process or equipment. The assembly of the shield includes several stages:

- Preparation of technical specifications;

- Selection of components for the assembly of the shield;

- Shield assembly;

- Installing a shield on an object;

- Start-up and adjustment of the shield.

Engaged in the assembly and installation of control and automation panels, specialized organizations.

Installation of ventilation systems

Before the installation of ventilation systems with automatic components, a competent drafting of the project is required. To do this, you need to have certain engineering skills, so it is best to entrust such work to professionals.

Current technologies make it possible to design quite complex automatic control systems for ventilation systems. For this reason, their installation and subsequent adjustment, even if there is a well-designed project, should only be carried out by experienced specialists. Doing such work with your own hands is not recommended, especially when it comes to a very complex scheme. Any shortcomings and mistakes made during installation can provoke a serious violation of air exchange, due to which conditions will occur in the available space that are impossible for people to stay.

An equally important stage in carrying out such work will be commissioning. At this point, the operation of the assembled ventilation system as a whole is checked, and all the necessary indicators are given in accordance with the project developed in advance.