- What materials are needed to connect the restrictions when choosing a pump

- Main differences

- We make a closed heating system of a private house with our own hands

- Features of an open heating system and a closed

- Complete set of water heating of closed type

- Rules for choosing a boiler for closed heating

- The principle of operation of a closed heating system

- Installation of a feed line for a closed heating system

- Installation of a closed heating system

- What is the heating system made of?

- Natural circulation system

- System with forced circulation of the coolant

- Heating system installation

- 6 Ways to supply coolant

- Gravity circulation

- Where to put

- forced circulation

- natural circulation

- Mounting Features

- Heating a house without a pump. Two proven options

What materials are needed to connect the restrictions when choosing a pump

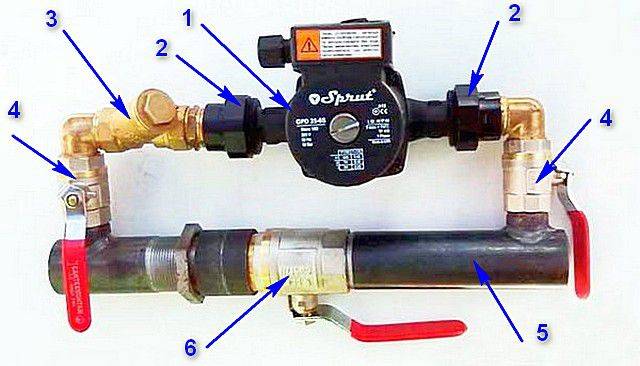

The device of a heating system with water heating, operating on the basis of natural or forced circulation, will allow you to create the necessary level of heat in the room. This process will not depend on central heating. So that the circulation pump correctly moves the water in the forced heating system. it must be installed correctly.The installation of the pump structure does not require much space. According to the connection diagram, among the components of the heating system, along with the pump, there must be such parts and tools as:

Correct installation of the circulation pump.

- membrane tank.

- Mesh filter.

- Clutch connection.

- Control block.

- Signal system.

- Valves.

- System make-up line.

- Grounding.

- Circulation pump.

- Alarm and temperature sensors.

- Wrenches (19-36 mm).

- Check valve.

- Bypass.

- Stop valve.

- Plug.

- Electrical cord.

- Welding machine.

The forced circulation system allows you to hide the main pipeline deep into the wall.

In order to optimize the heating system, it is necessary to carefully consider how it will function using the installed pump. The correct selection of the device, that is, equipped with a detachable thread, will speed up the installation of the pump. This will allow you not to purchase connections separately. After carrying out the preparatory work, you should read the instructions for the purchased pump and the diagram of its device in order to confidently proceed with the installation yourself.

Connecting the circulation pump to the heating is a popular procedure necessary to create the required pressure during the operation of the entire system. In this case, it becomes possible to create structures, the principles of connection and operation of which are different.

The natural circulation system, unlike the forced one, will not make the return and main pipeline invisible, that is, hide it in the lower part of the wall. With a small height of the rooms, part of the window will be blocked by the injection pipe, so the appearance of the room will be disturbed.

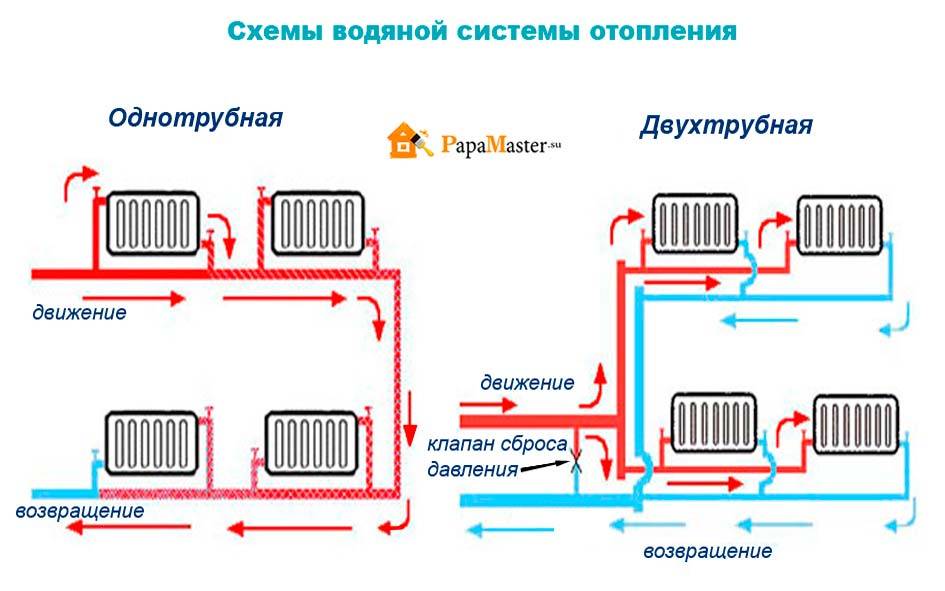

Main differences

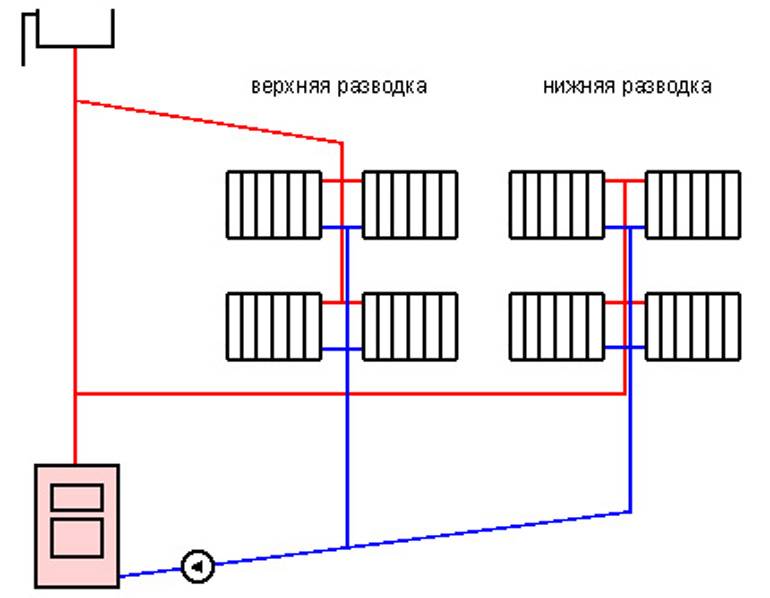

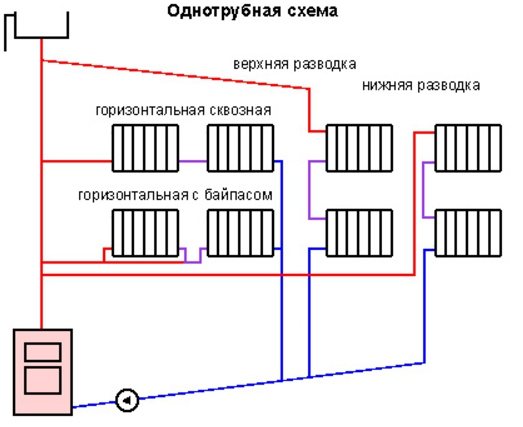

Heating systems using a liquid heat carrier are divided into 2 main types - these are single-pipe and two-pipe. The differences between these schemes lie in the method of connecting heat-releasing radiators to the main. The main line of a single-pipe heating system is a closed circular circuit. The heating main is laid from the heating device, the batteries are connected to it in series and pulled back to the boiler. The heating system with one pipeline is easy to install and does not have a large number of components, therefore it makes it possible to save a lot on installation.

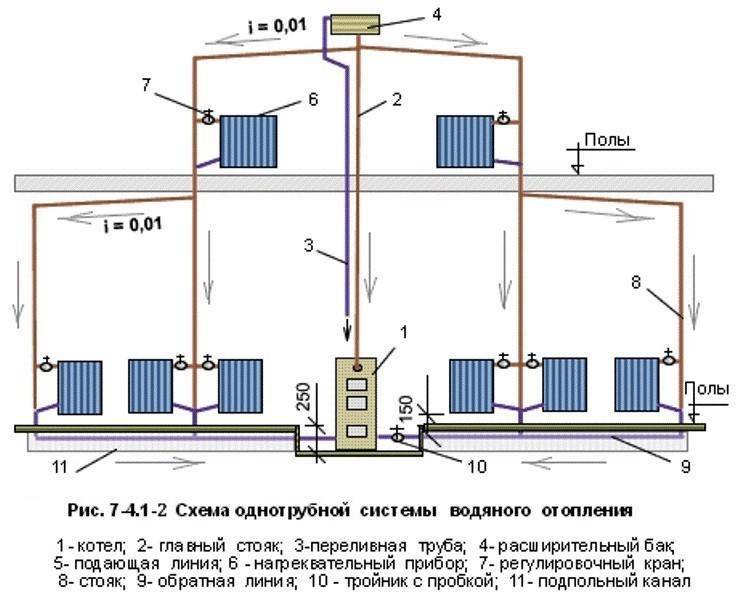

Single-pipe heating structures with natural movement of the coolant are constructed only with upper wiring. A distinctive feature is that in the schemes there are risers for the supply line, but there are no risers for the return pipe. The movement of the coolant of a double-circuit heating system is realized along 2 highways. The first one is designed to deliver the hot coolant from the heating device to the heat-releasing circuits, the second one - to remove the cooled coolant to the boiler.

Heating radiators are connected in parallel - the heated coolant enters each of them directly from the supply circuit, due to which it has an almost equal temperature. In the battery, water gives off energy and, when cooled, is sent to the outlet pipe - the “return”. Such a system needs twice the number of pipes, fittings and fittings, however, it makes it possible to organize complex branched structures and reduce heating costs due to individual regulation of the batteries. The double-circuit system heats large rooms and multi-storey buildings with high efficiency.In low-rise buildings (1-2 floors) and houses with an area of \u200b\u200bless than 150 m², it is more rational to build a single-circuit heat supply from both a financial and an aesthetic point of view.

We make a closed heating system of a private house with our own hands

The mass construction of private houses requires the improvement of many systems - sewerage, heating, pipelines. After all, it is necessary to mount entire structures in a short time. For many years, preference was given to an open heating system. However, in recent years this trend has begun to change. Increasingly, a closed heating system of a private house is being installed. What is the difference between these structures?

Features of an open heating system and a closed

At the time of launching the open-type heating system, the performance of all structural elements should be checked. First of all, it is required to ensure uninterrupted operation of the pump. After all, it is he who ensures the circulation of the coolant in the system. The main advantage of this type of heating is the possibility of installing additional structural elements.

Closed heating system - the scheme is placed in the public domain. However, do not perform work without preliminary calculation. This also applies to the open type of heating at home. It is worth noting that a do-it-yourself mounted closed heating system has more advantages than disadvantages.

In an open structure, contact between the coolant and the atmosphere is undesirable. Unfortunately, this cannot be avoided. And as a result, air appears in the pipeline.

Complete set of water heating of closed type

During the installation of a closed heating system of a private house, it is important to ensure complete isolation from the influence of the environment. That is why it is required to carry out the installation as clearly as possible, in accordance with the scheme. The drawing also indicates the detailing and assembly of the heating structure.

The drawing also indicates the detailing and assembly of the heating structure.

- A closed-type boiler is one of the important elements in the heating system.

- Automatic air, balancing, safety and thermostatic valves.

- A certain number of heating radiators (according to the estimate).

- High quality expansion tank.

- Ball valve and pump.

- Do not forget about the filter and pressure gauge.

Rules for choosing a boiler for closed heating

We advise you to evaluate the power of the boiler. If you plan to heat a house, the height of the streams in which is up to 3 meters, then you select it like this: for every 10 sq. m room requires 1 kW. Of course, this is an average figure. After all, a do-it-yourself mounted closed heating system must also be reliable.

This means that there are many requirements for materials. Remember, it is better to entrust the calculations to an engineer. Only in this case the house will completely warm up in the cold.

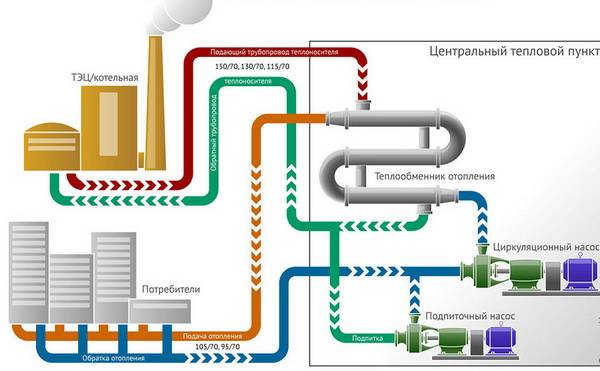

The principle of operation of a closed heating system

It consists of 2 compartments - hydraulic chamber and gas chamber. When heated, the water enters a hydraulic-type chamber. Nitrogen is supplied to the gas compartment under pressure.

Installation of a feed line for a closed heating system

The operation of the heating system directly depends on the ability to maintain the operating pressure and volume of the coolant

It is very important that these 2 parameters are constant. Unfortunately, the creation of tightness in heating cannot be achieved in full. Therefore, water leaks

Therefore, we must not forget about the periodic replenishment of the coolant

Therefore, water leaks occur. Therefore, we must not forget about the periodic replenishment of the coolant.

It is worth saying that the recharge of a closed heating system consists of the following components:

- The automatic make-up valve is located in the place where the pressure is lowest (usually before the inlet of the mains pumps).

- A faucet crashes into the pipeline. It is also required to mount a gate valve and a controlled valve. This will allow you to control the filling of the closed heating system.

- You can avoid accidental leakage of water into the supply line by installing a check valve. In this case, the high pressure in the closed heating system will not cause depressurization of the entire system.

- The use of manometers is proposed as control devices. These small devices will help keep track of any changes in the heating system.

Installation of a closed heating system

- Drawing up a scheme of the heating structure.

- Boiler installation.

- Installation of radiators.

- Laying a pipeline and providing the possibility of feeding a closed heating system.

- Placement of the pump, tank, fittings and taps. Filters are also installed at this stage.

- Installation of pressure gauges to control pressure in a closed heating system.

- Connecting metering devices and the boiler to the power line.

- Starting and checking the filling of a closed heating system.

This completes the installation technology of the heating system.

What is the heating system made of?

From the name itself - a water heating system, it becomes clear that water is needed for its operation. In this case, it is a coolant that constantly circulates in a closed circuit. Water is heated in a special boiler, and then - through pipes, it is delivered to the main heating element, which can be a "warm floor" system or radiators.

Of course, for better, safer and more economical operation of the system, you can use a large number of auxiliary equipment. However, the simplest water heating system looks like this:

The main elements of the heating system

Heating systems can differ according to the principle of coolant circulation:

- water heating with forced circulation;

- with natural.

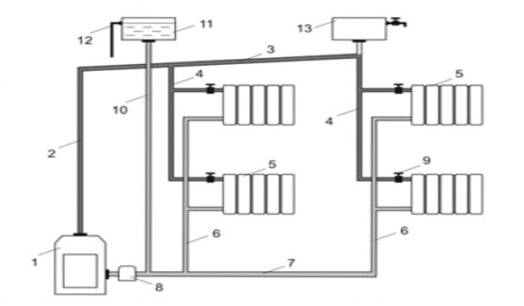

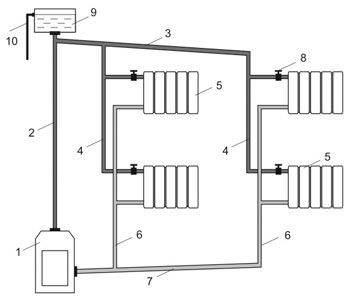

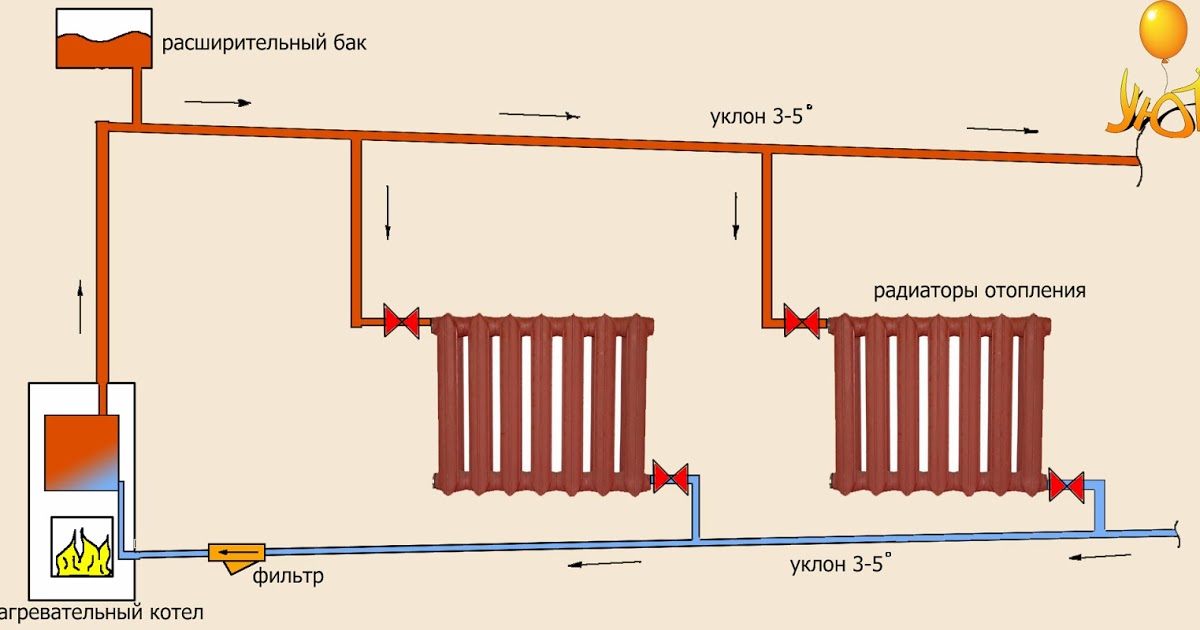

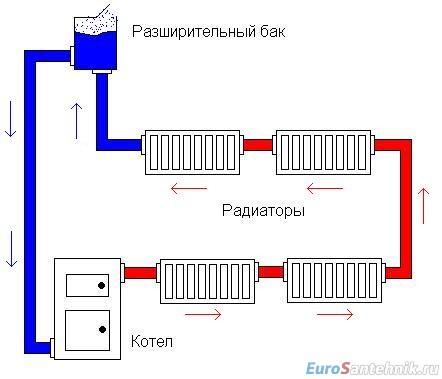

Natural circulation system

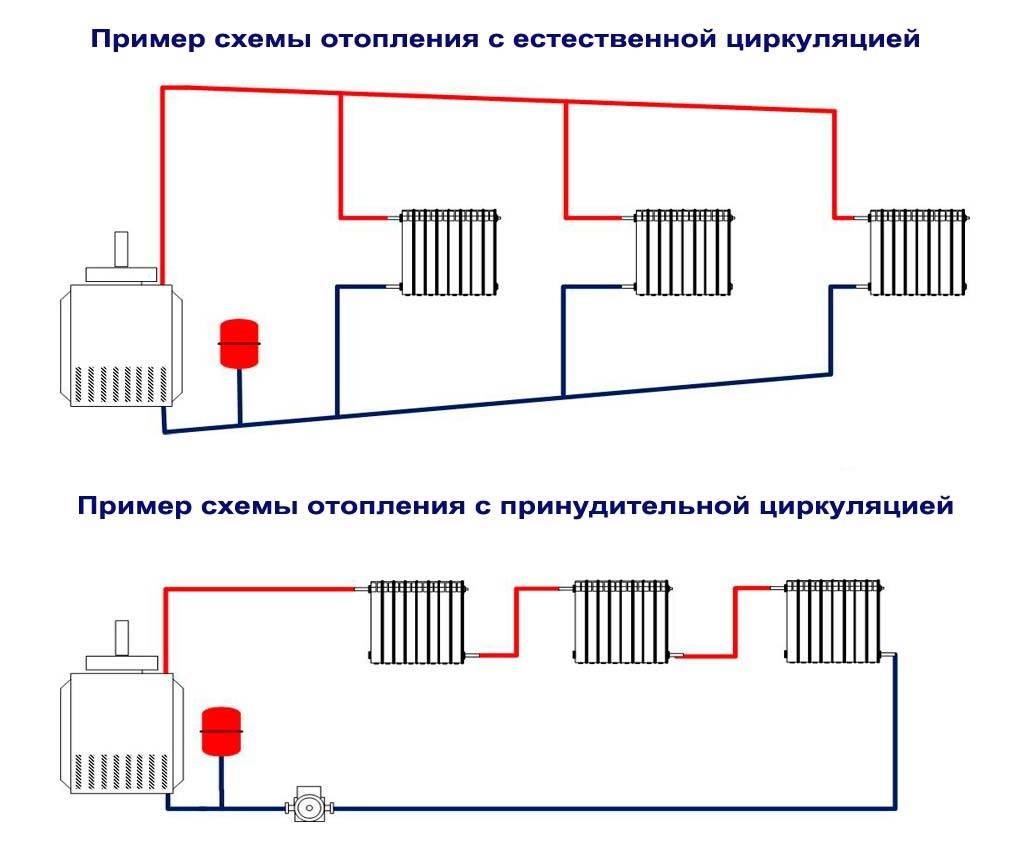

A system with natural circulation is a perfect example of man's use of the elementary laws of physics. The principle of its operation is actually simple - the movement of the coolant in the pipes occurs due to the difference in the density of cold and hot water.

Heating system with natural circulation

That is, the coolant heated in the boiler becomes lighter, its density decreases. Hot water is displaced from the boiler by the cold coolant entering it and easily rushes up the central riser pipe. And from it - to the radiators. There, the coolant gives off its heat, cools down, and, having regained its former heaviness and density, returns back through the return pipes to the heating boiler - displacing a new portion of the hot coolant from it. And this cycle repeats itself endlessly.

In order to independently create a water heating system with natural circulation of the coolant, it is important to remember a few simple rules. First of all, you should select pipes of the most suitable diameter for creating a central riser, and, in addition, observe the required slope angle when laying pipes. However, the natural circulation system also has several significant drawbacks.

First of all, the need to use heavy metal pipes (difficulties arise during installation). In addition, such a system excludes the possibility of regulating the level of heating of each individual room. Another disadvantage of the system can be called high fuel consumption.

However, the natural circulation system also has several significant drawbacks. First of all, the need to use heavy metal pipes (difficulties arise during installation). In addition, such a system excludes the possibility of regulating the level of heating of each individual room. Another disadvantage of the system can be called a high fuel consumption.

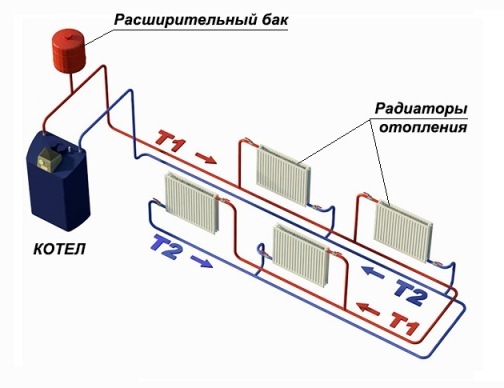

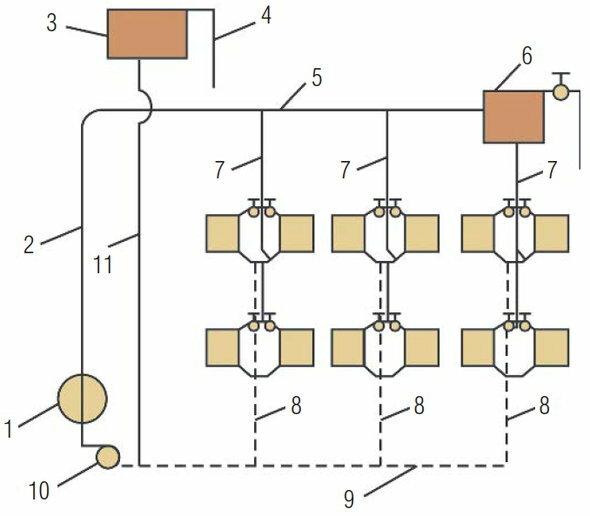

System with forced circulation of the coolant

Heating system with forced circulation of the coolant

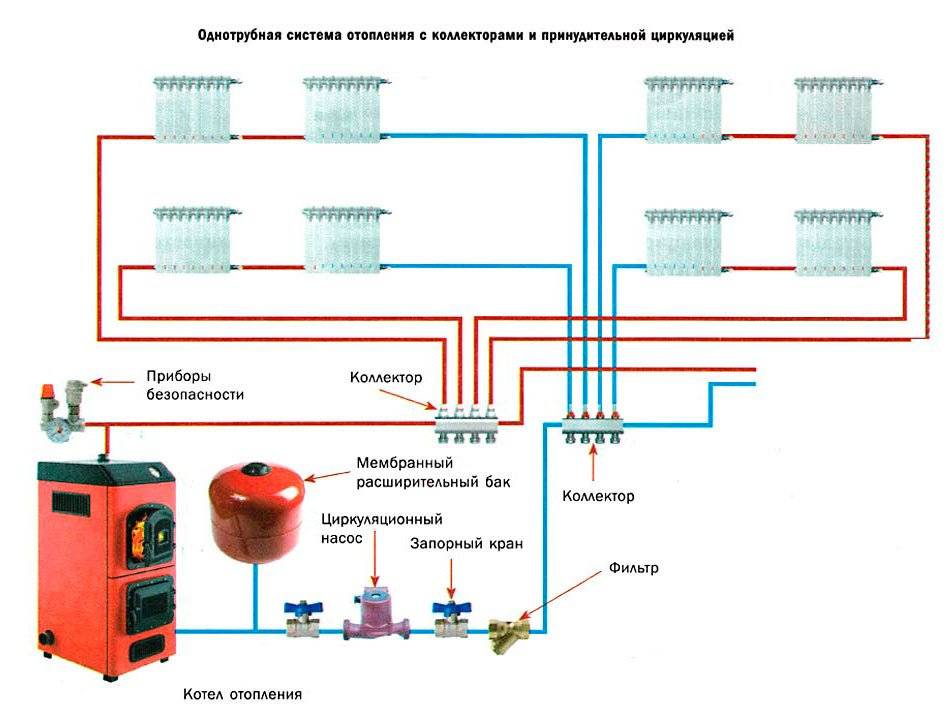

A distinctive feature of this type of system is the mandatory addition of a circulation pump. It is he who contributes to the movement of the coolant through the pipes. The system diagram looks like this:

One of the main advantages of a forced circulation system is that such water heating from electricity makes it possible to control the level of pressure in each radiator through special valves - thus, the level of heating of the room is also controlled.This fact allows, to some extent, to reduce the amount of fuel used for heating the coolant.

The disadvantage of the system is its energy dependence. In the event that power surges or power outages are possible in your home, the most reasonable solution would be to use a combined system that combines forced and natural circulation of the coolant.

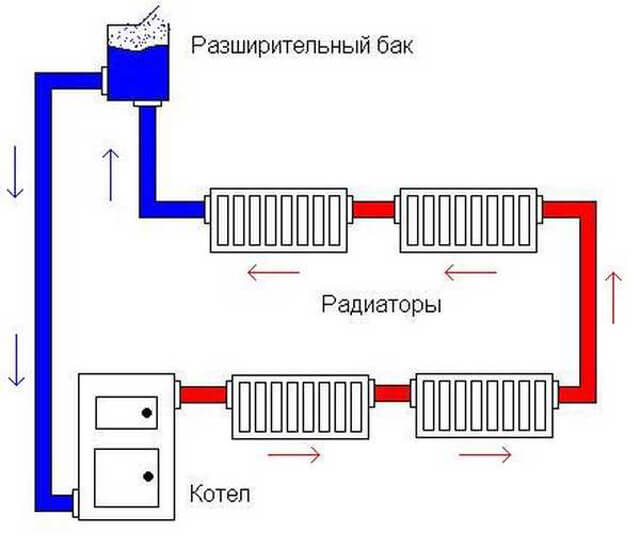

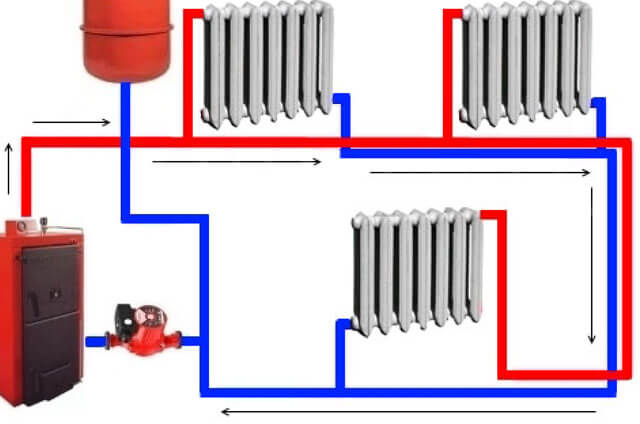

Heating system installation

The most practical is the creation of a two-pipe heating system in the house. It consists of two combined circuits, along one of which (supply pipes) a hot coolant moves to the radiators. And the cooled water from the radiator returns to the boiler through the second circuit - the return pipes.

The movement of the coolant in the heating system

A two-pipe forced circulation heating system is an excellent solution for any private home. It allows you to connect special thermostats that allow you to control the degree of heating on each individual radiator. The system can be supplemented with special collectors, which will make it even more efficient.

6 Ways to supply coolant

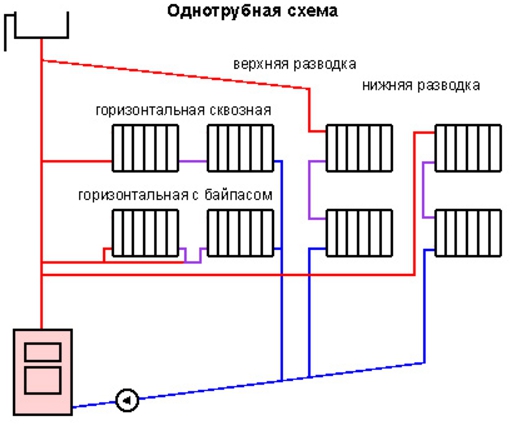

Depending on the location of the pipeline, there are two options for the connection - upper and lower. In open heating systems with the first type of wiring, it is not necessary to install additional air outlet units. Its residues are automatically discharged through the surface of the expansion tank.

Also, with this installation option, the hot coolant moves along the main riser, and then penetrates into the radiators through the distribution pipes.The system is ideal for rooms with one or two floors, as well as for small private houses.

The second option, which involves the use of lower wiring, is considered more practical and efficient. In this case, the supply pipe is at the bottom (near the return), and the coolant circulates in the direction from the bottom up. After passing through the radiators, the coolant returns to the boiler through the return line. All batteries have a special Mayevsky valve that allows you to remove air from the pipes.

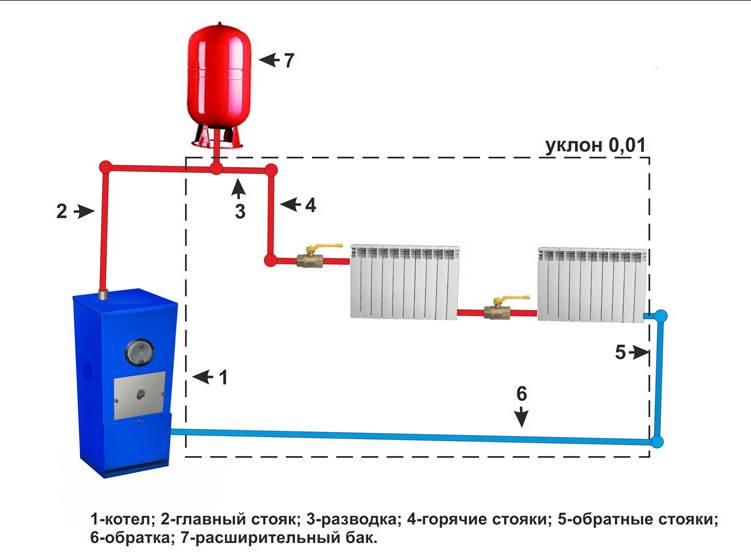

Gravity circulation

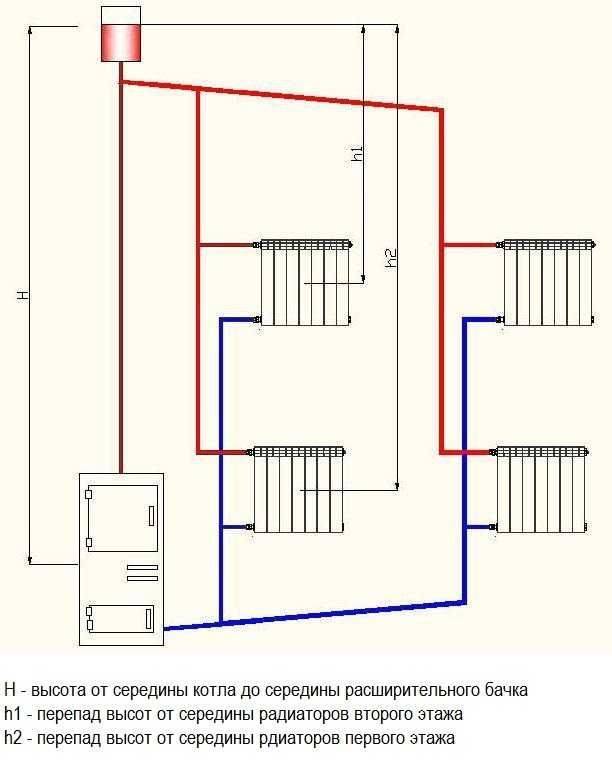

In systems where the coolant circulates naturally, there are no mechanisms to promote fluid movement. The process is carried out due to the expansion of the heated coolant. In order for this type of scheme to work effectively, an accelerating riser with a height of 3.5 meters or more is installed.

The main in the heating system with natural circulation of the liquid has some length restrictions, in particular, it should not exceed 30 meters. Therefore, such heat supply can be used in small buildings, in this case houses are considered the best option, the area of \u200b\u200bwhich does not exceed 60 m2. The height of the house and the number of floors are also of great importance when installing an accelerating riser. One more factor should be taken into account, in a natural circulation type heating system, the coolant must be heated to a certain temperature; in low-temperature mode, the required pressure is not created.

The scheme with the gravitational movement of a fluid has certain possibilities:

- Combination with underfloor heating systems. In this case, a circulation pump is installed on the water circuit leading to the heating elements.Otherwise, the operation is carried out in the usual mode, without stopping even in the absence of power supply.

- Boiler work. The device is installed in the upper part of the system, but at a lower level than the expansion tank is located. In some cases, a pump is installed on the boiler so that it runs smoothly. However, it should be understood that in such a situation the system becomes forced, which makes it necessary to install a check valve to prevent fluid recirculation.

Where to put

It is recommended to install a circulation pump after the boiler, before the first branch, but it does not matter on the supply or return pipeline. Modern units are made from materials that normally tolerate temperatures up to 100-115 ° C. There are few heating systems that work with a hotter coolant, therefore considerations of a more “comfortable” temperature are untenable, but if you are so calmer, put it in the return line.

Can be installed in the return or direct pipeline after/before the boiler up to the first branch

There is no difference in hydraulics - the boiler, and the rest of the system, it does not matter whether there is a pump in the supply or return branch. What matters is the correct installation, in the sense of tying, and the correct orientation of the rotor in space

Nothing else matters

There is one important point at the installation site. If there are two separate branches in the heating system - on the right and left wings of the house or on the first and second floors - it makes sense to put a separate unit on each, and not one common one - directly after the boiler. Moreover, the same rule is preserved on these branches: immediately after the boiler, before the first branch in this heating circuit.This will make it possible to set the required thermal regime in each of the parts of the house independently of the other, as well as save on heating in two-story houses. How? Due to the fact that the second floor is usually much warmer than the first floor and much less heat is required there. If there are two pumps in the branch that goes up, the speed of the coolant is set much less, and this allows you to burn less fuel, and without compromising the comfort of living.

There are two types of heating systems - with forced and natural circulation. Systems with forced circulation cannot work without a pump, with natural circulation they work, but in this mode they have a lower heat transfer. However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is slammed into it. This gives high efficiency and reliability of heating. It is clear that the installation of a circulation pump in these systems has differences.

All heating systems with underfloor heating are forced - without a pump, the coolant will not pass through such large circuits

forced circulation

Since a forced circulation heating system is inoperative without a pump, it is installed directly into the gap in the supply or return pipe (of your choice).

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They are able to jam the impeller and stop the motor.Therefore, a strainer must be placed in front of the unit.

Installing a circulation pump in a forced circulation system

It is also desirable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps, remove the unit. Only that part of the water that was directly in this piece of the system is drained.

natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not running. One ball shut-off valve is installed on the bypass, which is closed all the time while pumping is in operation. In this mode, the system works as a forced one.

Scheme of installation of a circulation pump in a system with natural circulation

When electricity fails or the unit fails, the faucet on the jumper is opened, the faucet leading to the pump is closed, the system works like a gravitational one.

Mounting Features

There is one important point, without which the installation of the circulation pump will require alteration: it is required to turn the rotor so that it is directed horizontally. The second point is the direction of the flow. There is an arrow on the body indicating in which direction the coolant should flow. So turn the unit around so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, only when choosing a model, see that it can work in both positions. And one more thing: with a vertical arrangement, the power (created pressure) drops by about 30%.This must be taken into account when choosing a model.

Heating a house without a pump. Two proven options

Until the 90s of the last century, heating a house without a pump was the only one available, since the direction for the manufacture of circulation pumps and their promotion to the masses was not developed. Thus, the owners and developers of private houses were forced to install heating in their houses without a pump.

But when good boiler equipment, pipes and compact circulation pumps began to be brought to the CIS in the 90s, the situation changed dramatically. Everyone started installing heating systems. which do not work without a pump. They began to forget about gravity systems. But today the situation is changing. Builders of private houses again recall the heating of the house without pumps. Since everywhere you can trace interruptions and shortages of electricity, which is so necessary for the operation of the circulation pump.

The issue of quality and quantity of electricity supply is especially acute in new buildings.

That is why today, more than ever, one proverb is remembered: “Everything new is a well-forgotten old!”. This proverb is very relevant today, for heating a house without a pump.

For example, in the past, only steel pipes, homemade boilers and open expansion tanks were used for heating. The boilers were of low efficiency, the pipes were bulky steel, and it is not recommended to hide them in the walls.

Expansion tanks were located in attics. because of this, there were heat losses and the threat of a flood of the roof or freezing of the pipes in the tank. Which in turn often led to an explosion of the boiler, rupture of pipes and human casualties.

Today, thanks to modern boilers, pipes and other heating devices, it is possible to make a smart, economical heating system without a pump. Thanks to modern economical boilers, significant savings can be achieved.

Modern plastic or copper pipes can be easily hidden in walls. The same heating of the house today can be done, both with radiators and with warm floors.

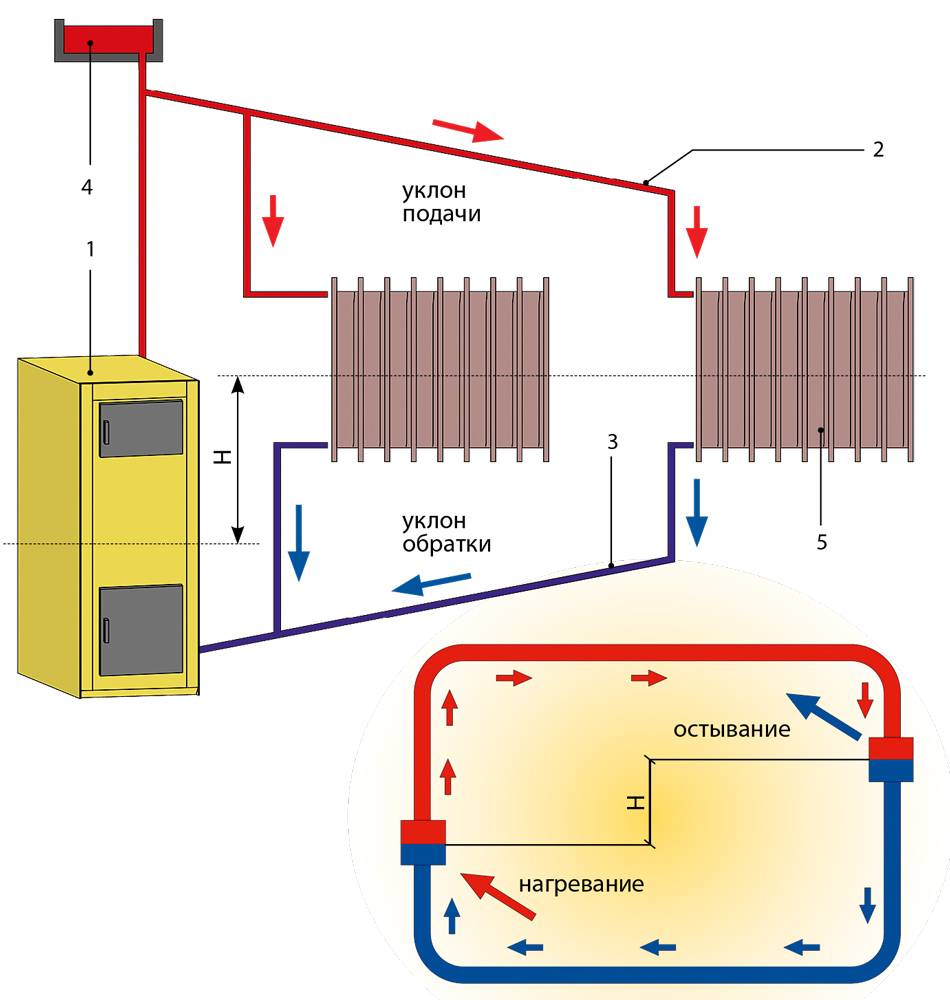

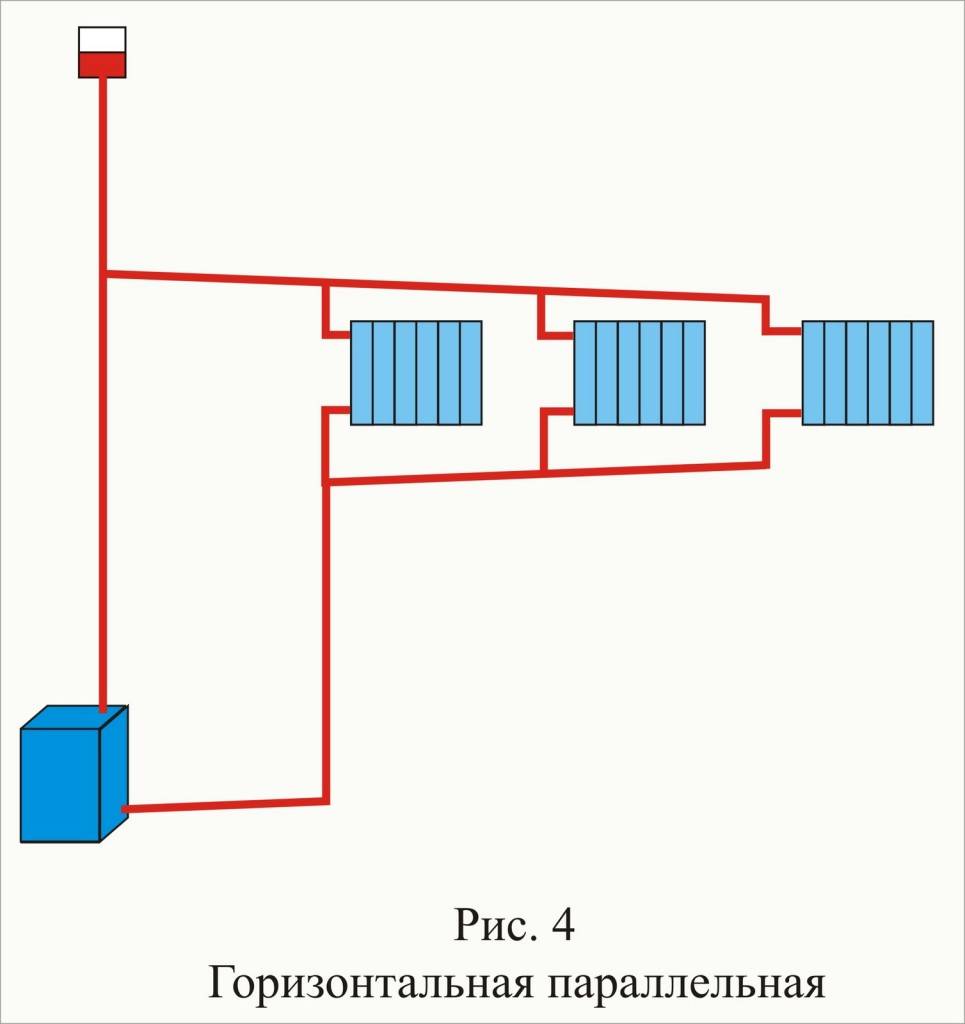

Today, there are two main home heating systems without a pump.

The first and most common system is called Leningradka. or with horizontal spill.

The main thing in home heating systems without a pump is the slope of the pipes. Without a slope, the system will not work. Due to the slope, "Leningradka" is not always suitable, since the pipes run around the entire perimeter of the house. Also, due to the fact that the slope may not be enough, you have to lower the boiler below the level of your floor. The boiler in this case is inconvenient to heat and clean.

Also, when installing a heating system at home without a Leningradka pump, doorways interfere along the route of the pipes. In this case, it is necessary to make window sills with a height of at least 900mm.

This is necessary so that the radiator is mounted and there is enough height for the pipes along the slope. Otherwise, the system is fully functional, with cast iron, steel and aluminum radiators.

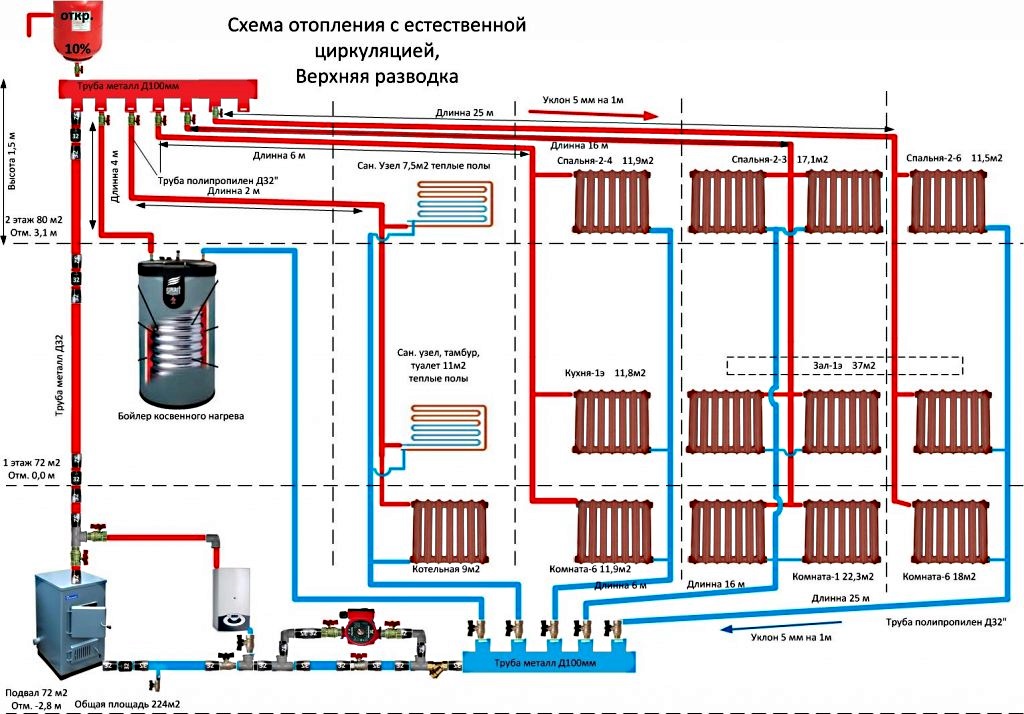

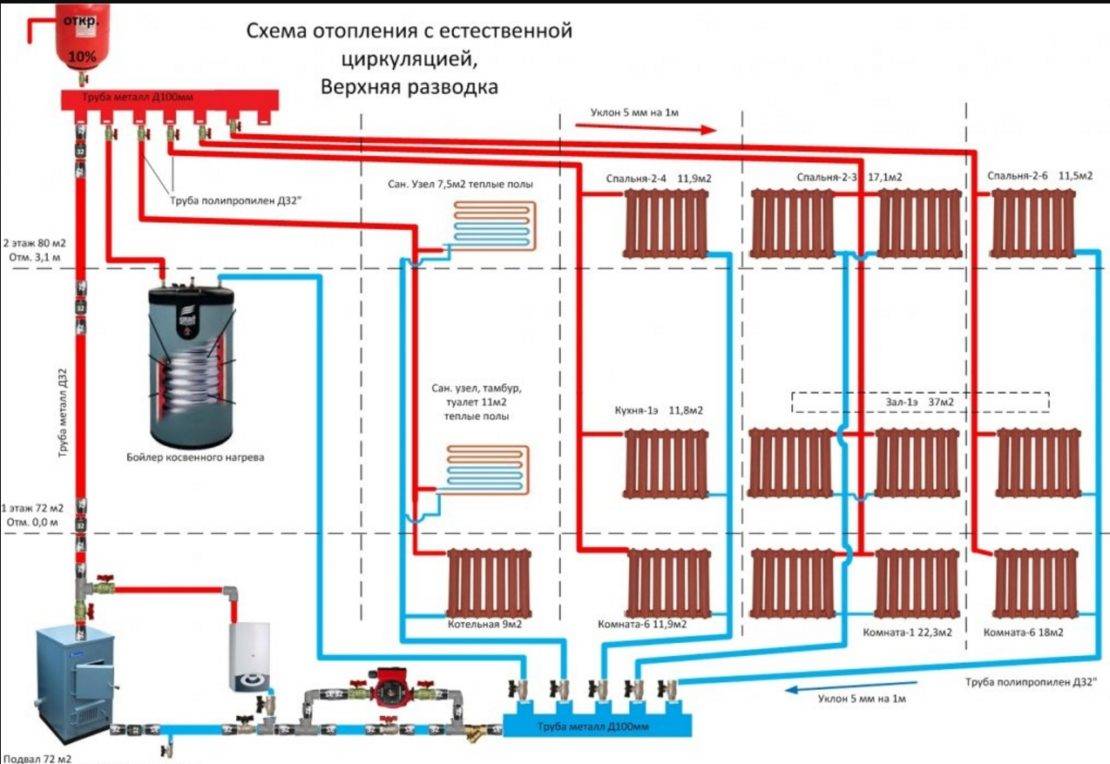

The second home heating system without a pump is called the "Spider" or vertical top-spill system.

Today it is the most reliable and practical home heating system without a pump. The main thing is that the "Spider" system is devoid of all the shortcomings of "Leningradka", with the exception of the slope of the return line, due to which the boiler also has to be lowered below the floor.

Otherwise, the Spider system is the most efficient system.Any radiators and underfloor heating can be screwed to the Spider system. It is possible to mount valves under the thermal head on radiators in the "Spider" system and hide the pipes in the walls and so on.

Today, it is increasingly necessary to recommend the Spider system to developers, because. today it is an ideal home heating system without a pump.

Thank you for reading this article!