- Where to put

- forced circulation

- natural circulation

- Mounting Features

- The principle of operation of electric boilers

- Who invented the induction heating unit

- Where to put

- forced circulation

- natural circulation

- Mounting Features

- 3 Rules for choosing components

- Dry rotor heating pumps

- How to install a circulation pump in a heating system

- Rules for the selection and installation of pipes

- Rules and nuances of installation

- Mounting diagram

- How to connect to the power supply

- When to install additional equipment

- Electric heater installation

Where to put

It is recommended to install a circulation pump after the boiler, before the first branch, but it does not matter on the supply or return pipeline. Modern units are made from materials that normally tolerate temperatures up to 100-115 ° C. There are few heating systems that work with a hotter coolant, therefore considerations of a more “comfortable” temperature are untenable, but if you are so calmer, put it in the return line.

Can be installed in the return or direct pipeline after/before the boiler up to the first branch

There is no difference in hydraulics - the boiler, and the rest of the system, it does not matter whether there is a pump in the supply or return branch.What matters is the correct installation, in the sense of tying, and the correct orientation of the rotor in space

Nothing else matters

There is one important point at the installation site. If there are two separate branches in the heating system - on the right and left wings of the house or on the first and second floors - it makes sense to put a separate unit on each, and not one common one - directly after the boiler. Moreover, the same rule is preserved on these branches: immediately after the boiler, before the first branch in this heating circuit. This will make it possible to set the required thermal regime in each of the parts of the house independently of the other, as well as save on heating in two-story houses. How? Due to the fact that the second floor is usually much warmer than the first floor and much less heat is required there. If there are two pumps in the branch that goes up, the speed of the coolant is set much less, and this allows you to burn less fuel, and without compromising the comfort of living.

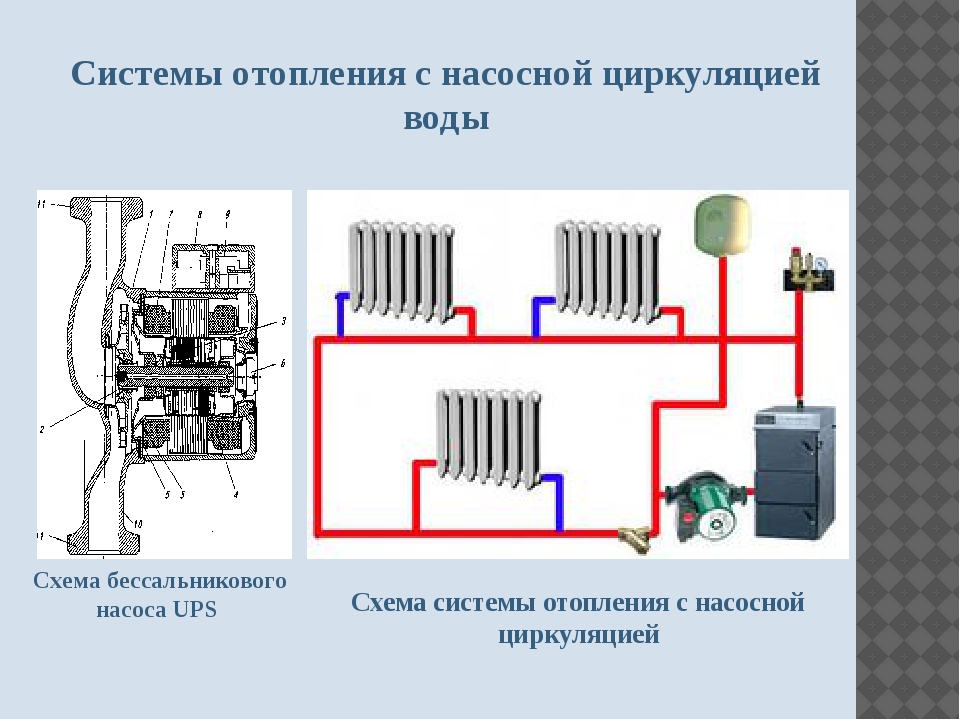

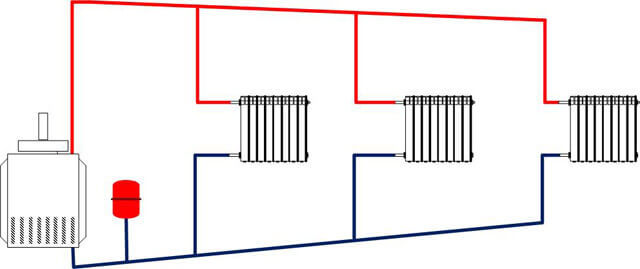

There are two types of heating systems - with forced and natural circulation. Systems with forced circulation cannot work without a pump, with natural circulation they work, but in this mode they have a lower heat transfer. However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is slammed into it. This gives high efficiency and reliability of heating. It is clear that the installation of a circulation pump in these systems has differences.

All heating systems with underfloor heating are forced - without a pump, the coolant will not pass through such large circuits

forced circulation

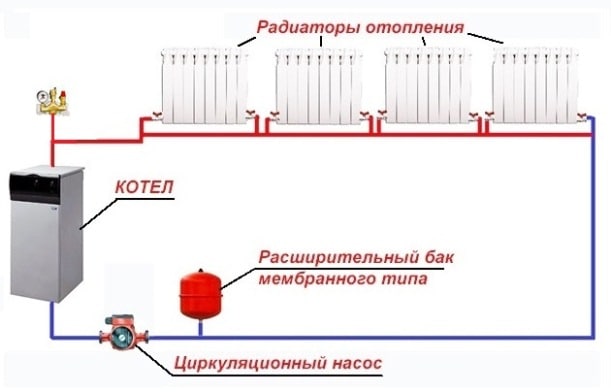

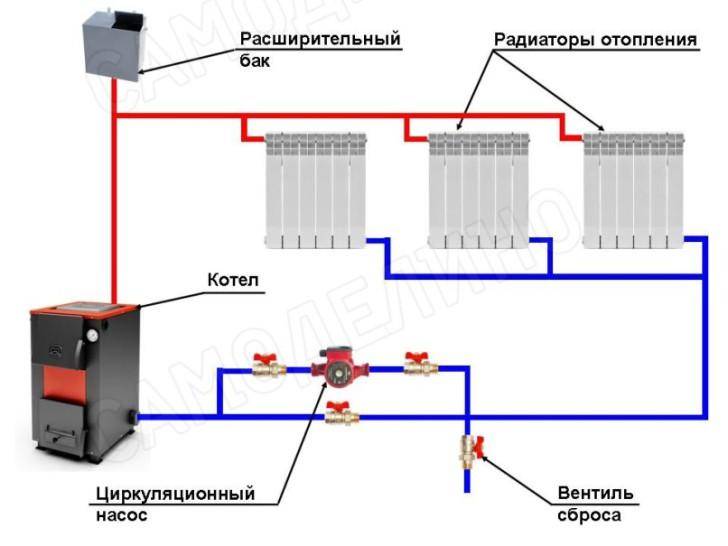

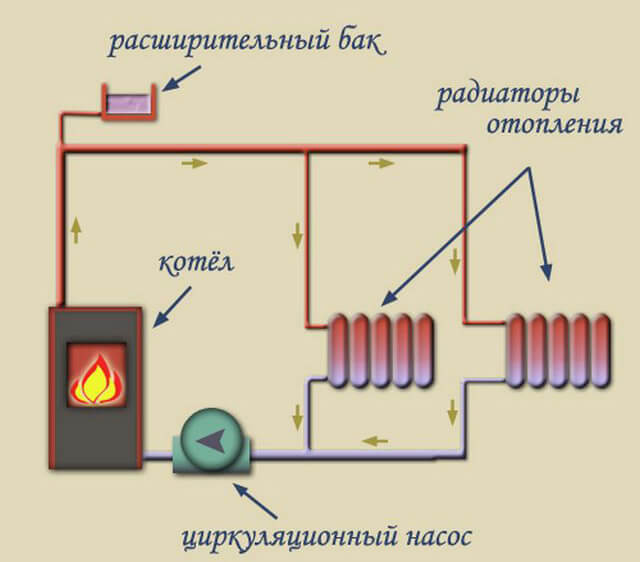

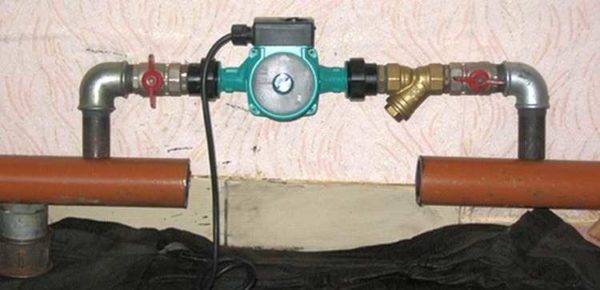

Since a forced circulation heating system is inoperative without a pump, it is installed directly into the gap in the supply or return pipe (of your choice).

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They are able to jam the impeller and stop the motor. Therefore, a strainer must be placed in front of the unit.

Installing a circulation pump in a forced circulation system

It is also desirable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps, remove the unit. Only that part of the water that was directly in this piece of the system is drained.

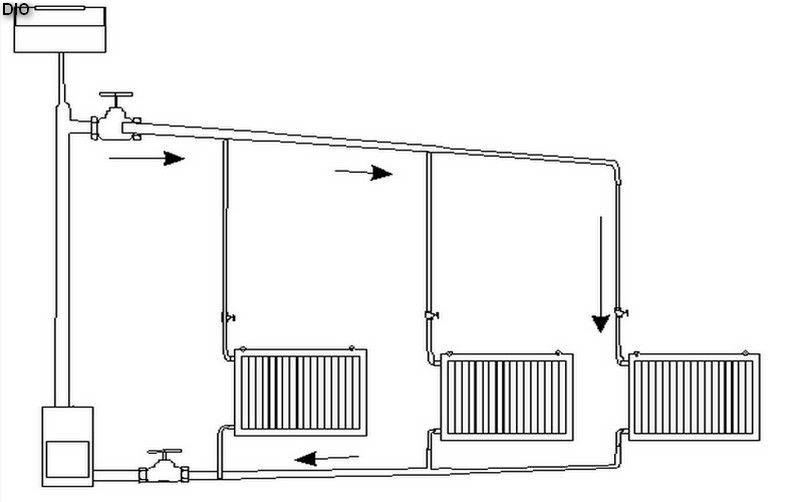

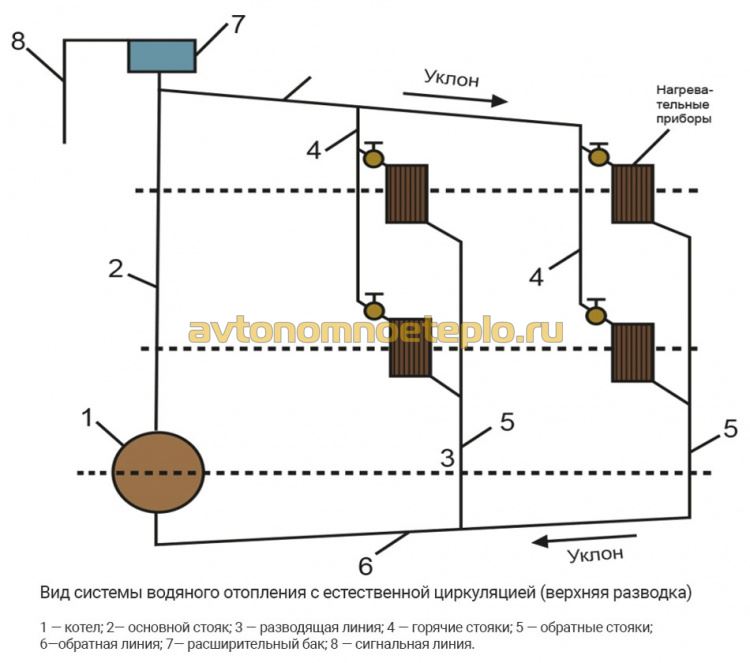

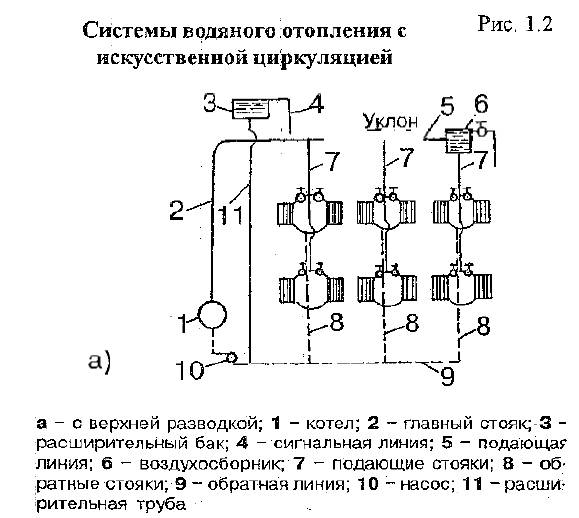

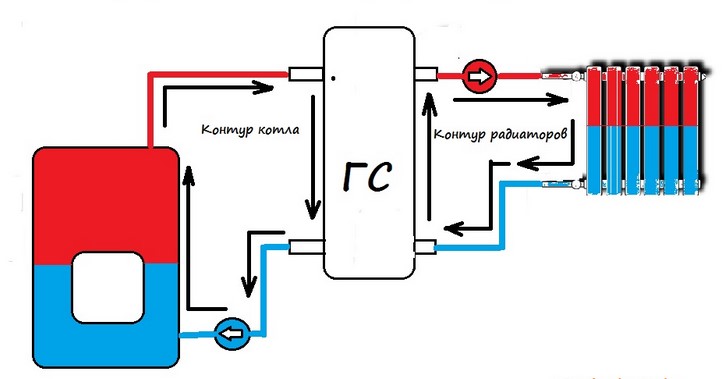

natural circulation

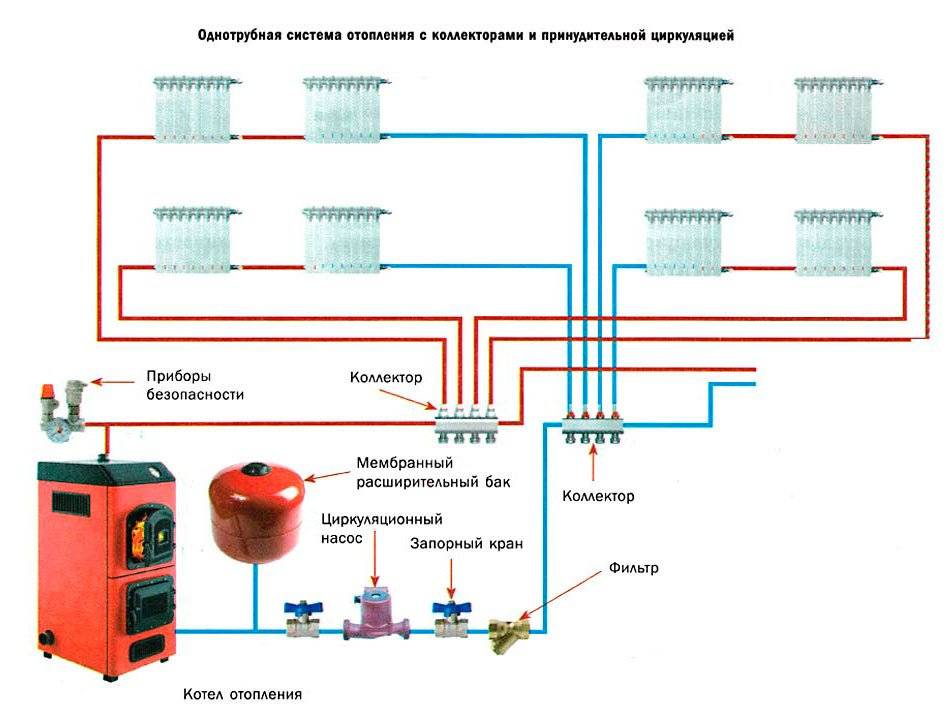

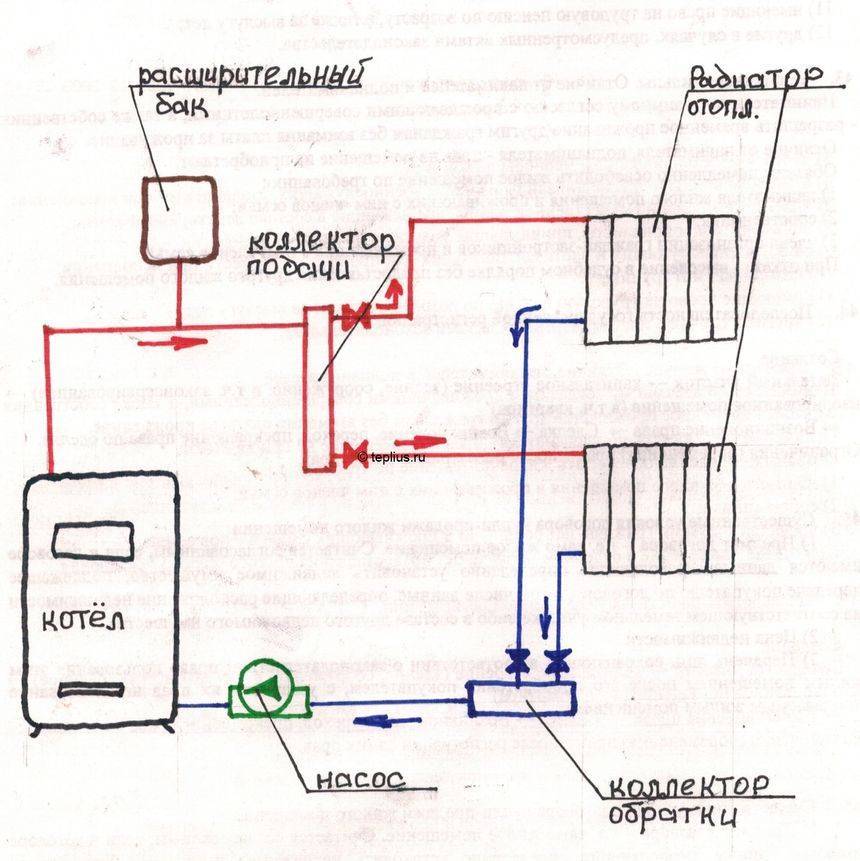

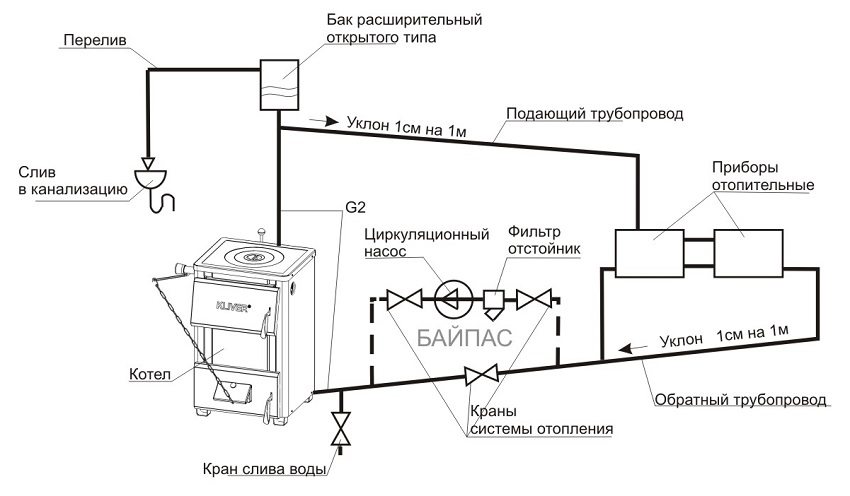

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not running. One ball shut-off valve is installed on the bypass, which is closed all the time while pumping is in operation. In this mode, the system works as a forced one.

Scheme of installation of a circulation pump in a system with natural circulation

When electricity fails or the unit fails, the faucet on the jumper is opened, the faucet leading to the pump is closed, the system works like a gravitational one.

Mounting Features

There is one important point, without which the installation of the circulation pump will require alteration: it is required to turn the rotor so that it is directed horizontally. The second point is the direction of the flow.There is an arrow on the body indicating in which direction the coolant should flow. So turn the unit around so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, only when choosing a model, see that it can work in both positions. And one more thing: with a vertical arrangement, the power (created pressure) drops by about 30%. This must be taken into account when choosing a model.

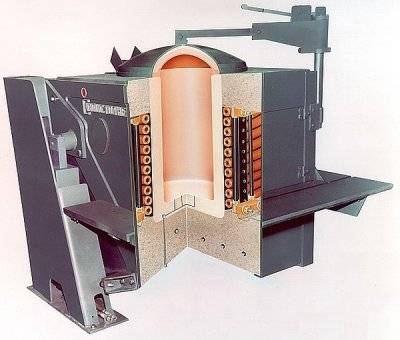

The principle of operation of electric boilers

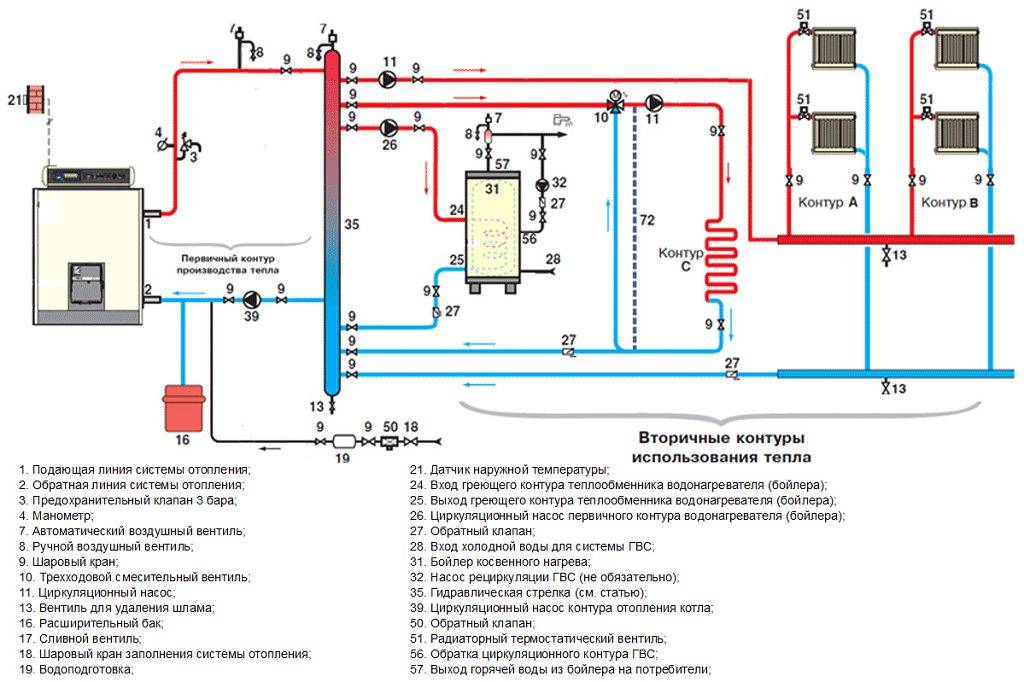

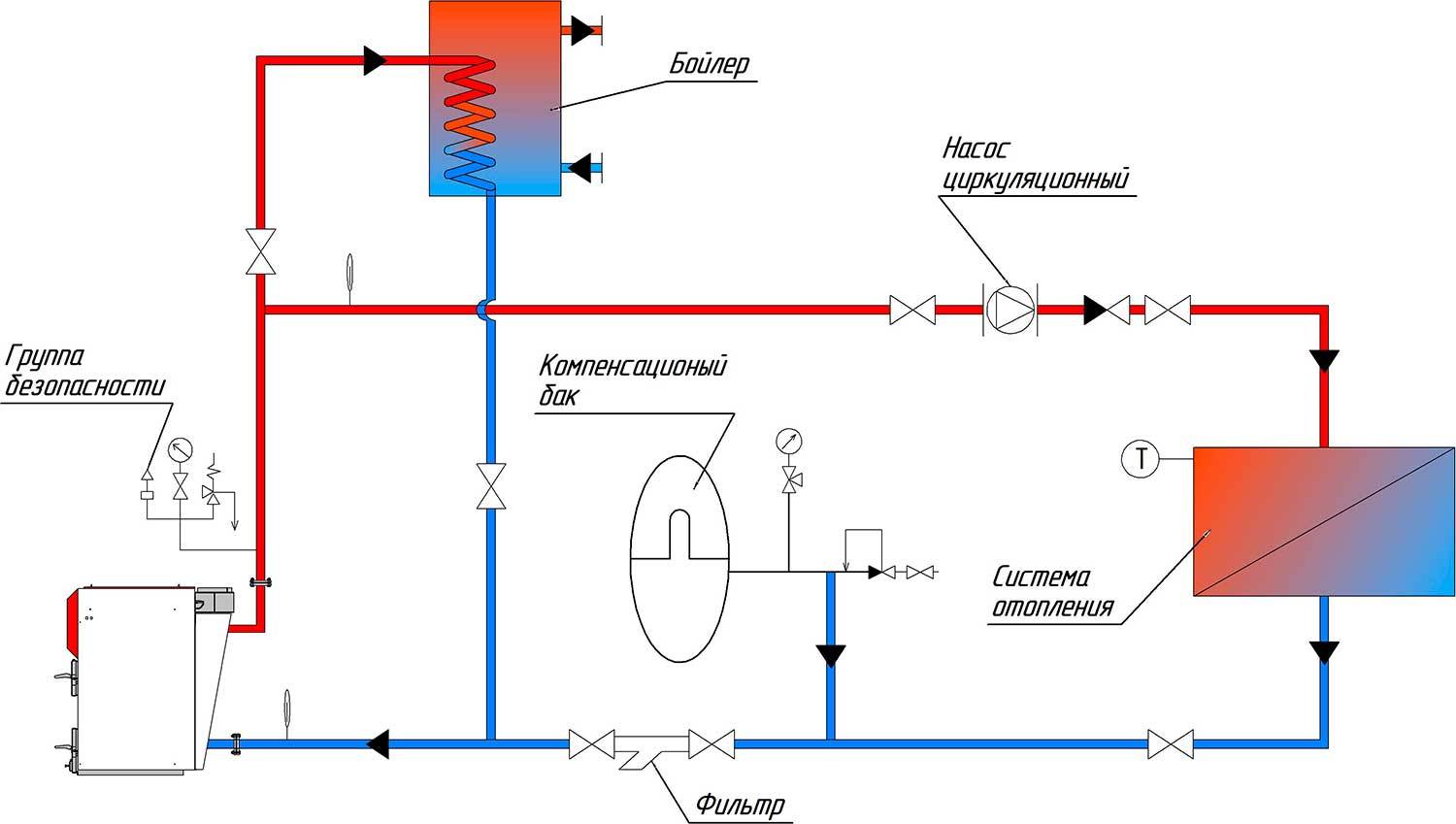

Scheme heating boiler piping.

The electric boiler can be connected everywhere, it works normally where there is power supply, it does not need to purchase and store fuel or equip a special room. It is enough just to connect to the mains and remove the pipeline. For many people, such boilers have become an indispensable tool. Due to its compact size, the electrode boiler can be installed even in a very small room, while the modern design of the equipment will allow it to fit seamlessly into any interior. The basic equipment includes an expansion tank, a heating element, elements for regulating and controlling the operation of the heat generator.

The principle of operation of the equipment is extremely simple: a coolant is supplied to the expansion tank, which is heated by electricity and then distributed through radiators and pipes. Heating electric boilers are distinguished by high efficiency, which often reaches 100%, ease of operation, affordable cost of units, silent operation, safety and environmental friendliness are also undeniable advantages of such heating equipment.Of course, in addition to the advantages, heating boilers powered by electricity also have certain disadvantages, which are largely related to the domestic organization of the electrical system. It is necessary to remember about the cost of electricity, which is increasing all the time, about frequent interruptions in the supply of electricity, power surges that adversely affect the functional part of the equipment and its service life.

Electric boilers for heating are endowed with a stylish and modern design, ease of maintenance and step-by-step power switching. Equipment can be connected in cascade to create a powerful installation.

Electric boiler: advantages and disadvantages

Scheme of the device of the electric boiler.

Like any other equipment, an electric boiler has its advantages and disadvantages. Among the indisputable advantages, one can single out, first of all, compactness. This equipment is really very compact and almost imperceptible in the overall design of the system. Such boilers are low cost, have a smooth output to the rated power and, among other things, the peculiarity of their operation eliminates the possibility of an emergency in case of water leakage. If water suddenly disappears in the system, the equipment simply will not work.

Among the shortcomings are the following points:

- the need for water treatment. The equipment will work effectively only if certain values of water resistivity are provided, which very often cannot be measured and brought into line with the standards;

- ensuring optimal circulation of the coolant. Under the condition of weak circulation, the water in the electric boiler can boil. If the forced circulation is too fast, the equipment may not start;

- non-freezing liquids cannot be used as a heat carrier.

Who invented the induction heating unit

The marketing argument about the innovation of the induction boiler does not stand up to scrutiny. The principle of induction was discovered back in the first third of the 19th century by Michael Faraday, a researcher known to us from a school physics course.

And at the very beginning of the 20th century, the world's first melting induction furnace for the metallurgical industry was launched in Sweden.

Of course, engineers and scientists even then considered induction for heating boilers in everyday life. But, having studied the pros and cons, they considered this option irrational.

An induction heater for home and everyday life began to be used in the CIS in the mid-90s. Prior to this, high-power induction boilers were used in the USSR only in heavy industry for melting metals.

Where to put

It is recommended to install a circulation pump after the boiler, before the first branch, but it does not matter on the supply or return pipeline. Modern units are made from materials that normally tolerate temperatures up to 100-115 ° C. There are few heating systems that work with a hotter coolant, therefore considerations of a more “comfortable” temperature are untenable, but if you are so calmer, put it in the return line.

Can be installed in the return or direct pipeline after/before the boiler up to the first branch

There is no difference in hydraulics - the boiler, and the rest of the system, it does not matter whether there is a pump in the supply or return branch.What matters is the correct installation, in the sense of tying, and the correct orientation of the rotor in space

Nothing else matters

There is one important point at the installation site. If there are two separate branches in the heating system - on the right and left wings of the house or on the first and second floors - it makes sense to put a separate unit on each, and not one common one - directly after the boiler. Moreover, the same rule is preserved on these branches: immediately after the boiler, before the first branch in this heating circuit. This will make it possible to set the required thermal regime in each of the parts of the house independently of the other, as well as save on heating in two-story houses. How? Due to the fact that the second floor is usually much warmer than the first floor and much less heat is required there. If there are two pumps in the branch that goes up, the speed of the coolant is set much less, and this allows you to burn less fuel, and without compromising the comfort of living.

There are two types of heating systems - with forced and natural circulation. Systems with forced circulation cannot work without a pump, with natural circulation they work, but in this mode they have a lower heat transfer. However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is slammed into it. This gives high efficiency and reliability of heating. It is clear that the installation of a circulation pump in these systems has differences.

All heating systems with underfloor heating are forced - without a pump, the coolant will not pass through such large circuits

forced circulation

Since a forced circulation heating system is inoperative without a pump, it is installed directly into the gap in the supply or return pipe (of your choice).

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They are able to jam the impeller and stop the motor. Therefore, a strainer must be placed in front of the unit.

Installing a circulation pump in a forced circulation system

It is also desirable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps, remove the unit. Only that part of the water that was directly in this piece of the system is drained.

natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not running. One ball shut-off valve is installed on the bypass, which is closed all the time while pumping is in operation. In this mode, the system works as a forced one.

Scheme of installation of a circulation pump in a system with natural circulation

When electricity fails or the unit fails, the faucet on the jumper is opened, the faucet leading to the pump is closed, the system works like a gravitational one.

Mounting Features

There is one important point, without which the installation of the circulation pump will require alteration: it is required to turn the rotor so that it is directed horizontally. The second point is the direction of the flow.There is an arrow on the body indicating in which direction the coolant should flow. So turn the unit around so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, only when choosing a model, see that it can work in both positions. And one more thing: with a vertical arrangement, the power (created pressure) drops by about 30%. This must be taken into account when choosing a model.

3 Rules for choosing components

Due to the fact that the highest temperature of the coolant passes in the collector (riser), the pipe itself must be installed metal. In addition, if a stove is used, and not a boiler, as a heat source, then steam can pass inside, which can adversely affect the operation of the system.

It should also be taken into account that with gravity-type heating, the diameter of the pipes of the water circuit should be slightly larger than in the scheme with a pump. As practice shows, for heating a house of 160 square meters, two-inch pipes are enough at the outlet (riser) and at the inlet to the heat exchanger. This is necessary because the water velocity is slower in the natural pattern, which can lead to the following problems:

- at low pressure, water will not be able to break through blockages and air pockets;

- several times less heat is received by the room from the boiler during the period of water passage from the start to the end point.

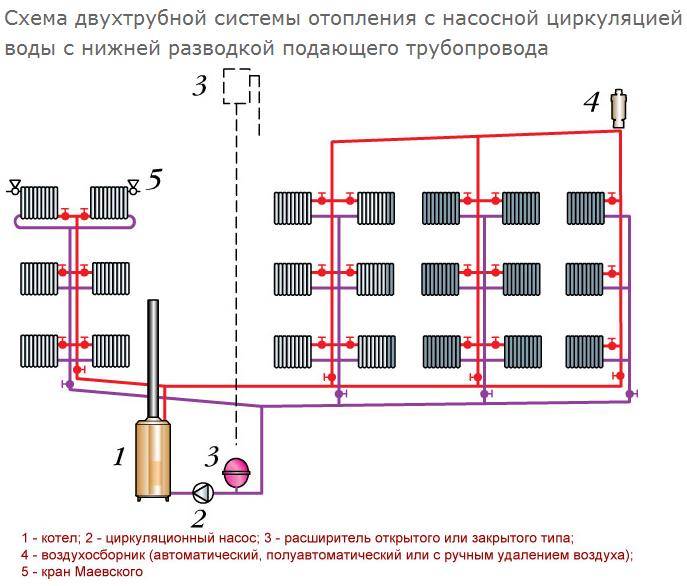

If the scheme provides for the supply of water from below the radiator batteries, then an important task remains to arrange the removal of air from the system.It cannot be completely removed through the expansion tank, since water enters through a line that is lower in level than the consumer appliances themselves (radiators)

If a forced circuit is used, then the pressure is sufficient for oxygen to escape through the air collectors installed at the top of the device. With the help of Mayevsky cranes, heat transfer can be regulated. Such taps in the gravity circuit are just used to vent air from a system in which water is supplied through a pipe located below the batteries.

Dry rotor heating pumps

The design of the unit in question is designed so that the pumped water does not have direct contact with the engine. That is why it is considered to be safer. In the design of the pump part, there are two rings that perform rotational movements between themselves. The pump part, in turn, is separated from the motor by the installed seal. With the help of the pumped liquid, the pump mechanisms are lubricated, thereby preventing its wear. The rings are tightly fastened together with a spring. This allows you to adjust the clamping force if abrasion occurs. All this helps to increase the life of the pump, and also makes it more reliable.

Most often, this type of pump, with a dry rotor, is used in industrial enterprises with a large volume of water.

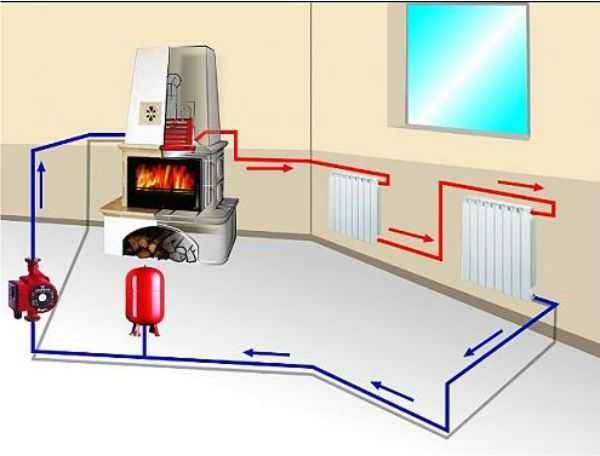

How to install a circulation pump in a heating system

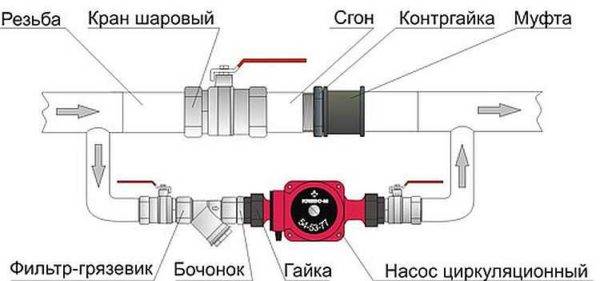

Installing a circulation pump will benefit the operation of the heating system. He can make it universal. To do this, you will need to assemble a node in which there is a bypass (jumper) and a system of shut-off valves. Study the connection diagram of the circulation pump to the heating system:

The device is usually connected to a pipe with a return flow of the coolant (pos. 1), to which a jumper is attached (welded) on threaded connections so that there is a stopcock (pos. 2) on each side of the pump. It is recommended to install an oblique dirt filter (pos. 3) at the pump inlet. An additional shut-off valve (pos. 4) is mounted between the embedded bends.

If electricity enters the house uninterruptedly, the lower tap is closed, the upper ones are open, and the coolant moves through the pump, then the premises will be heated stably. In the event of a power outage, you will need to open the bottom tap, which will switch the heating system to work on the principle of natural circulation. Taps on the edges of the circulation pump for heating systems facilitate the removal of the device during maintenance work (when replacing the pump) - it will not be necessary to drain the water from the system.

Quite often, not a tap is installed on such a node, but a check valve (pos. 5), which will perform its task automatically, shutting off (opening) the movement of fluid through the pipeline when the pump is turned on (off).

When choosing a circulation pump for heating systems, we offer you the help of specialists from our company SantekhStandard, which has been a supplier of engineering plumbing in Russia since 2004.

Cooperating with "SantekhStandart", you get the following benefits:

-

quality products at reasonable prices;

-

constant availability of products in stock in any quantities;

-

delivery of goods to the regions through any transport companies;

-

individual approach and flexible work with each client;

-

discounts and various promotions for regular customers;

-

certified and insured products;

-

trademarks registered in Russia, which is an additional protection against low-quality fakes.

The specialists of our company "SantekhStandard" are ready to help both individuals and companies choose plumbing equipment. All you need to do is call:

-

in Novosibirsk: 8 (383) 33-578-33;

-

in Samara: 8 (846) 203-61-05.

Or you can ask a question through the feedback form on our official website.

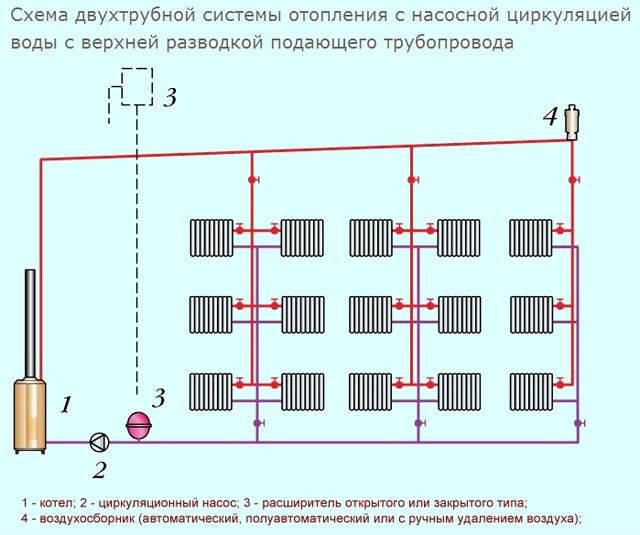

Rules for the selection and installation of pipes

The choice between steel or polypropylene pipes for any circulation occurs according to the criterion of their use for hot water, as well as from the standpoint of price, ease of installation and service life.

The supply riser is mounted from a metal pipe, since water of the highest temperature passes through it, and in the case of stove heating or a malfunction of the heat exchanger, steam can pass through.

With natural circulation, it is necessary to use a slightly larger pipe diameter than in the case of using a circulation pump. Usually, for space heating up to 200 sq. m, the diameter of the acceleration manifold and the pipe at the inlet of the return to the heat exchanger is 2 inches.

This is caused by the slower water velocity compared to the forced circulation option, which leads to the following problems:

- reduction in the volume of heat transferred per unit of time from the source to the heated room;

- the appearance of blockages or air jams that a small pressure cannot cope with.

Particular attention when using natural circulation with a bottom supply scheme must be given to the problem of removing air from the system.It cannot be completely removed from the coolant through the expansion tank, because

boiling water first enters the devices through a line located lower than themselves.

With forced circulation, the water pressure drives the air to the air collector installed at the highest point of the system - a device with automatic, manual or semi-automatic control. With the help of Mayevsky cranes, heat transfer is mainly adjusted.

In gravitational heating networks with a supply located below the appliances, Mayevsky taps are used directly to bleed air.

All modern type heating radiators have air outlet devices, therefore, to prevent the formation of plugs in the circuit, you can make a slope, driving air to the radiator

Air can also be removed using air vents installed on each riser or on an overhead line that runs parallel to the mains of the system. Due to the impressive number of air exhaust devices, gravity circuits with lower wiring are used extremely rarely.

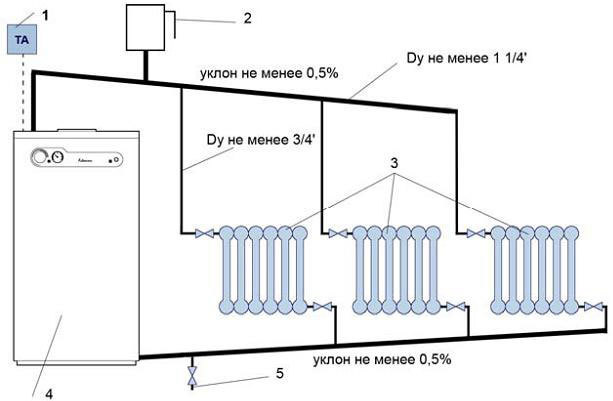

With a low pressure, a small air lock can completely stop the heating system. So, according to SNiP 41-01-2003, it is not allowed to lay pipelines of heating systems without a slope at a water velocity of less than 0.25 m / s.

With natural circulation, such speeds are unattainable. Therefore, in addition to increasing the diameter of the pipes, it is necessary to observe constant slopes to remove air from the heating system. The slope is designed at the rate of 2-3 mm per 1 meter, in apartment networks the slope reaches 5 mm per linear meter of a horizontal line.

The supply slope is made in the direction of the water flow so that the air moves to the expansion tank or air bleed system located at the top of the circuit. Although it is possible to make a counter-slope, in this case it is necessary to additionally install an air vent valve.

The slope of the return line is made, as a rule, in the direction of the chilled water. Then the lower point of the contour will coincide with the inlet of the return pipe to the heat generator.

The most common combination of flow and return slope direction to remove air pockets from a natural circulation water circuit

When installing a warm floor in a small area in a circuit with natural circulation, it is necessary to prevent air from entering the narrow and horizontal pipes of this heating system. An air extractor must be placed in front of the underfloor heating.

Rules and nuances of installation

It is advisable to entrust the installation of the pump to the master. In the technical documentation, the manufacturer indicates the installation rules, so you can try to do the work yourself. The main thing is to follow the rules for handling the device.

In order to avoid air pockets that can lead to equipment failure, it is important to choose the correct location of the rotor relative to the horizon. On the body of the device there is a hint in the form of an arrow indicating in which direction the fluid in the system should move

The site must be selected in a place convenient for the operation of the unit.

Mounting diagram

There are several schemes for connecting the pump to the boiler. The desired option is selected based on the type of system and type of heating equipment. In all schemes, the device is mounted so that it is comfortable to service.

Possible ways:

- The unit is installed on the return line directly in front of the heat generator.

- The pump is mounted at the beginning of the circuit after the safety group.

- A device with a shut-off valve is placed on the bypass.

- Used when connecting the pump to a solid fuel boiler. It is better to fix the device on the line that goes from the heating system to the heat generator.

Installation of a circulation device on the return line.

How to connect to the power supply

The device operates from a 220 V network. Three wires are required for connection: phase, zero and ground.

It can be connected to the power supply in two ways:

- Directly by cable or via terminal block. It is necessary to conduct a separate electrical line with a circuit breaker, and use this cable to connect the device. The terminals are usually located under a plastic cover. It must be removed by unscrewing a few bolts, find three connectors. They are signed: pictograms N - neutral wire, L - phase, and "earth" has an international designation.

- Through a three-prong socket and plug. You need to make new wiring. Install an external or internal socket. To connect the unit to the mains, you will need a power cable with a plug equipped with grounding.

When to install additional equipment

The operation of the entire heating system depends on the performance of the pump. To prevent a sudden shutdown of the unit, it is worthwhile to additionally provide backup power. To do this, you can install a stabilizer with connected batteries. The main thing is to choose and calculate the capacity of the devices correctly and make sure that they are not discharged.

You can reduce energy costs and increase the life of the device by installing a thermostat that measures the temperature of the liquid. The pump will start if the indicator reaches the required level.

Electric heater installation

Installation of such a device is not particularly difficult. It is quite possible to do it with your own hands.

If we are dealing with a wall-mounted device, then to install it, it will be necessary to drill holes in the wall for dowels.

Drilling holes in the wall

The floor boiler is usually placed on stands. After that, it must be connected to the heating system using couplings and adapters.

Electric boiler connection diagram

Having finished this work, it is necessary to draw water into the system and turn on the device. If the pipes began to heat up, then everything was done correctly. You can watch a more detailed description of the installation process in the video that is on our website.

We hope that the above arguments have convinced you that electric heating can be a very appropriate and convenient option for heating a summer house. And you can verify this on your own experience by installing an electric boiler.