- For a one-story house

- Closed systems diagrams

- Rules for the selection and installation of pipes

- Pipe selection

- How to choose a heating pump

- Two-pipe scheme of heating systems

- Two-pipe classic wiring

- Passing scheme or "Tichelman loop"

- Fan (beam)

- What is the heating system made of?

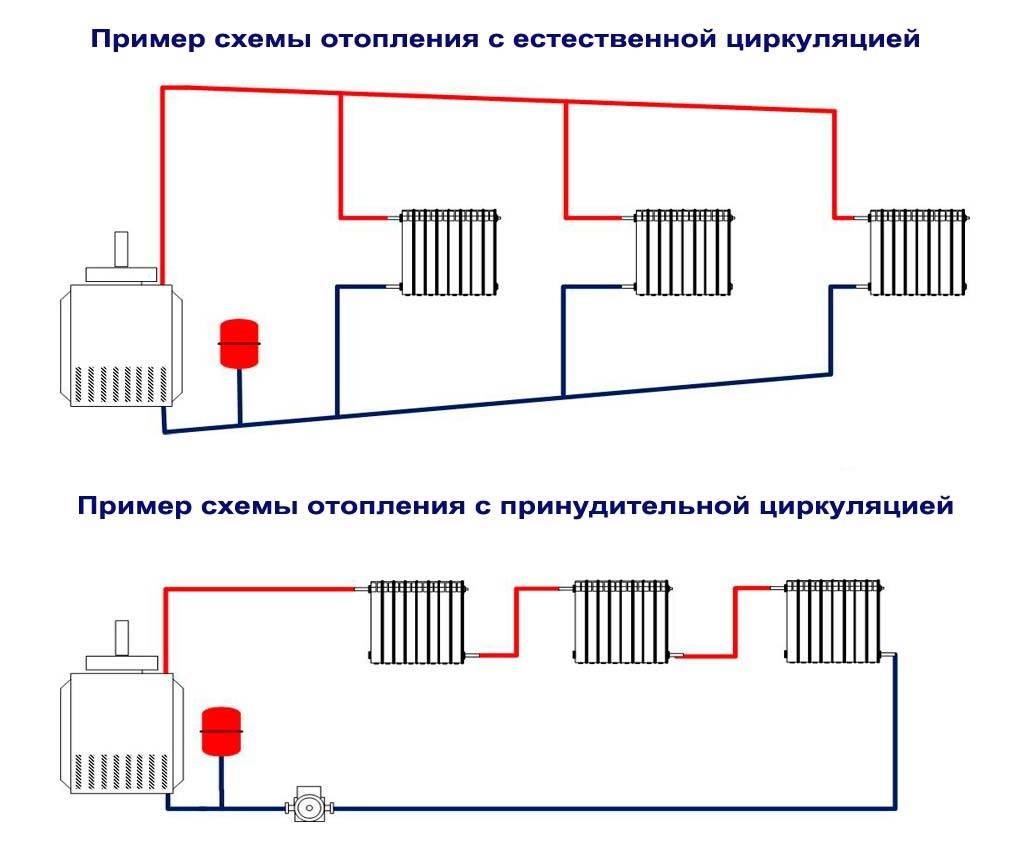

- Natural circulation system

- System with forced circulation of the coolant

- Heating system installation

- Types of boilers and other water heaters

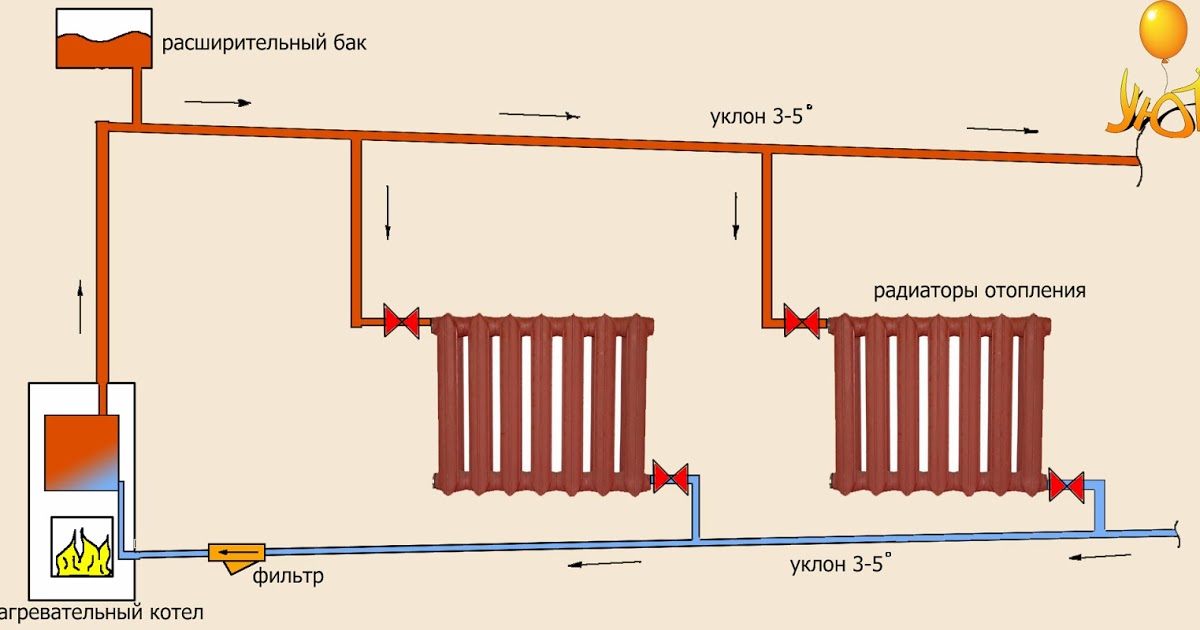

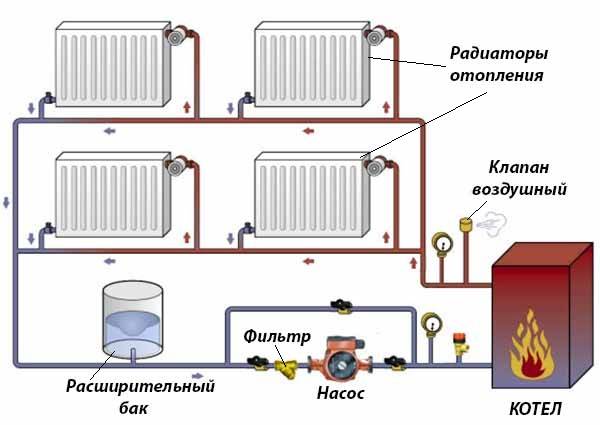

For a one-story house

The simplest single-pipe heating scheme, which has been used by developers for more than half a century, is Leningradka.

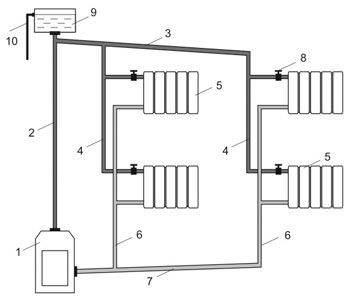

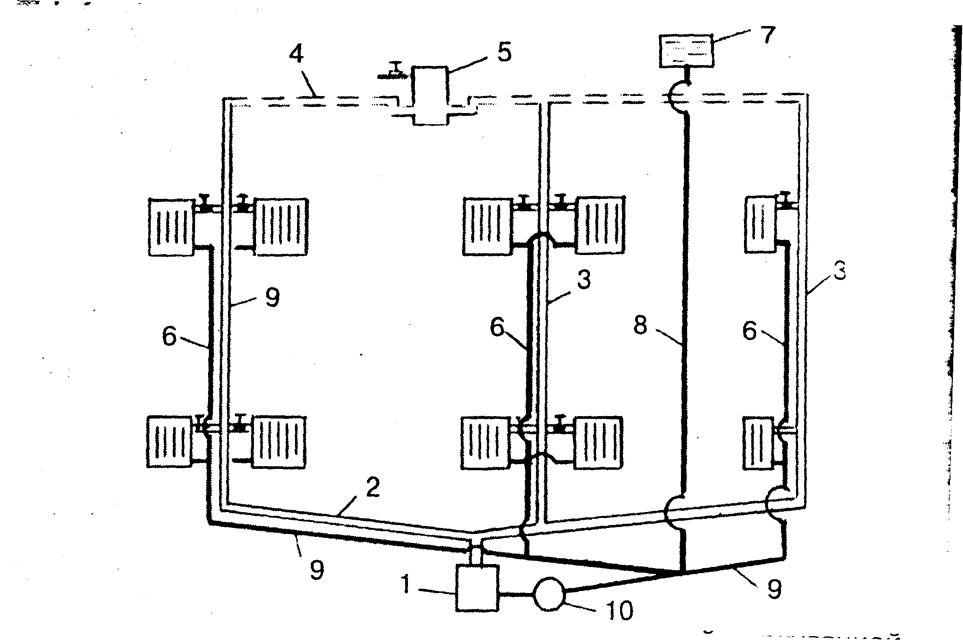

The figure shows a sketch of a modernized version of Leningradka, with a diagonal connection of radiators. The figure shows the following elements (from left to right):

- Heating installation. Boilers operating on solid fuel, gas (natural or liquefied) and electricity are suitable for the implementation of this CO. Theoretically, liquid fuel boilers are also suitable, but the problem of storing fuel in a private house arises.

- Safety group, which consists of a blast valve set to a certain pressure in the system, an automatic air vent and a pressure gauge.

- Radiators connected to the system through shut-off ball valves.Needle balancing valves are installed in the jumper between the inlet and outlet of each radiator.

- A membrane expansion tank is installed on the return branch of the pipeline to compensate for the thermal expansion of the coolant.

- A circulation pump that creates a forced movement of the coolant through CO.

Now about what is not yet indicated on this sketch, but is an indispensable element for the reliable operation of this circuit. Only the pump was mentioned above, but its piping was not indicated, which includes three ball shut-off valves, between which a coarse filter and a pump are installed. Quite often, a pumping group with a piping is connected to the CO through a jumper, thereby forming a bypass.

Often, developers ask if they need bypass in a single-pipe heating system? The thing is that this CO scheme is self-sufficient and efficient. But in the event of a power outage, the circulation pump will stop and the movement of the coolant will stop. A bypass is optional, but it is better to build it to switch from forced to natural circulation of the coolant in the event of an emergency.

As for the pipeline: since the temperature at the outlet of the boiler can reach 80 ° C, it is recommended to use reinforced polypropylene pipes of the required diameter for the Leningradka circuit. Why reinforced? The thing is that polymer pipes are quite cheap and practical, they are easy to install and they have a small mass. But, polymer pipes change their length when heated. Reinforced polymer does not suffer from such a “disease”.

Tip: despite the fact that this version of the CO provides an automatic air vent, there are cases of airing the circuit. To solve this problem, it is recommended to use Mayevsky taps on radiators.

Closed systems diagrams

The following types of wiring are used for heating country and country houses:

- Single pipe. All radiators are connected to a single line running around the perimeter of the room or building. Since the hot and cooled coolant move along the same pipe, each subsequent battery receives less heat than the previous one.

- Two-pipe. Here, heated water enters the heating devices through one line, and leaves through the second. The most common and reliable option for any residential buildings.

- Associated (Tikhelman's loop). Same as two-pipe, only chilled water flows in the same direction as hot water, and does not return in the opposite direction (shown in the diagram below).

- Collector or beam. Each battery receives coolant through a separate pipeline connected to a common comb.

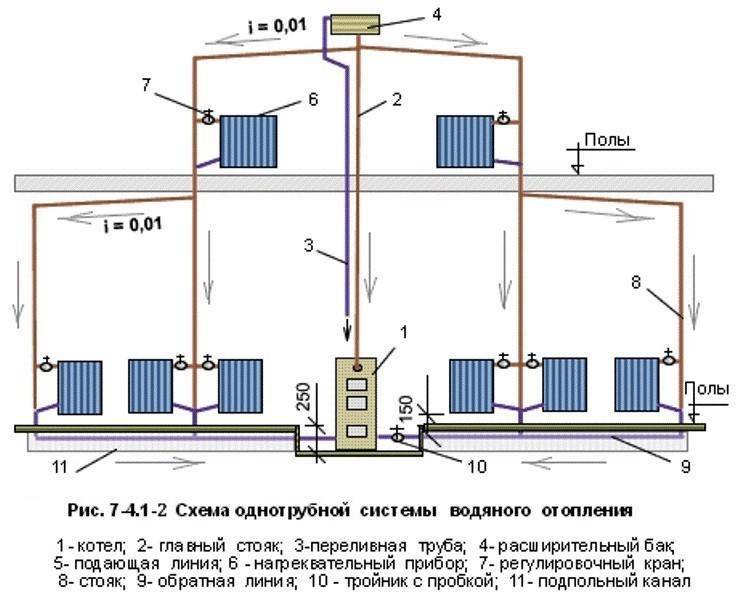

Single-pipe horizontal wiring (Leningradka)

A single-pipe horizontal scheme justifies itself in one-story houses of a small area (up to 100 m²), where 4-5 radiators provide heating. You should not connect more to one branch, the last batteries will be too cold. The option with vertical risers is suitable for a building of 2-3 floors, but in the process of implementation, almost every room will have to be covered with pipes.

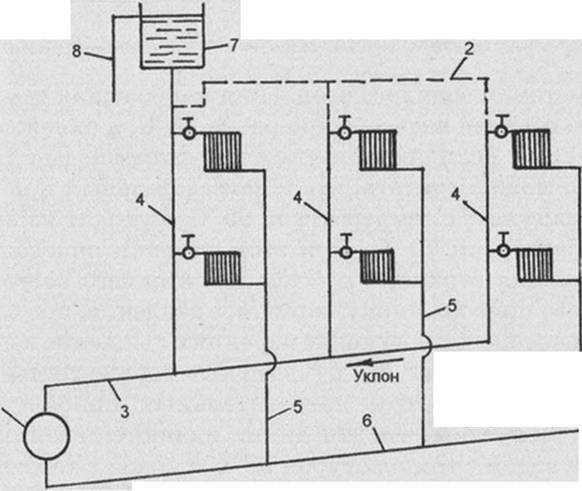

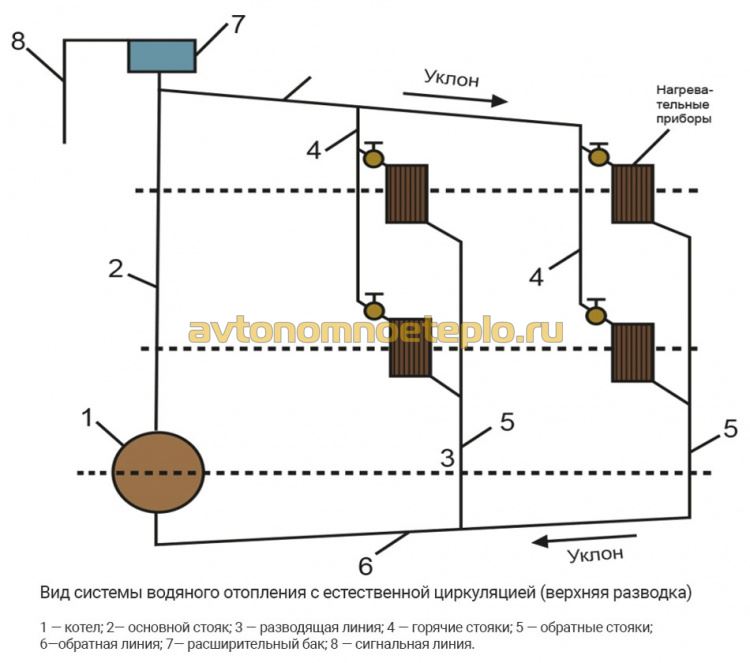

Single-pipe scheme with top wiring and vertical risers

The two-pipe circuit with dead-end branches (shown at the beginning of the article) is quite simple, reliable and definitely recommended for use.If you are the owner of a cottage with an area of up to 200 m² with a height of 2 floors, then make the wiring of the mains with pipes with a flow section of DN 15 and 20 (outer diameter - 20 and 25 mm), and for connecting radiators, take DN 10 (outside - 16 mm).

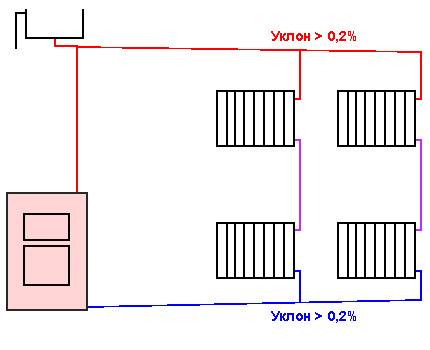

Passing scheme of water movement (Tichelmann's loop)

The Tichelman loop is the most hydraulically balanced, but more difficult to install. Pipelines will have to be laid around the perimeter of the rooms or the whole house and pass under the doors. In fact, a “ride” will cost more than a two-pipe one, and the result will be approximately the same.

The beam system is also simple and reliable, in addition, all wiring is successfully hidden in the floor. The connection of the nearest batteries to the comb is carried out with 16 mm pipes, the distant ones - 20 mm. The diameter of the line from the boiler is 25 mm (DN 20). The disadvantage of this option - the price of the collector unit and the complexity of installation with the laying of highways, when the flooring has already been done.

Scheme with individual connection of batteries to the collector

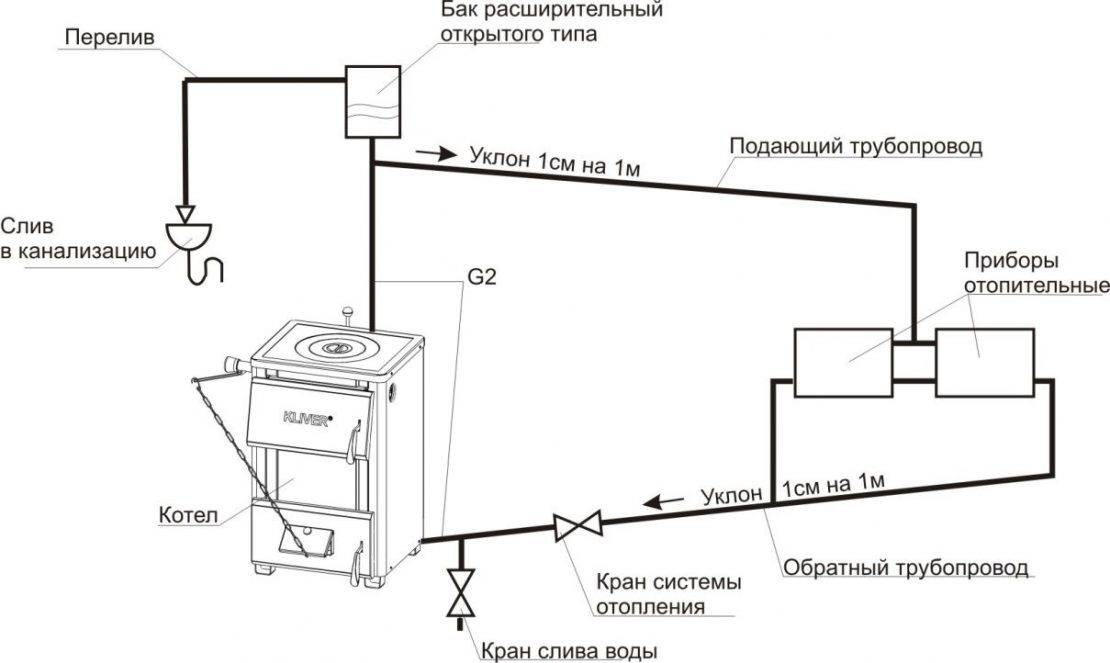

Rules for the selection and installation of pipes

The choice between steel or polypropylene pipes for any circulation occurs according to the criterion of their use for hot water, as well as from the standpoint of price, ease of installation and service life.

The supply riser is mounted from a metal pipe, since water of the highest temperature passes through it, and in the case of stove heating or a malfunction of the heat exchanger, steam can pass through.

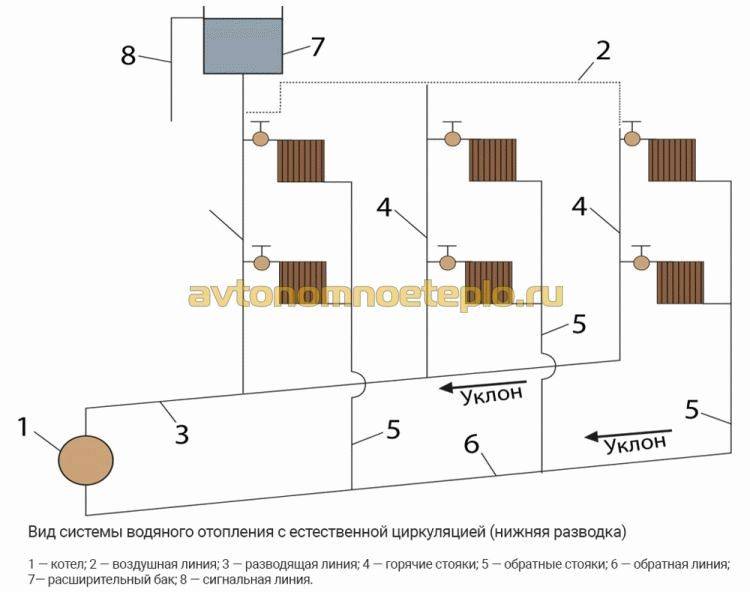

With natural circulation, it is necessary to use a slightly larger pipe diameter than in the case of using a circulation pump. Usually, for space heating up to 200 sq.m, the diameter of the acceleration manifold and the pipe at the inlet of the return to the heat exchanger is 2 inches.

This is due to the slower water velocity compared to forced circulation option, which leads to the following problems:

- reduction in the volume of heat transferred per unit of time from the source to the heated room;

- the appearance of blockages or air jams that a small pressure cannot cope with.

Particular attention when using natural circulation with a bottom supply scheme must be given to the problem of removing air from the system. It cannot be completely removed from the coolant through the expansion tank, because

boiling water first enters the devices through a line located lower than themselves.

With forced circulation, the water pressure drives the air to the air collector installed at the highest point of the system - a device with automatic, manual or semi-automatic control. With the help of Mayevsky cranes, heat transfer is mainly adjusted.

In gravitational heating networks with a supply located below the appliances, Mayevsky taps are used directly to bleed air.

All modern type heating radiators have air outlet devices, therefore, to prevent the formation of plugs in the circuit, you can make a slope, driving air to the radiator

Air can also be removed using air vents installed on each riser or on an overhead line that runs parallel to the mains of the system. Due to the impressive number of air exhaust devices, gravity circuits with lower wiring are used extremely rarely.

With a low pressure, a small air lock can completely stop the heating system. So, according to SNiP 41-01-2003, it is not allowed to lay pipelines of heating systems without a slope at a water velocity of less than 0.25 m / s.

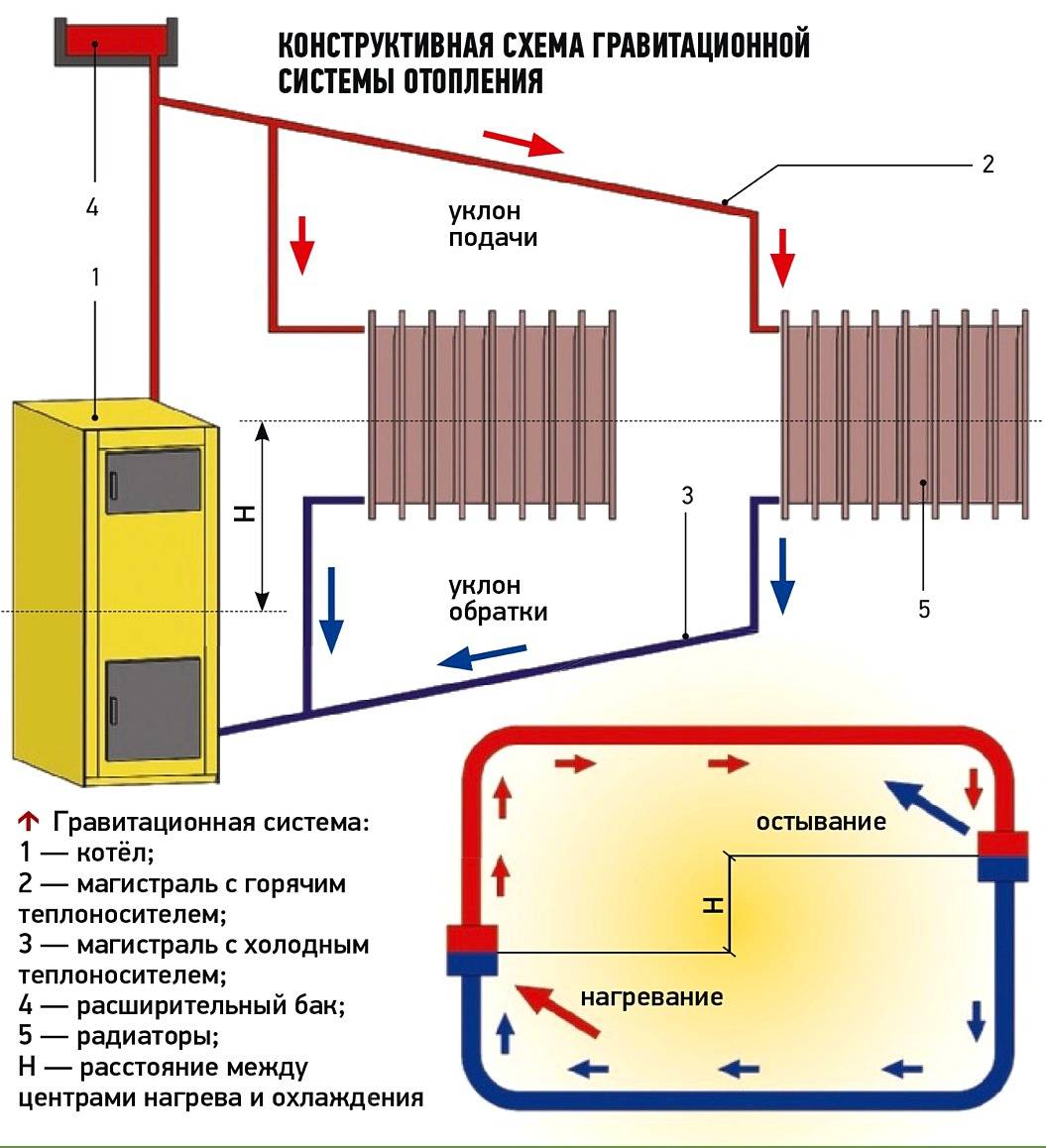

With natural circulation, such speeds are unattainable. Therefore, in addition to increasing the diameter of the pipes, it is necessary to observe constant slopes to remove air from the heating system. The slope is designed at the rate of 2-3 mm per 1 meter, in apartment networks the slope reaches 5 mm per linear meter of a horizontal line.

The supply slope is made in the direction of the water flow so that the air moves to the expansion tank or air bleed system located at the top of the circuit. Although it is possible to make a counter-slope, in this case it is necessary to additionally install an air vent valve.

The slope of the return line is made, as a rule, in the direction of the chilled water. Then the lower point of the contour will coincide with the inlet of the return pipe to the heat generator.

The most common combination of flow and return slope direction for removal air pockets from water circuit with natural circulation

When installing a warm floor in a small area in a circuit with natural circulation, it is necessary to prevent air from entering the narrow and horizontal pipes of this heating system. An air extractor must be placed in front of the underfloor heating.

Pipe selection

Also, the choice of material is greatly influenced by the boiler, since in the case of solid fuel, preference should be given to steel, galvanized pipes or stainless steel products, due to the high temperature of the working fluid.

However, metal-plastic and reinforced pipes require the use of fittings, which significantly narrows the clearance, reinforced polypropylene pipes will be an ideal option, at an operating temperature of 70C, and a peak temperature of 95C.

Products made of special PPS plastic have an operating temperature of 95C, and a peak temperature of up to 110C, which allows them to be used in an open system.

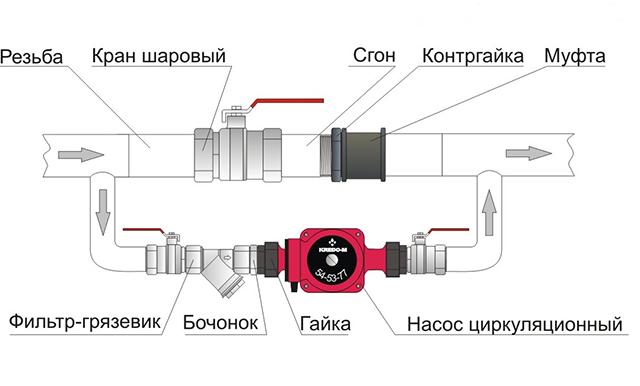

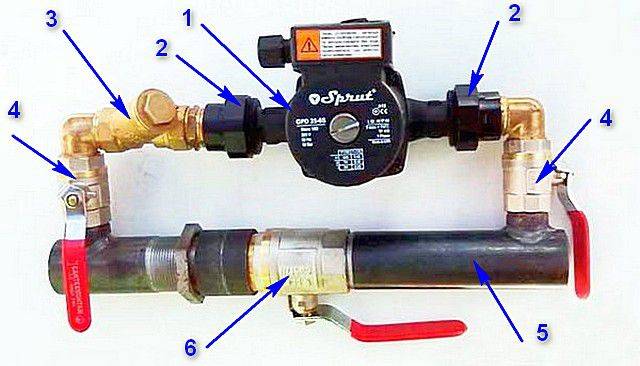

How to choose a heating pump

Best suited for installation are special low-noise centrifugal-type circulation pumps with straight blades. They do not create excessively high pressure, but push the coolant, accelerating its movement (the working pressure of an individual heating system with forced circulation is 1-1.5 atm, the maximum is 2 atm). Some models of pumps have a built-in electric drive. Such devices can be installed directly into the pipe, they are also called "wet", and there are devices of the "dry" type. They differ only in the rules of installation.

At installation of any type of circulation pump an installation with a bypass and two ball valves is desirable, which allows the pump to be removed for repair/replacement without shutting down the system.

It is better to connect the pump with a bypass - so that it can be repaired / replaced without destroying the system

The installation of a circulation pump allows you to adjust the speed of the coolant moving through the pipes. The more actively the coolant moves, the more heat it carries, which means that the room heats up faster. After the set temperature is reached (either the degree of heating of the coolant or the air in the room is monitored, depending on the capabilities of the boiler and / or settings), the task changes - it is required to maintain the set temperature and the flow rate decreases.

For a forced circulation heating system, it is not enough to determine the type of pump

It is important to calculate its performance. To do this, first of all, you need to know the heat loss of the premises / buildings that will be heated

They are determined based on losses in the coldest week. In Russia, they are normalized and installed by public utilities. They recommend using the following values:

- for one- and two-story houses, losses at the lowest seasonal temperature of -25 ° C are 173 W / m 2. at -30 ° C, losses are 177 W / m 2;

- multi-storey buildings lose from 97 W / m 2 to 101 W / m 2.

Based on certain heat losses (denoted by Q), you can find the pump power using the formula:

c is the specific heat capacity of the coolant (1.16 for water or another value from the accompanying documents for antifreeze);

Dt is the temperature difference between supply and return. This parameter depends on the type of system and is: 20 o C for conventional systems, 10 o C for low-temperature systems and 5 o C for underfloor heating systems.

The resulting value must be converted into performance, for which it must be divided by the density of the coolant at operating temperature.

In principle, when choosing the pump power for forced circulation of heating, it is possible to be guided by averaged norms:

- with systems that heat an area up to 250 m 2. use units with a capacity of 3.5 m 3 / h and a head pressure of 0.4 atm;

- for an area from 250m 2 to 350m 2, a power of 4-4.5m 3 / h and a pressure of 0.6 atm are required;

- pumps with a capacity of 11 m 3 / h and a pressure of 0.8 atm are installed in heating systems for an area from 350 m2 to 800 m2.

But you need to take into account that the worse the house is insulated, the greater the power of the equipment (boiler and pump) may be required and vice versa - in a well-insulated house, half of the indicated values \u200b\u200bmay be required. These data are average. The same can be said about the pressure created by the pump: the narrower the pipes and the rougher their inner surface (the higher the hydraulic resistance of the system), the higher the pressure should be. Full calculation is a complex and dreary process, which takes into account many parameters:

The power of the boiler depends on the area of the heated room and heat loss.

- resistance of pipes and fittings (read how to choose the diameter of heating pipes here);

- pipeline length and coolant density;

- number, area and type of windows and doors;

- the material from which the walls are made, their insulation;

- wall thickness and insulation;

- the presence / absence of a basement, basement, attic, as well as the degree of their insulation;

- type of roof, composition of the roofing cake, etc.

In general, heat engineering calculation is one of the most difficult in the region. So if you want to know exactly what power you need a pump in the system, order a calculation from a specialist. If not, choose based on average data, adjusting them in one direction or another, depending on your situation. It is only necessary to take into account that at an insufficiently high speed of movement of the coolant, the system is very noisy. Therefore, in this case, it is better to take a more powerful device - the power consumption is small, and the system will be more efficient.

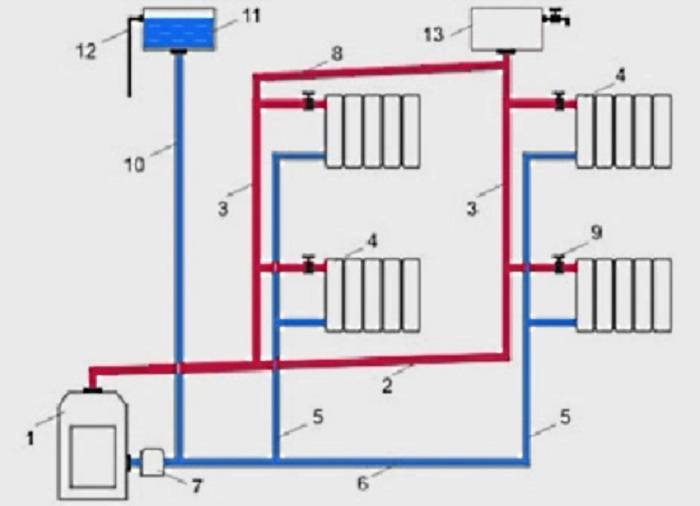

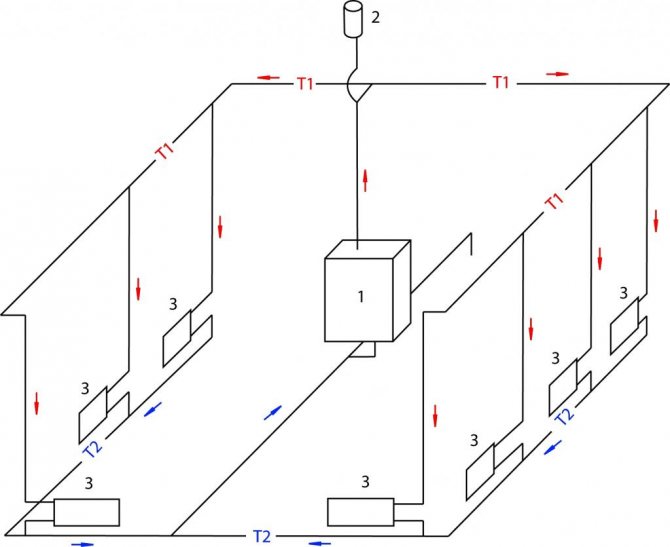

Two-pipe scheme of heating systems

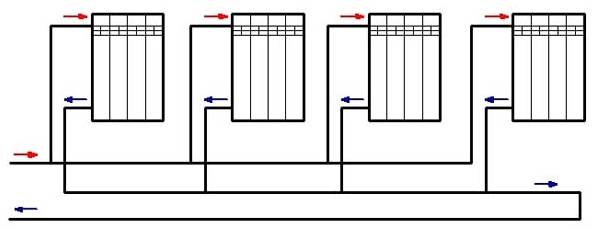

In two-pipe schemes, the hot coolant is supplied to the radiator and the cooled coolant is removed from the radiator through two different pipelines of the heating systems.

There are several options for two-pipe schemes: classic or standard, passing, fan or beam.

Two-pipe classic wiring

The classic two-pipe wiring diagram of the heating system.

In the classical scheme, the direction of movement of the coolant in the supply pipeline is opposite to the movement in the return pipeline. This scheme is most common in modern heating systems, both in multi-storey buildings and in private individual buildings. The two-pipe scheme allows you to evenly distribute the coolant between the radiators without temperature loss and effectively regulate heat transfer in each room, including automatically by using thermostatic valves with installed thermal heads.

Such a device has a two-pipe heating system in a multi-storey building.

Passing scheme or "Tichelman loop"

Associated heating wiring diagram.

The associated scheme is a variation of the classical scheme with the difference that the direction of movement of the coolant in the supply and return is the same. This scheme is used in heating systems with long and remote branches. The use of a passing scheme allows you to reduce the hydraulic resistance of the branch and evenly distribute the coolant over all radiators.

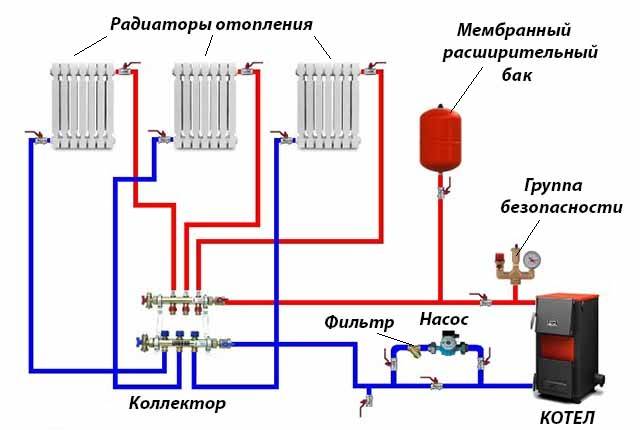

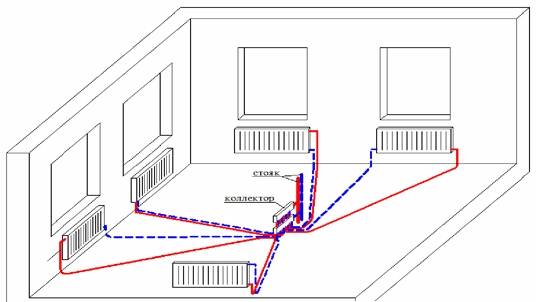

Fan (beam)

The fan or beam scheme is used in multi-storey construction for apartment heating with the possibility of installation in each apartment heat meter (heat meter) and in private housing construction in systems with floor-by-floor piping.With a fan-shaped scheme in a multi-storey building, a collector is installed on each floor with exits to all apartments of a separate pipeline and an installed heat meter. This allows each apartment owner to take into account and pay only for the consumed heat.

fan or radiant heating system.

In a private house, a fan pattern is used for the floor distribution of pipelines and for the beam connection of each radiator to a common collector, that is, a separate supply and return pipe from the collector is connected to each radiator. This method of connection allows you to distribute the coolant as evenly as possible over the radiators and reduce the hydraulic losses of all elements of the heating system.

What is the heating system made of?

From the name itself - a water heating system, it becomes clear that water is needed for its operation. In this case, it is a coolant that constantly circulates in a closed circuit. Water is heated in a special boiler, and then - through pipes, it is delivered to the main heating element, which can be a "warm floor" system or radiators.

Of course, for better, safer and more economical operation of the system, you can use a large number of auxiliary equipment. However, the simplest water heating system looks like this:

The main elements of the heating system

The main elements of the heating system

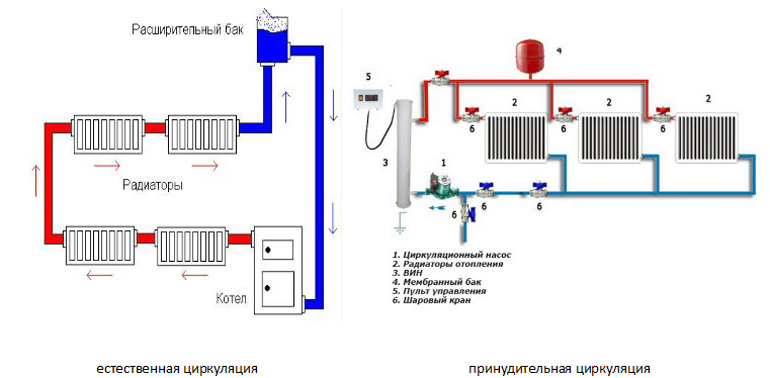

Heating systems can differ according to the principle of coolant circulation:

- water heating with forced circulation;

- with natural.

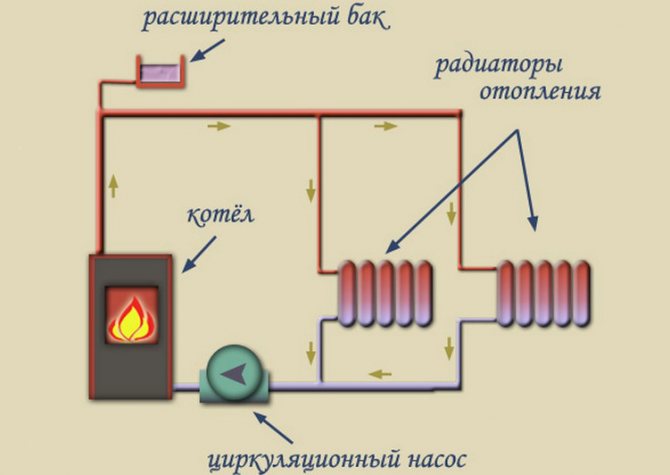

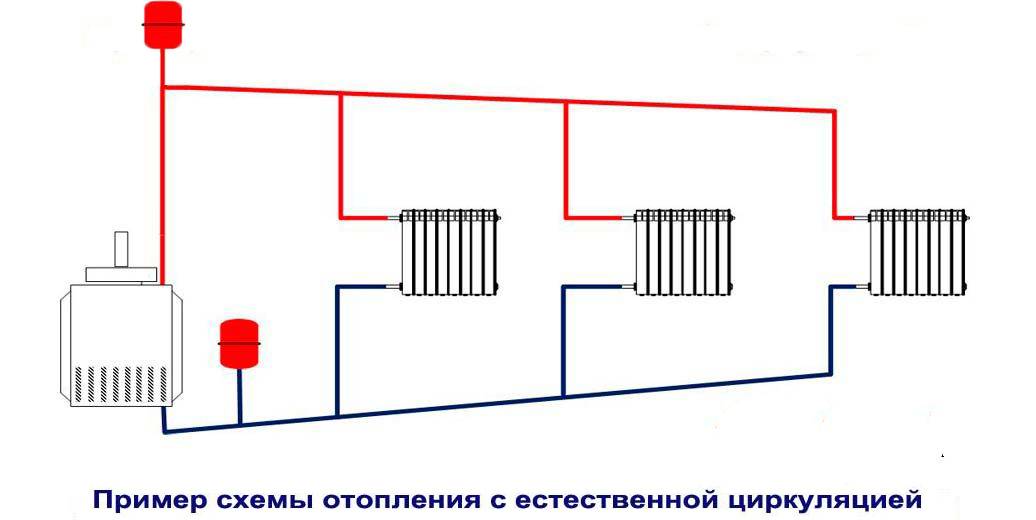

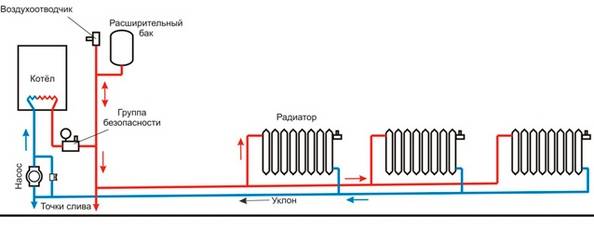

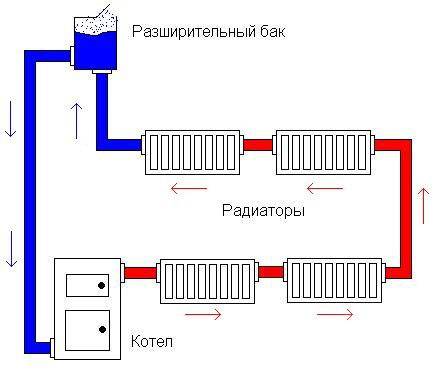

Natural circulation system

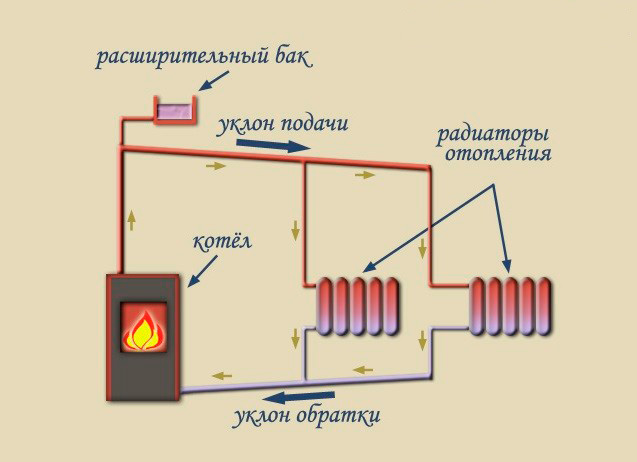

A system with natural circulation is a perfect example of man's use of the elementary laws of physics. The principle of its operation is actually simple - the movement of the coolant in the pipes occurs due to the difference in the density of cold and hot water.

Heating system with natural circulation

Heating system with natural circulation

That is, the coolant heated in the boiler becomes lighter, its density decreases. Hot water is displaced from the boiler by the cold coolant entering it and easily rushes up the central riser pipe. And from it - to the radiators. There, the coolant gives off its heat, cools down, and, having regained its former heaviness and density, returns back through the return pipes to the heating boiler - displacing a new portion of the hot coolant from it. And this cycle repeats itself endlessly.

In order to independently create a water heating system with natural circulation of the coolant, it is important to remember a few simple rules. First of all, you should select pipes of the most suitable diameter for creating a central riser, and, in addition, observe the required slope angle when laying pipes. However, the natural circulation system also has several significant drawbacks.

First of all, the need to use heavy metal pipes (difficulties arise during installation). In addition, such a system excludes the possibility of regulating the level of heating of each individual room. Another disadvantage of the system can be called high fuel consumption.

However, the natural circulation system also has several significant drawbacks. First of all, the need to use heavy metal pipes (difficulties arise during installation).In addition, such a system excludes the possibility of regulating the level of heating of each individual room. Another disadvantage of the system can be called a high fuel consumption.

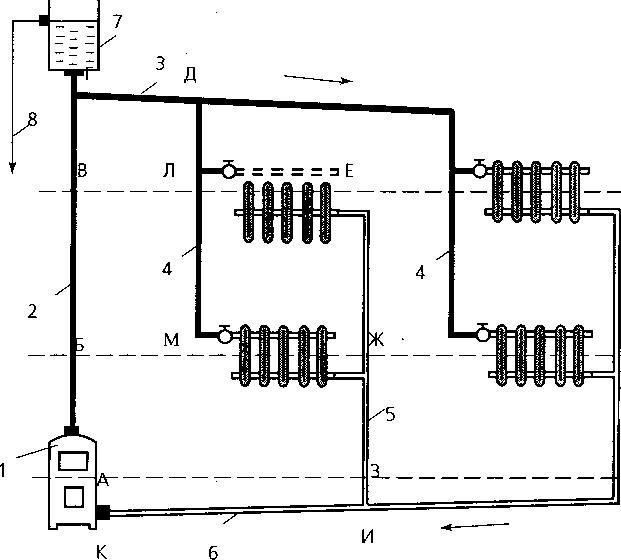

System with forced circulation of the coolant

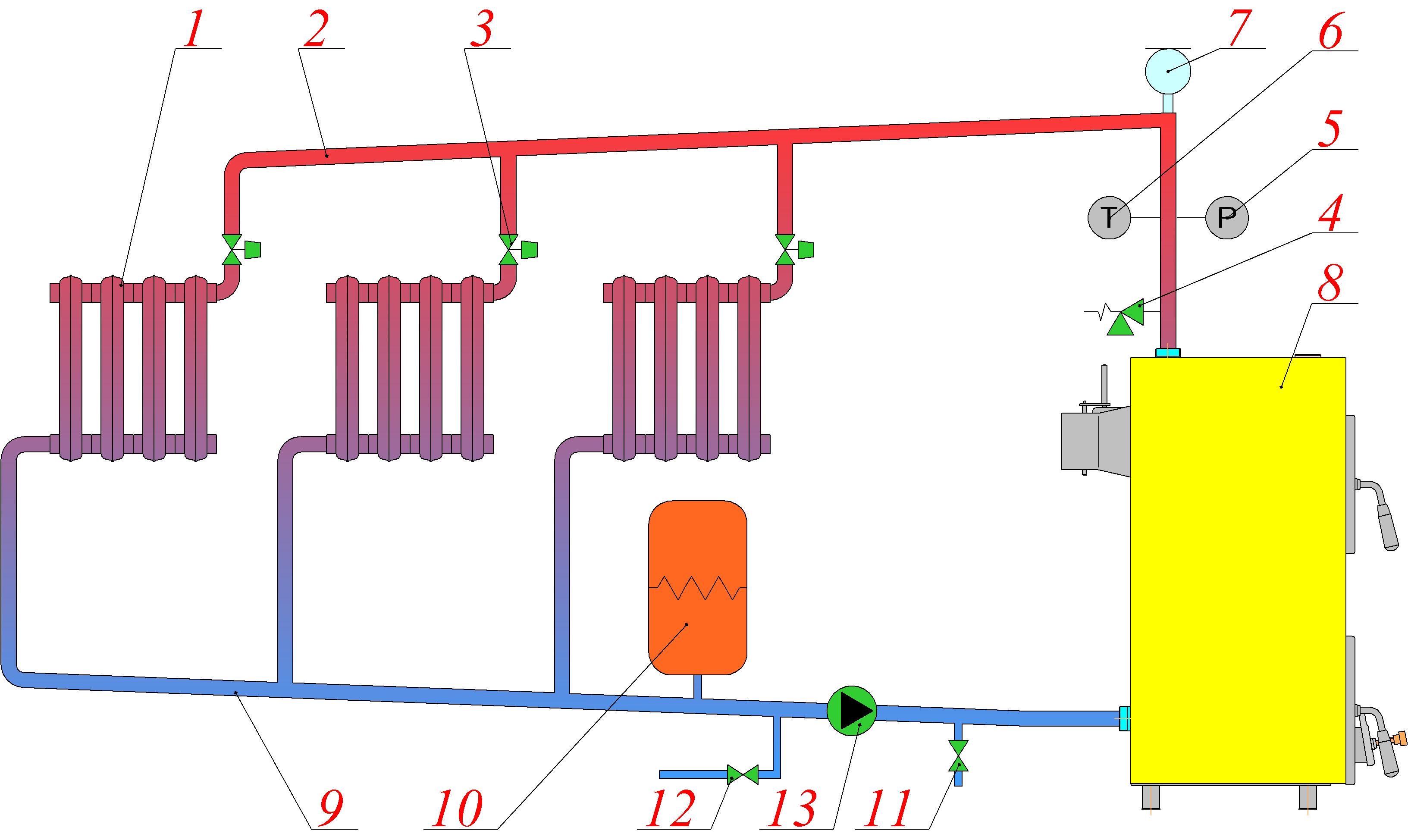

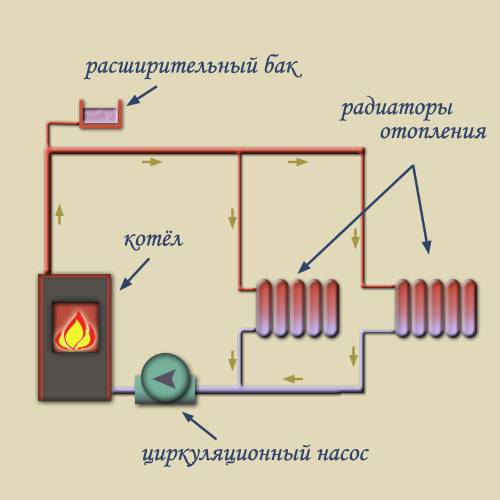

Heating system with forced circulation of the coolant

Heating system with forced circulation of the coolant

A distinctive feature of this type of system is the mandatory addition of a circulation pump. It is he who contributes to the movement of the coolant through the pipes. The system diagram looks like this:

One of the main advantages of a forced circulation system is that such water heating from electricity makes it possible to control the level of pressure in each radiator through special valves - thus, the level of heating of the room is also controlled. This fact allows, to some extent, to reduce the amount of fuel used for heating the coolant.

The disadvantage of the system is its energy dependence. In the event that power surges or power outages are possible in your home, the most reasonable solution would be to use a combined system that combines forced and natural circulation of the coolant.

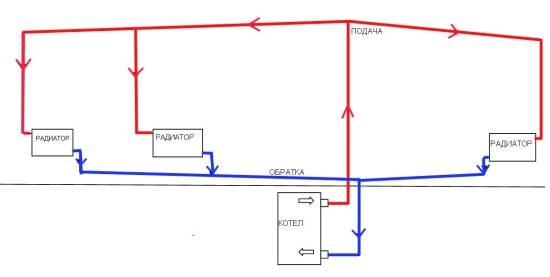

Heating system installation

The most practical is the creation of a two-pipe heating system in the house. It consists of two combined circuits, along one of which (supply pipes) a hot coolant moves to the radiators. And the cooled water from the radiator returns to the boiler through the second circuit - the return pipes.

The movement of the coolant in the heating system

The movement of the coolant in the heating system

A two-pipe forced circulation heating system is an excellent solution for any private home.It allows you to connect special thermostats that allow you to control the degree of heating on each individual radiator. The system can be supplemented with special collectors, which will make it even more efficient.

Types of boilers and other water heaters

The efficiency of heating in a private house depends on the installation that heats the working fluid (water). A properly selected unit generates the amount of heat required for radiators and an indirect heating boiler (if any), saving energy.

Autonomous water system can be powered by:

- a hot water boiler that uses a certain fuel - natural gas, firewood, coal, diesel fuel;

- electric boiler;

- wood-burning stoves with a water circuit (metal or brick);

- heat pump.

Most often, boilers are used to organize heating in cottages - gas, electric and solid fuel. The latter are made only in the floor version, the rest of the heat generators - wall and stationary. Diesel units are used less often, the reason is the high price of fuel. How to choose the right domestic hot water boiler is discussed in a detailed guide.

Stove heating combined with water registers or modern radiators is a good solution for cottage heating, a garage and a small residential house with an area of 50-100 m². Disadvantage - the heat exchanger placed inside the stove heats the water uncontrollably

To avoid boiling, it is important to ensure forced circulation in the system

Modern gravity system without a pumping unit, powered by brick kiln water circuit

Heat pumps are not widely used in the countries of the former Soviet Union.The reasons:

- the main problem is the high cost of equipment;

- due to the cold climate, air-to-water devices are simply inefficient;

- geothermal systems "land - water" are difficult to install;

- electronic units and compressors of heat pumps are very expensive to repair and maintain.

Due to the high price, the payback period of the units exceeds 15 years. But the efficiency of installations (3-4 kW of heat per 1 kilowatt of electricity consumed) attracts craftsmen who are trying to assemble home-made analogues from old air conditioners.

How to make the simplest version of a heat pump with your own hands, see the video: