- Design features

- Advantages and disadvantages of systems

- Pipes for heating

- What to consider when arranging any system

- Elements of the collector heating circuit

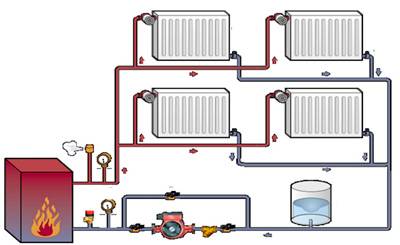

- Scheme with natural circulation

- Scope and disadvantages of gravity

- Design Tips

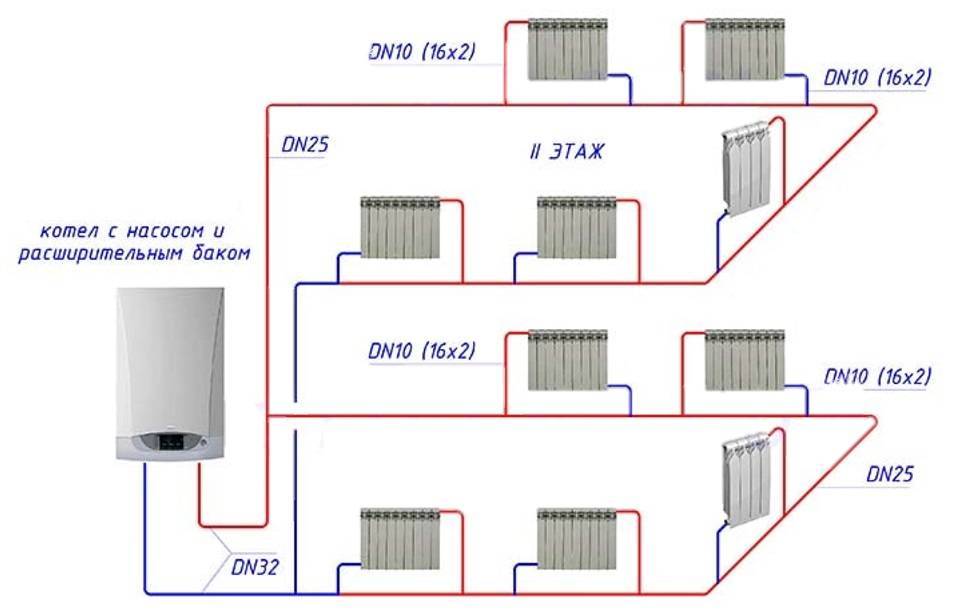

- Two-pipe heating system for a two-story building

- Main differences

- Heating wiring diagrams

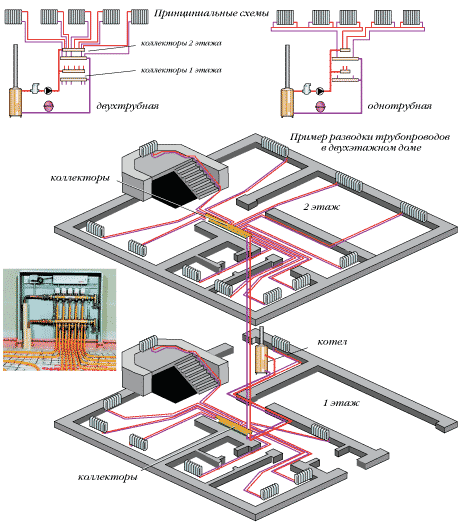

- Collector systems

- Do-it-yourself installation of a two-pipe heating system in a private house

- Calculation

- Installation

- Connection

- Trial run

Design features

In order for the gravity system to work effectively, the following requirements must be met:

- any non-volatile heat generator with outlet pipes with a diameter of 40-50 mm acts as a heat source;

- at the outlet of the boiler or stove with a water circuit, an accelerating riser is immediately mounted - a vertical pipe through which the heated coolant rises;

- the riser ends with an open-type expansion tank installed in the attic or under the ceiling of the upper floor (depending on the type of wiring and design of a private house);

- tank capacity - 10% of the volume of the coolant;

- under gravity, it is desirable to choose heating devices with large dimensions of internal channels - cast iron, aluminum, bimetallic;

- for better heat transfer, heating radiators are connected according to a versatile scheme - lower or diagonal;

- on radiator connections, special full-bore valves with thermal heads (supply) and balancing valves (return) are installed;

- it is better to equip batteries with manual air vents - Mayevsky cranes;

- replenishment of the heating network is organized at the lowest point - near the boiler;

- all horizontal sections of pipes are laid with slopes, the minimum is 2 mm per linear meter, the average is 5 mm / 1 m.

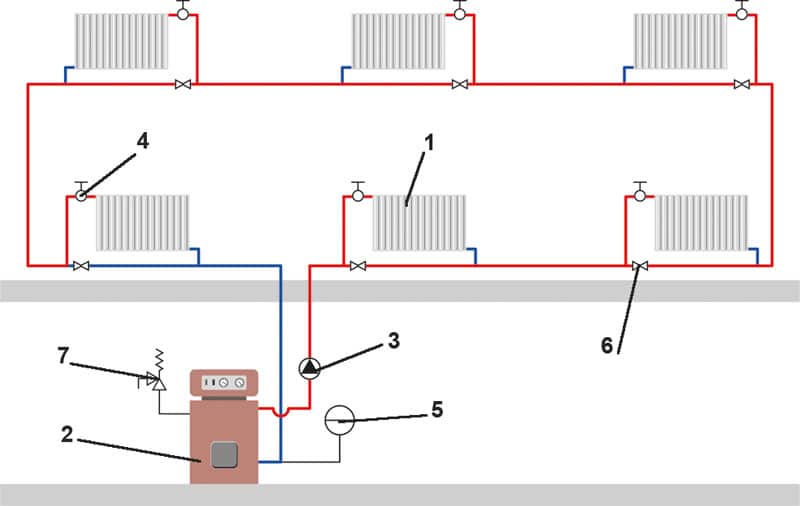

On the left in the photo - the heat carrier supply riser from the floor-standing boiler with a pump on the bypass, on the right - the connection of the return line

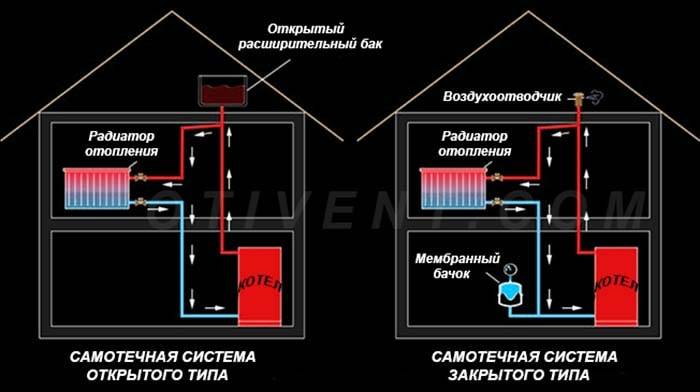

Gravity heating systems are made open, operated at atmospheric pressure. But will gravity flow work in a closed circuit with a membrane tank? We answer: yes, natural circulation will continue, but the speed of the coolant will decrease, the efficiency will drop.

It is not difficult to substantiate the answer, it is enough to mention the change in the physical properties of liquids under excess pressure. With a pressure in the system of 1.5 bar, the boiling point of water will shift to 110 ° C, its density will also increase. The circulation will slow down due to the small difference in the masses of the hot and cooled stream.

Simplified gravity flow diagrams with an open and membrane expansion tank

Advantages and disadvantages of systems

To begin with, it is worth noting that the optimal heating scheme in a two-story house can combine different options. That is, open circuits can be both with natural and forced current of the coolant. The same can be said about the closed circuit.However, in most cases, open systems are used with natural or combined fluid flow, and closed circuits are used with forced fluid movement, because they are easier to adjust.

Among the advantages of open systems with gravitational current are the following:

- The expansion tank allows you to remove air and performs the functions of a safety group.

- There are no complex nodes in such a circuit, so it is easier to operate. The service life depends on the durability of the radiators and pipes.

- The system is completely non-volatile and does not consume electricity.

- Silent operation due to the absence of electromechanical components.

- If necessary, forced circulation of the liquid can be provided.

- The system is self-regulating.

The disadvantages of open circuits with natural current are the need to install an expansion tank at the highest point. Usually this place is located in the attic, so it and the tank have to be insulated. In open-type tanks, antifreeze is not used as a coolant, and water is constantly in contact with oxygen, which contributes to the corrosion of the metal elements of the system. For the same reason, there is an increased gas formation in pipelines.

Additional cons:

- the slope of the return pipeline must be observed;

- pipes of different diameters are used;

- not suitable for underfloor heating and with a considerable distance of radiators from the boiler;

- a significant drawback is the inertia of the system.

Closed circuits with forced circulation have the following advantages:

- If you choose the right pumping equipment, then the scheme is not limited to the number of storeys and dimensions of the building.

- Due to the forced current, the radiators heat up quickly and evenly.The work is easier to set up and fine-tune.

- The coolant does not evaporate and is not saturated with oxygen, so water or antifreeze can be used.

- Due to tightness, gas formation is reduced to zero.

- Smaller pipes can be used.

- The expansion tank can be installed anywhere. If this is done in a heated room, it will not freeze.

- The temperature difference in the supply and return lines is less, which affects the life of the equipment.

- Various heating devices can be used.

Cons of closed circuits with forced current:

- for effective work, you need to perform a calculation;

- you need to mount a security group;

- they are energy dependent systems.

Pipes for heating

And a little about pipes and other devices. Today there is no need to complain about the lack of their diversity. Until recently, only steel analogues were used, which have already lost their relevance due to the high price, difficulty in installation and quick failure due to corrosion. They were replaced by copper and metal-plastic pipes with high performance characteristics. And if copper pipes are still used less often because of their high cost, then plastic is in great demand today.

Mayevsky crane

We also note that for better operation of the heating system, various devices began to be used:

- Mayevsky crane - it is usually installed on radiators and allows you to bleed air from the system.

- Shut-off valves - with its help, you can block the supply of coolant to each radiator. This makes it possible to repair it without shutting down the entire system.

- Control valves - they allow you to reduce or increase the supply of hot water.

- All kinds of sensors that control various processes in the heating system.

All these devices serve only one purpose - the efficient operation of the heating system. Of course, all this costs money, but quality always costs money. True, you will have to invest only once, and then reap the benefits.

What to consider when arranging any system

Scheme of the heating boiler.

It is important not to forget to install regulating thermal valves at the radiator inlet and outlet, as well as a drain valve, which is usually located at the lowest point of the heating structure. The purchase of used or “cheap” pipes and fittings in any heating system in the future can result in very serious problems requiring major repairs not only of the entire heating structure, but also of the house itself due to a possible rupture of hot water pipes and its flooding. The purchase of used or “cheap” pipes and fittings in any heating system in the future can result in very serious problems requiring major repairs not only of the entire heating structure, but also of the house itself due to a possible rupture of hot water pipes and its flooding

The purchase of used or “cheap” pipes and fittings in any heating system in the future can result in very serious problems requiring major repairs not only of the entire heating structure, but also of the house itself due to a possible rupture of hot water pipes and its flooding.

Two-pipe heating distribution is possible for a private house with any number of floors.And its work can take place without the use of a circulation pump. But these systems have a rather low efficiency and nowadays few people use them.

When deciding to place a two-pipe wiring in a house with a collector equipment, you need to carefully consider and plan the placement of the coolant distribution unit, the so-called comb. It will be correct to make the length of the pipes extending from it commensurate, since a significant difference in length from the comb to the radiators can lead to a significant difference in pressure. And this will complicate the adjustment of the system as a whole. The best comb placement solution is one where to each of the radiators from it will be approximately equal distance.

Pipes for arranging heating can be copper, steel, polypropylene and metal-plastic, but in no case should galvanized ones be used. The required type of pipes is selected depending on the construction project and with the preferred characteristics: economic, environmental. But the priority should be hydraulic characteristics.

The flow rate of the pipes needed for laying this system will depend on the chosen heating layout (two-pipe or single-pipe). Private houses with a large area require the equipment of a two-pipe system, into which a circulation pump is additionally cut. Adjustment of temperature conditions in each room is carried out with the help of thermostats.

Elements of the collector heating circuit

Radiant heating of a private house is a structure consisting of several main elements:

- heating boiler. This device is the starting point, since from it the hot coolant is directed to pipelines and radiators. The power of the heat unit must correspond to the heat transfer of the heating equipment. Here there is the following nuance: the ray scheme heating system wiring unlike other options for piping, it has a greater degree of heat loss, which must certainly be taken into account when calculating equipment parameters.

- Circulation pump. According to the peculiarities of its device, the radiant heating distribution is of a closed type and its operation requires forced circulation of a liquid coolant. For this purpose, a special pump is installed that creates a certain pressure and pumps liquid. As a result, the required temperature regime is ensured, which guarantees the efficient operation of the heat supply system.

When choosing a circulation pump for radiant heating, you should pay attention to a number of parameters, including the length of the pipelines and the materials used to manufacture the radiators. In addition, the power of the pump is not one of its most important characteristics; the speed at which the liquid will be pumped should be taken into account. This parameter shows the volume of coolant moved by the circulating device per unit of time

This parameter shows the volume of coolant moved by the circulating device per unit of time

In addition, the power of the pump is not one of its most important characteristics; the speed at which the liquid will be pumped should be taken into account. This parameter shows the volume of coolant moved by the circulating device per unit of time.

Collector (it is also called a comb).It is also an important element of the beam wiring of the heating system. The comb is assigned the function of a switchgear designed for centralized supply of heating radiators with coolant (for more details: “The distribution comb of the heating system - purpose and principle of operation“).

The beam scheme of the heating system always contains a variety of thermostatic or shut-off and control elements. They provide the necessary consumption of the carrier of thermal energy in each branch of the structure. To create additional conditions for more efficient operation of the heating structure without unnecessary costs, the installation of thermometers and air vents operating in automatic mode will help.

Collectors in the domestic market are offered to consumers in a wide range. The choice of a specific device is based on the number of designed heating circuits or connected radiators. Combs are made from various materials - it can be brass or steel, as well as polymer products.

Cabinets. The radiant heating scheme requires that all elements included in it be located in special structures equipped for them. Distribution manifold for heating. shut-off valves, pipelines must be placed in manifold cabinets that have a simple design. They are both built into a wall niche and outdoor, but at the same time they differ in functionality and practicality.

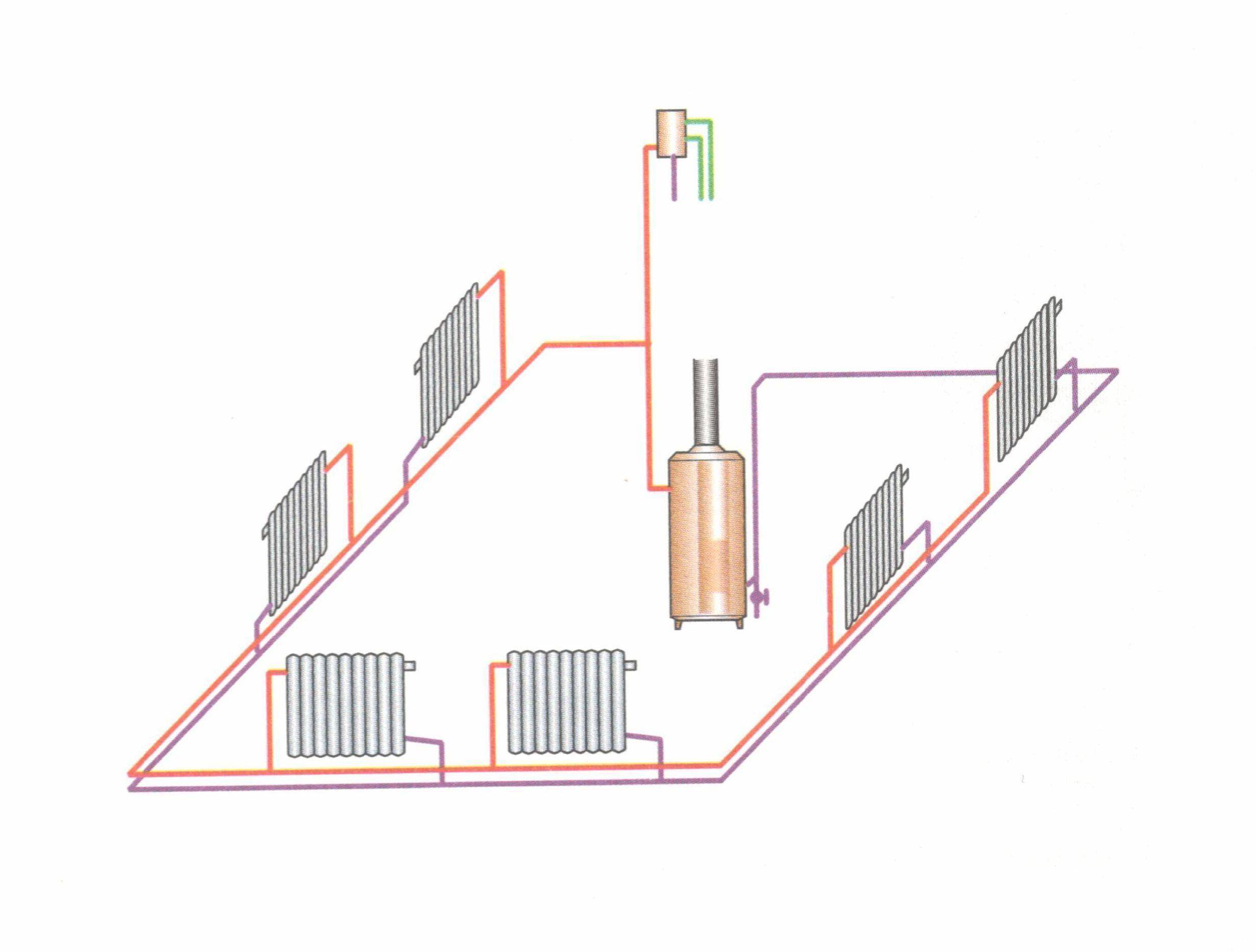

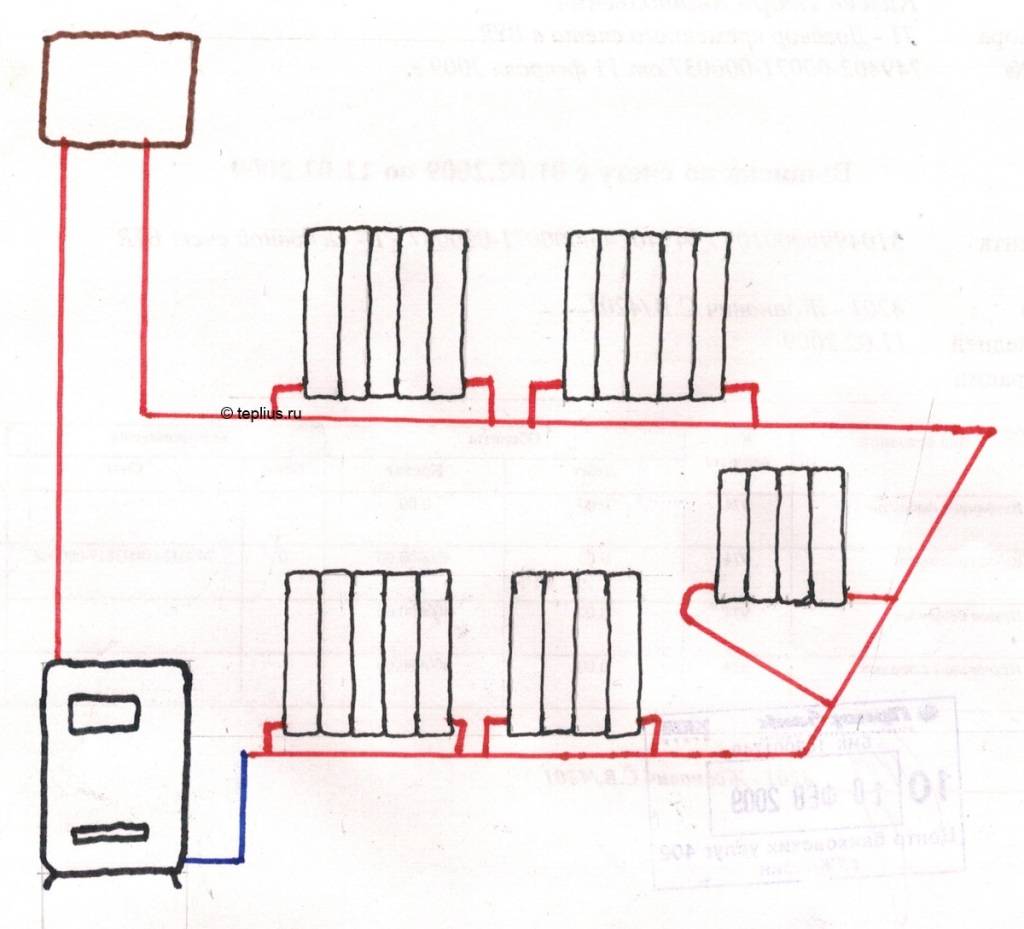

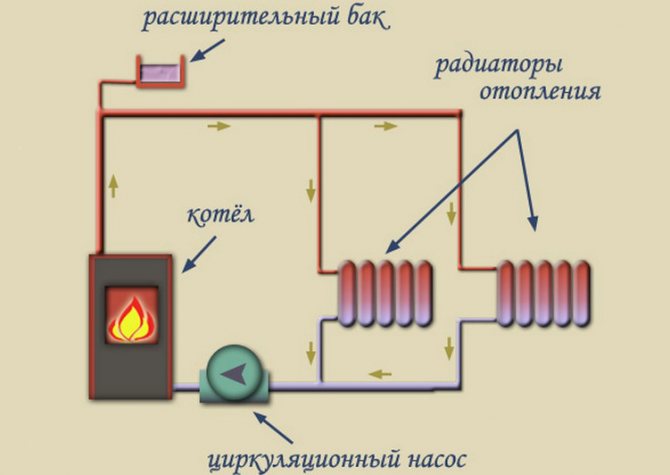

Scheme with natural circulation

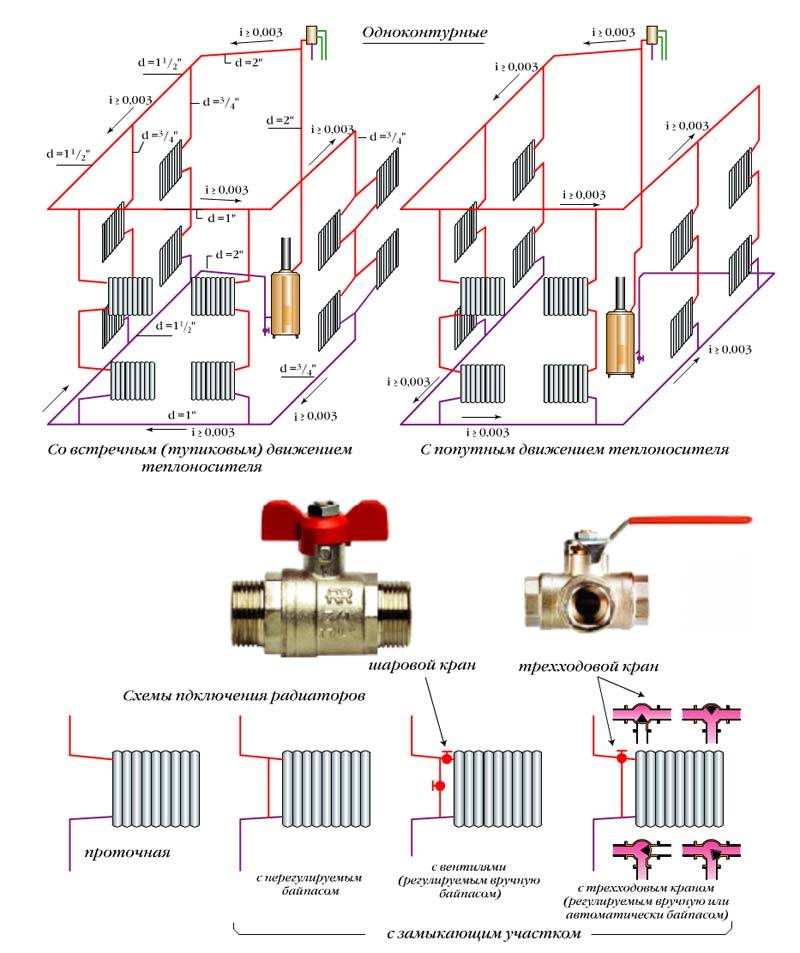

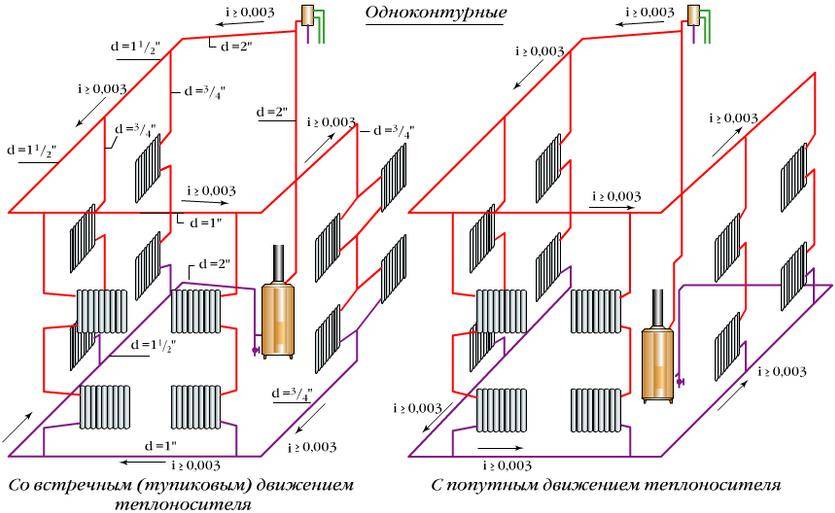

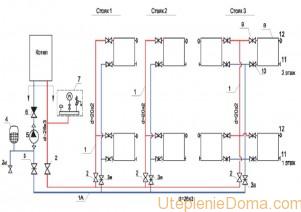

To understand the principle of operation of the gravity system, study the typical scheme used in two-story private houses.Combined wiring is implemented here: the supply and return of the coolant occurs through two horizontal lines, united by single-pipe vertical risers with radiators.

How gravity heating of a two-story house works:

- The specific gravity of the water heated by the boiler becomes smaller. A colder and heavier coolant begins to displace hot water up and take its place in the heat exchanger.

- The heated coolant moves along a vertical collector and is distributed along horizontal lines laid with a slope towards the radiators. The flow velocity is low, about 0.1–0.2 m/s.

- Diverging along the risers, the water enters the batteries, where it successfully gives off heat and cools. Under the influence of gravity, it returns to the boiler through the return collector, which collects the coolant from the remaining risers.

- The increase in water volume is compensated by an expansion tank installed at the highest point. Typically, the insulated container is located in the attic of the building.

Schematic diagram of gravity distribution with a circulation pump

In the modern design, gravity systems are equipped with pumps that accelerate the circulation and heating of the premises. The pumping unit is placed on the bypass parallel to the supply line and operates in the presence of electricity. When the light is turned off, the pump is idle, and the coolant circulates due to gravity.

Scope and disadvantages of gravity

The purpose of the gravity scheme is to supply heat to dwellings without being tied to electricity, which is important in remote regions with frequent power outages.A network of gravity pipelines and batteries is able to work together with any non-volatile boiler or from furnace (formerly called steam) heating.

Let's analyze the negative aspects of using gravity:

- due to the low flow rate, it is necessary to increase the coolant flow rate through the use of large diameter pipes, otherwise the radiators will not warm up;

- in order to “spur” natural circulation, horizontal sections are laid with a slope of 2-3 mm per 1 m of the main;

- healthy pipes running under the ceiling of the second floor and above the floor of the first floor spoil the appearance of the rooms, which is noticeable in the photo;

- automatic regulation of air temperature is difficult - only full-bore thermostatic valves should be purchased for batteries that do not interfere with the convective circulation of the coolant;

- the scheme is unable to work with underfloor heating in a 3-storey building;

- an increased volume of water in the heating network implies a long warm-up and high fuel costs.

In order to fulfill requirement No. 1 (see the first section) in conditions of unreliable power supply, the owner of a two-story private house will have to bear the cost of materials - pipes of increased diameter and lining for the manufacture of decorative boxes. The remaining disadvantages are not critical - slow heating is eliminated by installing a circulation pump, lack of efficiency - by installing special thermal heads for radiators and pipe insulation.

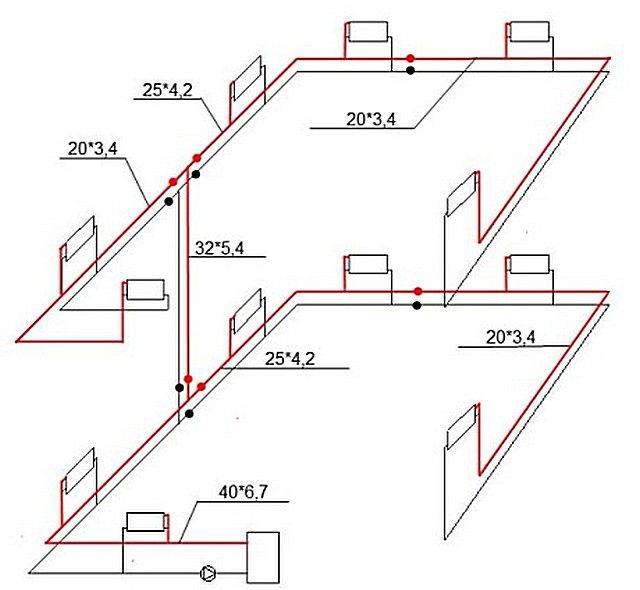

Design Tips

If you took the development of a gravity heating scheme into your own hands, be sure to consider the following recommendations:

- The minimum diameter of the vertical section coming from the boiler is 50 mm (meaning the internal size of the nominal bore of the pipe).

- The horizontal distributing and collecting manifold can be reduced to 40 mm, in front of the last batteries - up to 32 mm.

- A slope of 2-3 mm per 1 meter of pipeline is made towards the radiators on the supply and the boiler on the return.

- The inlet pipe of the heat generator must be located below the batteries of the first floor, taking into account the slope of the return line. You may have to make a small pit in the boiler room for installing a heat source.

- On the connections to the heating appliances of the second floor, it is better to install a direct bypass of small diameter (15 mm).

- Try to lay the upper distribution manifold in the attic so as not to lead under the ceilings of the rooms.

- Use an open-type expansion tank with an overflow pipe leading to the street, and not to the sewer. So it is more convenient to monitor the overflow of the container. The system will not work with a membrane tank.

The calculation and design of gravity heating in a complex-planned cottage should be entrusted to specialists. And the last thing: lines Ø50 mm and more will have to be made with steel pipes, copper or cross-linked polyethylene. The maximum size of metal-plastic is 40 mm, and the diameter of polypropylene will come out simply menacing due to the wall thickness.

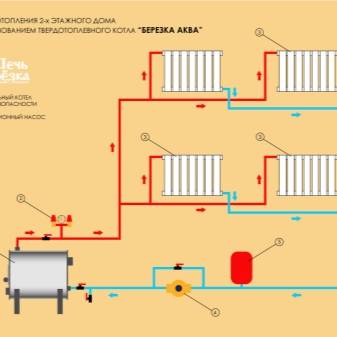

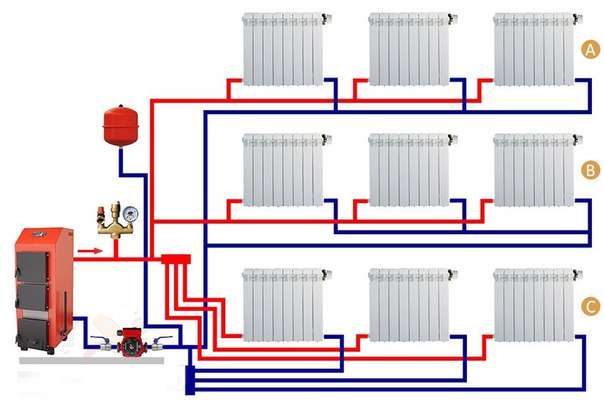

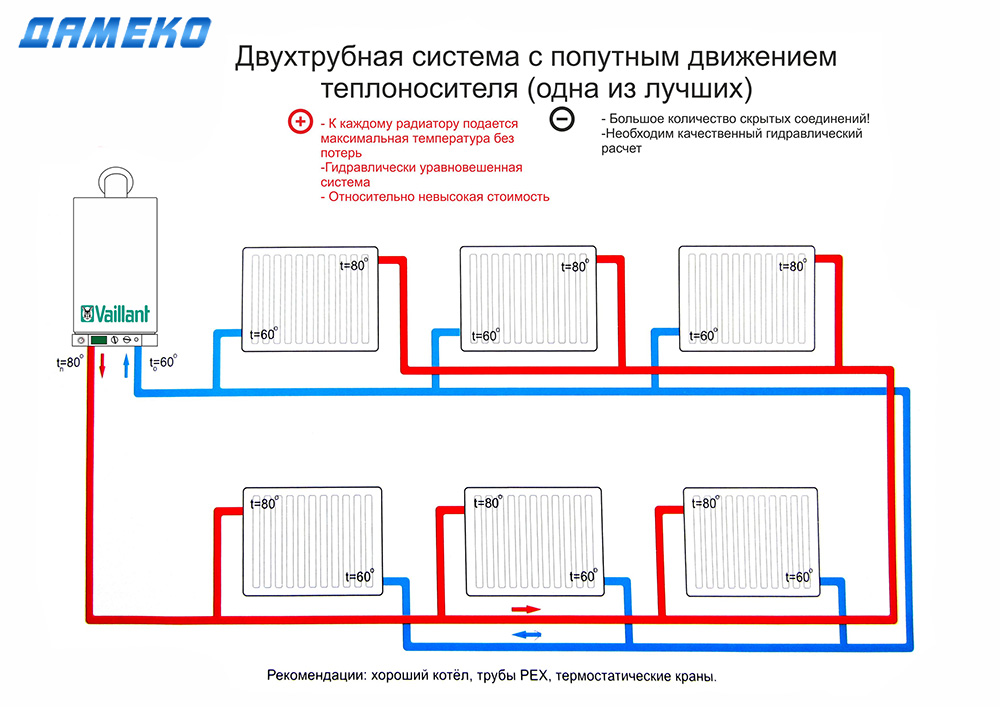

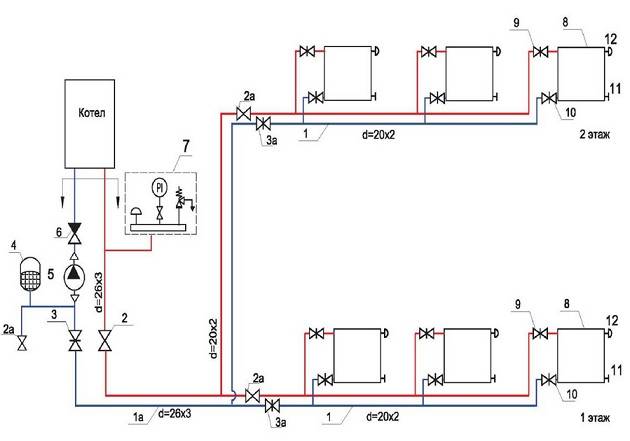

Two-pipe heating system for a two-story building

By using two-pipe heating system You can adjust the air temperature in each room separately.

This wiring, although it has a complex design, is more popular than its single-pipe counterpart. In this case, a branch pipe goes to each heating device from a common pipe supplying hot coolant. Through it, heated water flows into the radiator or battery.Having passed the entire heating device and given up all its heat, the coolant leaves it, but through a different pipe, which is connected to a common return. That is, supplying the heated coolant and returning it back to the boiler to heat the pipe are two different chains.

Although the installation and subsequent maintenance of this version of the heating system of a two-story house are associated with economic costs, the two-pipe system allows you to control the air temperature in each room separately. This contributes to the creation of a pleasant microclimate in the house.

Whichever option of heating wiring for a two-story house is chosen, the main thing here is to make the correct calculations regarding the required power of all heating elements and professionally perform all installation work.

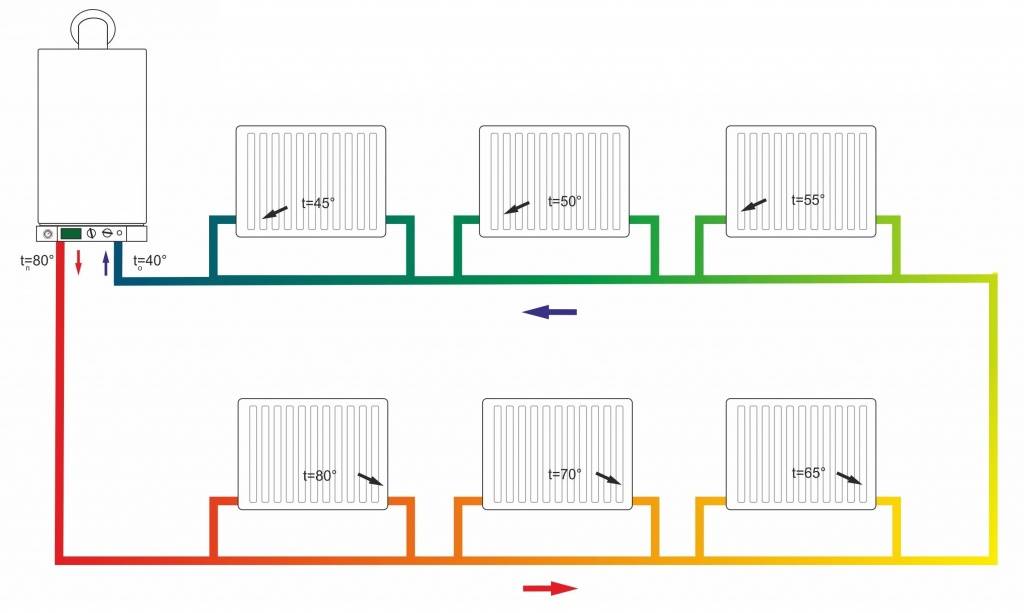

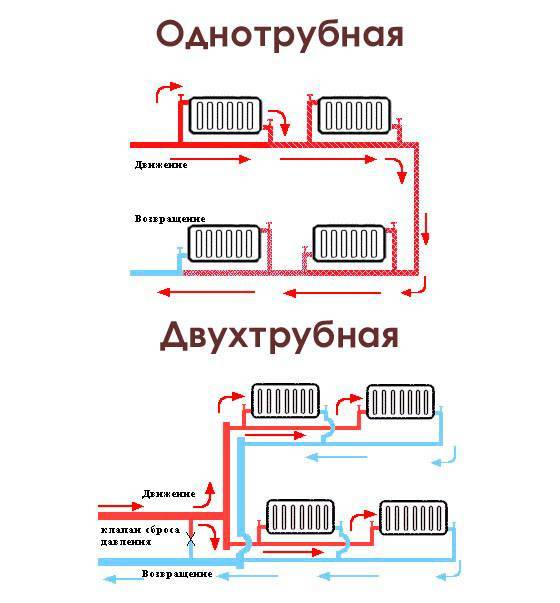

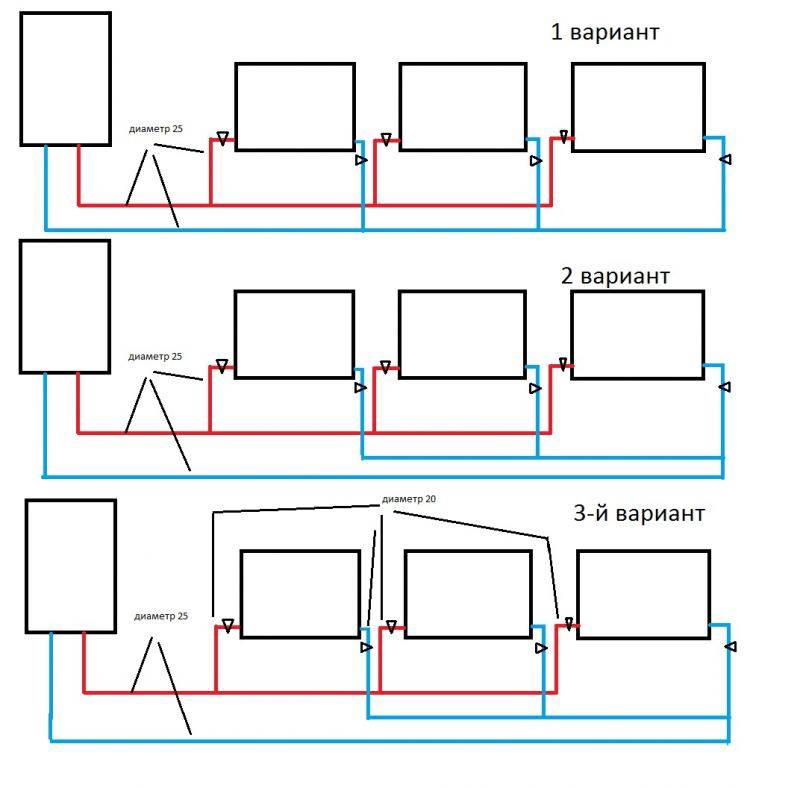

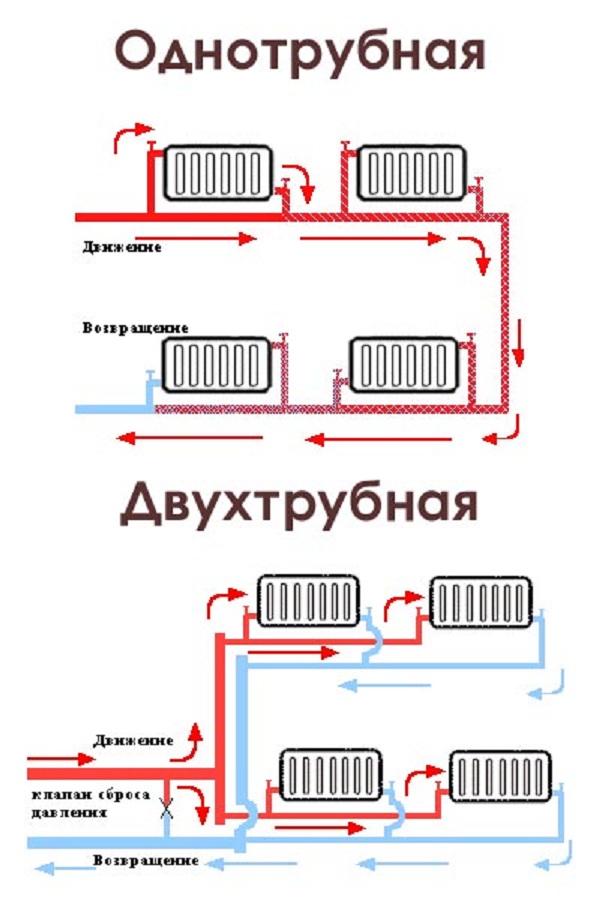

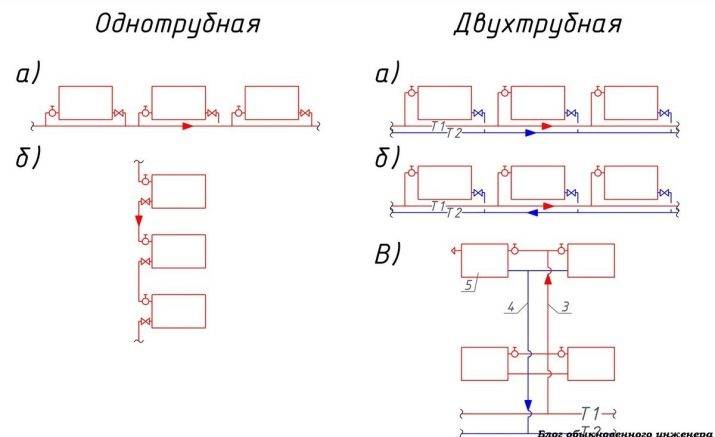

Main differences

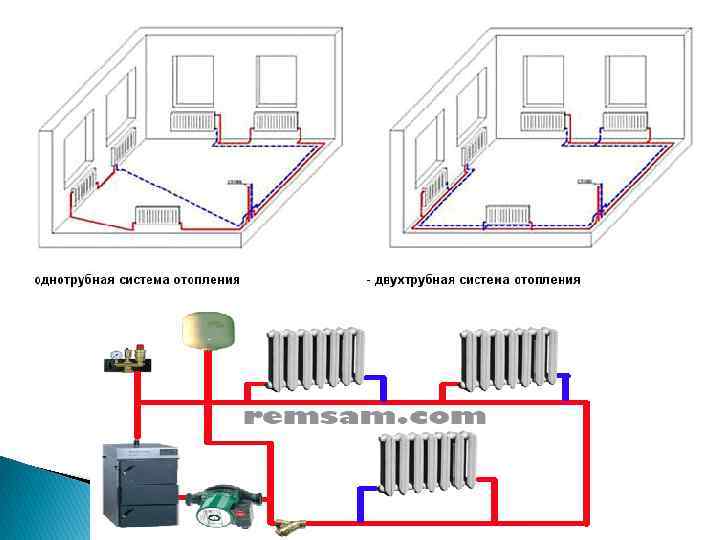

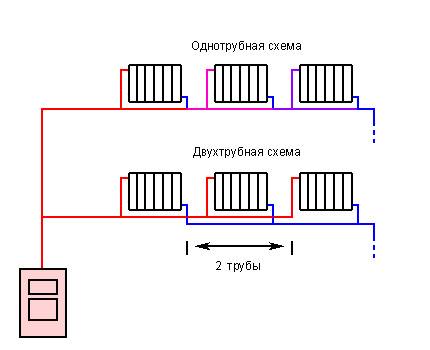

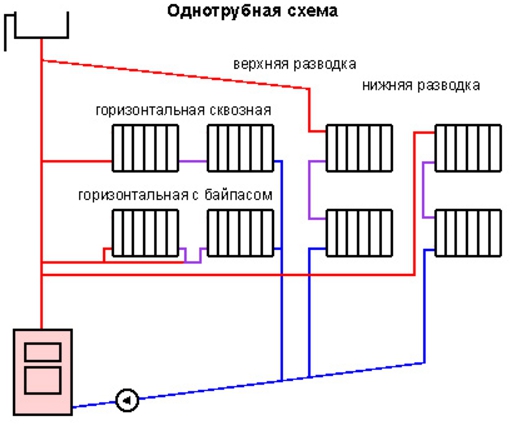

Heating systems using a liquid heat carrier are divided into 2 main types - these are single-pipe and two-pipe. The differences between these schemes lie in the method of connecting heat-releasing radiators to the main. The main line of a single-pipe heating system is a closed circular circuit. The heating main is laid from the heating device, the batteries are connected to it in series and pulled back to the boiler. The heating system with one pipeline is easy to install and does not have a large number of components, therefore it makes it possible to save a lot on installation.

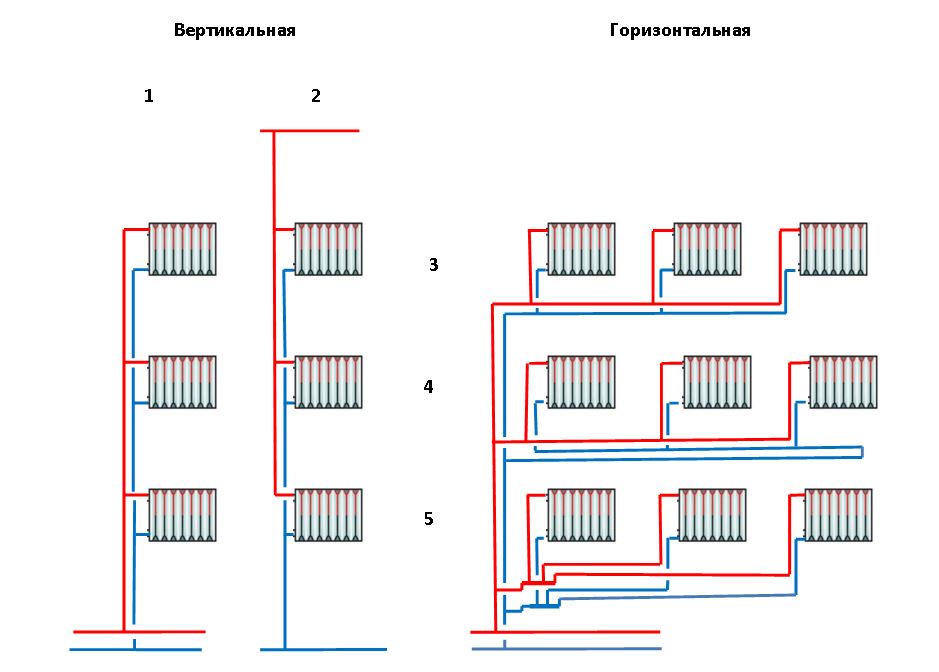

Single-pipe heating structures with natural movement of the coolant are constructed only with upper wiring. A distinctive feature is that in the schemes there are risers for the supply line, but there are no risers for the return pipe.The movement of the coolant of a double-circuit heating system is realized along 2 highways. The first one is designed to deliver the hot coolant from the heating device to the heat-releasing circuits, the second one - to remove the cooled coolant to the boiler.

Heating radiators are connected in parallel - the heated coolant enters each of them directly from the supply circuit, due to which it has an almost equal temperature. In the battery, water gives off energy and, when cooled, is sent to the outlet pipe - the “return”. Such a system needs twice the number of pipes, fittings and fittings, however, it makes it possible to organize complex branched structures and reduce heating costs due to individual regulation of the batteries. The double-circuit system heats large rooms and multi-storey buildings with high efficiency. In low-rise buildings (1-2 floors) and houses with an area of \u200b\u200bless than 150 m², it is more rational to build a single-circuit heat supply from both a financial and an aesthetic point of view.

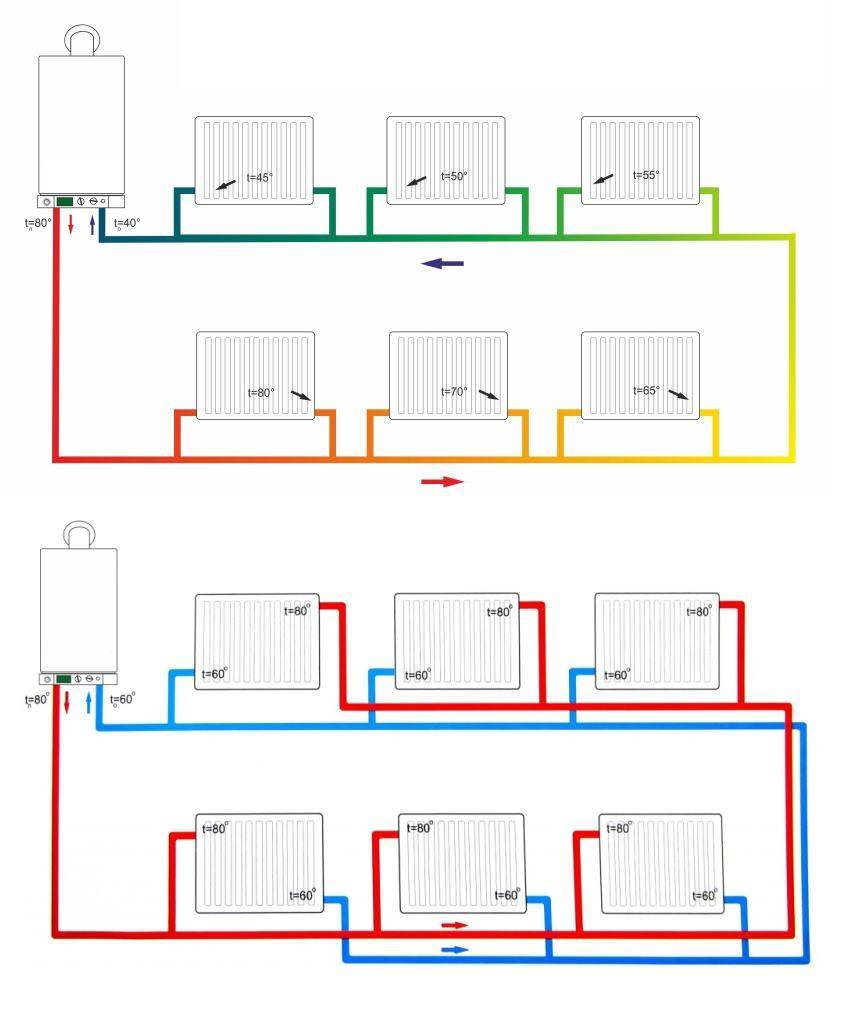

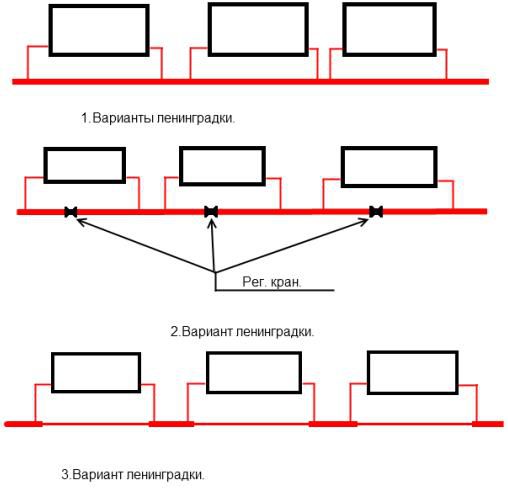

Heating wiring diagrams

In two-story houses, the following heating distribution schemes are used: one-pipe, two-pipe, and also a collector. With a single pipe, it is quite difficult to regulate the temperature in the building. This is due to the fact that there is no way to shut off one of the radiators when all other heaters are working. Therefore, when hot water passes from one battery to another, it cools more and more.

Since each heating unit has two pipes, hot water flows through one, and already cooled down through the other.This system also differs from a single-pipe system in that it has a different procedure for connecting heating devices. Experts recommend installing an adjusting tank in front of each radiator.

Scheme of a two-pipe heating system

Scheme of a two-pipe heating system

In order for a two-story house to have normal circulation, there is enough distance between the center of the boiler and the upper point of the supply line, while you can put the expansion tank on the top floor, and not in the attic. And the supply pipe is laid under the ceiling or under the window sills.

Therefore, it is recommended to install an additional bypass together with the circulation pump, which will significantly save time when starting a system such as a heating scheme for a two-story country house, and at the same time heat will be more evenly distributed in the building.

Heating scheme with bypass and pump

Heating scheme with bypass and pump

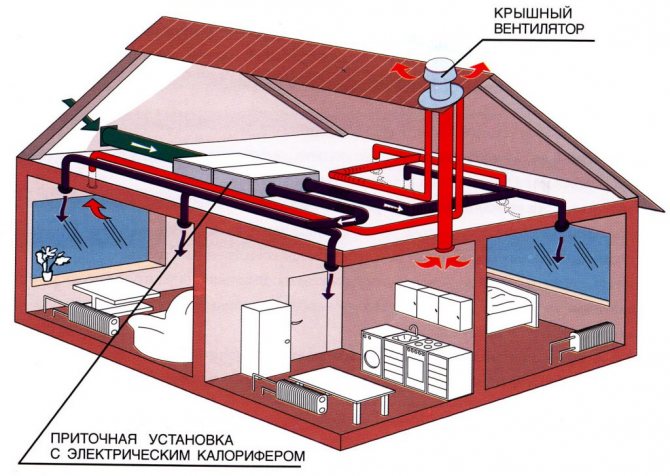

In addition to installing radiators, in a two-story house using a boiler, along with a built-in circulation pump, you can also install a “warm floor” system, connect a heated towel rail simultaneously on two floors. Experts advise connecting the risers of the second floor near the boiler itself.

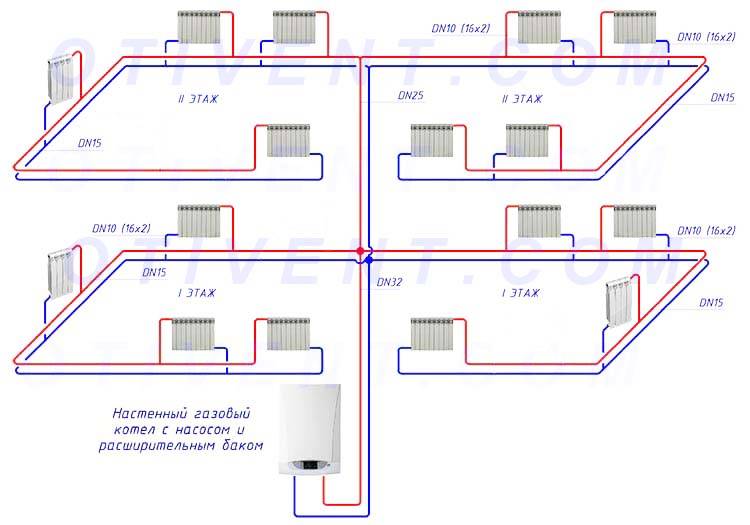

When performing installation, it is best to use a beam and collector system, it is most convenient, you can adjust the temperature in all rooms. For all heating devices, two pipes are carried out: direct and return

Collectors are placed on each floor, it is very important that they be in a cabinet specially designated for this, in which all the shut-off valves are located

Combined heating system: radiators and underfloor heating

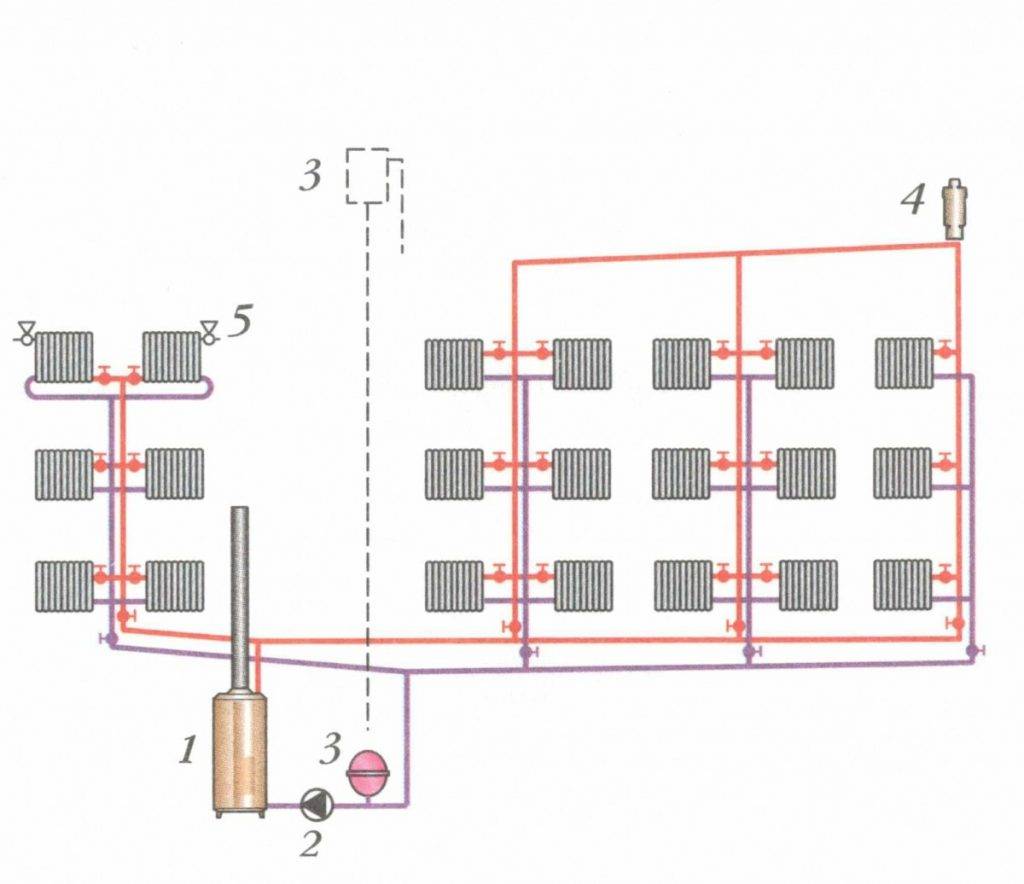

Collector systems

This is a universal heating scheme for a two-story house, a video on the device of which can be viewed below.Such systems make it possible to carry out heating of a two-story cottage with hidden conductive pipes. Installation is very easy, so even a person without special skills can do it.

Scheme of collector heating of a two-story house

Scheme of collector heating of a two-story house

Water heating can be carried out both on one floor, and on all at once, but it is recommended to place the boiler only on the first floor, and an expansion tank can be placed on the second. It is recommended to lay pipes with hot water under the ceiling or under the windowsill, that is, in the most vulnerable places for cold air. Be sure to install a separate control valve for each radiator.

When choosing a heating plan for a two-story house, it is very important to make the right decision, it depends on how comfortable you will be in cold weather, how long the entire heating scheme of a two-story house will last, how often you will need to repair or change pipes and much more. With the wrong choice, if you want to save money, now it may happen that you have to constantly repair something, change, hire workers, which means spending money, so there is no question of any savings in this case.

It is better to install high-quality pipes, radiators and more at the very beginning, even if it costs more and more now, but it will last longer and still come out cheaper in the future. A properly installed scheme of the heating system of a two-story house made of high-quality sustainable materials will last for several generations.

Do-it-yourself installation of a two-pipe heating system in a private house

The production of the structure takes place in several stages.

Calculation

Before proceeding with the installation, it is necessary to build a clear plan, for which specialists always carry out a hydraulic calculation. During this process, the following results are achieved:

- it turns out the number of heating devices;

- the sizes and numbers of circumferential risers are calculated;

- future losses are determined.

Attention! The calculation is made in strict accordance with the heating scheme. Hydraulic calculation gives an understanding of the existing resistances, provides information on water flow and temperature of each individual section

Installation

- First, in a separate ventilated room, a heating boiler is installed. Its location should be remote from the walls, and it should be accessible. The walls themselves, as well as the floors in the room, should be finished with refractory material.

- After that, you need to put a pump, a distribution hydrocollector, and measuring instruments / meters at the boiler.

- From the boiler room, straight through the walls, a pipeline is drawn to the radiators.

Connection

The final stage is the connection of radiators. Batteries are mounted on brackets, under the window. In addition, it is recommended to install thermal sensors. With their help, water flows, as well as its temperature, are regulated.

Trial run

When the structural elements are connected, crimping is done. A trial run of the boiler is possible after the execution of the relevant documents, in the presence of gas specialists.