- Possibilities of main filters for water purification

- Reverse osmosis

- Do-it-yourself water purification systems from a well

- Homemade water purification tips

- Details

- Do-it-yourself method for cleaning a well in a country house

- Features of cleaning yourself

- How to clean a well with a pump

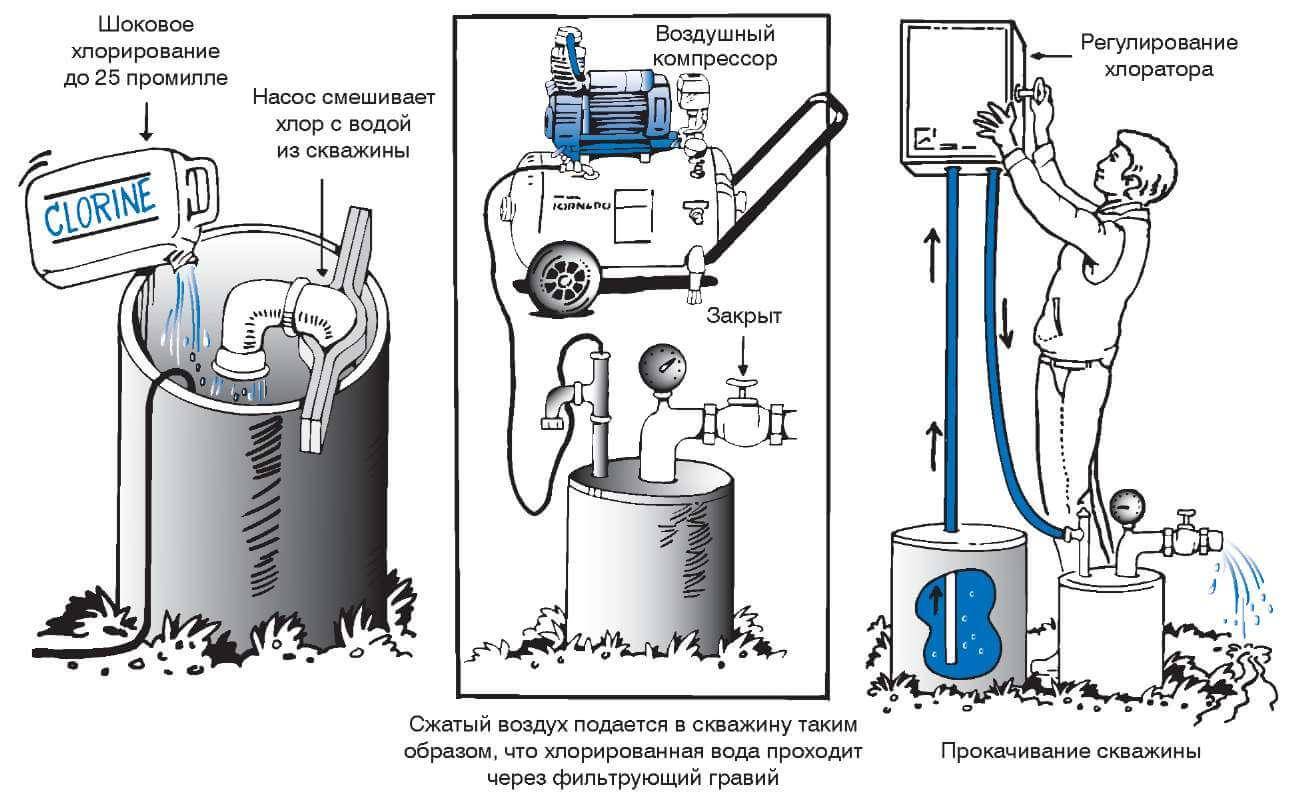

- Preparation for disinfection treatment

- The main causes of cloudiness

- When is it necessary to disinfect?

- Do-it-yourself water purification in a well

- Mechanical cleaning method

- Biological water treatment

- Chemical cleaning

- mechanical cleaning

- Existing cleaning technologies

- The use of ilosos

- Vacuum pumping aids

- Hydrodynamic cleaners

- Washing with chemicals

- Conclusions and useful video on the topic

Possibilities of main filters for water purification

To solve the problem of water purification from a well, it is quite effective to use main filters, which are installed directly on the pipes that are an element of the system. Can be used for both cold and hot water supply.

The main purpose of their installation is:

- water purification from mechanical insoluble impurities, chlorine, heavy metals, microorganisms, etc.;

- removal of unpleasant odor and improvement of taste due to the neutralization of hydrogen sulfide and organic compounds;

- reduction of water hardness;

- preventive measures to protect household appliances and plumbing equipment from scale, sediment.

You can install main filters for water purification from a well almost anywhere in the system, but it is important to take into account the availability of their maintenance, for example, to replace a spent cartridge

Main filters are represented by a fairly wide range, but when choosing, you should pay attention to the following parameters:

- the number of mechanical cleaning steps (from 1 to 3);

- purpose - for hot or cold water;

- cleaning method - chemical, mechanical, biological,

- body material - metal or plastic, matte or transparent, etc.;

- the type of cartridges used and the sorbent used in it.

In addition, according to design features, main filters are divided into devices for:

- coarse cleaning (mesh type);

- fine cleaning;

- with flushing (self-flushing type);

- with ion filtration;

- magnetic;

- osmotic type.

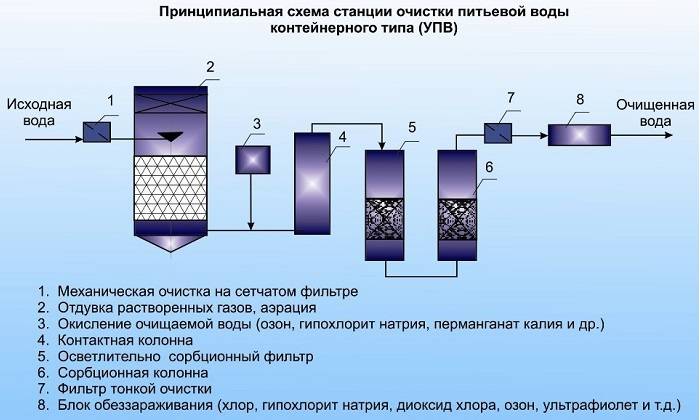

Reverse osmosis

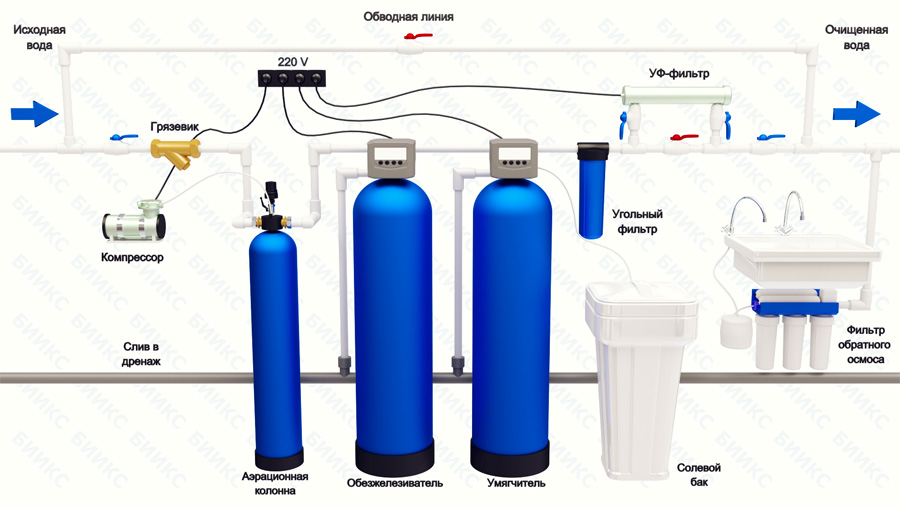

This multi-stage system will provide high quality water in several stages of purification:

- It will rid the liquid of large sandy-clay particles due to the mechanical filter located immediately after the pump.

- Next is the turn of membrane purification from bacteria and viruses, salts of heavy metals. The appropriate filter will not pass any microorganism up to half a micron in size.

- The process will end with coal cleaning.

The multi-stage design can be equipped with an ion exchanger for water softening, a device for enriching the liquid with useful salts and microelements.

Loading …

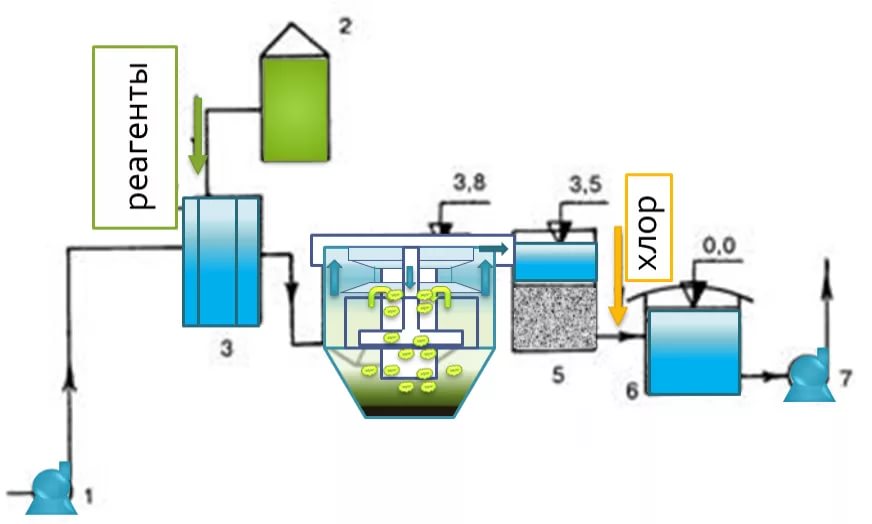

Do-it-yourself water purification systems from a well

One of the options for home-made water purification from a well using the aeration method is shown in the photo below. Two stages of aeration are used here for a more complete water purification and removal of all impurities. The need for the second stage is determined based on the results of cleaning the first stage: the quality is far from always satisfactory. Re-aeration can help with this, but this is far from the only way: you can put one of the filters. He will do a good job, and will rarely clog.

Two-stage well water purification system

In this embodiment, water from the well is supplied through shower heads. Thus, primary oxygen enrichment occurs. There is also a submersible atomizer from an aquarium compressor. The water level is controlled by a float switch (used to control the water in the pool). At the bottom of the tank there is a tap for draining settled substances.

From the first tank, water is taken in the same way as in the previous version, from the lower third. the system is organized in the same way. From there, water can be supplied to the final cleaning and disinfection filter, and then it is diluted around the house.

See the video for another example of a home-made water purification system from a well.

Homemade water purification tips

If we talk about home-made systems, water purification from a well, then different approaches and methods are often used. Here are some quotes:

I remove iron cheaply and simply. I have a 120 liter tank. I pour 7-10 grams of lime into it, then blow it out with a compressor from the aquarium for 4-5 hours and let it settle for 3 hours. Then I supply water to a filter with a 2 micron cartridge, and from there into the system. This method was made in the country. I change the filter once a month.A friend at home made the system larger - by 500 liters. There are two compressors running 12 hours. If you increase their power, the time can be reduced.

This is how the primary enrichment of water with oxygen in a home-made version looks like: a shower head through which water flows. Only it is desirable to raise it higher so that more oxygen is captured

The second option is no less interesting:

I had a lot of sand and silt coming out of the well: my consumption is high and it “pulls” a lot of all sorts of rubbish. I solved the problem by installing a filter. I only gutted my own cassette (after the filter became unusable), and poured crushed shells into it. Some pour marble chips. Works fine too. Only the fraction is needed not small, otherwise it will be quickly clogged. And then I have a tank with blowing (aeration), and after it there is already a filter that removes what the first two could not. The last filter I have is a barrel filled with BIRM. It has a faucet for washing. So once every couple of weeks I wash the backfill, and it needs to be changed after three years.

Details

Do-it-yourself method for cleaning a well in a country house

When cleaning the well, follow the sequence of actions. They include these steps:

1. pumping out liquid.

1. pumping out liquid.

2.cleaning the walls inside the well hands.

3. replacement of the layer at the bottom of the well.

4. flushing of the walls with chemical compounds.

5. filling the shaft with water, adding cleaning solutions to it.

Features of cleaning yourself

If cleaning is done on your own, then the first step is to pump out the water with buckets. If there is a self-priming pump, you can use it, this will facilitate the work.

Then you need to prepare tools to clean the walls inside the shaft manually. This will require a ladder with a scraper.Instead of a scraper, you can use a hoe, hoe, which have a 2.5 meter handle. Next, you need to scrape off the plaque from the rings. First, they clean the shaft, standing on the ground, to the level to which the scraper reaches. Next, you need to install a ladder in the well, go down and clean the shaft of the remaining rings.

Then the natural layer is cleaned. Old sand, gravel is taken out in buckets, fixing it on a rope. During the procedure, you need to dress in special boots for hunting. New gravel is laid on the clean bottom of the mine with a layer of up to fifteen centimeters.

Chemical cleaning begins with the preparation of a special agent. For these purposes, bleach is used 10 percent, or Whiteness 0.5 liters. The agent is diluted in a bucket of water.

Attention! To clean the walls, use a cleaning solution based on chlorine or whiteness. A sponge is wound on a long stick, moistened with a solution, and the walls are rubbed

Do not leave gaps on the walls that are not impregnated with the product. The whole procedure is carried out with gloves, a mask, glasses, because the solution is very caustic

A sponge is wound on a long stick, moistened with a solution, and the walls are rubbed. Do not leave gaps on the walls that are not impregnated with the agent. The whole procedure is carried out with gloves, a mask, glasses, because the solution is very caustic.

How to clean a well with a pump

To make it easier to clean the well with your own hands. Some operations can be performed by automatic equipment. For these purposes, organize the circulation of water in the mine. A drainage type pump should be installed at the bottom of the well. With the help of it they pump it up.An injection-type unit is placed near the head to pour liquid into the well.

To make it easier to clean the well with your own hands. Some operations can be performed by automatic equipment. For these purposes, organize the circulation of water in the mine. A drainage type pump should be installed at the bottom of the well. With the help of it they pump it up.An injection-type unit is placed near the head to pour liquid into the well.

Each device has its own role in the cleaning process. A drainage type pump will remove water from the shaft and particles of dirt that are in it. With the help of a pressure pump, a stream of water is created, which, under pressure, will act like a scraper to clean the walls and bottom. Cleaning the structure involves the following steps:

1. At the drainage pump, a stand of 10 centimeters is installed so that it does not get stuck in the silt, and lowered into the well.

2. The hose from the pump is placed in a container; an old bath can be used as it.

3. A hose is attached to the top of the tank to suck liquid from pressure equipment. A wire filter is put on the end. A hydraulic nozzle is put on a pressure-type hose, it will allow you to supply water with a high-speed pressure.

4. turn on the drainage type pump, pump out water, pumping back to knock down dirt. You can control the water jet outside and inside the well. Silt with sand will be in the tank.

5. When the cleaning of the walls from mud deposits is completed, chemical cleaning begins. 10 percent chloride of lime is added to the spray gun, and sprayed onto the walls of the well.

6. Next, the collected water is chemically cleaned according to the standard method.

Preparation for disinfection treatment

Preparatory work is recommended to be carried out without fail immediately before the disinfection procedure. The speed and quality of disinfection treatment largely depends on the correct preparation.

First of all, it is necessary to pump out the water. If there is not enough water in the well, then it will be enough to use a surface pump.

If the water level is significant, then a powerful submersible pump will be required. Before starting the pump, floating debris must be removed from the well; a long-handled net with a fine mesh is best suited for this purpose.

After pumping out the water, a descent into the well is carried out and its bottom and walls are inspected for cracks, leaks, deposits.

If there are cracks, they must be repaired with a special waterproofing solution. It also removes debris, algae, silt from the walls of the well.

Image gallery

Photo from

The quality of water extracted from a well can decrease not only in old structures

A well with a silty bottom, in which algae has appeared, must be cleaned before disinfection and a new bottom filter should be laid

If the decrease in water quality is associated with a violation of the tightness of the walls, it is necessary to carry out repairs before disinfecting the source.

After the disinfection and emptying of the shaft, the water should be checked for the content of chemicals in it 2-3 times. If there are excesses, pumping is carried out several more times, then the sample is carried for analysis to the SES

Poor quality of water from the well

Do-it-yourself well cleaning

Wall repair before disinfection

Checking the composition of water for acidity

The tools used are hard brushes, spatulas. The bottom of the well is cleared of sediment, as far as possible, the old bottom backfill is removed and a new one is filled up.

Fine crushed stone, gravel, sand can be used as bottom backfill. Expanded clay cannot be used because of its too low specific gravity and high toxicity.

If there is plaque on the concrete rings, it should also be removed.For this, various substances are used, the composition of which depends on the nature of the deposits.

Salt deposits are removed with acidic solutions, such as a weak solution of hydrochloric acid or vinegar.

It is recommended to carefully remove corrosion spots with a jackhammer or grinder, and treat the surface with a waterproof anti-corrosion compound. In the presence of moldy deposits, treatment with copper sulphate is required.

Before the disinfection procedure, it is necessary to thoroughly clean the shaft and the bottom of the well from debris and various deposits using special tools.

The main causes of cloudiness

Before you start cleaning, you need to find out what exactly caused the cloudiness. The main causes of water pollution include:

- ingress of soil particles due to depressurization of the walls;

- active development of microorganisms, for example, when exposed to direct sunlight;

- improper use and care of the device;

- stagnation during very rare operation of the well;

- a faulty pump, which during operation raises silty masses from the bottom;

- harmful chemicals entering the groundwater;

- decomposition of organic compounds accidentally found in the mine;

- mixing well water with sedimentary moisture falling from above due to the lack of a cover;

- improper arrangement of the above-ground part of the structure.

After determining the cause of the pollution of the well, you can begin cleaning work. They can be done on your own or you can seek help from specialists.

Soil particle pollution

If the turbidity of the water is caused by the ingress of soil or sand particles into it, a mechanical filter will help.If the dirt seeps along with the perch, it is necessary to put in order the broken sealing of the butt joints.

To clean a dirty well, you need to act in a certain order. It must be dried first. To do this, the contents are completely pumped out of the shaft using a pump.

A person in special clothes must descend into an empty well with a cable. Using a brush with a hard bristle or a special scraper, he will clean the inner surface of the accumulation of silt masses and dirt.

Layers removed from the walls and bottom must be collected in a bucket and lifted out. Cleaned surfaces should be treated with a disinfectant to remove harmful microorganisms and odors. All butt joints or cracks caused by water pressure should be sealed with a moisture-resistant compound.

How to make a clay castle? If the clay castle was not equipped during the digging of the well, the water will inevitably be polluted by precipitation. Therefore, it is necessary to provide protection from rain. A ditch 1 m wide must be dug around the above-ground head of the well. The minimum depth is 0.5 m.

In the prepared ditch, it is necessary to tightly lay the clay in several layers. Each layer is carefully compacted. Crushed stone or other bulk material is poured over the clay. The final layer is a cement mortar. With its help, a slope is formed from the mine to the side. This will ensure the runoff of rain and melt water from the structure.

Pump problems

Sometimes turbidity in the well is observed during pump operation.This occurs when the device malfunctions or is incorrectly installed. After checking and reinstalling, the pump can be connected.

If turbidity occurs again, you need to purchase a different type of pump - with a different liquid suction pattern. When buying a device, it is necessary to take into account the chemical composition of the water in the well. You can check it in the laboratory of Rospotrebnadzor.

Silting water

If the cloudy water has a yellow or greenish tint, then it is silting. This is due to an incorrectly laid and/or partially destroyed bottom filter.

In this case, it is necessary to drain the well. Then disassemble the bottom filter and extract it in parts to the surface. If bulk materials have become unusable, they must be updated.

Partially damaged gravel or crushed stone should be sorted out and washed. After that, the material can be reused, adding new masses if necessary. The bottom filter must be laid out again, carefully observing all the rules for its installation.

Water stagnation

If the well is rarely used, the water in it stagnates and becomes cloudy. In this case, it is necessary to drain its trunk. Thoroughly clean the bottom and walls of debris, silt, mucus and treat with a disinfectant solution. When the shaft is full, you need to add a solution of bleach.

To avoid stagnation, you need to periodically use the well. Additional cleaning will be provided by installing a special filter purchased at the store.

ferruginous water

With an increased iron content, well water becomes yellowish and acquires a metallic taste. If it settles, a precipitate will surely appear, resembling rust in color.

It is not dangerous to health, but it is unpleasant to drink it.The taste of dishes prepared with its use deteriorates noticeably. Special filters equipped with iron removal cartridges will help to correct the situation.

When is it necessary to disinfect?

Disinfection includes two stages: cleaning the well shaft and disinfecting the water. All wells are subjected to this process, regardless of their purpose and frequency of use.

The reasons why it is necessary to carry out disinfection measures can be very different:

- flooding due to spring flood;

- infiltration of sewage or groundwater;

- penetration of agricultural or industrial chemicals;

- falling into the well of the corpses of birds and animals;

- intensive operation of the well, as a result of which subsidence of the bottom soil occurs;

- the formation of mucus, dirt, salt and moldy deposits on the walls;

- the presence in the open well of small debris, dust.

It is recommended to carry out preventive disinfection of the well at least once a year, and it is better to do it twice - after the spring flood and in early spring.

Remember that poor-quality, polluted water not only has an unpleasant taste and smell, but is also a breeding ground for pathogenic microorganisms dangerous to humans and farm animals.

That is why it is necessary to carry out regular cleaning of well water and mines.

The quality of water and the content of pathogenic microorganisms and harmful impurities in it depend on the frequency of disinfection measures.

The quality of water and the content of pathogenic microorganisms and harmful impurities in it depend on the frequency of disinfection measures.

Do-it-yourself water purification in a well

So, water purification requires the following procedure:

-

Preliminary inspection of the well and finding the causes of water pollution.

-

Fluid sampling for analysis and its implementation.

-

Elimination of visible defects and cleaning of the well.

-

Installation of bottom filters.

-

Disinfection and chlorination based on analysis data.

-

Selection and installation of a filtration complex.

Note that all manipulations can be reproduced independently (except for analysis). The most important thing is to understand what technological nuances each cleaning method has.

Mechanical cleaning method

The well and its cleansing is the first step in bringing water back to normal, since the mucus on its walls is a source of bacteria.

Cleaning should be done once every two years for frequent use and once a year for occasional use.

For this procedure, prepare the following materials and tools:

-

putty knife;

-

Master OK;

-

metal brush;

-

cement and sand mortar;

-

bucket;

-

belt for insurance;

-

ladder;

-

winch;

-

slings for holding;

-

water pump;

-

blocking and descent design.

Mechanical cleaning involves cleaning the entire surface of the well. The suggested course of action is as follows:

-

At the same time, after the gradual pumping out of the liquid, the walls are cleaned.

-

Surfaces are cleaned with a metal brush.

-

Then organic residues and debris are removed from the bottom.

-

The presence of cracks will require their sealing with cement.

-

To prevent displacement of the rings, reinforce the integrity of the structure with steel braces.

-

Wash the bottom filter or install a new one.

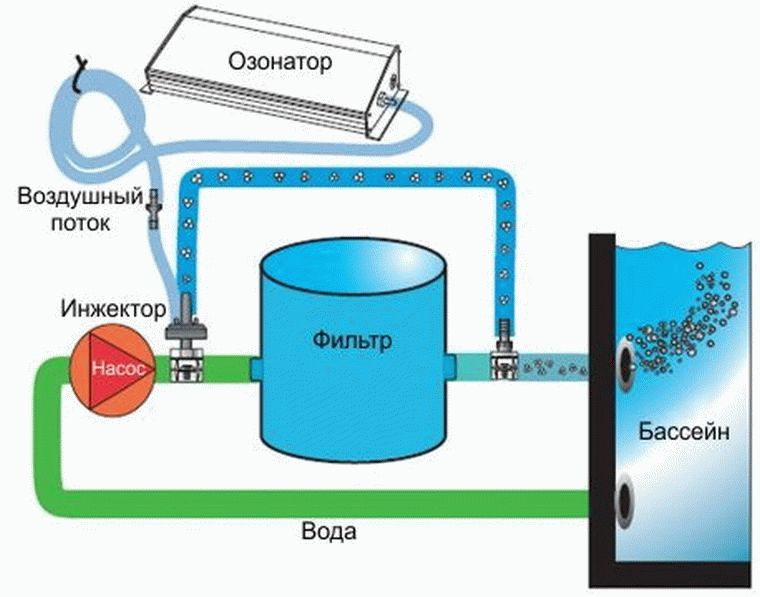

Biological water treatment

Biological treatment involves the arrangement of a filter layer at the bottom of the well. For such a filter, it is fashionable to use shungite, silicon gravel or natural sorbents.

Note that the substance of volcanic origin - zeolite, will provide a high degree of filtration.

To backfill the shungite layer, you must:

-

Lay out a layer of geotextile with high permeability on the bottom. In the future, it will greatly simplify the cleaning of the bottom filter.

-

First, fill in shungite with a fine fraction, and on top with a large one.

-

After waiting for the dust particles to shrink, go down into the well in a respirator and carefully distribute the shungite.

-

In order to remove excess dust, you can pre-wash the shungite.

After 3-4 weeks, the water quality will noticeably improve. Shungite thoroughly neutralizes sulfur bacteria, reduces iron content and has a positive effect on the formation of beneficial microflora. Purification of well water is necessary, especially in conditions of deterioration of the general environmental situation.

Chemical cleaning

If an unpleasant taste and smell is detected, it is necessary to disinfect the well. As a means for purifying water in a well, a solution of potassium permanganate or preparations with chlorine can be used.

It is necessary to follow a special sequence of actions.

-

Preparation of working solution:

-

300 grams of bleach is diluted in a small amount of water to a mushy state;

-

the mixture is poured into a ten-liter bucket of water;

-

mix thoroughly and let stand for 3-4 hours;

-

poured into an airtight container and put in a dark place.

Wall treatment with a brush or sprayer.

Preparation of a more concentrated solution and its settling.

Filling the well with water.

Moving the chlorine solution into the well and sequential mixing with a pole.

Closing the well for a day.

Repeat the procedure depending on the degree of contamination.

Then it is necessary to pump out all the water from the well and repeat filling / pumping out until the smell of chlorine disappears.

Do not forget that during the disinfection operation of the well is prohibited! Water purification in this way must be carried out in compliance with all prescribed measures.

A more gentle method of disinfection is the use of potassium permanganate. Here is the sequence:

-

a teaspoon of the powder is dissolved in a bucket of water.

-

The solution is poured into the well.

-

Leave for a day.

-

Pump out several times and add water.

-

Fill with clean water and lower a nylon bag with crumbs of silicon to the bottom.

-

The solution can also be applied to the walls.

After all the manipulations, it is recommended to re-analyze the water. If the situation has not improved, chlorine cartridges should be used. These are cylindrical containers with calcium hypochlorite. While under water, the cartridge continuously releases chlorine. It needs to be recharged every month. Installation of such products should be carried out by professionals who can accurately calculate the safe threshold for chlorine in water.

Read the material on the topic: Integrated water treatment

mechanical cleaning

To clean the wells by mechanical actions, we dive into them. At the same time, we comply with the safety criteria:

- We work with 2-3 people.

- An employee diving into the mine is tied with a rope. He also wears rubber boots. The head is protected by a helmet.

- If the mine is gassed, a gas mask is used.

For cleaning we use a broom, a metal brush and a scraper.They eliminate moss deposits, fungal formations, dirt and slush, as well as detached elements of the cement structure.

The work is done on the board, which we hang on the ropes. If we find defects in the sealing of the butt sections, we eliminate them and restore the sealing. For this, we use a cement-sand composition. The share of cement in is significantly lower.

After cleaning the walls, we wash them with water in two cycles. Then we remove the debris accumulated during previous work. We also remove silted soil.

Put the trash in a bucket. It is lifted up with a strong rope. Upstairs, his partner takes him.

We also replace the drain filter. It is formed by gravel, pebbles and sand. We put a new filter mechanism.

Then we fill and empty the well twice.

Existing cleaning technologies

Proper operation of the sewer system will always be the key to quality work. To do this, you must regularly perform the procedure for cleaning all communications. The regularity of such actions is always due to the type of design, as well as the volume of the reservoir for the accumulation of wastewater. As mentioned earlier, due to irregular cleaning, garbage collects in sewer systems, an unpleasant odor appears, and harmful microbes multiply intensively. Even systems with installed drainage pumps will necessarily require constant cleaning so that various debris and silt do not collect at the bottom.

Today, sewer wells can be cleaned using the following technologies:

- Vacuum pumping.

- Washing with chemicals.

- Removing dirt with a sludge pump.

- Hydrodynamic cleaning.

- Washing with hot liquid.

Vacuum pumping and removal of sludge is possible only with the use of special equipment at the disposal of the sewage services. Maximum results can only be achieved by manually cleaning the well.

The use of ilosos

The use of sludge pumping equipment is considered optimal when pumping sewer wells. This technique is used in the performance of various types of sewage works. The simplest technical tool consists of a volumetric tank and a special vacuum pump.

All-season use is a positive feature of this method. Such sludge pumps are used everywhere in the process of performing various preventive and cleaning works.

Vacuum pumping aids

This technology involves the use of a powerful vacuum portable pumping station to clean the well from wastewater. After using such devices, the procedure for collecting and disposing of hazardous waste is carried out. Vacuum cleaning fully complies with current environmental regulations and is considered one of the most efficient technologies in terms of maintaining appropriate sanitary conditions.

Hydrodynamic cleaners

The principle of operation of hydrodynamic sewer cleaning systems involves the removal of accumulated deposits from the walls of the well with a powerful pressure. With the help of such devices, organic and inorganic substances are removed without much effort. After completion of the cleaning procedure, the collected waste is subject to subsequent disposal. The volume of accumulated deposits determines the required number of pumping tanks.

Washing with chemicals

This technique involves the use of potent chemicals. Thanks to such means, the procedure of softening and subsequent transformation of various condensate deposits is carried out without much difficulty. The special chemical composition creates a sufficient amount of foaming mass.

Thus, the surface of the inner walls of sewer systems is processed as efficiently as possible. Chemical cleaning is performed relatively rarely due to the high cost of reagents, but the effectiveness of this technology, as well as environmental safety, has been confirmed by many years of experience.

After reviewing the above materials, each owner of a private house with an equipped sewer system can choose the most suitable cleaning method that meets specific needs and financial capabilities.

Interesting materials:

- sewer wells;

- septic Microbe;

- sewerage pumping.

Conclusions and useful video on the topic

Video review of the tableted disinfectant Aquabreeze:

Video presentation of the lamp for ultraviolet disinfection system:

Don't expect thunder from a clear sky. After all, water is what we use every day.

That is why it is so important to be sure that it does not contain harmful substances. To protect yourself and your loved ones, do not neglect the rules of operation and regularly check the composition of the water, even if it seems crystal clear

We are waiting for your stories about self-cleaning and disinfection of well water. Please write in the comment box. Here you can ask questions, share your impressions, useful information and thematic photos.