- What is Film Radiant Electric Heater?

- Equipment internals

- Principle of operation

- Types of infrared heating

- Ceiling infrared heating systems

- Wall Mounted Infrared Heating Systems

- Floor standing infrared heating systems

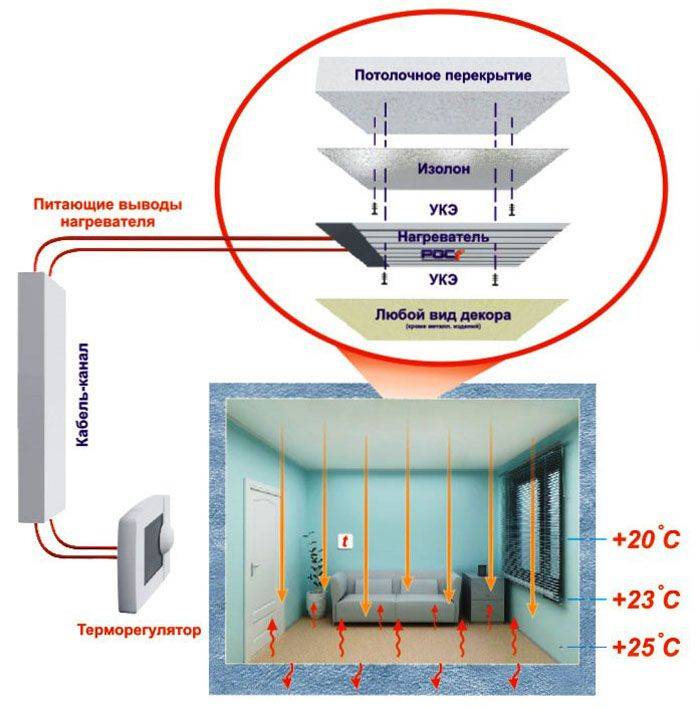

- Installation of film heating on the ceiling

- Arguments for and against IR panels

- What is radiant heating?

- Efficient operation of film heating

- Pros and cons of a film electric heater

What is Film Radiant Electric Heater?

All existing heating systems today use one of the well-known methods of heat transfer:

- electromagnetic radiation in the infrared range;

- convection;

- with direct heat transfer.

As practice shows, the first option turns out to be the most effective and economical, which underlies the new method of space heating.

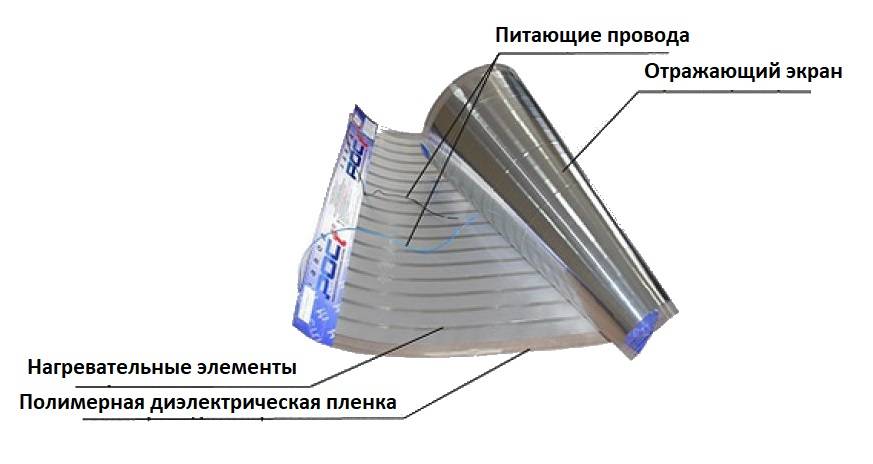

Equipment internals

The PLEN heating system is arranged quite simply. It is an aluminum foil with resistive heating elements placed on it. The device is laminated on both sides with a special durable film.

In general, the thickness of the structure does not exceed 1.5 mm. The materials used for the production of the system are characterized by increased heat resistance and strength.The equipment is attached to the ceiling of the heated room.

Plane is a film-laminated system of resistive heaters deposited on aluminum foil.

Principle of operation

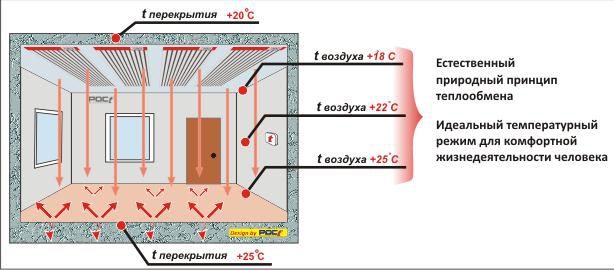

After the power is connected, the resistors in the film begin to heat up. They emit infrared waves with a length of 10-15 microns, which, in turn, heat the surfaces below them. It can be the floor or even large furniture. The floor accumulates thermal energy, after which it begins to gradually release it. Thus, it becomes part of the heating system.

The principle of operation of the plan system is simple, but very effective.

It should be noted that the ceiling heating plan works cyclically. The first stage is the emission of infrared waves, the second is the absorption, accumulation and release of heat by the floor. In this case, the first stage takes only 10% of the system operation time, and the remaining 90% is heat transfer. Therefore, the equipment is very economical. The device can be equipped with an automatic control system and a thermostat, which ensures that the system is turned on and the set temperature is maintained without human intervention.

Types of infrared heating

Ceiling infrared heating systems

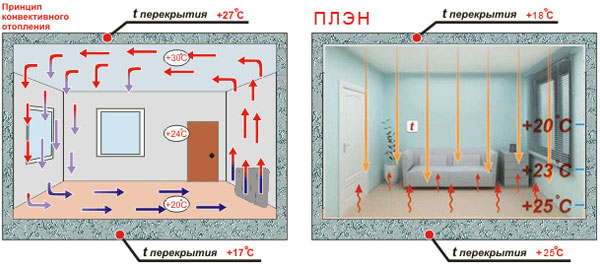

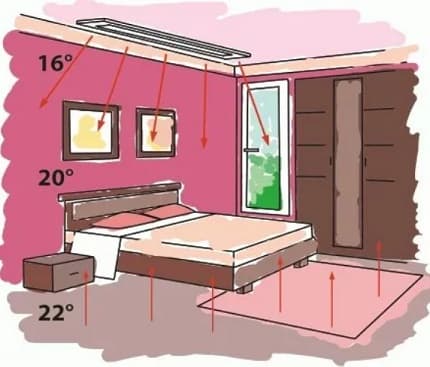

With infrared heating of the ceiling type, the heating devices are suspended from the ceiling - due to this, the heat flow is directed downwards and slightly to the sides. Thus, the main surface that is heated by IR rays is the floor covering. Therefore, the temperature at the level of a person's legs with this method of heating is a couple of degrees higher than at the level of his head.With the convective principle of air heating, the floor is always the coldest surface, and the bulk of the warm air “lives” under the ceiling.

Quite often, ceiling heaters are used as an auxiliary source of heat in a private house. By maintaining the background temperature in the room with another type of heating and using ceiling IR heaters, it is possible to create "islands" of heat, for example, in a recreation area, workplace or dining group. Note that this does not take up the useful area of \u200b\u200bthe room.

Ceiling-mounted infrared heaters can heat a room both in full and in zones.

Having a built-in temperature sensor, the infrared heater will turn off when the set temperature is reached and turn on for heating if the room temperature drops below the set point. Thus, a considerable amount of electricity is saved. Heating with infrared heaters ceiling type is also good because the heaters can be dismantled and transported, say, to a new place of residence.

In the ceiling space of a private house, infrared film heating can be successfully installed, which will keep the height unchanged. premises and residential area space

This is especially important on attic floors with sloping ceilings and small wall planes. More recently, a new type of IR ceiling panels has appeared on the market of finishing materials, mounted in an Armstrong-type profile - a simple and economical solution for common areas in a private house

Wall Mounted Infrared Heating Systems

Installing wall-mounted infrared heating panels can be a good alternative to traditional heating with radiators. With a small thickness and a wide variety of sizes, IR heating panels can be easily installed in a private house with your own hands.

Panel-type infrared heaters can be an excellent alternative to a traditional water radiator.

Infrared panel heaters are available as:

- wall-mounted IR panels installed instead of the usual radiator in a niche under the window;

- designer wall IR panels of various sizes and in a wide range of colors;

- strips of warm IR skirting boards, which are attached around the perimeter of the room instead of a regular skirting board.

A universal version of wall heating is a film heating system mounted in the thickness of the wall. It is rational to install this type of heat source indoors with one or more external walls - this will ensure sufficient heating of planes prone to freezing and mold formation

An important point to pay attention to when installing film IR system – obligatory use of a shielding film that prevents heat loss

Floor standing infrared heating systems

As floor IR heating systems, film mats are used, in which flat heating elements are soldered, connected in series. The minimum thickness of this heating system allows you to mount a warm floor under any finish - whether it be tiles, laminate, carpet or linoleum. In this case, not a single centimeter of the height of the room will be lost.The most efficient combination of IR heating in terms of heat transfer is with ceramic tiles, a little worse with laminate. The greatest shielding of infrared radiation is seen behind linoleum and carpet.

Infrared film system heating can be mounted on the floor, walls and ceiling

In addition to the above advantages, the laying of the infrared film is carried out quickly, it is not accompanied by dirty work, as, for example, when arranging a water-heated floor. Installation of decorative flooring can be done right there, without the numerous steps that accompany the installation of other types of underfloor heating.

Installation of film heating on the ceiling

In order for the finished heating system to be effective, the following rules should be followed when working:

- Before installation, it is necessary to perform thermal insulation of the room (walls, doors, windows).

- Do not install film heating in a room with high humidity or at low temperatures.

- The heating system, which acts as the main one, must occupy at least 80% of the total ceiling area. For additional, 40% is enough.

- The current power must correspond to the value specified in the passport of the heating system. If it is less than required, it is necessary to install a distribution block.

- The temperature sensor must be installed at a level of 170 cm from the floor level.

- It is forbidden to bend the roll heater at an angle of 90 °.

- For ceilings that are too high - above 360 cm - standard models will not work, since the energy consumption in this case will be unreasonably large.

- In order to reduce heat loss, it is recommended to mount a foil film under the IR film. It will reflect heat into the room.

- The roll heater should be cut only along the marked lines.

- You need to fix the IR heater with a stapler or special fasteners, while the fasteners must be located on the transparent sections of the film.

- The distance between the film strips should be no more than 50 mm.

- During installation, make sure that the heating surfaces do not come into contact with flammable or combustible materials.

- Electrical wiring contacts must be carefully insulated using insulating tape and plastic caps.

Film infrared heating is mounted in four stages:

- Calculation of materials for the installation of a film heating system.

- Carrying out work on thermal insulation of the ceiling.

- Installation of elements of the heating system, installation of a temperature sensor.

- Connection to the network and thermostat.

After determining the required amount of materials and their purchase, proceed to the thermal insulation of the ceiling. To do this, use a foil heat insulator (folgoizol penofol and others). The material should be reinforced over the entire surface of the ceiling and go a little on the walls to reduce heat loss.

An IR film is mounted on top. Fix it on the fasteners included in the kit, positioning it so that it falls on the places marked for the cut - this way the heating elements will not be damaged.

When the film is fixed, on the one hand it is necessary to isolate the contacts, and on the other, connect the wires. Then you need to install a thermostat on the wall. Testing the operation of the system. If it works as it should, move on to finishing.

You can close the IR film with various finishing materials: MDF, plastic clapboard, drywall and others. The main thing is that they do not have heat-reflecting properties.

House heating infrared heaters - modern alternative to traditional electrical systems. Its high cost is justified by ease of use, ease of installation, reliability and efficiency.

Efficiency and economy are the main indicators when choosing infrared ceiling heating. The cost of energy sources is high, and many owners of private houses try to use them rationally. These two indicators form the basis for the creation of a unique and modernized IC heating system. How does this system work and is it possible to install it yourself?

Ceiling infrared heating

Arguments for and against IR panels

Those who plan to install infrared heating panels in their homes naturally want to know not only about their advantages, but also about the moments that can cause inconvenience. Therefore, an objective assessment of both the positive aspects and the disadvantages of this heating method is presented below.

In favor of infrared panels, the following pros can be given:

- Impact resistance and increased strength. IR panels are not afraid of even bumps and falls. And all thanks to its shockproof body and heavy-duty materials.

- Easy installation and simple operation. It is only necessary to fix the panel on the wall or ceiling and plug it into a power outlet. This does not require any special knowledge, welding machine, etc.

- Small energy consumption. Firstly, there are no energy losses for air heating.Secondly, IR radiation reduces the overall temperature of the space by 3-5 ºС, which saves up to 25% energy. That is, the air temperature is felt on average 5 degrees higher than that shown by the thermometer during measurement. And all because not only the air that is measured is heated, but also the objects in the room and even the person himself.

- Quiet operation. Such heaters will not “crack” or “gurgle”, which means they will not interfere with sleep and other vital processes.

- Independence from power surges. Even if the voltage changes, this will not affect the operation of the heater in any way.

- Preservation of normal air humidity. IR thermal panels do not dry out the air, like other electric convectors, which make breathing difficult and dry the mucous membranes. They do not allow mixing of air (cold / warm), so the dust caused by heated air masses does not rise.

- Compact dimensions and lack of related equipment. No need to install bulky piping, radiators, boilers.

However, quite often on the Internet you can find information about the dangers of infrared radiation and the negative effect on the human body. Such myths have no scientific justification under them.

Radiant heating benefits in that it evenly warms up the room without creating zones of "stagnation" of warm masses.

On the contrary, in this sense they are “more useful” than other common heating methods, because:

- do not dry the air and do not burn out the air;

- do not raise dust, as there is no convection;

- keep the body in good shape due to a slight temperature contrast.

In addition, such heaters are even recommended for people suffering from joint diseases, since they warm up the human body itself well, as a result of which inflammation and pain soon disappear.

When long-wave infrared rays hit the skin, its receptors are irritated, to which the hypothalamus reacts, the smooth muscles of the vessels relax, as a result of which they expand.

Thus, infrared rays contribute to the stimulation and improvement of blood circulation.

Please note that they are absolutely harmless to the skin, unlike UV rays, which can even cause pigmentation changes. If you use infrared radiation rationally, it will be difficult to find flaws

Infrared heating panels are not harmful to health. On the contrary, they help to cure diseases of the joints, it is not for nothing that they are used in medicine.

In cases of poor-quality service and negligent attitude of devices, the following not very pleasant consequences are possible:

- If installed incorrectly, the space will warm up in the wrong area that would need to be processed in the first place. Infrared radiation is characterized by a clearly defined segment of action.

- The infrared heating system does not always fit harmoniously into the surrounding space.

- Excessive radiation can adversely affect electronics (TV, computer and other electrical appliances). However, it all depends on whether the operating standards are observed and what the dimensions of the room are.

Infrared panels are a new generation heating system. It provides safe and efficient home heating at minimal financial cost.You will not encounter any significant drawbacks when installing or using the panels, because they simply do not exist.

What is radiant heating?

PLEN is a low-temperature film electric heater with a thickness of up to 1 mm, characterized by flexibility and ease of installation. The working surface of the Plen heater is heated in the range of 40-65 °C. This equipment is used to organize IR floor heating, but more often the ceiling method of placement is practiced to create a heating ceiling.

In fact, this is an infrared film with a reflector in which several layers of resistors are installed.

In general, there are only three options for the transfer of thermal energy: direct heat transfer, convection and infrared radiation.

The most common is the second method, when the room is heated by mixing and circulating cold and hot air currents. For this, an electrical device or a liquid heat carrier can be used. But this method has serious drawbacks - excessive drying of the air, significant temperature changes in the room, and rapid cooling.

At the same time, the convective system does an excellent job of heating rooms in which thermal insulation is at a low level. Therefore, this system has become widespread.

Heating with infrared radiation is different. According to physical laws, all bodies with a temperature above -273 ° C emit infrared waves. The higher the temperature of an object, the higher the intensity of its radiation.

The transparent airspace is completely permeable to the propagation of infrared waves.They easily overcome it and are only absorbed by opaque objects such as walls, ceilings, floors or furniture. Absorbing IR energy, the bodies heat up and begin to radiate IR waves more intensely. This is how the room heats up.

Consider the general design principle of film heaters, which include three main components:

- Heating element. Designed for the transformation of electrical energy into heat. When current passes through a heater (tape or wire resistor, carbon fiber), thermal energy is released on it. In this case, it is necessary to take into account the resistivity and the amount of current that passes through it.

- transmitting element. It is necessary to move thermal energy from the heating element over the entire area of the PLEN. Usually, aluminum foil is used as the transmission component, which has a high degree of thermal conductivity. Some models do not have a transmission element.

- emitting element. This is the plane of the electric heater, which consists of a PET film, which, by its physical properties, has a considerable emissivity of infrared waves. Since the PET film is considered an excellent dielectric, it is used in PLEN for reliable insulation of current-carrying parts. Live parts are laminated on both sides.

Radiant heat spreads very quickly, effectively heats the room and maintains the temperature in it for a long time. In addition, IR radiation is better tolerated by living organisms, since we also generate infrared waves. Whereas with the standard method of heating, cold walls and floors absorb our infrared heat, then we feel discomfort and say that we are “pulling”.

In a room with radiant heating, everything is different. Heated objects spontaneously exude heat and nourish a person with it, so it is always comfortable in such a room.

Efficient operation of film heating

The manufacturer claims that its products will work economically and efficiently. However, you need to understand that this is true only for certain conditions.

If, for example, the building is not insulated, it is at least pointless to expect efficient operation from the PLEN film heating system. What requirements must be met to get the most out of infrared equipment?

One of the main ones is thorough thermal insulation of walls, doors and windows in the building. If everything is clear with the latter, then there are some nuances regarding the thermal insulation of the walls.

Wall insulation must be carried out from the outside. Various materials can be used for this: thermal insulation followed by plastering, sandwich panels, etc. To get acquainted with the types of insulation for house walls outside, follow this link.

If you insulate the walls from the inside, infrared heating will be useless.

For the most efficient operation of infrared heating, it is important that the walls of the building are insulated from the outside. Walls insulated from the inside will not be able to accumulate heat. Walls covered with heat-insulating material will not accumulate and give off heat, since the insulator will prevent this.

To equip an efficient heating system, it is not necessary to completely cover the floor or ceiling with IR film

Walls covered with heat-insulating material will not accumulate and give off heat, since the insulator will prevent this. To equip an efficient heating system, it is not necessary to completely cover the floor or ceiling with IR film.

If it is assumed that such heating will be the main one, it is enough to cover 70-80% of the area of the ceiling or floor surface.

To arrange additional heating, it will be enough to cover 30-40% of the area

It is important to choose the right mounting height for the thermostat. For the ceiling version of the film installation, it must be at a height of about 1.7 m from the floor level

For floor installation, it is raised 10-15 cm above the floor. If you make a mistake with the fixing height of the device, the system will not work correctly.

Another important point is to ensure that the current power is sufficient for the full functioning of the system. This must be done, otherwise the cost-effectiveness of the plan will decrease significantly. To solve the problem, it will be enough to install a special load distribution unit.

The device allows you to turn on alternately different circuits of the heating system, thereby increasing the power supplied to each of them.

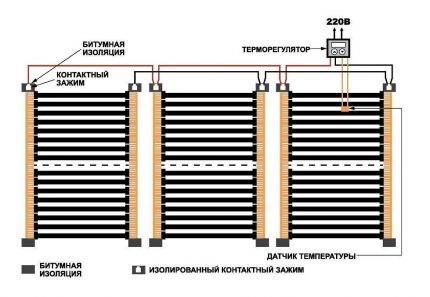

The figure shows the installation scheme of film heaters

The figure shows the installation scheme of film heaters

Installation of the film heater should be carried out only on a special substrate. It has reflective properties and does not allow the base on which the film is laid to absorb infrared radiation.

It is redirected in the opposite direction, which ensures the most efficient operation of the equipment.Without such a substrate, part of the infrared waves is absorbed by the base, which leads to unjustified energy losses.

Installation of infrared film heaters should be carried out only on a special substrate, otherwise heat loss is inevitable.

Another important point is the height of the heated room if the system is fixed on the ceiling. Standard models of film emitters are designed for the infrared wave to cover a distance of no more than 3.5 m.

If it is larger, the radiation does not reach the floor. And, accordingly, the system will not work correctly.

Thus, if the room has high ceilings, you need to choose the floor mounting option or look for more powerful non-standard models of film heaters.

Pros and cons of a film electric heater

A fairly large list of advantages can be devoted to this type of heating system, which, according to manufacturers' forecasts, will help the film infrared electric heater to take a leading position in the consumer market. Disadvantages, of course, also make themselves felt, but they rather relate to the correct installation and operation of the equipment. So, the advantages of heating PLEN are as follows:

- Savings on installation and during operation of the system. The total cost of all necessary equipment and installation work is much less than for any other type of heating, whether electric or gas. And if you believe the words of the manufacturers, then the cost of heating Plain will pay off in just one year, due to the savings in electrical energy consumed;

- High fire safety.As mentioned earlier, resistive elements can only heat up to 45 degrees, which is indisputable proof of fire safety. This property allows you to install such heating even in wooden houses;

- Rational use of free space. Film infrared heating does not require additional installation of any boilers, batteries and pipes, which significantly increases the free space in the house;

- Maintaining the optimal level of humidity in the room. Dry air is a problem for almost all heating equipment, so humidity has to be maintained at the required level in various ways, this is especially true in the winter season. Plain is an exception and absolutely does not harm the normal humidity in the room;

- Does not require maintenance during operation;

- Environmentally friendly materials. The Plain heating system is made exclusively from environmentally friendly materials, and many years of experience have shown its beneficial effect on the human body;

- Big warranty period. As a rule, companies that distribute and install this type of heating provide a guarantee of 10 years;

- Ease of controls. This positive feature lies in the ability to independently set the desired temperature, which will be maintained in the room, as well as in connecting a remote control.

The main disadvantages of film heaters are two main points. The first of them is the obligatory warming of the whole house, and the second is the impossibility of using plaster, painting and wallpapering as interior decoration.