- Advantages

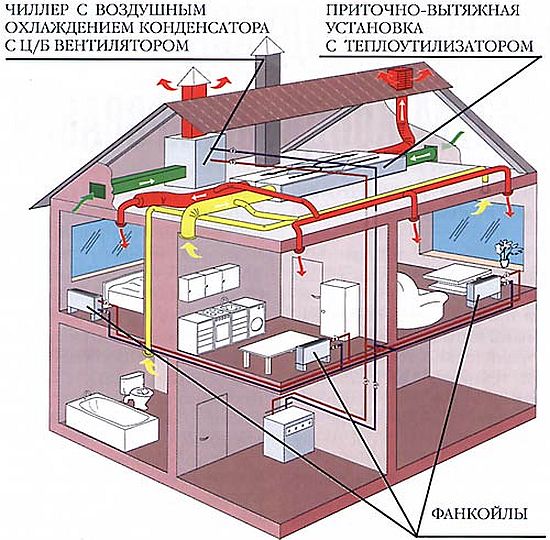

- The device of the chiller-fan coil system

- Fan coil types

- Channel fan coil

- Completion of installation of channel systems

- Wall mounted fan coil

- Cassette fan coil

- For air cooling

- Terminology

- Differences

- Flaws

- Faults

- Basic liquid cooling schemes

- Water or glycol mixtures

- Installation Benefits

- Application area

- Price

- Operation features

- The role of the fan coil in the air conditioning system

- Why install an air conditioner?

- Fancoil and its features

- What is the basis of this system

- Advantages and disadvantages

- Principle of operation

- Unit diagram

- Design features

- Mounting Features

- Conclusions and useful video on the topic

Advantages

Chiller-fan coil differs from similar systems in that it:

- Easy to maintain

. Filters are easy to clean and quick to change - It is possible to serve a large number of consumers, that is, rooms in which fan coil units are installed. Their number is determined by the power of the unit, chiller.

- A device that heats or cools a coolant, a chiller, is installed in one place. And this means that for its placement does not need a lot of space

. - If the pipes have high-quality thermal insulation, and the heat carrier has a high heat capacity, then the distance to the rooms in which air conditioning is performed from the chiller does not matter. You can install it at a considerable distance

. In the case of using gas, this advantage disappears. - Low cost of installation work

. It is due to the use of conventional pipes in the system, standard valves, simple automation. - environmentally friendly

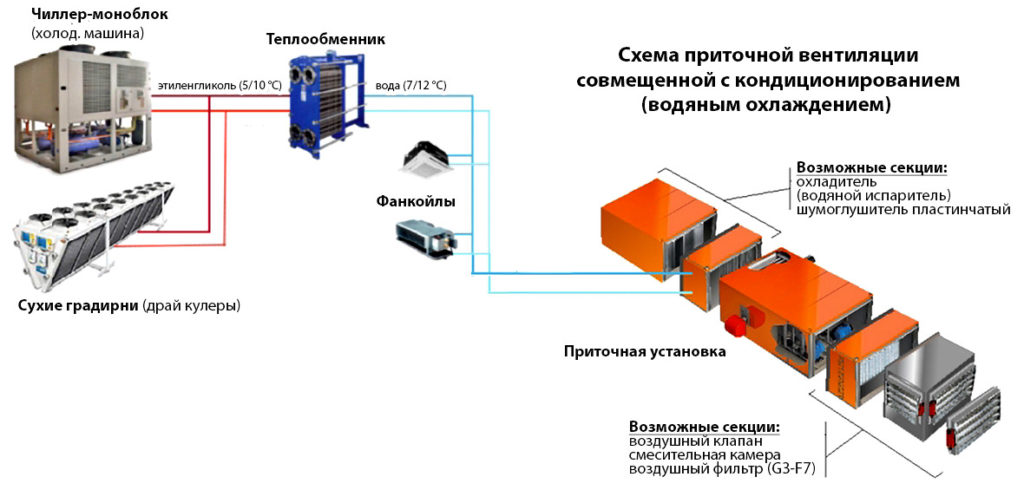

. The heat carrier is water or ethylene glycol mixed with water. The latter, although toxic, can only be poisoned by prolonged inhalation of its vapors. But at the first hit inside the body, it causes a painful cough and forces you to leave the room. The refrigerant, which poses a certain danger, circulates only in the chiller. And it is mounted either in the attic, or, if the device is made in the form of a monoblock, on the roof. - The system can be used together with ventilation

, preferably with a supply and exhaust type, and with heating. - Relatively low cost

the system itself.

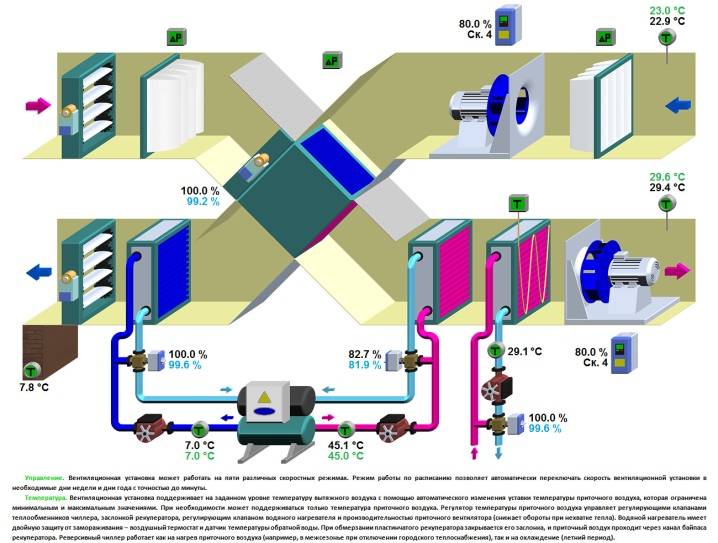

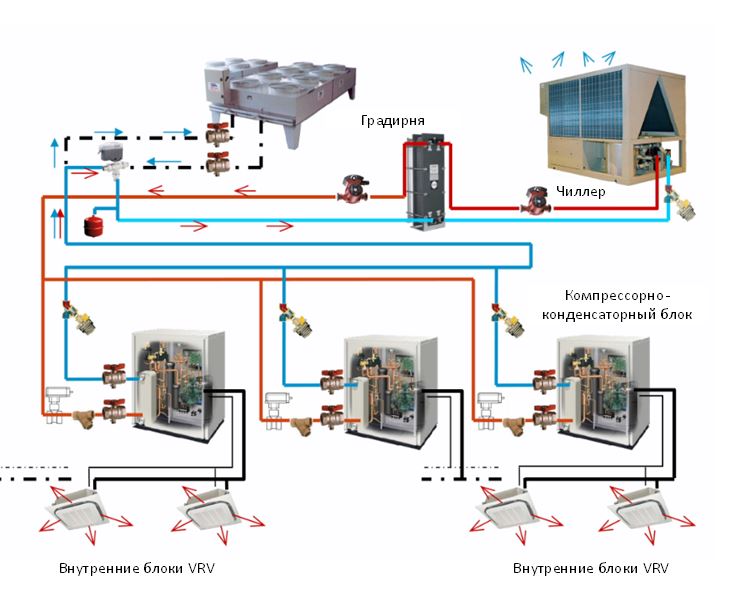

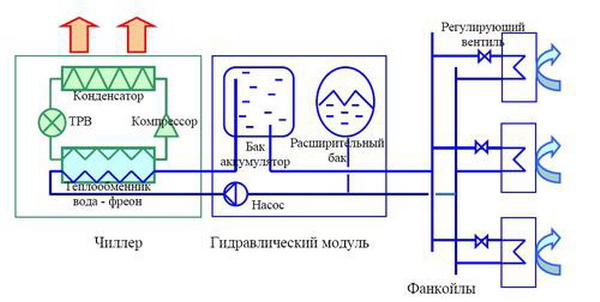

The device of the chiller-fan coil system

Simplified, this air conditioning system looks like this: its external unit is a water-cooling machine, called a chiller, connected by a pipeline with an internal heat exchanger - a fan coil unit, which is blown by a fan.

Such a system is easy to operate and can effectively cool or heat the air in a large room or in several rooms at once. It does not have such restrictions as freon. The length of the line with the coolant is limited only by the capacity of the booster pumps.

In addition, this air conditioning option can operate at any ambient temperature, unlike freon, which must be stopped already at -10 ° C in order to avoid breakage.To move the coolant, you can use ordinary water pipes, both metal and PVC, which significantly reduces the cost of the entire system. Chiller installation

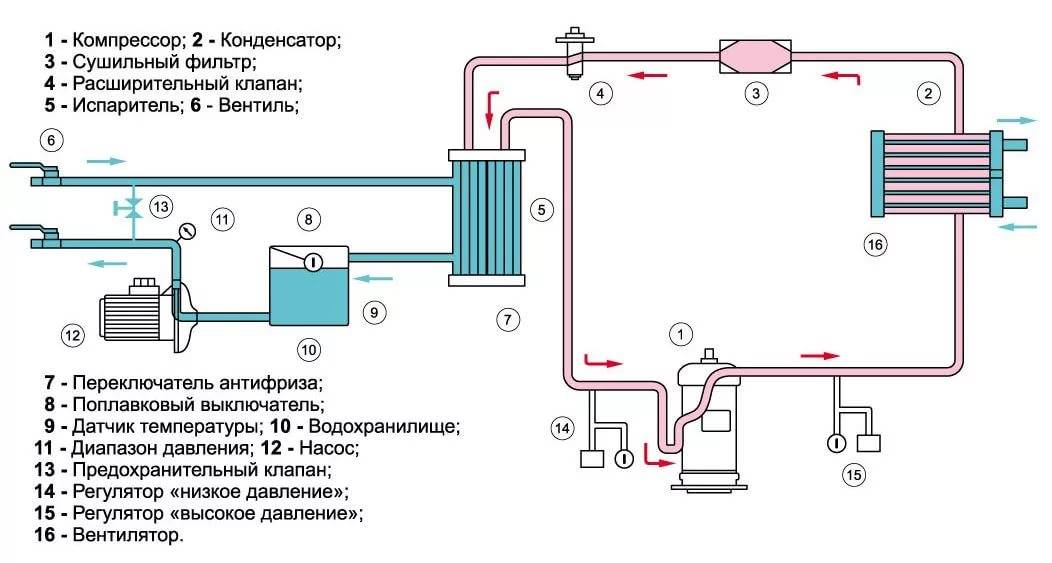

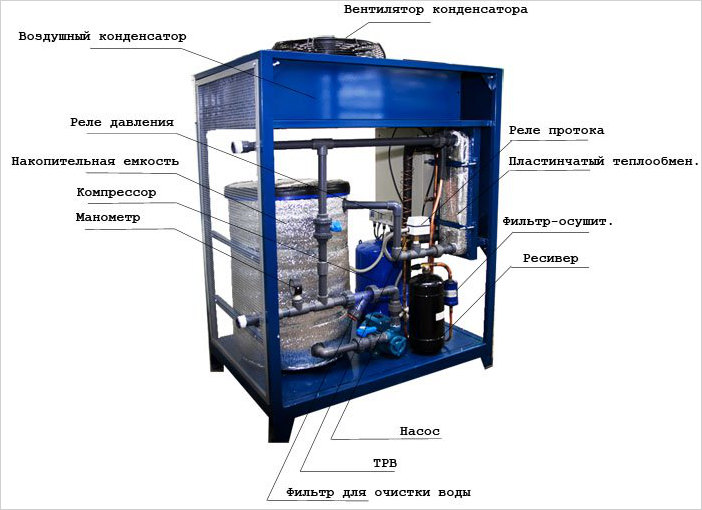

A chiller is a conventional powerful refrigeration machine in which an evaporative heat exchanger discharges the accumulated cold not into the air, as in an air conditioner, but into water, which, when cooled, enters the fan coils through the pipeline system. There are two main types of chillers - these are absorption and vapor compression. Absorption ones are quite expensive, bulky and have a rather narrow application. The most common are vapor compression chillers, which come in several types:

- Chillers with air cooling of external installation. In such installations, the cooling of the heat exchanger-condenser occurs with the help of axial fans.

- Air-cooled indoor units. In them, the intake of air for cooling and the release of hot air flow is carried out through air ducts, for the movement of which a centrifugal pump is used.

- Refrigeration units with water-cooled heat exchanger. Most often they are mounted in places where it is possible to cool the condenser with running water from natural reservoirs.

- Chillers are reversible. They allow both cooling the air and heating it, so that they can be used in air conditioning systems without installing additional water heating equipment.

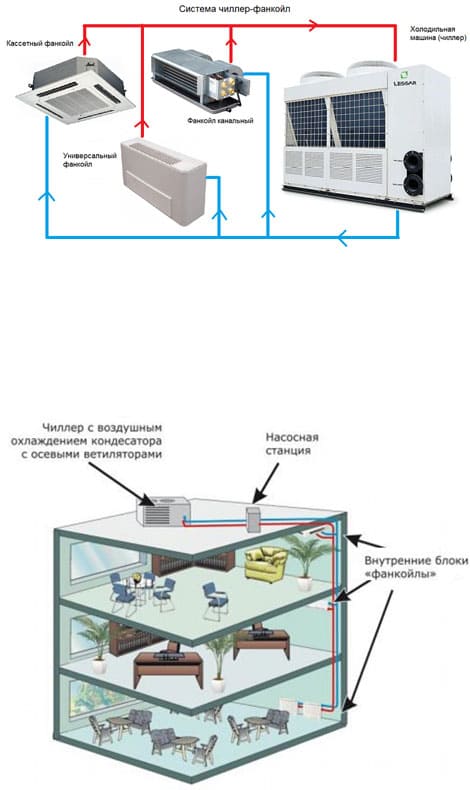

Fan coil device

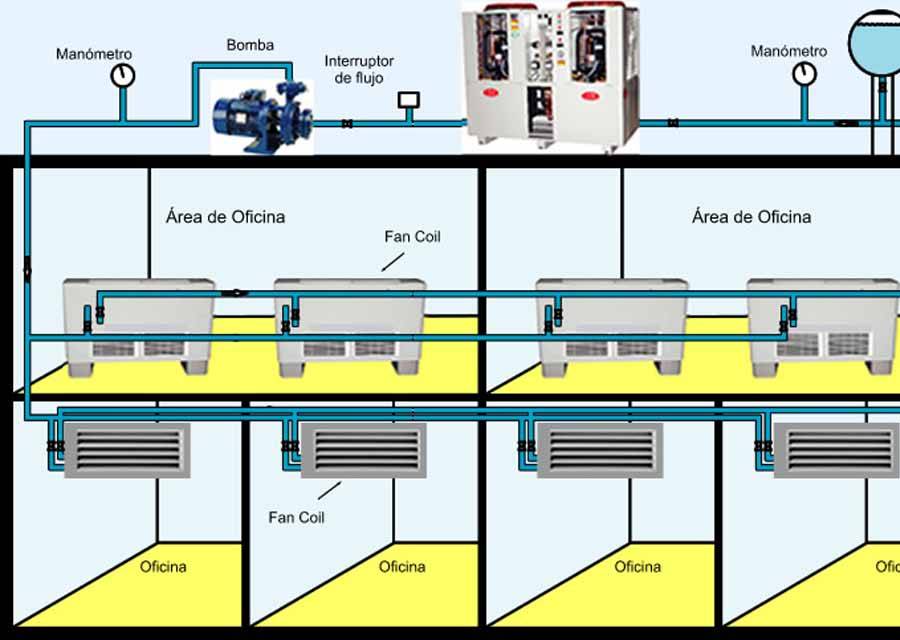

Fancoils are the so-called indoor units of the chiller-fancoil air conditioning system, which are also called closers. Their device consists of a heat exchanger and a powerful fan that blows it.In addition, they are equipped with easily removable air filters and a control unit. In more modern models, wireless control panels for the device are provided. There are several types of this equipment:

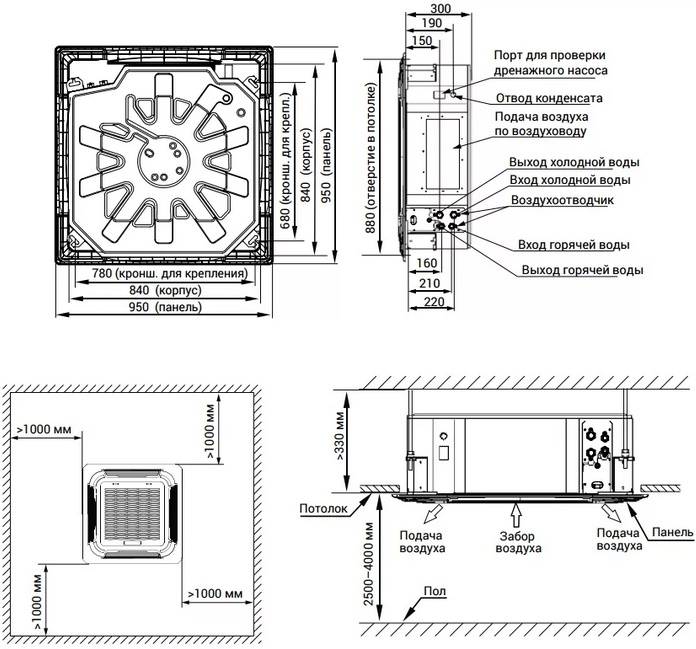

- Cassette fan coil units are designed for cooling or heating air in large rooms, the design of which provides for suspended ceilings. It is in them that these devices are mounted. They can distribute the airflow on two or four sides.

- Channel fan coil units are mounted in separate rooms. Air intake is carried out through separate air ducts, and air is discharged into the premises through air ducts located behind suspended ceilings.

Fancoils are divided into: wall-mounted, floor-mounted and ceiling-mounted. By the way, many companies produce universal devices that can be mounted both on the wall and on the ceiling. Optional equipment

Fancoils are divided into: wall-mounted, floor-mounted and ceiling-mounted. By the way, many companies produce universal devices that can be mounted both on the wall and on the ceiling. Optional equipment

In order for the equipment to operate smoothly and year-round, various devices and devices are used that significantly expand the functions of this air conditioning system.

- To be able to control the air temperature in each room, in front of each indoor unit - fan coil unit, special devices are installed that allow you to adjust the coolant flow.

- In addition, a hot water gas boiler is installed to heat the air, which works in the cold season instead of a chiller.

- It is also equipped with a storage and expansion tank to compensate for the expansion of the coolant when heated.

Fan coil types

Like conventional air conditioners, there are several types of equipment, depending on the intended installation site.A wide range allows you to place equipment almost anywhere.

Channel fan coil

The positive aspects include the possibility of providing a completely hidden installation: all communications, including equipment, are sewn under the draft ceiling.

An example of the installation of channel blocks. First stage.

The second stage, the repair is over. Ceiling option gratings.

Wall-mounted option for air supply through grilles.

Indoor unit with air ducts: installation

Completion of installation of channel systems

As a result of the completion of work related to the installation of a duct fan coil unit, only decorative grilles are visible, to which rectangular or round air ducts are connected for distributing cooled or heated (depending on the type and mode of operation) air. Increasingly, equipment of this type is being installed in new residential complexes. The only negative is the need to additionally lower the finishing ceiling at the installation sites of the fan coil itself and during the laying of communications.

Wall mounted fan coil

It is mounted where it is not possible to place a channel type, and is often installed at the expense of savings: when the developer commissions a residential complex, communications for the supply of coolant are already installed in the apartment, all that remains is to connect. There is no need to lay additional communications, such as air ducts, silencers, mixing chambers, etc. Just choose a place for installation of internal block. Yes, it will be visible and much easier than a regular freon air conditioner in an apartment, but cheaper.

The lines from the chiller are brought into the apartment

Laying piping to indoor units

An example of connecting a pipeline to a fan coil unit

The result of the installation of fan coil units in the apartment

Cassette fan coil

office space central system

- increase efficiency due to modern engineering solutions for cooling and heating;

- avoid "Shanghai" from "birdhouses" of external blocks on the facade of the building, installed by tenants.

This type is becoming more and more popular. Distribution in four independent directions makes the air exchange more comfortable, no drafts, easy maintenance, and concealed installation (like a duct type) - only a decorative panel is visible. But, like ducted fan coil units, cassette units also need free space under the ceiling.

Below are a few examples installation of cassette fan coils and air conditioners at our facilities:

Connection, piping of a cassette fan coil unit.

Installation of equipment under repair.

Fancoils and ventilation in the office.

Cassette type in a country house.

But, we must pay tribute, this is still a more commercial type of equipment: 97% of the objects on the "cassettes" are commercial real estate, offices, government agencies.

Horizontal installation - it is also under-ceiling - is used more in commercial premises and general-purpose premises, where it is not possible to lower the final ceiling and in which there are no special requirements for interior design.

For air cooling

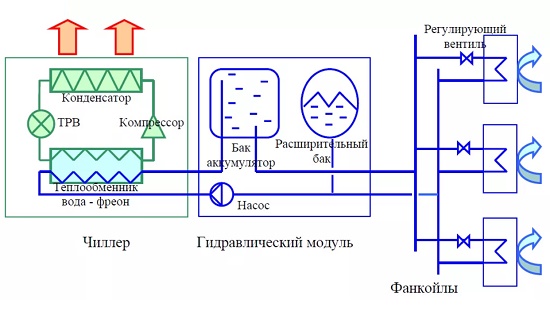

Chiller-fancoil system - a centralized, multi-zone air conditioning system in which the coolant between the central cooling machine (chiller) and local heat exchangers (air cooling units, fan coil units) is a cooled liquid circulating under relatively low pressure - ordinary water (in tropical climates) or an aqueous solution of ethylene glycol ( in temperate and cold climates). In addition to the chiller (s) and fan coils, the system includes piping between them, a pumping station (hydraulic module) and an automatic control subsystem.

Terminology

There is no translation for the English "chiller" in GOST 22270-76 "Equipment for air conditioning, ventilation and heating". For the term “fan coil unit”, GOST gives the translation “fan coil” (a closer that, using a built-in fan, locally recirculates and supplies a mixture of indoor air with outdoor air, previously processed in a central air conditioner, as well as heating and / or cooling air).

Differences

Compared to VRV/VRF systems that circulate gas refrigerant between the chiller and the local units, chiller-fan coil systems have the following differences:

Twice the maximum distance between chiller and fan coil units. The length of the routes can reach hundreds of meters, since with a high heat capacity of the liquid heat carrier, the specific losses per linear meter of the route are lower than in systems with a gas refrigerant.

Distribution cost. To connect chillers and fan coils, ordinary water pipes, valves, etc. are used.Balancing water pipes, that is, equalizing the pressure and flow rate of water between individual fan coil units, is much simpler and cheaper than in gas-filled systems.

Safety. Potentially volatile gases (gas refrigerant) are concentrated in the chiller, which is usually installed outdoors (on the roof or directly on the ground). Piping accidents within a building are limited by the risk of flooding, which can be reduced by automatic shut-off valves.

Flaws

Chiller-fan coil systems are more economical in terms of electricity consumption than rooftop systems, but certainly lose in efficiency to systems with variable refrigerant flow (VRF). However, the ultimate performance VRF-systems is limited (the volume of refrigerated premises is up to several thousand cubic meters).

Faults

- Freon leak. Freon leakage can occur as a result of a leaky connection of the freon circuit.

- Compressor failure. In the compressor, as a rule, the stator winding burns out or the valves (piston group) are destroyed.

- Moisture in the refrigeration circuit. Moisture (water) can get into the refrigeration circuit as a result of a leak in the evaporator, as a result of which the two freon-water circuits are mixed.

Basic liquid cooling schemes

- Direct cooling.. The most common option. The liquid is cooled in the liquid/freon heat exchanger. The temperature difference between the inlet/outlet is no more than 7°C. Standard air conditioning mode +7/12°С.

- Cooling using an intermediate coolant. This type of circuit is used when the temperature difference between the liquid at the inlet and outlet of the chiller is more than 7°C.

Water or glycol mixtures

The main disadvantage of water is its high freezing point. Under normal conditions (that is, at atmospheric pressure), once the temperature drops below zero, the water will freeze, and if it freezes in the pipes, the system will defrost. This happens because the density of ice is less than the density of water, i.e. the volume of ice is greater, and the ice literally breaks the pipelines.

There is only one way out - to use a coolant, the freezing point of which is lower than the temperatures typical for the winter period of time for this particular region. And, given the excellent physical properties of water, they simply began to add other substances to it in such a way as to achieve the required freezing temperature of the mixture.

The most widely used aqueous solutions of glycols: ethylene glycol and propylene glycol. The first one is more favorable in terms of its thermodynamic properties and its cost is lower, while the second one is safe and environmentally friendly.

Also, keep in mind that ethylene glycol is poisonous. When using it, the question inevitably arises of complicating maintenance work and subsequent disposal. Moreover, at some sites with a permanent stay of people, its use is prohibited.

However, you should always consider both options and make your own informed choice on a case-by-case basis.

Installation Benefits

Above, we have already talked about the advantages of the system itself. We would like to emphasize once again that it is not difficult to mount it.

The cost of components is low. It is easy to maintain and repair. In addition, it can be designed for any type of building.

Application area

Basically, devices of this type are used in:

- In office premises.

- hospitals.

- Supermarkets and other outlets.

- hotel complexes.

Price

The price of the product depends on the cost of components, that is, the chiller and fan coil unit.

For example, consider the cost of two products.

Fancoil series TRUST

- 12678 rubles.

Homo series

– 15609.

Devices are chosen randomly. At the same time, the first unit has higher productivity and it serves a large area of \u200b\u200bthe premises, but its price is lower than that of the second.

Hence the conclusion: the main factor that determines the price of the unit is the manufacturer.

Operation features

The main feature of servicing this type of unit is to charge the device with refrigerant.

In this case, you must strictly follow the instructions set out in the technical documentation of the device. In all other respects, the system is serviced in the same way as similar units.

February 2019

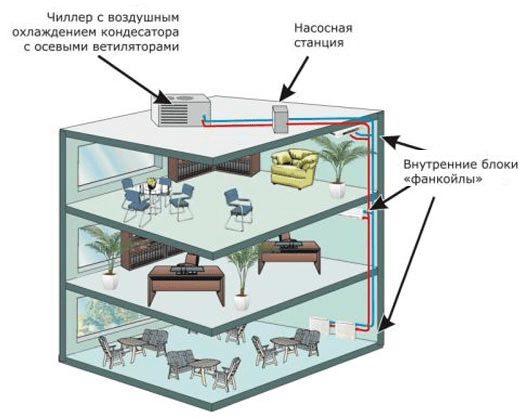

The role of the fan coil in the air conditioning system

Fancoil is an important element of a centralized air conditioning system. The second name is a fan coil. If the term fan-coil is literally translated from English, then it sounds like a fan-heat exchanger, which most accurately conveys the principle of its operation.

The design of the fan coil includes a network module that provides connection to the central control unit. The durable case hides structural elements and protects them from damage. Outside, a panel is installed that evenly distributes air flows in different directions

The purpose of the device is to receive media with a low temperature.The list of its functions also includes both recirculation and cooling of the air in the room where it is installed, without the intake of air from outside. The main elements of the fan-coil are located in its body.

These include:

- centrifugal or diametral fan;

- heat exchanger in the form of a coil consisting of a copper tube and aluminum fins mounted on it;

- dust filter;

- Control block.

In addition to the main components and parts, the design of the fan coil unit includes a condensate trap, a pump for pumping out the latter, an electric motor, through which the air dampers are rotated.

Pictured is a Trane ducted fan coil unit. The performance of double-row heat exchangers is 1.5 - 4.9 kW. The unit is equipped with a low-noise fan and a compact housing. It fits perfectly behind false panels or suspended ceiling structures.

Depending on the installation method, there are ceiling, channel, mounted in channels, through which air is supplied, unframed, where all elements are mounted on a frame, wall-mounted or console.

Ceiling devices are the most popular and have 2 versions: cassette and channel. The first are mounted in large rooms with false ceilings. Behind the suspended structure, a body is placed. The bottom panel remains visible. They can disperse air flow on two or all four sides.

If the system is planned to be used exclusively for cooling, then the best place for it is the ceiling. If the design is intended for heating, the device is placed on the wall in its lower part

The need for cooling does not always exist, therefore, as can be seen in the diagram that transmits the principle of operation of the chiller-fincoil system, a container is built into the hydraulic module that acts as an accumulator for the refrigerant. The thermal expansion of the water is compensated by an expansion tank connected to the supply pipe.

Fancoils are controlled both in manual and automatic modes. If the fan coil is working for heating, then the cold water supply is cut off in manual mode. At work it for cooling block hot water and open the way for the flow of the cooling working fluid.

Remote control for both 2-pipe and 4-pipe fan coil units. The module is connected directly to the device and placed near it. The control panel and wires for its power are connected from it.

To work in automatic mode, the temperature required for a particular room is set on the panel. The specified parameter is supported by thermostats that correct the circulation of coolants - cold and hot.

The advantage of a fan coil unit is expressed not only in the use of a safe and cheap coolant, but also in the rapid elimination of problems in the form of water leaks. This makes their service cheaper. The use of these devices is the most energy-efficient way to create a favorable microclimate in a building.

Since any large building has zones with different temperature requirements, each of them must be served by a separate fan coil unit or a group of them with identical settings.

The number of units is determined at the design stage of the system by calculation.The cost of individual components of the chiller-fan coil system is quite high, therefore, both the calculation and the design of the system must be carried out as accurately as possible.

Why install an air conditioner?

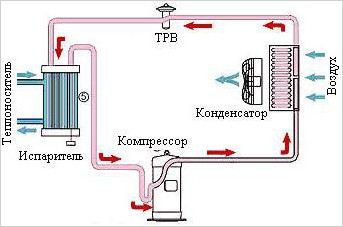

An air conditioner is a device that creates the most comfortable temperature in the room, with its subsequent maintenance. The mechanism of operation of the air conditioner is based on the transformation of the aggregate state of the refrigerant. Changes depend on temperature and pressure in a closed system. The design of the air conditioner consists of the following elements: ventilation system, compressor, condenser, condenser fan, dryer, expansion valve.

Schematic representation of the operation of the air conditioner:

Classification of air conditioners by purpose, type and area of \u200b\u200buse:

Offices, cottages, rooms in living quarters.

Premises ranging from 50 to 300 m². Trade halls, utility rooms, production areas.

Premises over 300 m².

Administrative buildings, sports complexes, specialized premises.

Fancoil and its features

Fancoil includes the following elements:

- heat exchanger;

- fan;

- air filter;

- automatic control subsystem.

The fan coil mechanism consists of the following steps:

- Through pipes, the chiller transports cold water to the fan coil heat exchanger;

- Meanwhile, the fan provides airflow;

- From this, the coolness from the water enters the building.

The functionality of the fan coil unit also includes space heating. The peculiarity is that this mechanism can both air-condition the room and heat at the same time. The remote control comes to the rescue here, thanks to which you can set the desired temperature.

Fancoil operation scheme:

The scope of fan coils is extensive.They are perfect for bars, restaurants, public institutions, hostels, industrial buildings.

What is the basis of this system

As mentioned above, the most common chillers are vapor compression devices. The principle of operation of this type of chiller is quite simple:

Fan coil units can have one or two heat exchangers, respectively, the chiller-fan coil system can be two-pipe or four-pipe. In the first version, two pipes depart from the heat exchanger, through which only cold and hot working fluid circulates, and in the second, to supply the coolant from the chiller to the fan coil and supply hot water from the heating to the second heat exchanger.

Advantages and disadvantages

The main disadvantage of this air conditioning option is the complexity and, accordingly, the high cost of installation. Also, a very important aspect in its effective operation is the choice of equipment installation site. In addition, there are other disadvantages:

- The noise of the system.

- The high price of devices.

- Low energy efficiency.

The main advantage of the chiller-fan coil system is that there are no restrictions on the length of communications between fan coil units.

. There is another significant advantage - you can add the required number of indoor units to an already operating system, as the building is put into operation. Very often this property is decisive when choosing a particular air conditioning system. In addition, the advantages include the following:

- Safety and environmental friendliness, due to the absence of freon and other volatile gases in its lines.

- It does not require the presence of several external blocks, which significantly spoil the appearance of the building.

We love it when the temperature is comfortable at home, even if it's hot or cold outside. Air conditioners save us in the summer. But can one air conditioner cope with a large private house? But what if you need to cool an office or an entire shopping center?

Many people think that air conditioners are limited. Of course, this type is the most common, but there are other types that are no less effective. One of them is a chiller-fan coil air conditioning system. The word is complicated, but it is not difficult to guess from it what this system consists of. Let's try to disassemble each of the parts of the system - fan coil and chiller - and understand what are its advantages.

Principle of operation

The chiller, which is an air conditioner, heats or cools the coolant entering it. It can be water or other non-freezing liquid. Then, with the help of pumps, the liquid is pumped into the system and transferred through the pipes to the fan coil units.

This device receives air from the room, which is mixed with the help of a fan with the air inside the unit, already heated or cooled.

After this operation, the air mixture is released into the external environment. This is how the air conditioning of the premises occurs with the help of a chiller-fan coil.

Unit diagram

The chiller heat exchanger is connected to the pump and storage tank. An expansion tank is also displayed on the pump. The coolant is supplied to the fan coils through a pipeline through a system of control valves.

Design features

The main feature of the system is that a chiller-fan coil project is developed individually for each building.For example, the design of one building does not allow the chiller to be placed anywhere other than on the roof. And the other is built in such a way that the main device of the system can only be located in the attic.

The main feature of the system is that a chiller-fan coil project is developed individually for each building.For example, the design of one building does not allow the chiller to be placed anywhere other than on the roof. And the other is built in such a way that the main device of the system can only be located in the attic.

In addition, the development takes into account the requirements for the microclimate created in the premises, their purpose, and the infrastructure around the building.

The chiller, its type and modification, is selected in accordance with the specified requirements, the number of fan coil units is also determined, how the system will be used, the intensity of its operation, what its mode will be, whether the air will be cooled or, conversely, heated, or both , and others together.

Mounting Features

Given the complexity of fan coil-chiller systems, highly professional specialists should be involved in its installation and configuration. Only they will be able to perform high-quality installation of fan coil units by performing competent:

- installation of the unit in the place where its operation will be most effective;

- assembly of piping units by installing the necessary taps, valves, temperature and pressure control devices;

- laying and thermal insulation of pipes;

- installation of a condensate drainage system;

- work on connecting devices to the mains;

- pressure testing of the system and checking its tightness;

- carrier (water) supply.

They will also make all the necessary calculations before starting work, taking into account what functional load this or that fan coil unit will perform, as well as the features of each room in the building.

Thus, you could be convinced not only that fan coil-chiller systems are very efficient, economical and reliable, but also that they require complex installation and commissioning of the system.And for this, it is necessary to involve employees of organizations specializing in the creation of such turnkey systems.

The multi-zone climate system chiller-fan coil is designed to create comfortable conditions inside a large building. It works constantly - it supplies cold in summer, and heat in winter, warming the air to a predetermined temperature. It’s worth getting to know her device, do you agree?

In our proposed article, the design and components of the climate system are described in detail. Methods for connecting equipment are given and analyzed in detail. We will tell you how this thermoregulation system is arranged and functions.

The role of the cooling device is assigned to the chiller - an external unit that produces and supplies cold through pipelines with water or ethylene glycol circulating through them. This is what distinguishes it from other split systems, where freon is pumped as a coolant.

For the movement and transfer of freon, refrigerant, expensive copper pipes are needed. Here, water pipes with thermal insulation perfectly cope with this task. Its operation is not affected by the outdoor temperature, while split systems with freon lose their efficiency already at -10⁰. The internal heat exchange unit is a fan coil unit.

It receives low temperature liquid, then transfers the cold to the room air‚ and the heated liquid returns back to the chiller. Fancoils are installed in all rooms. Each of them works according to an individual program.

The main elements of the system are a pumping station, a chiller, a fancoil. The fancoil can be installed at a great distance from the chiller. It all depends on how powerful the pump is. The number of fan coil units is proportional to the chiller capacity

Typically, such systems are used in hypermarkets‚ shopping malls‚ buildings‚ built underground‚ hotels. Sometimes they are used as heating. Then, through the second circuit, heated water is supplied to the fan coils or the system is switched to a heating boiler.

Conclusions and useful video on the topic

Video #1 Everything about the device, operation and principle of operation of the thermoregulation system:

Video #2 About how to install and commission the chiller:

The installation of a chiller-fan coil system is suitable for medium and large buildings with an area exceeding 300 m². For a private house, even a huge one, the installation of such a thermoregulation system is an expensive pleasure. On the other hand, such financial investments will provide comfort and well-being, and this is a lot.

Please write your comments in the box below. Ask questions on points of interest, share your own opinions and impressions. Perhaps you have experience in the field of installing a chiller-fan coil climate system or a photo on the topic of the article?

The chiller-fancoil system is the most advanced in terms of space cooling or heating, but it requires preliminary development of project documentation, as well as special knowledge in the field of air conditioning installation, electrical circuits. The system is complex, in addition, it needs regular maintenance. With the help of the equipment, it is possible to heat not only small rooms, but also industrial facilities with large production areas, as well as residential buildings.