- How to make a chimney valve with your own hands?

- Manufacturing technology at home

- Multifunctional butterfly valve

- Universal fixture

- How to install a chimney damper

- DIY manufacturing

- Manufacturing of sliding gate

- Throttle valve manufacturing instructions

- Rooftop chimney trim

- Materials and methods of sewing

- Functions, purpose and characteristics

- What is a valve for?

- Principle of use

- Do-it-yourself chimney valve installation

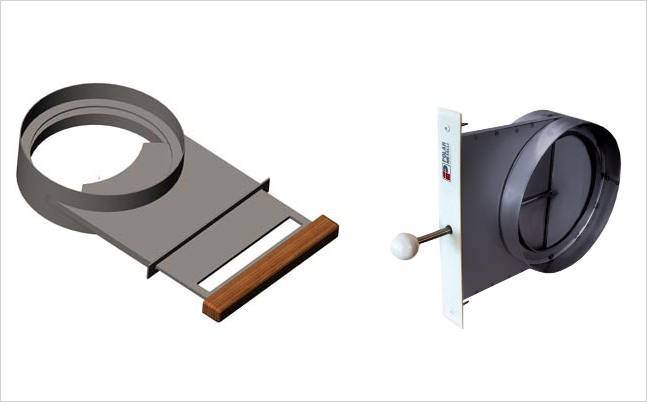

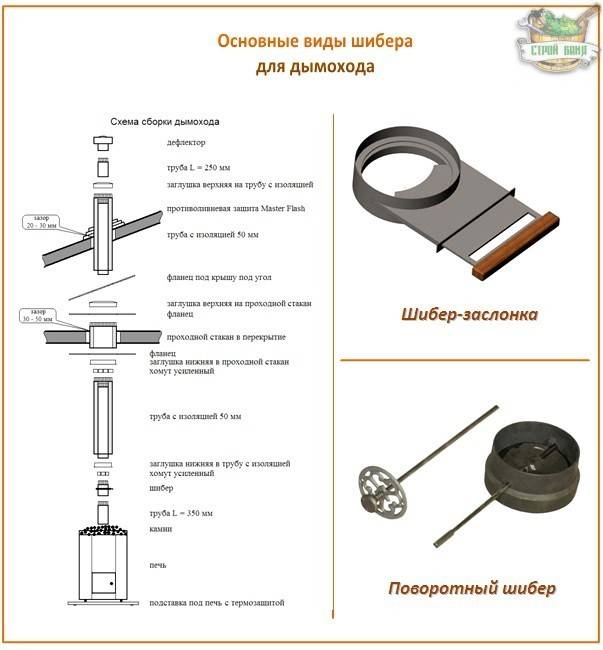

- Main types of dampers

- Retractable model

- Cast iron products

- Throttle variant

- High quality stainless steel blade

- Features, characteristics and purpose of the gate

- Varieties of gate valves

- How to make a gate valve with your own hands

- Preparation of materials and tools

- Drawing up a diagram (drawing)

- Marking and cutting parts

- Valve installation steps

How to make a chimney valve with your own hands?

Many owners are interested in the question: how to make valves in round pipes? For a round or square chimney, you can make a valve with your own hands. For round structures, a rotary valve is best suited, however, you can also use a horizontal one.

The gate valve can be made by hand, as its design is very simple.Self-production of this shaped element of the chimney structure is relevant if the nearest stores do not have a valve of the required section.

The step-by-step process for making a chimney valve looks like this:

- First of all, it is necessary to prepare a frame in which the sliding plate will be located. It is recommended to make a frame made of heat-resistant stainless steel. The width of the shelves of steel corners should be from 3.5 to 4.5 cm. The corners are joined using welding equipment.

- At the second stage, you need to make a hole for the axle. It is worth remembering that if you need to make the shutter with a "straight" turn, then it is recommended to drill a hole at a point that corresponds to the center of the parallel sides of the frame. And for devices that rotate at an angle, the hole is made diagonally.

- Next, you need to install special bushings that can be made from ordinary pipes. The sleeve size should be approximately half an inch, which corresponds to 1.25 cm. Welding equipment must be used to install the tubes. Bushings should not interfere with the movement of the axis of the bar.

- Then the workpiece is selected for the gate plate. To do this, you need a sheet of stainless steel of the appropriate thickness, from which you need to cut a part that fits the section of your chimney. It is worth noting that the damper thickness can be higher than 1 mm (for example, 2 or 3 mm).

- At the fifth stage, the finished plate is inserted into the frame and welded to its axis. Experts advise leaving a small gap between the frame and the plate (at least 1 mm).

- The restrictive element is fixed, which is necessary to hold the gate plate in the desired position.

- And, finally, it remains only to attach a handle to the axis, which is necessary to regulate the position of the valve.

Manufacturing technology at home

Qualified specialists always focus on the fact that even a novice master can make a rotary and retractable gate. After all, in order for the finished product to perfectly cope with its main task, you need to correctly make all the necessary measurements.

If the finished damper fits tightly into the chimney, then over time it may jam, as it will be affected by high temperature. And when there is a large gap between the valve and the pipe, it will be difficult to regulate the intensity of thrust during operation.

Multifunctional butterfly valve

For the manufacture of this kind of gate, you need to use a steel corner 30x30 mm, as well as strong sheet steel, the thickness of which is at least 1.5 mm. The manufacturing process itself consists of several main stages, which must be implemented in strict sequence:

- Initially, you need to make measurements of the inside of the chimney. This is done in order to prevent errors during the manufacture of a frame from a corner, which is fixed by a welding machine.

- On one side of the frame, a small hole must be drilled exactly in the center (diameter 7-8 mm). It is useful for the rotary axis.

- A similar hole must be made on the other side of the frame.

- The damper plate must be cut from a steel sheet. This part must fully correspond to the internal dimensions of the frame being made.

- To make a guide axis, you need to take a piece of wire with a diameter of 9 mm and a length that will exceed the size of the frame itself by 7 cm. Threads must be cut on one side of the wire (a die does this best).

- The finished axle is carefully threaded into the holes on the frame and fixed with a nut.

- All sections on the plate are processed with a grinder and inserted into the frame.

- At this stage, the master must weld the axis exactly in the center of the plate.

- It remains only to make a comfortable handle for the guide from high-quality improvised materials.

Universal fixture

Modern gate valves include the valve itself, as well as a special guide frame. That is why, before starting work, the master must measure the internal section of the pipe or brick chimney. In accordance with the available measurements, a neat rectangle is cut out of sheet steel (thickness 5 mm). On one side, a small longitudinal fold is made, the width of which should not exceed 30 mm.

These manipulations are necessary in order to make it convenient to extend the finished damper. Each cut must be ground, due to which the dimensions of the product are reduced immediately by 2 mm on each side. Such actions of the master will ensure the free movement of the damper inside the chimney.

When the gate is made for a brick fireplace, the frame itself can be made of thick steel wire, the diameter of which is within 6 mm. During this procedure, the metal blank is simply bent in the shape of the letter P in strict accordance with the available measurements.

If the chimney has a rectangular shape and is made of steel, then the frame is best made from a metal strip 2 mm thick and up to 35 mm wide.The prepared strip is bent along, while leaving a neat gap along the thickness of the plate. Only then can small cuts be made in two places at an angle of 45 ° to give the workpiece a U-shape. All gaps in the places of cuts must be welded end-to-end.

To connect the ends of a homemade damper, you need to use two pieces of metal, which should be positioned in such a way that the gate leaf passes freely between them. At the end of all these manipulations, the master should have a rectangular frame with grooves for the shutter.

To make a valve in a round pipe, you need to take two identical metal sheets 2 mm thick. Round holes are cut in the center according to the diameter of the chimney. The valve plate must be manufactured separately. After that, the sheets are interconnected using a welding machine.

It is necessary to weld only three sides around the perimeter so that the holes of the finished gate on the pipe exactly match. A gap of 5 mm must be left between the top and bottom sheet. On this, the gate manufacturing process can be considered completed, since the master only has to insert the valve and fix the finished product on the chimney.

How to install a chimney damper

The gate is installed simultaneously with the installation of the heating system. It can be placed in several ways, but the most common is to mount the damper on the first meter of the chimney. Such placement is quite justified, since in this case it is convenient to control the valve. Let's consider this installation method in more detail.

After laying the first row of brick chimney, you can proceed with the installation of the gate. You need to start by cutting out a piece of the valve.In one of the bricks, make a through hole for the handle and lay out the second row, taking into account the thickness of the layer of sand-cement mixture on which the gate will be placed. Make sure that it fits as closely as possible to the first. Eliminate the formation of cracks

Lay the subsequent rows on a cement-sand mortar, paying attention to eliminate the risk of cracks

Advice! In the event that you are not confident in your abilities and do not know whether you can install the gate yourself, entrust this matter to professionals.

DIY manufacturing

If desired, a gate of any type can be constructed with your own hands. To work, you need a welding machine and a grinder. Initially, you need to take accurate measurements of the pipe so that the slide valve does not fit tightly into the pipe. If the requirement is not observed, there is a risk of jamming of the damper when the pipe is heated. Too much clearance makes it difficult to adjust the traction force.

Materials used in the manufacture of a sliding gate valve for a rotary type chimney:

- stainless steel pipe blanks with an inner diameter of 6 mm;

- nails;

- stainless steel sheet 2 mm wide;

- bolts with a diameter of 8 mm.

Manufacturing:

- After measuring the inner diameter of the pipe, transfer the dimensions to the steel sheet.

- Cut circles, sand.

- Try on the workpiece to the damper and cut off the desired section.

- Drill holes for threads.

- Weld the dampers to the pipe.

- Put holes on the chimney, install dampers.

For the manufacture of a home-made sliding-type gate, you will need a valve blank, a guide frame.The sliding element is pre-cut to the desired dimensions, corresponding to the dimensions of the chimney. Bend one side for ease of movement during use. Perform grinding. Cut out the plate for the sliding element. Connect the parts by welding and fix on the pipe.

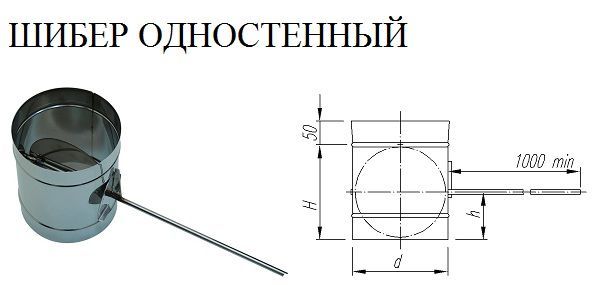

Manufacturing of sliding gate

Sliding gate

The design of the gate valve consists of the valve itself and the guide frame. First you need to measure the internal section of the pipe or brick chimney. According to measurements, a rectangular valve is cut out of sheet steel 4-5 mm thick. On the one hand, a longitudinal fold is made with a width of 20-30 mm, so that it is more convenient to extend the damper. All sections are carefully polished, while reducing the size of the product by 1-2 mm on each side. This will ensure free movement of the damper inside the chimney.

Gate scheme

If the chimney is steel and has a rectangular shape, the frame is made of a steel strip 2 mm thick and 30-35 mm wide. The strip is bent along, leaving a gap along the thickness of the plate, then it is cut in two places at an angle of 45 degrees and given a U-shape. The gaps in the places of cuts are welded end-to-end. The ends of the self-made profile are connected by two pieces of metal, positioning them so that the valve blade passes freely between them. You should get a rectangular frame with grooves for the gate. In this case, the inner perimeter of the frame must necessarily be equal to the cross section of the chimney.

Gate valve manufacturing

Ready-made gate design for a round chimney

Now the sheets must be connected by welding on three sides around the perimeter so that the holes for the pipe coincide, and there is a gap of 4-5 mm between the top and bottom sheets.After that, it remains only to insert the valve and fix the gate on the pipe.

Throttle valve manufacturing instructions

To make a rotary gate valve, you will need more tools and time. Most often, this type of damper is used for a metal chimney for modern fireplaces and metal freestanding stoves.

A set of tools for work:

- Bulgarian;

- drill;

- pliers;

- welding machine;

- compass;

- roulette;

- marking marker.

For the manufacture of the gate, sheet steel up to 3 mm thick is needed, a stainless pipe with an internal diameter of 6 mm, fasteners (bolts, nuts) 8 mm, a metal rod.

- First, measure the inside diameter of the chimney pipe with a compass.

- According to him, draw a circle on sheet steel.

- Bulgarian cut a circle.

- Place the cut fragment into the pipe and check the fit. If necessary, finish the shutter with a grinding disc.

- Put a metal tube with a diameter of 6 cm on a circle in the center and make marks on it, retreating 3 mm from each side of the circle.

- Cut off the tube with a grinder.

- In the resulting pipe section, drill the thread to 6.8 mm on both sides.

- Drill holes for welding in the steel circle (one in the center, two 1 cm from the edge on opposite sides).

- Weld the threaded tube to the steel circle.

The slide damper is ready, it remains to install it in the chimney pipe.

Rooftop chimney trim

Finishing work includes sealing the joints of the chimney and roof, equipment for protecting chimneys and ventilation ducts from moisture, and thermal insulation work. An important point is to give a beautiful look to all structures on the roof.

The lining of the chimney is done in the case of using low-quality bricks, when there is a risk of destruction under the influence of precipitation. If the level of draft is insufficient, and the installation height of the chimney meets the above requirements, a layer of thermal insulation made of non-combustible materials is laid behind the casing.

Materials and methods of sewing

Regardless of the method of finishing, the manufacture of a supporting frame is required, on which insulation and sheathing material will be attached. For the chimney, the frame is made only of metal. The profile for fixing drywall sheets is excellent for this. Fasteners must also be metal.

The optimal material for sheathing is galvanized sheet or corrugated board. This cladding is low cost and easy to install. Galvanization is fastened with self-tapping screws with silicone or rubber sealing washers placed under the cap.

The chimney can be finished with the same material from which the roof is made

Finishing is also done with natural or artificial stone. In this case, it is necessary to additionally fix the stone to the surface of the chimney using dowels.

Stone trim perfectly decorates the chimney and gives it the appearance of a small medieval turret

The upper part of the chimneys is protected from moisture ingress with the help of caps. Since the installation of the hood has the ability to worsen traction, the height of the hood should not be less than 150 millimeters. What the cap will be made of depends only on the personal preferences and financial capabilities of the owner of the chimney - you can make it from ordinary galvanization or use a beautiful forged design with a weather vane.

Chimney lining work must be carried out in accordance with the requirements of fire regulations. The products of combustion, which are diverted from fireplaces, stoves and solid fuel boilers, have a high temperature. In gas-fired boilers, the temperature at the outlet of the pipe is much lower, so they can be considered safe. But still, for all types of stoves and boilers, the chimney must provide good draft. The main requirement is the use of only materials that do not support combustion.

In the case when the chimney and ventilation ducts are located in the same box, the chimney cut should be located significantly higher than the ventilation cut.

For proper operation of the chimney, it is required to clean it from soot, inspect and eliminate comments with a frequency of 2 times a year. It is necessary to operate the boiler strictly in accordance with the rules and not to use it for other purposes.

Functions, purpose and characteristics

Being the main draft regulator inside the chimney, the damper regulates the combustion of fuel. To reduce draft and reduce the intensity of the flame in the furnace, it is enough to cover the slide valve. To increase traction, on the contrary, it is necessary to open it.

In fact, the gate is an ordinary metal plate that allows you to adjust the thrust.

It can be installed both in single-wall boiler systems and in double-wall boiler systems.

If the fireplace with the stove is not in use, then during this period the gate valve must be in the closed position.

But on the site of a well-insulated chimney, on the contrary, it is not recommended to install a valve. Especially when it comes to double-circuit pipes. When the metal of the inner and outer pipes expands, the slide gate may jam.

So, the main tasks of the gate valve are:

- The function of the draft regulator in the chimney.

- Partial overlapping of the section of the chimney channel.

- Flame intensity regulator in the furnace.

The gate valve is a thin metal plate, manually adjustable using a special handle. The latter is located outside the chimney pipe so that the user can manually adjust the position of the plate.

Depending on the design and type of damper, it is installed using a special metal frame, or inserted into the pipe and fixed with an axial rod.

The damper in the chimney performs the following functions:

- increases traction power in difficult weather conditions;

- increases the intensity of combustion in the furnace by increasing the flow of oxygen;

- reduces draft with a strong rumble in the chimney during strong winds;

- saves fuel by reducing the intensity of combustion;

- prevents heat leakage after the heater has warmed up.

What is a valve for?

The use of a damper allows you to close the chimney channel after the operation of the furnace. The holes in this device prevent complete blockage of the cross section of the chimney channel. It is worth remembering that the closed position of such a valve indicates that the chimney is not in use, and the open position means the beginning of the furnace.

The draft in the chimney is a very important indicator that determines not only the efficiency of the removal of combustion products from the chimney, but also the efficiency of the heating system as a whole. Therefore, the regulation of thrust, carried out with the help of a sliding element, is very important. If the level of thrust in the system exceeds the allowable parameters, it is necessary to adjust the position of the gate element.Such a valve regulates draft by reducing or increasing the cross-sectional index of the chimney channel.

In addition, slide elements perform another important function, which is to regulate the combustion of products in the heating device. The intensity of combustion is controlled due to the fact that such an element regulates the movement of air flow inside the system. It should be noted that it is impossible to mount gate products if the processing of heating raw materials is carried out in the device due to supply air flows.

The most durable and easiest to maintain are stainless or galvanized gate valves.

As a rule, such products are made of stainless steel, which has good strength characteristics. Stainless steel is resistant to destructive corrosive influences, and is also resistant to active chemical compounds formed inside the chimney. The thickness of the gate varies from 0.5 to 1 mm. Gates are characterized by high thermal stability and are able to withstand temperatures up to 900 degrees Celsius.

Useful information! It is recommended to select dampers with a polished surface. A polished damper is easier to operate, easier to clean from soot.

The damper has rolling seams and is able to cover a fairly large area of the chimney channel (up to 85 percent). Such characteristics have made this product very popular among consumers.

Principle of use

In order to reduce the draft, you need to close the damper a little. If, on the contrary, you want to increase traction, you need to open the gate. The principle of use is extremely simple.

The main thing is to choose the right device for your oven and learn how to use it (although it is very simple). An important nuance is that when the furnace is idle for a long time, you must keep the gate closed to avoid foreign elements from entering there.

Also, the damper separates the insulated part of the chimney from the non-insulated part. The gate is usually installed at the beginning of the pipe. At the end, where the pipes are well insulated, the installation of a valve is not recommended.

What are the functions of the damper we have derived?

- With its help, traction is regulated.

- It protects the chimney from temperature changes.

Do-it-yourself chimney valve installation

You can install a damper for a fireplace or heating unit in one of three ways:

- The damper is mounted directly in the fireplace insert. It is placed at a distance of 100 centimeters from the heating device, which allows them to be easily controlled.

- Combining the gate with other elements of the heating structure without the use of additional fasteners. This method of installation is called "pipe-to-pipe".

- The damper is installed in the ventilation pipes. It is used so that the fan motor does not overheat during its operation.

Installation must be carried out in the closed position of the gate in order to prevent unnecessary load on the motor.

Since there are a variety of models of stove units and fireplaces, and heating with their use is performed in different ways, each of them requires its own type of valve.

For example, a gas-fired stove will require a classic rotary damper or a rotary automatic damper, since they are able to completely block the chimney and then the flame will not be able to escape.

At the same time, rotary valves should not be installed when arranging a sauna stove, since they will let steam through when closed, and in the open position they are very difficult to clean.

As a rule, a damper for a fireplace or stove unit is sold as a complete set along with a chimney. But there are smoke exhaust structures without a damper, so you can do it yourself by buying elements for it at a hardware store. The main thing to do before purchasing them is to decide on the required dimensions.

It is better to buy valves made of stainless steel. The main part of the gate installation is the shell. As part of the gate there are several shells.

Main types of dampers

According to the manufacturers, the gate is a specific device that is designed to control the traction force in the smoke exhaust system of heating and cooking stoves, as well as in fireplaces for a country house. The popularity of this product is due to the fact that the good combustion of the filled fuel, the removal of the generated smoke, as well as the rate of heating the room depend on the draft. If the house is heated by a stove, then it is the gate that will provide the fire safety function.

Retractable model

This type of chimney damper is considered one of the most reliable and powerful in terms of operation. This part consists of a smooth plate, on which there is a small longitudinal hole. The movement of the gate is due to special grooves in the chimney. The installation process takes place only in a horizontal position, the traction force depends on the position of the plate. It is used in brick ovens, as well as in modern chimneys made of steel pipes.

In this video you will learn how to make your own gate:

Cast iron products

The material itself is distinguished by its strength and durability. Most often, this kind of gates is used for the manufacture of durable furnace valves. The only downside to this product is its weight.

Throttle variant

The gate is presented in the form of a strong metal plate, where a special guide piece is welded in the center. Mounted inside the chimney. The end of the guide must be located outside. You can adjust the traction force by rotating the plate. Among specialists, such a product is considered not very reliable, since over time the welding connection weakens, due to which the damper opens slightly in random order. But despite this, a rotary damper is often used in steel chimneys.

There are several variations of the gate

There are several variations of the gate

High quality stainless steel blade

The advantage of using this steel is that it is not at all afraid of the negative effects of corrosion, has a long service life, is light in weight and does not affect the efficiency of the furnace. The process of cleaning the chimney is greatly simplified, since soot does not accumulate on the smooth polished surface. In addition, stainless steel dampers can have absolutely any shape, so they can be installed in both brick and steel chimneys.

Features, characteristics and purpose of the gate

What is a gate valve? It is designed to control and adjust the draft in the chimney system. From German, the word shiber is translated as a part made of metal (metal can be different). Any stove maker knows that good traction is the most important condition in order to properly operate the fuel system.

If there is not enough thrust in the system, then oxygen, which is so important for combustion, does not get there. As a result, the process of ignition and combustion itself will be problematic. On the other hand, in the absence of draft, all the smoke will enter the room, which leads to negative consequences. But if the draft is good, and it is precisely this that is provided by the rotary damper for the chimney, combustion will be effective:

- First, it will be much easier to ignite the fuel.

- Secondly, the combustion process improves, the fuel burns quickly, bringing more and more heat into the room.

- Thirdly, smoke does not get inside, and the heating process is much better.

So, the gate valve allows you to improve traction, prevent negative consequences when burning solid fuel in a stove or fireplace. Experts advise mounting this part when heating with any fuel, be it gas, coal or wood.

The gate valve itself is installed directly in the chimney. It is the main thrust regulator, controlling the process of fuel combustion. It should be clarified that too strong traction is also not very acceptable, since the fuel will burn intensively, the consumption will increase significantly. The valve works like this: in order to reduce draft and reduce the intensity of combustion inside the furnace, you need to cover it. And if you need to increase traction, then the opposite action is performed. The process is carried out mechanically with the participation of a person.

The gate valve looks like a metal plate, thanks to which the chimney can be blocked or released. It is mounted both for systems of single-walled, and for double-walled coppers.

Note! In the case when the fireplace and stove are not in use, it is necessary to close the slide valve for the entire period.

Usually, a chimney valve is installed near the stove, in the initial section of the chimney pipe. This is about 1 m from the oven. So a person can easily reach it. In addition, this area is not insulated. Experts do not recommend mounting the gate on a site that is well insulated. This is especially true for double-circuit pipes. Why? The thing is that under the influence of high temperature, the metal of the inner and outer pipes expands, and the valve itself often jams and does not protrude back.

Summing up, we can consider the main tasks that a gate valve performs:

- It is able to regulate the draft in the chimney, reducing or increasing it.

- Partially covers the section of the chimney pipe.

- The damper serves as a flame intensity regulator in the furnace.

Although the gate is small and inconspicuous, it is simply impossible to do without it. However, it must be understood that in the case when the combustion process in the furnace is carried out with the supply of fresh air, then it is not necessary to install a gate valve.

Now with regard to the material of manufacture of the gate. Most often, stainless steel is used for this purpose, the thickness of which is not more than 1 mm. A gate valve made of this metal of this thickness will be capable of:

- withstand temperatures reaching as much as 900 degrees Celsius;

- the gate valve is resistant to corrosion;

- has a small coefficient of thermal expansion.

So that the operation of the part and the chimney itself is as simple as possible, and there are no problems with cleaning soot, you should choose a sliding gate valve with a polished surface. Docking of seams is done by rolling.

The note! A conventional damper can cover up to 85% of the chimney section. This is the best option to effectively remove combustion products and ensure proper combustion of the fuel.

Varieties of gate valves

Since chimneys are different, our gate valves are also different from each other. Basically, this difference lies in the form and in the way of functioning. There are several types of gate valves:

- Horizontal slide gate valve that retracts. This is the most common type of gate valve. Inside the structure there is a plate, which is retractable, it is thanks to it that the cross-sectional area is regulated. Most often, this design is used for brick chimneys. So that in the closed position of the element, the smoke channel does not overlap 100%, small holes are made in the plate. This is done for a reason, because the technology of creation corresponds to fire safety. A feature of the horizontal gate is the simplicity of design and ease of installation, as well as the efficiency of work.

- Swivel gate. It also has a second name - "throttle valve". The design is fundamentally different from the previous version. It is made in the form of a branch pipe, inside of which there is a metal plate. Only it does not extend, but is located on a rotating axis. The device is equipped with a removable rotary disk, which becomes unusable over time.However, due to the scheme of the rotary mechanism, it is easy to repair and replace the part yourself. The valve is located inside the chimney pipe. The principle of operation is to rotate the plate inside. The advantage of this gate valve design is that it is easy to operate. The owner of the house will not need to constantly monitor the position of the gate.

Since the second option is more difficult to implement, this do-it-yourself chimney damper is not made. Most often, it is the first option that is created - a horizontal valve. I would like to note a few more nuances. A gate valve is needed for wood-burning stoves and other heating equipment that runs on solid fuels. If we talk about gas boilers and those running on liquid fuel, then the damper is needed more in order to protect the chimney structure from the penetration of atmospheric precipitation, debris and animals.

If we talk about installing a rotary gate for a bath, then it is better not to do this. Why? During operation, the structure will partially pass steam when closed. And cleaning in the open is difficult to perform.

There are three ways to install the gate:

- Installation of the product in the fireplace insert. For this purpose, it is installed at a distance of 100 cm from the heating device (stove, fireplace, boiler), which simplifies operation.

- The pipe-to-pipe method is based on combining the gate valve with the rest of the elements of the heating system, without the use of additional fasteners.

- Installation of the valve directly in the ventilation pipe. The purpose of such manipulation is completely different. The valve is needed more to protect the channels from the penetration of foreign objects, debris, rainfall and animals.This is done to protect the fan motor.

There are two options for how to proceed if you need to install a valve. The first is to simply buy a kit and do the installation yourself according to the instructions from the manufacturer. The second is to make a chimney damper yourself. We will consider options for creating both a rotary and a horizontal device.

How to make a gate valve with your own hands

Consider how to make both options for chimney valves - retractable and rotary. Each of them has its own nuances of manufacturing and installation. Let's start with the retractable view.

Preparation of materials and tools

To create the simplest model of a retractable gate, galvanized steel is suitable. It is lightweight, thanks to its smooth surface it is easily cleaned of soot, and if necessary, the moving part can be easily replaced.

Millimeter steel is not suitable, as it easily bends, and if deformed, it will be difficult to slide the plate into the chimney. The minimum sheet thickness is 1.5 mm, and preferably 2-2.5 mm

The main tools are a welding machine, electrodes, a grinder, metal shears (we choose depending on the thickness of the sheet), a drill with a grinding disc, metal drills, a file. Work is best done on a workbench with a vise. Among other things, you will need a sheet of paper for the template, a tape measure, a marker.

Drawing up a diagram (drawing)

Dimensioning must be taken seriously, as even a few millimeters can cause the chimney to malfunction. To find out the dimensions of the frame, you should measure the cross section of the chimney channel with a tape measure - it will coincide with the dimensions of the inner side of the frame.To this value, add 20-30 mm on three sides and calculate the outer side of the frame.

Drawing of a damper with a wire frame. A wire frame is more difficult to fix to masonry than a profile with flat, wide sides.

In order for the valve to slide out easily, without effort, it should be slightly narrower in width than the width of the frame (considering the outer sides). To simplify the calculations, it is necessary to draw a design diagram and designate all possible dimensions, so that in the future, while working with metal, you can navigate by them.

For metal pipes, they usually combine the design of a flat damper with a fragment of a chimney located perpendicularly.

Design dimensions for a rectangular pipe. The damper must completely block the chimney, but at the same time have small holes for air penetration drilled with a drill, or a gap

For brick chimneys, a flat frame made of wire or a profile with a valve moving along guides (two parallel sides) is sufficient.

Marking and cutting parts

Having determined the exact dimensions, we cut out the frame for the gate. If the chimney is small (for example, in a bathhouse or in a summer kitchen), you can use a thick wire by bending it in the shape of the letter P.

A more detailed frame is a strong corner profile. To make it, we cut a strip from sheet steel and bend it along at an angle of 90º. To give the profile the desired shape, in places where the corners are marked, we cut one of the planes. When bending, we get a frame. We weld the places of the folds.

Next, cut out the shutter itself. It should be about 5-10 mm narrower than the frame width. We adjust the length so that in the closed state only a small fragment of the valve looks out.You can decorate it in different ways: in the form of an ear with a hole or just a folded edge.

We clean the edges of the cut gate with a disk so that the closing / opening process takes place easily and silently. Details cannot be painted.

Valve installation steps

The photo shows the stages of installing a factory-made gate. By the same principle, a home-made device is mounted.

Image gallery

Photo from

In accordance with the scheme of the furnace device, we determine the installation location of the slide gate and mark the bricks that need to be cut

We take out the bricks that serve as the basis for mounting the damper, and cut them to the size of the gate frame with a grinder

We use masonry mortar to fix the valve. We apply it to the installation site, and then to the edges of the frame from above

The valve "stood" on the same level with the rest of the bricks, so there are no obstacles for further masonry, it is done in the usual manner - according to the ordering scheme

Step 1 - determine the installation location

Step 2 - cutting bricks around the perimeter of the hole

Step 3 - planting the gate on the solution

Step 4 - brickwork over the gate

The installation height of the damper largely depends on the design of the stove, in sauna stoves it is lower, in home heating stoves it is higher. The minimum height is 0.9-1 m from the floor, the maximum is about 2 m.