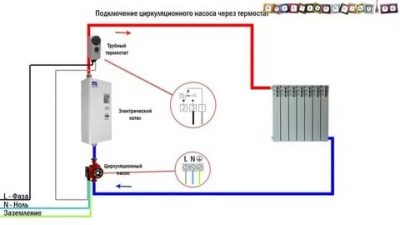

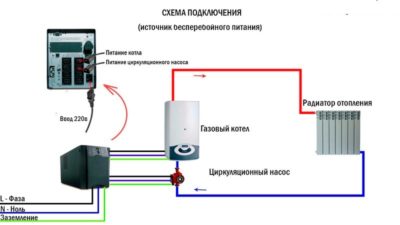

- The circuit for connecting a circulation pump through an uninterruptible power supply UPS is as follows

- Direct installation

- Place for tie-in

- Improving Efficiency

- Structural scheme

- Sequence of work

- 6 Strapping methods

- Where to put

- forced circulation

- natural circulation

- Mounting Features

- Connection of emergency systems

- Safety valve

- emergency heat exchanger

- Additional circuit

- thermostatic mixer

- When is a circulation pump needed?

- Do I need an additional pump for a double-circuit boiler Navien

- Why do you need a hydraulic gun

- Installation nuances

- Filling methods built-in mechanism and pumps

- Filling the heating with antifreeze

- Automatic filling system

- Where to put

- forced circulation

- natural circulation

- Mounting Features

- Steam heating type

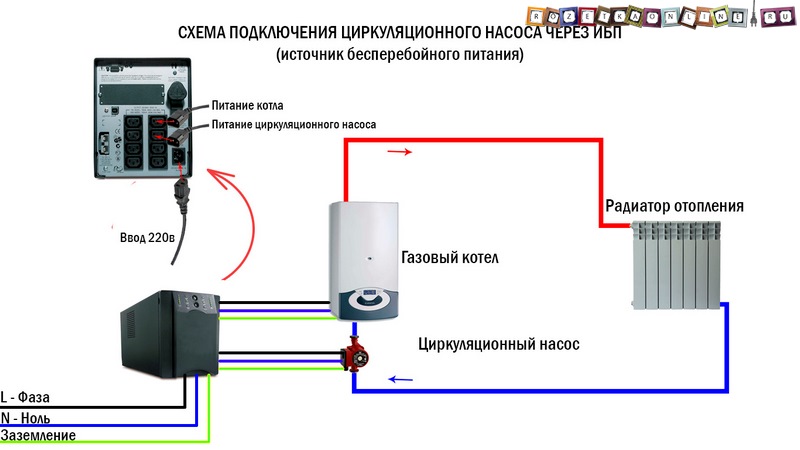

The circuit for connecting a circulation pump through an uninterruptible power supply UPS is as follows

The general principle of connecting a pump through a UPS is as follows. the power supply of the home network is connected to the uninterruptible power supply, and the circulation pump and, in this case, the gas boiler are already powered from it. Now, when there is a power outage, the house will continue to heat in the same mode for as long as the battery in the UPS lasts.

The uninterruptible power supply is selected depending on the installed equipment, its quantity, power consumption and some other factors. In heating systems consisting of a large number of electricity consumers or in systems that require a sufficiently long battery life, it is allowed to use both several UPSs at once, and one, but with additional batteries in the circuit, for example, automobile ones.

This UPS connection scheme can be combined with the circulation pump connection scheme through a thermostat, then the house heating system will be most efficient.

Direct installation

The process of installing a pump for heating requires the prior purchase of equipment with a split thread. In the absence of it, installation will be difficult due to the need for self-selection of transition elements. For long-term operation, you will also need a deep filter and check valves that provide pressure operation.

Installation is carried out using a set of wrenches of appropriate sizes, valves and bypasses equal to the diameter of the riser.

Place for tie-in

When connecting the pump, take into account its periodic maintenance and place it within direct reach. The priority installation site is also determined by other nuances. In the past, wet pumps were often mounted in return circuits. Cooled water, which washed the working part of the equipment, extended the life of seals, rotors and bearings.

The details of modern circulation devices are made of durable metal, protected from the effects of hot water, and therefore can be freely attached to the supply pipeline.

Improving Efficiency

A properly installed pump unit can increase the pressure in the suction area and thus increase the heating efficiency. The connection diagram implies the installation of the device on the supply pipeline near the expansion tank. This creates a high temperature zone in a given section of the heating circuit.

Before inserting the bypass with the pump, you will need to make sure that the device can withstand the onslaught of hot water. If a private house is equipped with underfloor heating, the device must be installed on the coolant supply line - this will protect the system from air pockets.

A similar method is suitable for membrane tanks - bypasses are mounted on the return line in the minimum proximity to the expander. This can make it difficult to access the unit. The problem will be corrected by installation on the supply circuit with a tie-in vertical check valve.

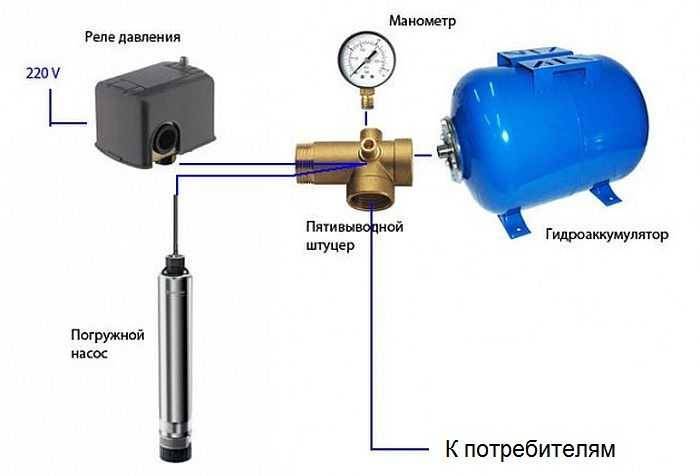

Structural scheme

The installation of circulation equipment requires compliance with the rules regarding the sequence of fastening elements:

- ball valves mounted on the sides of the pump provide the possibility of removing it for inspection or replacement;

- a filter embedded in front of them protects the system from impurities clogging the pipes. Sand, scale and small abrasive particles quickly destroy the impeller and bearings;

- The upper parts of the bypasses are equipped with air bleed valves. They can be opened manually or operate automatically;

- the scheme for the correct installation of a "wet" pump implies its horizontal mounting. The arrow on the body must coincide with the direction of water movement;

- protection of threaded connections is ensured by the use of sealant, and all mating parts are reinforced with gaskets.

For safety reasons, pumping equipment can only be connected to a grounded outlet. If grounding has not yet been carried out, it must be provided before the machine is put into operation.

The dependence of the pump on the availability of electricity is not an obstacle to normal functioning. When developing a project, it is necessary to include the possibility of natural circulation in it.

Sequence of work

When connected to an existing heating network, you will need to drain the coolant from it and blow the system. If the pipeline has been actively used for many years, it must be flushed several times to remove scale residues from the pipes.

The functional chain of the circulation pump and its fittings is mounted in a pre-selected location in accordance with the connection rules. When the installation cycle is completed and all additional devices are attached, the pipes are again filled with coolant.

To remove residual air, you need to open the central screw on the cover of the device. A signal of successful bleeding will be water flowing from the holes. If the pump has manual control, the gases will need to be removed before each start. To save equipment and reduce interference in the heating process, you can install an automatic pump with a work control system.

6 Strapping methods

First you need to finally decide how many pumps will be installed. For one circuit, one device is enough, but during a complex circuit it is better to install two or more.

If you plan to install a heated floor or use a boiler, then it is advisable to increase the number of units to two. If there are two boilers in the house, then separate pumping equipment for each of them will also be needed.

In the heating system, ball valves are mandatory for installation. They are installed simultaneously with the pump unit. A check valve is also required so that the coolant moves in one direction. The valve is installed on the pipe immediately after the pump in the direction of fluid movement.

It is necessary to install a coarse filter to prevent sand and dirt from entering the device body. Fine filters are not installed in the heating system. If purified water is required, then it is pre-cleaned before being poured into the boiler.

After installation of the equipment, an electrical connection is required. Do not connect to an ordinary socket without grounding. This is a gross violation of safety regulations, which during an emergency can lead to sad consequences.

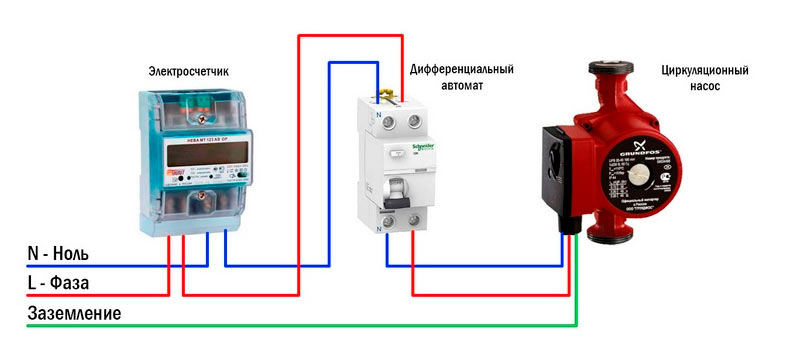

There are more reasonable connection options:

- using a boiler connected to automation;

- differential circuit breaker;

- uninterruptible service.

It is best to use a circuit breaker. This requires a direct 8 A switch, contacts and cables. If you plan to use a UPS, then you can simultaneously connect it to both pumping equipment and the boiler.

When connecting the equipment to electricity, it is necessary to exclude the possibility of condensate penetrating into the terminal box. A heat-resistant cable is used if the heat carrier is heated in the heating system to more than 95 °C.It is forbidden to contact the cable with the pump housing, electric motor, pipe walls.

Where to put

It is recommended to install a circulation pump after the boiler, before the first branch, but it does not matter on the supply or return pipeline. Modern units are made from materials that normally tolerate temperatures up to 100-115 ° C. There are few heating systems that work with a hotter coolant, therefore considerations of a more “comfortable” temperature are untenable, but if you are so calmer, put it in the return line.

Can be installed in the return or direct pipeline after/before the boiler up to the first branch

There is no difference in hydraulics - the boiler, and the rest of the system, it does not matter whether there is a pump in the supply or return branch. What matters is the correct installation, in the sense of tying, and the correct orientation of the rotor in space

Nothing else matters

There is one important point at the installation site. If there are two separate branches in the heating system - on the right and left wings of the house or on the first and second floors - it makes sense to put a separate unit on each, and not one common one - directly after the boiler. Moreover, the same rule is preserved on these branches: immediately after the boiler, before the first branch in this heating circuit. This will make it possible to set the required thermal regime in each of the parts of the house independently of the other, as well as save on heating in two-story houses. How? Due to the fact that the second floor is usually much warmer than the first floor and much less heat is required there.If there are two pumps in the branch that goes up, the speed of the coolant is set much less, and this allows you to burn less fuel, and without compromising the comfort of living.

There are two types of heating systems - with forced and natural circulation. Systems with forced circulation cannot work without a pump, with natural circulation they work, but in this mode they have a lower heat transfer. However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is slammed into it. This gives high efficiency and reliability of heating. It is clear that the installation of a circulation pump in these systems has differences.

All heating systems with underfloor heating are forced - without a pump, the coolant will not pass through such large circuits

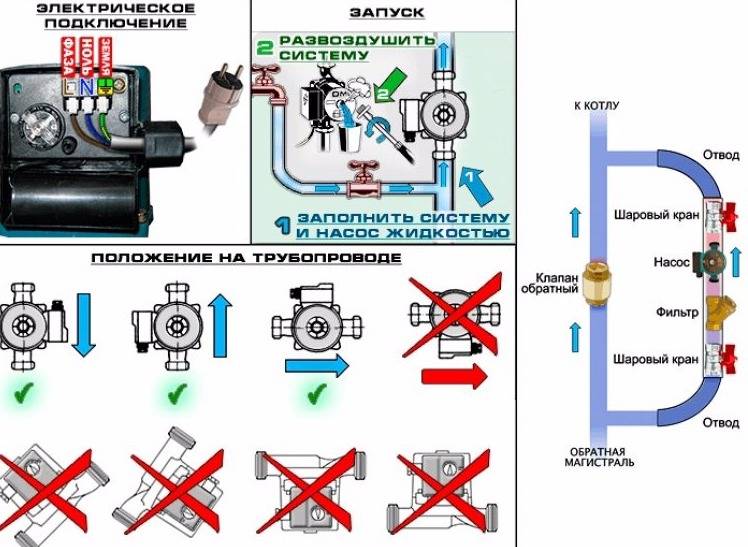

forced circulation

Since a forced circulation heating system is inoperative without a pump, it is installed directly into the gap in the supply or return pipe (of your choice).

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They are able to jam the impeller and stop the motor. Therefore, a strainer must be placed in front of the unit.

Installing a circulation pump in a forced circulation system

It is also desirable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps, remove the unit.Only that part of the water that was directly in this piece of the system is drained.

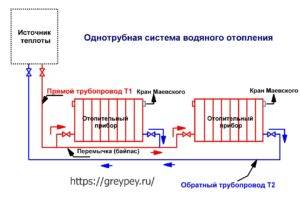

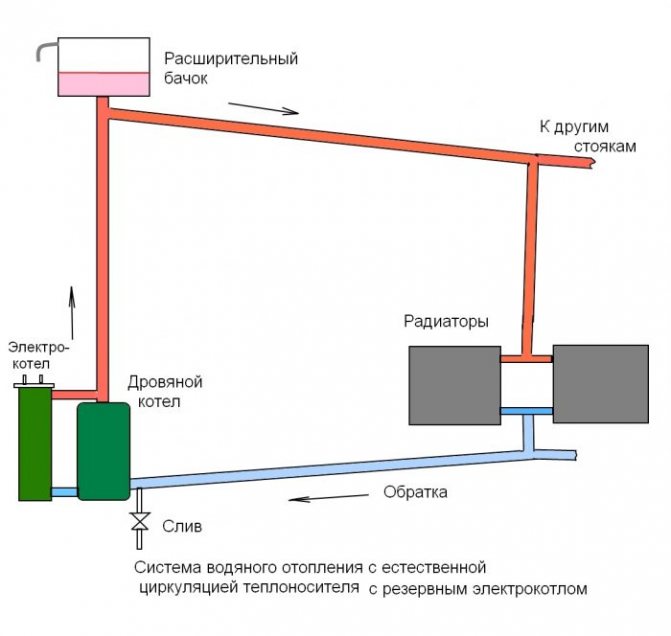

natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not running. One ball shut-off valve is installed on the bypass, which is closed all the time while pumping is in operation. In this mode, the system works as a forced one.

Scheme of installation of a circulation pump in a system with natural circulation

When electricity fails or the unit fails, the faucet on the jumper is opened, the faucet leading to the pump is closed, the system works like a gravitational one.

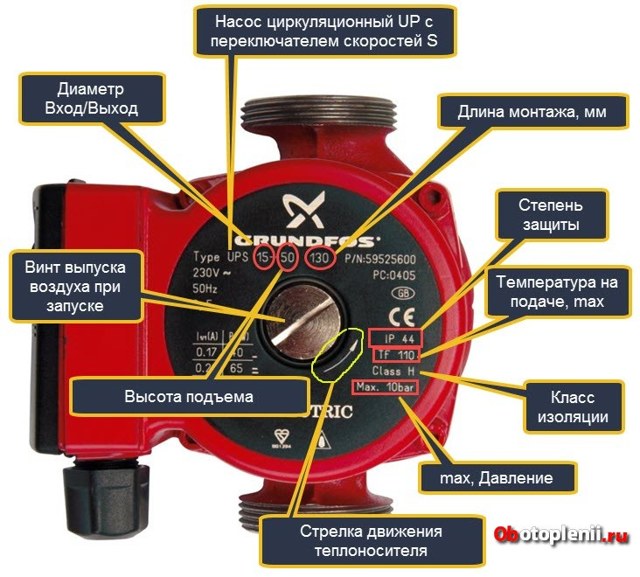

Mounting Features

There is one important point, without which the installation of the circulation pump will require alteration: it is required to turn the rotor so that it is directed horizontally. The second point is the direction of the flow. There is an arrow on the body indicating in which direction the coolant should flow. So turn the unit around so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, only when choosing a model, see that it can work in both positions. And one more thing: with a vertical arrangement, the power (created pressure) drops by about 30%. This must be taken into account when choosing a model.

Connection of emergency systems

The elements of emergency systems in the piping scheme are used for the following purposes:

- protection against increasing the maximum working pressure in the system;

- protection against exceeding the maximum allowable outlet temperature of the coolant, overheating of the boiler and elements of the heating system;

- preventing the formation of condensate in the boiler due to the large temperature difference of the coolant at the inlet and outlet of the device.

Safety valve

Protection of the boiler and system elements in case of excess of the working pressure of the heat-carrying liquid is provided by a safety valve installed on the supply line at the outlet of the boiler. Such a valve may be part of the boiler safety group, which is built into the boiler itself or connected separately.

How a safety valve works

A drain hose is connected to the pressure relief port of the valve. When the valve is actuated, the excess heat-carrying fluid from the system is drained through the hose into the sewer.

emergency heat exchanger

An emergency heat exchanger is needed to protect the boiler and system elements from overheating.

Overheating of equipment can occur in two cases:

- when the power generated by the boiler exceeds that required for heat consumers;

- when the circulation pump stops working due to its breakdown or power outage.

The heat exchanger consists of a cooling module and a thermal valve with an external thermal sensor set to a certain temperature. They can be installed inside the boiler itself or separately on the coolant supply line to the heating system.

How a heat exchanger works

When the permissible temperature is exceeded, the thermal valve is activated by a signal from a thermal sensor.

It supplies cold water from the water supply line to the cooling module, in which excess heat is removed from the coolant. From the cooling module, the water that has taken away the heat enters the sewer.

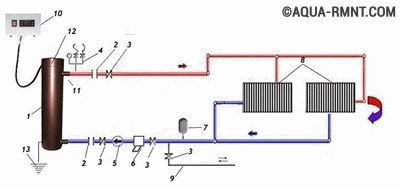

Additional circuit

The protection of the boiler against overheating in systems with forced circulation can also be ensured by using an additional natural circulation circuit, to which a DHW storage tank is connected.

Boiler piping with an additional circuit

During normal operation of the system, the pressure created by the circulation pump in the main circuit closes the additional circuit with a check valve, preventing the heat-carrying liquid from circulating in it.

When the pump is turned off for any reason, the forced circulation of the coolant in the main circuit stops and natural circulation begins in the additional circuit. Due to this, it happens cooling of the heat-carrying liquid in the system to the required temperature.

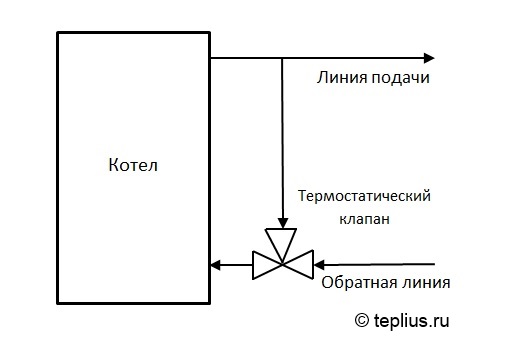

thermostatic mixer

Maintaining the minimum required temperature at the inlet to the boiler, in order to prevent the formation of condensate in it, is provided by a thermostatic mixer.

The device is installed on the return pipeline and connected to the supply line using a jumper (bypass).

Installing a thermostatic mixer

At a low temperature of the heat carrier in the return line, the thermal mixer opens and mixes hot liquid into it. After reaching the required temperature, the thermal mixer closes and stops supplying hot coolant through the bypass to the return line.

This scheme can be used in systems with any type of circulation.

Is it possible to make a solid fuel boiler with your own hands from improvised means?

When is a circulation pump needed?

When there are problems with the uniform distribution of heat in the house, one of two options is used to solve them: replacing pipes or installing additional equipment. To balance the distribution of heat allow new pipes of a larger diameter than the previous ones.

This option is efficient and practical. However, replacing pipes is not only time-consuming, but also expensive.

The second solution is to add a circulation pump to the heating system. It allows you to balance the temperature in the rooms throughout the building. It also prevents the formation of air bubbles that hinder the flow of water. And the cost of a circulation pump is several times lower than the fee for pipes, their delivery and installation.

The device is also easy to install. Therefore, owners of private houses tend to install a circulation pump.

Replacing pipes is time consuming and expensive. Installing a circulation pump will help save both money and time.

Planning for heating a house includes not only the calculation of the boiler power, the choice of locations for radiators, but also an analysis of the movement of the coolant. Of course, a large living area is an opportunity for a comfortable life for more than one person. On the other hand, the circulation rate of the coolant decreases. Therefore, a pump is installed that makes the water circulate faster.

Do I need an additional pump for a double-circuit boiler Navien

After installing a condensing double-circuit boiler, many users are considering installing an additional pump in the heating system of a country house.The need to use an additional booster device is explained by the uneven heating of the living quarters of a two-story house with sufficient power of the boiler equipment.

Advice! If the temperature drops of the coolant in the supply and return pipelines exceed 20 degrees, it is necessary to switch the circulation pump to a higher speed or get rid of air locks.

Installation of another pump is necessary in such cases:

- When installing the heating of a private house with an additional circuit, or in the case when the length of the pipes is more than 80 meters.

- For uniform supply of coolant through the heating system.

There is no need to install an additional pump if the heating is balanced using special valves. Therefore, before buying booster equipment, bleed the air from the heating radiators and add water, check the circuit for leaks using a manual pressure test pump. If, after carrying out such procedures, the autonomous heating of a private house will work normally, then another pump will not be needed.

Why do you need a hydraulic gun

If several pumps are installed in the heating system of a summer house or cottage, a hydraulic separator or a hydraulic arrow must be included in the circuit. The specified device can be operated together with a single-circuit diesel boiler or a solid fuel unit. In the latter case, the device regulates the supply of coolant in different phases (fuel ignition, combustion phase and attenuation). Installing a hydraulic arrow allows you to balance the operation of the heating system. The main tasks of the hydraulic separator are:

- Automatic removal of accumulated air;

- Capturing dirt from coolant flows.

Important! The hydraulic arrow in heating allows you to balance the operation of the system, protects it from airing, and prevents the accumulation of dirt in pipelines. Such a device must be installed without fail in the presence of several booster units

Installation nuances

When installing heating on a turnkey basis, the master plumber installs a circulation pump with a wet rotor. Such a device does not create much noise, its rotor rotates without lubrication. A coolant is used here as a coolant and lubricant. When installing pumping equipment, you need to consider the following nuances:

- The shaft of the device that injects pressure is placed horizontally with respect to the floor plane.

- Carry out the installation in such a way that the direction of the water coincides with the arrow on the device.

- Mount the instrument with the terminal box up to prevent water from entering the electronics.

Important! Experts recommend installing a pump on the return pipeline of the heating system of a one-story or multi-story residential building. Despite the fact that such equipment is designed to operate in hot water with temperatures up to 110 degrees, warmer liquid in the return pipeline will only extend the service life. Installation of the unit is carried out only after draining the water from the system

In the event of a power outage, the pump will not be able to pump the coolant, so it is connected through a bypass, a strainer is installed in front of the inlet pipe to prevent scale and debris from entering the impeller. In addition, shut-off valves are provided at the inlet and outlet of the device for possible replacement and repair of the device.

Installation of the unit is carried out only after draining the water from the system. In the event of a power outage, the pump will not be able to pump the coolant, so it is connected through a bypass, a strainer is installed in front of the inlet pipe to prevent scale and debris from entering the impeller. In addition, shut-off valves are provided at the inlet and outlet of the device for possible replacement and repair of the device.

As we can see, the installation of a circulation pump requires certain skills, so the installation of this equipment should be carried out by a professional. To order the service, you can leave a request on the website or call +7 (926) 966-78-68

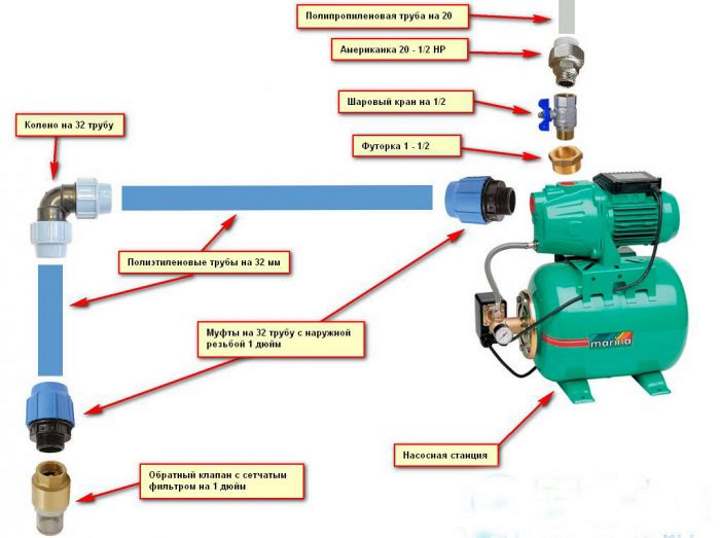

Filling methods built-in mechanism and pumps

Heating filling pump

How to fill the heating system in a private house - using the built-in connection to the water supply using a pump? This directly depends on the composition of the coolant - water or antifreeze. For the first option, it is enough to pre-flush the pipes. Instructions for filling the heating system consists of the following items:

- It is necessary to make sure that all shut-off valves are in the right position - the drain valve is closed in the same way as the safety valves;

- The Mayevsky crane at the top of the system must be open. This is necessary to remove air;

- Water is filled until water flows from the Mayevsky tap, which was opened earlier. After that, it overlaps;

- Then it is necessary to remove excess air from all heating devices. They must have an air valve installed. To do this, you need to leave the system filling valve open, make sure that air comes out of a particular device. As soon as water flows out of the valve, it must be closed.This procedure must be done for all heating devices.

After filling the water in a closed heating system, you need to check the pressure parameters. It should be 1.5 bar. In the future, to prevent leakage, pressing is performed. It will be discussed separately.

Filling the heating with antifreeze

Before proceeding with the procedure for adding antifreeze to the system, you need to prepare it. Usually 35% or 40% solutions are used, but to save money, it is recommended to purchase a concentrate. It should be diluted strictly according to the instructions, and only using distilled water. In addition, it is necessary to prepare a hand pump to fill the heating system. It is connected to the lowest point of the system and, using a manual piston, the coolant is injected into the pipes. During this, the following parameters must be observed.

- Air outlet from the system (Mayevsky crane);

- Pressure in pipes. It must not exceed 2 bar.

The whole further procedure is completely similar to the one described above. However, you should take into account the features of the operation of antifreeze - its density is much higher than that of water.

Therefore, special attention should be paid to the calculation of the pump power. Some formulations based on glycerin may increase the viscosity index with increasing temperature. Before pouring antifreeze, it is necessary to replace the rubber gaskets at the joints with paronite

This will greatly reduce the chance of leaks.

Before pouring antifreeze, it is necessary to replace the rubber gaskets at the joints with paronite ones. This will greatly reduce the chance of leaks.

Automatic filling system

For double-circuit boilers, it is recommended to use an automatic filling device for the heating system. It is an electronic control unit for adding water to pipes. It is installed on the inlet pipe and operates fully automatically.

The main advantage of this device is the automatic maintenance of pressure by the timely addition of water to the system. The principle of operation of the device is as follows: a pressure gauge connected to the control unit signals a critical pressure drop. The automatic water supply valve opens and remains in this state until the pressure stabilizes. However, almost all devices for automatically filling the heating system with water are expensive.

A budget option is to install a check valve. Its functions are completely similar to the device for automatic filling of the heating system. It is also installed on the inlet pipe. However, the principle of its operation is to stabilize the pressure in pipes with a water make-up system. When the pressure drops in the line, the pressure of tap water will act on the valve. Due to the difference, it will automatically open until the pressure stabilizes.

In this way, it is possible not only to feed the heating, but also to fully fill the system. Despite the apparent reliability, it is recommended to visually control the coolant supply. When filling the heating with water, the valves on the devices must be opened to release excess air.

Where to put

It is recommended to install a circulation pump after the boiler, before the first branch, but it does not matter on the supply or return pipeline. Modern units are made from materials that normally tolerate temperatures up to 100-115 ° C. There are few heating systems that work with a hotter coolant, therefore considerations of a more “comfortable” temperature are untenable, but if you are so calmer, put it in the return line.

Can be installed in the return or direct pipeline after/before the boiler up to the first branch

There is no difference in hydraulics - the boiler, and the rest of the system, it does not matter whether there is a pump in the supply or return branch. What matters is the correct installation, in the sense of tying, and the correct orientation of the rotor in space

Nothing else matters

There is one important point at the installation site. If there are two separate branches in the heating system - on the right and left wings of the house or on the first and second floors - it makes sense to put a separate unit on each, and not one common one - directly after the boiler. Moreover, the same rule is preserved on these branches: immediately after the boiler, before the first branch in this heating circuit. This will make it possible to set the required thermal regime in each of the parts of the house independently of the other, as well as save on heating in two-story houses. How? Due to the fact that the second floor is usually much warmer than the first floor and much less heat is required there. If there are two pumps in the branch that goes up, the speed of the coolant is set much less, and this allows you to burn less fuel, and without compromising the comfort of living.

There are two types of heating systems - with forced and natural circulation.Systems with forced circulation cannot work without a pump, with natural circulation they work, but in this mode they have a lower heat transfer. However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is slammed into it. This gives high efficiency and reliability of heating. It is clear that the installation of a circulation pump in these systems has differences.

All heating systems with underfloor heating are forced - without a pump, the coolant will not pass through such large circuits

forced circulation

Since a forced circulation heating system is inoperative without a pump, it is installed directly into the gap in the supply or return pipe (of your choice).

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They are able to jam the impeller and stop the motor. Therefore, a strainer must be placed in front of the unit.

Installing a circulation pump in a forced circulation system

It is also desirable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps, remove the unit. Only that part of the water that was directly in this piece of the system is drained.

natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not running.One ball shut-off valve is installed on the bypass, which is closed all the time while pumping is in operation. In this mode, the system works as a forced one.

Scheme of installation of a circulation pump in a system with natural circulation

When electricity fails or the unit fails, the faucet on the jumper is opened, the faucet leading to the pump is closed, the system works like a gravitational one.

Mounting Features

There is one important point, without which the installation of the circulation pump will require alteration: it is required to turn the rotor so that it is directed horizontally. The second point is the direction of the flow. There is an arrow on the body indicating in which direction the coolant should flow. So turn the unit around so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, only when choosing a model, see that it can work in both positions. And one more thing: with a vertical arrangement, the power (created pressure) drops by about 30%. This must be taken into account when choosing a model.

Steam heating type

Some consumers confuse steam heating with water heating. In essence, these systems are very similar, except that the coolant is steam rather than water.

Inside the heating boiler of the natural circulation system, water is heated to boiling point and converted to steam, which then moves to the pipeline and is further supplied to each radiator in the circuit.

The design of a steam heating system with natural circulation of the coolant includes the following components:

- a special heating boiler, inside which water is heated to the boiling point, and steam is accumulated;

- valve for releasing steam into the heating system;

- pipeline;

- heating radiators.

The classification of steam type heating according to wiring diagrams and other criteria is exactly the same as that of water heating systems. Recently, a boiler has also been used to heat a private house, which also has its advantages.