- Advantages and disadvantages of the material

- Benefits of using polypropylene in heating systems

- Installation of polypropylene pipes

- Pipe fixture

- Video lesson on soldering pipes

- Solder heating time

- Mounting options

- Natural circulation systems

- Forced circulation systems

- Emergency schemes

- Option for working with a wall-mounted boiler

- Versions

- vertical

- Horizontal

- Tying with polypropylene pipes

- Features of connecting radiators

- 2 Choosing the type of pipes based on polypropylene for a private house

- How to install

- wall mount

- Floor fixing

- Conclusions and useful video on the topic

Advantages and disadvantages of the material

In order not to make a mistake with the choice, it is necessary to carefully study all the characteristics and features of a particular material. Polypropylene pipes are no exception. They have a number of advantages.

- Light weight - this quality greatly facilitates installation work. In addition, using polypropylene pipes for heating can significantly reduce the load on the supporting structures of the house.

- Durability - in cold water systems, this material can last up to 50 years. Transportation of hot liquids through such pipes reduces this figure to 25-30 years.

- Resistance to "overgrowth" - the diameter of polypropylene pipes for heating always remains the same. The smooth inner surface does not allow salts to be deposited on the pipeline walls, which means that the clearance does not decrease throughout the entire operational period.

- Affordable price - this material is in the middle price segment, it is quite affordable for most consumers, but it cannot be called the cheapest.

- Resistance to lower temperatures - this quality allows you to successfully use propylene pipes for heating country houses, where the owners are not in the stomach all year round, and in winter I visit only periodically. The fact is that having sufficient elasticity, such a pipe will not burst if the liquid inside it freezes.

- Low thermal conductivity eliminates the need for insulation of pipes passing through unheated rooms or along the street. The absence of insulation, in turn, prevents the formation of condensate on the outer surface of the pipe.

- Resistance to high temperatures of the transported liquid. This allows you to use polypropylene pipes for heating - the temperature characteristics of the coolant range from 90 to 100 degrees. And some manufacturers claim that their pipes can withstand a short-term increase in temperature up to 110 degrees.

- No electrical conductivity.

- Ease of installation - a polypropylene heating system can be installed 2-3 times faster than a metal one.

- Soundproofing - this quality allows the heating system to work absolutely silently. You will not hear the sounds of flowing water and the noise of water hammer.

- Aesthetics - even if you decide to mount the pipeline in the classical way - along the walls, polypropylene pipes will not spoil the interior.In addition, they do not require regular maintenance (painting). High-quality polypropylene does not turn yellow under the influence of temperature and has an attractive appearance throughout the entire service life.

As you know, "there is no perfection in the world." Polypropylene was no exception. pipes for heating, this material has disadvantages and they are as follows:

Elasticity - polypropylene cannot be bent. This means that many fittings will have to be used to mount a system of complex shape. And this will not only affect the speed of work, but also lead to a significant rise in cost.

Diffusion welding devices - a welding machine is an absolute must, it allows you to make a very strong connection

- The need for soldering - the pipe and fitting are connected using a special soldering iron. This process cannot be called complicated, but the tool itself is not cheap. It must be said that in many cities a soldering iron for polypropylene pipes can be rented for a very reasonable fee.

- Large linear expansion - at elevated temperatures, the material tends to expand, which leads to a significant elongation of the pipe. This makes it difficult to install heating from polypropylene pipes inside the wall.

Benefits of using polypropylene in heating systems

There are many such advantages:

- Easy installation. As already mentioned, even one person with a soldering iron can handle it, while a welder is required to install steel pipes.

- Heating with plastic pipes will cost you many times cheaper.

- This material is not subject to corrosion, so it can last up to fifty years.

- Its use has a positive effect on the heat transfer of the system.

- Such pipes do not “overgrow”, that is, salts are not deposited on their inner surface.

- Finally, polypropylene, although flexible, is also very strong, so it can be used at high pressures or temperatures.

Pipe selection video

All this contributes to the fact that heating systems using polypropylene pipes are increasingly common today.

Which pipes should be used for heating systems?

When choosing pipes made of polypropylene, it is necessary to compare the features of your future heating with the conditions under which this or that material can be used. For heating systems, it is desirable to use the following brands of pipes:

- PN25.

- PN20.

The fact is that they perfectly tolerate the coolant temperature of ninety degrees, and for some time (albeit limited) withstand an unexpected jump to one hundred degrees. Such pipes must be used under conditions where the pressure will not exceed 25 and 20, respectively, atmospheres. But if you choose between these options, then, of course, for heating systems it is better to choose a reinforced pipe PN25.

Read also how to connect a thermostat to a heating system

Why is that? The fact is that its design has a foil that significantly increases the strength of the product. So it will be less deformed due to thermal expansion.

The main thing is a competent project

If your plans include the installation of heating from polypropylene pipes on your own, then the first thing to do is to draw up the right project. It is extremely difficult to do this without the appropriate education, so let the experts do it.

Everything is explained by the fact that there are a lot of factors affecting the operation of heating, and an ignorant person can hardly take all of them into account. Here they are:. Correct selection of diameter

Correct selection of diameter

It is worth remembering that there are pipes of different diameters in the system, which makes it possible to obtain the most efficient circulation of the heat carrier.

The number of heating devices, as well as their location, will play an important role in the temperature.

The angles of inclination of plastic pipes must be normalized, which is especially important in systems with natural circulation. Although, if you look, and in the case of forced circulation, this is also important.

The temperature and pressure of the coolant also largely depend on the marking of the pipes. The best option is reinforced pipes made of polypropylene.

The best option is reinforced pipes made of polypropylene.

Important! Before drawing up a project, it is necessary to take into account all the features of the room, to find out whether it is possible to install one or another heating system in it. Based on this, you should draw up a project. This project should include the following:

This project should include the following:

- Drawing of the boiler piping.

- All pipe diameters used.

- Nuances of fastening and installation of all heating devices.

- Information about pipe inclination angles.

If you are planning to install a heating system in a greenhouse, see the instructions here

It is for this project that further installation of heating from polypropylene pipes should be carried out. It will look something like this.

In addition, it is worth adding that there are two types of plastic pipe installation schemes:

- With bottom spill. There is a special pump that distills water. The advantage of such a system is that it can be used even in houses with two or more floors. Moreover, the diameter of the pipes here may be smaller, and the wiring diagram does not play any role at all.

- With an overflow, in which the coolant moves on its own, driven by the difference in temperature. This system is very common in the private sectors. It is characterized by simplicity and convenience, it does not need pumps or other additional equipment, so there will be no special costs.

Installation of polypropylene pipes

Important! Due to the fact that the strength of polypropylene pipes is not as great as, for example, steel pipes, then the fasteners during installation should be installed more often, somewhere every fifty centimeters. So, let's look at the main components of such a heating system.

So, let's look at the main components of such a heating system.

- Fasteners necessary to ensure that the entire structure remains stationary.

- AGV, or maybe any other heating boiler.

- Expansion tank, necessary so that the water, which expands at high temperatures, cannot damage the entire system.

- Radiators, other heat-releasing elements.

- And, in fact, a pipeline that allows the coolant to circulate between the radiators and the heating device.

Pipe fixture

For such soldering, special soldering irons are used. They heat up the material to two hundred and sixty degrees, after which it becomes a homogeneous monolithic compound.This is explained by the fact that the atoms in it, as it were, penetrate from one piece of pipe to another. Moreover, such a connection is characterized by strength and tightness.

Video lesson on soldering pipes

Soldering consists of several stages, consider them:

- The soldering iron turns on. We wait until the signal indicator on it goes out a second time.

-

We cut a piece of pipe according to the dimensions we need, for this we use specialized scissors, which are sold with a soldering iron.

- We clean the cut ends of the pipes from everything superfluous, in particular, from the foil. To do this, you can use a regular knife, or you can use a channel.

- The pipe is inserted into the fitting and held there for some time.

Important! The time that the pipe must spend in the fitting depends entirely on its diameter, a special table must be included with the soldering iron, which indicates all these values. The parts are neatly joined, there should not be any distortions.

We hold them like this for some time, it is forbidden to turn the channel.

The parts are neatly joined, there should not be any distortions. We hold them like this for some time, it is forbidden to turn the channel.

Particular attention should be paid to swivel fittings, especially for polypropylene pipes. Be sure to check if they are set correctly, because if the turn is directed in the wrong direction, the entire assembly will have to be completely redone, and the attached part will completely become unusable

The pipes are interconnected by means of "American women" - special devices that are quickly put on and taken off. They are attached to the ends of the pipes.So that during thermal expansion deformation does not occur (after all, pipe reinforcement does not completely save from this, it only reduces it), all pipes should be securely fastened to the surface of the walls and ceiling, while the step, as already mentioned, should be no more than fifty centimeters.

For fixing radiators, special devices are also used, they must be present in the kit. It is not advisable to use hand-made appliances for radiators. The fact is that factory fasteners were specially calculated for the weight of radiators completely filled with coolant, so home-made fasteners may simply not withstand it.

Solder heating time

In order for pipe soldering to be as efficient as possible, it is strongly recommended to adhere to the specified warm-up time. You can find out about it from the table below.

| Diameter cm | 11 | 9 | 7.5 | 6.3 | 5 | 4 | 3.2 | 2.5 | 2 |

| Warm-up time, sec | 50 | 40 | 30 | 24 | 18 | 12 | 8 | 7 | 7 |

| Time to connect, sec | 12 | 11 | 10 | 8 | 6 | 6 | 6 | 4 | 4 |

| Cooling, min | 8 | 8 | 8 | 6 | 5 | 4 | 4 | 3 | 2 |

| What should be the seam, cm | 4.2 | 3.8 | 3.2 | 2.9 | 2.6 | 2.2 | 2 | 1.8 | 1.6 |

It is important to know that if the part is heated to a higher temperature than the soldering technology requires, then it will simply deform. And if the heating is insufficient, then the full fusion of the material will not occur, which in the future will cause leaks

We talked about fastening to the walls, the step there is 50 centimeters. In the case of ceiling mounting, this distance should be the same, but not greater.

It is desirable to use movable clamps, and any suspended compensating devices are not needed. It should also be fastened firmly, reliably, because the thermal expansion of the pipe can deform it.

In general, we figured out how to make a heating installation from polypropylene pipes. We hope the article will be useful to you.

Mounting options

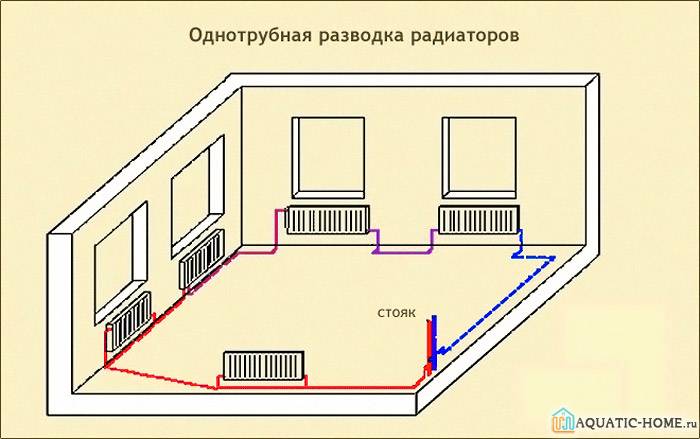

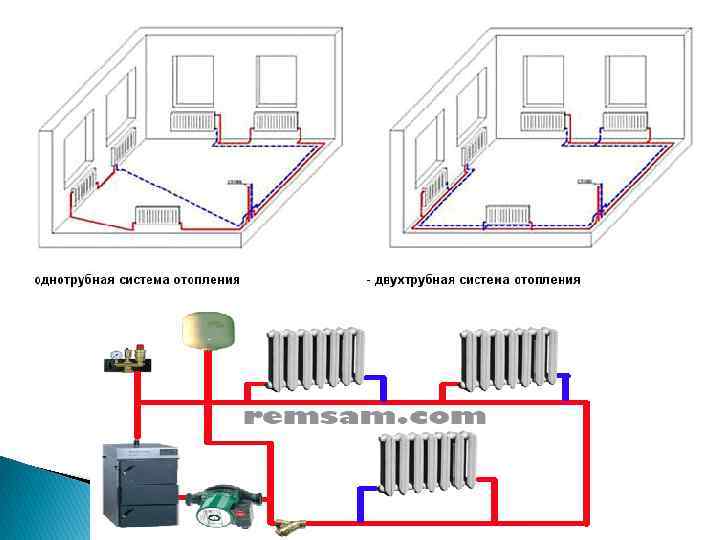

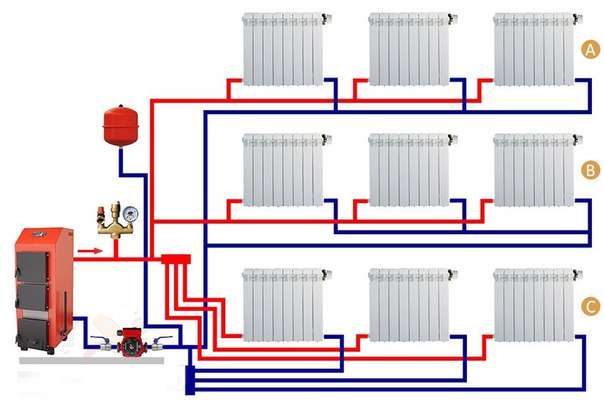

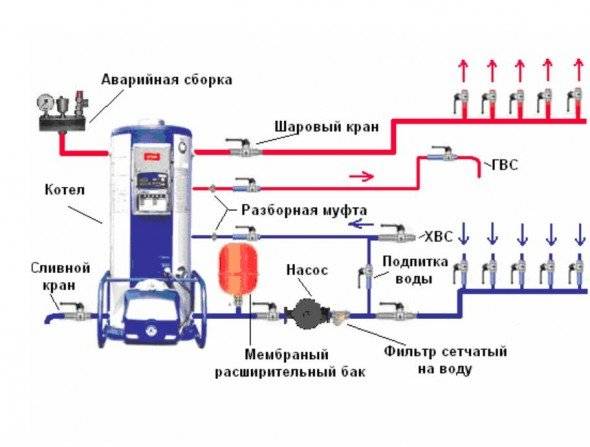

Conventionally, all piping options are divided into 2 types, depending on the principle of the passage of the coolant along the circuit - with natural or forced circulation.

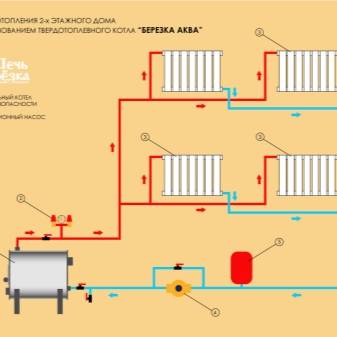

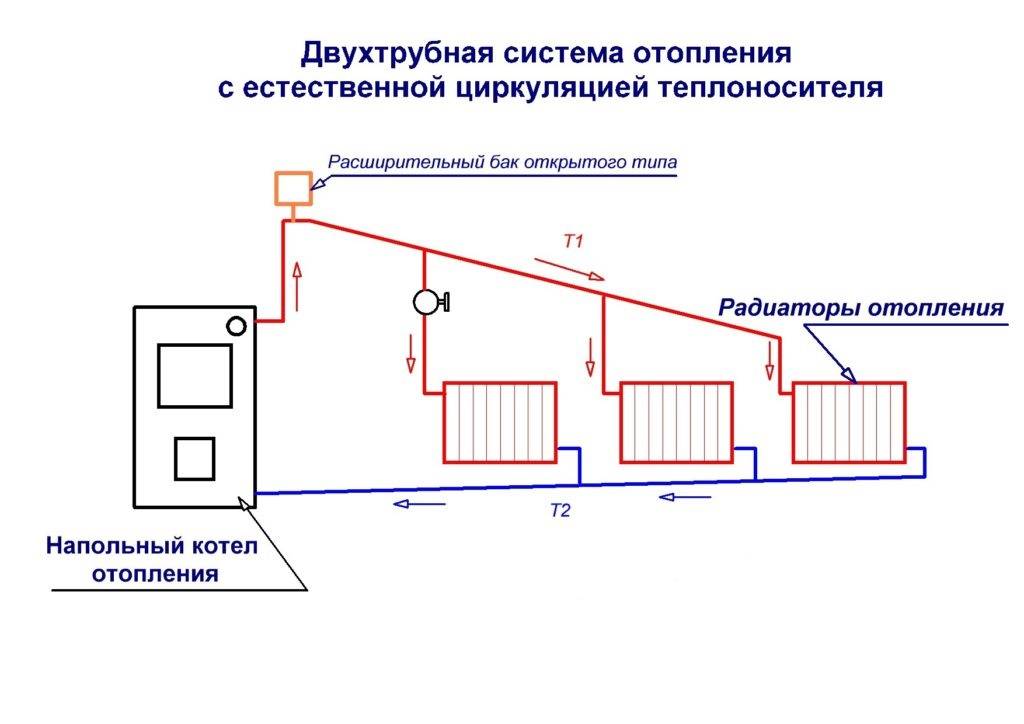

Natural circulation systems

Natural circulation systems do not have a pump, and gravity performs its function

These are simple and cheap circuits that are easy to install due to the lack of a pump. Its function is performed by gravity, which sets in motion the coolant of small heating systems in cottages or country houses. It is easier to tie a floor boiler with polypropylene in this way, since in this case the system will consist of a boiler, an expansion tank and radiators, and at the same time have a number of advantages:

- Ease of installation;

- Autonomy of work due to the lack of binding to fuel or electricity;

- No need for special maintenance;

- Compactness;

- Reliability due to the absence of additional devices that periodically fail;

- Availability.

Due to the impossibility of adjustment, it is modernized - a circulation pump is built into it, which allows you to perform the necessary manipulations.

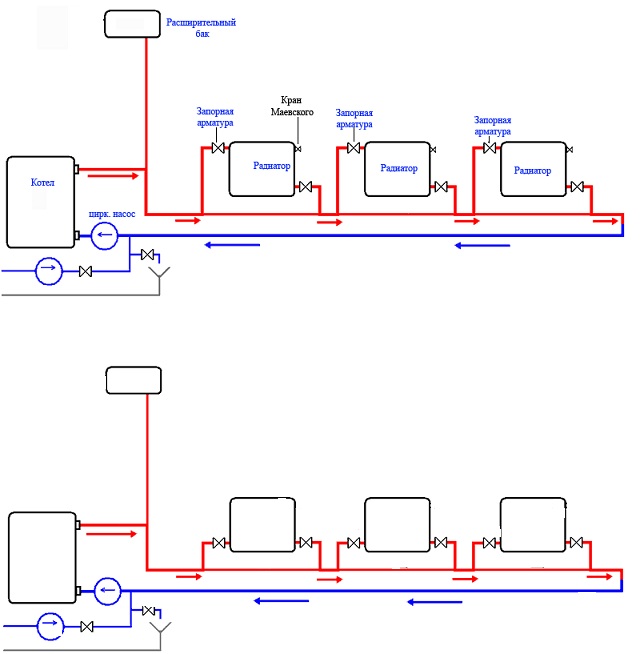

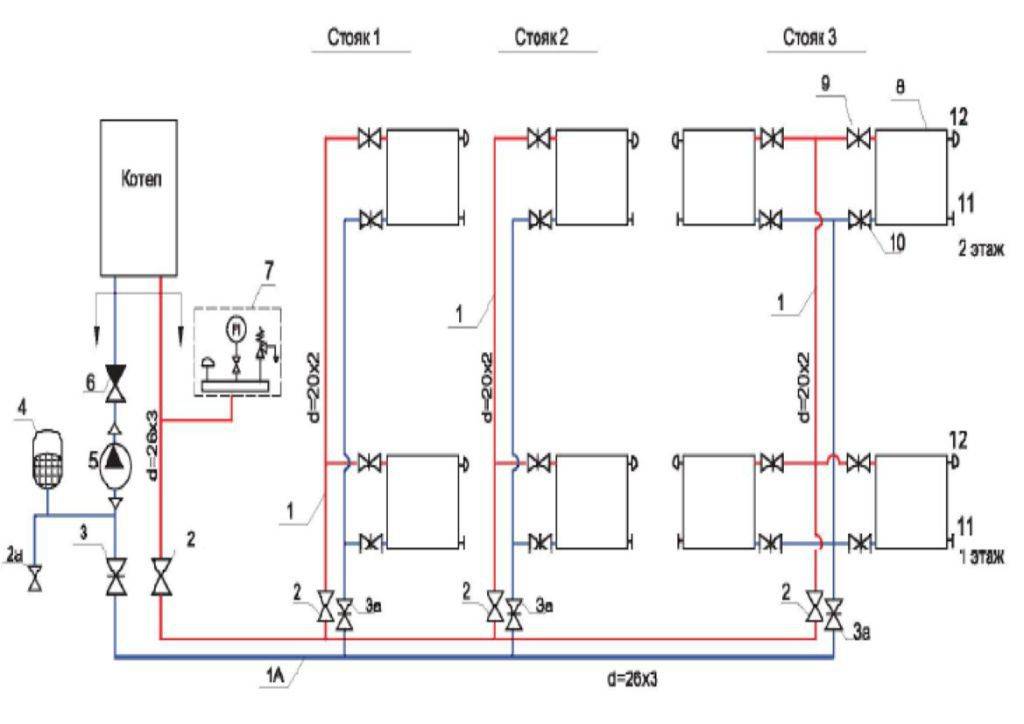

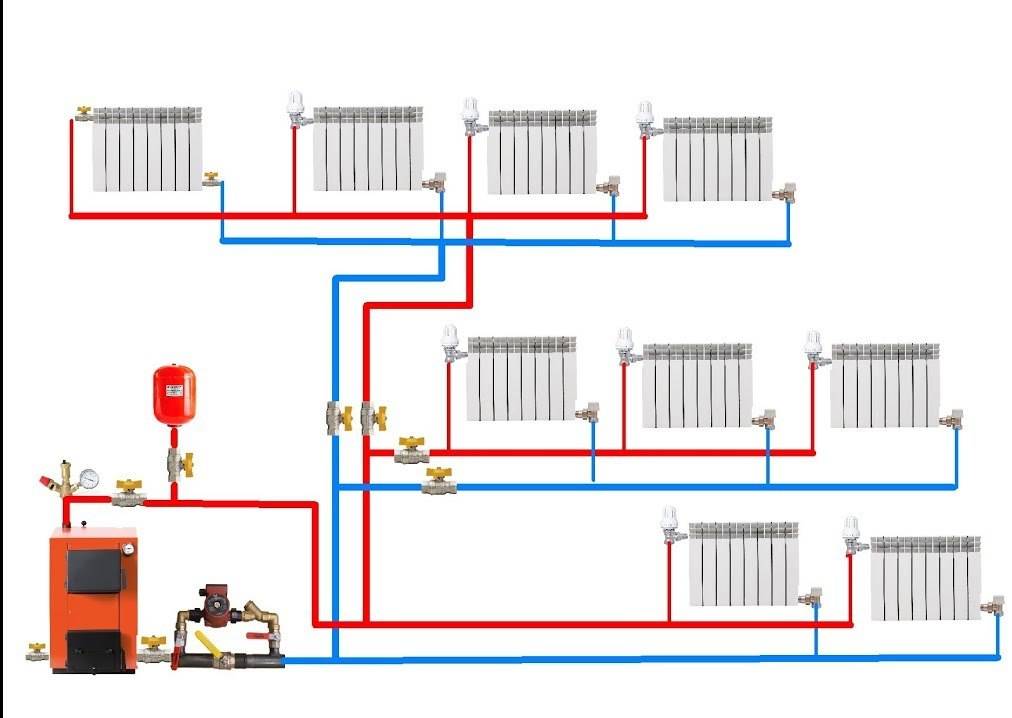

Forced circulation systems

In systems with forced circulation, special devices are installed that ensure the movement of the coolant

These are circuits in which the coolant moves thanks to special devices. They are convenient, as they allow you to set the optimal heating mode for each room, which will be maintained automatically. They work on electricity, and this is not their only drawback.

- They are difficult to install, as they provide for the connection of several devices - for measuring pressure and flow and for distributing energy when piping a wall-mounted double-circuit boiler.

- They require device balancing.

- Their serviceability should be checked regularly.

- Elements for such systems are not cheap.

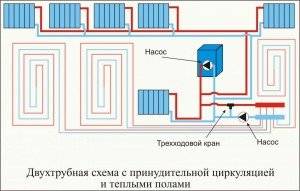

In houses with boilers with a capacity of over 50 kW and a system of "warm floors", when installing the strapping, hydraulic arrows are used, thanks to which all appliances are provided with heat in the right amount. Moreover, the pressure in different places of the system is compensated. You can replace the hydraulic arrows with comb collectors.

Emergency schemes

Tying two boilers allows you to keep the system working even if one of them fails

It is advisable to use them when tying double-circuit boilers, as they are responsible for the uninterrupted operation of heating in the event of a lack of electricity or other force majeure situations.

There are several effective options for such schemes:

- Installing an uninterruptible power supply to drive the circulation pump. But she has her shortcomings. Such a device may not work at the right time. In addition, it requires regular maintenance - battery charging.

- Installation of a gravitational circuit, which is necessary for the heat removal of excess heat. It turns on after the pump is turned off, but provides partial heating of the building.

- Installation of an emergency circuit. As part of the heating system, it is responsible for the smooth operation of the gravity and forced circuits, but only when the pump is on.

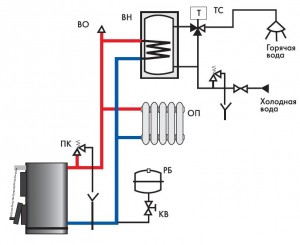

Option for working with a wall-mounted boiler

Tying a wall-mounted boiler has its advantages - you can connect a boiler and 'warm floors' to it

Its advantage is that you can connect "warm floors" and a boiler to it and perform it for a single-circuit or double-circuit boiler. In the latter case, the system can be assembled in a mixing circuit, when the adjustment is carried out by a burner and a servo-driven mixer, or in a straight line, when only the burner is activated.

The heat accumulator is mounted according to the type of hydraulic arrow - between the direct supply and the return flow.

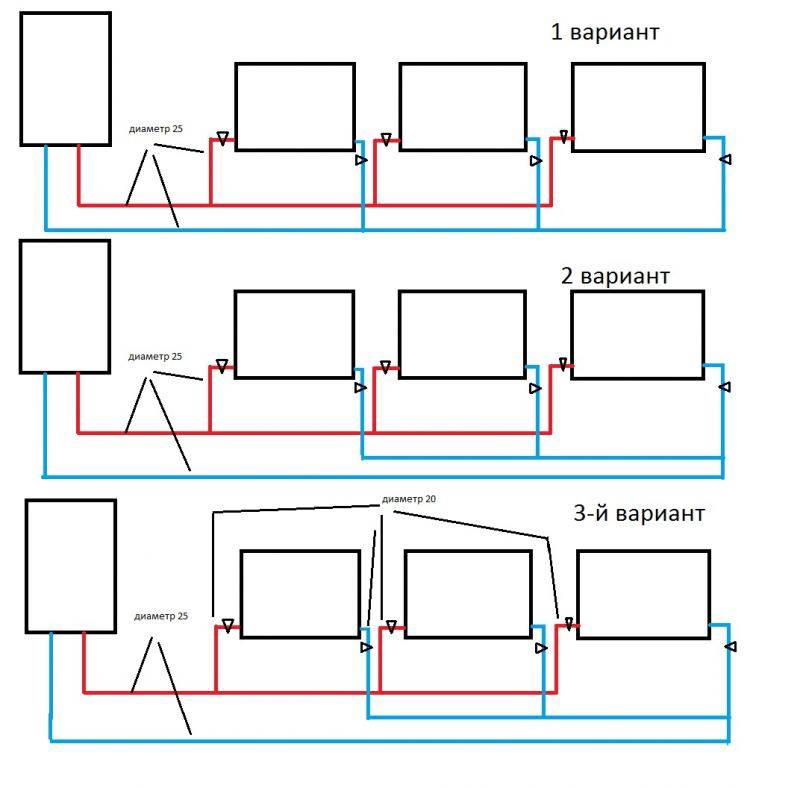

Versions

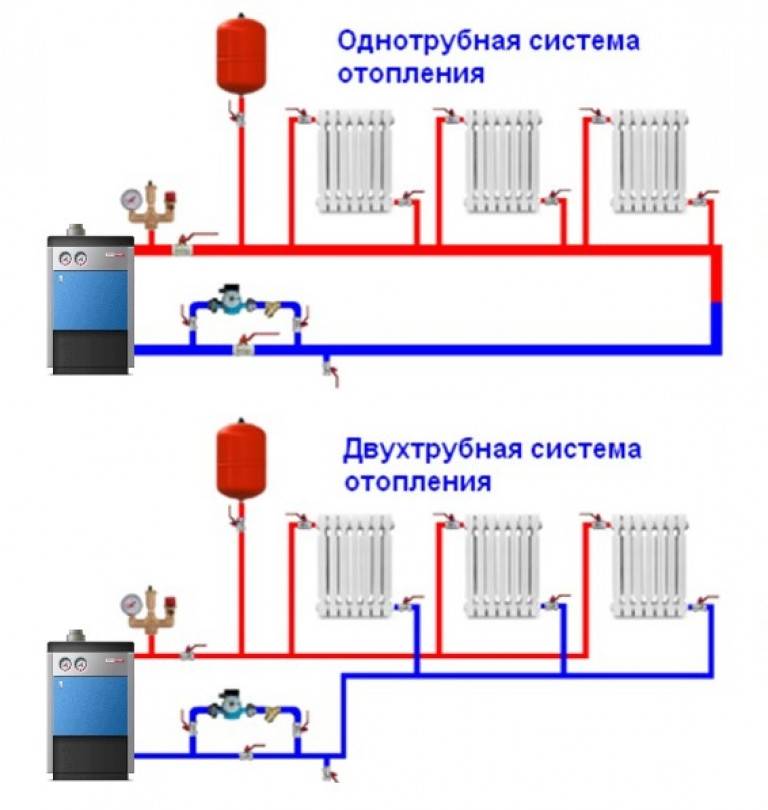

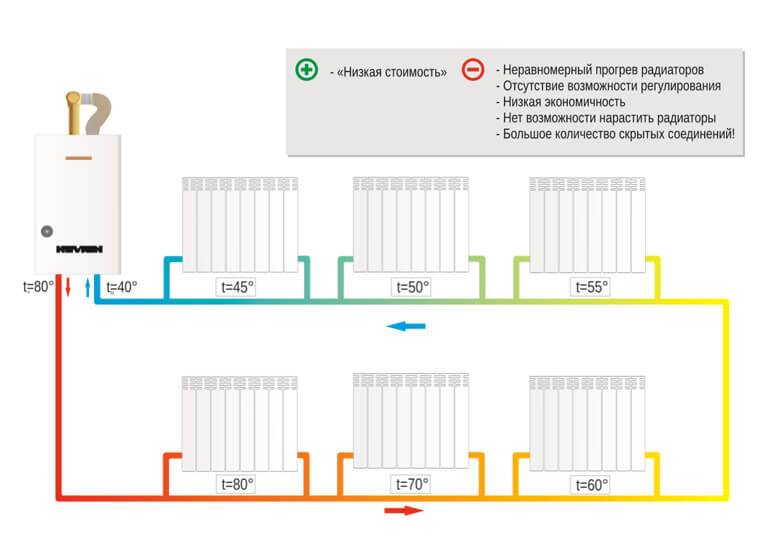

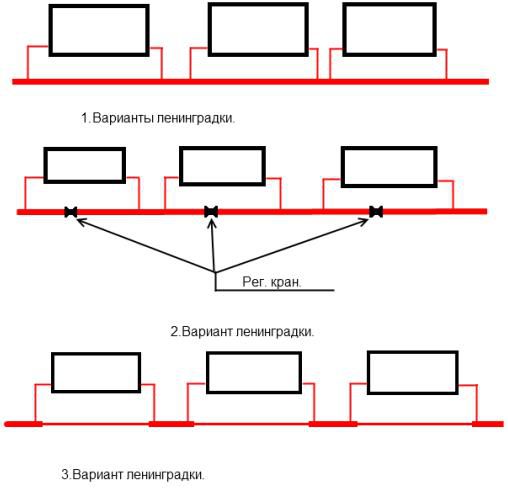

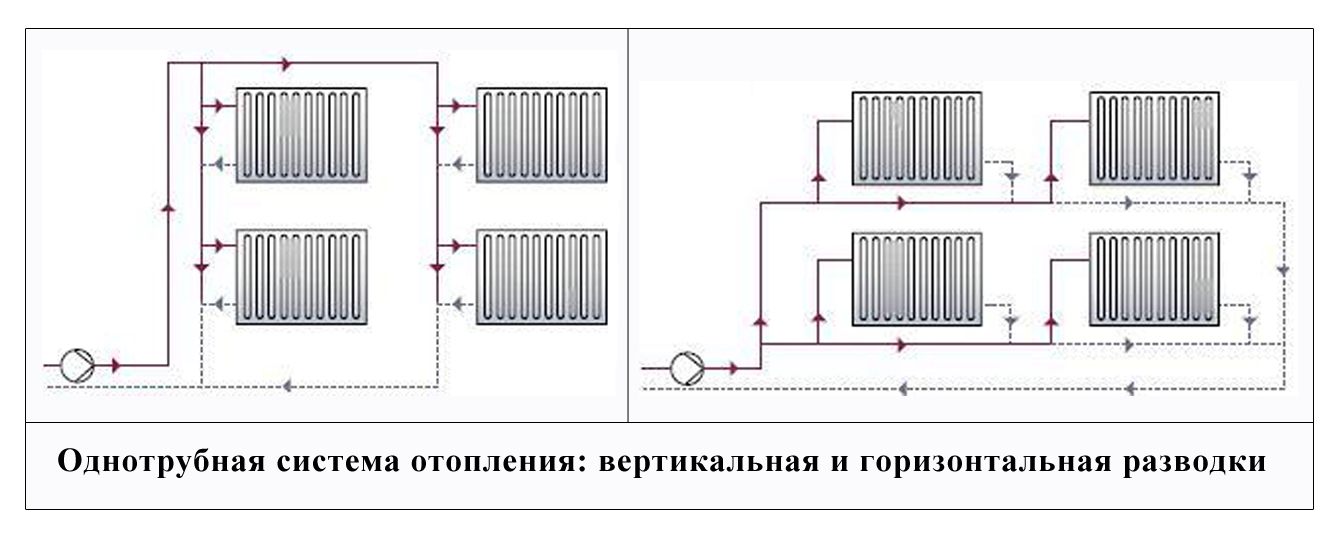

Depending on the orientation of the Leningradka highway, it happens:

- vertical;

- horizontal.

vertical

Used for multi-storey buildings. Each circuit substitutes a vertical riser, passing from the attic to the basement on all floors. Radiators are connected sideways parallel to the main line and in series on each floor.

The effective height of the "Leningradka" vertical type is up to 30 meters. If this threshold is exceeded, the distribution of the coolant is disturbed. It is not advisable to use such a connection for a private house.

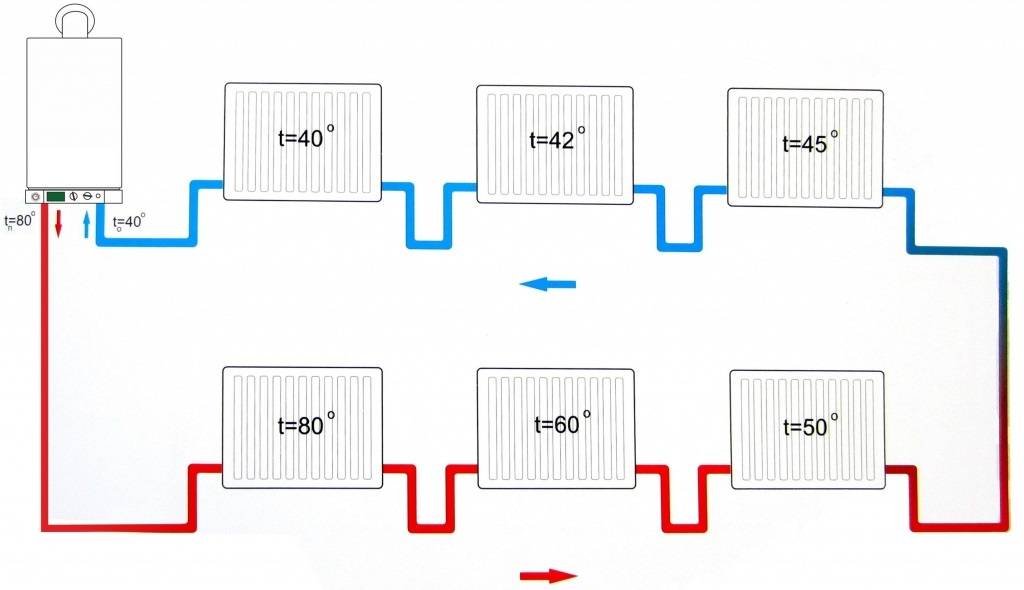

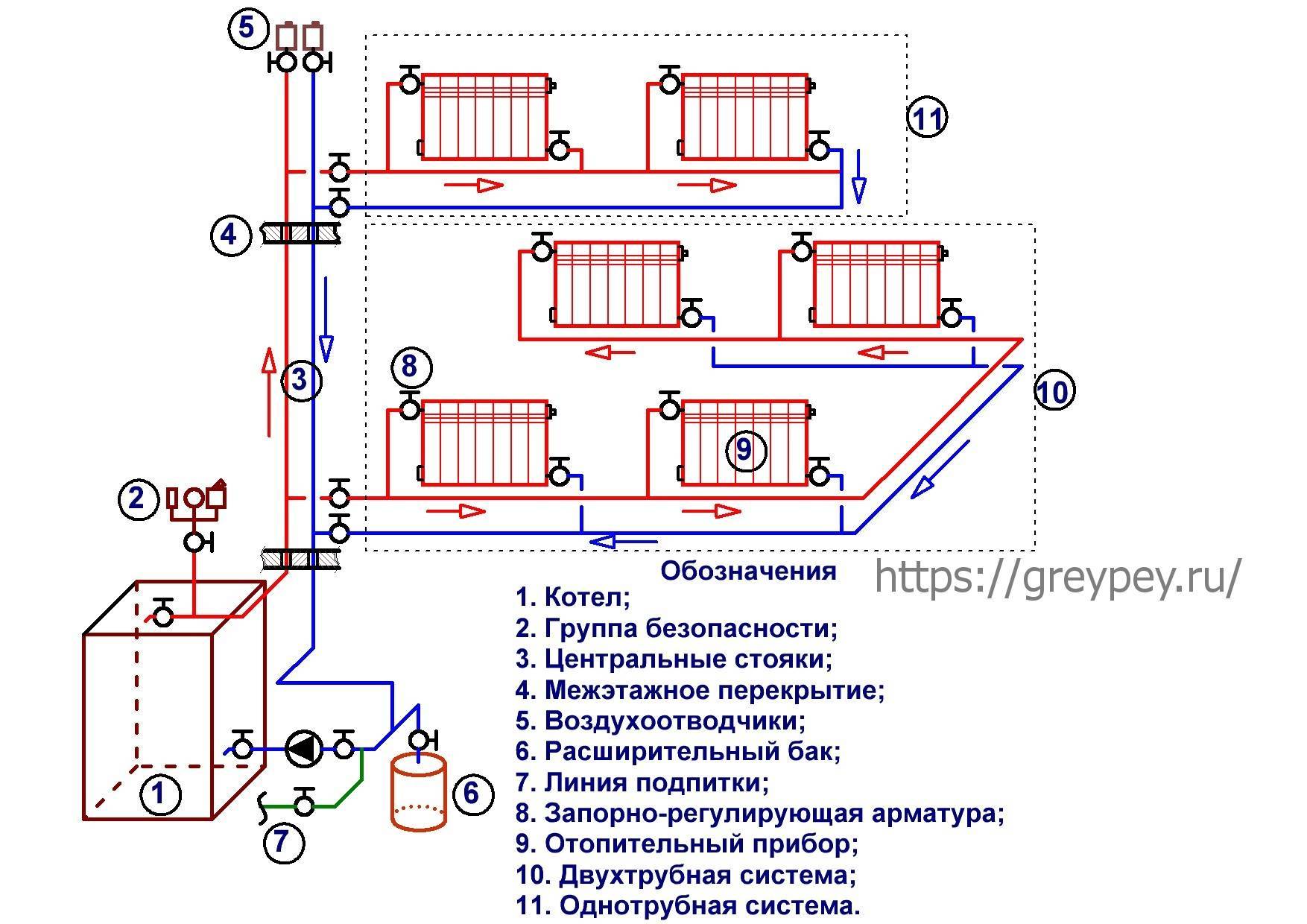

Horizontal

The best option for an autonomous heating system of a private house with one or two floors. The highway bypasses the building along the contour and closes to the boiler. Radiators are installed with a bottom or diagonal connection, with the top point oriented to the hot end of the line, and the bottom point to the cold end. Radiators are supplied with a Mayevsky crane for air release.

The circulation of the coolant can be:

- natural;

- forced.

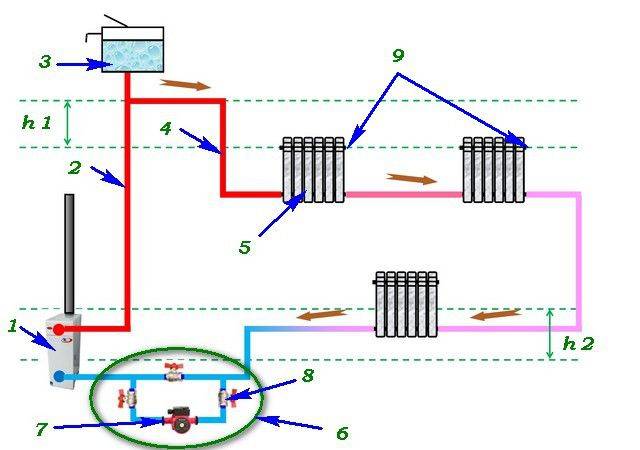

In the first case, the pipes are distributed along the contour with a mandatory slope of 1–2 degrees.The hot outlet from the boiler is located at the top of the system, the cold outlet is at the bottom. To increase circulation, the section of the line from the boiler to the first radiator or the point of inclusion of an open expansion tank is laid with a slope upwards, and then evenly downwards, closing the circuit.

- boiler (hot output);

- open-type expansion tank (top point of the system);

- heating circuit;

- branch pipe with a ball valve for draining and filling the system (the lowest point of the system);

- ball valve;

- boiler (cold input).

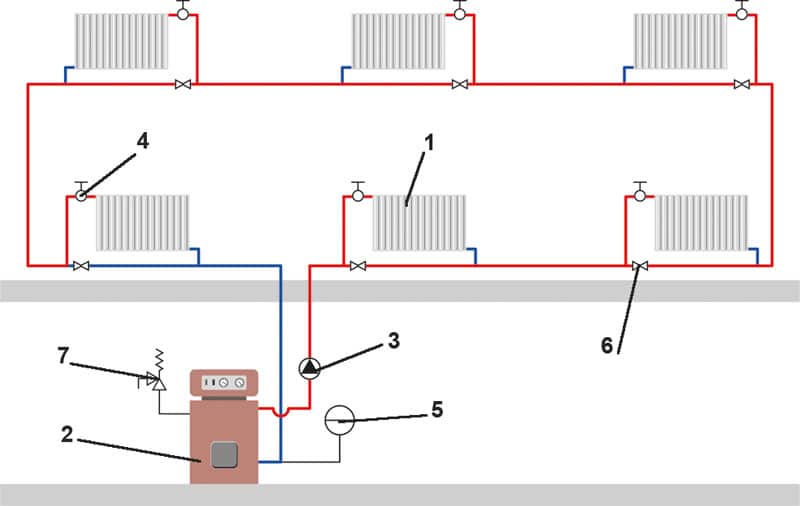

1 - heating boiler; 2 - expansion tank of open type; 3 - radiators with bottom connection; 4 - Mayevsky crane; 5 - heating circuit; 6 - valve for draining and filling the system; 7 - ball valve

There is no need for a one-story house to make the upper and lower wiring of the main, a lower wiring with a slope is enough. The coolant circulates mainly along the contour of the common pipe and boiler. Hot coolant enters the radiators due to the pressure drop caused by the water temperature drop.

The expansion tank provides the required coolant pressure in the system. An open-type tank is installed under the ceiling or in the attic. A membrane-type tank for a closed heating system is installed on the return after connecting parallel circuits, but before the boiler and pump.

Forced circulation is preferable. There is no need to observe the slope, you can perform a hidden installation of the main pipe. The expansion tank of the membrane type allows you to accurately set the pressure in the system.

- boiler (hot output);

- five-pin fitting for connecting a pressure gauge, air vent and explosion valve;

- heating circuit;

- branch pipe with a ball valve for draining and filling the system (the lowest point of the system);

- expansion tank;

- pump;

- ball valve;

- boiler (cold input).

1 - heating boiler; 2 - security group; 3 - radiators with diagonal connection; 4 - Mayevsky crane; 5 - expansion tank of membrane type; 6 - valve for draining and filling the system; 7 - pump

Tying with polypropylene pipes

Piping of radiators can be carried out using a variety of pipes, but experts recommend using polypropylene. Ball valves for strapping are also bought in polypropylene, they can be straight and angled, this option is the simplest and most inexpensive. Brass fittings are more expensive, and installation is more difficult.

Polypropylene strapping is performed as follows:

- the coupling with the union nut is inserted into the multiflex, which is easily connected to any outlet;

- the pipes themselves are attached to the walls at a convenient height, they should not fit snugly against the surface, it is better to leave a gap of 2-3 cm. The pipes are fixed with special brackets, which are fixed to the wall with nails or self-tapping screws.

Polypropylene strapping to radiators can also be carried out when pipes are laid into the wall, in which case they come to the surface only at the connection points.

Piping of radiators can be carried out using a variety of pipes, but experts recommend using polypropylene.

Fasteners for batteries can be very different, most often it is a pin connection, which is fixed on the wall surface. Corner brackets can also be used, which also allow hanging radiators at the required height.For panel batteries, fasteners are supplied in the kit, for sectional batteries, you need to buy separately. Usually, two brackets or pins are enough for one section.

The connection of cranes is carried out in this way:

- the crane is disassembled, a fitting and a union nut are screwed into the radiator;

- the nut is tightly tightened with a special wrench.

As you can see, this process is extremely simple. To perform such work, you only need to purchase a special plumbing key for American women, without which it is unlikely that you can simply install a tap.

The following materials and tools are required for battery installation and piping:

- a set of special keys;

- seals for threaded connections;

- tow and thread paste;

- thread for carving.

Features of connecting radiators

Installation of heating differs in some features:

- It is necessary to observe the distance from the radiator to the window sill of 100 mm. If the gap between the batteries and the bottom of the window sill is different, then the heat flow is disturbed, the effect of the heating system will be low.

- From the floor surface to the battery, the distance should be 120-150 mm, otherwise a sharp temperature drop occurs.

- In order for the heat transfer of the equipment to be correct, the distance from the wall must be at least 20 mm.

At the same time, we take into account that the installation method and the efficiency of heating radiators are greatly influenced by the installation method: under the window sill in the open form, the efficiency of the heating system is maximum - 96-97%, in a niche in the open form - up to 93%, in a partially closed form - 88-93 %, fully closed - 75-80%.

The heating radiator can be installed using a variety of methods, its piping is carried out with metal, polyethylene, polypropylene pipes

It is important during installation to correctly position not only the pipes, but also the batteries themselves, to connect in accordance with all recommendations and standards. In this case, the heating system will work very efficiently and will not require repairs. Share this helpful article:

Share this helpful article:

2 Choosing the type of pipes based on polypropylene for a private house

The heating system in a private household has some differences from that in an apartment building. The main ones are the following:

- The possibility of independent design with a change in the finished project "on the go", which opens up great opportunities for the implementation of various installation schemes.

- Low main pressure and almost complete absence of water hammer.

- The choice of coolant in the system is determined by the owner of a private house. It is possible to change the coolant at any time.

- The short length of the pipe line eliminates air pockets.

- Installing a circulation pump will increase the flow rate of the coolant and ensure a more even distribution of heat throughout the building.

There is a wide range of sizes of polypropylene pipes

The modern industry offers the widest selection of types and sizes of polypropylene pipes. In order to correctly select the necessary option for a particular private house, we list the most common polypropylene pipes offered on the market, indicating performance characteristics.

Pipe PN-10

Polypropylene conductors of this type are produced with an outer diameter of 20 - 110 mm and an inner diameter of 16.2 - 90 mm. The wall thickness of the material in this case ranges from 1.9 to 10 mm, depending on the diameter. They are made of thin-walled polypropylene, most often single-layer, which has a working temperature of up to 20 C and a pressure of up to 1 MPa. Available in 4 meter lengths. Such pipes cannot be used in heating systems; they are intended for domestic needs for supplying cold water over short distances without pressure in the line.

Pipe PN-16

This type of product is characterized by thicker walls compared to the above option. At the same time, the outer diameter is identical to PN-10 products, but the inner one is slightly smaller - it varies from 14.4 to 79.8 mm. The operating temperature range of the coolant is from 0 C to 60 C, and the operating pressure is 1.6 MPa. The release form is 4 m lengths. It is worth noting that this type of pipe is rarely used in heating, since the upper limit of withstand temperatures of 60 C is low for heating systems, and the cost of such products is comparable to the cost of more functional products. It is recommended to use such conductors for the installation of underfloor heating, where the operating temperature is usually not higher than 50 C, or for hot water supply.

Pipe PN-20

Products are characterized as universal conductors used for heating and hot water supply.However, when used in the heating mains of a private house, it is recommended to install only return water from them, since the temperature of the coolant supplied from an individual heating boiler, unlike the central heating main, can reach up to 100 C, and the maximum operational for this type of conductors is 80 C. They have a two-layer structure, which provides increased strength and ductility. External diameter - from 16 to 110 mm, internal - from 10.6 to 73.2 mm, with a wall thickness of 1.6 - 18.4 mm. As the name suggests, the maximum working pressure is 2 MPa. The use of this product is advisable for arranging underfloor heating, heating greenhouses, hot water supply, when installing a heating main in apartments with central heating.

Pipes PN-25

They are the best for arranging heating systems in a private house. Due to the two-layer design and the presence of aluminum or fiberglass reinforcement between the layers, it has improved performance. Such products are able to withstand a constant temperature of the filler up to 95 degrees, have improved strength characteristics, high thermal insulation properties. The outer diameter of PN-25 pipes varies from 21.2 to 77.9 mm, the inner diameter - from 13.5 to 50 mm. The release form is standard - segments of 4 m.

The inner reinforcing layer reduces the expansion coefficient of the pipeline, which reduces deformation microdamages of polypropylene and increases the service life of the product.

How to install

Now about how to hang the radiator. It is highly desirable that the wall behind the radiator be flat - it is easier to work this way.The middle of the opening is marked on the wall, a horizontal line is drawn 10-12 cm below the window sill line. This is the line along which the upper edge of the heater is leveled. The brackets must be installed so that the upper edge coincides with the drawn line, that is, it is horizontal. This arrangement is suitable for heating systems with forced circulation (with a pump) or for apartments. For systems with natural circulation, a slight slope is made - 1-1.5% - along the course of the coolant. You can’t do more - there will be stagnation.

Proper installation of heating radiators

wall mount

This must be taken into account when mounting hooks or brackets for heating radiators. Hooks are installed like dowels - a hole of a suitable diameter is drilled in the wall, a plastic dowel is installed in it, and the hook is screwed into it. The distance from the wall to the heater is easily adjusted by screwing and unscrewing the hook body.

Hooks for cast iron batteries are thicker. This is fasteners for aluminum and bimetallic

When installing hooks for heating radiators, please note that the main load falls on the top fasteners. The lower one serves only for fixing in a given position relative to the wall and it is installed 1-1.5 cm lower than the lower collector. Otherwise, you simply will not be able to hang the radiator.

One of the brackets

When installing the brackets, they are applied to the wall in the place where they will be mounted. To do this, first attach the battery to the installation site, look where the bracket will “fit”, mark the place on the wall. After putting the battery, you can attach the bracket to the wall and mark the location of the fasteners on it.In these places, holes are drilled, dowels are inserted, the bracket is screwed onto the screws. Having installed all the fasteners, the heater is hung on them.

Floor fixing

Not all walls can hold even light aluminum batteries. If the walls are made of lightweight concrete or sheathed with drywall, floor installation is required. Some types of cast iron and steel radiators come with legs right away, but they do not suit everyone in terms of appearance or characteristics.

Legs for installing aluminum and bimetal radiators on the floor

Floor installation of radiators from aluminum and bimetallic is possible. There are special brackets for them. They are attached to the floor, then a heater is installed, the lower collector is fixed with an arc on the installed legs. Similar legs are available with adjustable height, there are fixed ones. The method of fastening to the floor is standard - on nails or dowels, depending on the material.

This is interesting: What is the slope of the sewer pipe is considered optimal in various situations - we tell the main thing

Conclusions and useful video on the topic

Video #1 How to choose PPR pipes:

Video #2 Solid fuel boiler piping technology:

Video #3 How to tie a heater in a two-story cottage:

When choosing a scheme for piping a boiler with polypropylene pipes, it is necessary to take into account all the features of a particular building. The process of installing pipelines and connecting equipment is simple, even a novice master can handle it.

A soldering iron for polypropylene fittings and pipes is easy to work with. But it is better to entrust the preparation of a heating system project to a specialist, mistakes are unacceptable here.

Do you want to share your personal experience gained during the assembly of polypropylene strapping with your own hands, have you found any shortcomings or want to get answers to your questions? Please write comments in the block located under the test of the article.