- Installation of a pumping station - interior work

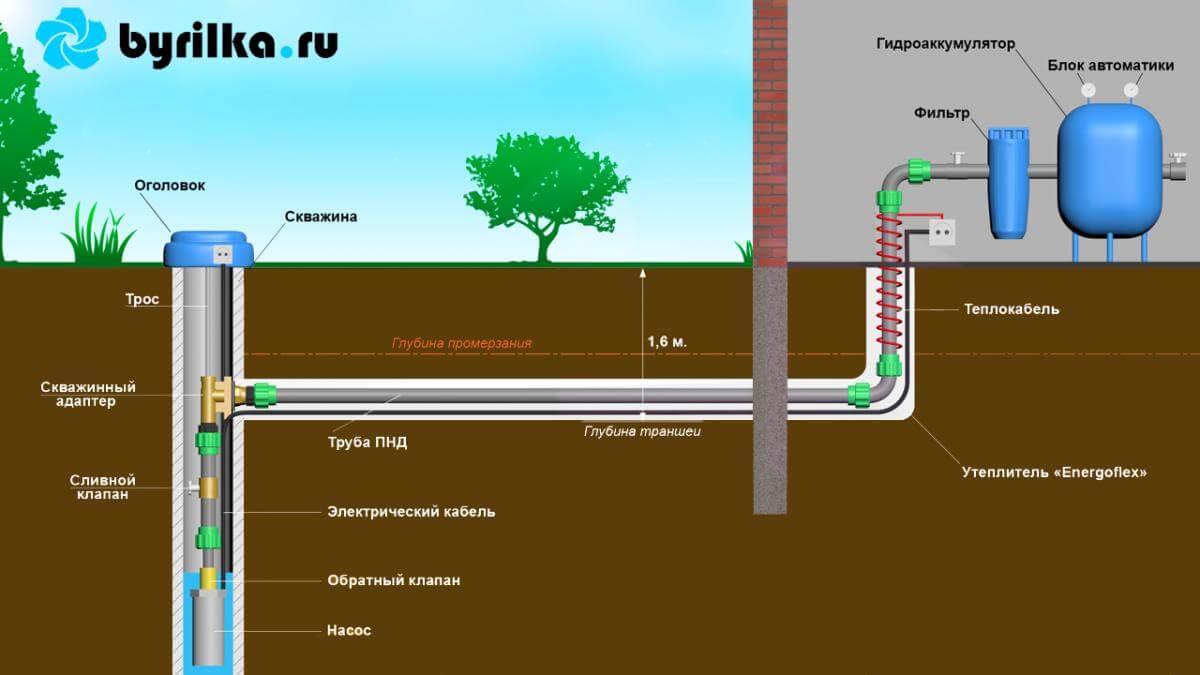

- Pipeline laying

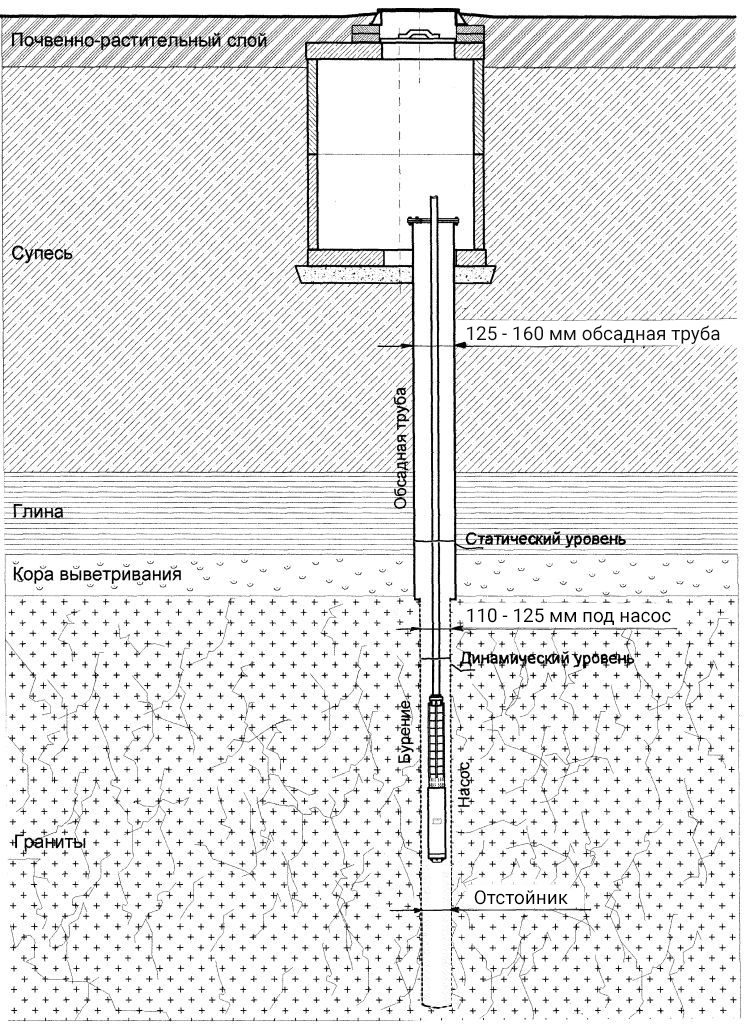

- Drilling a well

- Ensuring the tightness of the casing

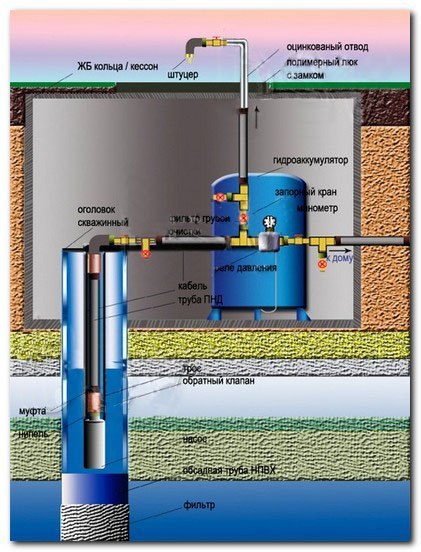

- Well with caisson

- Application of PE pipes for outdoor use

- Drilling a well - before or after building a house

- Sewer system

- Winter well arrangement

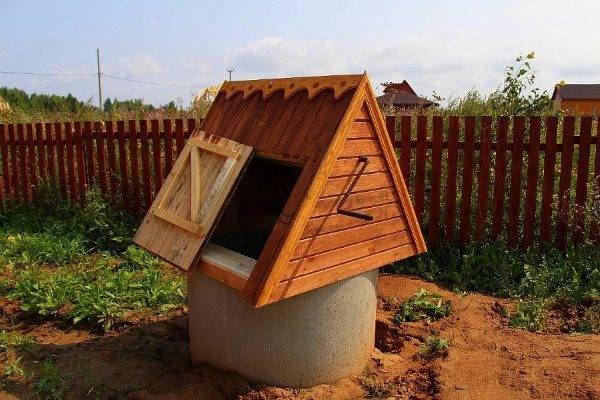

- ground room

- Placement of a well in a house

- Pit construction

- Arrangement with a caisson

- Plastic caisson

- Metal caisson

- Arrangement of a well in a well made of concrete rings

- Harness with adapter

- Main types of wells

- Ordinary well

- Abyssinian well

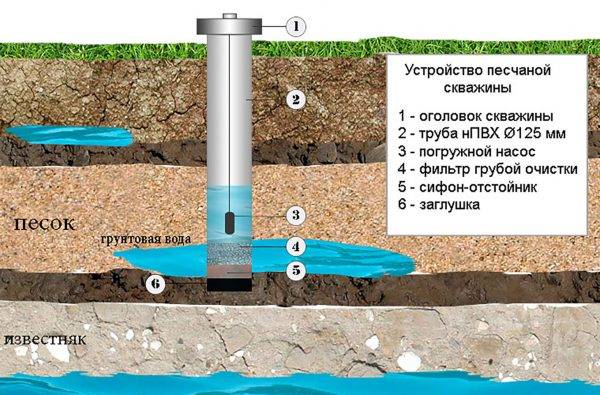

- medium depth

- Artesian

- Legal side of the problem

- How to choose and where to install water filters

- The device and principle of operation of pumping stations

- Why furnish?

- Well pumps

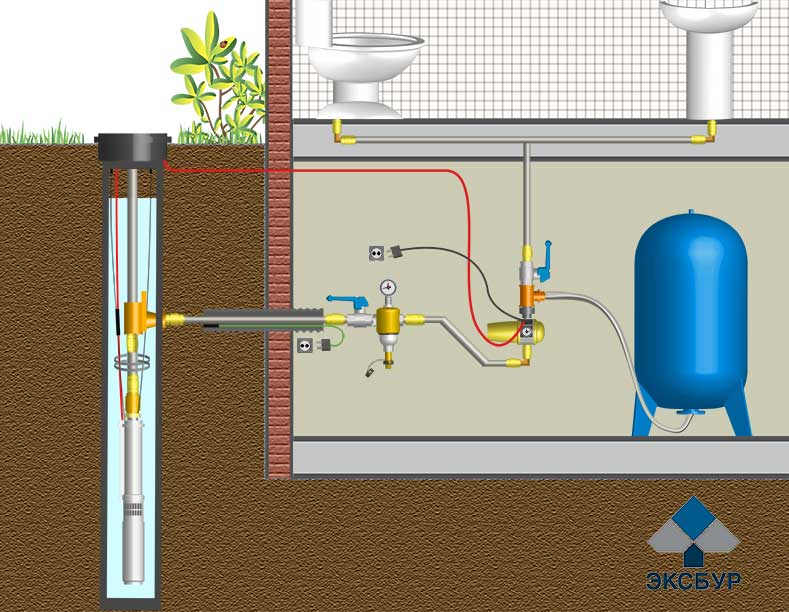

Installation of a pumping station - interior work

Internal work with home plumbing equipment can be divided into two parts: installation of a pressure line to a primary filter and piping around the house to the planned water points. Here the wiring to the filter will be considered.

This part of the pressure line is made with a polyethylene pipe. First of all, a shut-off valve is installed, which can be used to shut off the water supply to the entire house if necessary.It must meet two requirements - to be reliable and to be able to quickly dismantle without dismantling the entire line. These requirements are best met by a brass ball valve with an "American".

After the pump, a tee with a tap to fill the system with water with a valve and a check valve on the water line to the consumer must be placed

You should not buy a cheap silumin crane - its service life rarely exceeds 5 years, after which it crumbles, which is fraught with the threat of flooding.

The next step is to install the primary filter housing. It is mounted on the wall in a place convenient for maintenance. Most of these filters are self-cleaning. The frequency of maintenance depends on the quality of the water in the region. Maintenance is reduced to washing the cartridge and freeing the flask from sediment. An example of such a filter is shown in the photo below.

Installation of the primary filter

The filter is supplied with a key for the flask, which simplifies its installation. Water is supplied to the inlet through a PE pipe, and a transition to a PPR pipe is installed at the outlet. From this place, the distribution of pressure water supply through the house to consumers begins. The pipe must be well fixed on the walls and floors with rubber grips. To connect to the filter, you can use plastic fittings - elbows and couplings, which may differ in design, but the main thing to consider when working with them is that the pipe must go into the fitting tightly and reach the stop. Otherwise, under pressure, it may gradually squeeze out, which threatens to flood. The first photo shows a disassembled plastic elbow for a PE pipe, and the second photo shows a general view of the finished line from the station to the filter.

Pipeline laying

At the bottom of the well, it is necessary to pour fine gravel (crushed stone) or coarse sand. This will protect the pipeline from silting. Before filling, the bottom of the well is necessarily cleaned with a bailer. It is necessary to pre-prepare the first pipe in order to lower it into the well immediately after drilling is completed. Thus, you will not allow the walls to crumble.

Along the perimeter of the pipe, at a distance of approximately 29 cm from its bottom, holes must be made. Due to them, the pipe will "collect" a larger volume of water.

Due to the fact that it is best to lay pipes 220-260 cm long for the construction of a well, most often one elbow is not enough. Longer pipes are not so easy to maintain and install. Pipes are fastened with each other by “screwing” along the thread. The first pipe must be lowered so that it rests on the bottom of the pit. After installing the pipes, you can begin the device of the caisson and the installation of the pump.

Drilling a well

The first step is to create a well. Best for drilling shock-rope methodA: It's simple but effective.

First, prepare the main working mechanism - a support tripod with a driving glass: weld a tripod structure from metal pipes and fix the glass on it using a winch with a special cable. The height of the support is determined by the length of the driving device used: the tripod should be 1.5-2 m higher than the glass.

Shock-rope well drilling technology

Shock-rope well drilling technology

When the mechanism is assembled, start drilling:

- with pressure, drive the glass into the designated working area;

- take the soil with a glass;

- raise the glass and free it from the ground;

- repeat the steps until the required depth is obtained.

After drilling, place the casing in the well.It can be either made of steel or plastic, but always with a threaded connection.

It is also important to fix the pipe well - it should fit as tightly as possible to the ground.

Next, dirty water and the upper layers of clay and sand should be pumped out of the finished well. To do this, use a conventional pump.

Ensuring the tightness of the casing

The casing pipe must be protected from the penetration of dust and melt water, which are sources of microorganisms. For sealing, a special device is used - a head made of cast iron or plastic, capable of withstanding a load of 200 kg. The device consists of:

- flange;

- covers;

- carbine;

- cuffs;

- fasteners.

The head is selected according to the diameter of the casing pipe and, after being put on it, is fixed with a flange. The inlet cover has openings for the supply electrical cable and water pipes. All joints with pipes and cables are securely sealed with rubber seals. A gasket is installed under the cover before fixing with bolts.

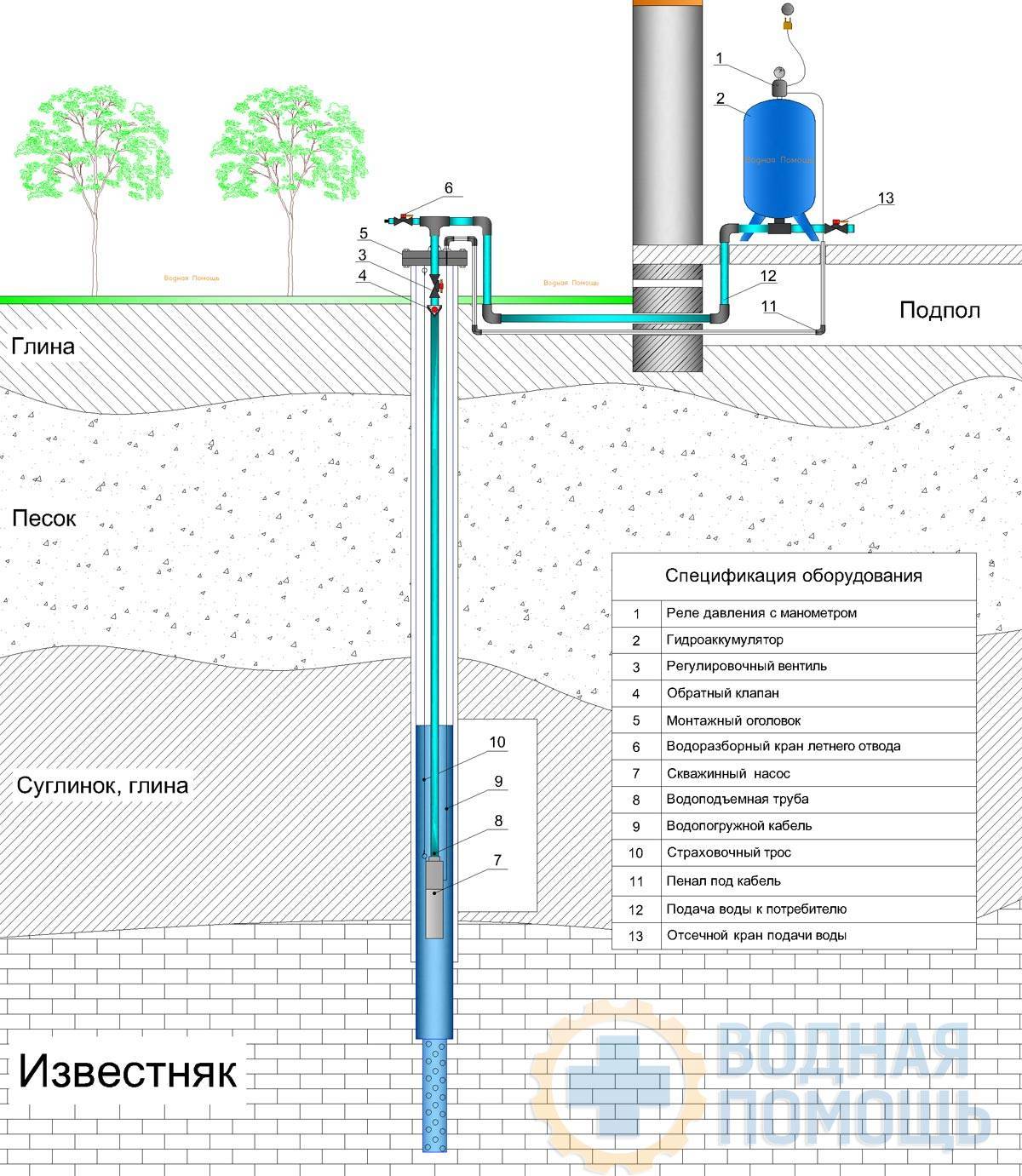

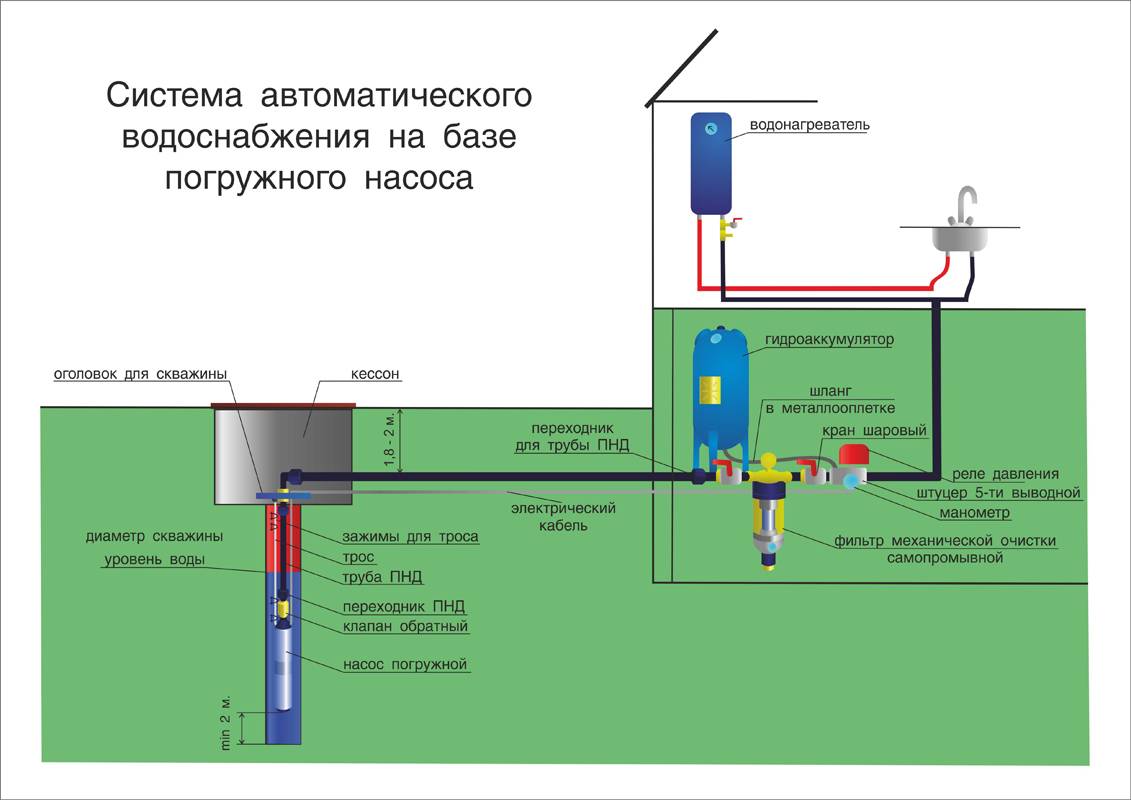

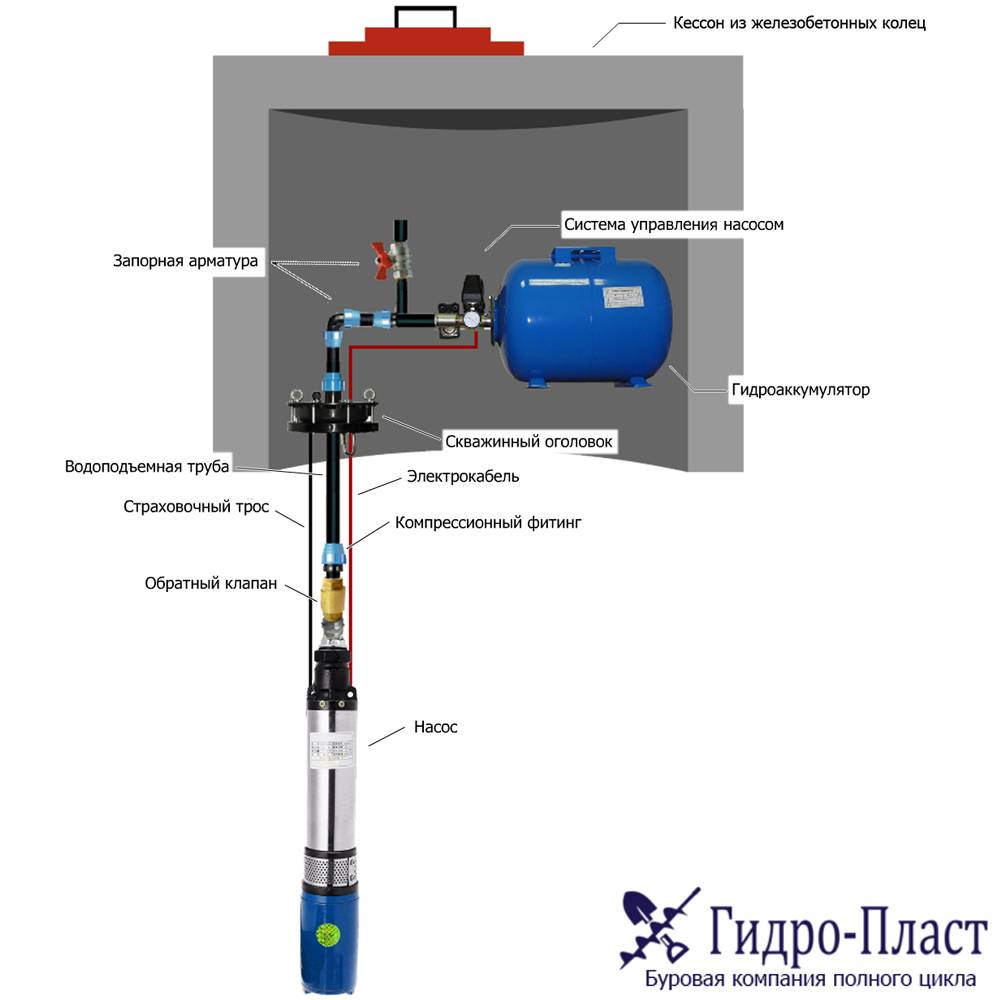

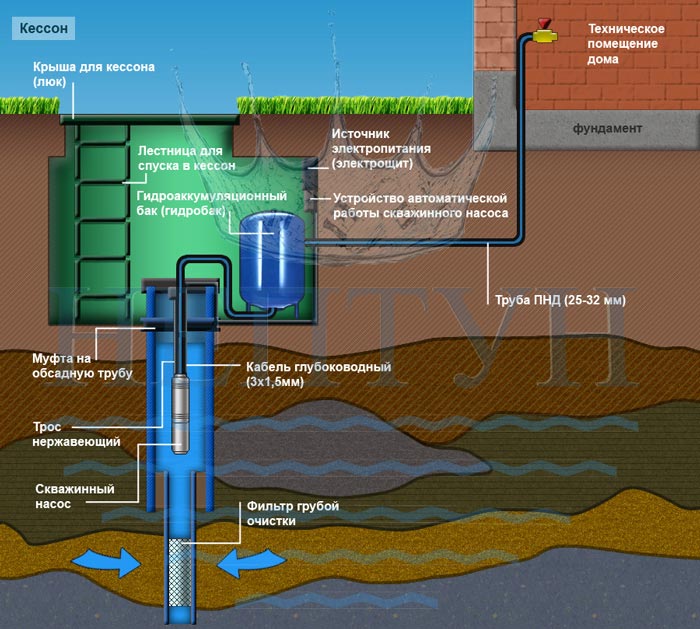

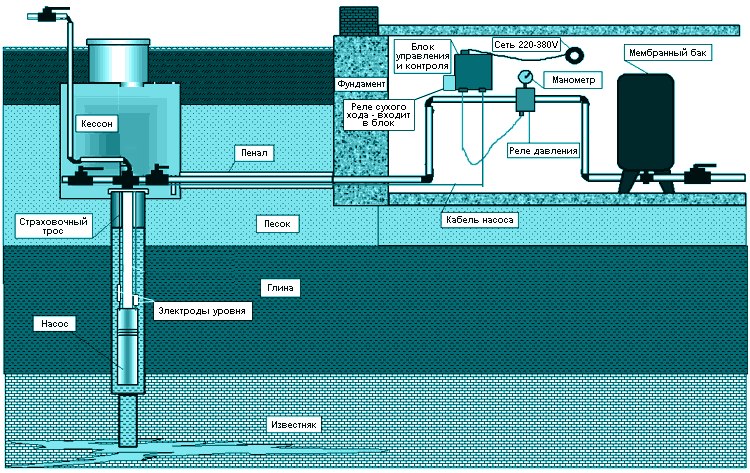

Well with caisson

If you build wells according to the technological level, a well with a caisson will be at the top of the rating. The caisson is a special container buried in the ground in the area of the well, so that the mouth of the well is inside it. After the installation of the necessary equipment, the caisson is covered with a layer of earth, and a technical hatch remains on the surface. Often, instead of a container, a caisson is built of concrete rings or bricks, in the form of a small underground room.

The caisson performs several important tasks.

- Firstly, it does not allow the well to freeze in the winter. If necessary, the caisson is insulated;

- Secondly, the caisson allows you to place the necessary equipment for lifting and delivering water, including a pump, a hydraulic accumulator, automation, individually or as a complex in the form of a pumping station.

At the same time, all equipment will be protected from precipitation, groundwater and other weather troubles.

Application of PE pipes for outdoor use

Polyethylene pipes are replacing steel everywhere. They are used for outdoor wiring and are used to transport various liquids and gases. Their advantage is high strength, low cost, complete absence of corrosion, resistance to aggressive environmental factors, ease of installation and a very long service life (warranty period - 50 years).

PE pipes intended for water have blue marking stripes and the inscription "Drinking" along their entire length. There are two types of pipes - "C" and "T". "C" - medium pipes, designed to work under pressure up to 6 atm. "T" - heavy, with a maximum working pressure of 10 atm.

All types of PE pipes can be laid directly into the ground. One of the positive qualities is the ability to work with them in winter at temperatures down to -20 degrees. When water freezes in a pipe, it does not burst, it can be easily warmed with boiling water. Replacement of such a pipe in the event of an accident is carried out without additional equipment. The low price is another advantage of PE pipes over steel ones.

Drilling a well - before or after building a house

The location of the well on the territory of the land plot is best determined within the boundaries of the future home.To do this, you need to decide on the project and tie the boundaries of the foundation to the terrain. The well should be in the basement or basement. This is the most convenient location, in which it is easiest to protect pipelines and pumping equipment from freezing and install it compactly in one place.

But more often than not, the idea to drill a well and equip your own home plumbing comes after the house is under a roof. In this case, the well should be located as close to the foundation as possible in order to reduce the length of the suction lines, which affects the performance of the pumping station, the cost of piping insulation and the arrangement of the well itself.

Sewer system

When arranging your own water supply system, a sewerage system in accordance with all sanitary standards is a prerequisite.

All waste water must be collected in sealed septic tanks or discharged into the soil after proper treatment. The most common sewerage system is considered to be gravity flow of wastewater through a pipe system with their direction into filtering septic tanks (wells). In rare cases, forced movement of the runoff with the help of pumps is used.

The sewer line, as a rule, is mounted from plastic or metal pipes with a diameter of 120-160 mm. To ensure gravity flow, the slope of the route must be at least 3 °. With a long route, manholes are installed every 50 m.

Water supply in a private house from a well solves the problem of water consumption even in the complete absence of a centralized water supply.However, it should be borne in mind that such a system may require obtaining the necessary permits and requires compliance with all applicable regulations. When arranging your own water supply, it is necessary to ensure the desired quality of water and not harm nature.

Winter well arrangement

The most time-consuming point in arranging a well for water is protecting equipment from freezing. Russia is a northern country. Our winters are long and cold. If the hydraulic structure is not protected, it will only work in the summer. For the winter, it must be preserved by draining pipes.

ground room

If the size of the site is large, then it is possible to equip a separate building above the well. It can be a modular building, an insulated container, or a beautifully designed house that will become an element of landscape design.

The disadvantage of this method is the heating of the room. An unheated building will be useless at sub-zero temperatures - the water in the pipes will freeze.

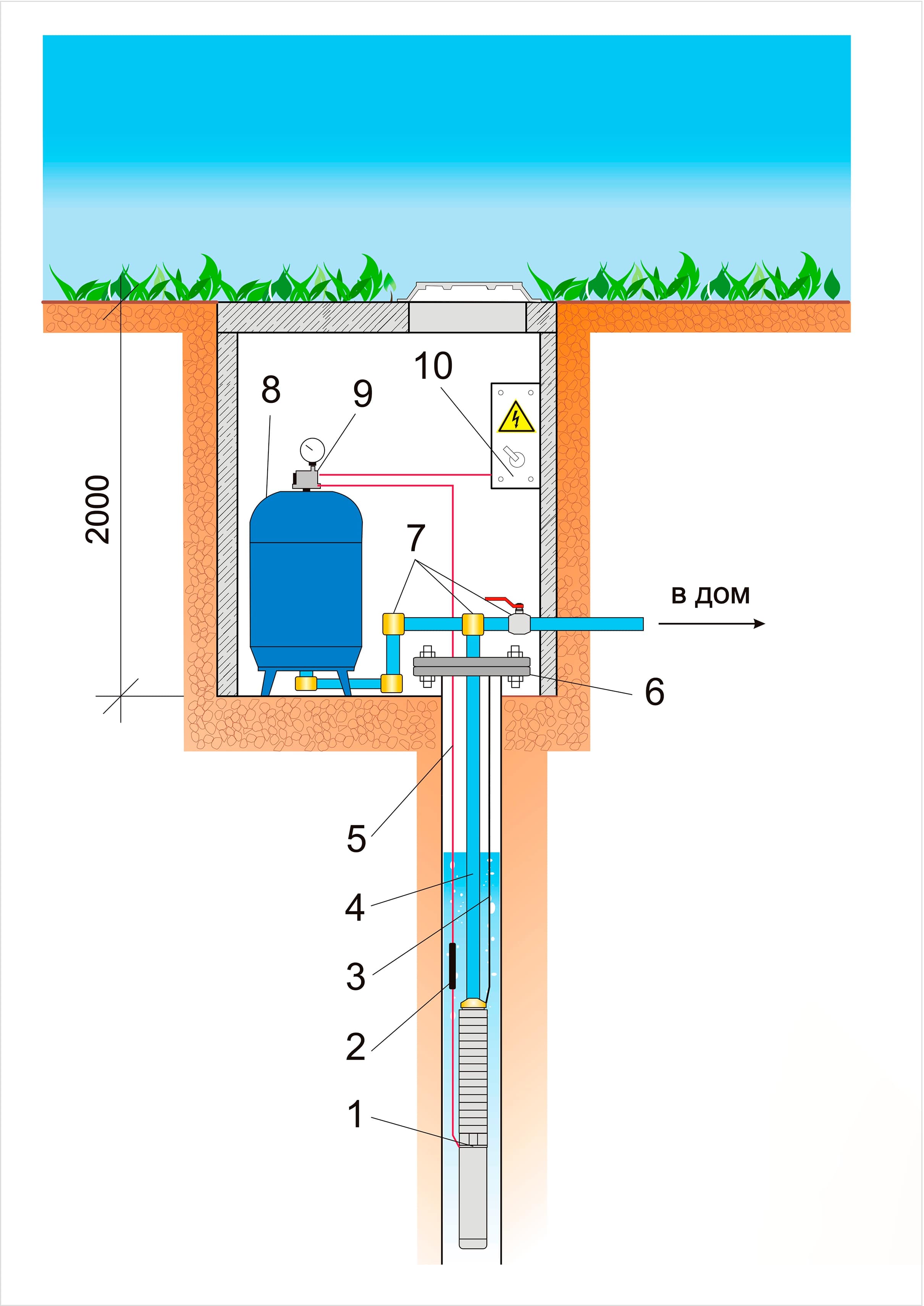

Placement of a well in a house

Arrangement of a well inside the house will remove all issues with heating. You can place the piping elements close to the source, which is economical: less pipes and cables are required. The disadvantages of this method in the prevention of equipment. The pump will need to be repaired - you will have to pull the entire bundle from the well into the house.

A well drilled close to the foundation can damage it. This strapping option should be planned before building a house, when all calculations of the strength of the structure can be made. We do not recommend drilling a deep well in a finished house.

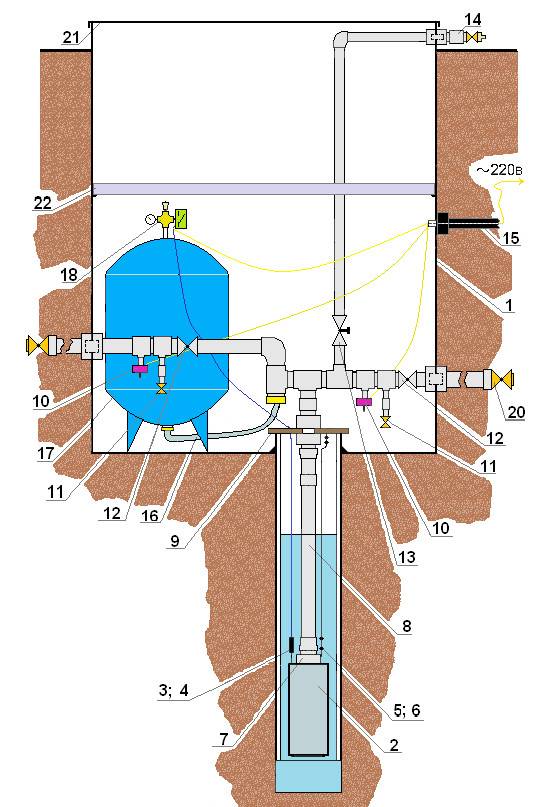

Pit construction

The underground version of the strapping does not violate the landscape with additional buildings.Sufficient depth is a guarantee of maintaining a temperature that is comfortable for the operation of the equipment.

It is not necessary to heat the underground space.

The pit looks like a garden underground cellar, at the bottom of which the mouth of the well comes out. When building a pit, reinforce the walls from shedding to make it airtight.

The pits are made of concrete, poured through the formwork. The brickwork option is less airtight, used for sandy soil.

Arrangement with a caisson

For houses with water supply from a well, the caisson works well in winter. The advantage of the structure is tightness. It is established if groundwater passes at a depth of up to 3 meters, and when clay soils are located at the same depth. This retains moisture near the caisson, protects the well from contamination, and protects equipment.

Caisson for a well - a sealed structure to protect equipment from low temperatures.

Containers for caissons are made of plastic or metal.

Plastic caisson

Plastic caissons began to be used in the 2000s. Caissons are made from non-toxic plastics and fiberglass.

Plus plastic caissons in tightness and lightness. PVC caisson can be installed by 2-3 workers without lifting equipment.

Minus - the walls of the caisson can push through the ground and deform.

Pour concrete into the free space between the walls of the caisson and the boiler. This will insulate the caisson and protect it from deformation.

Metal caisson

An iron caisson will not warp with soil. Well-welded seams and metal coated with an anti-corrosion coating are a guarantee of tightness. If the metal caisson is not insulated, frost will form on the cold inner surface.

Minus iron caisson - weight. For setting in the pit, a crane is required.

Arrangement of a well in a well made of concrete rings

Winter arrangement of the well with concrete rings is done in areas where rainwater does not accumulate.

The disadvantage of arranging a well with a caisson made of concrete rings is that the joints are not tight, through which the liquid will fill the well and damage the equipment.

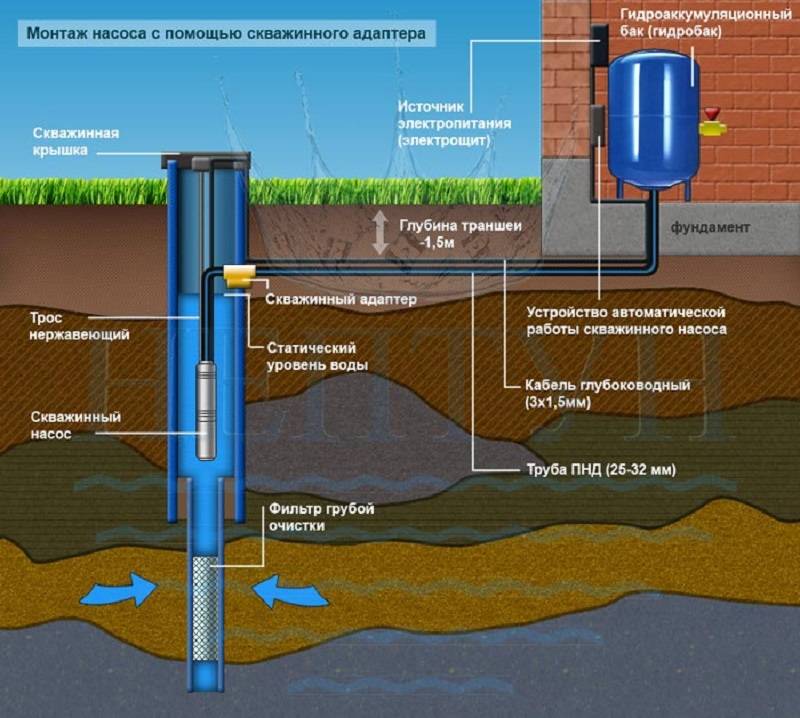

Harness with adapter

The adapter is placed inside the casing string. This is a replacement for a warm room.

- an adapter that secures the pump below the freezing point, and the role of the caisson is performed by the casing pipe itself.

The advantage of the invention is the protection of the well from groundwater and the price. However, there are disadvantages:

- The adapter is mounted in buildings with one column.

- Tightness is provided only by a metal casing string. Plastic pipes do not keep seals tight.

- The adapter is disassembled once a year and the connections are disconnected to prevent the "growth" of the nodes.

Adapter installation video:

The borehole adapter for a well cannot be installed in areas with long severe winters.

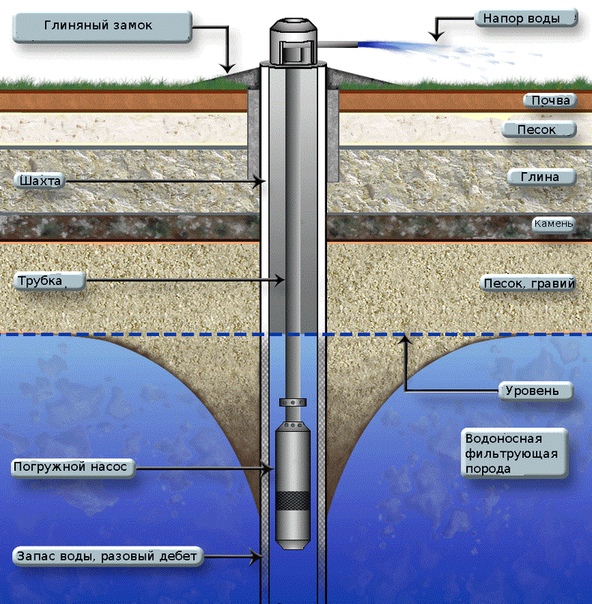

Main types of wells

To date, there are several massive, time-tested structures that will ensure the flow of water from workings in the ground. Selection of the type of well is a responsible matter, which should be based on the results of hydrogeological surveys. The use of the type of well is dictated, along with the conditions on the site, by the needs of the owners for water.After all, the water supply schemes of a summer country house with a garden and a vegetable garden and a two-story house for year-round living of two families will be very different.

Ordinary well

This attribute of country life, familiar to everyone at least from movies and cartoons, is the easiest way to get water. Its depth rarely exceeds 4-5 meters, two or three cubes of water always accumulate at the bottom. When connecting a submersible pump and water conduit equipment to the house, it is quite possible to use a well for water supply. True, intensive use of such water will not work, and its quality leaves much to be desired.

Abyssinian well

This name hides a system of thick-walled pipes with a mesh or perforated filter at the end. Pipes are hammered into the ground by a special device, colloquially referred to as a "woman". The intake end with the filter reaches the aquifer. At the top, either a manual or electric pump is arranged. The performance of this needle well is slightly greater than that of a standard well, and its installation is cheaper, but since there is no storage in the system, you will have to forget about intensive flow.

It is generally accepted that the water from the Abyssinian well is technical and is suitable only for irrigation. However, with a favorable hydrogeological situation, it may well be clean. Of course, you should not drink it without filtration and boiling, but you should wash and wash in it, since it is quite soft.

medium depth

Its second name is a well in the sand. For it, drilling is already used up to aquifer sand layer. Typically, the depth of this formation is 15–30 meters.To strengthen the structure, casing pipes are used - steel, and now cheaper and non-corrosive polymer pipes. Wells in the sand provide fairly clean water, which, however, is also better to pass through a filter and disinfectant. A well of medium depth has its own service life. Its failure is not even connected with the strength of the structure, but with the fact that the filter on the water intake is silted up. Over time, it becomes impossible to clean it, and you have to drill a new well. The average normal service life is about ten years. With active use, it is reduced.

Artesian

The deepest of domestic wells and serves much longer than all the others - about 80 years, or even more. But it has a tangible minus - high complexity and a large amount of work make the price very high. It's all about the depth at which drilling is carried out. An artesian well reaches a depth of more than 100 m. It passes through several soft and hard layers - loam, clay, water-bearing sand, until it reaches limestone or even harder rocks with aquifers.

A deep well in a stone does not need end casing and filters - after all, the water comes directly from the rocks, where sand is no longer found. In addition, at such a depth, water is under pressure and enters the system by gravity - a pump is already needed to supply water to the room. On the other hand, such water withdrawal already requires state registration. Well, the complexity of the work carried out determines their high cost.

Legal side of the problem

The question of the eligibility of constructing wells in one's own area for water supply is regulated by the Law of the Russian Federation "On Subsoil" and a number of regulatory documents.In accordance with Art. 19 of this law, land owners have the right to build wells and boreholes for using water from the upper aquifer, which does not require any permits, except for compliance with sanitary standards. If the well is drilled to lower formations (artesian wells), then a license in the prescribed form must be obtained, and water consumption is taxed.

For obtaining a license for the construction of a deep well, the following set of documents is submitted:

- technical passport for the well;

- conclusion from the sanitary and epidemiological station and based on the results of a hydrogeological study;

- cadastral documents;

- results of water tests;

- established water consumption limits;

- tax return.

The tax on the use of the well is set based on local regulations and depends on the volume of consumption. To clarify the amount, the water supply must be equipped with consumption metering devices.

When planning the construction of a well, local legislation should be clarified. The fact is that in a number of regions of the country where there are problems with the water balance and special sanitary zones have been established, the law also allows licensing of shallow water sources. In such cases, restrictive measures are possible in terms of consumption limits, drilling depth, pump power. In order to exclude legal problems after the start of operation of your water supply, it is recommended to clarify all the nuances with the relevant local supervisory authorities.

How to choose and where to install water filters

Water in different places differs in its chemical and bacteriological composition. A lot of salts are dissolved in it, or, conversely, there is an almost complete absence of them. Both can negatively affect the well-being of the person who uses it, and the performance of household appliances that use water in their work. Therefore, the set of primary filters in different places will be different.

The general filtration scheme recognizes the division into water used for domestic purposes and for cooking and drinking. For domestic purposes, it is sufficient to install coarse filters and, in some cases, filters that absorb iron and calcium salts. They are installed immediately after the water exits the pumping station. Drinking water must undergo additional purification from pathogenic microflora, salts of heavy metals and excessive mineralization (or, conversely, must be replenished with salts and ions deficient in the area).

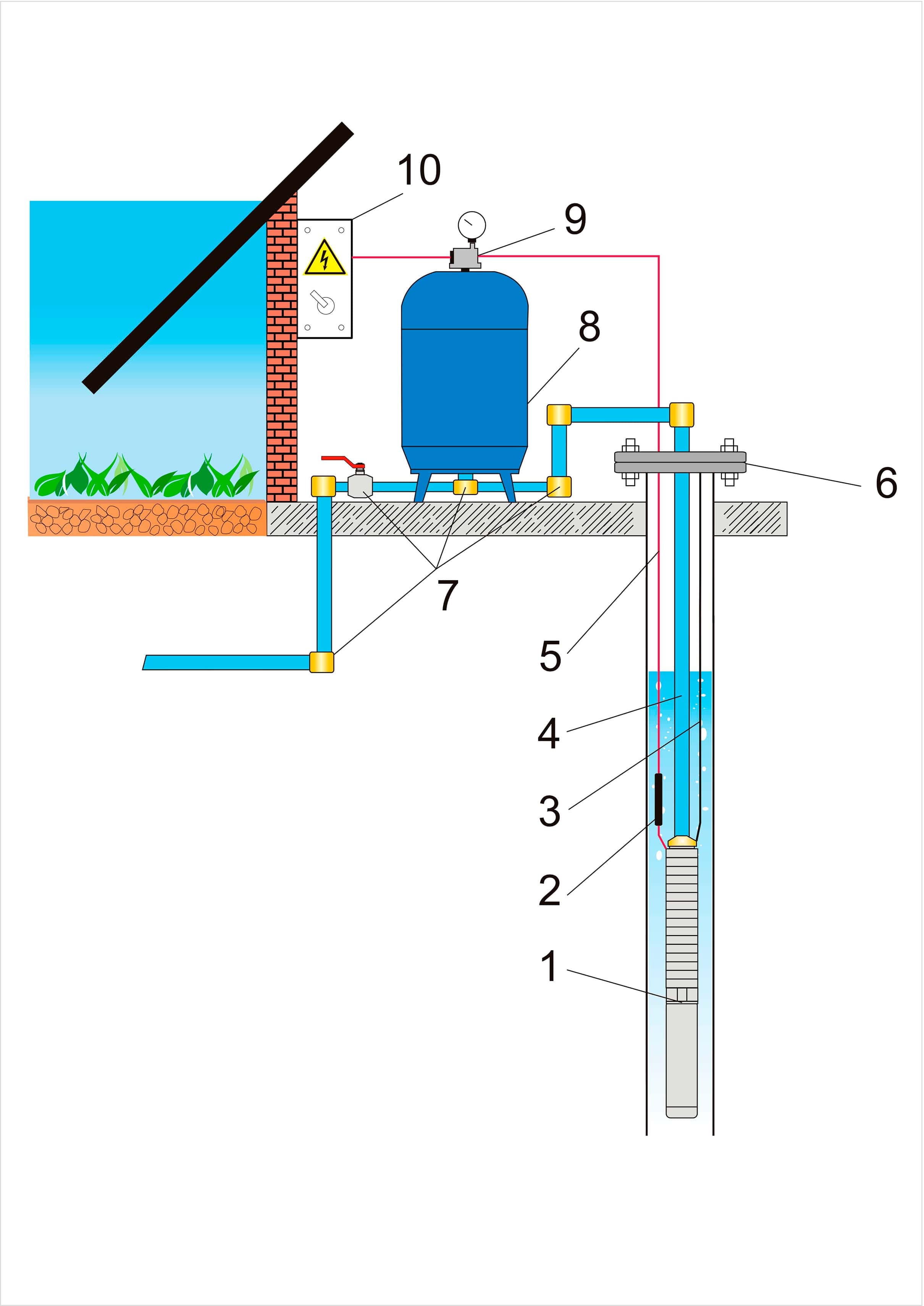

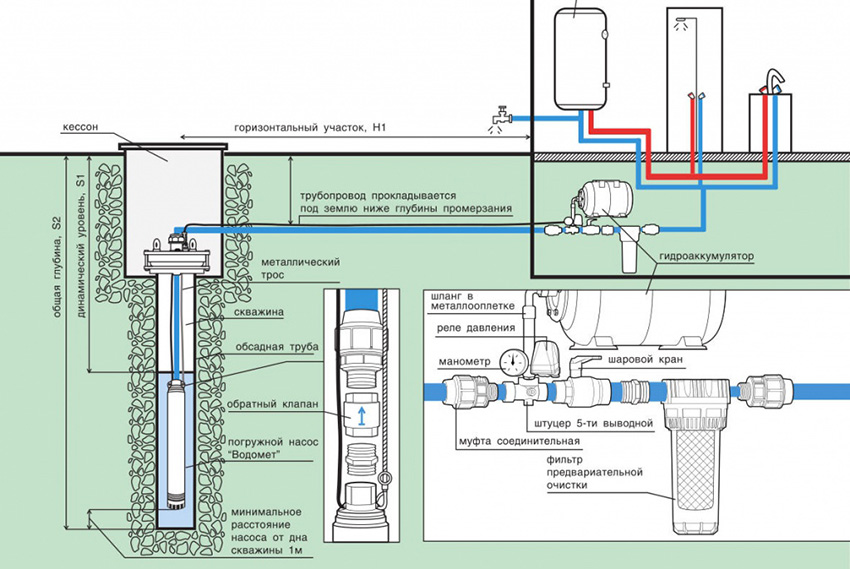

The device and principle of operation of pumping stations

Methods for lifting water from the bowels to the surface depend on the depth of the well. If it exceeds 20 meters, then this will require a deep pump and an intermediate tank equipped with sensors for the upper and lower water levels, which will be automatically filled by the pump when it is parsed. Water from the tank flows through the check valve to the inlet of a device that maintains a given pressure in the water supply network of the house - a hydrophore.

If the depth of the well is less than 20 meters, then a compact and reliable device, an automatic pumping station, can be installed to extract the life-giving vaga. It combines two units in one - a deep pump and a hydrophore.At the same time, the intermediate tank and the automation system for controlling its filling disappear, since the raised water immediately enters the water supply system.

1 - hydrophore; 2 - flexible hose; 3 - pump with electric drive; 4 - pressure switch; 5 - input for water supply

All pumping stations consist of the following functional units:

- water intake with a grid and a check valve, located directly in the well;

- suction line, through which water rises from the well and is supplied to the pump housing;

- a centrifugal pump, which creates a vacuum on the one hand, due to which water rises, and on the other hand, pressure, due to which water enters the house and is distributed in it to consumers;

- a pressure switch that turns on the electric motor when the pressure drops below the set value and turns it off when the upper pressure is reached;

- tank - a receiver (or hydraulic accumulator), consisting of two halves, separated by an elastic membrane, which compensates for the effect of hydraulic shock that occurs when the station is turned on;

- an electric motor, which is mechanically coupled to the pump, and electrically to the pressure switch;

- pointer pressure gauge, which is used to visually control the pressure in the line and adjust it if necessary.

In addition, according to the arrangement of the suction pipeline, pumping stations are divided into single-pipe and two-pipe (ejector). Single-pipe stations have a simple water intake design, and water enters the pump housing through one line. Two-pipe stations have a more complex device, which includes a cast iron ejector that is completely immersed in water. The advantage of single-pipe stations is ease of installation.Two-pipe pumping stations use to lift water not only the vacuum created by the pump impeller, but also an additional increase in it due to the inertia of the water circulating in a circle during the operation of the station. They are capable of lifting water from a greater depth with less power.

Why furnish?

After drilling, the well must be equipped to avoid pollution, atmospheric phenomena and adverse factors. They negatively affect further operation. Between drilling a well and powering the water supply in the house, equipment is selected, the source is arranged and the selected equipment is installed. This kind of arrangement solves a number of problems:

- protection of equipment and the source itself from freezing during the cold season;

- ensuring cleanliness inside the source, which is guaranteed by its hermetic closure together with the used equipment;

- formation of conditions for servicing and connecting equipment.

Well pumps

The choice of pump for the well is important. The purchased pump determines the duration of operation of the water supply system and its efficiency. When choosing, you should focus on a number of important parameters:

- Performance. The performance indicator describes the amount of water produced per unit of time. The parameter is measured in liters of water per minute.

- Power. Power in equipment refers to the power of operation. Resource intensity and performance directly depend on power. The need to choose a high-quality solution for needs and budget should not be focused on the most powerful models. The selection criteria should reflect the farm's water needs.

- Depth and diameter of the well.The parameters of depth and diameter are of fundamental importance when choosing a pump. The use of equipment and the fact whether it can fit into a particular well directly depends on them. The parameters are specified by a specialist. He is consulted before choosing a specific device model. A purchase based on the opinion of professionals is successful.

- Head. The parameter is fundamental for objects with the need to raise water to a great height, for organizing watering plants on the site. The greater the pressure, the better the water supply on the upper floors of buildings and during irrigation. Pressure is directly related to performance. You will have to pay more for more power.

- Price. Powerful machines are more expensive. The dependency is simple, so that buyers have the opportunity to get the desired product after determining its main characteristics. Expensive devices are those produced by foreign well-known brands of professional equipment. The equipment has a guarantee for a long time and high quality workmanship. In order not to overpay, you will have to find the optimal ratio of price and functionality.