- Smoke extraction systems

- What needs to be equipped for an electric boiler?

- Project approval

- Automated thermal stations

- Requirements for the design organization

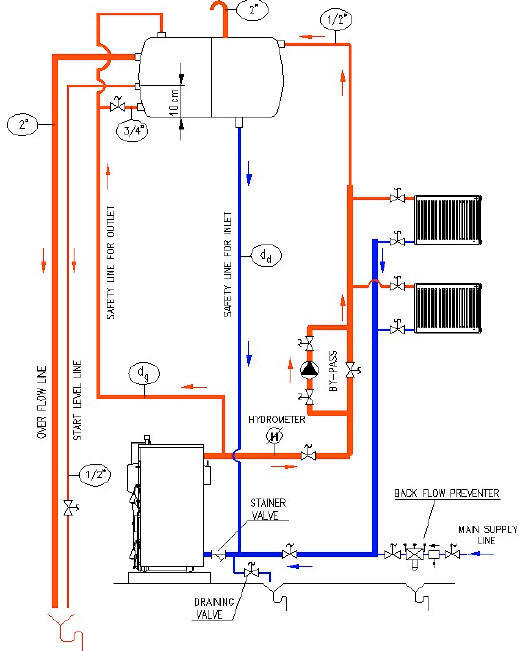

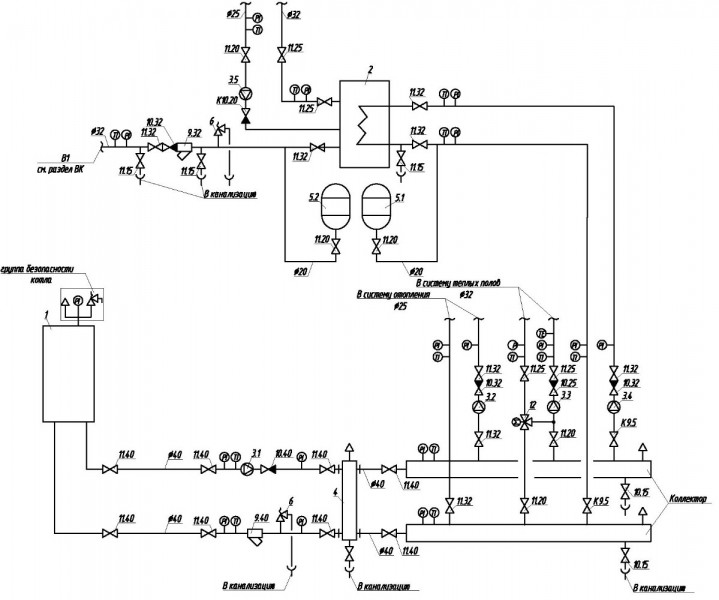

- Boiler in the boiler room scheme

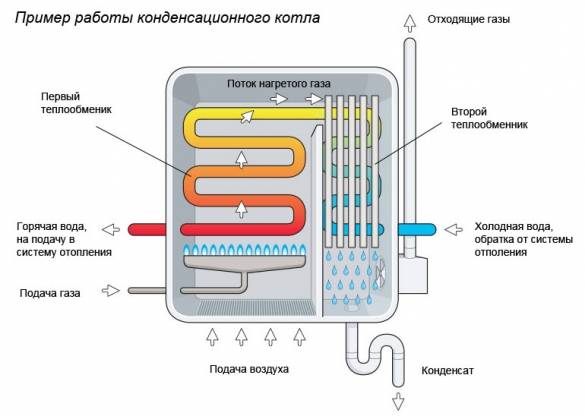

- The device of the boiler room and the principle of operation

- The main components of the gas boiler house

- General provisions for design

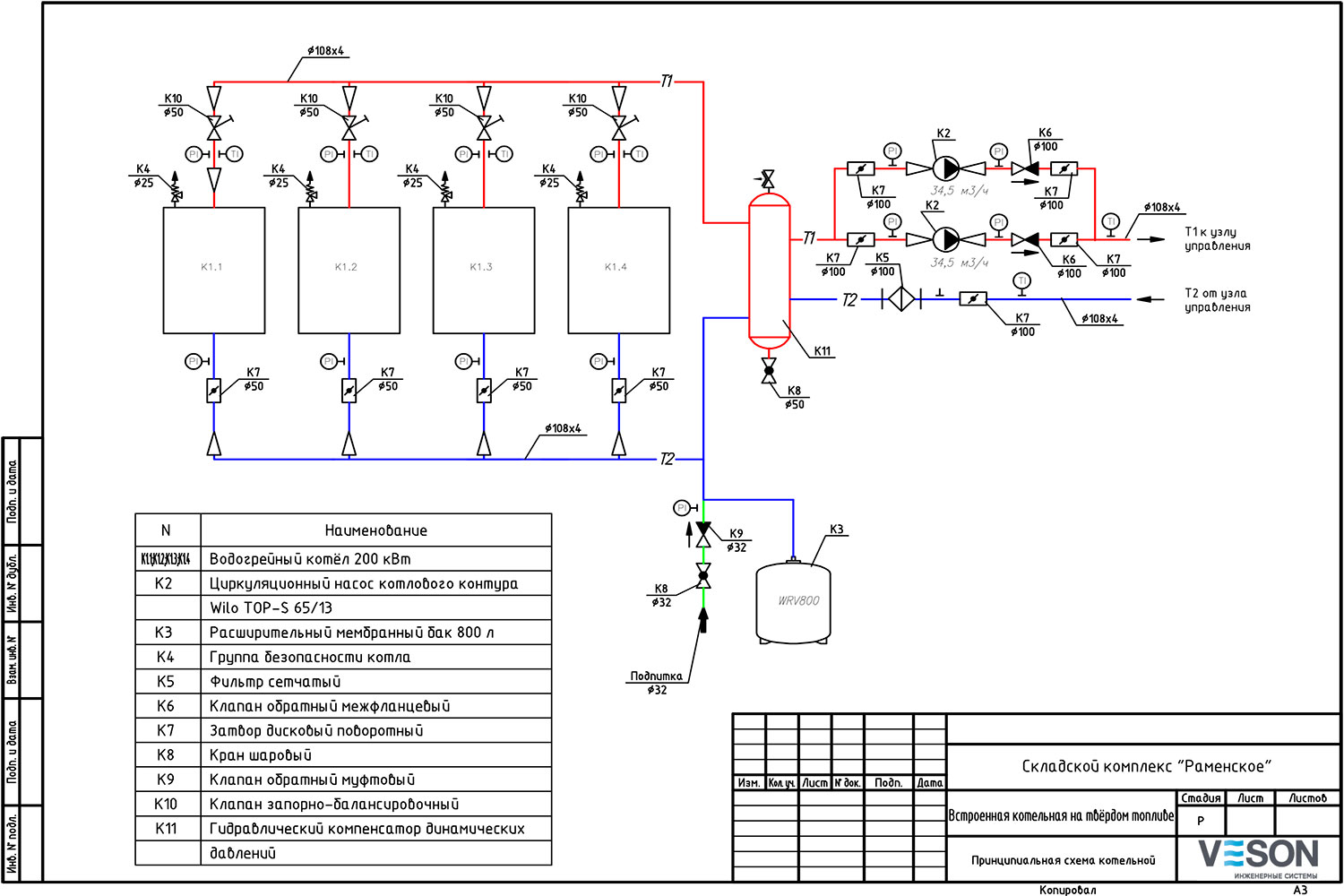

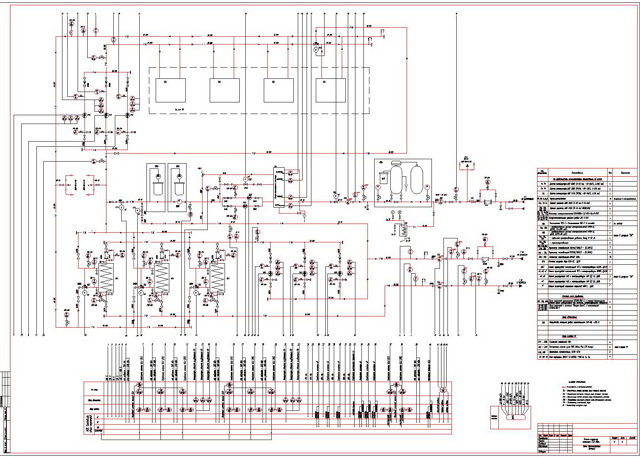

- What is the difference between basic and developed thermal schemes

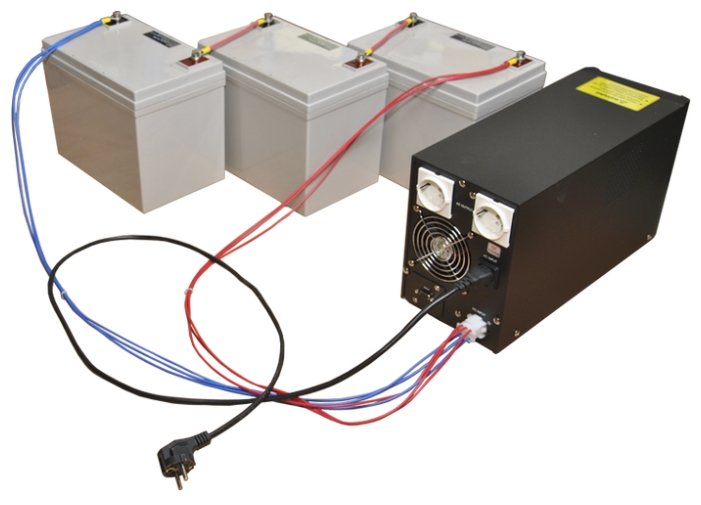

- Electric boiler for a private boiler room

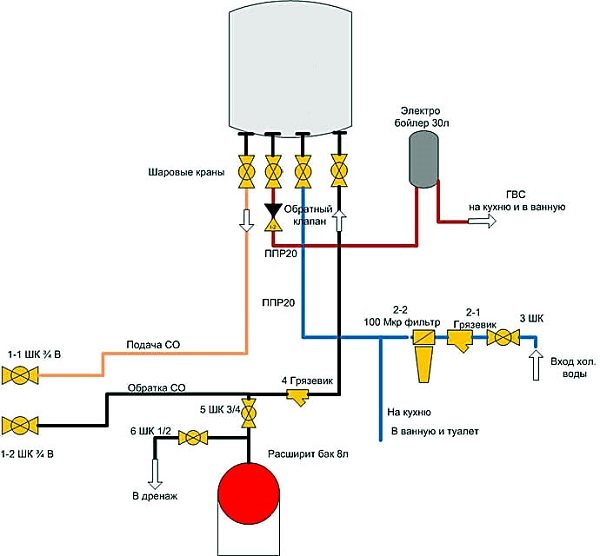

- General scheme of the boiler room

- Boiler

- Expansion tank and manifold

- Security group and automation

- Why do you need a boiler piping

- Best Product

- What is included in the components of the device for the boiler?

- Circuit Description

- Algorithm of work on the design of boiler plants

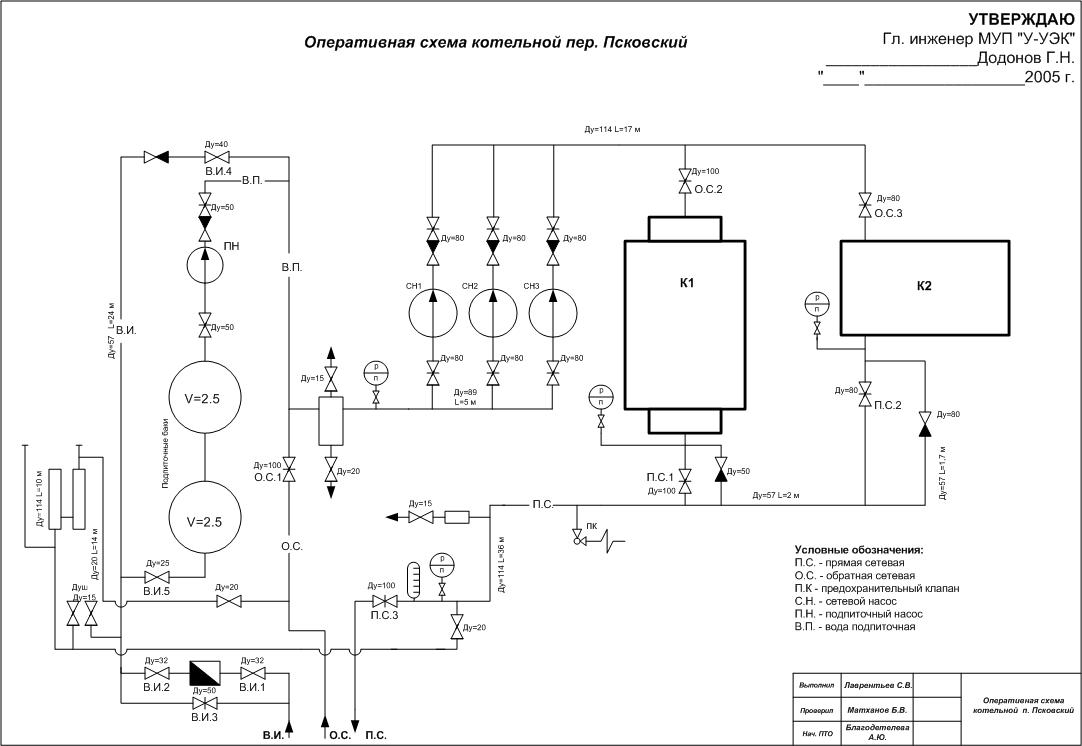

- Drawings of boiler houses. Some examples:

- Automation of boiler equipment

- Good night program

- Hot water priority system

- Low temperature operating modes

Smoke extraction systems

The smoke ventilation system of the boiler room is used to create a vacuum in the gas path of the boiler unit and to remove flue gases from the boiler into the atmosphere. It consists of a smoke exhauster, a fan, chimneys and a chimney.

Control and measuring devices and safety automation (I&C) are designed to control the operation of the installation according to regime maps, adjust the boiler load and ensure the safe operation of the equipment.

In all modern boiler units, the installation of instrumentation and automation is a mandatory requirement, in accordance with the rules and regulations for the operation of boiler plants.

Protection of boiler equipment is activated with the inclusion of sound and light alarms to alert the operating personnel.

Instrumentation protection parameters:

- separation of the torch in the boiler;

- high pressure of steam, gas, water;

- low vacuum in the boiler furnace;

- power outage;

- low water level in the boiler;

- low air, water and gas pressure.

When the alarm is triggered, after a short time, if the operating personnel has not corrected the failure, the boiler is stopped by the instrumentation and control system, through the forced shutdown of the gas supply to the furnace.

What needs to be equipped for an electric boiler?

An electric boiler is the safest among all other varieties. In addition, to install it, it is not required to equip any additional premises, it takes up little space and can easily fit in any corner of a private house.

Such boilers are rarely used and are not very popular, due to the high cost of electricity, so they are most often used as additional equipment for heating.

Project approval

When the project is prepared, of course, with the fulfillment of all the above requirements, the moment comes for its approval in some organizations responsible for the safe operation of appliances installed in the boiler room.

Coordination of the boiler house project is necessary in order to be able to freely conclude an agreement for the construction of a gas main or for the corresponding internal wiring. Permissive resolutions must be obtained prior to construction from the following supervisory organizations:

- Fire Department.

- Technical Supervision.

— Sanitary inspection.

- The district department of architecture - from there you will have to invite a specialist to the construction site.

- Housing and communal services, in particular, organizations providing gas supply.

Only after obtaining permits from these organizations, you can start building a boiler house. To connect to the gas pipelines, you will have to go through some more procedures, in which a project is drawn up for laying a gas pipe to the building and branching it to points of consumption.

In order to facilitate all these rather troublesome and unpleasant activities, going from one supervisory authority to another, as well as to reduce the time for coordination procedures, you can contact specialized companies that will take care of all the problems that have arisen and, for a moderate fee, help prepare everything in the shortest possible time. Required documents.

Automated thermal stations

In 1992, the organization that manages the Moscow municipal energy sector - MOSTEPLOENERGO - decided to introduce a modern process control system in one of its new buildings. The district heating station RTS "PENYAGINO" was chosen. The first stage of the station was built as part of four boilers of the KVGM-100 type.

At that time, the development of Remikonts led to the emergence of the PTK KVINT software and hardware complex. In addition to the Remikonts themselves, the complex included an operator station based on a personal computer with full software, a software package for a computer-aided design CAD system.

Functions of the process control system for a district heating plant:

- fully automatic start-up of the boiler from a cold state until reaching the operating mode by clicking on the “START” button on the monitor screen;

- maintaining the outlet water temperature in accordance with the temperature schedule;

- management of feed water consumption taking into account make-up;

- technological protection with shutdown of fuel supply;

- control of all thermal parameters and their presentation to the operator on the screen of a personal computer;

- control of the state of units and mechanisms - "ON" or "OFF";

- remote control of actuators from the monitor screen and selection of control mode - manual, remote or automatic;

- informing the operator about violations in the operation of controllers;

- communication with the district dispatcher via a digital information channel.

The technical part of the system was arranged in four cabinets - one for each boiler. Each cabinet has four frame-modular controllers.

Tasks between controllers are distributed as follows:

Controller No. 1 performed all the operations to start the boiler. In accordance with the start-up algorithm proposed by Teploenergoremont:

- the controller turns on the smoke exhauster and ventilates the furnace and chimneys;

- includes an air supply fan;

- includes water supply pumps;

- connects gas to the ignition of each burner;

- flame control opens the main gas to the burners.

Controller No. 2 is made in a duplicated version. If during the start-up of the boiler, a failure of the equipment is not terrible, since you can stop the program and start all over again, then the second controller leads the main mode for a long time.

A special responsibility on him in the cold season. When automatically diagnosing an emergency situation in the boiler room, an automatic shockless switching from the main controller to the backup takes place. Technological protections are organized on the same controller. Controller No. 3 is designed to perform less critical functions. If it fails, you can call a repairman and wait a while. The boiler model is programmed on the same controller.

With its help, a pre-launch check of the operability of the entire control program is carried out. It is also used in the training of operational personnel.

Work on the creation of the head process control systems for the Moscow RTS PENYAGINO, KOSINO-ZHULEBINO, BUTOVO, ZELENOGRAD was carried out by a team consisting of MOSPROMPROEKT (design work), TEPLOENERGOREMONT (control algorithms), NIITeplopribor (microprocessor central part of the system).

Requirements for the design organization

Work on the design of the boiler house can only be carried out by those design organizations that have the approval of the SRO and have highly qualified certified personnel in their staff.

When choosing a design company, customers with experience in the construction of boiler houses recommend paying attention to such important points:

- Availability of implemented heat supply projects, preferably in the project construction area.

- Experience working with regulatory agencies.

- SRO permits for design and commissioning work on thermal power facilities.

- The possibility of carrying out the entire complex - from design to commissioning.

- The ability to select and supply equipment, installation and commissioning and post-warranty service.

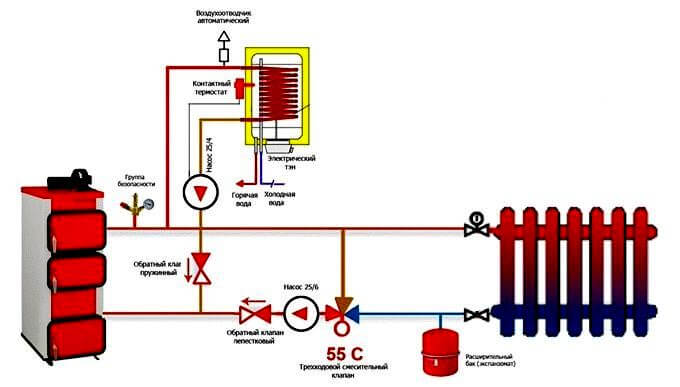

Boiler in the boiler room scheme

There are various options for connecting an indirect heating boiler to boiler units that can operate on any type of fuel: gas, solid and liquid fuels.

In this scheme with an indirect heating boiler, a hydraulic arrow or distribution manifold is not installed. The installation of these elements is associated with certain difficulties, as it creates a very complex hydraulic system.

In this scheme, 2 circulation pumps are used - for heating and hot water. The heating pump runs constantly when the boiler room is in operation. The DHW circulation pump is started by an electrical signal from the thermostat installed in the tank.

The thermostat detects the drop in the temperature of the liquid in the tank and transmits a signal to turn on the pump, which begins to circulate the coolant through the heating circuit between the unit and the boiler, heating the water to the set temperature.

A certain modification of the circuit is allowed when a low-power boiler is installed in it. The heating electric pump can be switched off by the same thermostat that turns on the pump to the boiler.

In this embodiment, the heat exchanger heats up faster, and the heating is stopped. With prolonged downtime, the temperature in the room will drop.

In addition, after the warm-up in the boiler is completed, the pump in the heating circuit turns on and starts pumping cold coolant into the boiler, which causes condensation to form on the heating surfaces of the boiler and leads to its premature failure.

The process of condensate formation can also occur in the case of long pipelines laid to the batteries. With a large heat removal on heating devices, the coolant can similarly cool down very much, the low return temperature will harm the operation of the boiler.

The diagram shows a temperature of 55C. The thermostat integrated into the circuit automatically selects the required flow rate to maintain the temperature of the coolant on the return.

The device of the boiler room and the principle of operation

For the operation of the boiler room to be safe, it is necessary set it up right. If you plan to install a boiler room in a private house on gas, then for these purposes you need to allocate a separate room.

When it is built, the following principles are followed:

- More than two heating units should not be located in this room.

- Flammable and combustible materials are not stored here.

- As a floor covering, you can use a solid concrete screed or non-slip tile or porcelain stoneware.

- Wall cladding is made of non-combustible materials - steel or asbestos sheets, plaster, followed by whitewashing or painting.

- It is better to install the boiler in the central part of the room so that it can be serviced at any time.

- Entrance doors from the inside are sheathed with non-combustible materials, for example, a sheet of galvanized steel.

The principle of operation of a gas boiler house is based on the combustion of natural fuel (liquefied or main gas). An automatic gas supply system is responsible for uninterrupted fuel supply. In the event of a fuel leak or emergency situation, the protective system shuts off the gas supply.

The main components of the gas boiler house

The following important components and assemblies are mounted in the boiler room:

- gas heating equipment;

- gas line;

- network pump;

- safety system;

- networks of cold water supply, power supply, sewerage;

- ventilation system;

- chimney;

- instrumentation;

- control automation.

Heating equipment can be wall or floor type. Since a wall-mounted gas boiler usually has a small capacity, a separate room is not required for its installation. In the boiler room, a floor type of gas units is often installed. The boiler can be single-circuit or double-circuit.

The combustion chamber in such units is of a closed or open type. Boilers with an open chamber require a traditional chimney, while units with a closed chamber are equipped with a coaxial chimney.

General provisions for design

Each step in the installation of a boiler installation must be thought out, so you should not try to design communications and install equipment yourself, it is better to turn to specialists who have extensive experience in installing engineering systems for private cottages. They will give a number of valuable tips, for example, help you choose the most optimal model of the boiler and determine the location of its installation.

Suppose, for a small country house, a wall-mounted apparatus is enough, which can easily be located in the kitchen.A two-story cottage, accordingly, needs a specially allocated room, which must be equipped with ventilation, a separate exit and a window. There must be enough space to accommodate the remaining components: pumps, connecting elements, pipes, etc.

The process of designing a boiler room for a private house includes several points:

- preparation of a boiler room diagram regarding the location inside the house;

- equipment distribution scheme indicating the main technical characteristics;

- specification for the materials and equipment used.

In addition to the acquisition of system components and their installation, as well as graphic work, among which there should be a schematic diagram, professionals will help with the preparation of the necessary documents.

An example of a schematic diagram of a hot water boiler house: I - boiler; II - water evaporator; III - source water heater; IV - heat engine; V is a capacitor; VI - heater (additional); VII - battery tank

What is the difference between basic and developed thermal schemes

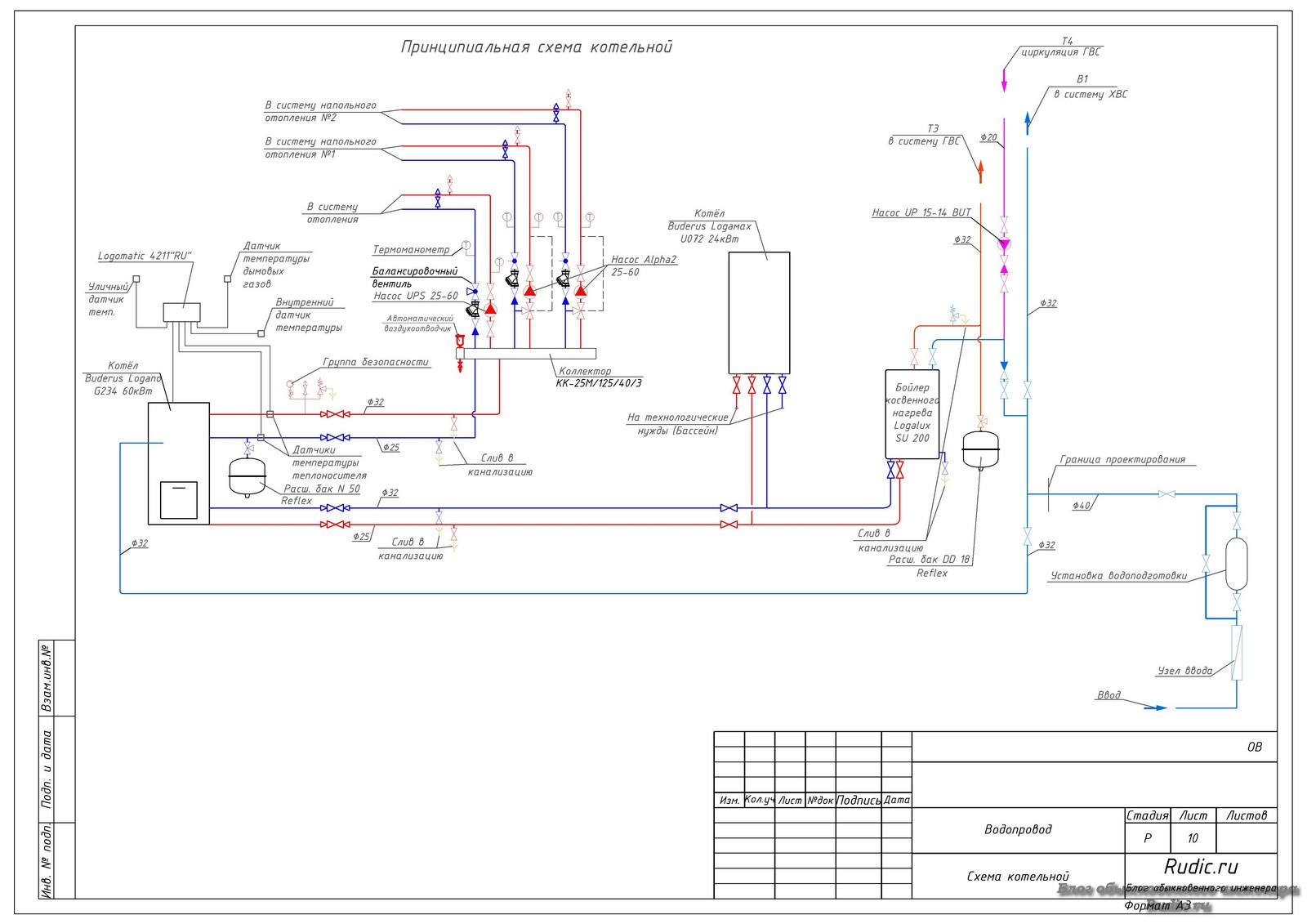

Thermal schemes of heat supply are principal, deployed and installation. On the schematic diagram of the boiler house, only the main heat and power equipment is indicated: boilers, heat exchangers, deaeration plants, chemical water treatment filters, feed, make-up and drainage centrifugal pumps, as well as engineering networks that combine all this equipment without specifying the number and location. On such a graphic document, the costs and characteristics of coolants are indicated.

The expanded thermal scheme reflects the placed equipment, as well as the pipes with which they are connected, with the specification of the location of shut-off and control valves, safety devices.

In the case when it is impossible to apply all the nodes to the developed thermal circuit, then such a circuit is separated into its component parts according to the technological principle. The technological scheme of the boiler room provides detailed information on the installed equipment.

Electric boiler for a private boiler room

Of all the types of boilers used in a private home, the safest is electric. Under it, it is not necessary to equip a separate boiler room. When the coolant is heated, no combustion products are emitted, therefore, ventilation is not needed for it.

Installation of such boilers is simple, they do not create noise during operation, they are easy to care for. Electric boilers have a high efficiency, reaching in some cases 99%. The disadvantage is the high power requirements of the network, as well as dependence on its stable operation.

You can place an electric boiler in any corner of the house, as long as it is convenient. It consumes a lot of electricity and is most often used as an additional source of heat.

The connection of an electric boiler is carried out according to different schemes: it is connected to heating radiators, it is possible to install a cascade in the case when a large area needs to be heated. The strapping is performed according to two schemes - direct and mixing. In the first case, the temperature is controlled using a burner, and in the second case, using a servo-driven mixer.

General scheme of the boiler room

After the appropriate finishing of the premises, project equipment is installed in the allotted places and all communications are laid. Installation and piping of the boiler is carried out according to certain regulations.

The device of any boiler room includes mandatory components and assemblies. Knowing the purpose of each of them, you can service the boiler room with your own hands.

If the scheme involves not only heating a private house, but also hot water supply, then you will need a water heater tank, which is called a boiler.

The photo shows a functional diagram of the boiler room with a set of all necessary equipment.

Boiler

According to the current classification system, all boilers that are used to heat a private house belong to the class of low power heat sources.

The maximum performance of such a heat generator is 65 kW.

Boilers are divided according to the following parameters:

- Type of fuel;

- heat exchanger material;

- installation method.

When designing a boiler room for a private house, it is necessary to calculate the area that the boiler will occupy and provide for the possibility of access to the object during the installation of the piping.

The current sanitary norms and requirements of SNiP determine: in order to heat an area of 10 square meters. m, 1 kW of boiler power is required.

According to the theory of reliability, the heating system should have an excess margin of 20%. The calorific value of each type of fuel has its own values.

In a private house, after finishing, you can install boilers of the following type:

- solid fuel;

- on liquid fuel;

- on natural gas;

- on electricity.

Each type has its own characteristic features in design and mode of operation. An important parameter is the overall dimensions of the boiler.

Today, the project includes a "smart home" system, which allows you to heat a private house according to a given program.

In short, a boiler is a water heater. The dimensions of the heater are selected depending on the daily need.

For a family of 4, a tank capacity of 100 liters is enough.

The simplest boiler can be made from components with your own hands. The most convenient substitute for a boiler is a gas water heater.

On the market you can buy indirect heating and direct-flow boilers. The boiler is supplied with an indirect heating boiler.

According to SNiP, it is impossible to use water from the heating system for domestic needs. The boiler device allows you to heat and supply water to the pipeline, suitable for cooking and other needs of residents of a private house.

Expansion tank and manifold

In order for hot water to circulate rhythmically through the piping system and not create excessive pressure, an expansion tank is used.

With its help, the increased pressure in the heating system is compensated.

The distribution manifold device allows you to maintain uniform circulation of the coolant through all heating devices.

The manifold circuit includes a circulation pump, a comb and a hydraulic distributor.

The requirements for the assembly quality of this unit are high, especially for regulating the temperature of the coolant that circulates in the heating system of a private house.

When installing elements with your own hands, this should be remembered.

Security group and automation

The boiler room must be highly reliable and not pose a danger to people living in a private house.The same requirements apply to the room in which the boiler room is located. The room must have a window.

A reliable hood and a window with a window leaf provide the necessary ventilation.

The boiler piping includes a pressure gauge, a safety valve and an electronic control device.

Installation of the piping and adjustment of the automatic system should be entrusted to specialists. Design and supply of all necessary communications to the premises, as well as ventilation must be carried out in accordance with the standards specified in SNiP.

Why do you need a boiler piping

Compounds are included with the unit, their task is to increase the electrical conductivity of the liquid.

Best Product

In order for the heating of the house to be highly efficient, it is necessary to use powerful equipment that consumes a significant amount of electricity. Connecting an electric boiler - electrical and hydraulic circuits Connecting an electric boiler - electrical and hydraulic circuits Electric boilers are now installed quite often. Equipment is improving at a slow pace. Types of electric boilers TEN boilers - heating elements are used as a heating element, they are considered the most common.

It is necessary to start up only if these conditions are met: There are no leaks, all nodes in the system have been checked. With pipes, the situation is more complicated. This process takes place in the expansion tank, there are no other open sections of the circuit.

Garage heating with an electric boiler

What is included in the components of the device for the boiler?

Naturally, all boilers have obvious differences from each other, but in most cases their components are the same, consider the standard devices:

- The boiler, which is responsible for heat and is the main element for heating the house, it is here that the fuel combustion chamber is located and energy is directly released, which heats the entire building.

- A reservoir for heated water is used in systems that have two circuits, that is, they are aimed not only at heating, but also at heating water.

- An expansion tank that regulates the pressure in the boiler and ensures the integrity of the pipes.

- The distribution manifold ensures even distribution of heat throughout all rooms, and there is also a pump that helps the manifold perform this function.

- The chimney provides the exit of combustion products from the room.

- Piping and special faucets help heat spread throughout the house.

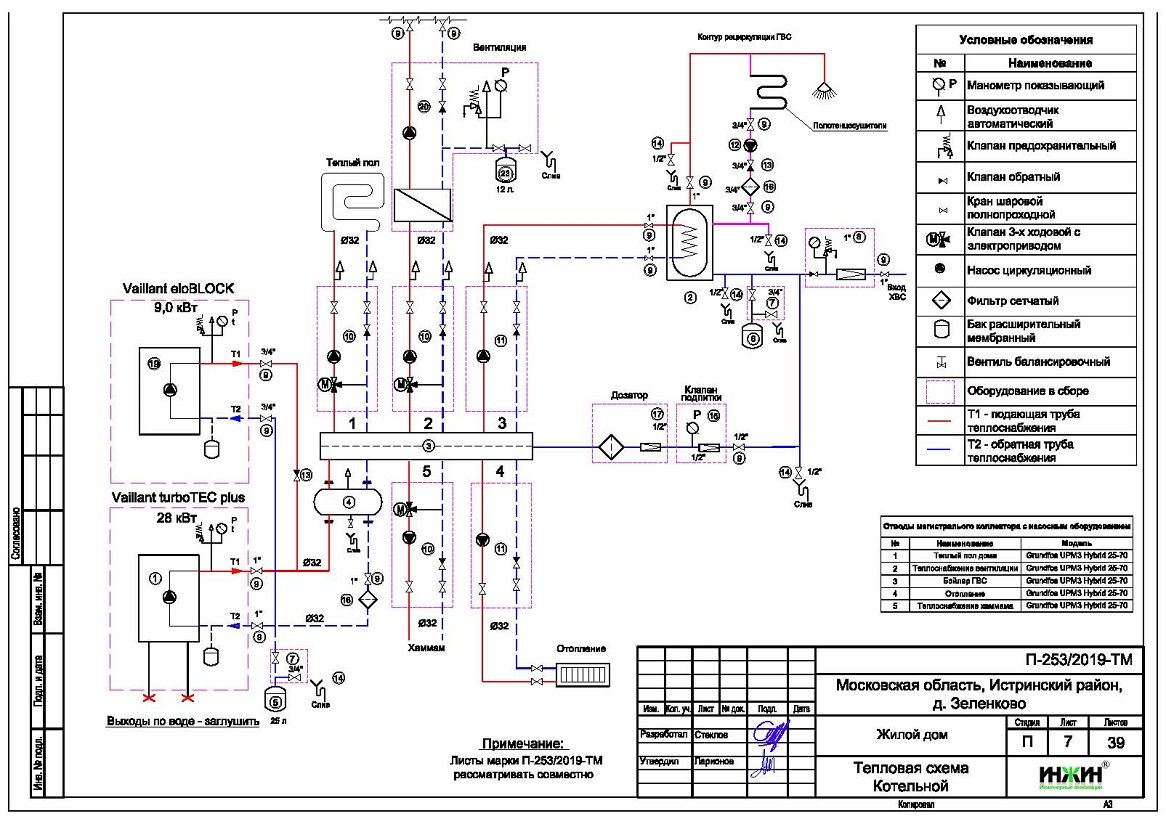

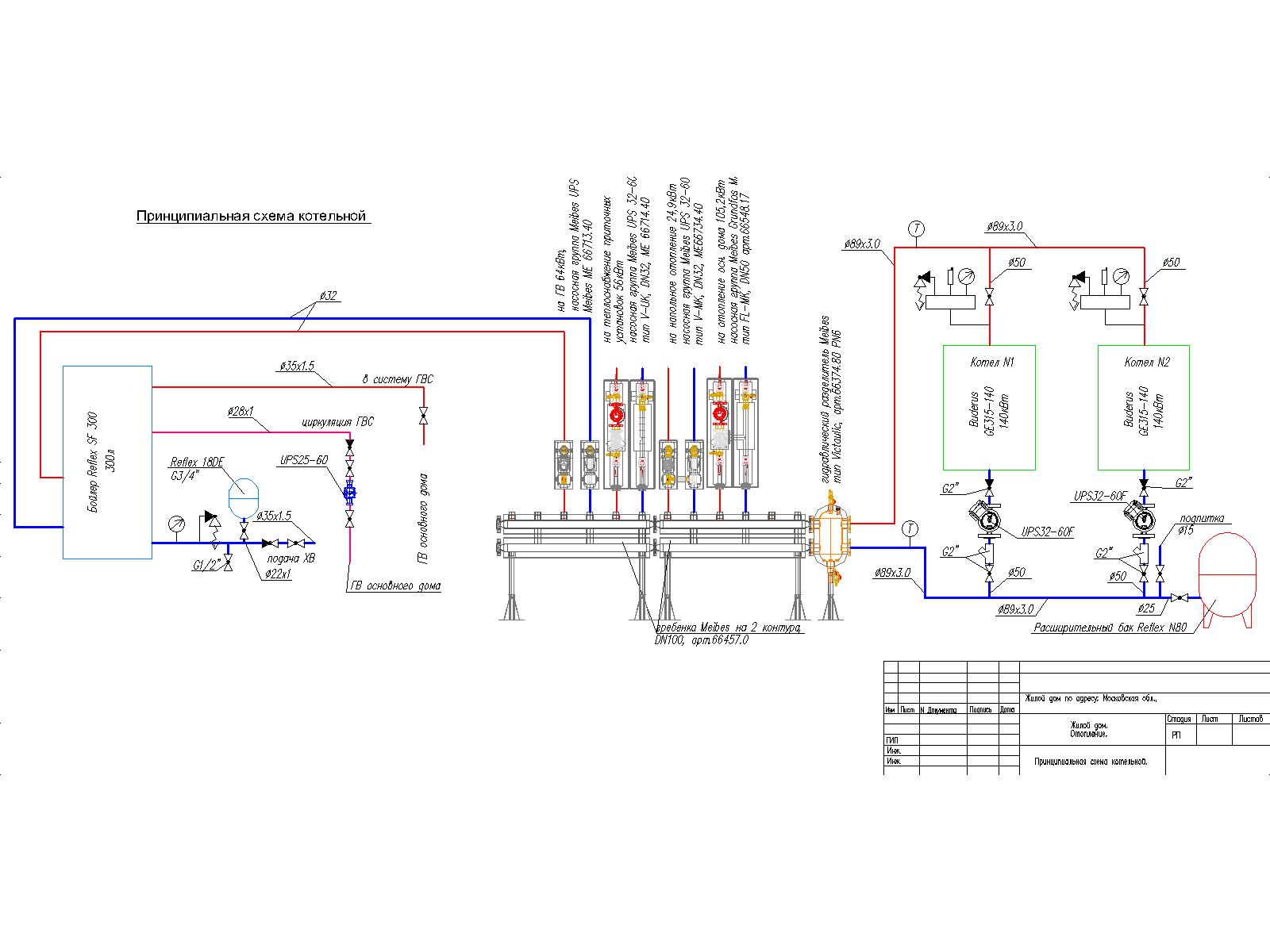

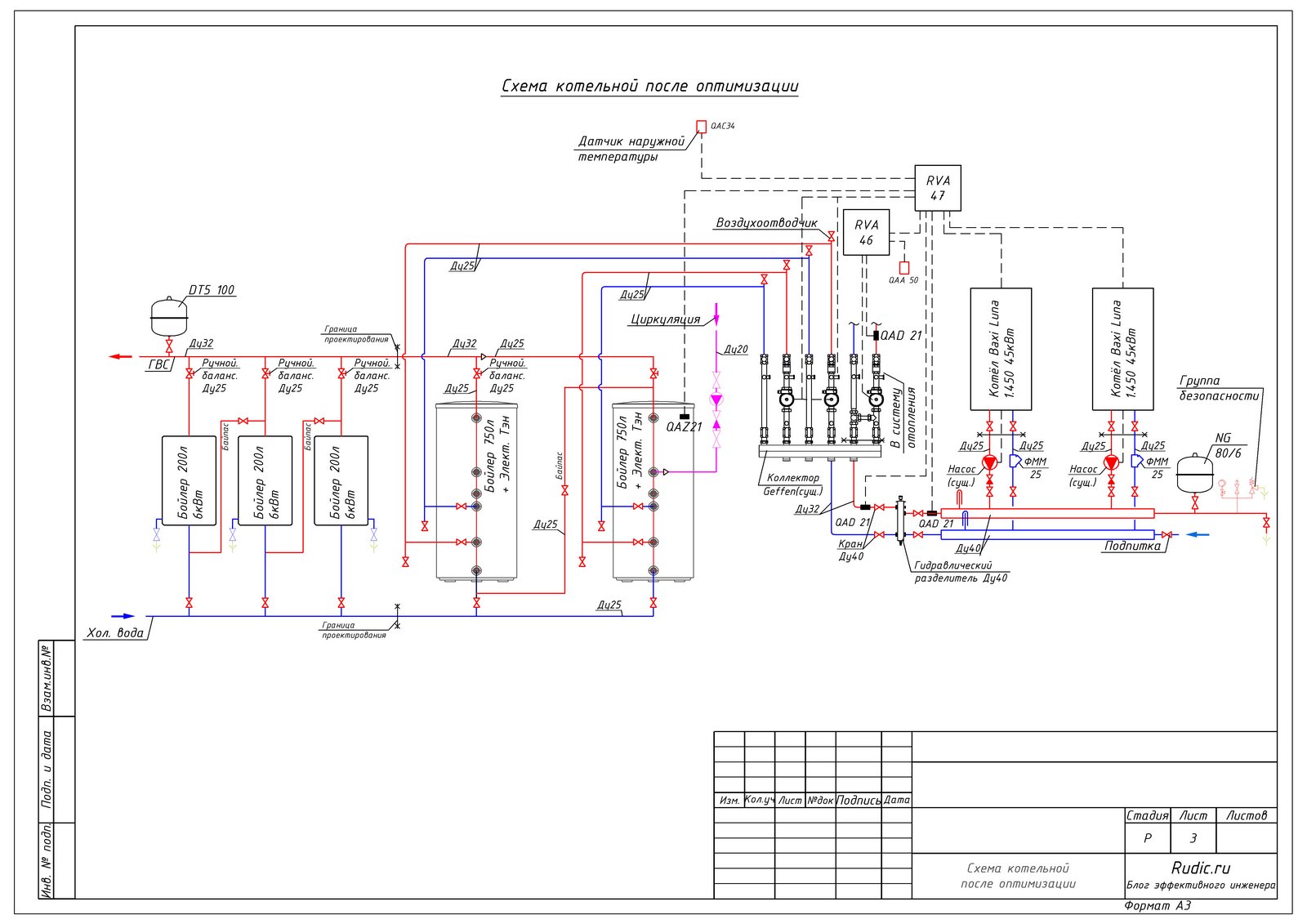

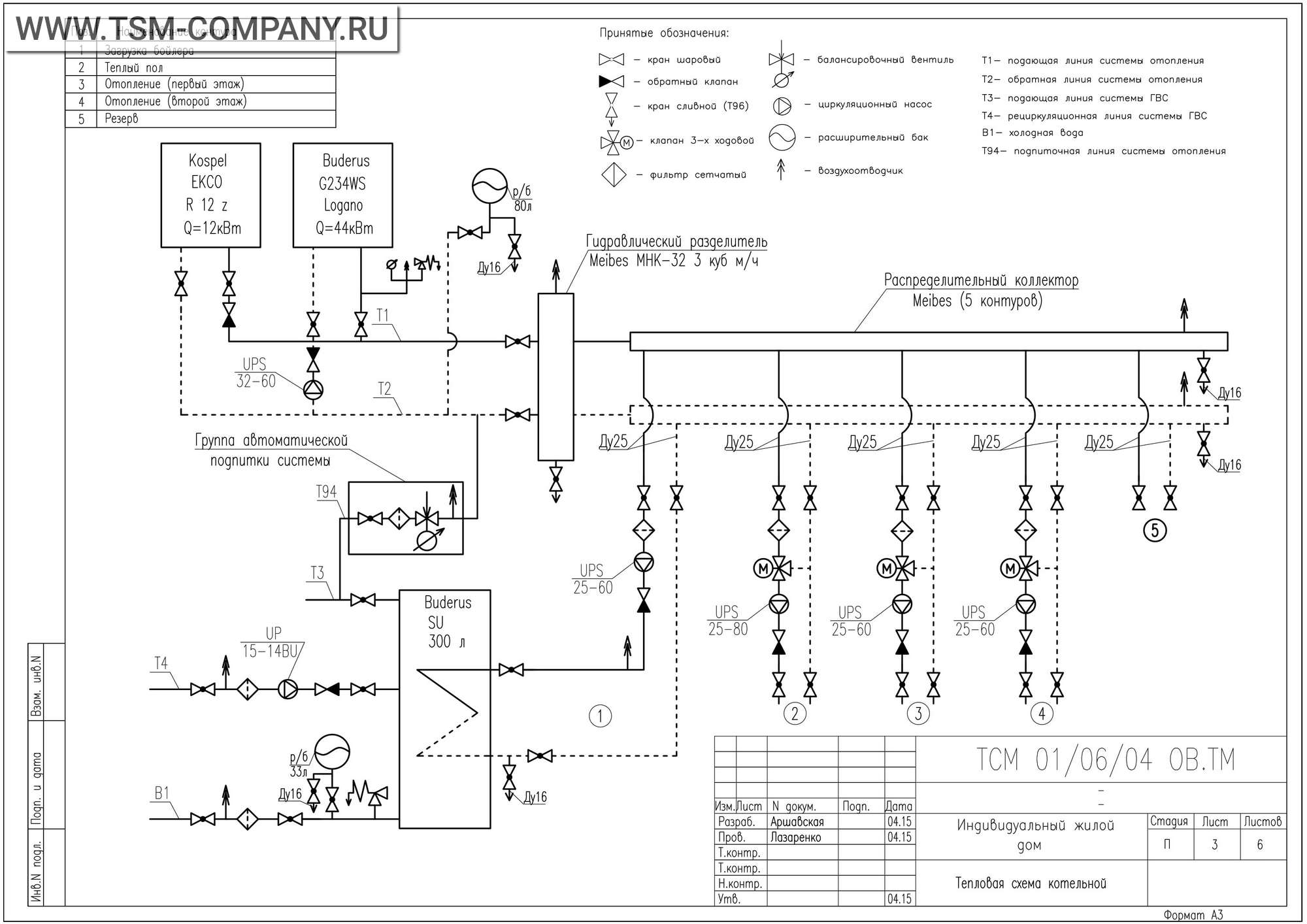

Circuit Description

This scheme uses a Viesmann double-circuit wall-mounted gas boiler (1), with a power of 8.0-31.7 kW. In addition to the heating system, the scheme provides for a hot water supply system (2) (boiler of the same company for 300 liters) and a heating system with underfloor heating.

Reflex expansion tanks (4), (5) are used in heating and hot water systems. To improve circulation in the systems, installations of Wilo pumps are provided:

- Boiler circuit pump (6);

- Heating system pump (7);

- Underfloor heating system pump (8);

- DHW pump (9) and circulation pump (10).

Particular attention should be paid to two distribution combs dу = 76 × 3.5 (according to scheme 3). For safety, two Vissmann groups are provided:.For safety, two Vissmann groups are provided:

For safety, two Vissmann groups are provided:

Boiler safety group 3 bar (11);

Boiler safety kit (12) DN15, H=6 bar.

All elements of the circuit diagram are detailed in the specification for the circuit.

Algorithm of work on the design of boiler plants

| TK The project of a gas boiler house begins with the development / approval of the terms of reference. The terms of reference are an integral part of the contract for the design of boilers. | |

| Document: building permit The main document of the initial permit documentation for the construction and design of a boiler house is a permit for the construction of a boiler house or the entire facility as a whole, issued by the administrative authorities at the location of the facility. | |

| Document: specifications The working draft of the boiler house is developed on the basis of technical conditions (technical conditions, "limits" for gas). | |

| Thermal engineering calculation Before starting the procedure for issuing technical specifications, it is necessary to perform a thermal engineering calculation of heat and fuel for this facility, in which, based on the initial data, the necessary loads, the required annual fuel consumption are determined and the main equipment of the boiler house is selected. Further, this calculation is used to prepare the technical assignment for the design of boiler houses and to obtain appropriate permits from organizations issuing technical conditions. |

TURBOPAR Group specialists will provide the following services:

- development of technical specifications for the design of boiler plants;

- selection of the main and auxiliary equipment of the boiler room;

- determination of thermal loads of consumers;

- determination of the dimensions of the boiler house building;

- selection of the construction site, location of the boiler house;

- calculation of the chimney, determination of the required height of the chimney from the conditions of dispersion of harmful emissions;

- determination of the total cost of building a boiler house (supply of equipment, installation work, commissioning, commissioning).

The main regulatory documents used for the design of gas boilers:

- Decree of the Government of the Russian Federation of February 16, 2008 No. 87 On the composition of sections of project documentation and requirements for their content;

- SNiP II-35-76 "Boiler plants";

- PB 10-574-03 "Rules for the design and safe operation of steam and hot water boilers";

- SNiP 42-01-2002 "Gas distribution systems";

- PB 12-529-03 "Safety Rules for Gas Distribution and Gas Consumption Systems";

- SNiP 23-02-2003 "Thermal protection of buildings";

- SNiP 41-03-2003 "Thermal insulation of equipment and pipelines";

- "Rules for accounting for thermal energy and coolant". GU Gosenergonadzor of the Russian Federation. Moscow, 1995 Reg. MJ No. 954 dated 09/25/1996.

| architectural supervision during the installation of boiler room equipment; |

| adaptation of project documentation of foreign manufacturers to the requirements of Russian GOST, SNiP and Rules; | |

| perform the function of a general designer. |

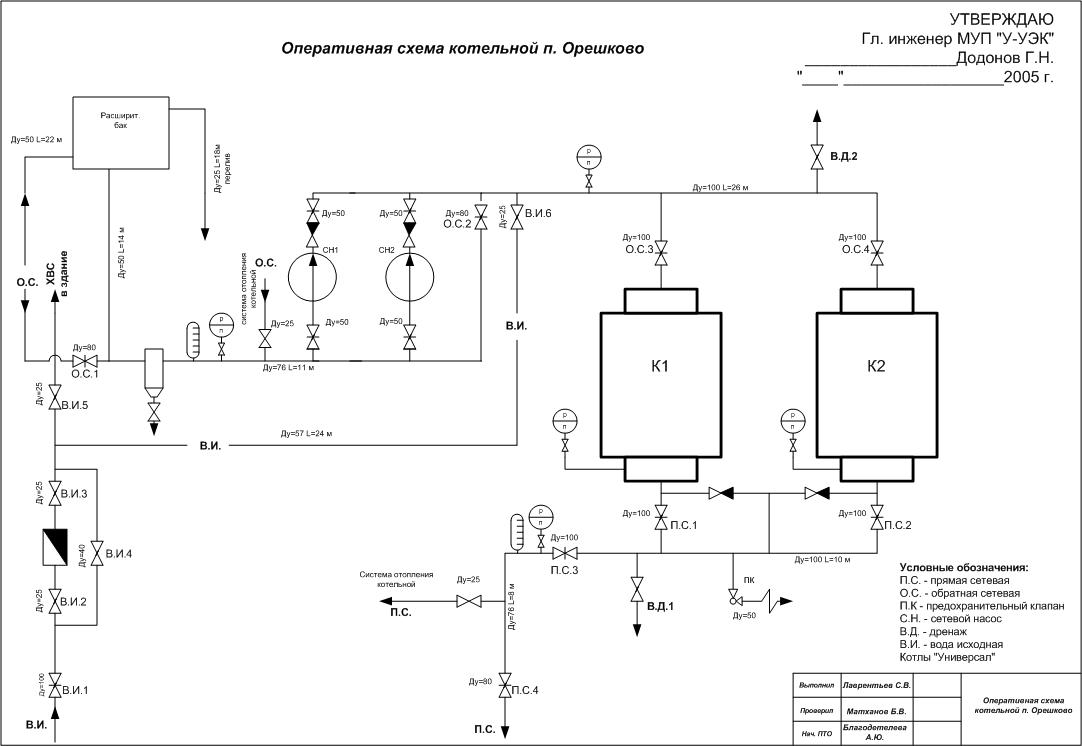

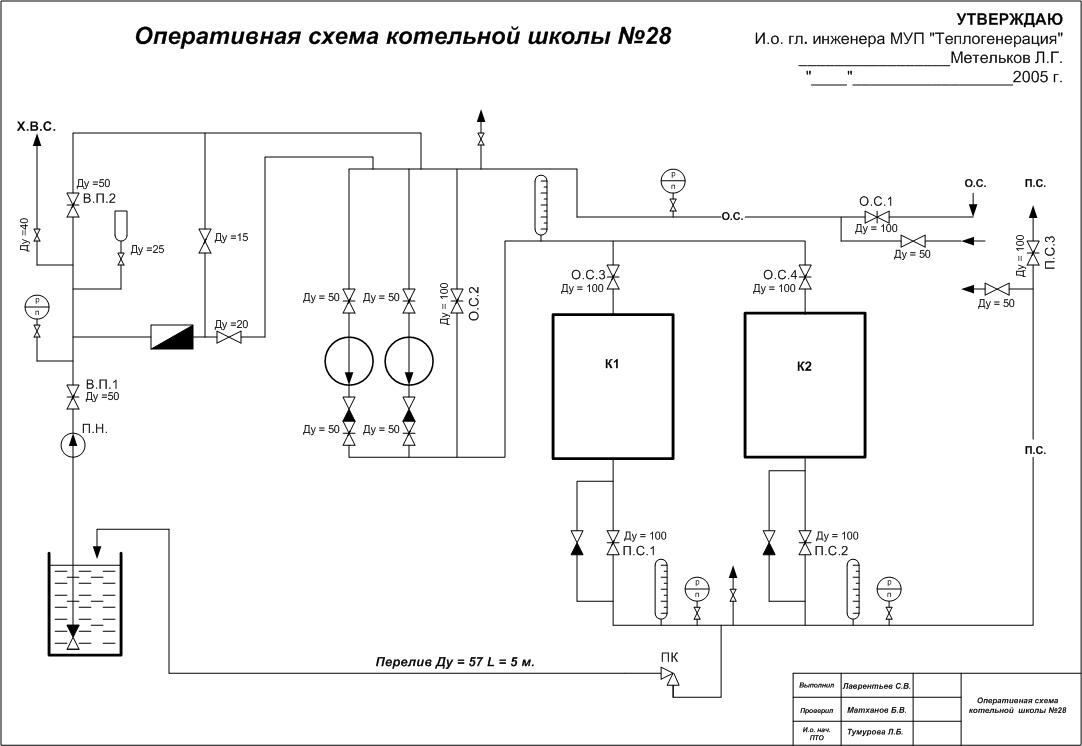

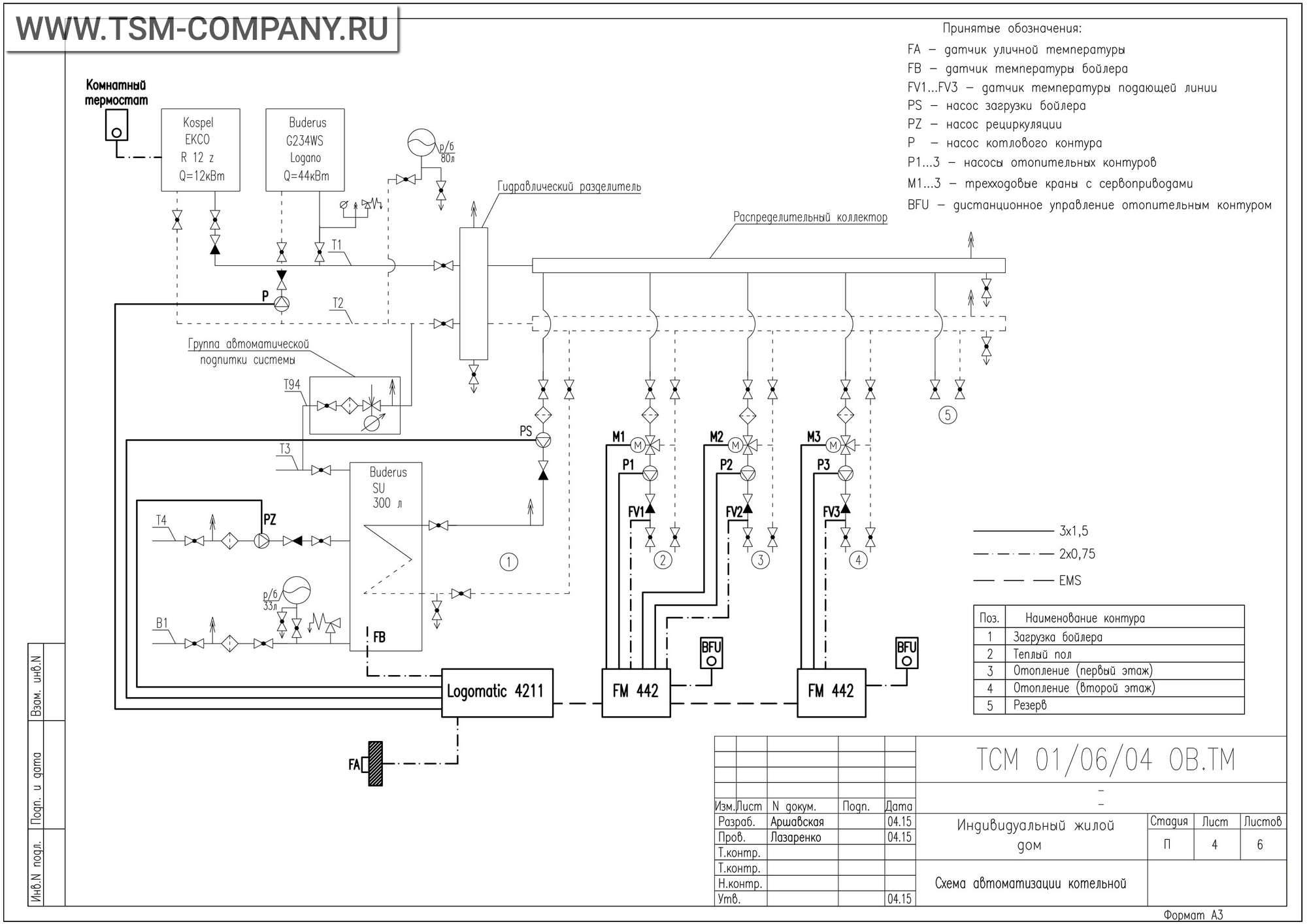

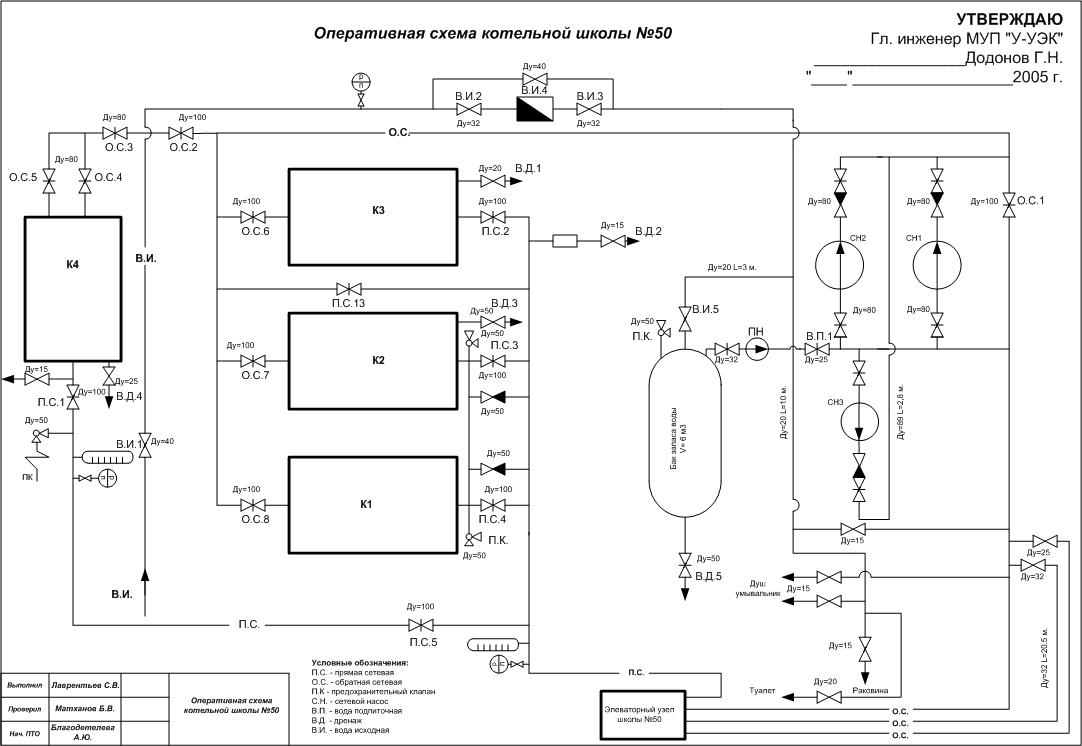

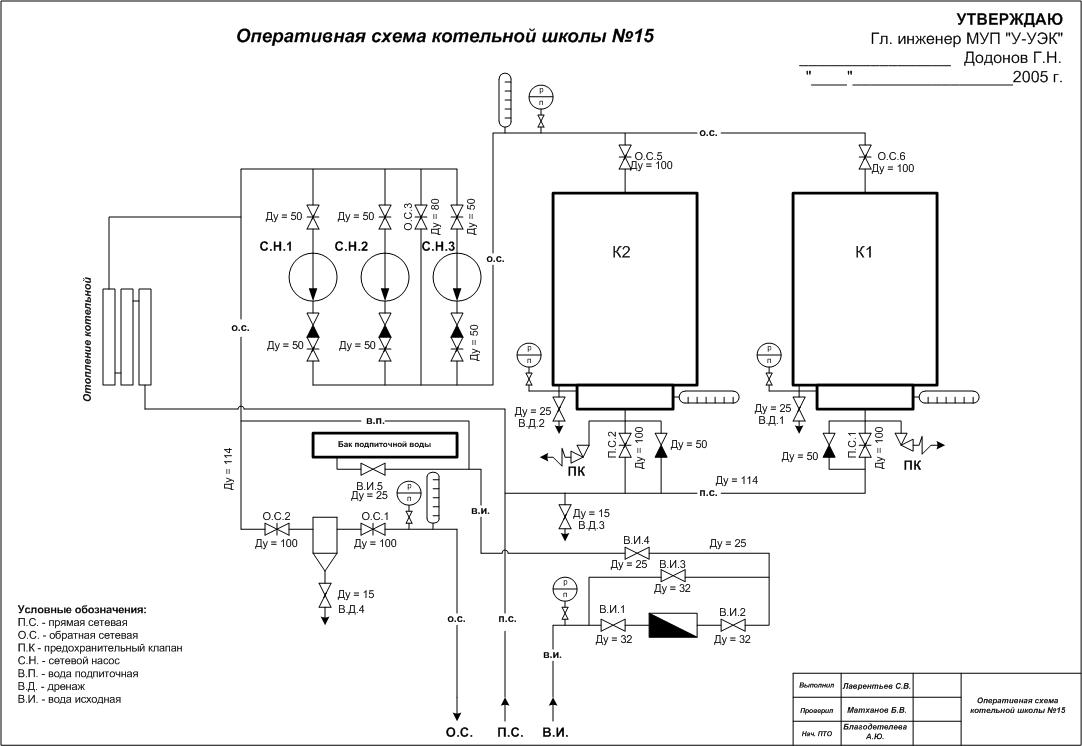

Drawings of boiler houses. Some examples:

- Boiler house project 8MW, water heating boilers Buderus, download in PDF format (316Kb)

- 16MW boiler house project, Buderus boiler equipment, download in PDF format (299 Kb)

| Boiler room design references | Working project of the boiler house | Questionnaire for ordering a project | About the Design Institute | Sample Design Drawings |

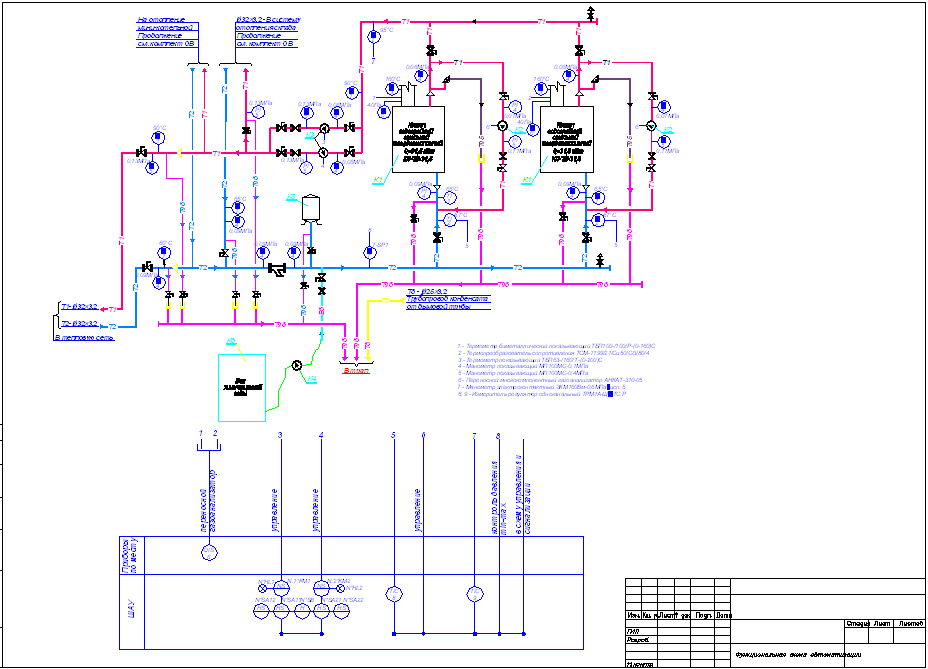

Automation of boiler equipment

It would be foolish not to take advantage of the opportunities that facilitate the operation of heating systems. Automation allows you to use a set of programs that control heat flows depending on the daily routine, weather conditions, and also help to additionally heat individual rooms, for example, a pool or a nursery.

An example of an automated circuit diagram: the automatic operation of the boiler house controls the operation of the water recirculation circuits, ventilation, water heating, heat exchanger, 2 underfloor heating circuits, 4 building heating circuits

There is a list of user functions that adapt the operation of the equipment depending on the lifestyle of the inhabitants of the house. For example, in addition to the standard program for providing hot water, there is a set of individual solutions that are more convenient and even economical for residents. For this reason, a boiler room automation scheme can be developed with the choice of one of the popular modes.

Good night program

It has been proven that the optimal night air temperature in the room should be several degrees lower than the daytime temperature, that is, the ideal option is to lower the temperature in the bedroom by about 4 ° C during sleep. At the same time, a person experiences discomfort when waking up in an unusually cool room, therefore, early in the morning the temperature regime must be restored. Inconveniences are easily solved by automatically switching the heating system to night mode and back. Night time controllers are operated by DE DIETRICH and BUDERUS.

Hot water priority system

Automatic regulation of hot water flows is also one of the functions of the general automation of equipment. It is divided into three types:

- priority, in which during the use of hot water the heating system is completely turned off;

- mixed, when the boiler capacities are delimited to service water heating and home heating;

non-priority, in which both systems act together, but in the first place is the heating of the building.

Automated scheme: 1 - hot water boiler; 2 – network pump; 3 – source water pump; 4 - heater; 5 – HVO block; 6 – make-up pump; 7 - deaeration block; 8 - cooler; 9 - heater; 10 - deaerator; 11 – condensate cooler; 12 - recirculation pump

Low temperature operating modes

The transition to low-temperature programs is becoming the main direction of the latest developments of boiler manufacturers. The advantage of this approach is an economic nuance - a reduction in fuel consumption. Just automation allows you to adjust the temperature, choose the right mode and thereby reduce the level of heating. All of the above points must be taken into account at the stage of drawing up a thermal scheme for a hot water boiler.