- Color combinations

- Types of steam heating systems

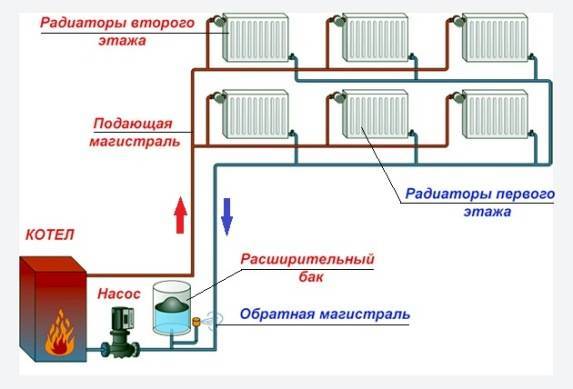

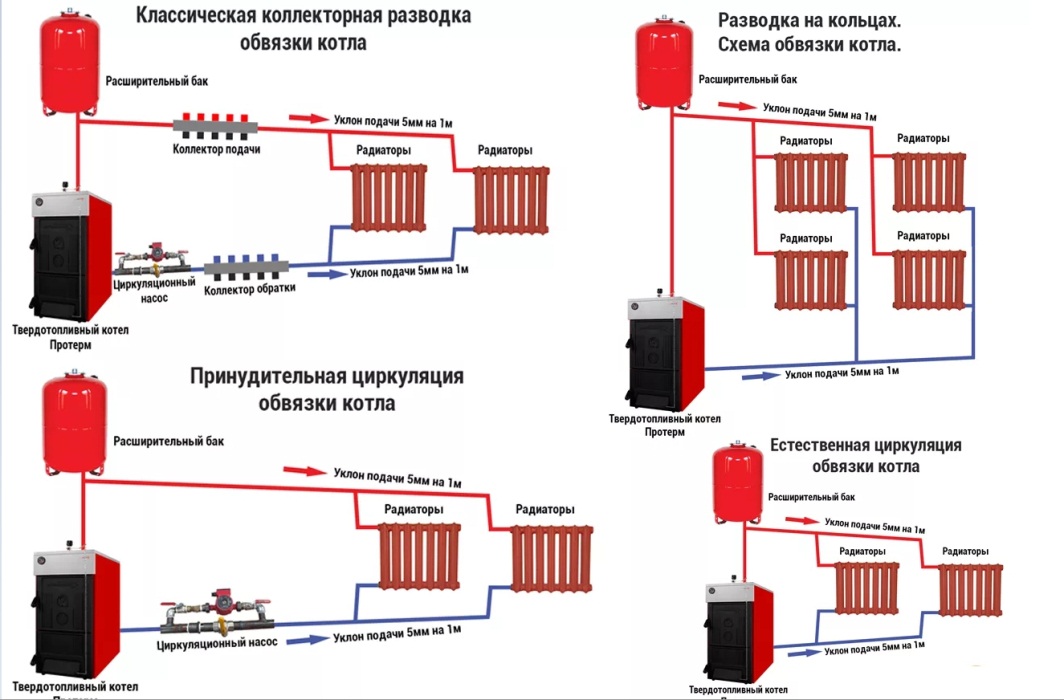

- Wiring types

- Boiler selection

- Which pipes to use

- Residential heating options

- The project comes first

- About the boiler

- About the heating scheme

- Pipes for steam heating

- About the price of such a system

- Scopes of steam boilers and purpose

- Installation of steam heating in a private house

- Main components of the steam system

- Equipment

- heating elements

- steam boiler

- Pipes and radiators

- The principle of operation of steam heating

- What are the types of steam heating

- How to choose a heating boiler

Color combinations

Stylists are advised to take into account such nuances:

- direction in the interior;

- combination of shades;

- illumination.

It is much easier to choose a palette if the style for the kitchen with the living room is already chosen. For example, neoclassicism and Provence are characterized by their own combinations. In a classic interior, designers combine pastel colors, pale colors, which are slightly diluted with dark shades.

In French country houses, you can often see soft blue, pink, pistachio colors. Art Deco designers make up objects and finishing materials in black and white, sometimes beige and brown or silver and black. The main thing is to choose a shade for the walls. White will become universal, it will expand the space, and later you can paint over them with any paint.

However, in the cooking area, the whiteness ceases to look fresh. Beige or gray shades will be more practical. This background will accentuate other colors. In a monochrome interior, designers advise to glue wallpapers of an unusual color or with a photo print.

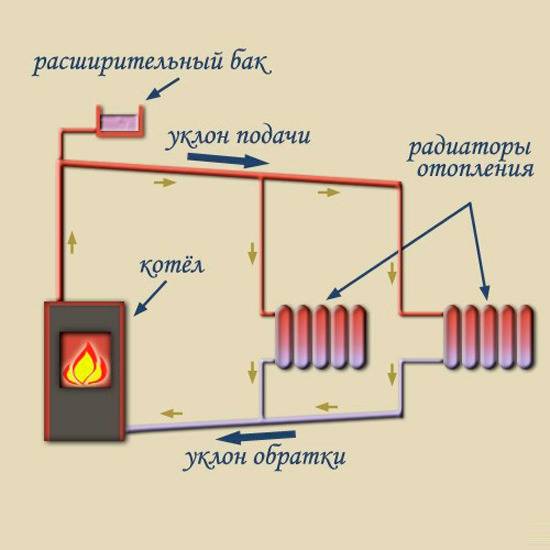

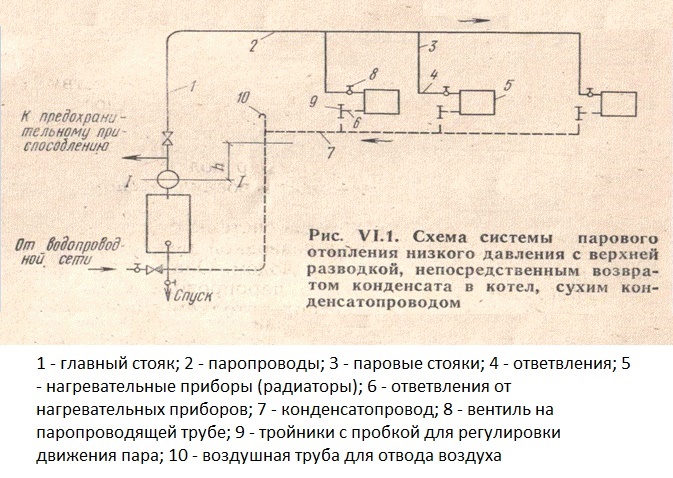

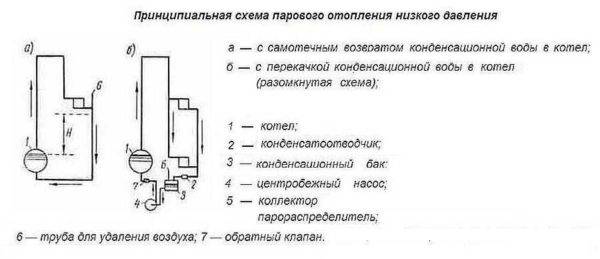

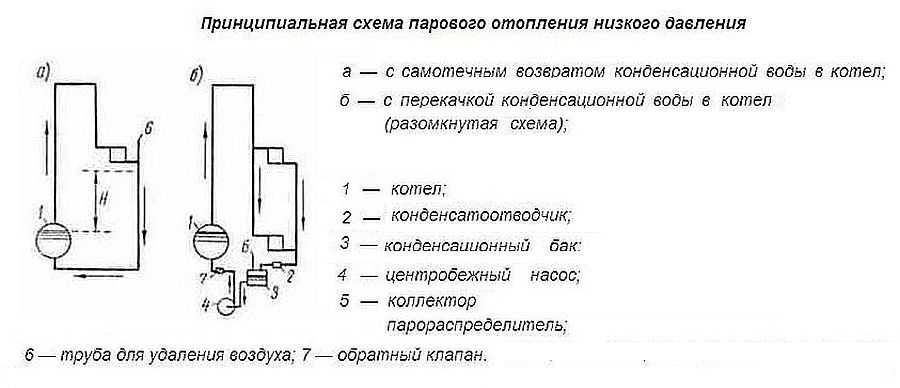

Types of steam heating systems

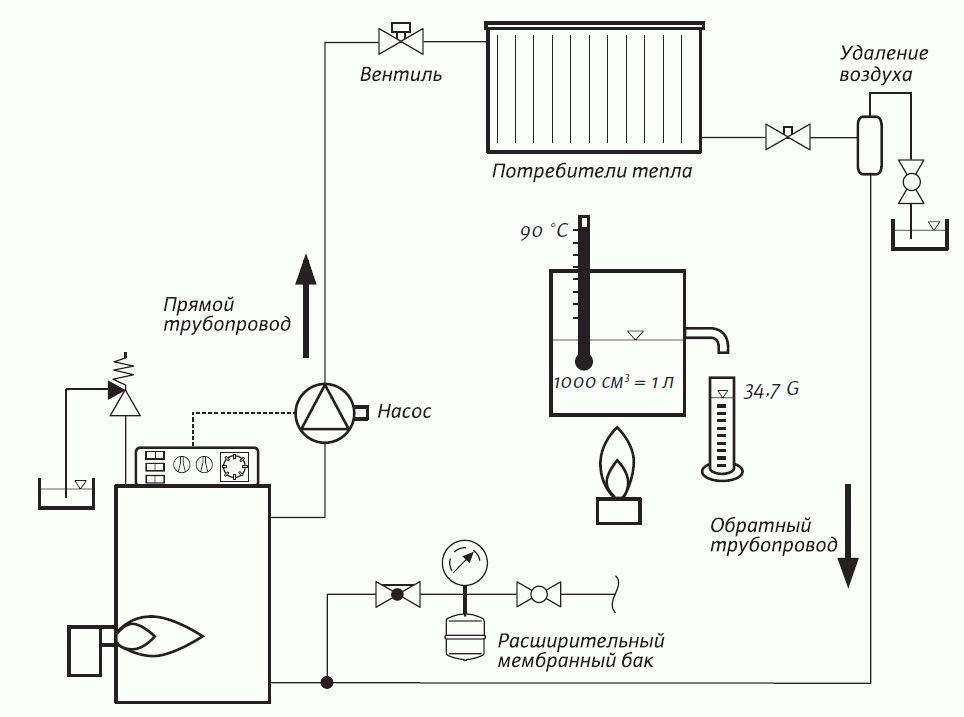

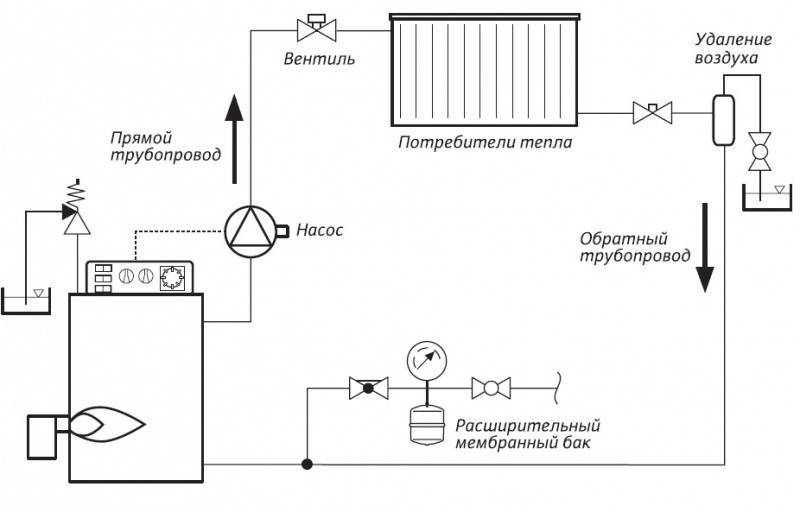

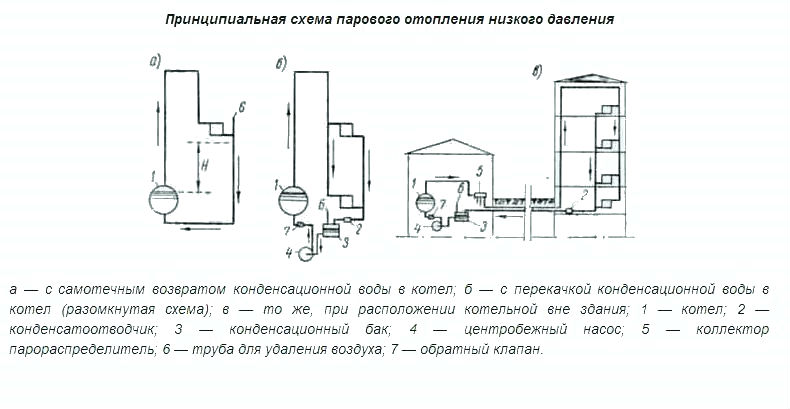

According to the method of the device, two types of steam heating are distinguished: with a closed and open system. In a closed system, condensate flows into a special receiving pipe, which is connected to the corresponding inlet of the cat. It is laid with a slight slope, so that the condensate flows through the system by gravity.

Schemes of open and closed steam heating systems

In an open system, condensate is collected in a special container. When it is filled, it is fed into the boiler using a pump. In addition to the different construction of the system, different steam boilers are also used - not all of them can work in closed systems.

In general, there are steam heating systems with pressure close to atmospheric or even lower. Such systems are called vacuum-vapor systems. What is so attractive about this setup? The fact that at low pressure the boiling point of water decreases and the system has a more acceptable temperature. But the difficulty in ensuring tightness - air is constantly sucked through the connections - has led to the fact that these schemes are practically never found.

Steam heating with low pressure is more common. Available steam boilers for domestic purposes can create a pressure not exceeding 6 atm (at a pressure of more than 7 atm, the use of equipment requires permission).

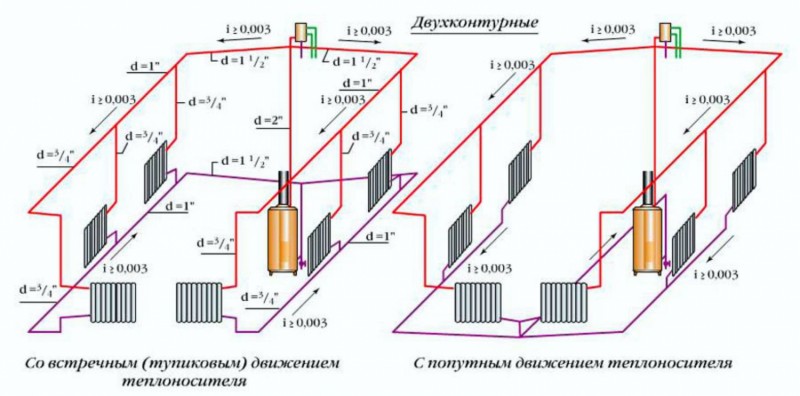

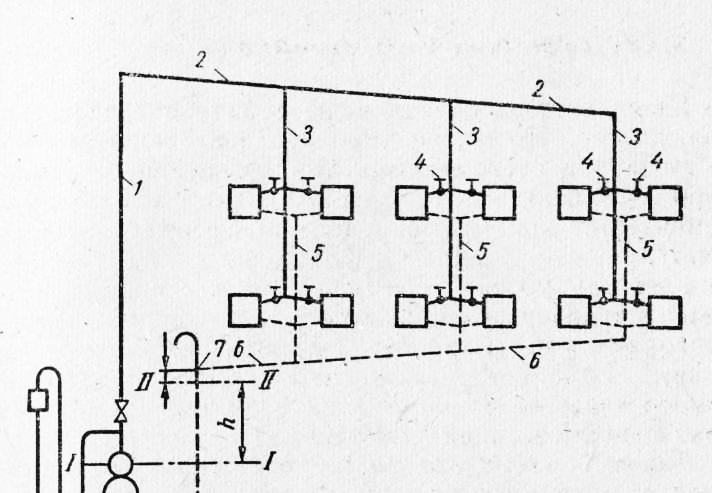

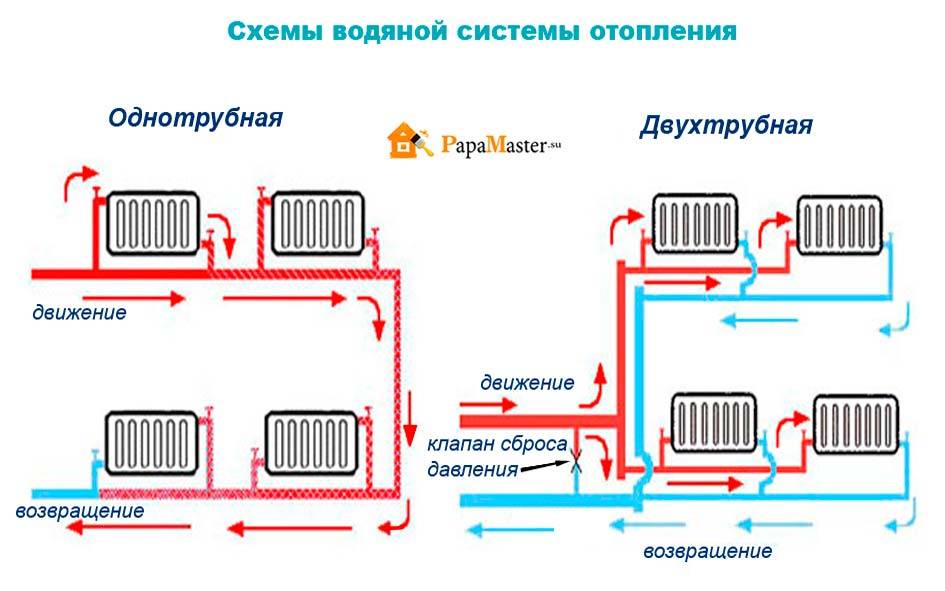

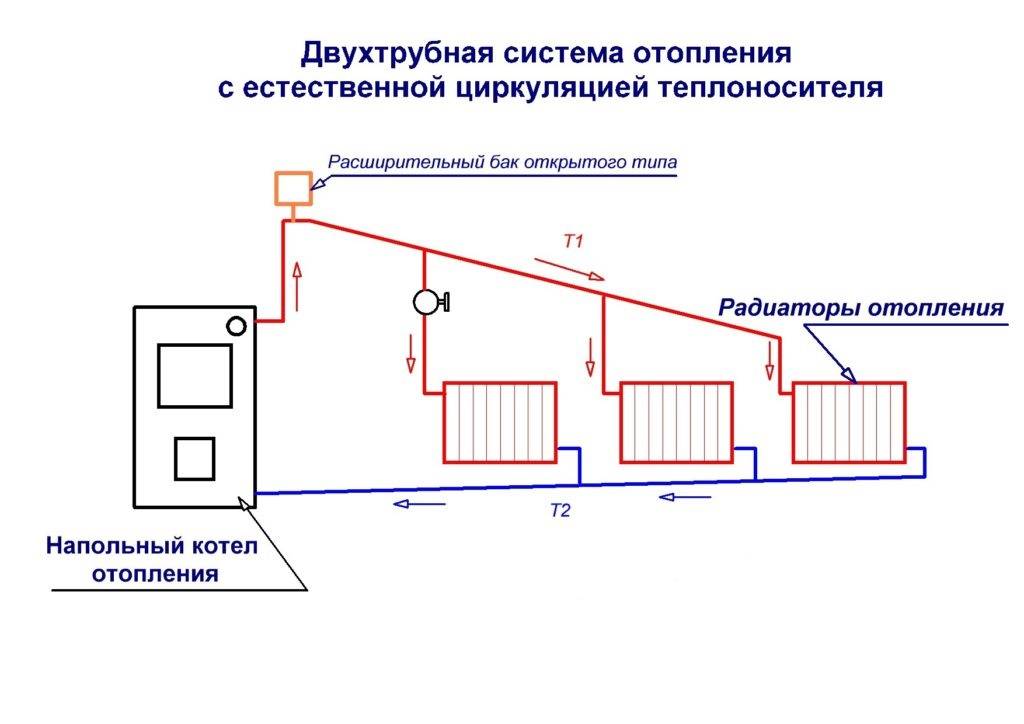

Wiring types

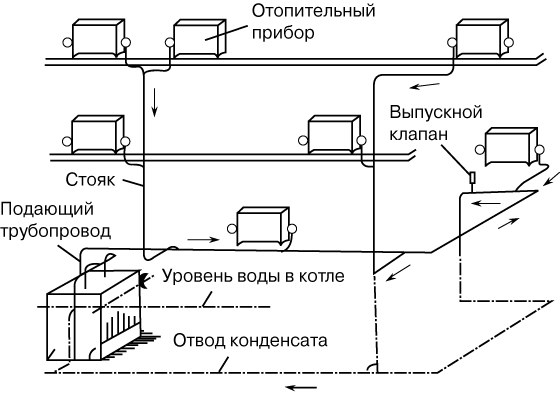

By type of wiring, steam heating happens:

-

With upper wiring (the steam pipeline is located under the ceiling, pipes go down from it to the radiators, a condensate pipeline is laid below). Such a scheme is the easiest to implement, since hot steam moves through one pipes, cooled condensate through others, the system is stable.

- With bottom wiring. The steam pipe is located at floor level. This scheme is not the best choice, since hot steam moves up through one pipe, condensate moves down, which often leads to water hammer and depressurization of the system.

- With intermediate wiring. The steam pipeline is laid just above the radiators - approximately at the level of the window sills. The system has all the advantages of overhead wiring, except that hot pipes are within reach and there is a high risk of burns.

When laying, the steam pipeline is made with a slight slope (1-2%) in the direction of steam movement, and the condensate pipeline - in the direction of condensate movement.

Boiler selection

Steam boilers can operate on all types of fuel - gas, liquid and solid fuels. In addition to the choice of fuel, it is necessary to correctly select the power of the steam boiler. It is determined depending on the area that will need to be heated:

- up to 200 m2 - 25 kW;

- from 200 m2 to 300 m2 - 30 kW;

- from 300 m2 to 600 m2 - 35-60 kW.

In general, the calculation method is standard - 1 kW of power is taken per 10 square meters. This rule is true for houses with a ceiling height of 2.5-2.7 m. The choice of a specific model follows. When buying, pay attention to the presence of a quality certificate - the equipment is dangerous and must be tested.

Which pipes to use

Temperatures during steam heating can normally only be tolerated by metals. The cheapest option is steel. But to connect them, welding is required.It is also possible to use threaded connections. This option is budgetary, but short-lived: steel quickly corrodes in a humid environment.

Copper pipes don't corrode.

Galvanized and stainless pipes are more durable, but their price is not at all modest. But the connection is threaded. Another option is copper pipes. They can only be soldered, they are expensive, but they do not rust. Due to their higher thermal conductivity, they transfer heat even more efficiently. So such a heating system will be super efficient, but also very hot.

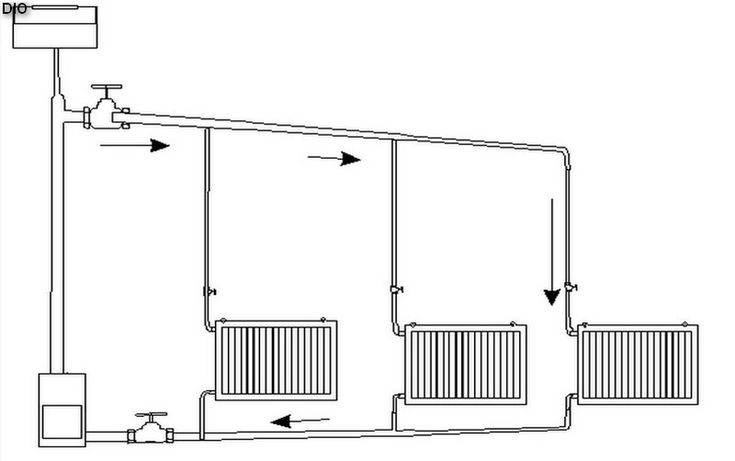

Residential heating options

The well-known and most common way to heat your own house or apartment is to make a water system. Principle of operation: the coolant is heated by a boiler or other source, then it is transferred through pipes to heating devices - radiators, underfloor heating (abbreviated as TP) or baseboard heaters.

A heat exchanger placed inside the stove heats the water sent by the pump to the batteries

Now we list alternative heating options:

- Furnace. A metal potbelly stove is being installed or a full-fledged brick oven is being built. If desired, a water circuit is built into the furnace or smoke channels of the stove (shown above in the photo).

- Purely electric - convectors, infrared and oil heaters, spiral fan heaters. A more modern way is the installation of heating floors using resistive cables or a polymer film. The latter is called infrared, carbon.

- Air. The heat source warms up the filtered outdoor air, which is forced into the rooms by a powerful fan. A simpler and cheaper option is the installation of gas convectors in residential premises.

- Combined - wood-burning stove + electric heaters of any type.

Bathroom heating scheme with electric underfloor heating

To move on, you need to decide which type of heating is better - more profitable, more efficient, more convenient. We definitely recommend choosing a water system. The reasons:

- to heat water, you can use any energy carrier or combine several types of fuel by installing 2-3 boilers;

- with high requirements for interior design, piping is mounted in a hidden way, baseboard heaters or TP circuits are used instead of batteries;

- the ability to organize hot water supply (DHW) - install a double-circuit boiler or an indirect heating boiler (depending on the amount of water consumed);

- alternative energy sources can be connected to the system - solar collectors, heat pump;

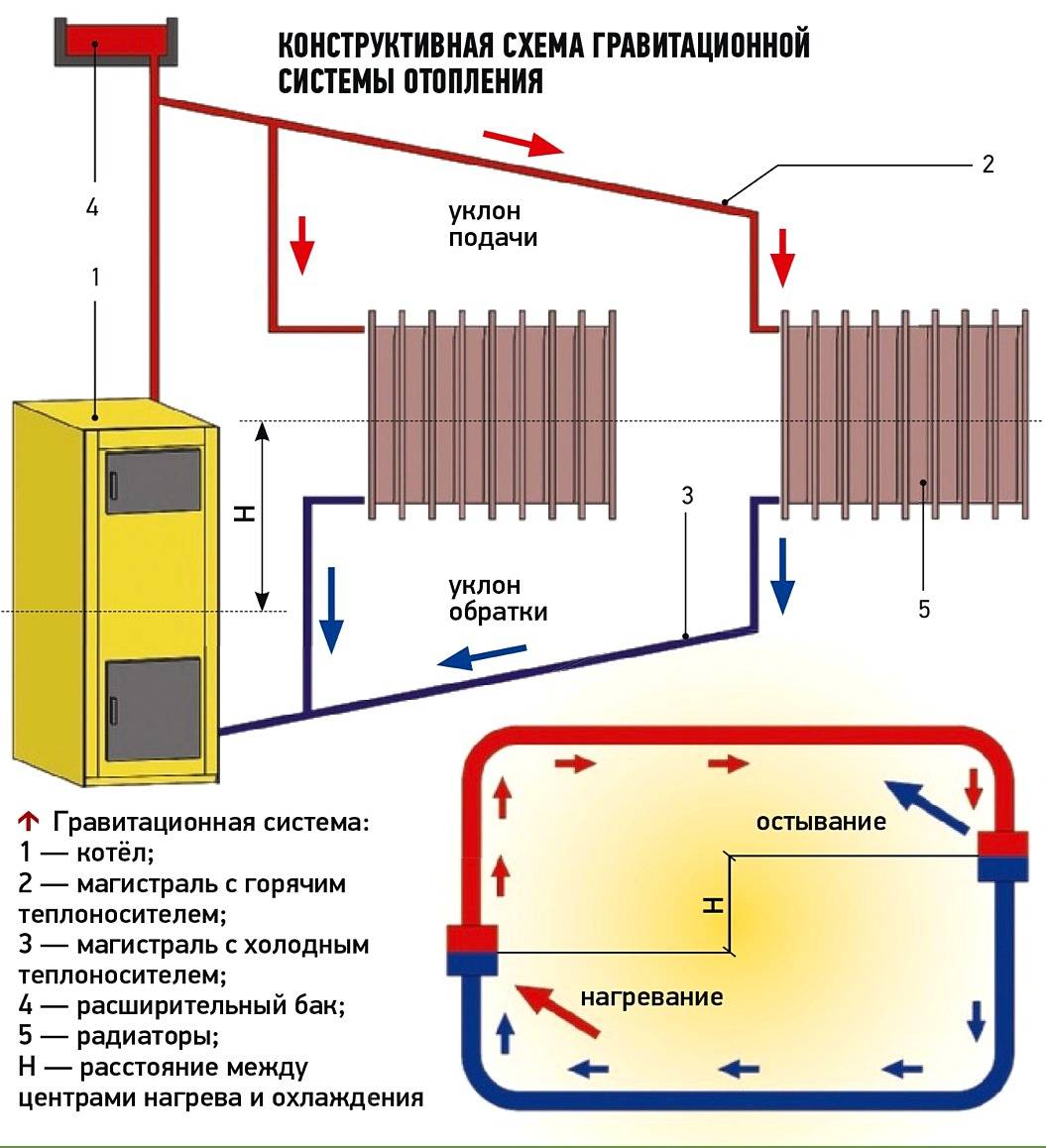

- if necessary, heating in a private house is made completely autonomous - pipes are laid according to a gravity (gravitational) scheme, plus a boiler unit is installed that does not require connection to the mains;

- the system lends itself well to adjustment, automation and remote control via cellular communication or the Internet.

The only drawback of water networks is the cost of installation, equipment and valves. Purchase and connection of electric heaters will cost less, but the restriction in terms of fuel choice will increase operating costs.

The device in a country cottage of full-fledged air heating will cost even more than building a stove.It is necessary to purchase a ventilation unit with a heat exchanger, which plays the role of a blower, purifier and air heater. Then organize the supply and exhaust - to conduct air ducts to all rooms. The expert will tell about the pitfalls of air heating in the video:

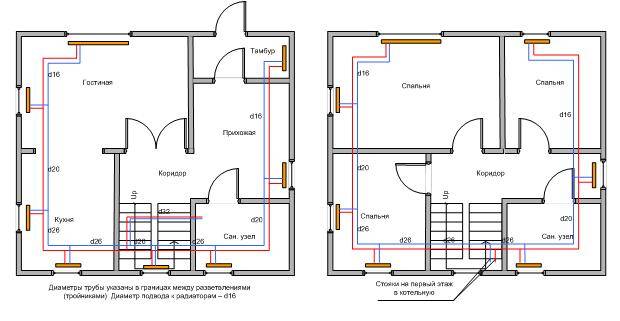

The project comes first

When deciding on the creation of steam heating, one must be aware that in this case the heat carrier will be steam with all the associated features. Among them, the most important one should be noted - the increased temperature of the radiators, which results in a significant likelihood of getting burned in case of contact. But leaving aside all sorts of pros and cons, let's just see how you can become the owner of steam heating by doing it yourself in a private house.

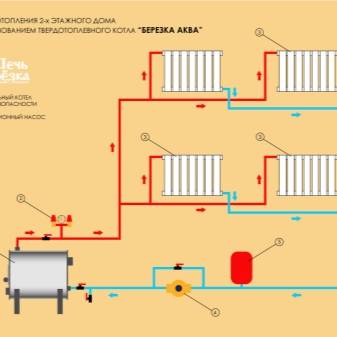

Heating project for a two-story cottage

Heating project for a two-story cottage

About the boiler

As it should be in any serious business, it is necessary to start with a project. The first step is to determine the power of the thermal boiler. It depends on the size of the house. So, with an area not exceeding two hundred square meters, a power of up to twenty-five kilowatts will suffice, with a house area of up to three hundred square meters. m. already require power up to thirty kilowatts. Based on such data, a steam boiler is selected. In addition to its power, it is necessary to take into account such factors:

- type of fuel used for work (coal, firewood, peat, gas, diesel fuel, etc.);

- the possibility of obtaining hot water for household needs.

|

|

|

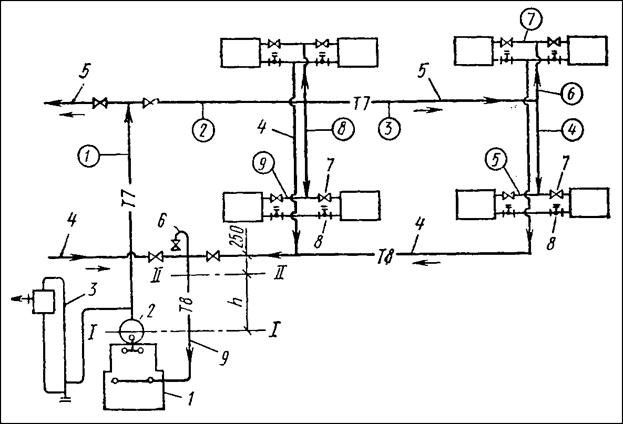

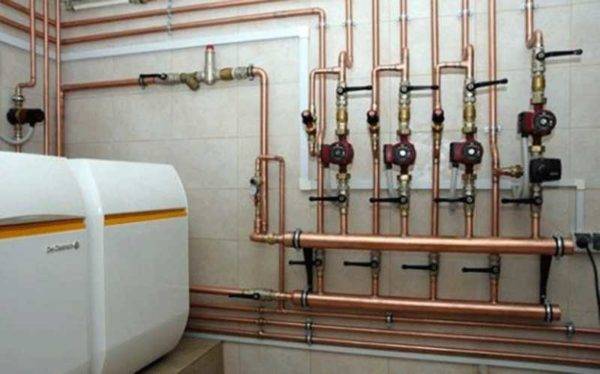

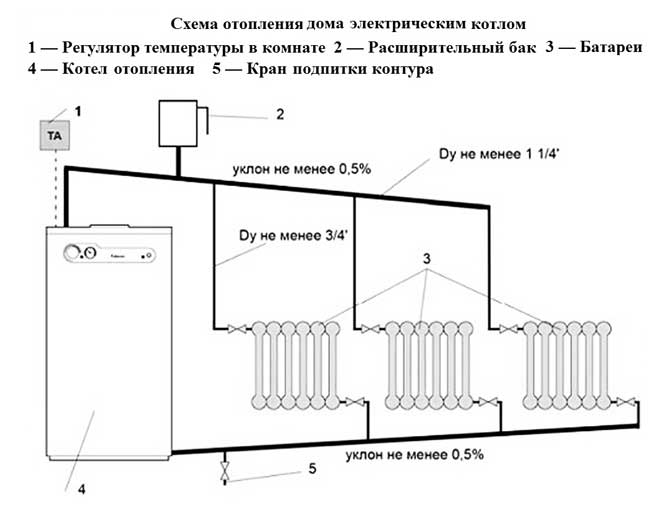

About the heating scheme

It must also be determined before starting work. The steam heating scheme depends on:

- the size of the heated area;

- the number and location of heating batteries, filters, valves and control valves, control devices, etc., everything that is necessary for the normal functioning of such a system;

- opportunities for equipment placement;

- where and how the heating boiler will be located.

The question of choosing a specific heating option is quite complicated, perhaps a video will not be superfluous in this situation

Pipes for steam heating

As already mentioned, with steam heating, the entire system is characterized by an elevated temperature, so the use of synthetic pipes is impossible, they are not designed to work at such values.

So, when determining how to make steam heating, you need to pay special attention to the choice of pipes, although it is small, it is

- Steel pipes. For their application, welding equipment is needed. The advantage of pipes is high mechanical strength and the ability to withstand significant impacts, but they are susceptible to corrosion.

- Copper. For their installation, soldering is used, they are distinguished by a high price.

- Galvanized and stainless pipes. They combine the advantages of the previous ones, docking is carried out using threads, resistant to corrosion, but have an increased price.

|

|

|

To facilitate further work, it is necessary to determine where to place the radiators (or other devices, if you prefer them), the length of the pipes, the location of the adapters, branches, manifold distributors, etc. In short, the steam heating connection diagram should be drawn on paper with all the necessary details (equipment, pipe length, etc.).

About the price of such a system

Once the project is completed and it is clear which equipment to use, you can determine your costs. Without reference to specific conditions, equipment, pipes, volumes of installation work, it is impossible to say specifically how much steam heating costs.

Scopes of steam boilers and purpose

Steam boilers are actively used in the following industries:

- Heating systems. There are industrial and domestic models of steam boilers that allow the use of steam as a heat carrier. Steam passes through the heating circuits and / or enters the heat exchangers of hot water devices, thereby ensuring the movement of thermal energy. A household steam heating boiler is often combined with solid fuel heating devices. Industrial facilities use more powerful and reliable devices that produce superheated steam with increased heat transfer.

- Energy. Steam engines convert heated steam into electrical energy. The working process looks quite simple: steam moves into the turbine and rotates the shaft, due to which electricity is generated. This principle has been successfully used in many power plants.

- Industry. Steam devices may well provide mechanical movement of various elements of systems. The principle of operation of a steam boiler for industrial use looks the same as in the previous case, but the generated energy is directed to the implementation of a mechanical effect on the elements that must move.

Knowing what a steam boiler is for and where it is used allows you to use the device with maximum efficiency.

Installation of steam heating in a private house

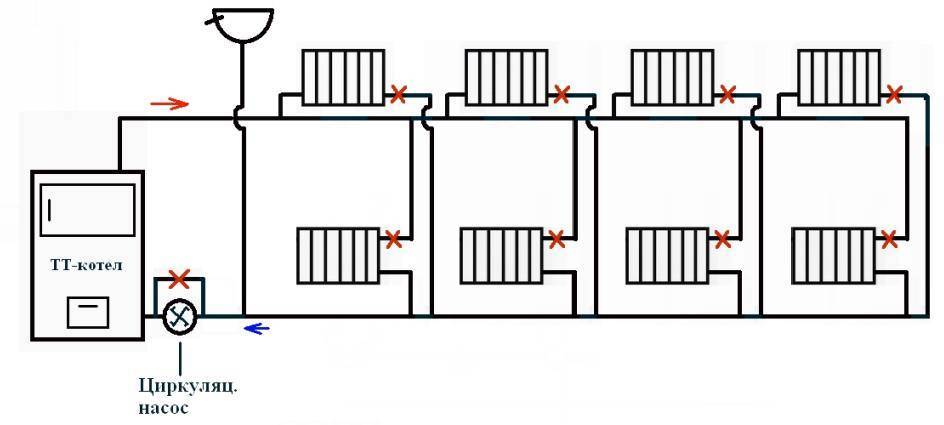

Before installing the system, you need to calculate the area of \u200b\u200bthe rooms, determine the location of radiators, valves, filters and other components of the structure.

Next, you should choose the option for distributing heating:

- top way. It implies the installation of a steam pipeline above the heating device. Pipes are lowered from the boiler to the batteries, and condensate systems are laid on the floor.

- bottom way. Steam pipes are laid below the heating units.

- The mixed option involves laying the pipeline just above the batteries, otherwise the system repeats the upper installation method.

To facilitate the installation work, it is necessary to draw an arrangement diagram in advance, indicating all the elements of the system, the length and diameter of pipelines, the number of radiators, etc.

Consider how to conduct steam heating in a private house with your own hands:

- Prepare planes, surfaces for mounting equipment: strengthen the walls, level the floor surface. Then the installation of fixtures for radiators, fixing the batteries. It is recommended to place radiators under windows, this will prevent drafts, fogging of windows and shift the “dew point” beyond the window openings.

- Install the steam generator on a concrete base. Floors must be covered with non-combustible material to prevent the possibility of fire. It is better to mount the boiler in the basement so that the steam rises up. When forming underfloor heating, preference is given to a double-circuit boiler, which separates the work for heating the circuit in underfloor heating and the system of mounted radiators.The steam generator in this case is mounted above the floor surface.

- The expansion tank is mounted at the highest heating point. Fixation on special fasteners, location area in the line between the steam generator and radiators. Experts advise to mount an open-type expansion tank as close as possible to the heating boiler.

- Now the installation of the pipeline. The starting point of the connection is the steam generator, then the pipe is led to the first heating structure, then the connection of the outlets and inlets. All subsequent pipes are connected in the same way. The connection to the main line is carried out with a slope of 3 mm per 1 m - this is necessary for the natural circulation of the coolant.

- Each radiator is equipped with a Mayevsky valve to eliminate air locks, and a storage tank is mounted in front of the steam generator to collect condensate, from where the liquid will flow into the boiler for heating and subsequent circulation.

The entire line is also closed on the heating boiler - a closed circuit is obtained. To eliminate the possibility of clogging the system, a filter is mounted on the boiler. Also, a condensate distillation pump is mounted on the boiler, the pipe from the boiler to the pump is selected so that the diameter of the pipe is smaller than the diameter of the other pipes. At the outlet of the boiler, a pressure gauge and an excess pressure relief valve are installed.

It remains to supplement the line with a water drain / fill unit, check the system for operability, leaks, and you can start the equipment in constant circulation. Despite the ease of installation, it is necessary to carefully verify all the parameters of the units and calculate the length of the pipelines.

When calculating how much it costs to carry out steam heating, one should take into account the price of the main components, auxiliary elements, measuring and control devices. When ordering a service from a company, the owner will have to pay from $ 300, provided that equipment, radiators and other components of the system have already been purchased.

Main components of the steam system

Equipment and materials:

- steam generator (boiler);

- batteries (radiators);

- measuring and control instruments;

- pump;

- collector for condensate accumulation;

- shut-off and control valves.

When forming a system with your own hands, you need to remember that all elements must withstand extremely high heating temperatures. For example, a membrane expander with a maximum temperature of +85 C is not suitable for steam, a storage tank with temperature limits of +100 C is needed.

If the system is equipped with a stove, the chimney will become clogged more often, so cleaning should be given more careful attention. An oven with a heat exchanger can be used for cooking, but only during the cold season

In the summer, by flooding the stove, the owner will receive the circulation of the coolant in the heating system, and this is inconvenient, uneconomical. Experts recommend installing a separate cooking appliance in the kitchen in the summer, and using the oven in the cold seasons.

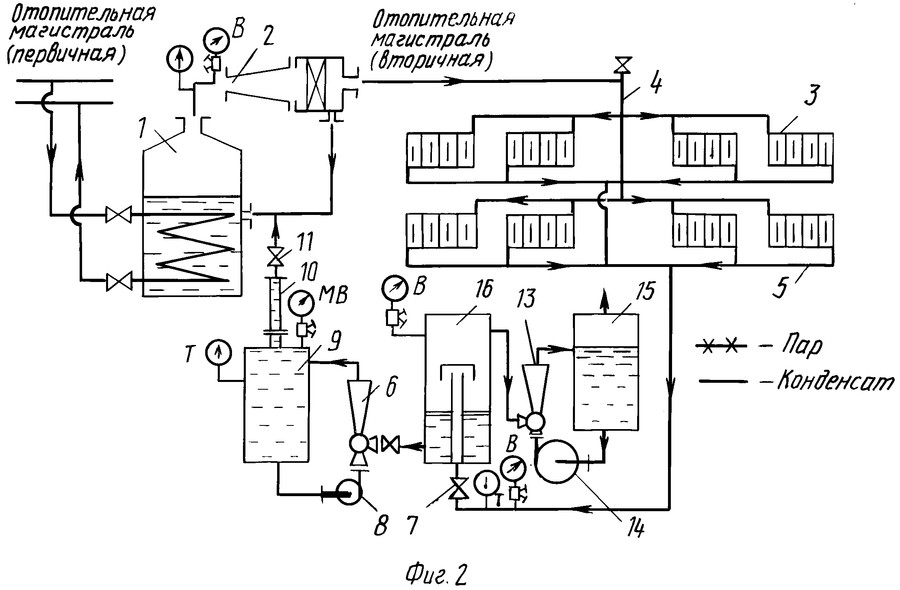

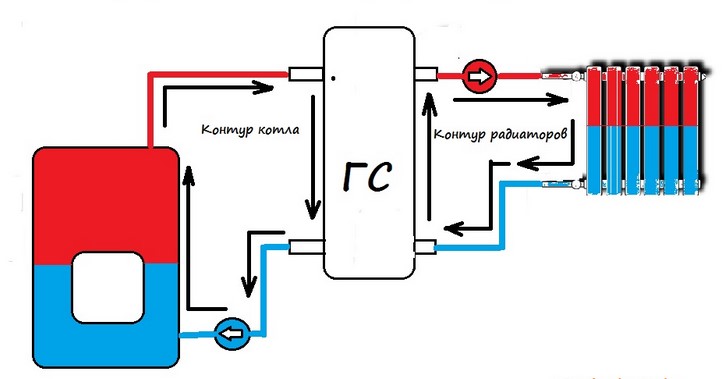

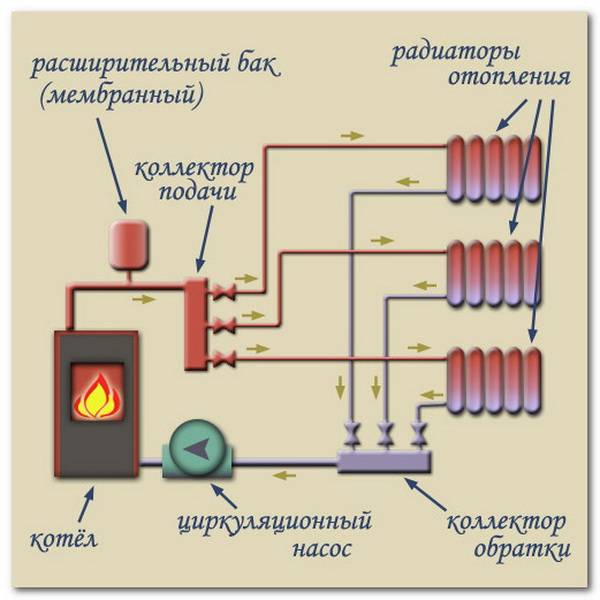

Equipment

The entire chain of the heating system includes mandatory elements, the presence of which does not depend on the scheme you have chosen. These are heating equipment, a steam generator, pipes for moving the coolant, radiators and valves. Let's take a closer look at each of the links in this chain.

heating elements

Various devices can act as heating equipment.Since steam heating is a traditional, time-tested method of heating, an ordinary stove often acts as a heating element. It is possible to use an oven already existing in the house for steam heating. It can be a traditional solid fuel oven or various liquid fuel modifications. It is enough to add a steam boiler to the existing furnace and make the distribution of steam heating throughout the room. You can heat the boiler using gas equipment or by means of electric heaters. In each specific case, the use of this or that special equipment is justified and it is necessary to choose it correctly at the design stage.

steam boiler

Sectional view of a steam boiler

The efficiency of the steam heating system of a private house largely depends on the boiler. The table below shows the dependence of its power on the area of \u200b\u200bthe heated room.

| Heating boiler power (kW) | Heated area (sq.m.) |

| 25 | up to 200 |

| 30 | 200-300 |

| 60 | 600 |

| 100 | 1200 |

It should be borne in mind that the greater the boiler power, the higher the fuel consumption. However, if you install a steam boiler for heating a house with a lower power than is permissible for a particular area, this can lead to insufficient heating of the home. Uncomfortable living room temperature is not a very pleasant alternative. So do it right calculation of steam system elements heating, so that they do not have to be changed in the first months of operation.

Pipes and radiators

The scheme of steam heating can be any, but there are always components such as pipes and radiators. The pipes carry out the movement of the coolant, in this case steam.And radiators serve to increase the heat transfer area in individual rooms. When choosing the material of pipes and radiators, the aggressive effect of hot steam on metal should be taken into account. So, for example, steel pipes are the most economical option, but the most susceptible to corrosion.

Copper pipes are not subject to corrosion

Galvanized pipes - the most popular option

Copper pipes - ideal for steam heating a house, they practically do not collapse under the influence of steam, do not rust or oxidize, but their cost is very high. "Golden mean" - pipes made of galvanized steel. They are less susceptible to corrosion than steel ones, are easily mounted on threaded connections and are much cheaper than copper ones.

Radiators are chosen not only by material, but also by size and number of links. It depends on how large the room they have to heat.

The principle of operation of steam heating

The operation of such a heating system can be described something like this: there is a special boiler in which water is heated under high pressure to a boiling point. As a result, steam is formed, which enters through the lines directly into the heating radiators. When it completely gives off heat, it returns back in the form of condensate. It is worth noting that in such a system hot steam squeezes out air. The temperature of the radiators can reach 100o C, and this is not the limit.

Main advantages.

Consider the advantages of steam heating:

- No heat is lost in the heat exchanger. Steam accumulates heat, so small pipes are needed for such a system.

- With the help of such heating, you can heat the building you need in record time, as there is a small inertia.

- The steam boiler used in the system accumulates steam.

This is all, of course, good, but the steam heating system also has some disadvantages. So, its service life is quite short. Moreover, the heat-releasing surface during operation is heated to a high temperature.

Touching it can cause severe burns.

What are the types of steam heating

There are several classifications of heating, which depend on a number of principles and aspects of the application. So, according to the method of returning condensate back to the boiler, heating systems are:

- Closed, in which condensate is immediately sent to the heating boiler.

- Open, where it first accumulates in a special tank.

Move on. Depending on the number of circuits, heating can be:

- Single-circuit, designed exclusively for heating the building.

- Double-circuit, capable, in addition, to provide heating of water for household needs.

Finally, steam systems can differ in the way they are wired, which can be:

- Lower.

- Upper.

The wiring itself is selected based on the functional features of the structure and the type of pipes used.

How to choose a heating boiler

The boiler is the basis of the system, its core. It will function properly only when it is selected in accordance with the characteristics of the heated room. In other words, the heating boiler must have sufficient power to heat the desired room. To help with this, we have provided the following indicators:

- For a building with an area of up to three hundred meters, the required power is 30 kilowatts.

- Up to six hundred meters - 60 kilowatts.

- Up to one thousand two hundred meters - 80-100 kilowatts.

In addition, steam heating in a private house can be powered by various types of fuel:

- Solid.

- liquid.

- Combinations.

- Gaza.

The most important role in the device of the heating boiler is assigned to the drum, to which all the relevant sensors, pipelines and so on are attached. In addition, the boiler can be water-tube and gas-tube.

Which pipes suit us best.

In this case, everything will depend mainly on your desires and preferences. Classify such pipes depending on the material used for manufacturing.

- Steel pipeline. When installing it, you will need welding equipment. It is distinguished by good stability and strength, but at the same time it has a significant disadvantage - over time, its surface becomes corroded.

- Copper pipeline. It is also quite reliable, it showed itself perfectly in such pipelines, where the coolant circulates under high pressure and high temperature. In order to mount such a system, you will need to use the soldering method. She also has disadvantages. So, it will be very expensive to equip a house with a copper pipeline, which is why it is found mainly in expensive luxurious mansions.

- Galvanized and stainless pipeline.

Unlike the first option, this highway system is extremely resistant to rust. The connection is made with a thread. The only disadvantage, as in the case of copper, can be considered the high cost of working materials.

Installation features.

If you are planning to install a heating system, then first of all you must decide on the material from which the pipes will be made.Moreover, for the most successful installation, it is necessary to take into account the following aspects:

- Number of available adapters.

- The total length of the pipeline.

Actually, here we have examined what steam heating is in a private house.

Wall mounted gas boiler

Wall mounted gas boiler Floor standing solid fuel boiler

Floor standing solid fuel boiler

metal pipes

metal pipes Copper pipes

Copper pipes