- forced circulation

- What is the difference between solid fuel boilers

- Common mistakes when tying a gas boiler

- Boiler piping schemes with polypropylene

- natural circulation

- Forced circulation system

- emergency circuit

- Scheme with a wall-mounted boiler

- Features of binding boilers with polypropylene

- Wiring diagrams

- Boilers with automatic control

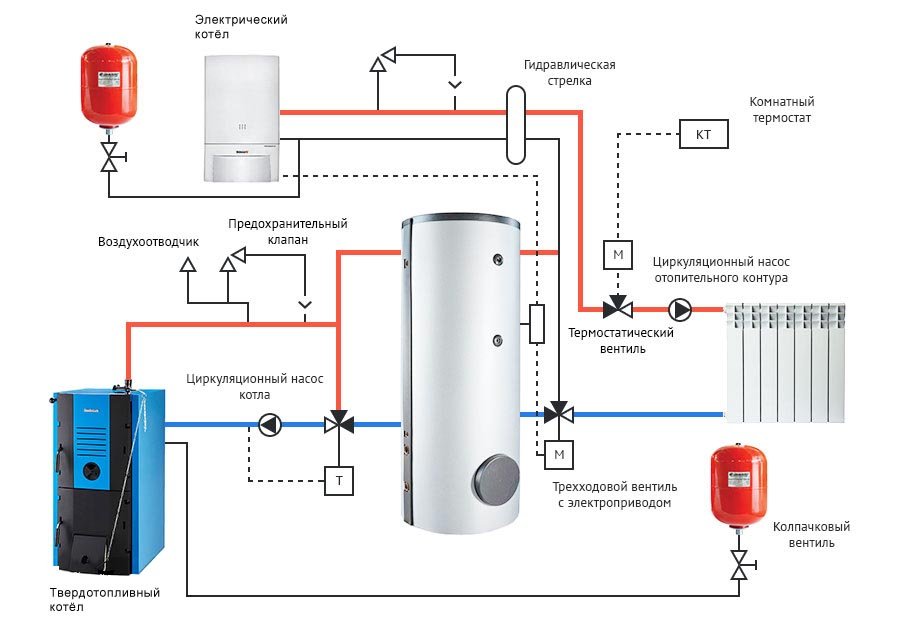

- Connection diagram for 2 boilers with manual control

- Series and parallel connection

- Schemes for connecting a water heater to a gas boiler.

- Heating boiler piping schemes for various types of circulation and circuits

- Varieties of heating schemes for a private house

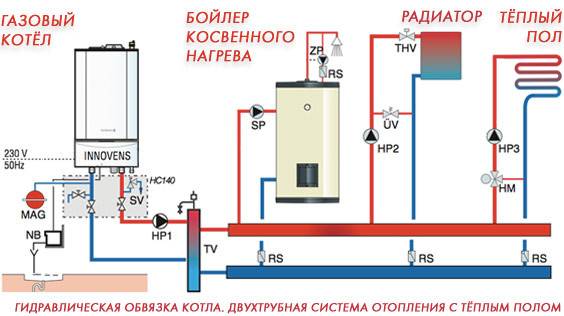

- Heated floor trim

- Ability to implement joint connection

- Strapping schemes

- Connections for solid fuel boilers.

- Conclusions and useful video on the topic

forced circulation

The method is most widely used, since the pump intensively pumps the coolant through the system and the heating efficiency increases by 30%.

The advantages also include the ability to control the temperature and low pipe consumption during installation. The system will still cost significantly more because it is more complex and requires more instrumentation. Installed elements require balancing, and the entire system requires regular maintenance. In addition, a source of electricity is needed.

If you install a combined system, it will combine the advantages of both previous ones. It can be switched to any mode using the bypass installed with the pump. In this case, the work of heating will not depend on the supply of electricity to the house.

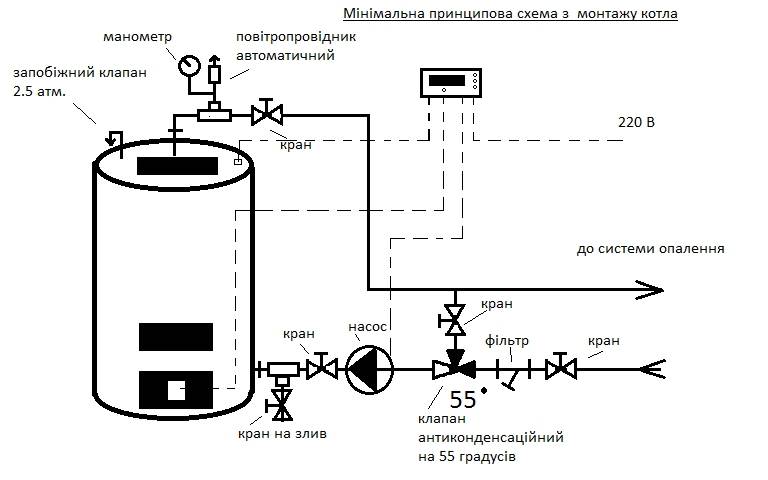

What is the difference between solid fuel boilers

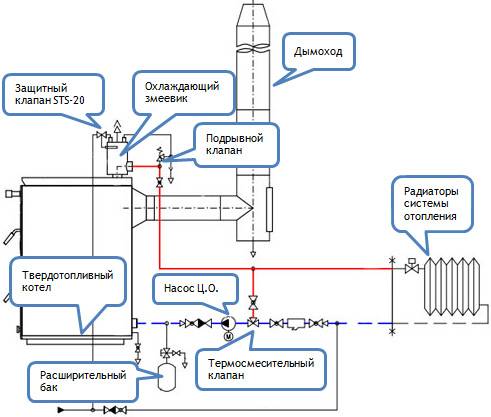

In addition to the fact that these heat sources produce heat energy by burning various types of solid fuels, they have a number of other differences from other heat generators. These differences are precisely the result of burning wood, they must be taken for granted and always taken into account when connecting the boiler to a water heating system. Features are as follows:

- High inertia. At the moment, there are no ways to abruptly extinguish a burning solid fuel in a combustion chamber.

- Formation of condensate in the firebox. The peculiarity manifests itself when a heat carrier with a low temperature (below 50 °C) enters the boiler tank.

Note. The phenomenon of inertia is absent only in one type of solid fuel units - pellet boilers. They have a burner, where wood pellets are dosed, after the supply is stopped, the flame goes out almost immediately.

The danger of inertia lies in the possible overheating of the water jacket of the heater, as a result of which the coolant boils in it. Steam is formed, which creates high pressure, tearing the body of the unit and part of the supply pipeline. As a result, there is a lot of water in the furnace room, a lot of steam and a solid fuel boiler unsuitable for further operation.

A similar situation may arise when the heat generator is connected incorrectly.After all, in fact, the normal mode of operation of wood-burning boilers is the maximum, it is at this time that the unit reaches its passport efficiency. When the thermostat responds to the heat carrier reaching a temperature of 85 ° C and closes the air damper, combustion and smoldering in the furnace still continues. The temperature of the water rises by another 2-4°C, or even more, before its growth stops.

In order to avoid excess pressure and a subsequent accident, an important element is always involved in the piping of a solid fuel boiler - a safety group, more about it will be discussed below.

Another unpleasant feature of the operation of the unit on wood is the appearance of condensate on the inner walls of the firebox due to the passage of an unheated coolant through the water jacket. This condensate is not God's dew at all, since it is an aggressive liquid, from which the steel walls of the combustion chamber quickly corrode. Then, having mixed with the ash, the condensate turns into a sticky substance, it is not so easy to tear it off the surface. The problem is solved by installing a mixing unit in the piping circuit of a solid fuel boiler.

Such a deposit serves as a heat insulator and reduces the efficiency of a solid fuel boiler.

It is too early for owners of heat generators with cast-iron heat exchangers that are not afraid of corrosion to breathe a sigh of relief. They can expect another misfortune - the possibility of destruction of cast iron from temperature shock. Imagine that in a private house the electricity was turned off for 20-30 minutes and the circulation pump, which drives water through a solid fuel boiler, stopped. During this time, the water in the radiators has time to cool down, and in the heat exchanger - to heat up (due to the same inertia).

Electricity appears, the pump turns on and sends the cooled coolant from the closed heating system to the heated boiler. From a sharp temperature drop, a temperature shock occurs at the heat exchanger, the cast-iron section cracks, water runs to the floor. It is very difficult to repair, it is not always possible to replace the section. So even in this scenario, the mixing unit will prevent an accident, which will be discussed later.

Emergencies and their consequences are not described in order to scare users of solid fuel boilers or encourage them to purchase unnecessary elements of piping circuits. The description is based on practical experience, which must always be taken into account. With the correct connection of the thermal unit, the likelihood of such consequences is extremely low, almost the same as for heat generators using other types of fuel.

Common mistakes when tying a gas boiler

A large boiler heats water faster, which means it consumes more fuel. This is also worth keeping in mind when buying and connecting gas equipment.

Pay special attention to controlling the pressure level in the expansion tank. An incorrectly selected tank size can also adversely affect the operation of the entire system as a whole. The piping scheme for a double-circuit boiler is not an easy task

The best solution would be to contact a specialized gas service, whose employees will quickly connect the unit to the gas supply system

The piping scheme for a double-circuit boiler is not an easy task. The best solution would be to contact a specialized gas service, whose employees will quickly connect the unit to the gas supply system.

More and more owners of not only private houses, but also city apartments, not wanting to depend on communal structures, are installing autonomous heating systems in their homes, the “heart” of which is a boiler - a heat generator. But on its own, it cannot work. The heating boiler piping scheme is a set of all auxiliary devices and pipes that are connected according to a certain scheme and represent a single circuit.

Why is it necessary

- Ensuring the circulation of fluid through the system and the transfer of thermal energy to the premises in which heating devices - radiators are installed.

- Protection of the boiler from overheating, as well as protection of the home from the penetration of natural or carbon monoxide gases into it in case of emergency situations. For example, the loss of a burner flame, water leakage, and the like.

- Maintaining the pressure in the system at the required level (expansion tank).

- A properly installed gas boiler connection diagram (piping) allows it to operate stably in the optimal mode, which significantly reduces fuel consumption and saves on heating.

Main elements of the circuit

- Heat generator - boiler.

- Membrane (expansion) tank - expandomat.

- Pressure regulator.

- Pipeline.

- Stop valves (faucets, valves).

- Coarse filter - "mud".

- Connecting (fittings) and fasteners.

Depending on the type of the selected heating circuit (and boiler), there may be other components in it.

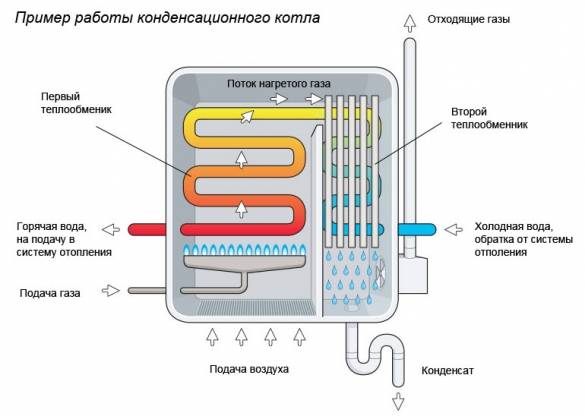

The piping scheme for a double-circuit heating boiler, like a single-circuit one, depends on many factors.These are the capabilities of the unit itself (including its equipment), and operating conditions, and features of the system design. But there are also differences, which are determined by the principle of movement of the coolant. Since private dwellings use boilers that provide both heat and hot water, consider an example of a classic piping of a double-circuit device with forced circulation of the coolant.

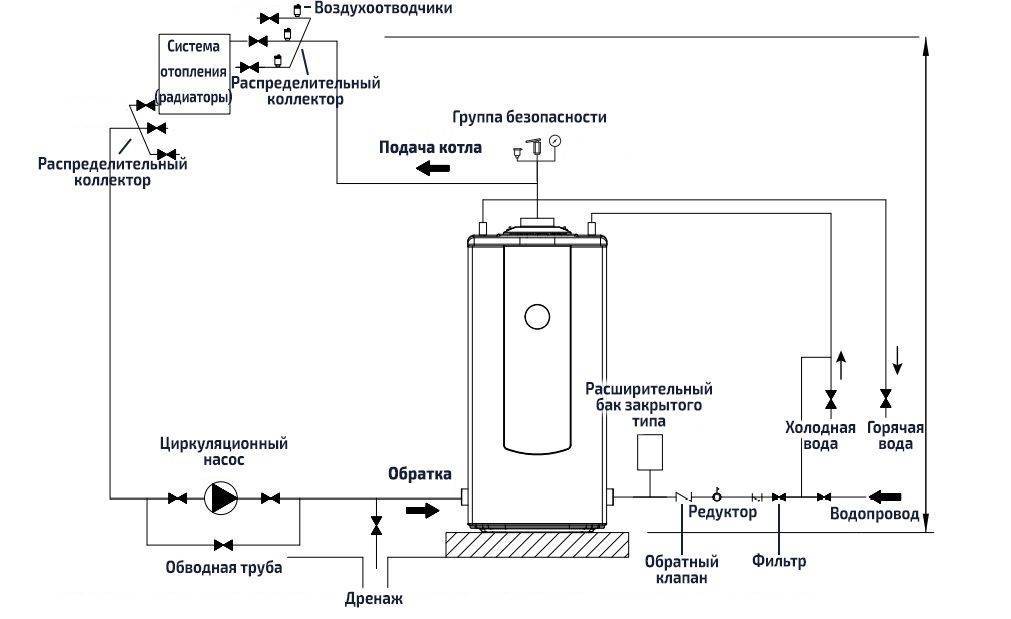

Heating circuit

The water, heated in the heat exchanger to the desired temperature, “leaves” from the boiler outlet through pipes to radiators, to which it transfers thermal energy. The cooled liquid is returned back to the inlet of the heat generator. Its movement is controlled by a circulation pump, which is equipped with almost every unit.

An expansion tank is installed between the last radiator in the chain and the boiler to compensate for possible pressure drops. There is also a “mud collector” here, which protects the heat exchanger from small fractions that can get into the coolant from batteries and pipes (rust particles and salt deposits).

A pipe insert for supplying cold water (feed) is made in the area between the boiler and the first radiator. If it is equipped on the "return", then this can cause deformation of the heat exchanger due to the temperature difference between it and the "feed" liquid.

DHW circuit

Works just like a gas stove. Cold water from the water supply system is supplied to the DHW inlet of the boiler, and from the outlet, the heated water goes through pipes to the points of water intake.

The piping scheme for wall-mounted boilers is similar.

There are a number of other types as well.

Gravity

It does not have a water pump, and the circulation of the liquid occurs due to the temperature difference at the inlet and outlet of the circuit. Such systems do not depend on the power supply.Open-type membrane tank (placed at the very top of the route).

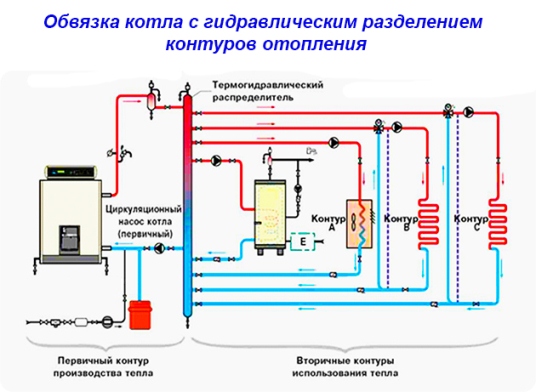

With primary-secondary rings

In principle, this is an analogue of the already mentioned comb (collector). Such a scheme is used if it is necessary to heat a large number of rooms and connect the "warm floor" system.

There are others that do not apply to private houses. In addition, there may be some additions to the listed ones. For example, a mixer with a servo.

| Articles |

Boiler piping schemes with polypropylene

Efficient and safe operation of the boiler can only be achieved if it is properly tied. There are differences for schemes with natural and forced circulation, both in the number of elements and in the limiting pressure of the coolant.

natural circulation

This is the simplest scheme, it is quite possible to perform it yourself. The principle of operation is non-volatile. For the movement of the coolant along the circuit, a pump is not required, the process uses the gravitational principle, due to the temperature difference between cold and hot water.

Such a scheme is most preferable for heat supply of small and low-rise residential buildings. The advantages of schemes with natural circulation of heating include:

- Simplified installation and strapping;

- energy independence, operation without power supply, it is allowed to use rechargeable batteries for the operation of safety automation;

- compactness of the boiler and auxiliary equipment;

- low cost of system maintenance;

- high maintainability;

- reliable operation, as there is no equipment in the thermal circuit that can break.

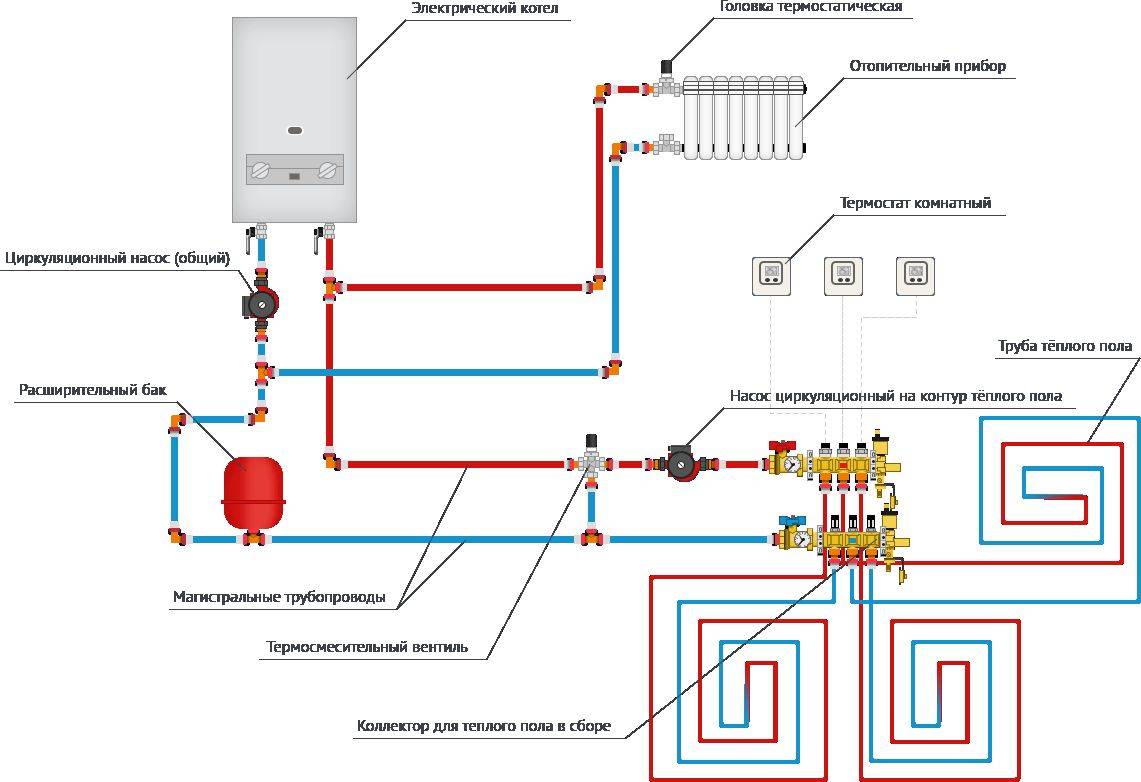

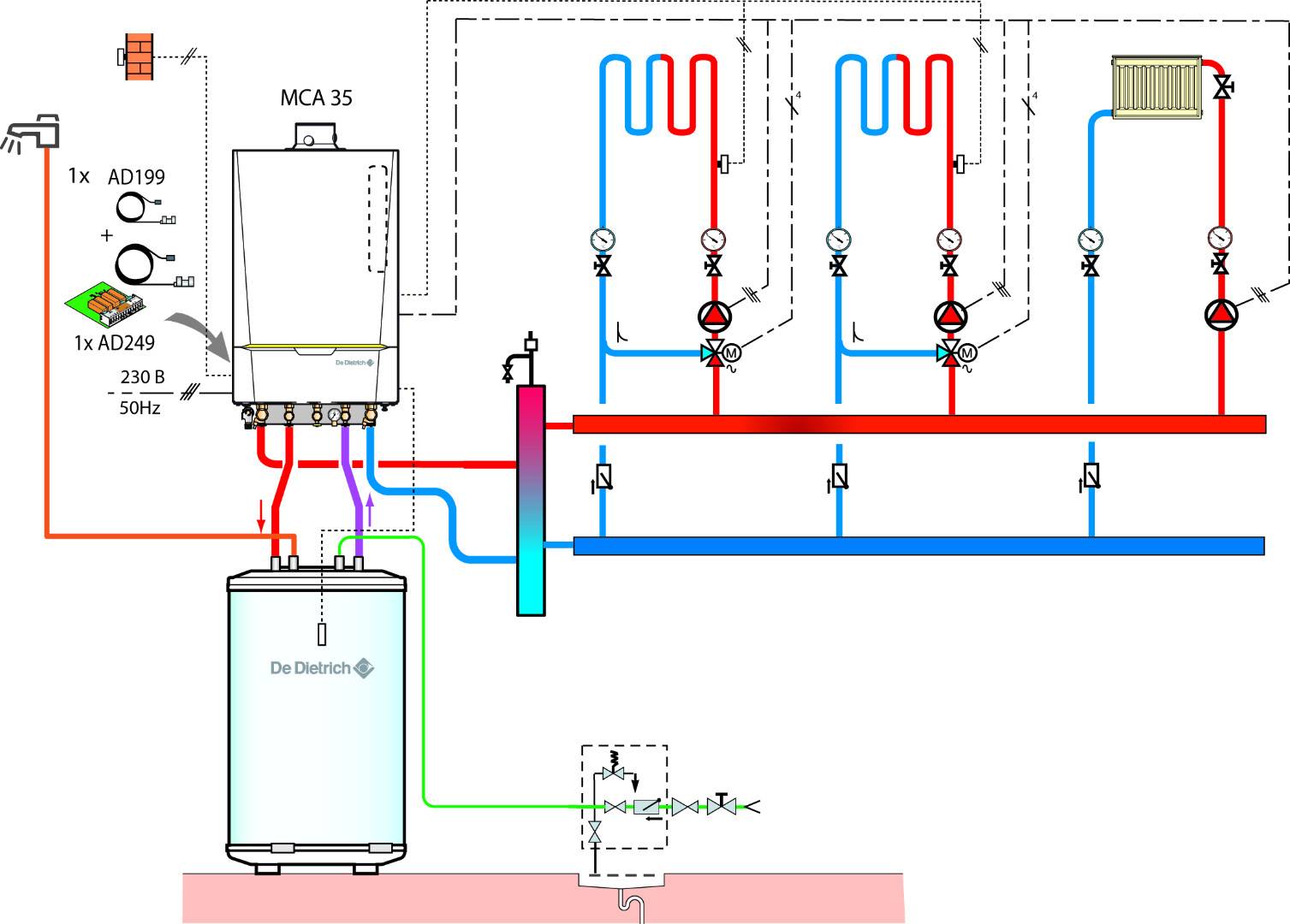

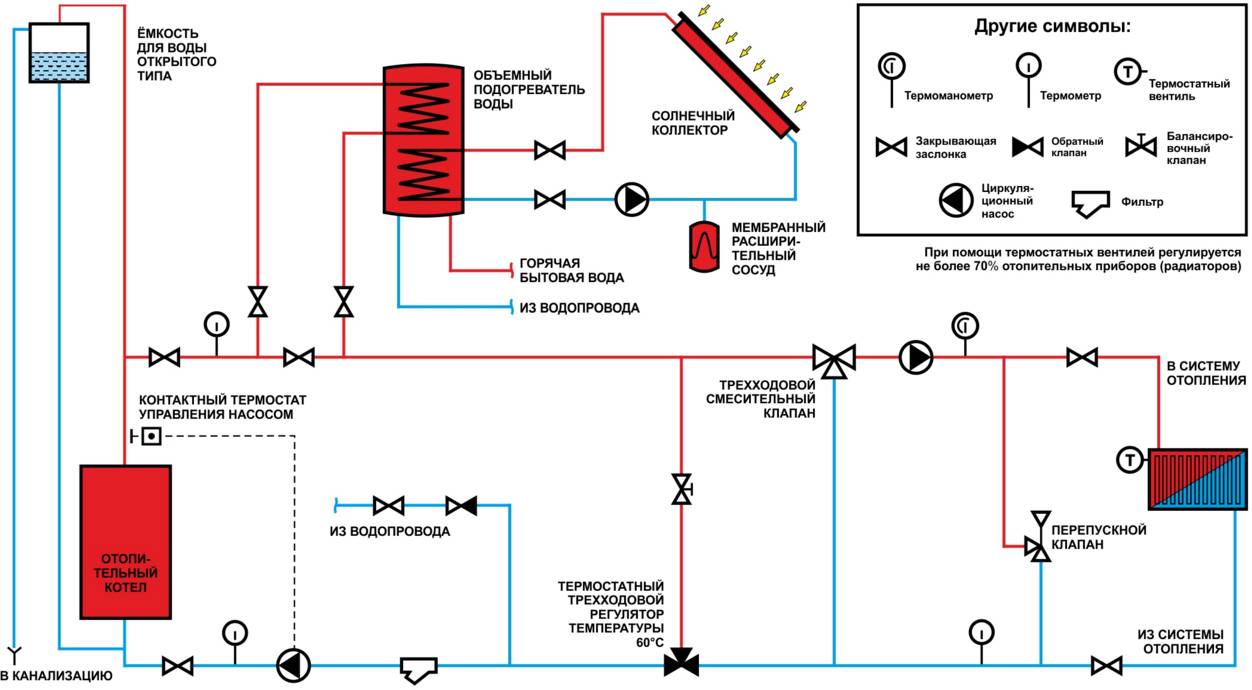

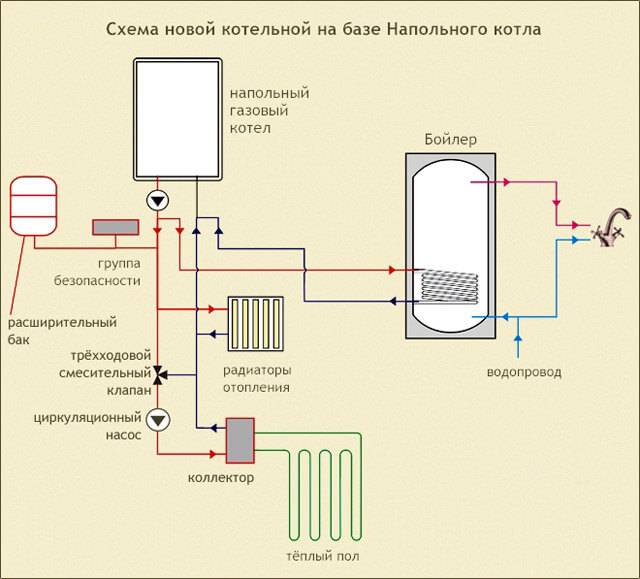

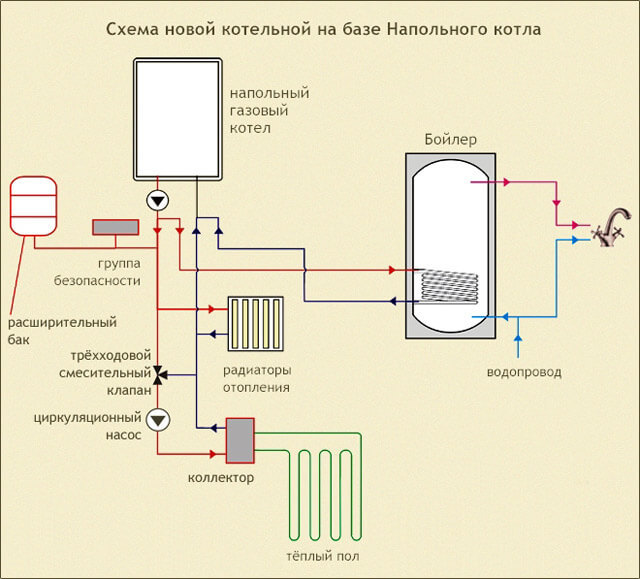

Forced circulation system

Such a heating system is used in houses with large and multi-level heat supply loads. It allows you to control each circuit separately, for example, in the DHW system, high-temperature heating in radiators and low-temperature heating in the "warm floor" system.

This option is the most expensive, but at the same time, its payback period does not exceed 4 years, since the system operates with increased efficiency in the power range from 20 to 100%, which can provide annual fuel savings of up to 30%.

The disadvantages of such boilers include:

- The need to have a reliable source of electricity.

- The need to balance the heating circuits.

- A complex executive circuit of heat supply requires additional expensive elements, in the form of a hydraulic switch, circulation pumps for each circuit and shut-off and control valves.

- Complicated installation and adjustment, requires the participation of a qualified installation organization.

- High price.

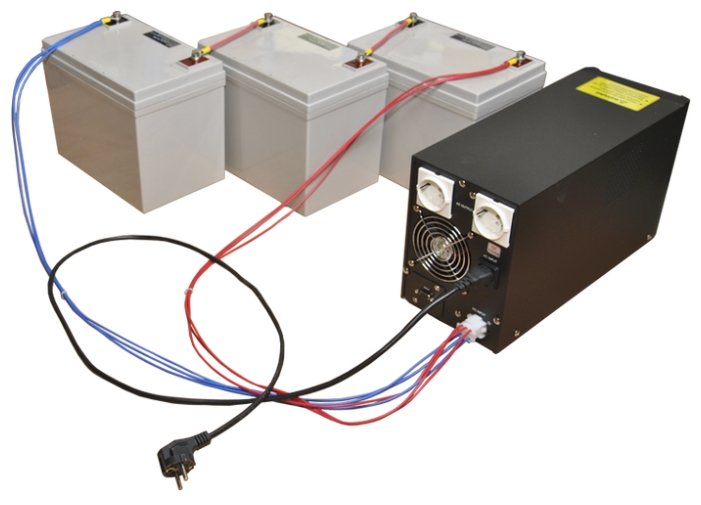

emergency circuit

Protective equipment is installed in the volatile circuits of a double-circuit boiler, which should protect the boiler structure in the event of a sudden power outage. In practice, several effective protective schemes are used:

- Uninterruptible battery-powered power source used to operate the circulation pump, fan and security systems.

- Installation of a gravity circuit that provides additional heat removal of thermal energy when the circulation pump stops.

- Hybrid scheme with the installation of an uninterruptible current source and a protective gravitational circuit.

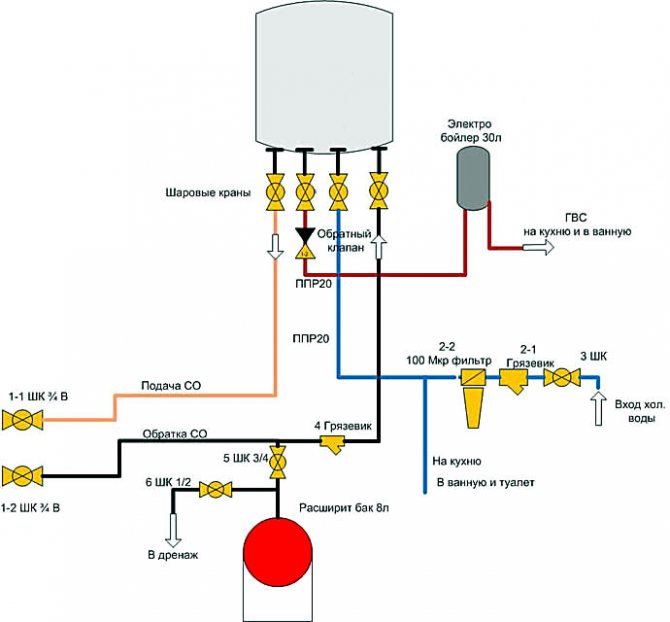

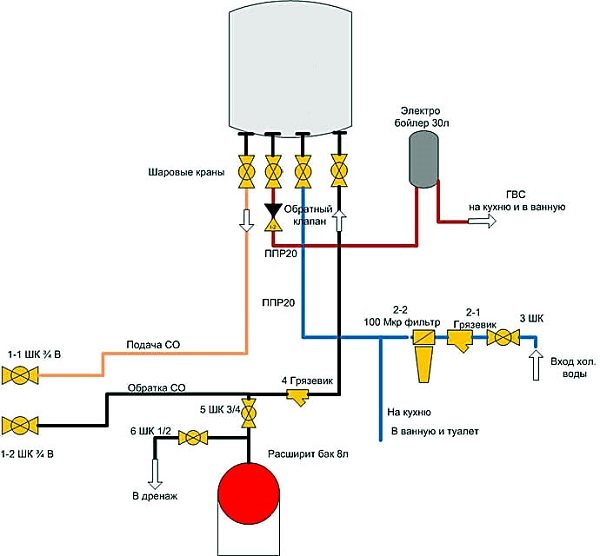

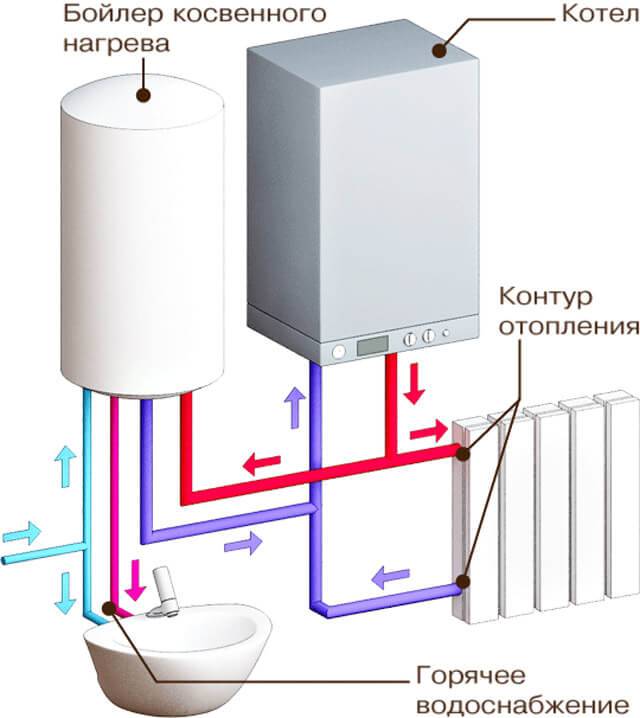

Scheme with a wall-mounted boiler

The wall-mounted design of a gas boiler is the most suitable for small residential facilities.For large objects, in order to increase the modulation range of the object's heat supply modes, it is possible to install several such units, each of which can carry the load on the heating and hot water circuits.

Such a scheme is especially preferable when the floor-by-floor heating scheme is made of heating devices operating in different temperature conditions: “warm floors” and bimetallic radiators.

In a house in which there is a large load on the hot water supply, an external indirect heating boiler is integrated into the thermal circuit with a wall-mounted single-circuit gas boiler.

Such schemes allow you to remove the high temperature of the coolant and the pressure of the medium in the circuit, established by the rules for the operation of polypropylene pipes.

Features of binding boilers with polypropylene

An important advantage of polypropylene pipes is the ability to create a circuit of almost any complexity from them, although complex systems are rarely required in domestic conditions. You can even say the easier the strapping will be done polypropylene heating boiler, the better - it will be easier to assemble it with high quality. When creating complex systems, there is a high probability of incorrect or insufficiently efficient operation of elements, so this work is best left to professionals.

Polypropylene strapping

To assemble the heating system at home, you can make connections by welding and using fittings. The first method requires a specialized soldering iron with a set of nozzles for various pipe diameters. The price of such a device is low. Assembly using fittings can be done with normal tools, but connections may leak over time.

Regardless of the assembly method, it is recommended to consider how the heating boiler will be tied up with your own hands. The system should have the least number of connections, otherwise the period of its use is reduced and the efficiency of the heating device is reduced. Smooth transitions are also preferable to sharp ones.

Connecting a gas boiler has some features. According to building codes, the gas supply to the device must be carried out using metal pipes. And the connection of the pipe with the generator must be done with a metal drive or "American". It is allowed to use gaskets only from paronite, the use of rubber materials, tow or fum tape is unacceptable. This material is made from a non-combustible mixture of mineral and asbestos fibers and rubber, it holds its shape well and provides tight joints.

A hard connection is required, based on safety requirements when using gas appliances. Pipes and gasket materials must be resistant to fire. The use of rubber as a gasket material is also bad in that it can reduce the cross section of the gas passage.

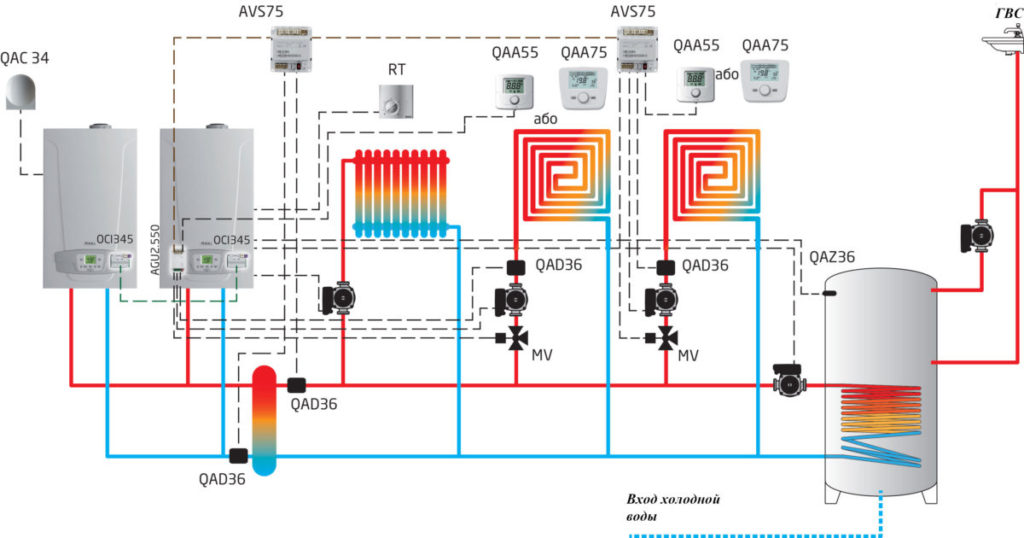

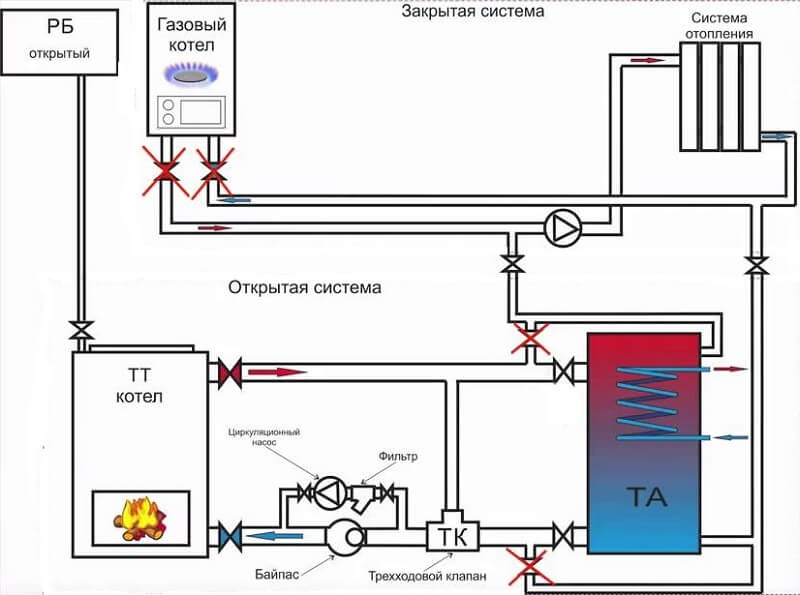

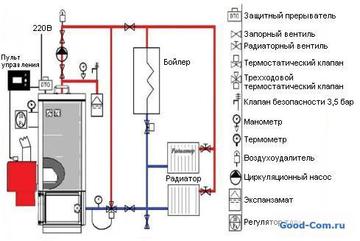

Wiring diagrams

To tie two different types of boilers in one thermal scheme is a very important stage. Any even a minor mistake, except for the inefficiency of the heating equipment, can create an emergency in the house.

The calculation of the two-boiler connection scheme must be entrusted to the design organization so that they can select the most optimal pair of units with parallel or serial piping and control options: automatic or manual.

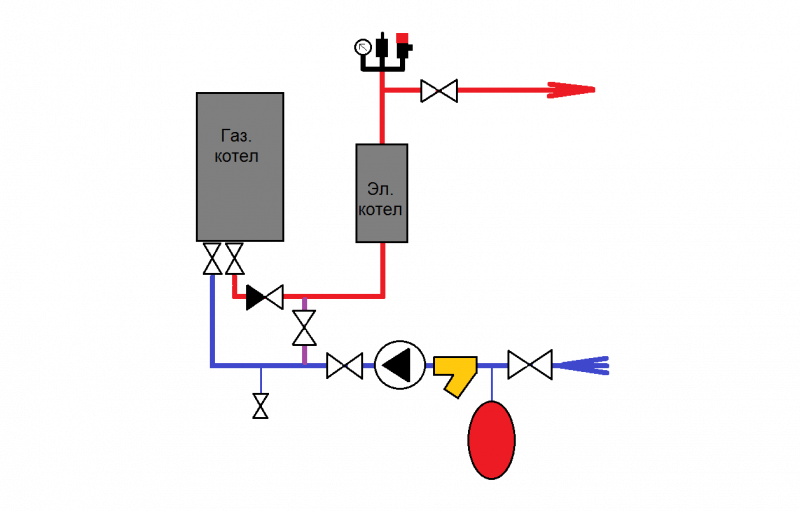

Boilers with automatic control

From the point of view of hydraulics, this scheme does not differ much from the manual control principle, only 2 check valves are installed in it.

This is required in order to exclude "stray" or idle coolant flows through the boiler, which is in reserve. This problem is also solved by installing a hydraulic gun. Check valves are installed on the return line, directed at each other.

This system will also require a thermostat that turns off the pump for forced circulation. When the coal burns out in the boiler, there will be no point in circulating idle water through the stopped apparatus, thereby creating resistance for the operation of the second device.

Connection diagram for 2 boilers with manual control

In this option, for the consistency of the operation of boiler units, only shut-off and control valves are needed. All operational switching between units is carried out by the operator's hands by opening/closing 2 valves on the return heat carrier line. To completely stop the movement of hot water, you will need to turn off the 4th valve, respectively, for the supply and return steam.

In such schemes, I provide for expansion tanks to compensate for the thermal expansion of water when the boiler is heated from a cold state. In order to save money, it is not recommended to leave one tank, since it may not be able to cope with the load during the operation of two boilers.

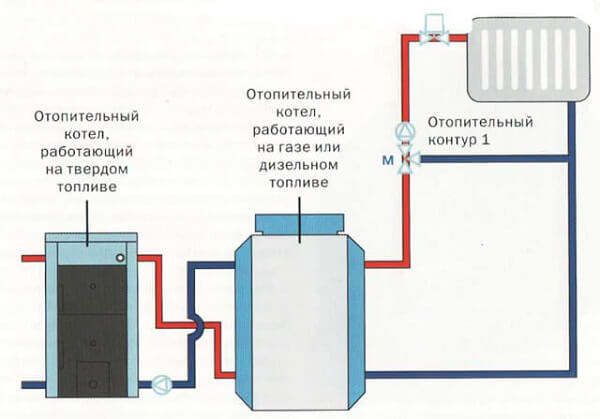

Series and parallel connection

These are two generally accepted piping schemes for two boilers operating in pairs.

Sequential, involves the sequential inclusion of units without additional lines and nodes. At the same time, the first unit in the direction of water movement heats it, and the second one heats it up to the desired temperature.

Series circuit

Series circuit

The first option is used for small heating sources. In practice, it is quite rare and is considered impractical, since it is impossible to remove one unit for repair operations without violating the performance of another.

Such a scheme will be inoperable if even one unit fails. Today, this scheme has been partially modernized by installing bypass lines and additional shut-off and control valves.

Parallel connection of different types of boiler units in a single piping is considered advantageous and allows the installation of a hydraulic switch and an automatic control unit.

Parallel connection

Parallel connection

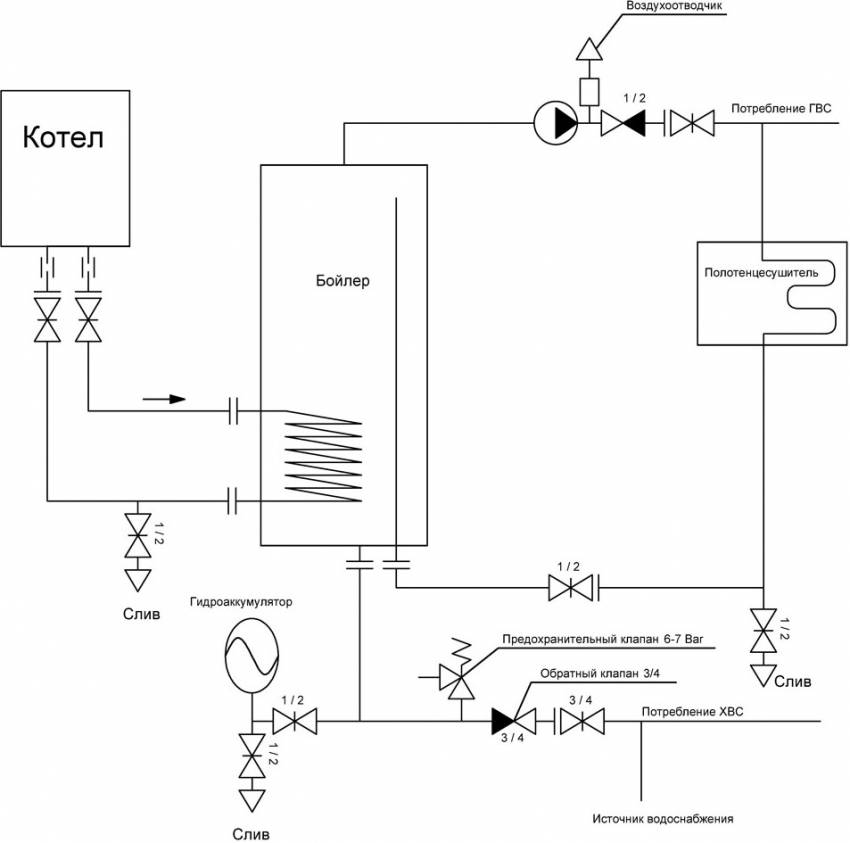

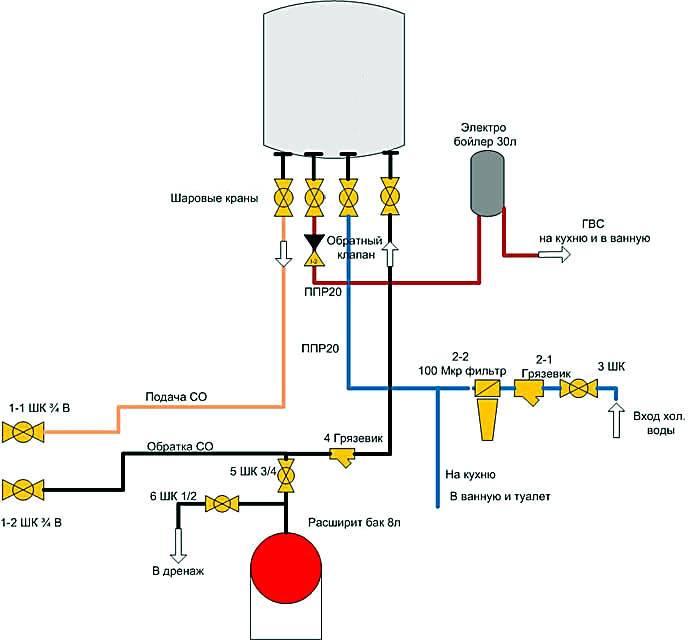

Schemes for connecting a water heater to a gas boiler.

Now let's move on to considering the connection diagram of the water heater to the DHW circuit of the boiler. So let's look at the picture below:

It can be seen from the figure that the storage water heater is connected separately to the boiler and to consumers. Separation is done by two 3-way valves with servomotors. Switching the servos and turning on the circulation pump is carried out by a certain device called the “power management circuit”. This device is connected to the water heater thermostat. There are no standard solutions here and this device will have to be invented from scratch.

For comparison, I will give you another diagram from the technical document:

There are no three-way valves in this circuit and no power management circuitry. The circulation pump is powered directly via the water heater thermostat. This is done according to the following scheme:

The upper diagram has one important feature - the water heater there has three connection pipes.This is a non-standard option for electric water heaters, but indirect heating boilers have a recirculation inlet and outlet, through which it is quite possible to organize a similar connection scheme. Well, for ordinary electric water heaters, you will again have to invent something. Sometimes, such a "collective farm" takes a lot of time, effort and money.

Now let's look at how the water circulates in the upper diagram. To do this, I will give two more pictures:

The arrows in the upper figures indicate the direction of water circulation in each operating mode. In this scheme, heating and water intake can occur simultaneously.

Heating boiler piping schemes for various types of circulation and circuits

When building autonomous heating at home, it is important to properly think over and complete the piping of gas, solid fuel and electric boilers. Let's look at possible circuits and strapping elements, talk about classic, emergency and specific circuits, as well as the main equipment of these circuits

The basic principles for piping a boiler of any design are safety and efficiency, as well as the maximum resource of all elements of the heating system. Consider various options for organizing heating in order to make a balanced and most suitable decision for a particular case during individual construction.

Varieties of heating schemes for a private house

In the simplest version of the boiler circuit, there is no piping at all.In the vast majority of cases, the factory equipment of boilers with electronic ignition consists of the following elements: a pump, an expansion tank, an automatic air vent and a valve (with a pressure setting of 2.5 kgf / cm2). The location of all piping nodes is the building: as a result, the complex is transformed into a mini-boiler room.

As additional elements, the system can be equipped with:

- filter. The place of its installation is the inlet pipe. As a result, the heat exchanger receives protection from contamination, while increasing the hydraulic resistance of the circuit. This leads to a decrease in the speed of movement of the coolant, and the pump itself experiences an additional load.

- Ball valves. They are mounted on the input and output sections. This makes it possible to dismantle the heat exchanger or boiler, while maintaining the heating circuit.

Heated floor trim

Often, clients, in view of not being particularly aware of the operation of a double-circuit gas boiler, offer to tie the second circuit to a water-heated floor, and leave the first one to a radiator heating system. Of course, if the boiler worked on both circuits at the same time, such an option could be implemented. But bad luck, double-circuit boilers operate in hot water priority mode.

In simple terms, the boiler works either for heating or for hot water, and the second circuit is always a priority. Therefore, combining the second circuit with a warm floor is a meaningless exercise.

Read also:

Ability to implement joint connection

Designing conventional gas-consuming heating is not so easy. That is, it is easy to create a working scheme, but getting it approved is problematic.The situation with electric boilers is less deplorable in terms of costs, time and problems with obtaining papers approving the procedure.

And here is the combination of 2 multi-fuel units. It would seem that you will not end up with problems and you will go through the authorities literally for years, for permits. But it's not.

There are no restrictions on the joint use of a gas and electric boiler in the regulatory documents. However, it is still necessary to coordinate such a project in the gas service and obtain permission if you exceed the established limit in the total capacity of the equipment for the use of electricity

There are no restrictions on the joint use of a gas and electric boiler in the regulatory documents. However, it is still necessary to coordinate such a project in the gas service and obtain permission if you exceed the established limit in the total capacity of the equipment for the use of electricity

In fact, building codes are quite supportive of such schemes. To be more precise, there are no restrictions.

Energy and fuel consumption meters are different. The consumption of resources is not exceeded, an explosive situation is not provoked - install the boilers, observing the standard norms, installation instructions for each. There shouldn't be any problems.

We remind you that the installation of gas boilers should be carried out in accordance with SP 402.1325800.2018 (moreover, this document is mandatory, not advisory).

Strapping schemes

Do-it-yourself piping of a gas heating boiler is most often performed according to the classical method. That is, at first the water begins to move upwards through the supply pipeline. Further, the coolant enters the risers, where special devices are installed that do not completely open the riser.

The heat level is regulated by radiators, which incorporate a choke and jumpers. Be sure to install a shut-off valve on the second supply line, and place an air vent in the upper part of the expansion tank circuit.The coolant is already returning back along the lower level of the supply.

To perform the piping of a double-circuit boiler yourself, you need to prepare some devices that will be needed during the work:

- thermal head or valve for distribution;

- pump for internal circulation;

- taps: drain and ball;

- expansion tank;

- balancing crane;

- inline filter;

- fasteners;

- valves: check and air.

- tee and corners.

Usually this method is used in simple heating systems of small apartments and houses.

The peculiarity of such heating units is that the control is automatic. For individual rooms, you can choose an individual temperature regime, the sensors of the system fully control this process.

However, such a strapping scheme also has its negative sides, namely:

- high cost of components;

- a complex strapping scheme that is beyond the power of an ordinary person - a non-professional;

- high service costs;

- constant balancing of parts.

If your house has a very complex heating system, for example, there is a “warm floor” and radiators, then there is some kind of inconsistency in the movement of the coolant. Therefore, hydraulic decoupling is necessarily included in the piping scheme. It forms several circuits of water movement - general and boiler.

To waterproof the circuits with each other, an additional heat exchanger is used. This is necessary if you combine closed and open systems. Such separate type installations must have their own circulation pump, feed and drain valves, and a security system.

Connections for solid fuel boilers.

Boilers of this type do not have the option of regulating the heat supply.Fuel combustion occurs continuously, therefore, in the event of a power outage, the pump will turn off, which is responsible for the forced movement of the coolant. But, heating will continue, and the pressure will increase, as a result, this process will disable the entire system.

To prevent such situations, several types of emergency schemes are provided that allow you to dump excess heat:

- Emergency supply of cold water;

- Connecting the pump to batteries or a generator;

- The presence of a gravitational circuit;

- Additional emergency circuit.

Conclusions and useful video on the topic

Synchronization of operation and shutdown of boilers in a parallel installation:

The installation of 2 heating boilers, gas and electric, is a wise decision to increase the capacity of the heating equipment, as well as for backup heating of the building. Parallel installation of units is not as difficult as it might seem at first.

The main thing is to correctly select the arrangement scheme and correctly calculate the total or reserve capacity of the equipment. If you are not confident in your abilities and cannot cope on your own, it is best to contact the plumbers. They will help you quickly and efficiently install a system for reliable and comfortable heat supply to your home.