- How to install a wall-mounted boiler

- Strapping options

- recycling

- Features of different strapping schemes

- Method 1: strapping in gravity systems

- Method 2: piping the boiler with a circulation pump

- Heated floor trim

- Electric and diesel heat generators

- Common mistakes when tying a gas boiler

- What is strapping and what is it made of

- What should be in the harness

- What pipes to make

- What is the connection of a solid fuel and gas boiler in one system

- Features of connecting two boilers

- Single-circuit boilers with hot water supply

- Manual make-up scheme

- What is a single-circuit boiler

- Expansion tank for closed heating system

- Volume calculation

- Place for installation of expansion tank of membrane type

- Conclusions and useful video on the topic

How to install a wall-mounted boiler

Before installation, unpack the heat generator and check that the appliance is complete. Make sure the stock fasteners fit your walls. For example, special fasteners are required for aerated concrete, ordinary dowels are not suitable.

We follow the following work order:

- Mark the contour of the heating unit on the wall. Make sure that technological indents from building structures or other surfaces are observed: 0.5 m from the ceiling, from below - 0.3 m, on the sides - 0.2 m.Typically, the manufacturer provides a diagram with dimensions in the instruction manual.

- For a turbo boiler with a closed chamber, we prepare a hole for a coaxial chimney. We drill it at a slope of 2–3 ° towards the street so that the resulting condensate flows out. The process of installing such a pipe is described in detail by us separately.

- The heat generator comes with a paper installation template with pre-drilled holes. Attach the sketch to the wall, align with the building level, fix the diagram with tape.

- Drilling points should be punched right away. Remove the template and make holes 50–80 mm deep. Make sure that the drill does not go to the side, this happens on brick partitions.

- Install plastic plugs in the holes, screw the hanging hooks to the maximum depth using pliers. With the help of a second person, carefully hang the machine.

When marking holes in a wooden log wall, make sure that the fastener is on the crest of the log. Hooks screw directly into the tree, without plastic plugs.

Strapping options

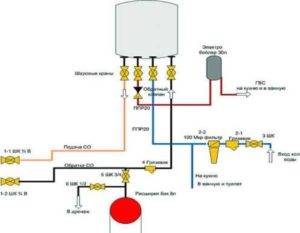

The device of a wall-mounted boiler with a closed combustion chamber

The choice of a piping scheme that is optimally suited for a system of a given configuration directly depends on the specific design of the purchased sample of boiler equipment. According to the method of placement within the premises chosen for it and the design of the eyeliner, these units are divided into the following classes:

- typical floor boilers;

- lightweight (compact) wall-mounted devices.

The main requirement for the installation of floor-mounted units is to prohibit the insertion of their working nozzles into the upper section of the pipeline distribution.

If this rule is violated when piping a floor boiler in systems not equipped with air valves, very dangerous formations (plugs) will appear. To reduce the likelihood of their occurrence in the absence of valves, the pipe into which the boiler crashes must be located strictly vertically and have a special expansion tank in the upper part.

The piping scheme should be oriented towards the uniformity of heat supply to all appliances

The piping scheme should be oriented towards the uniformity of heat supply to all appliances

In the lower zone of units of all categories, automatic devices are provided to ensure their reliable connection to the heating main. Unlike a floor-mounted boiler, its wall-mounted counterparts already have an expansion mechanism that eliminates the formation of traffic jams. When considering boiler room piping schemes for such systems, it must be borne in mind that the advantage of wall models - light weight and not too large dimensions - is also their disadvantage. This is due to the fact that compact units from DWG, for example, are limited in their energy capabilities. This means that the power declared by this manufacturer is enough for heating buildings with an area of \u200b\u200bno more than 100 square meters. Therefore, these devices are especially popular with owners of city apartments.

A distinctive feature is the presence of two versions, differing in their configuration. The complete set of equipment includes most of the strapping elements, and the incomplete set lacks some nodes that are purchased by the user on their own.

recycling

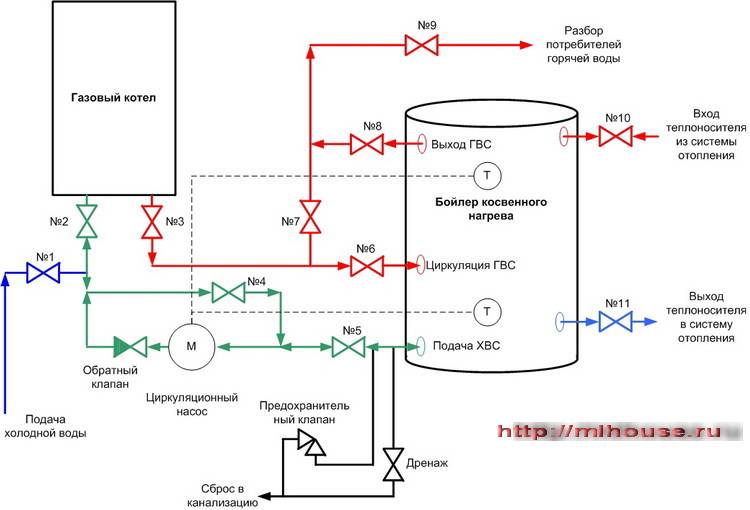

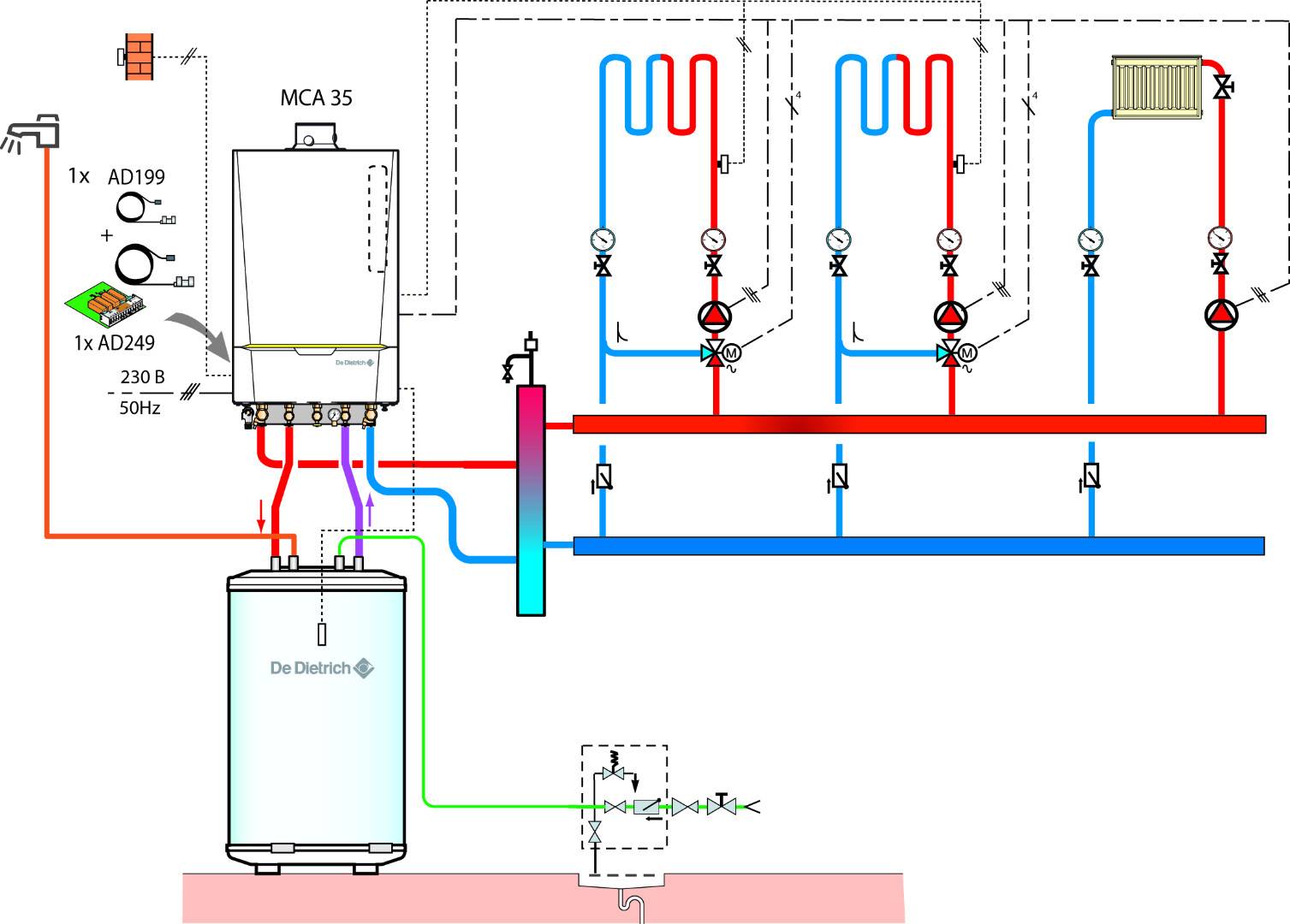

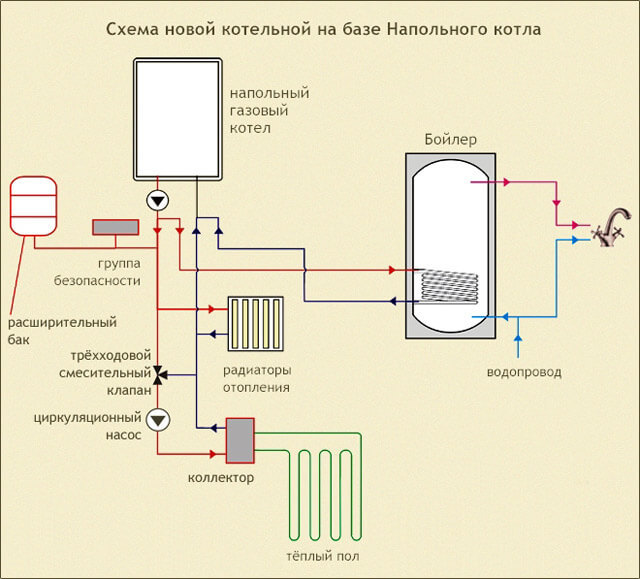

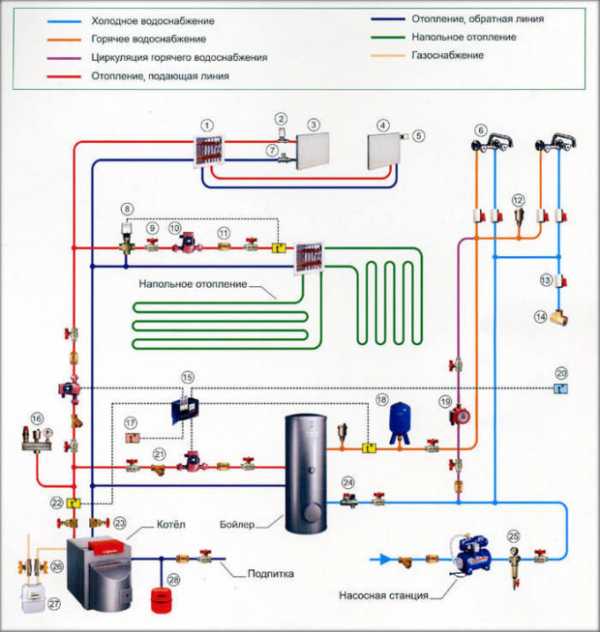

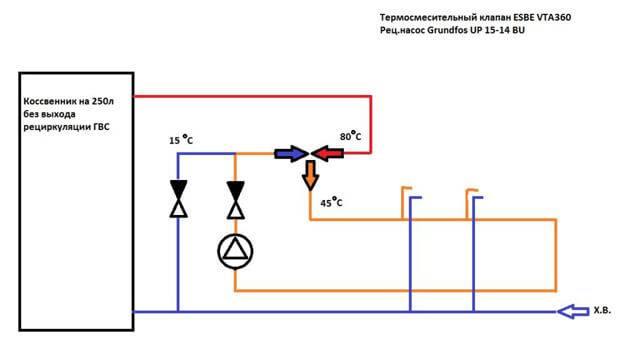

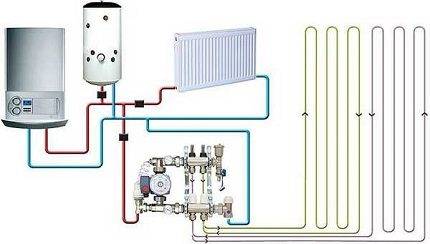

In a parallel position to the main radiator heating circuit or a small circuit in the area from the boiler to the hydraulic arrow, a low-temperature circuit is being arranged. It includes a bypass and a three-way thermostatic valve. Thanks to the pump, water constantly circulates inside the pipes of the warm floor.

A three-way mixer is used to take new portions of the hot coolant from the supply pipe when the temperature inside the return pipe drops. It can be replaced by a simple thermostatic valve equipped with a capillary-type remote temperature sensor or an electric thermocouple. The place of installation of the sensor is a niche on the return of the underfloor heating. The valve is activated when the coolant temperature drops.

Features of different strapping schemes

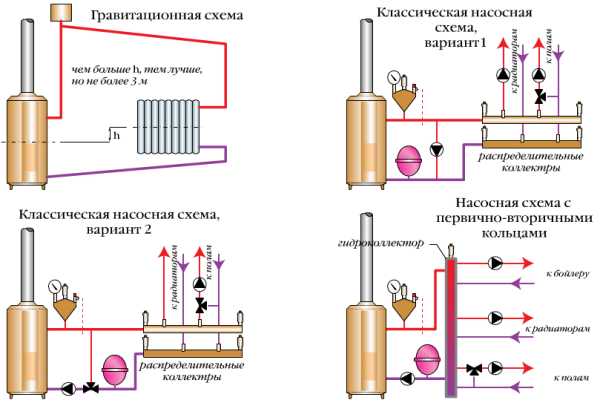

The coolant moves through the pipeline due to the slope of the system or is forcibly pumped by a circulation pump. Depending on this, a boiler piping scheme is selected.

Method 1: strapping in gravity systems

The piping of the boiler in a gravity heating system is simple and can be installed by anyone who knows how to handle tools. The coolant moves in accordance with physical laws.

This does not require any devices. The operation of the system does not depend on electricity, so a sudden shutdown will not affect the quality of heating.

The piping of the boiler will cost the minimum money, because. you do not have to buy additional devices, pay a team of craftsmen for installation. The operation of such a system is also cheap, and breakdowns can be fixed independently.

The boiler piping in the gravity heating system can be installed by hand, but it is not always possible to do it flawlessly.If errors are made when calculating the diameter and the heating does not work well, the situation can be corrected by installing a pump

The only negative: such a scheme can only be used for a small house. In addition, you will have to carefully calculate the diameter of the pipes and repeatedly double-check the data, otherwise normal heating of the house cannot be guaranteed. A large diameter pipeline spoils the interior, and it is problematic to disguise it.

Method 2: piping the boiler with a circulation pump

Systems with pumping equipment are easier to manage than gravity systems. When installing forced heating, the boiler piping is more complicated and expensive, but the result is a comfortable temperature in all rooms.

This heating is volatile, so it is advisable to play it safe and mount it so that in the event of a power outage, you can switch the system to the gravitational circulation of the coolant.

It is impossible to organize forced circulation if the house is not connected to the power grid, but this does not happen often. For a large building, this is the best heating scheme, although the boiler piping requires considerable effort.

The boiler piping scheme is complicated by additional devices that will require regular maintenance during operation. Without experience, it is difficult to cope on your own, so you will have to hire craftsmen and pay for their work.

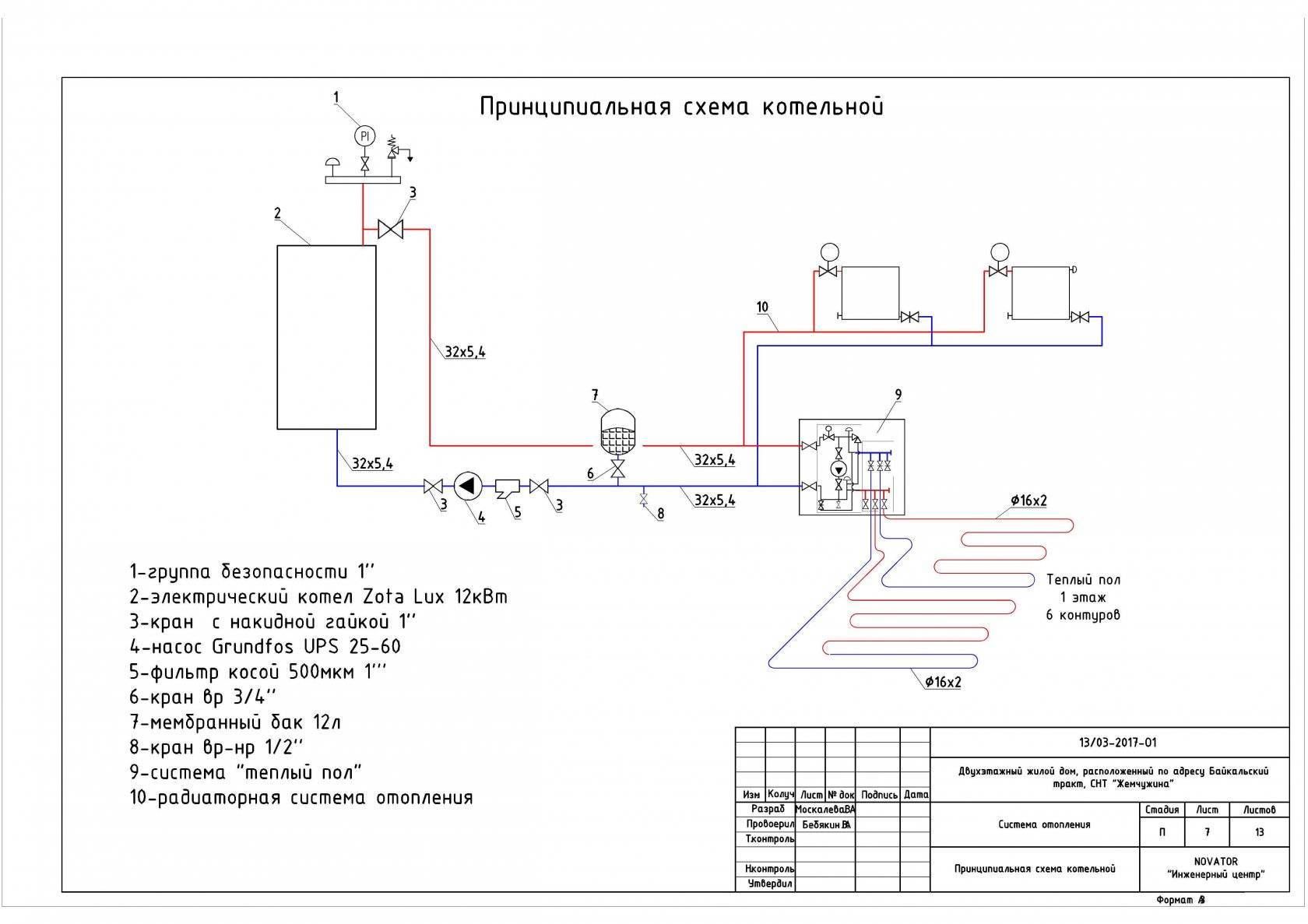

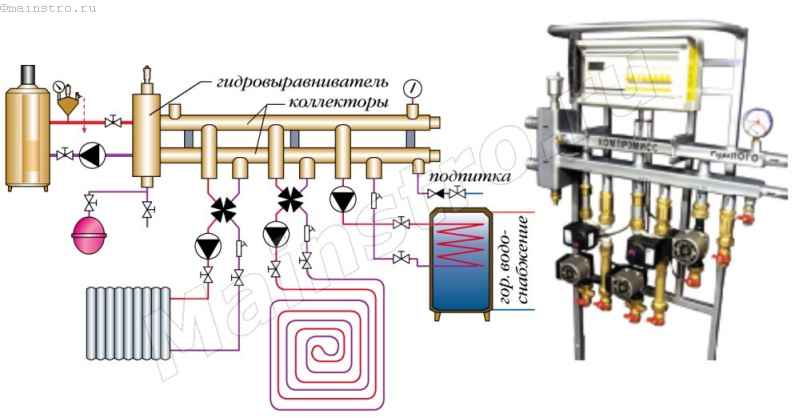

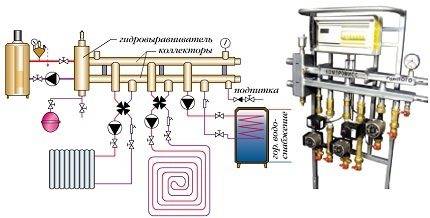

Hydro equalizers are connected to the heating of houses in which many people live. Devices are needed where several circuits are provided and powerful boilers are installed (more than 50 kW)

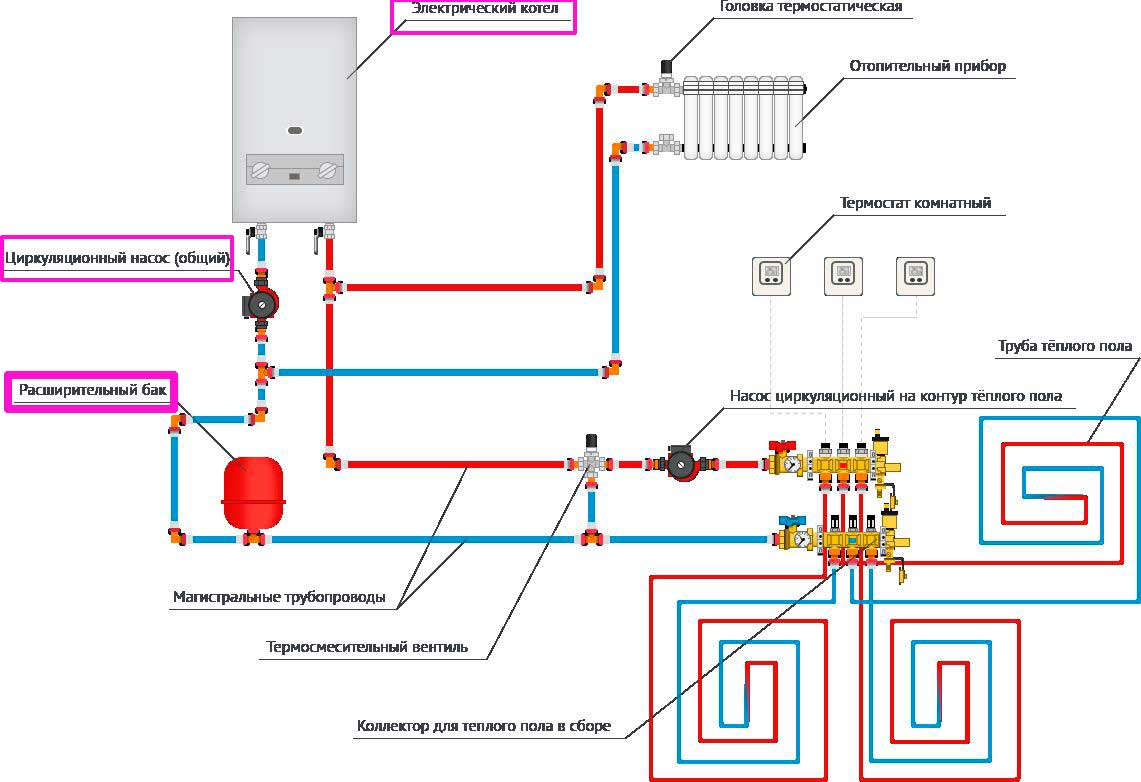

To minimize the number of additional devices, it is possible to implement a scheme with primary-secondary rings with circulation pumps in each of them.If the boiler power is less than 50 kW, then collectors should be included in the circuit, otherwise the batteries will heat up unevenly.

Combined systems are economical and efficient. The warm floor works due to the heated water coming from the radiator circuit. This allows you to use energy resources expediently and live with maximum comfort.

The best boiler piping for heating a small house is the simplest. No need to install extra devices, because the simpler the design, the more reliable. However, for a spacious building with several heating circuits, it is worth choosing a scheme with forced movement of the coolant and a comb collector.

Heated floor trim

Often, clients, in view of not being particularly aware of the operation of a double-circuit gas boiler, offer to tie the second circuit to a water-heated floor, and leave the first one to a radiator heating system. Of course, if the boiler worked on both circuits at the same time, such an option could be implemented. But bad luck, double-circuit boilers operate in hot water priority mode.

In simple terms, the boiler works either for heating or for hot water, and the second circuit is always a priority. Therefore, combining the second circuit with a warm floor is a meaningless exercise.

Read also:

Electric and diesel heat generators

Connecting a diesel fuel boiler to a radiator system is identical to piping gas-using installations. Reason: the diesel unit operates on a similar principle - an electronically controlled burner heats the heat exchanger with a flame, maintaining the set temperature of the coolant.

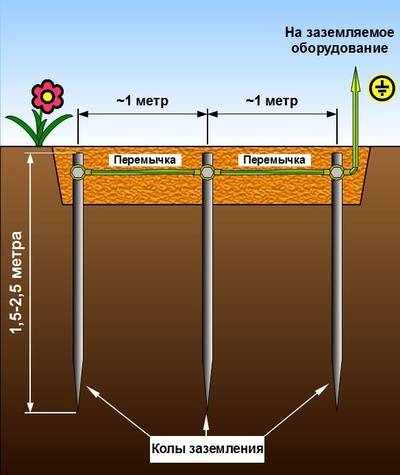

Electric boilers, in which water is heated by heating elements, an induction core, or due to the electrolysis of salts, are also connected directly to heating. For maintaining the temperature and safety, the automation is located in the electrical cabinet, connected to the network according to the above wiring diagram. Other connection options are shown in a separate publication on the installation of electric heating boilers.

Wall-mounted mini-boilers equipped with tubular heaters are intended only for closed heating systems. To work with gravity wiring, you will need an electrode or induction unit, which is tied according to the standard scheme:

If you figure it out, then the bypass is not needed here - the boiler will not work without electricity either.

Common mistakes when tying a gas boiler

A large boiler heats water faster, which means it consumes more fuel. This is also worth keeping in mind when buying and connecting gas equipment.

Pay special attention to controlling the pressure level in the expansion tank. An incorrectly selected tank size can also adversely affect the operation of the entire system as a whole. The piping scheme for a double-circuit boiler is not an easy task

The best solution would be to contact a specialized gas service, whose employees will quickly connect the unit to the gas supply system

The piping scheme for a double-circuit boiler is not an easy task. The best solution would be to contact a specialized gas service, whose employees will quickly connect the unit to the gas supply system.

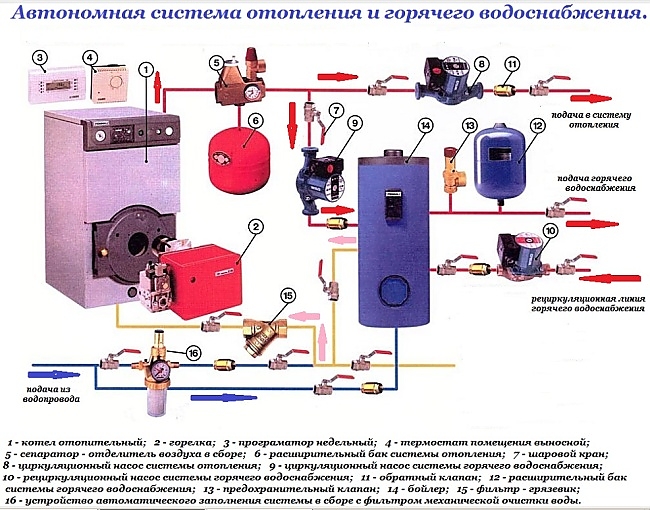

More and more owners of not only private houses, but also city apartments, not wanting to depend on communal structures, are installing autonomous heating systems in their homes, the “heart” of which is a boiler - a heat generator. But on its own, it cannot work. The heating boiler piping scheme is a set of all auxiliary devices and pipes that are connected according to a certain scheme and represent a single circuit.

Why is it necessary

- Ensuring the circulation of fluid through the system and the transfer of thermal energy to the premises in which heating devices - radiators are installed.

- Protection of the boiler from overheating, as well as protection of the home from the penetration of natural or carbon monoxide gases into it in case of emergency situations. For example, the loss of a burner flame, water leakage, and the like.

- Maintaining the pressure in the system at the required level (expansion tank).

- A properly installed gas boiler connection diagram (piping) allows it to operate stably in the optimal mode, which significantly reduces fuel consumption and saves on heating.

Main elements of the circuit

- Heat generator - boiler.

- Membrane (expansion) tank - expandomat.

- Pressure regulator.

- Pipeline.

- Stop valves (faucets, valves).

- Coarse filter - "mud".

- Connecting (fittings) and fasteners.

Depending on the type of the selected heating circuit (and boiler), there may be other components in it.

The piping scheme for a double-circuit heating boiler, like a single-circuit one, depends on many factors. These are the capabilities of the unit itself (including its equipment), and operating conditions, and features of the system design.But there are also differences, which are determined by the principle of movement of the coolant. Since private dwellings use boilers that provide both heat and hot water, consider an example of a classic piping of a double-circuit device with forced circulation of the coolant.

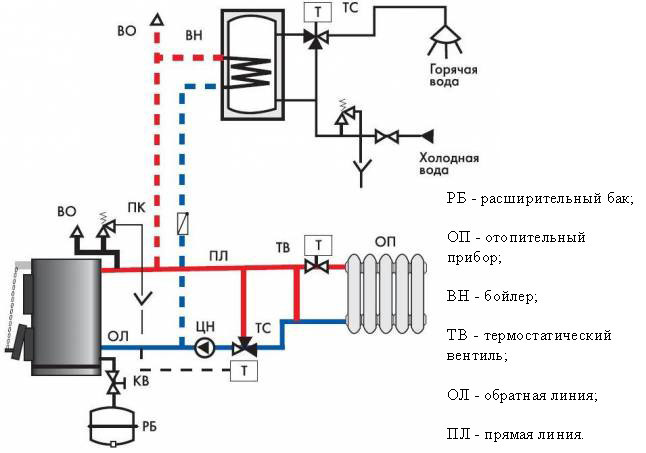

Heating circuit

The water, heated in the heat exchanger to the desired temperature, “leaves” from the boiler outlet through pipes to radiators, to which it transfers thermal energy. The cooled liquid is returned back to the inlet of the heat generator. Its movement is controlled by a circulation pump, which is equipped with almost every unit.

An expansion tank is installed between the last radiator in the chain and the boiler to compensate for possible pressure drops. There is also a “mud collector” here, which protects the heat exchanger from small fractions that can get into the coolant from batteries and pipes (rust particles and salt deposits).

A pipe insert for supplying cold water (feed) is made in the area between the boiler and the first radiator. If it is equipped on the "return", then this can cause deformation of the heat exchanger due to the temperature difference between it and the "feed" liquid.

DHW circuit

Works just like a gas stove. Cold water from the water supply system is supplied to the DHW inlet of the boiler, and from the outlet, the heated water goes through pipes to the points of water intake.

The piping scheme for wall-mounted boilers is similar.

There are a number of other types as well.

Gravity

It does not have a water pump, and the circulation of the liquid occurs due to the temperature difference at the inlet and outlet of the circuit. Such systems do not depend on the power supply. Open-type membrane tank (placed at the very top of the route).

With primary-secondary rings

In principle, this is an analogue of the already mentioned comb (collector). Such a scheme is used if it is necessary to heat a large number of rooms and connect the "warm floor" system.

There are others that do not apply to private houses. In addition, there may be some additions to the listed ones. For example, a mixer with a servo.

| Articles |

What is strapping and what is it made of

There are two main parts in the heating system - the boiler and radiators or underfloor heating. What binds them and provides security - this is the harness. Depending on the type of installed boiler, different elements are used, therefore, the piping of solid fuel units without automation and automated (more often gas) boilers is usually considered separately. They have different operation algorithms, the main ones are the possibility of heating the TT boiler in the active combustion phase to high temperatures and the presence / absence of automation. This imposes a number of restrictions and additional requirements that must be met when piping a solid fuel boiler.

An example of a boiler piping - first comes copper, then polymer pipes

What should be in the harness

To ensure the safe operation of heating, the boiler piping must contain a number of devices. Must be:

- Pressure gauge. To control the pressure in the system.

- Automatic air vent. To bleed air that has entered the system - so that plugs do not form and the movement of the coolant does not stop.

- Emergency valve. To relieve excessive pressure (connects to the sewerage system, as a certain amount of coolant is vented).

- Expansion tank. Needed to compensate for thermal expansion.In open systems, the tank is placed at the top of the system and is a regular container. In closed heating systems (mandatory with a circulation pump), a membrane tank is installed. The installation location is in the return pipeline, in front of the boiler inlet. It can be inside a wall-mounted gas boiler or installed separately. When using the boiler to prepare domestic hot water, an expansion tank is also required in this circuit.

-

Circulation pump. Mandatory for installation in systems with forced circulation. To increase the efficiency of heating, it can also stand in systems with natural circulation (gravitational). It is placed on the supply or return line in front of the boiler to the first branch.

Some of these devices are already installed under the casing of the gas wall-mounted boiler. The binding of such a unit is very simple. In order not to complicate the system with a large number of taps, the pressure gauge, air vent and emergency valve are assembled into one group. There is a special case with three taps. Appropriate devices are screwed onto it.

This is what a security group looks like

A safety group is installed on the supply pipeline immediately at the boiler outlet. Set so that it is easy to control the pressure and you can manually release the pressure if necessary.

What pipes to make

Today, metal pipes are rarely used in the heating system. They are increasingly being replaced by polypropylene or metal-plastic. Tying a gas boiler or any other automated (pellet, liquid fuel, electric) is possible immediately with these types of pipes.

The wall-mounted gas boiler can be connected with polypropylene pipes immediately from the boiler inlet

When connecting a solid fuel boiler, at least a meter of the pipe at the supply is impassable to make a metal pipe and, best of all, copper. Then you can put the transition to metal-plastic or polypropylene. But this is not a guarantee that polypropylene will not collapse. It is best to make additional protection against overheating (boiling) of the TT boiler.

If there is protection against overheating, the boiler piping can be made with polypropylene pipes

Metal-plastic has a higher operating temperature - up to 95 ° C, which is enough for most systems. They can also be used to tie a solid fuel boiler, but only if one of the systems for protecting against overheating of the coolant is available (described below). But metal-plastic pipes have two significant drawbacks: narrowing at the junction (fitting design) and the need for regular checks of connections, as they leak over time. So the piping of the boiler with metal-plastic is done subject to the use of water as a coolant. Anti-freeze liquids are more fluid, therefore it is better not to use compression fittings in such systems - they will still flow. Even if you replace the gaskets with chemically resistant ones.

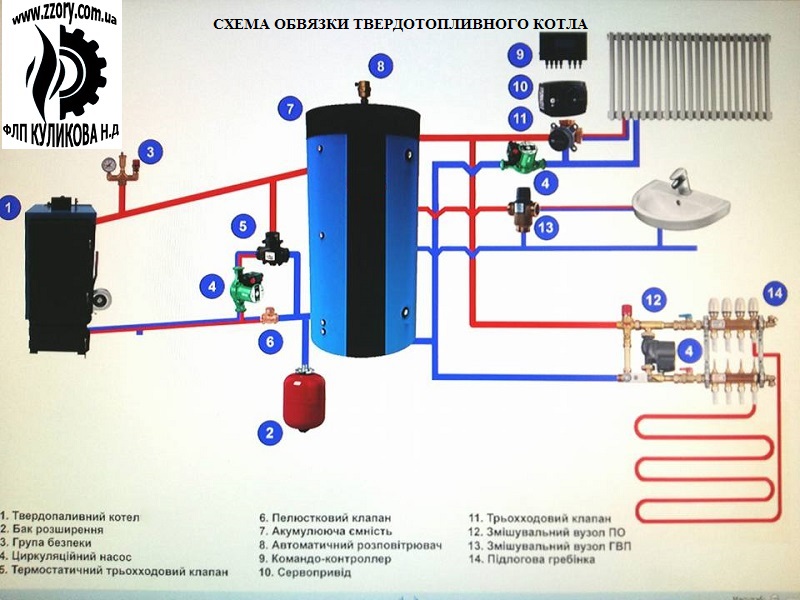

What is the connection of a solid fuel and gas boiler in one system

Connecting a solid fuel and gas boiler to one system solves the fuel issue for the owner. A single-fuel boiler is inconvenient in that if you do not replenish stocks in a timely manner, you can be left without heating. Combined boilers are expensive, and if such a unit breaks down seriously, all the heating options provided for in it will become unfeasible.

Perhaps you already have a solid fuel boiler, but want to switch to another one that is more convenient to use. Or the existing boiler does not have enough power, you need another one. In any of these cases, it will be necessary to connect a solid fuel and gas boiler to one system.

Features of connecting two boilers

Connecting two boilers to one heating system makes it difficult to combine them: gas units are operated in a closed system, solid fuel - in an open one. The open piping of the TD boiler allows you to heat water to a temperature of over 100 degrees, at a critically high pressure value (what is the piping of a solid fuel boiler).

To relieve pressure, such a boiler is equipped with an open-type expansion tank, and they cope with elevated temperatures by draining part of the hot coolant from this tank into the sewer. When using an open tank, airing of the system is inevitable, free oxygen in the coolant leads to corrosion of metal parts.

Two boilers in one system - how to connect them correctly?

There are two options:

- a sequential scheme for connecting two boilers to one heating system: a combination of an open (TD boiler) and a closed (gas) sector of the system using a heat accumulator;

- installation of a solid fuel boiler in parallel with a gas boiler, with safety devices.

A parallel heating system with two boilers, gas and wood, is optimal, for example, for a cottage with a large area: each unit is responsible for its own half of the house.

In this case, a controller and the possibility of cascade control are required.With a sequential scheme for connecting gas and solid fuel boilers into one system, it turns out, as it were, two independent circuits connected by a heat accumulator (what is a heat accumulator for heating boilers).

The two-boiler scheme has been very widely used recently, and there is quite a lot of interest. When two thermal units appear in one boiler room, the question immediately arises of how to coordinate their work with each other. Let's try to answer the question of connecting two boilers to one heating system.

This information will be of interest to those who are going to build their own boiler house, who want to avoid mistakes and for those who are not going to build with their own hands, but want to convey their needs to those people who will assemble the boiler house. It is no secret that each installer has his own ideas about how the boiler room should look and often they do not coincide with the needs of the customer, but the customer's desire is more important in this situation.

Let's look at examples of why in one case the boiler room operates in automatic mode (the boilers are coordinated with each other without the participation of the consumer), and in the other it is required that it be turned on.

Nothing is required here, except for shut-off valves. Switching between boilers is carried out by manual opening / closing of two taps located on the coolant. And not four, in order to completely cut off the idle boiler from the system. In both boilers, most often there are built-in ones and it is more profitable to use them both at the same time, because the volume of the heating system very often exceeds the capabilities of one expansion tank taken separately.In order to avoid the useless installation of an additional (external) expansion tank, it is not necessary to cut off the boilers from the system completely. It is necessary to block them according to the movement of the coolant and leave them simultaneously included in the expansion system.

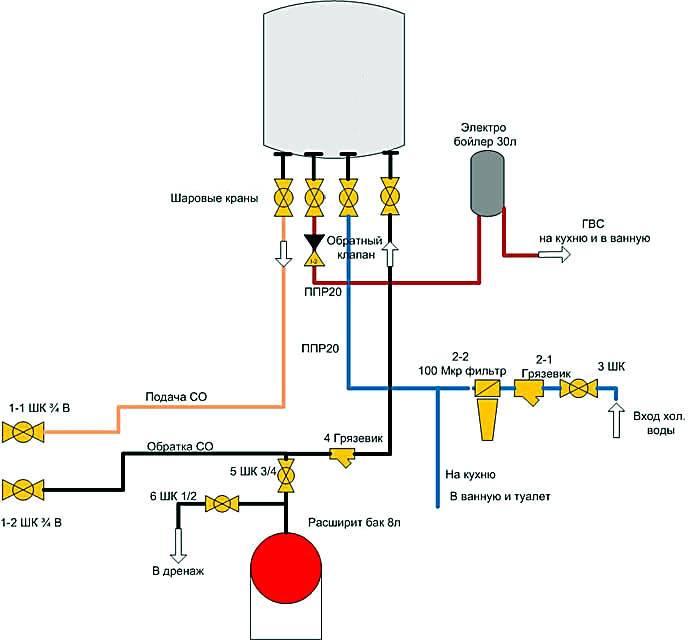

Single-circuit boilers with hot water supply

In order to provide hot water, along with a safety group, a pump and an expansion tank, the piping of a single-circuit gas boiler must include an indirect heating boiler. It is possible to connect an indirect heating boiler with recirculation. Water heating in this case is carried out thanks to the coolant from the heating circuit. This leads to the appearance of two circulation circuits - large (through the heating system) and small (through the boiler). Each of them has shut-off valves, which allows you to turn them on separately. To break the filling of the supply, a piping scheme for a single-circuit boiler with a boiler is used, immediately after which a bypass with a crane is mounted.

Manual make-up scheme

The simplest option for filling the system is implemented in 90% of double-circuit wall-mounted boilers, where a cold water supply pipe is a priori connected. A manual valve is installed inside the housing, connecting this line with the heating return line. Often, a boiler feed tap is found on solid fuel heat generators with and without a water circuit (for example, heating units of the Czech brand Viadrus).

In wall-mounted double-circuit heat generators, the make-up valve is located below, where pipelines are connected

To assemble a classic make-up unit suitable for any type of system, you will need the following parts:

- a tee with a side outlet DN 15-20, corresponding to the material of the pipe of the heating main, - a fitting for metal-plastic, polypropylene, and so on;

- poppet (spring) check valve;

- ball valve;

- couplings, fittings.

The task of the check valve is to prevent water from the heating network from returning to the water supply. If we are talking about pumping antifreeze with a pump, you can’t do without a valve at all. The fittings are installed exactly in the order of enumeration:

- The tee cuts into the heating return after the circulation pump.

- A check valve is connected to the branch pipe of the tee.

- Next comes the ball valve.

The principle of operation of the unit is simple: when the tap is opened, water from the centralized line enters the heating pipelines, since its pressure is higher (4–8 bar versus 0.8–2 bar). The filling process of a closed system is monitored by the pressure gauge of the boiler or the safety group. If you accidentally overpressure, use the Mayevsky tap on the nearest radiator and bleed off excess water.

To control the amount of coolant in the expansion tank of an open heating network located in the attic of the house, the tank must be equipped with 2 additional pipes with a diameter of ½ inch:

- The control pipeline, ending with a tap in the boiler room, cuts into the side wall at about half the height of the tank. By opening this valve, you can determine the presence of water in the tank without climbing into the attic. During the replenishment process, air bubbles exit through the tank lid, the maximum level is monitored by the outflow of water from the top fitting through the pipe

- The overflow pipe cuts 10 cm below the tank lid, the end is diverted into the sewer or just outside under the roof overhang. Being in the furnace and opening the make-up tap, you should see this pipe, when water flows from there, filling stops.

The scheme with a non-return valve and a stopcock is also applicable for filling solar systems (solar collectors) and geothermal circuits of heat pumps with antifreeze. How to use the make-up boiler valve is described in the video:

What is a single-circuit boiler

Of the two existing types of boilers, differentiated by the number of built-in heating circuits, the single-circuit one differs in that it is endowed with only one useful function - heat supply to the batteries to increase the room temperature. Its design itself is not capable of supplying hot water to the tap, so the role of the mixer in this case is reduced to zero. Boilers are electric (heating elements, induction, electrode) and gas, which is due to different methods of heating, power, consumption.

The electric boiler has the following nomenclature: a central tank that acts as a heat exchanger, tubular heating elements (heaters), inlet and outlet pipes in the lower part of the body, a circulation pump for water circulation in the system, a thermostat, indicators. In the induction boiler, instead of heating elements, coils are placed, which are driven by electromagnetic induction, the outlet pipe with hot water is installed on the top cover of the structure. Electrode boilers operate, respectively, by means of the poles of a closed electrical circuit (anode and cathode) installed in parallel, forming an electrical voltage and heat generation.

The gas single-circuit boiler is equipped with a heat exchanger, a combustion chamber for the incoming fuel from a gas burner, a three-code valve, a circulation pump, an expansion tank, a valve for connecting to a gas pipeline.

All modern models of single-circuit boilers, in addition to the water inlet-outlet pipe, have pipes for connecting to external water heating units. Thus, the possibility of synthesizing a single-circuit boiler with an indirect heating boiler is realized to create a multifunctional heating and hot water supply system at home.

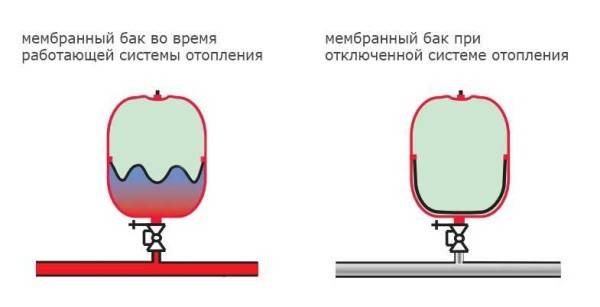

Expansion tank for closed heating system

The expansion tank for is designed to compensate for changes in the volume of the coolant depending on temperature. In closed heating systems, this is a sealed container, divided by an elastic membrane into two parts. In the upper part there is air or an inert gas (in expensive models). While the coolant temperature is low, the tank remains empty, the membrane is straightened (picture on the right in the figure).

The principle of operation of the membrane expansion tank

When heated, the coolant increases in volume, its excess rises into the tank, pushing the membrane and compressing the gas pumped into the upper part (in the picture on the left). On the pressure gauge, this is displayed as an increase in pressure and can serve as a signal to reduce the intensity of combustion. Some models have a safety valve that releases excess air/gas when a pressure threshold is reached.

As the coolant cools, the pressure in the upper part of the tank squeezes the coolant out of the tank into the system, the pressure gauge returns to normal.That's the whole principle of operation of the expansion tank of the membrane type. By the way, there are two types of membranes - dish-shaped and pear-shaped. The shape of the membrane does not affect the principle of operation.

Types of membranes for expansion tanks in closed systems

Volume calculation

According to generally accepted standards, the volume of the expansion tank should be 10% of the total volume of the coolant. This means that you have to calculate how much water will fit in the pipes and radiators of your system (it is in the technical data of the radiators, but the volume of pipes can be calculated). 1/10 of this figure will be the volume of the required expansion tank. But this figure is valid only if the coolant is water. If an antifreeze liquid is used, the tank size is increased by 50% of the calculated volume.

Here is an example of calculating the volume of a membrane tank for a closed heating system:

- the volume of the heating system is 28 liters;

- expansion tank size for a system filled with water 2.8 liters;

- the size of the membrane tank for a system with antifreeze liquid is 2.8 + 0.5 * 2.8 = 4.2 liters.

When buying, choose the nearest larger volume. Do not take less - it is better to have a small supply.

What to look for when buying

The stores have red and blue tanks. Red tanks are suitable for heating. Blue ones are structurally the same, only they are designed for cold water and do not tolerate high temperatures.

What else to pay attention to? There are two types of tanks - with a replaceable membrane (they are also called flanged) and with an irreplaceable one. The second option is cheaper, and significantly, but if the membrane is damaged, you will have to buy the whole thing

In flanged models, only the membrane is bought.

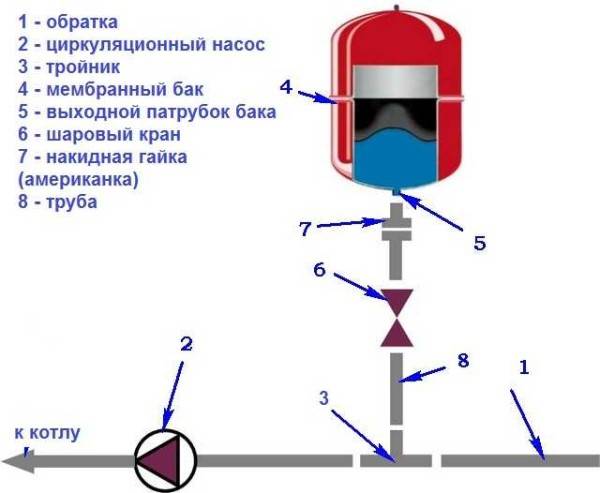

Place for installation of expansion tank of membrane type

Usually they put an expansion tank on the return pipe in front of the circulation pump (when viewed in the direction of the coolant). A tee is installed in the pipeline, a small piece of pipe is connected to one of its parts, and an expander is connected to it, through fittings. It is better to place it at some distance from the pump so that pressure drops are not created. An important point is that the piping section of the membrane tank must be straight.

Scheme of installation of an expansion tank for membrane type heating

After the tee put a ball valve. It is necessary to be able to remove the tank without draining the heat carrier. It is more convenient to connect the container itself with the help of an American (flare nut). This again facilitates assembly/dismantling.

Empty device weighs not so much, but filled with water has a solid mass. Therefore, it is necessary to provide a method of fixing on the wall or additional supports.

Conclusions and useful video on the topic

We offer several video tutorials that will help solve the problem of tying a gas boiler.

Video #1 Tips for the master on tying the boiler with polypropylene (a simple scheme):

Video #2 Installation instructions for a complex piping of a wall-mounted boiler model:

Video #3 The nuances of connecting the floor model:

It is advisable to choose a gas piping scheme that can be mounted without assistance. However, if in doubt, the advice of a professional does not hurt.

Pay special attention to the choice of pipeline material, take care of installing a filter to clean the coolant. Smooth inner walls of pipes and clean water in them are the key to long-term and stable operation of the heating system

Please write your comments in the box below. It is possible that you know the technical details of the boiler piping that are not noted in the article. Share useful information, ask questions, post photos on the topic of the article.