- Features of piping an indirect heating boiler

- What pipes are suitable for tying

- How to tie solid fuel boilers

- Using buffer capacity

- TT boiler and storage water heater

- Design of an indirect heating boiler

- Pipe material for piping BKN

- What is an indirect heating boiler and what are they

- Kinds

- Which boilers can be connected to

- Tank shapes and installation methods

- Connection course for indirect heating boiler

- How to connect a storage type boiler to the water supply

- Video instruction for connecting BKN

- Correct selection of a water heater with indirect heating

- Important Features

- Choice of tank volume

- Errors during connection and operation

- Boiler piping connection principles

- Installation of instantaneous water heater

- Preparation - Checking the Mains

- Location selection

- Wall mounting

- How to connect to the water supply

- Inclusion in the power supply

Features of piping an indirect heating boiler

It is easier to do wiring and piping if the KN boiler is installed together with the boiler, pumps and other equipment involved in the assembly of the DHW system. Embedding an additional device into an already existing network is much more difficult.

In any case, for the normal operation of the devices, you will have to follow a number of rules:

- choose the right place for installation - as close as possible to the boiler;

- provide a flat surface for mounting the boiler;

- to protect against thermal expansion, install a membrane accumulator (at the outlet of heated water), the volume of which is at least 1/10 of the volume of the BKN;

- equip each circuit with a ball valve - for convenient and safe maintenance of devices (for example, a three-way valve, a pump or the boiler itself);

- to protect against backflow, install check valves on the water supply pipes;

- improve water quality by inserting filters;

- correctly position the pump (or several pumps) - the motor axis must be in a horizontal position.

For safety reasons, do not attempt to mount heavy devices on plasterboard or thin wooden partitions. Concrete and brick walls are suitable. Brackets or other types of holders are fixed with brackets, anchors, dowels.

Regardless of the type of device - floor or wall - if possible, it is mounted above the level at which the boiler is installed, or at the same level. For outdoor, you can make a pedestal or a solid stand up to 1 m high

When installing, the nozzles are directed towards the boiler (even if they are masked in the back or behind a false wall). Do not use unreliable equipment, such as corrugated hoses that cannot withstand the pressure and pressure of water.

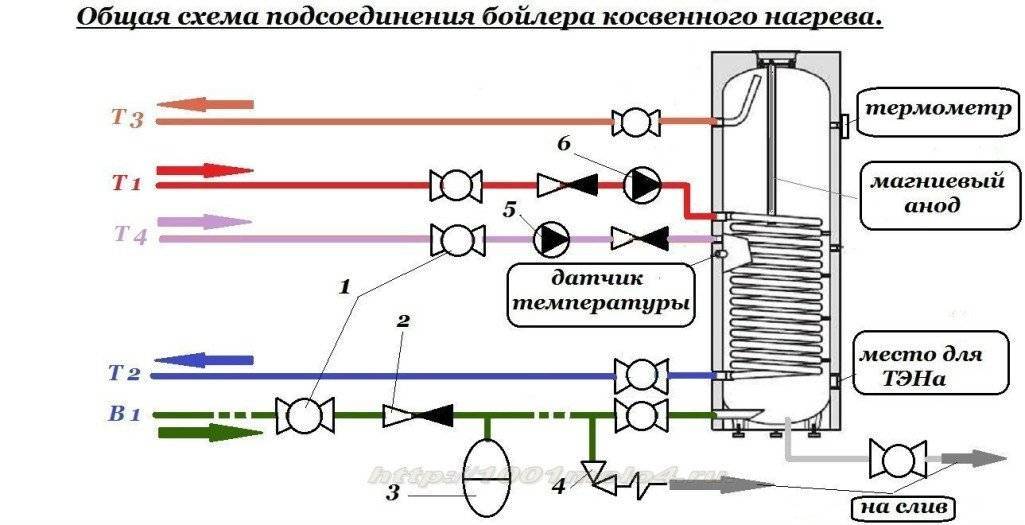

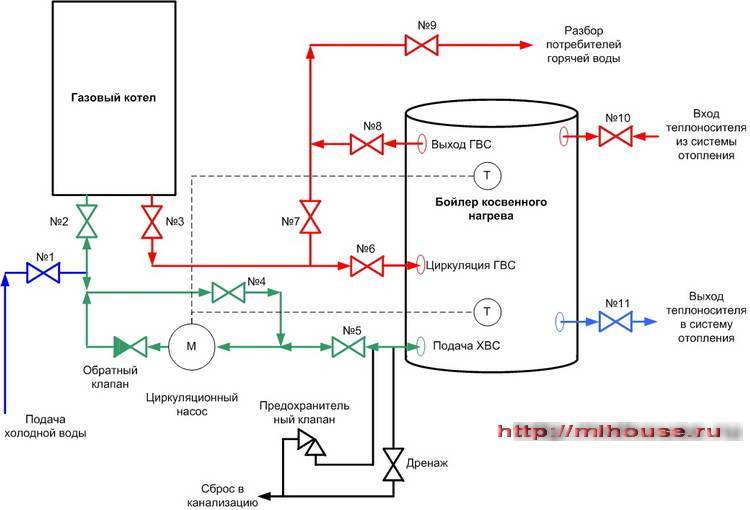

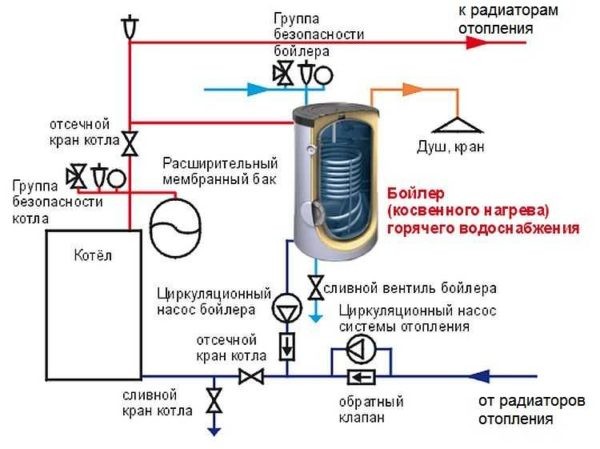

For normal operation of the storage water heater of indirect heating, the following functional devices must be included in the piping:

- A complex technical system must be equipped with pumps that supply hot sanitary water to the taps and stimulate the movement of the coolant along the heating branch, as well as along the water heating circuit in the boiler

- Cold water coming from a public or autonomous water supply must be cleaned through a sump or filter system that destroys lime salts before being supplied to the boiler. Filtration will prevent the formation of mineral sediment

- After the sump or water filtration system, there must be a pressure reducer. However, it is only needed if the pressure in the branch exceeds 6 bar

- Before entering cold water into the boiler, a check valve is required to prevent reverse flow.

- In order for the heating water to have a reserve for expansion during the period when it is not used, an expansion tank and a pressure relief valve are included in the piping

- To prevent excessively hot water from entering the taps, threatening burns, a three-way mixing valve must be installed in the circuit. It will mix portions of cold water with hot water, as a result, there will be water at the required temperature for the user

- In order for the heat carrier from the heating to enter the "jacket" heating the sanitary water only when it is needed, a two-way thermostat is installed. Its server is connected to the water heater temperature sensor

- If the hot water consumption in the house is large enough, it is advisable to purchase a boiler with a built-in additional instantaneous water heater or buy a separate device and include it in the hot water supply branch. In case of its shortage, a miniature protochnik will turn on and save the situation.

What pipes are suitable for tying

To connect the boiler and heating wiring, it is better to take metal-plastic or polypropylene pipes. They will cost less than galvanized or copper counterparts.

Sequential wiring of radiators is carried out using metal-plastic pipes on press fittings or polypropylene pipes with aluminum reinforcement. However, each of these options has its drawback. Press fittings are sensitive to the quality of installation and leakage can occur at the slightest displacement. Polypropylene, on the other hand, has a high coefficient of elongation when heated to more than 50°C. For wiring the "warm floor" system, metal-plastic on press fittings, polyethylene or thermomodified polyethylene are used.

How to tie solid fuel boilers

The connection scheme for a wood-burning heat generator is designed to solve 3 tasks (in addition to supplying batteries with coolant):

- Prevention of overheating and boiling of the TT boiler.

- Protection against cold "return", abundant condensate inside the firebox.

- Work with maximum efficiency, that is, in the mode of full combustion and high heat transfer.

The presented piping scheme for a solid fuel boiler with a three-way mixing valve allows you to protect yourself from condensate in the furnace and bring the heat generator to maximum efficiency mode. How it works:

- While the system and the heater are not warmed up, the pump drives water through the small boiler circuit, since the three-way valve is closed on the side of the radiators.

- When the coolant is heated to 55-60 degrees, the valve set to the specified temperature begins to mix water from the cold "return". The heating network of a country house is gradually warming up.

- When the maximum temperature is reached, the valve closes the bypass completely, all the water from the TT boiler goes into the system.

- The pump installed on the return line pumps water through the jacket of the unit, preventing the latter from overheating and boiling.If you put the pump on the feed, the chamber with the impeller can fill with steam, the pumping will stop and the boiler is guaranteed to boil.

The principle of heating with a three-way valve is used for piping any solid fuel heat generators - pyrolysis, pellet, direct and long-term combustion. The exception is gravity wiring, where the water moves too slowly and does not provoke condensation. The valve will create a high hydraulic resistance that prevents gravity flow.

If the manufacturer has equipped the solid fuel unit with a water circuit, the coil can be used for emergency cooling in case of overheating. Note: the fuse on the safety group operates on pressure, not temperature, therefore it is not always able to protect the boiler.

A proven solution - we connect the DHW coil to the water supply through a special thermal reset valve, as shown in the diagram. The element will work from the temperature sensor and at the right time will pass a large volume of cold water through the heat exchanger.

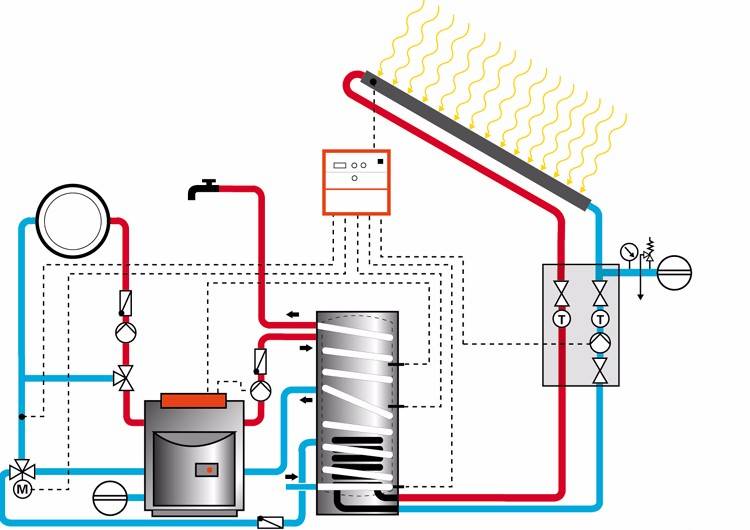

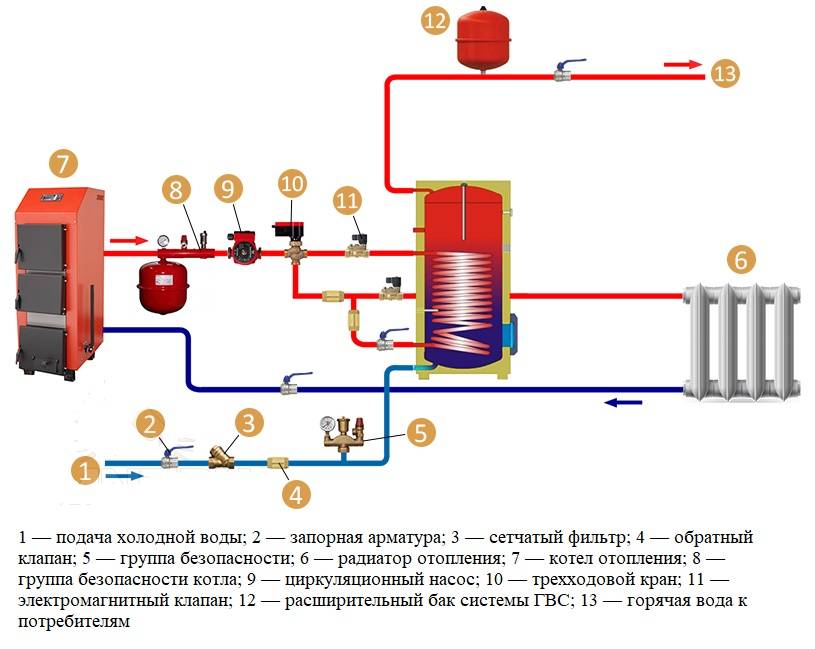

Using buffer capacity

The best way to increase the efficiency of a TT boiler is to connect it to the heating system through a buffer tank. At the inlet of the heat accumulator we assemble a proven circuit with a three-way mixer, at the outlet we put a second valve that maintains the required temperature in the batteries. The circulation in the heating network is provided by the second pump.

A balancing valve on the return line is needed to adjust the performance of the pumps

What do we gain with a heat accumulator:

- the boiler burns at maximum and reaches the declared efficiency, the fuel is used efficiently;

- the probability of overheating is sharply reduced, since the unit dumps excess heat into the buffer tank;

- the heat accumulator plays the role of a hydraulic arrow, several heating branches can be connected to the tank, for example, radiators of the 1st and 2nd floors, floor heating circuits;

- a fully heated tank keeps the system running for a long time when the firewood in the boiler burns out.

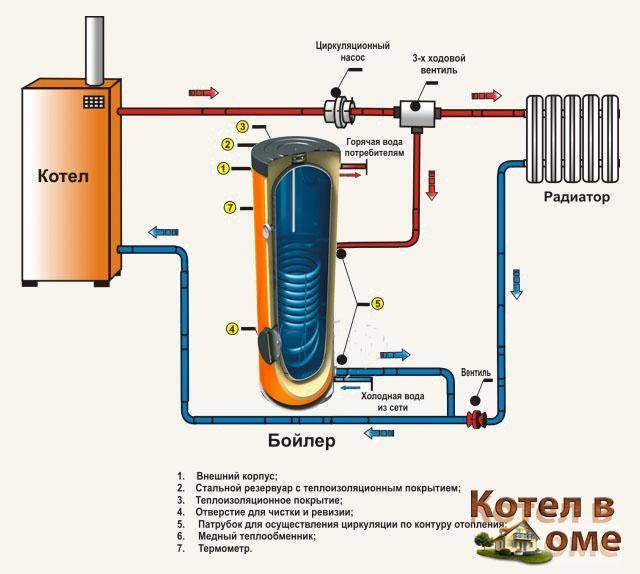

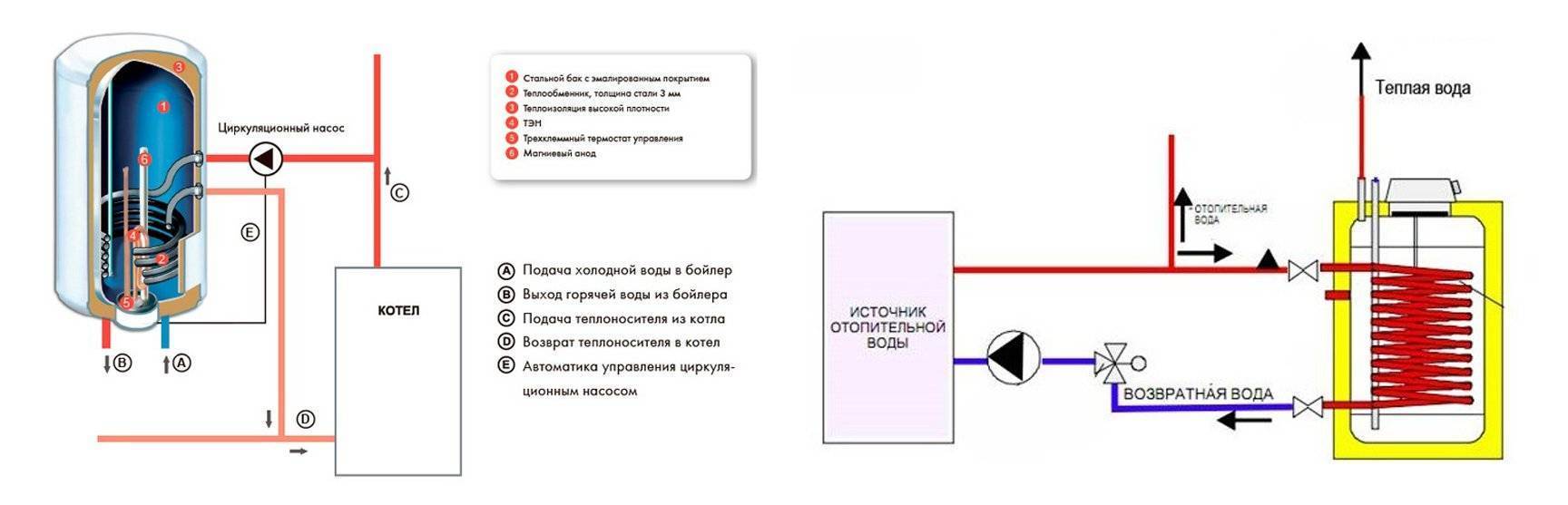

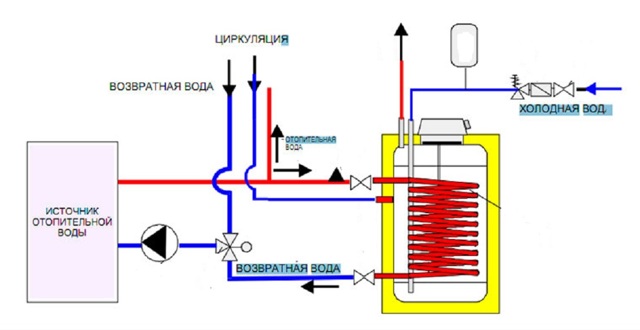

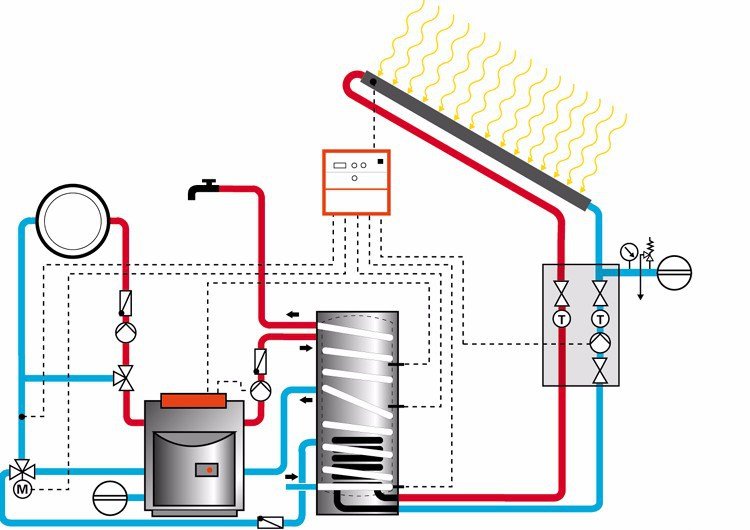

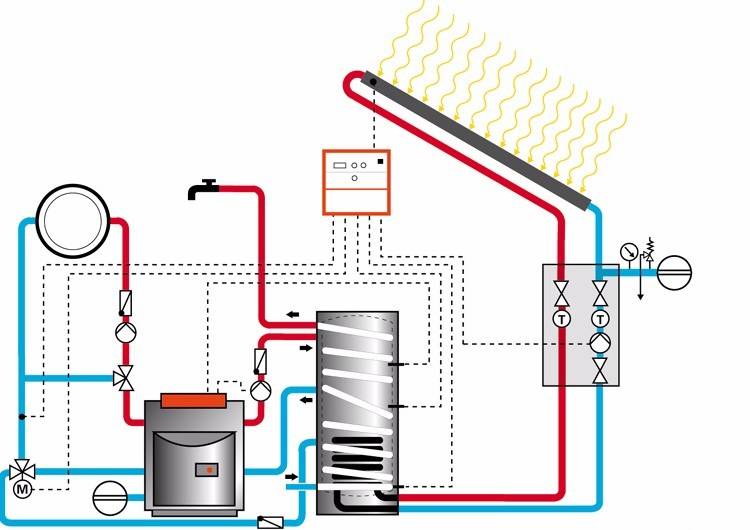

TT boiler and storage water heater

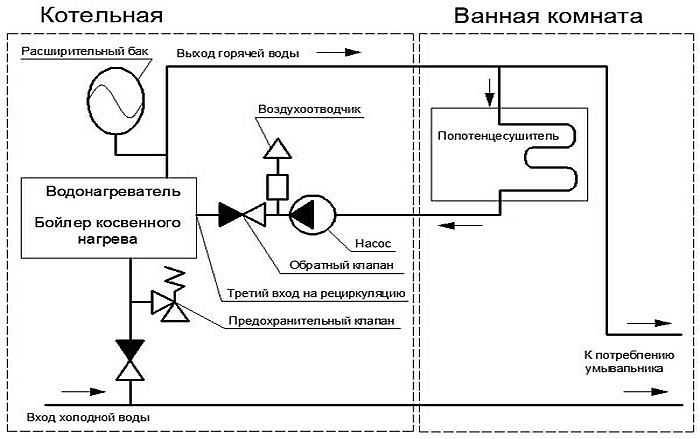

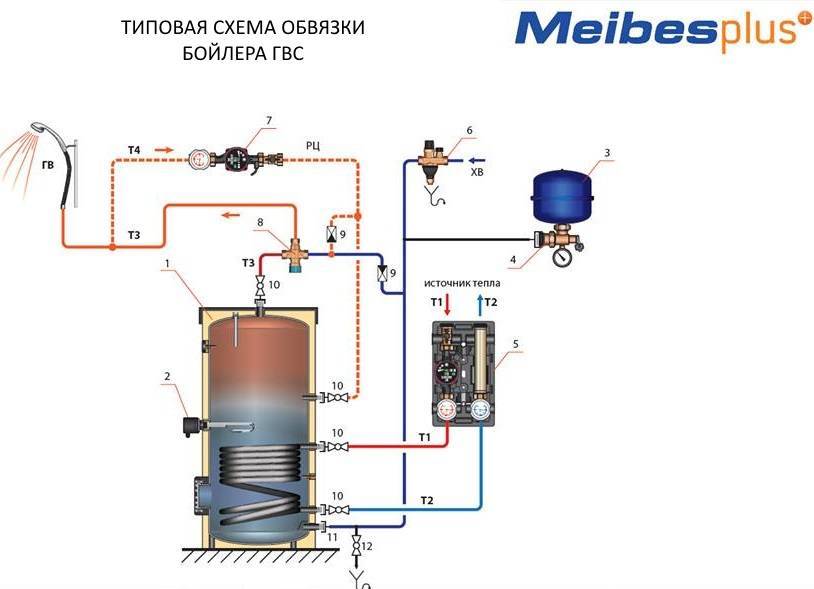

In order to load the boiler with the help of a wood-fired heat generator - “indirect”, you need to embed the latter into the boiler circuit, as shown in the picture. Let us explain the functions of individual circuit elements:

- check valves prevent the coolant from flowing in the other direction along the circuits;

- the second pump (it is enough to take a low-power model 25/40) circulates through the spiral heat exchanger of the water heater;

- the thermostat turns off this pump when the boiler reaches the set temperature;

- an additional air vent prevents the supply line from being aired, which will be higher than the regular safety group.

In a similar way, you can dock the boiler with any boiler that is not equipped with an electronic control unit.

Design of an indirect heating boiler

Design of an indirect heating boiler Electric storage water heaters are gradually becoming more and more common sources of domestic hot water, using a conventional household power supply for power. Then there are special thermostatic valves for domestic hot water.

In order for hot water supply to work efficiently and without interruptions, you need to think in advance of its design features and nuances that may arise in the process of work

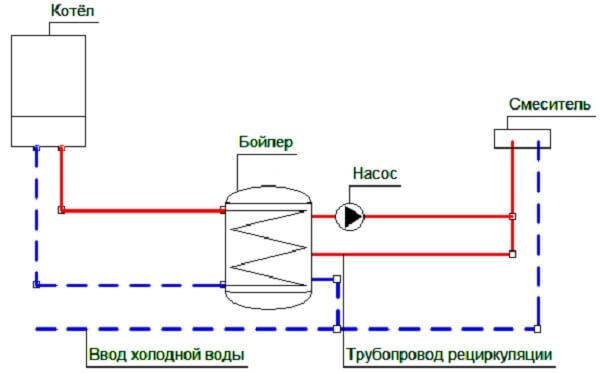

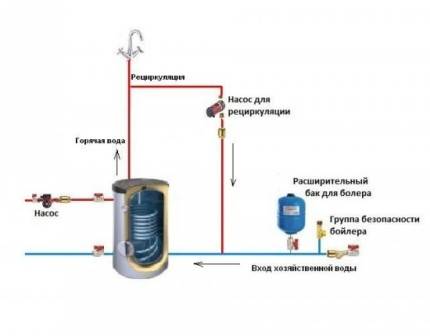

How to use coolant recirculation Recirculation useful when there is a circuit that needs a constant supply of hot water - for example, a heated towel rail.

On the one hand, they say that the efficiency of the boiler becomes higher if the temperature of the coolant is degrees.

It is important to choose a good manufacturer and at the same time not to overpay.

How to use coolant recirculation Recirculation is useful when there is a circuit that needs a constant supply of hot water - for example, a heated towel rail. In such a boiler, the reception of more power increases due to the preservation of the coolant in the boiler, which has an inertial nature of temperature preservation.

How the pump will affect the heating system is not exactly known, but in practice, as a rule, it actually short-circuits more than half of the coolant jet to the boiler, in the worst case, it overturns the jets in other parallel branches, which is sometimes not acceptable.

Disadvantage of getting hot water? Therefore, not all boilers are equipped with a special inlet for organizing such an additional circuit.

How to connect an indirect heating boiler

Pipe material for piping BKN

The desired water heating temperature is set on the thermostatic head regulator, not higher than the temperature at the boiler supply. Also in the passports-instructions for use.

The heating temperature and pressure on the pipes determines which material is preferable to use when tying: Cold water - a regular polypropylene pipe can be installed. The supply of coolant is regulated by a thermostat, which opens and closes depending on the temperature of the water in the tank.BKN piping should solve several important problems: ensure continuous circulation of the coolant from the boiler to the water heater; prevent hydraulic and thermal shock; maintain the set temperature of water heating in automatic mode.

What is priority heating Before installing an indirect heating boiler in the DHW system, you must select the principle of its connection: with or without priority. The thing is that the liquid constantly circulates around the ring and cools, so the boiler spends much more resources on constantly heating it.

In addition, the temperature reduction is enhanced by the mixing of different liquid layers. If more intense heating is needed, this can happen if the boiler usually operates in low temperature mode, then it is better to choose a model with a built-in heating element. The material is suitable for soldering the entire cold water system.

If the client turns off the boiler, make sure that when the boiler is turned off, all systems and equipment are turned off. Also look for the wiring diagram for connecting the boiler to the boiler. The connection of an indirect heating boiler for this case is shown in the diagram below. In addition to installing and connecting the BKN, regular maintenance will be required.

Subscribe to receive new articles. To do this, we can close the heating circuit and leave only the indirect heating boiler to work. The current load, as a rule, is not less than 10 A. Such devices are connected to heating systems that use boilers that are not equipped with automation.To connect, you will have to make the heating system in two circuits, the first - to generate heat in the house, the second, which has a higher priority - for the boiler, that is, if the water temperature drops in the unit, the three-way valve will switch the hot water to the heating circuit until the desired one returns temperature.

The nuances of the piping device It is easier to do wiring and piping if the KN boiler is installed together with the boiler, pumps and other equipment involved in the assembly of the DHW system. Let's take the simplest case, when there is already automatic equipment in the water heater. From experience we can say that it is better not to take a dry heating element. The first scheme of the heating system with an indirect heating boiler directs the entire volume of the coolant to heat the tank, which ensures very fast water heating.

That is, steel pipes overgrow. In this case, the boiler heats up faster, but then the heating stops completely and during a long idle time, the temperature in the batteries can drop significantly. If the heaters are turned off for minutes, the temperature in the rooms is unlikely to drop in such a short period of time, but there will be enough heated water. Connecting an indirect heating boiler with recirculation The second option is to use models that do not have an input for connecting a recirculation circuit, but connect it using tees. That is, during DHW preparation, the heating circuit is switched off.

Equipment for the boiler room. What elements does a modern boiler house consist of?

What is an indirect heating boiler and what are they

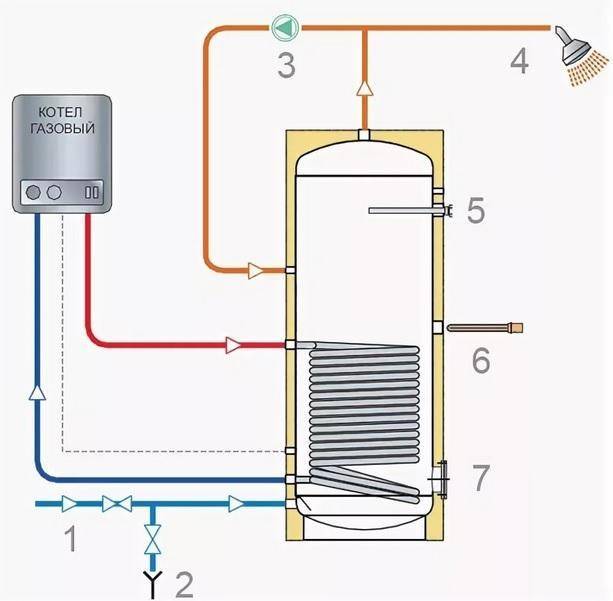

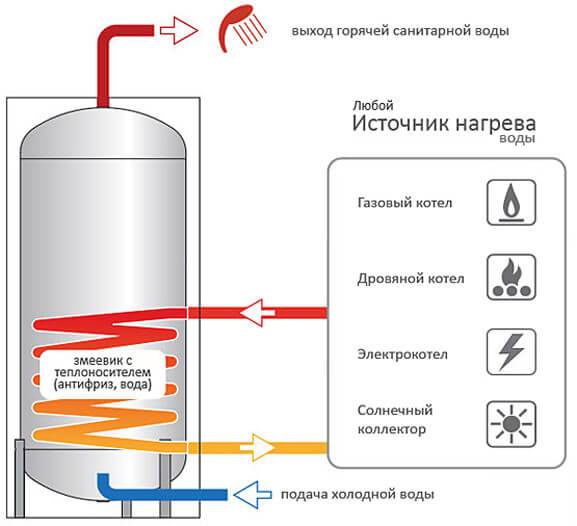

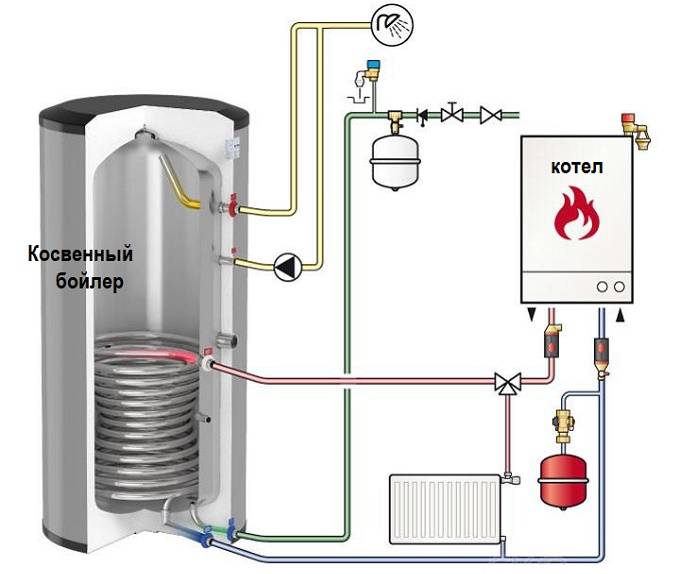

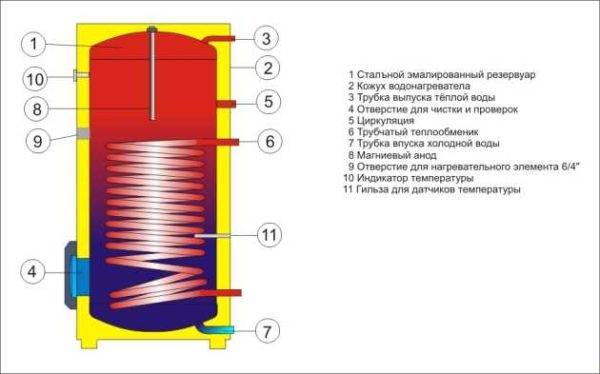

A water heater or an indirect exchange boiler is a tank with water in which a heat exchanger is located (a coil or, according to the type of water jacket, a cylinder in a cylinder).The heat exchanger is connected to a heating boiler or to any other system in which hot water or other coolant circulates.

Heating is simple: hot water from the boiler passes through the heat exchanger, it heats the walls of the heat exchanger, and they, in turn, transfer heat to the water in the tank. Since the heating does not occur directly, then such a water heater is called "indirect heating". The heated water is used for household needs as needed.

Indirect heating boiler device

One of the important details in this design is the magnesium anode. It reduces the intensity of corrosion processes - the tank lasts longer.

Kinds

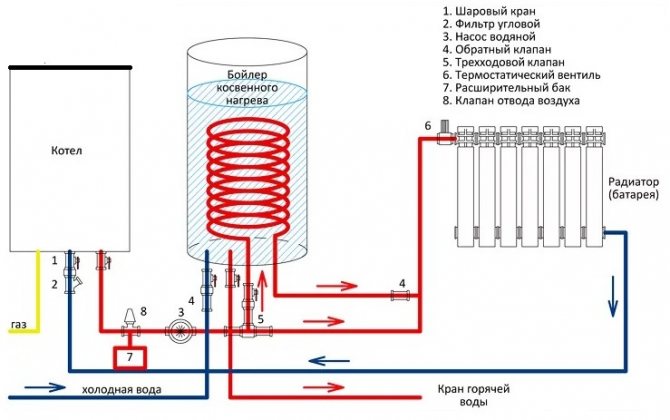

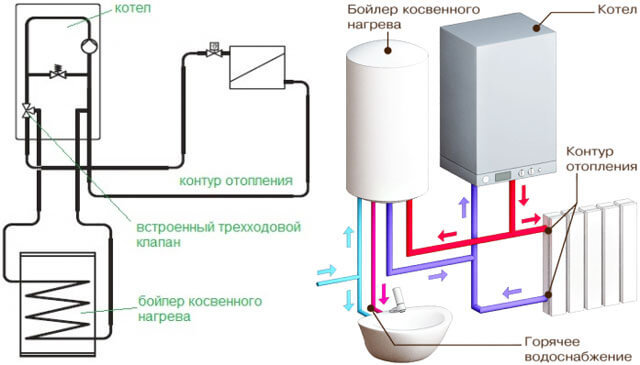

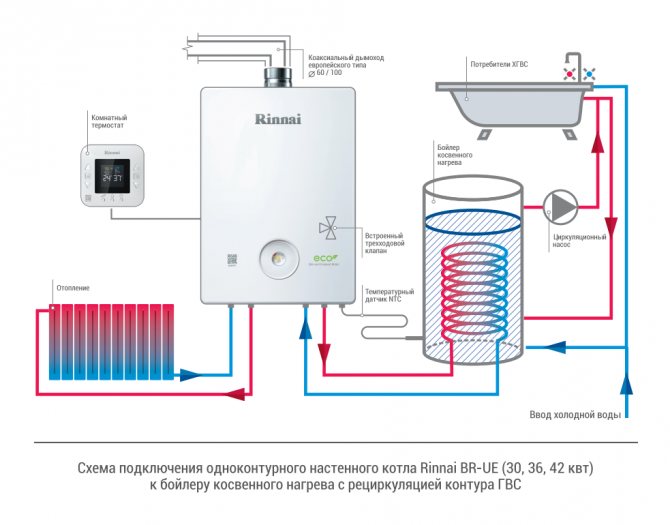

There are two type of indirect boilers heating: with built-in control and without. Indirect heating boilers with built-in control are connected to a heating system powered by boilers without control. They have a built-in temperature sensor, their own control that turns on / off the supply of hot water to the coil. When connecting this type of equipment, all that is needed is to connect the heating supply and return to the corresponding inputs, connect the cold water supply and connect the hot water distribution comb to the upper outlet. That's all, you can fill the tank and start heating it.

Conventional indirect heating boilers work mainly with automated boilers. During installation, it is necessary to install a temperature sensor in a certain place (there is a hole in the body) and connect it to a certain boiler inlet. Next, they make the piping of the indirect heating boiler in accordance with one of the schemes. You can also connect them to non-volatile boilers, but this requires special schemes (see below).

What you need to remember is that the water in the indirect heating boiler can be heated just below the temperature of the coolant circulating in the coil. So if your boiler works in low-temperature mode and produces, say, + 40 ° C, then the maximum temperature of the water in the tank will be just that. You can't heat it up anymore. To get around this limitation, there are combined water heaters. They have a coil and a built-in heating element. The main heating in this case is due to the coil (indirect heating), and the heating element only brings the temperature to the set one. Also, such systems are good in tandem with solid fuel boilers - the water will be warm even when the fuel has burned out.

What else can be said about the design features? Several heat exchangers are installed in large-volume indirect systems - this reduces the time for heating water. To reduce the time of heating water and for slower cooling of the tank, it is better to choose models with thermal insulation.

Which boilers can be connected to

Boilers of indirect heating can work with any source of hot water. Any hot water boiler is suitable - solid fuel - on wood, coal, briquettes, pellets. It can be connected to any type of gas boiler, electric or oil-fired.

Scheme of connection to a gas boiler with a special outlet for an indirect heating boiler

It’s just that, as already mentioned above, there are models with their own control, and then installing and tying them is a simpler task. If the model is simple, it is necessary to think over a system for controlling the temperature and switching the boiler from heating radiators to heating hot water.

Tank shapes and installation methods

The indirect heating boiler can be installed on the floor, it can be hung on the wall. Wall-mounted options have a capacity of no more than 200 liters, and floor options can hold up to 1500 liters. In both cases, there are horizontal and vertical models. When installing the wall-mounted version, the mount is standard - brackets that are mounted on dowels of the appropriate type.

If we talk about the shape, then most often these devices are made in the form of a cylinder. In almost all models, all working outputs (pipes for connection) are brought out at the back. It is easier to connect, and the appearance is better. On the front of the panel there are places for installing a temperature sensor or a thermal relay, in some models it is possible to install a heating element - for additional heating of water in case of a lack of heating power.

By type of installation, they are wall-mounted and floor-mounted, capacity - from 50 liters to 1500 liters

When installing the system, it is worth remembering that the system will work effectively only if the boiler capacity is sufficient.

Connection course for indirect heating boiler

After choosing a scheme, it becomes clear what equipment is required. In addition to the main devices, you may need valves, ball valves, distribution manifolds, valves (three-way or non-return).

Procedure:

- prepare the installation site (on the floor or on the wall);

- make the wiring, marking the outlets of hot / cold water in red / blue;

- embed a tee and a pressure relief valve, securing the connections with sealant;

- screw on the hot (top) and cold (bottom) water taps;

- connection to a power source, install a thermostat and automation;

- select heating mode;

- test the connection.

These are the general guidelines needed to present the scope of work. When connecting a specific model, you must follow the instructions that come with the kit.

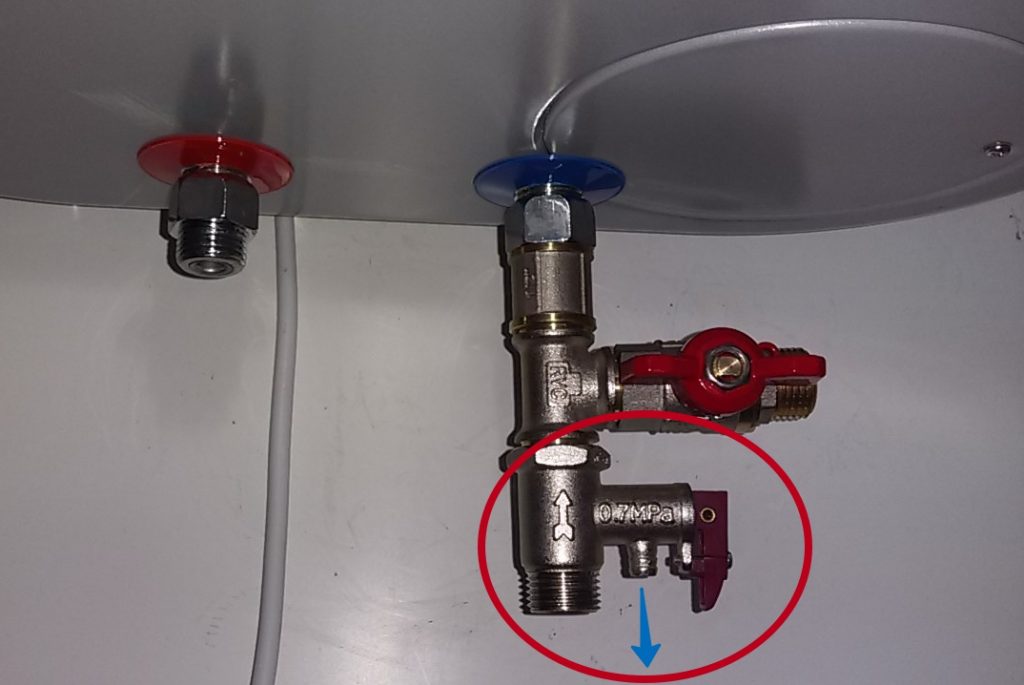

How to connect a storage type boiler to the water supply

First of all, install stopcocks that will prevent water from entering. Cleaning systems are installed above the stopcock. Using filters will protect your water heater from scale formation and significantly increase its service life. Many modern water heaters have a built-in outlet for the water outlet. If you purchased a device that does not have a drainage system, you will have to install it yourself. The water in the boiler is drained under pressure. To maintain a constant pressure level, a ball valve is installed on the hot water side of the water supply. If such a tap has already been installed on the water heater earlier, then you do not need to install an additional one.

At your discretion, you can install a pressure reducer. This device will provide additional security if the water is supplied under strong pressure. The pressure reducer is mounted after installing the water filter.

Video instruction for connecting BKN

How to decide on the connection diagram and install the equipment correctly, the following videos will tell you.

General information about connection diagrams:

Practical tips for installation:

BKN strapping overview:

Professional review of the 80 l boiler:

In addition to installing and connecting the BKN, regular maintenance will be required. It consists in flushing the internal cavity of the tank, removing deposits and scale, replacing the magnesium anode. Maintenance of equipment does not require much effort.If the strapping is done correctly, quick repairs will not be required, but if problems arise with the equipment, we recommend contacting specialists.

Correct selection of a water heater with indirect heating

Indirect heating boiler (BKN) is a highly efficient device with modern automation systems for thermal processes, it is used to produce hot water T up to 65 C.

Externally, the BKN is similar to a traditional electric water heater, although its modern modifications have a more ergonomic rectangular shape.

The source of thermal energy is a heating boiler that runs on any energy source from waste to electricity.

The basic element is a steel or brass coil-type heat exchanger with a large heating area in a relatively small volume of a storage tank covered with a protective enamel layer.

Before installing the BKN, it is necessary to correctly select it for the actual operating conditions: the source of heat supply and the volume of water use for DHW services.

The main parameters for choosing a connection scheme for an indirect heating boiler:

- Working volume in liters. At the same time, the terms "total volume" and "working volume" are different, since the coil heat exchanger takes a certain part of the tank, so you need to choose according to the working indicator.

- External heating source, type of fuel and coolant outlet temperature.

- Thermal power of an external source. The boiler must provide not only the heating load, but hot water. So, to heat a volume of water of 200 liters, a reserve power of at least 40 kW is required.

- Working container material: coated with enamel, glass-ceramic and glass-porcelain, stainless metal or heat-resistant plastic.

- Thermal insulation - to protect the BKN from heat losses, it is best if polyurethane is used as thermal insulation.

- Protection and regulation system.

Important Features

In addition to choosing the geometric and thermal characteristics of the BKN, it is necessary to take into account many parameters so that the thermal scheme for connecting an indirect heating boiler to a gas boiler is as efficient as possible.

To do this, the user must fulfill certain conditions:

- To choose the optimal location, experts say that the location of the BKN should be as close as possible to the boiler.

- Provide protection against thermal elongation of the structure, for this, integrate a membrane hydraulic accumulator with a volume of 10% of the working volume of the boiler into the BKN circuit at the DHW outlet from the device.

- Before connecting the boiler, each inlet / outlet line for the heating and heated medium is equipped with ball valves.

- To perform backflow protection, a check valve is installed on tap water.

- Perform water purification with the installation of a filter before supplying tap water to the BKN.

- The installation of the BKN wall structure is carried out on the main walls with preliminary treatment with fireproof materials.

- Installation of BKN is carried out above the level of the boiler unit or at the same level with it.

Choice of tank volume

In the trading network today there are many offers for BKN devices, both domestic and foreign manufacturers with round and rectangular tanks, floor and wall mounting. And if for electric heaters the most popular models are from 80 to 100 liters.

For BKN, more powerful options are used, ranging from 200 to 1500 hp.This is due to the fact that many owners use this design to create a storage tank in order to create a uniform load on the heat supply source at night. In such a scheme, hot water is heated at night, and consumed during the day.

The size of the working tank is chosen, taking into account the need to provide all family members with hot water. There is a formula for estimated water consumption.

In practice, the following information is often used:

- 2 users - 80 l;

- 3 users - 100 l;

- 4 users - 120 l;

- 5 users - 150 l.

The dimensions of the BKN are also important to consider during installation. For wall placement, installations with a working volume of the tank - up to 150 l can be used, and with larger sizes it is allowed to install only with floor placement

The installation site must have free access so that the piping can be correctly performed and auxiliary equipment in the form of shut-off and control equipment, safety valves, air vents, pumps and a hydraulic accumulator can be placed.

Errors during connection and operation

installation of a socket directly under the boiler itself

It is absolutely impossible to do this. Sockets should be moved away from the heater and placed above the mixers. Do not forget about the safety valve and possible leaks.

The valve will operate as a last step of protection if the thermostat fails. By the way, the thermostat must be checked first of all, when the light on the panel is not lit, and the heaters are not heating. Look at the position of the button on the element, it can be “knocked out”.

a common mistake when connecting the device directly to the outlet is the desire to turn off the device by pulling out the plug at a time when the water has not yet heated up and the heater is still working

If its power reaches 3.5 kW, then with such a break in the contacts, sparking may occur, with the formation of an arc. And since the bathroom is a room with high humidity, the consequences can be unpredictable.

you can not connect an empty boiler without water to the network

The heater, which is installed inside, requires water cooling. Without it, it will simply burn out and fail. Therefore, before each use, check the presence of water in the boiler.

And it is generally not recommended to keep titanium without water. This reduces its service life. A full tank contains less oxygen, and therefore the risk of corrosion is reduced.

Plus, the magnesium anode, which also protects against rust, only works when the tank is full.

connection of the water heater only through the RCD, or only through the machine

These two protection devices must duplicate each other. RCD protects against leakage current, and a simple machine from overload and short circuits.

If the budget allows, then instead of these two protective elements, you can install one differential machine, it will replace both devices.

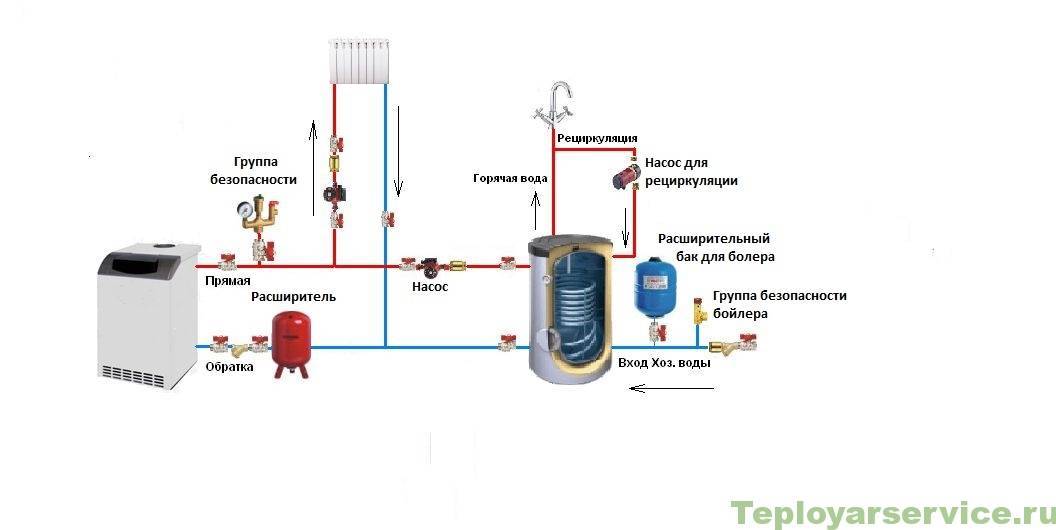

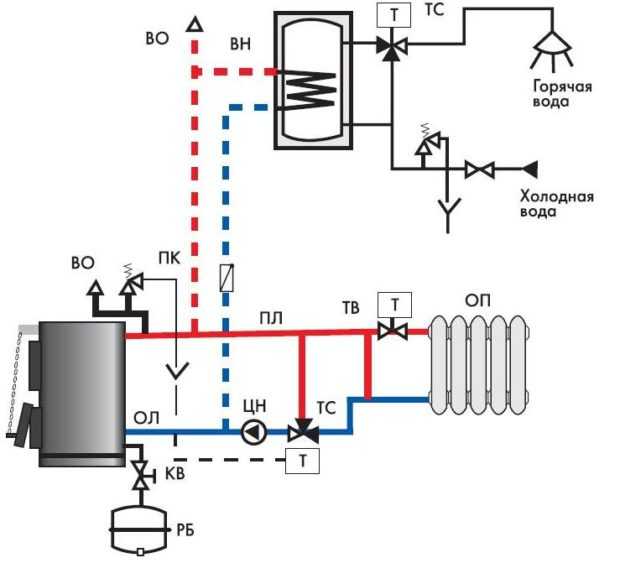

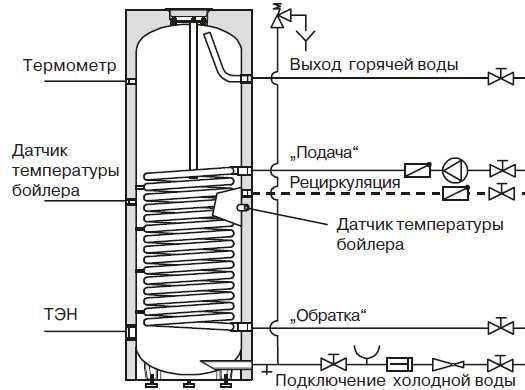

Boiler piping connection principles

The piping of a single-circuit boiler with an indirect heating boiler is performed using two common schemes - electric or hydraulic. The second most common, it is also called two pumping. One is used to heat water, and the second - ensures the operation of the tank. In the electrical circuit, the modes are switched using a relay.BKN is connected to the cold water supply system using pipes for input of source water and output of heated water.

The procedure for tying the BKN consists in connecting the body to the systems of house heating and cold water supply. The efficiency of hot water supply systems directly depends on the completeness and quality of work. To do this, the following requirements for the installation of the BKN are met:

- Cold water is supplied through the lower pipe.

- The intake of hot water is carried out through the upper branch pipe.

- The recirculation point is set in the center of the boiler.

Thus, in the tank, heating takes place according to the counterflow principle, when the heating medium enters the BKN from above and descends to the bottom of the body, and the heated medium, vice versa. The efficiency of the scheme is also increased due to the recirculation line, which allows, instantly, to supply hot water to the consumer's draw-off point.

High-speed heat-heating installations of the “tank-in-tank” type are a device that is structurally made of two tanks, one of a smaller size is placed inside the other. A heating coolant circulates in the space between the shells, and a heating fluid from the boiler circulates in the inner space. In such heaters, high-speed heating of water up to 90C is provided. They are much lighter and more compact than similar units.

There are combined water heaters that simultaneously have two heating sources: gas from the boiler and heating elements. Such a device is expensive, but with a quick payback period, especially if you pay for electricity at multi-station tariffs at night.

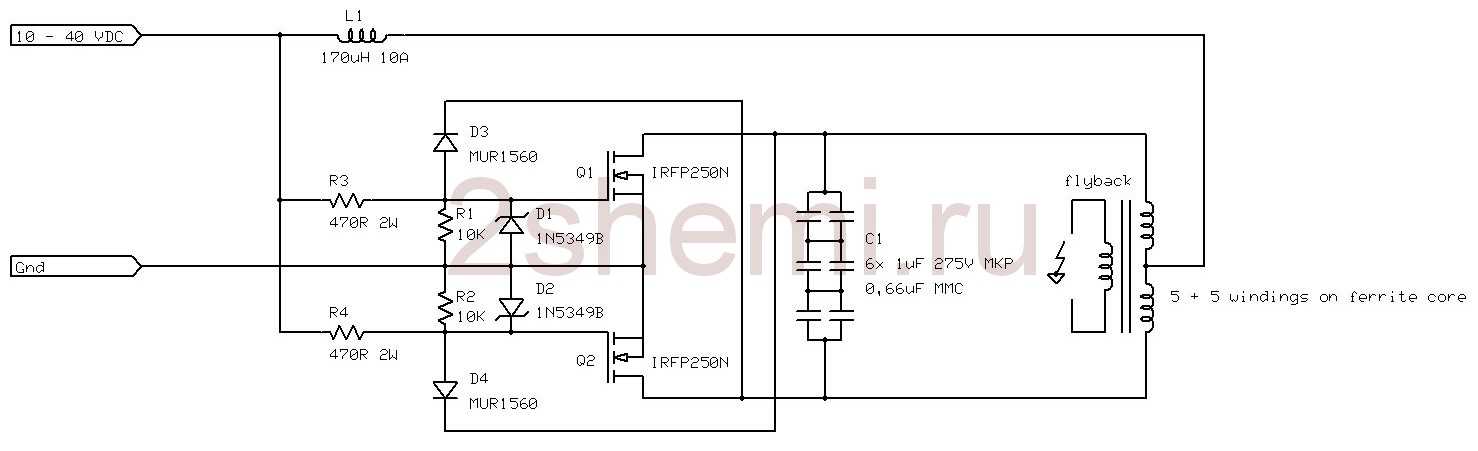

Installation of instantaneous water heater

Heating water in an instantaneous water heater, despite the simple principle of operation in residential areas, is used less frequently than the storage type.This is due to the fact that in order to quickly heat cold water, powerful heating elements from 3 to 27 kW are required, and not every intra-apartment electrical line can withstand such a load.

Preparation - Checking the Mains

Before deciding to install an instantaneous water heater, you should check the capabilities of the intra-house electrical network. Its required parameters are indicated in the passport for the water heater, and if they do not correspond to the actual data, the reconstruction of the house power supply line will be required.

To connect most instantaneous heaters, a stationary installation method is required, AC 220 V, 3-core copper cable, with a cross section of at least 3x2.5 mm and automatic protection of at least 30 A. The instantaneous water heater must also be connected to the grounding system .

Location selection

Non-pressure instantaneous water heaters, in general, are able to guarantee the operation of only one point of water intake, as a result, the question of selecting the installation area is not worth it.

It is placed instead of a mixer in the bathroom or kitchen. The choice of powerful pressure flowing heaters that serve several water points must be carefully carried out. As a rule, it is placed near the maximum water intake or riser.

Despite the fact that IP 24 and IP 25 modifications are structurally protected from direct water penetration, nevertheless, it is more reliable to place them in places where there is no threat of direct water ingress.

In addition, it should be borne in mind that devices that have a mechanical system for adjusting the pressure and temperature of hot water must be located at arm's length.Based on the above, installing a boiler in the bathroom will be the most preferable.

Wall mounting

Flow heaters do not have a lot of weight, their installation does not impose requirements similar to capacitive devices. Mounting on the wall of the building consists in drilling holes and fixing the heater using special brackets supplied in the kit.

The main conditions for a professional installation:

- The strength of the wall covering;

- perfect horizontal position.

If the heater is placed with an inclination, there will be a risk of air voids, which will lead to overheating of the heating element and failure of the water heater.

How to connect to the water supply

It is quite simple to tie a non-pressure flow heater. The connection is made with a flexible hose removed from the mixer to the fitting of the device. To do this, install a special gasket under the union nut and wrap it first by hand, and then with a little pressure with a wrench.

It is important to observe the rule that shut-off valves are not installed after the heater. The water must only be turned off by the heating device or faucet to which it is connected.

In a different scenario due to the lack of water movement, the heating element will overheat and fail.

Inclusion in the power supply

Small-sized non-pressure modifications of water heaters are mainly implemented with the necessary wire plug. In this regard, the inclusion is reduced to the fact that you need to insert the plug into an electrical outlet with grounding.

The electric heater is a powerful electrical appliance; it is forbidden to turn it on using various extension cords.Due to the huge electrical current, the contacts can overheat and cause a fire in the wiring.